Early strength concrete with super retarding effect, and preparation process thereof

A preparation process, concrete technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems that concrete cannot adapt to construction conditions, achieve the effect of improving anti-corrosion effect, preventing corrosion, and improving adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

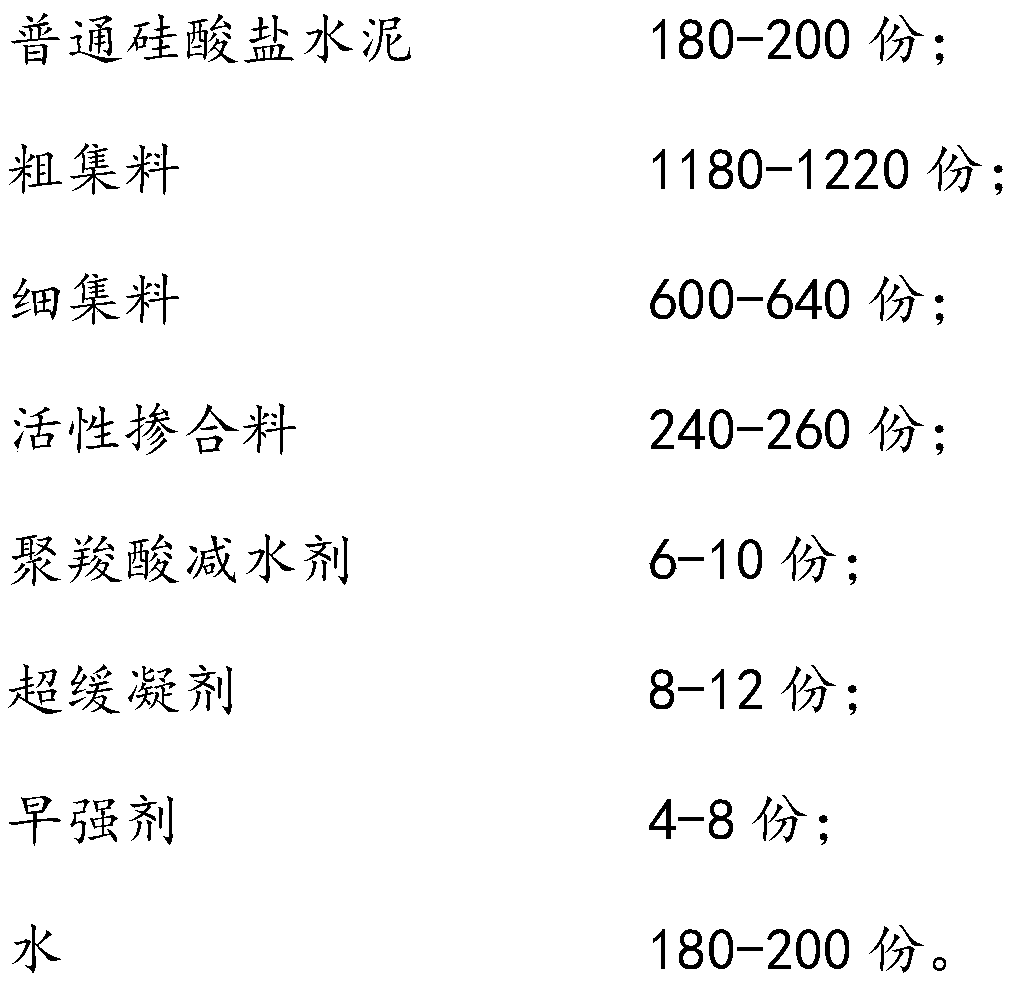

Method used

Image

Examples

Embodiment 1

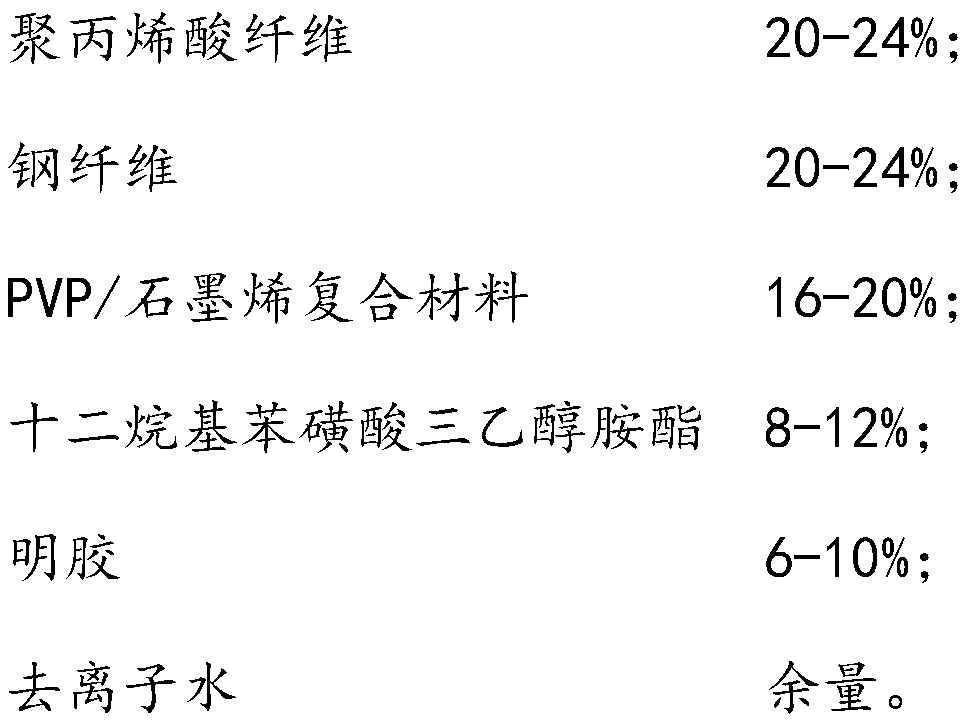

[0077] The difference between embodiment 10-13 and embodiment 1 is that the super retarder comprises the following raw materials in weight percent:

[0078]

[0079] The difference between embodiments 14-17 and embodiment 1 is that the early strength agent comprises the following raw materials in weight percentage:

[0080]

[0081] The difference between embodiment 18-21 and embodiment 1 is that the active admixture comprises the following raw materials in weight percent:

[0082]

[0083]

[0084] The difference between Embodiment 22-25 and Embodiment 1 is that the coating material comprises the following raw materials in weight percentage:

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com