Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Reduce adiabatic temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

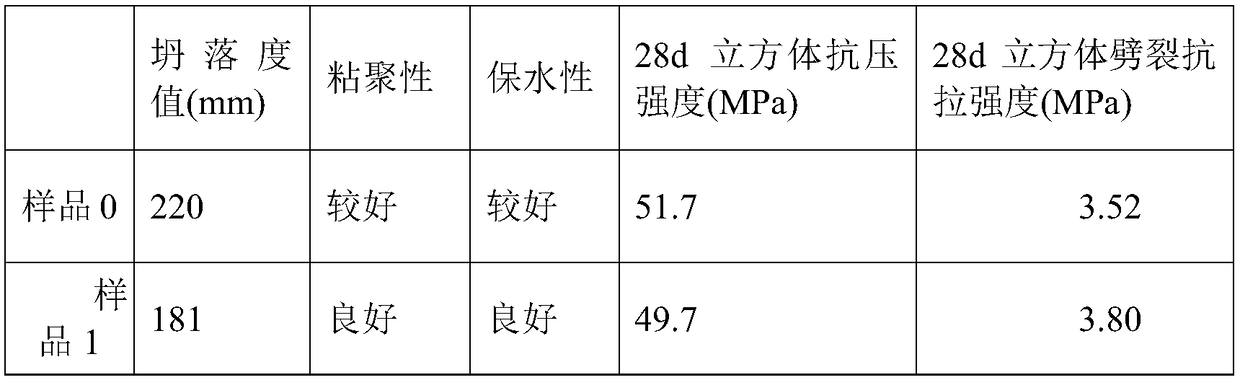

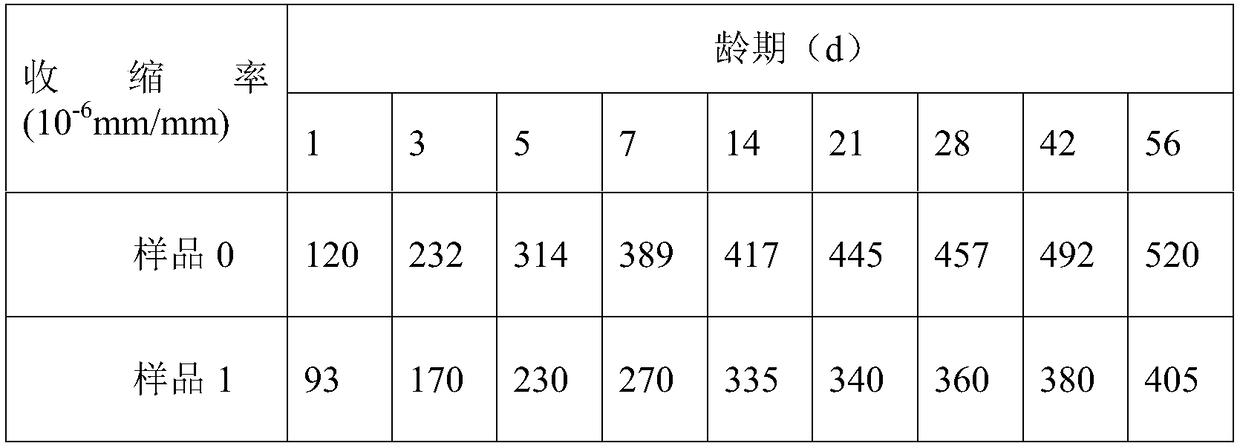

Ready-mixed concrete with phosphorus slag powder

InactiveCN101798207AImprove impermeabilityReduce heat of hydrationSolid waste managementSolid waste disposalTensile strainReady mixed concrete

The invention relates to a ready-mixed concrete with phosphorus slag powder, which is characterized in that the composition ratio and the weight ratio comprise the following parts: 120-150 parts of cement, 100-250 parts of phosphorus slag powder, 0-120 part(s) of fly ash, 0.5-20 part(s) of water reducing agent, 0-0.5 part of air entraining agent, 0-0.02 part of water retention agent, 50-17000 parts of coarse aggregate, 20-9000 parts of fine aggregate and 100-300 parts of water. The invention takes the industrial waste residue i.e. the phosphorus slag powder as the admixture part of the concrete to replace the cement to dope in the ready-mixed concrete, thereby reducing the use amount of the cement, uses the retarding characteristic of the phosphorus slag to reduce the gelled material cost of the concrete and the manufacture cost the of concrete pumping aid, simultaneously gives full play to the characteristic of the phosphorus slag so as to reduce the hydration heat and the adiabatic temperature rise of the concrete, decreases the elasticity modulus and improves the ultimate tensile strain capacity of the concrete, the strength growth rate is high, and the durability is significantly improved; and the invention can changes the waste into the valuable and turns the harmful into the beneficial.

Owner:SOUTHWEAT UNIV OF SCI & TECH

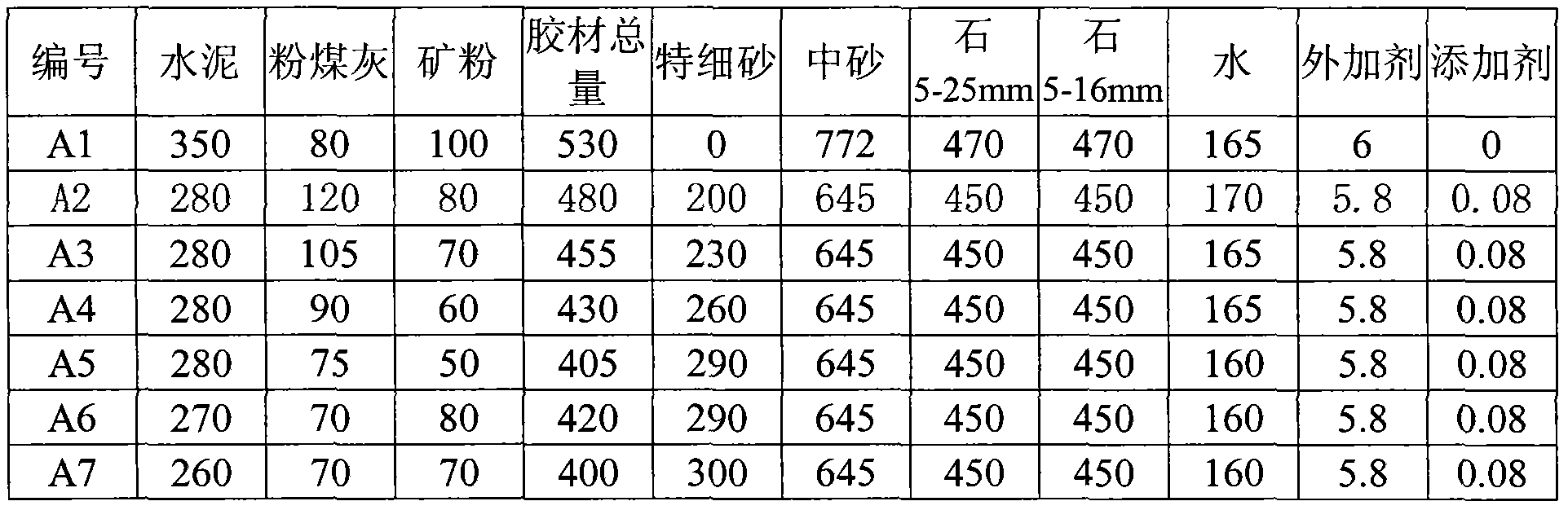

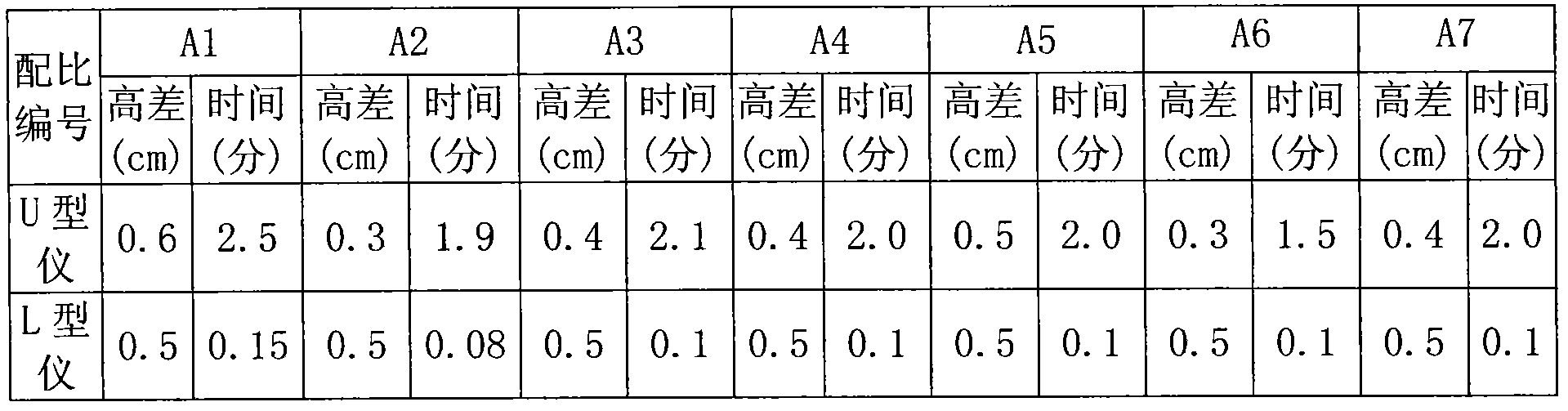

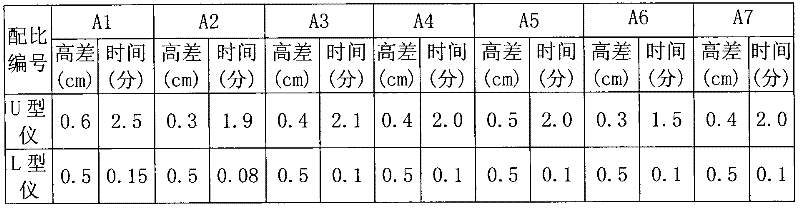

Self-compacting concrete

InactiveCN102060482AImprove volume stabilityIncreased durabilitySolid waste managementSuperplasticizerCoal

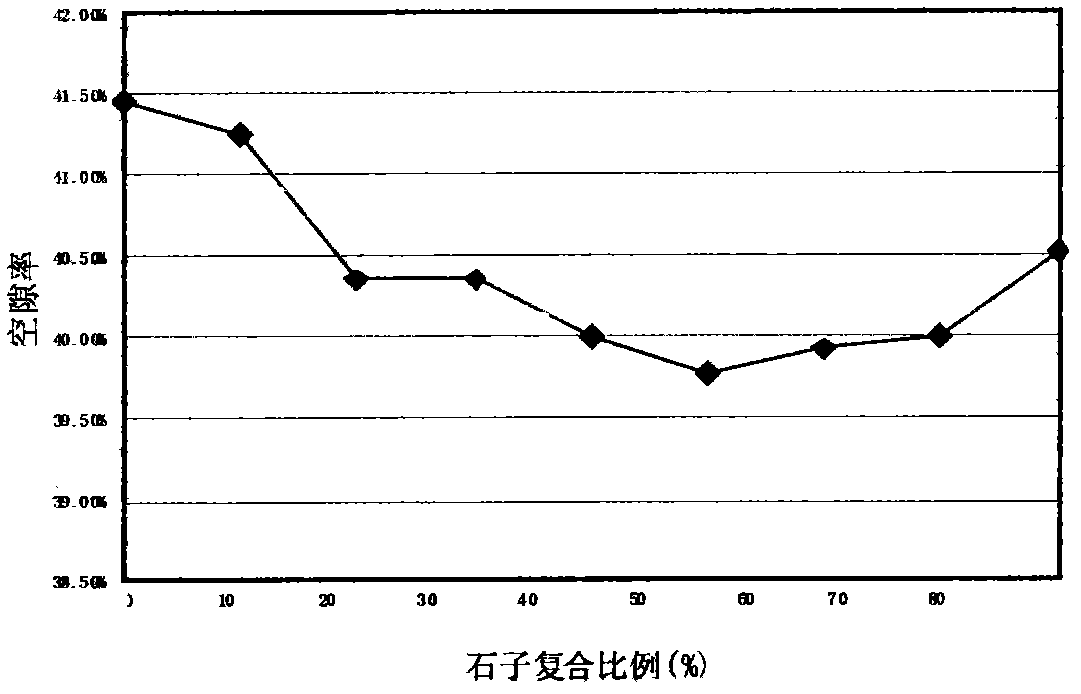

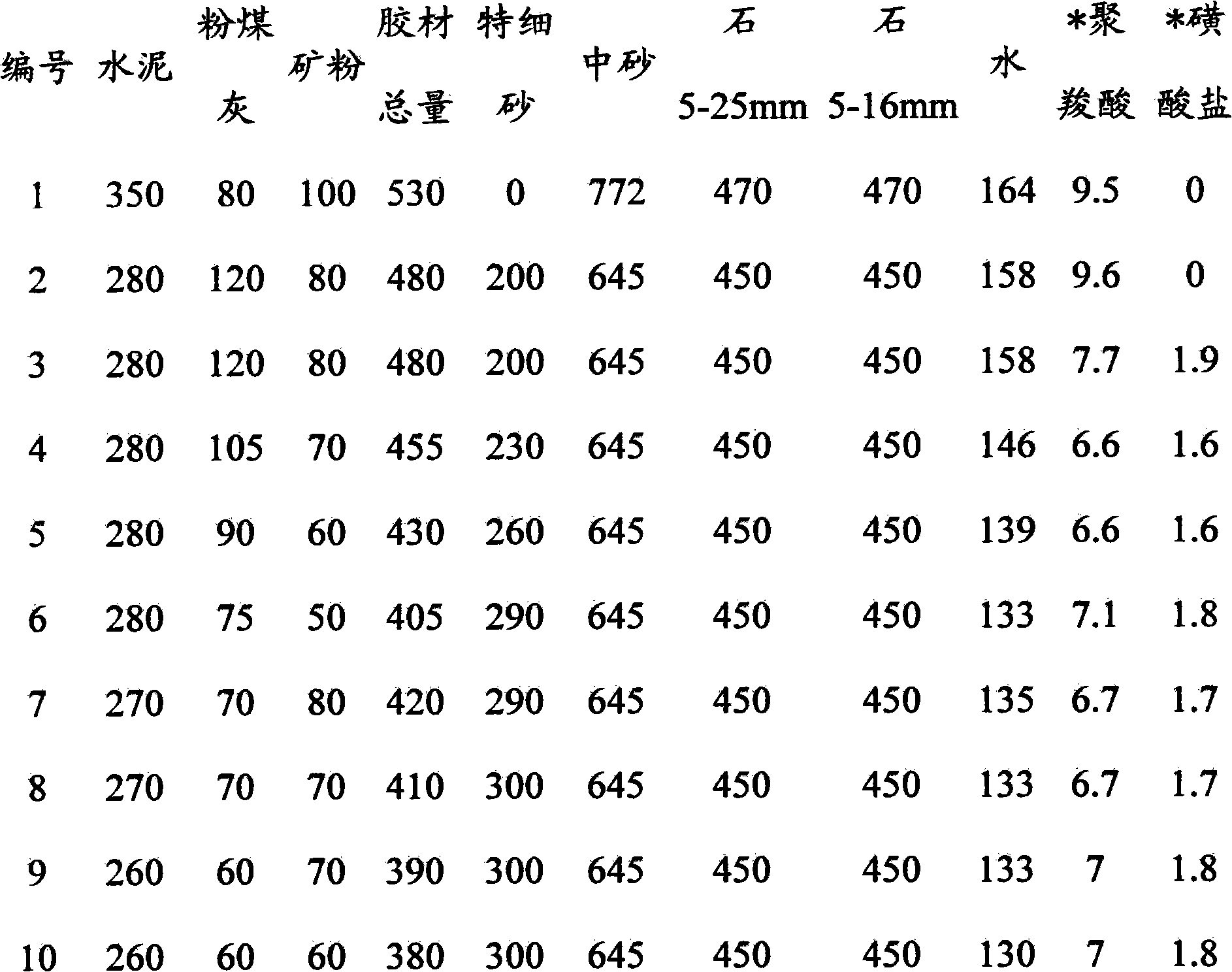

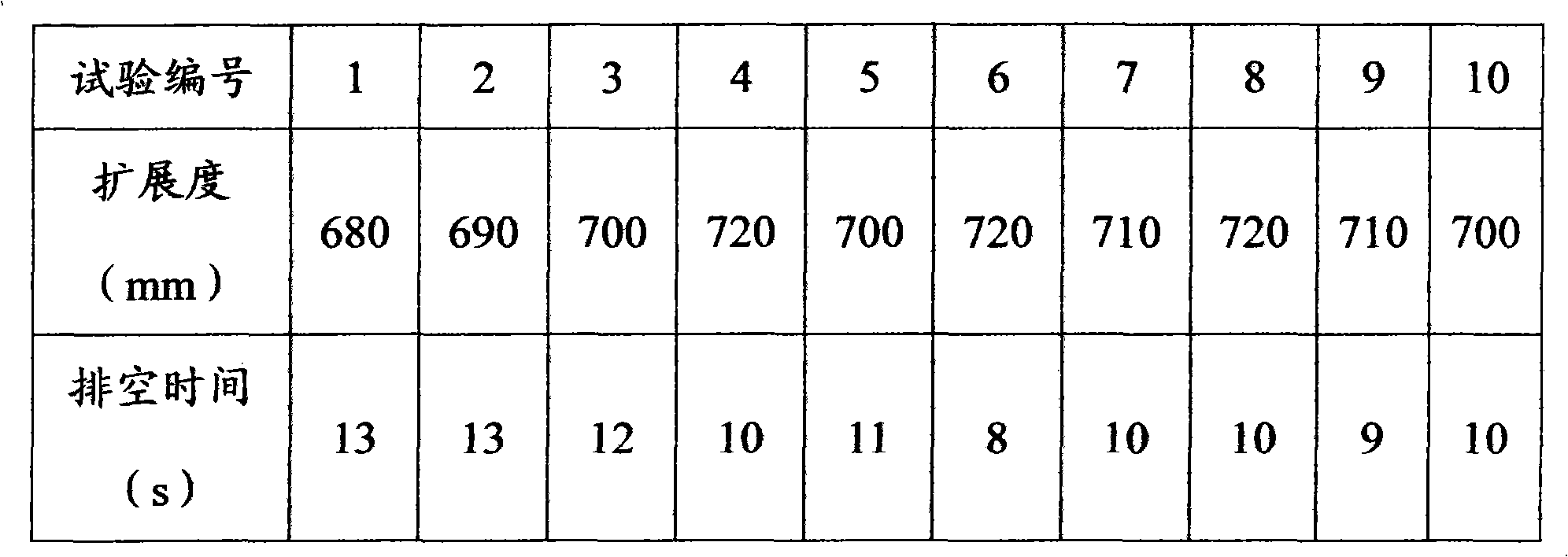

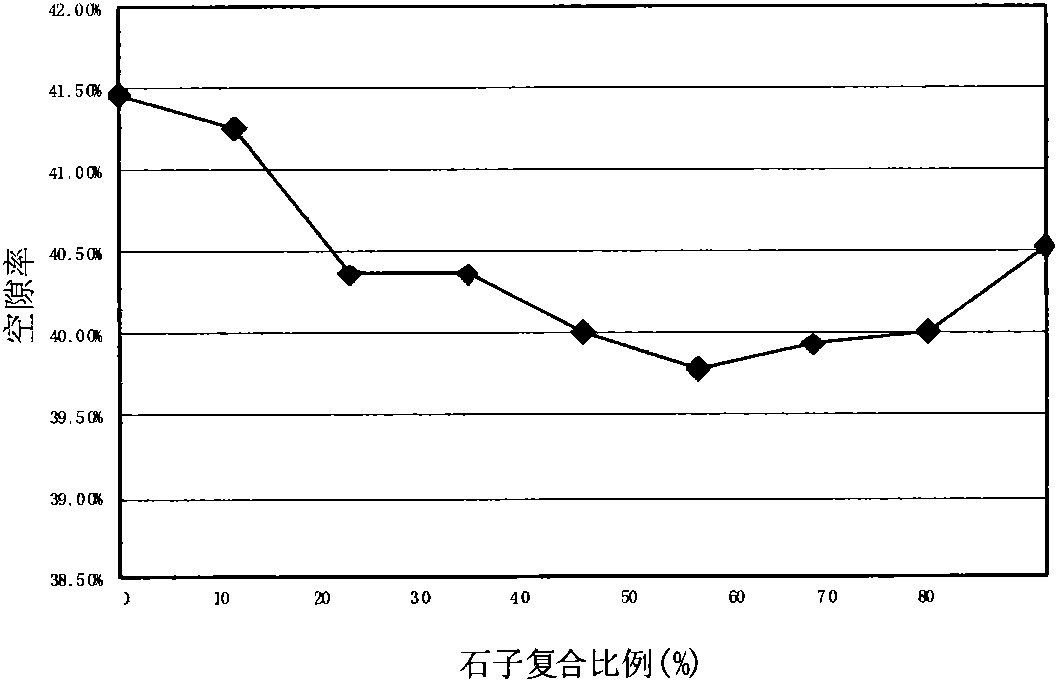

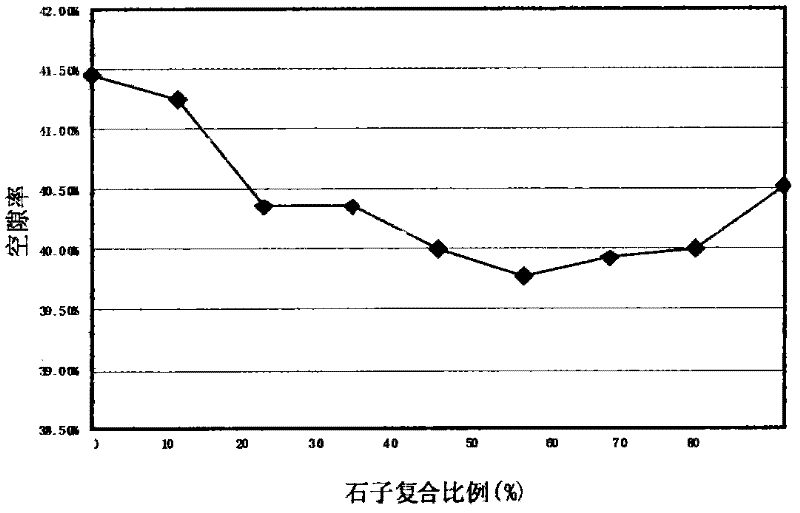

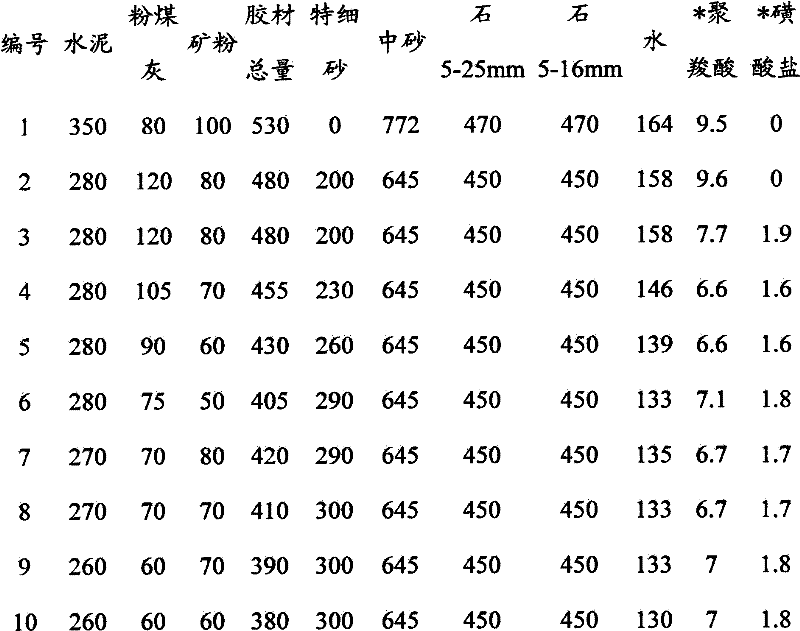

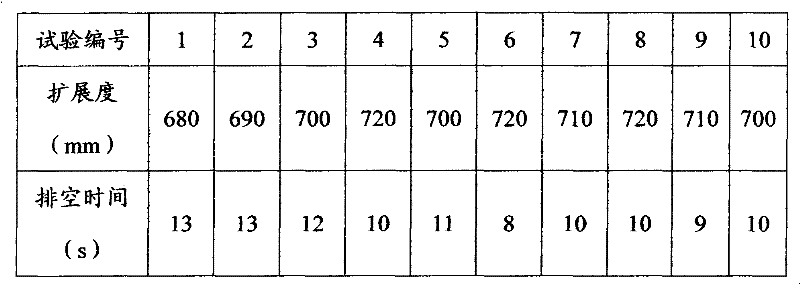

The invention relates to self-compacting concrete which is used for overcoming the contradiction between flowability and stability, early strength and delayed coagulation, contraction and expansion and the like of the self-compacting concrete in the prior art. In the invention, by means of combination of an aliphatic (hydroxyl) sulfonate superplasticizer and a polycarboxylic acid superplasticizer, selection and collocation of a cementing material and coarse and fine aggregates as well as specific mix design, the self-compacting concrete (more than C40) with low consumption of the cementing material is prepared from coal ash, mineral powder and tailings, wherein, a ketoaldehyde condensate is taken as the main component of the aliphatic (hydroxyl) sulfonate superplasticizer; and when the superplasticizer is added to cement paste, the mixed concrete has the advantages of good construction workability, less possibility of bleeding and segregation, no crystallization precipitate at low temperature and the like. Compared with the prior art, the self-compacting concrete prepared by the method provided by the invention has the advantages of lowering cement consumption by at least 70kg / m<3>, reducing consumption of the cementing material by at least 70kg / m<3>, comprehensively utilizing at least 470kg / m<3> of solid waste, and lowering concrete cost by at least **yuan / m<3>.

Owner:北京中联新航建材有限公司 +1

Low cementitious material self-compacting concrete

ActiveCN102060481AIncrease plastic viscosityIncrease the slurry-solid ratioHigh strength concreteSelf-consolidating concrete

The invention discloses low cementitious material self-compacting concrete. Cement is a main raw material in a cementitious material of the self-compacting concrete; and if the cement consumption is high, overhigh concrete shrinkage is easily caused due to overhigh hydration heat of the cement, which is unfavorable for concrete crack control and concrete durability improvement, and problems such as disintegration, bleeding and the like easily occur. An additive XAMC is added into the concrete formula and can adsorb onto surfaces of particles to form a close adsorption layer so as to prevent the particles from flocculating and aggregating to realize the dispersion and stabilization function. Water-washing superfine sand which is rich in resources replaces partial mineral admixture, the low cementitious material self-compacting concrete can meet the basic requirement of high strength concrete by adding the XAMC under the condition of reducing cement consumption, and has obvious thickening and water retaining functions; concrete mixtures do not bleed or disintegrate, the homogenization and workability of the concrete are improved, and the concrete has important significance for saving energy and reducing emission.

Owner:北京元泰达环保科技有限公司

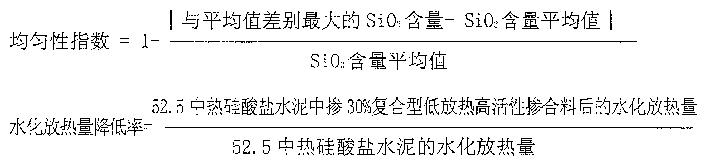

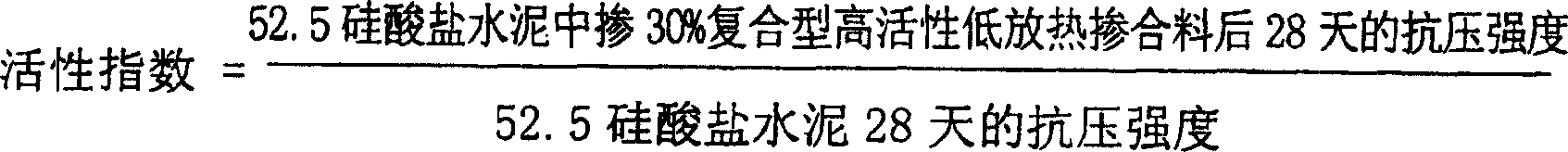

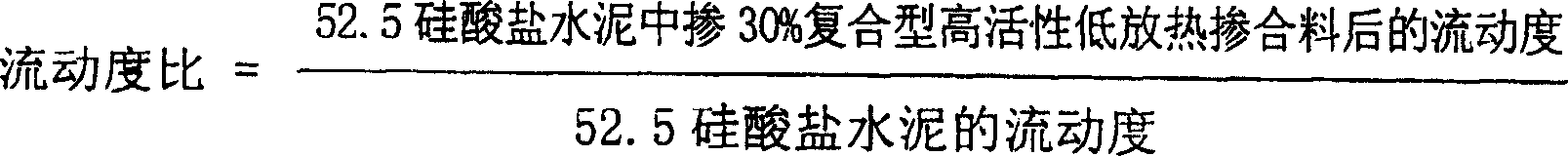

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

InactiveCN1401607ALow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

High strength silica powder concrete and construction technology

InactiveCN101538137AReduce cement consumptionReduce adiabatic temperature riseSolid waste managementSilica fumePozzolanic reaction

The invention discloses high strength silica powder concrete and a construction technology thereof. The optimal selection of raw materials and the optimal design of mixing proportion are used as footholds, the measure of mixing pulverized fuel ash and silica powder with selected moderate-heat or low heat cement replaces other measures of mixing composite high efficiency water reducing agent, fibers, and the like with parts of cement, so as to reduce the use level of the cement as much as possible and to reduce the adiabatic temperature rise of the cement, thereby greatly overcoming the disadvantages of the silica powder, improving the early-age cracking-resistance property of the cement, and giving full play to the gap filling efficacy and the pozzolanic reaction property of the silica powder. While strengthening the intensity of the concrete, the invention effectively avoids the technical problem of early-age cracking during the silica powder construction.

Owner:吴运华

Mineral admixture concrete

The invention relates to a mineral admixture concrete. Mineral admixtures are used as concrete cementitous materials, common concrete and a complex of gypsum and sodium sulfate are added and used as activity excitants so as to coordinate the combined action of naphthalenesulfonate formaldehyde condensate and a crude anthracene sulfonate superplasticizer, and the high-efficiency concrete is prepared. Compared with the prior art, the excitants in the invention has the advantages that early excitation effect is good, mixing amount is less, the early or later strength and durance of the concrete can be greatly improved, the concrete dosage is reduced by 5-20% under the condition of maintaining the strength and workability of the concrete not to be changed, and the gypsum and sodium sylfate are both industrial byproducts with low costs. In the invention, concrete plaster is mixed in advance by using a secondary feeding method, residual materials are added in the mixed concrete plaster, and the strength of the concrete is improved while reducing the abrasion of coarse aggregates on equipment. The concrete has the advantages of good workability and less bleeding, is convenient for construction, and can be applied to large-volume concrete engineering, underground engineering, seaport engineering and the like.

Owner:北京元泰达环保科技有限公司

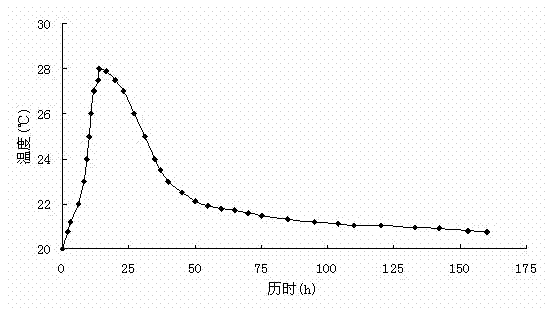

Concrete composite additive and preparation method and use thereof

ActiveCN102101759AReduce concrete temperature riseReduce temperature difference between inside and outside of concreteCalcium lignosulfonateCement Material

The invention relates to a concrete additive and discloses a concrete composite additive capable of optimizing a hydration heat release process of cement, which is prepared from the following raw materials in percentage by mass: 65 to 75 percent of naphthalene sulfonate-formaldehyde condensation product, 9 to 15 percent of lignosulfonic acid calcium salt, 8 to 10 percent of sodium gluconate and 8 to 10 percent of sucrose. When the additive is used, the hydration heat release of cement has the characteristic of two peaks and equal peak values. When other conditions are the same, the hydration heat half age of the cement mixed with the additive is three times longer than cement mixed with a naphthalene sulfonate water reducer and a concrete thermal-insulation temperature rise at a 7d age is reduced by about 7 DEG C; and the additive allows a cooling measure of introducing water to concrete to play a better cooling role, reduces the temperature rise peak value of the concrete by about 4 DEG C, ensures a remarkable cooling effect and has a great significance for the temperature control and cracking prevention of concrete. In addition, when the product provided by the invention is added, the pressure strength, working performance, durability and the like of concrete are all improved obviously.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

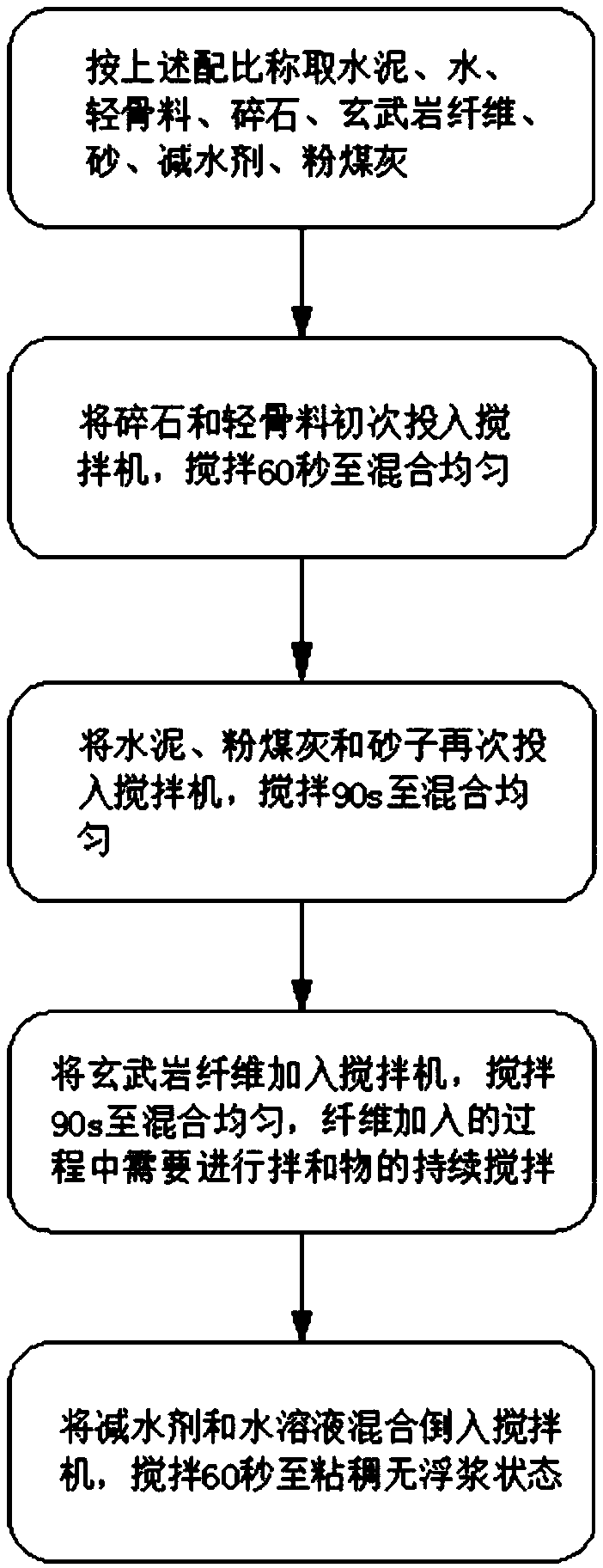

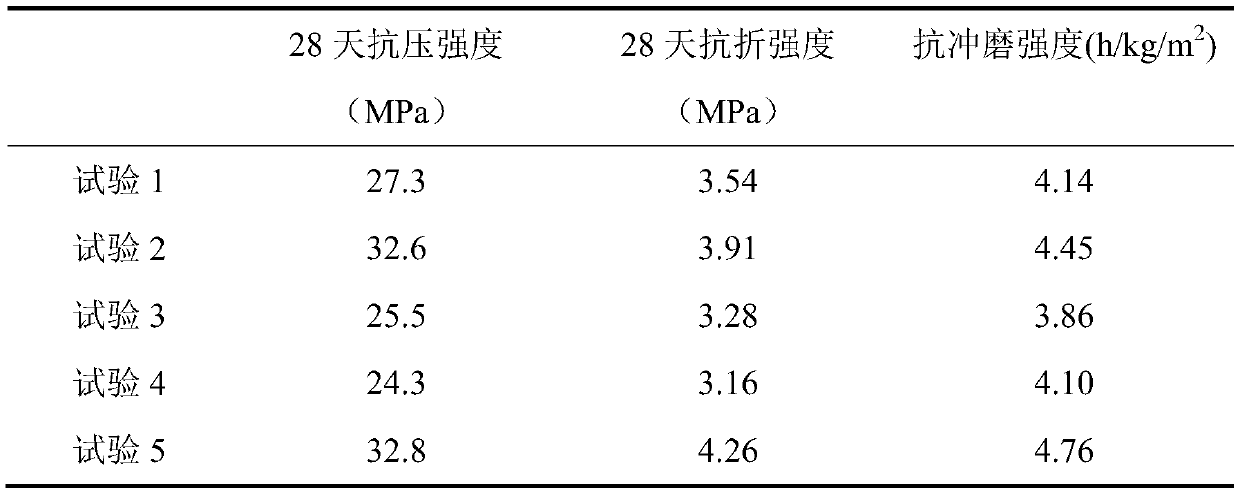

Shrinkage-reducing anti-cracking pavement cement concrete and preparing method thereof

Shrinkage-reducing anti-cracking pavement cement concrete and a preparing method thereof are disclosed. The cement concrete is prepared from water, cement, fly ash, basalt fibers, light aggregate, broken stone, sand and a water reducing agent in a mass ratio of (180-200):(400-410):(40-50):(2.65-5.3):(229-286):(465-559):(830-850):(4.1-4.5). The light aggregate is uniformly dispersed in the concrete, the concrete is not liable to crack, adhesive force between the fibers and cement slurry is high, microcrack development is slow, and the concrete has high fatigue resistance and tension resistance.

Owner:CHANGAN UNIV

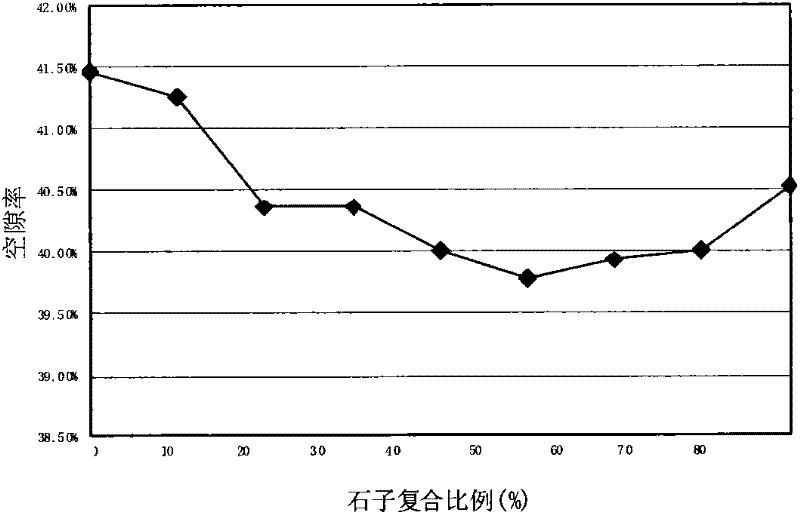

Pervious concrete

The invention discloses pervious concrete which is characterized in that the pervious concrete is prepared from the following components in parts by mass: 1500-1600 parts of coarse aggregate, 320-420parts of a cementing material, 105-114 parts of water and 4.5-5.9 parts of a water reducing agent. An anti-corrosion material in the formula has remarkable plasticizing effect, micro-aggregate effect,morphological effect and temperature peak reduction effect, and the mechanical property, abrasion resistance and denudation resistance of the pervious concrete can be improved through the excellent characteristics of the anti-corrosion material itself and the improvement of the continuous grading of the microstructure of the cementing material, so that the durability of the pervious concrete is improved, and the service lifetime of the pervious concrete is prolonged.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Marine fair-faced concrete containing limestone powder and preparation method of concrete

The invention discloses marine fair-faced concrete containing limestone powder. The marine fair-faced concrete is prepared from components as follows: a concrete additive, a mixed cementing material, aggregate and water, wherein the mixed cementing material is prepared from cement and a concrete admixture; the concrete admixture is prepared from the limestone powder and granulated blast-furnace slag powder, the added limestone powder accounts for 5%-20% of the total mass of the concrete, and the added granulated blast-furnace slag powder accounts for 15%-40% of the total mass of the concrete; the consumption of the cementing material is 320-450 kg / m<3>, and the ratio of water to the cementing material is 0.30-0.42. According to the fair-faced concrete, fly ash is replaced with the limestone powder, the problem of raw material shortage due to adoption of fly ash is solved, defects of the fair-faced concrete adopting the fly ash are also avoided, the homogeneity and the workability of the concrete are improved simultaneously, the concrete bleeding risk is reduced, the requirement for durability is met, the appearance quality of the concrete structure is stable, and the requirement for the appearance quality of the fair-faced concrete is met.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

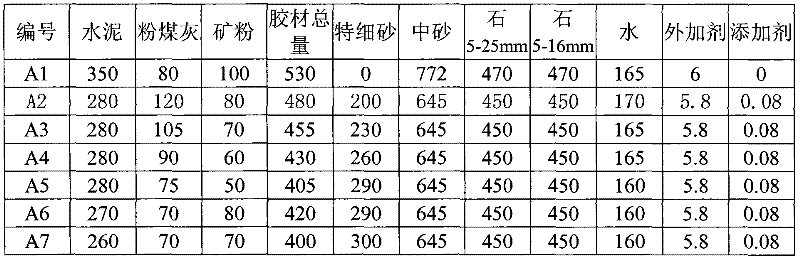

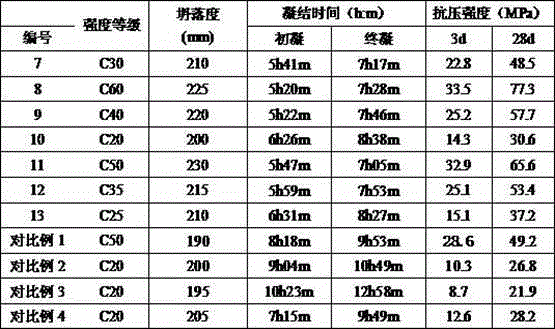

Modified phosphorous slag powder, concrete prepared from modified phosphorous slag powder and preparation method of concrete

ActiveCN103755186AReduce dosageReduce the effect of hydration reaction rateSolid waste managementMetallurgyStarch

The invention provides a modified phosphorous slag powder, a concrete prepared from the modified phosphorous slag powder and a preparation method of the concrete, and belongs to the technical field of concrete preparation. The modified phosphorous slag powder comprises a phosphorous slag powder, an organic salt and cationic starch. The organic salt and the cationic starch are used for modifying the phosphorous slag powder in stead of common chemical excitation carried out on the phosphorous slag by using an inorganic alkali activator in the prior art; when the modified phosphorous slag powder is used for preparing the concrete, the dosage of the modified phosphorous slag powder accounts for 38-70wt% of the total amount of the cementing material; the 3d compressive strength of the concrete ranges from 14.5 to 33.5MPa, and the 28d compressive strength of the concrete ranges from 30.6 to 77.3MPa, and the stability of the concrete is good; the utilization rate of the phosphorous slag powder is greatly reduced while the cost of the concrete is reduced, and therefore, the environmental pollution problem caused by the phosphorous slag can be reduced.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Concrete composite additive and preparation method and use thereof

The invention relates to a concrete additive and discloses a concrete composite additive capable of optimizing a hydration heat release process of cement, which is prepared from the following raw materials in percentage by mass: 65 to 75 percent of naphthalene sulfonate-formaldehyde condensation product, 9 to 15 percent of lignosulfonic acid calcium salt, 8 to 10 percent of sodium gluconate and 8to 10 percent of sucrose. When the additive is used, the hydration heat release of cement has the characteristic of two peaks and equal peak values. When other conditions are the same, the hydration heat half age of the cement mixed with the additive is three times longer than cement mixed with a naphthalene sulfonate water reducer and a concrete thermal-insulation temperature rise at a 7d age isreduced by about 7 DEG C; and the additive allows a cooling measure of introducing water to concrete to play a better cooling role, reduces the temperature rise peak value of the concrete by about 4 DEG C, ensures a remarkable cooling effect and has a great significance for the temperature control and cracking prevention of concrete. In addition, when the product provided by the invention is added, the pressure strength, working performance, durability and the like of concrete are all improved obviously.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

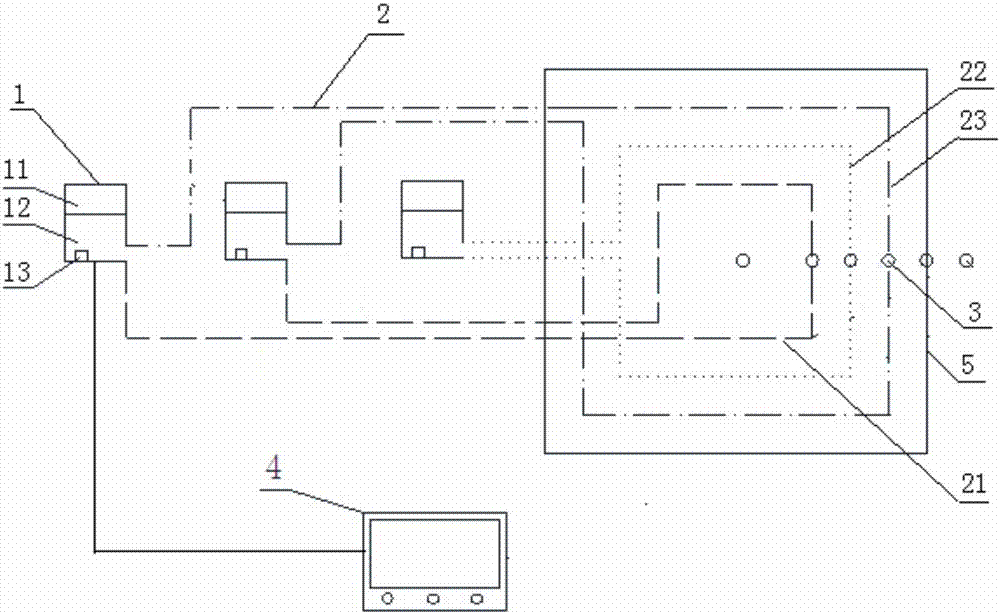

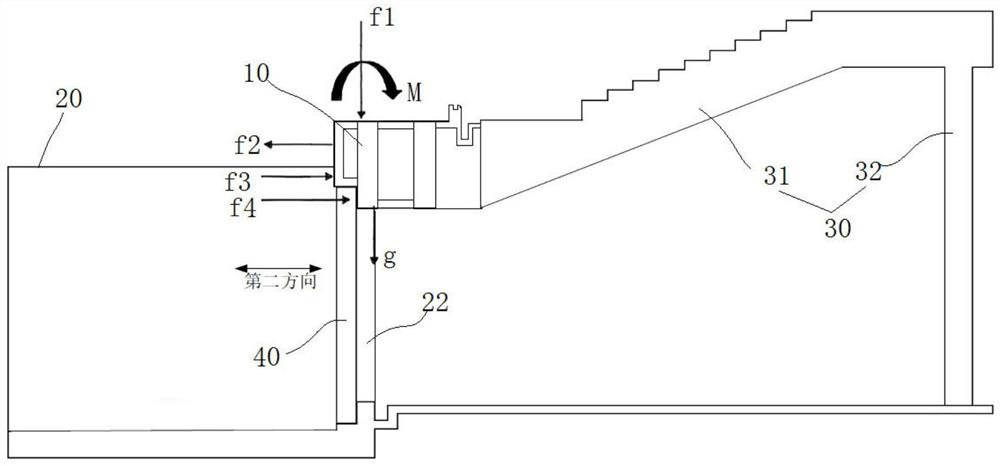

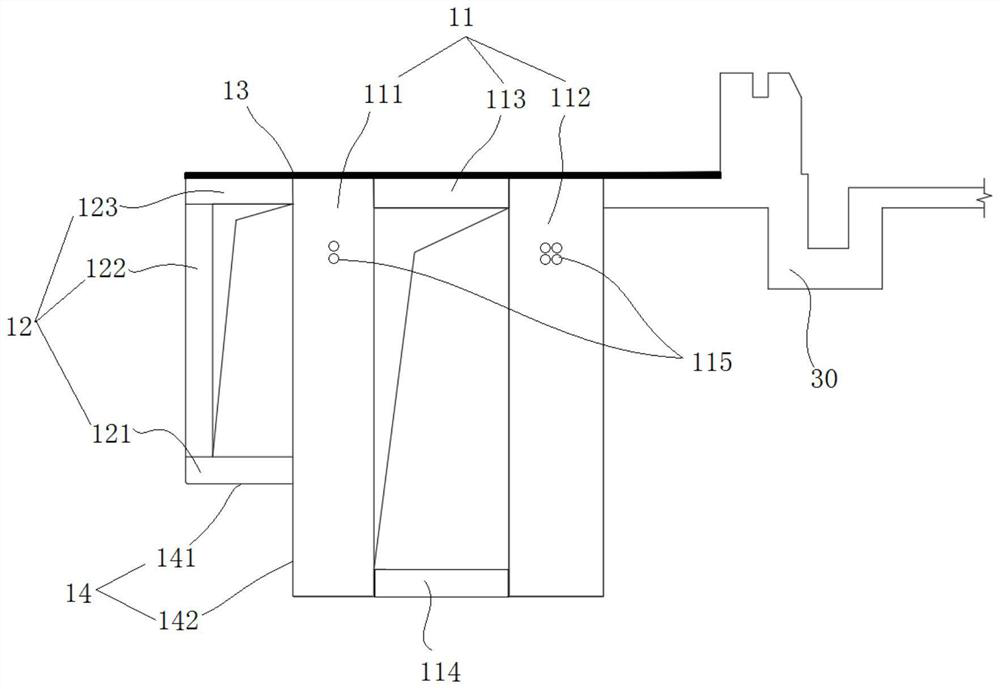

Gradient type concrete water pipe control system and control method

ActiveCN107013047ALower core temperatureReduce adiabatic temperature riseDomestic cooling apparatusLighting and heating apparatusInlet temperatureWater pipe

The invention relates to the field of civil engineering, in particular to a gradient type concrete water pipe control system and control method. According to the gradient type concrete water pipe control system and control method, in the temperature rising period of concrete, the center temperature of the concrete can be reduced as quick as possible with the highest efficiency, the temperature can be reduced by 20-25 DEG C at maximum, adiabatic temperature rising of the concrete is equivalently reduced, and the cracking risk is reduced; in the temperature decreasing period of the concrete, the temperature decreasing speed of the concrete can be reduced by adjusting the water temperatures of water pipes in different positions of the concrete, the temperature decreasing speed of the concrete is smaller than or equal to 3.0 DEG / day, impact of contraction deformation is reduced, and the cracking risk is reduced; and meanwhile the concrete water pipe control system can automatically read the temperatures of temperature measuring points inside the concrete and adjust the water inlet temperatures of the water pipes according to the actual temperatures of the parts inside the concrete, the temperature gradient among the interior, middle and exterior of the concrete and air is reduced to the maximum extent, and the cracking risk is reduced.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

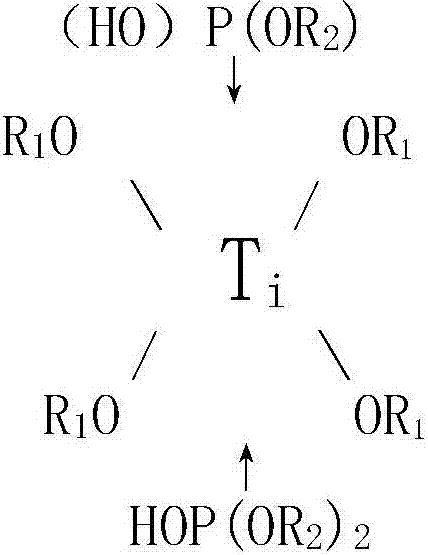

Efficient concrete performance enhancement additive and preparation method thereof

The invention relates to an efficient concrete performance enhancement additive. The additive is characterized by containing the following components in parts by mass: 10-15 parts of a coupling agent, 4-6 parts of zinc oxide powder, 4-5 parts of activated carbon, 20-25 parts of white carbon black and 30-40 parts of polyester fiber. The additive is prepared by the steps of mixing weighed titanic acid phosphate ester, zinc oxide powder, activated carbon and white carbon black powder into a stirring machine, mixing, distributing to packaging bags according to the weight, and weighing and feeding required polyester fiber into packaged powder bags, so as to obtain a finished product. According to the efficient concrete performance enhancement additive, the impaction resistance, wear resistance, durability, splitting tension strength, axial tension strength and bending strength of concrete are greatly enhanced, the adiabatic temperature rise is decreased, the cracking resistance and the permeability resistance are improved, and the waterproof protecting period of the concrete to a building is greatly prolonged.

Owner:江苏汉普顿新材料科技有限公司 +1

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

InactiveCN1185178CLow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

Prefabricated duplex block concrete construction mixing ratio and manufacturing technology thereof

The invention relates to a prefabricated duplex block concrete construction mixing ratio which is prepared by uniformly stirring the following raw materials according to the following ratio through a concrete stirring machine, wherein the bulk density is 2300-2500kg / m<3>, and the specific mixing ratio is as follows: 350-370kg / m<3> of cement, 770-790kg / m<3> of sand, 620-650kg / m<3> of broken stones 1, 415-435kg / m<3> of broken stones 2, 8.80-9.20kg / m<3> of a polycarboxylic high-performance water reducer, 60-80kg / m<3> of fly ash and 160-170kg / m<3> of water. A manufacturing technology comprises the following steps: sequentially adding the broken stones 1, the broken stones 2, the cement, the fly ash, the sand and the water in a stirring tank, and finally adding the polycarboxylic high-performance water reducer; and stirring for 90-120s after addition is finished, and finally forming a mixture with the 28d strength greater than or equal to 40MPa, the collapsing degree being 140-160mm and the out-of-machine temperature of a mixture lower than 30 DEG C. The prefabricated duplex block concrete construction mixing ratio can solve the problem of concrete quality such as concrete bubbles, cracking, cracks or the like and is suitable for regions with the temperature being 30-40 DEG C.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG +1

Preparation process and construction method of special external-adding hydraulic light burning magnesium oxide dam concrete having adjustable expanding process

ActiveCN106587693AGood engineering qualityReduce temperature control measuresBarrages/weirsTemperature controlThermal insulation

The present invention discloses a preparation process of special external-adding hydraulic light burning magnesium oxide dam concrete having an adjustable expanding process, wherein the adding amount, the fineness compostion, the active index, the calcining temperature and the calcining thermal insulation time of the special hydraulic light burning magnesium oxide expanding agent are adjusted so as to adjust and control the expanding-age process of the external-adding hydraulic light burning magnesium oxide dam concrete. The invention further discloses a construction method of the special external-adding hydraulic light burning magnesium oxide dam concrete having the adjustable expanding process. According to the present invention, the expanding process of the special external-adding hydraulic light burning magnesium oxide dam concrete can be adjusted, such that the expanding amount can be compensated according to the requirement of the dam concrete so as to achieve the accurate control, significantly improve the quality of the project, reduce the temperature control measures, save the temperature control cost, save the investment, and improve the benefits of the project.

Owner:GUANGDONG RES INST OF WATER RESOURCES & HYDROPOWER +1

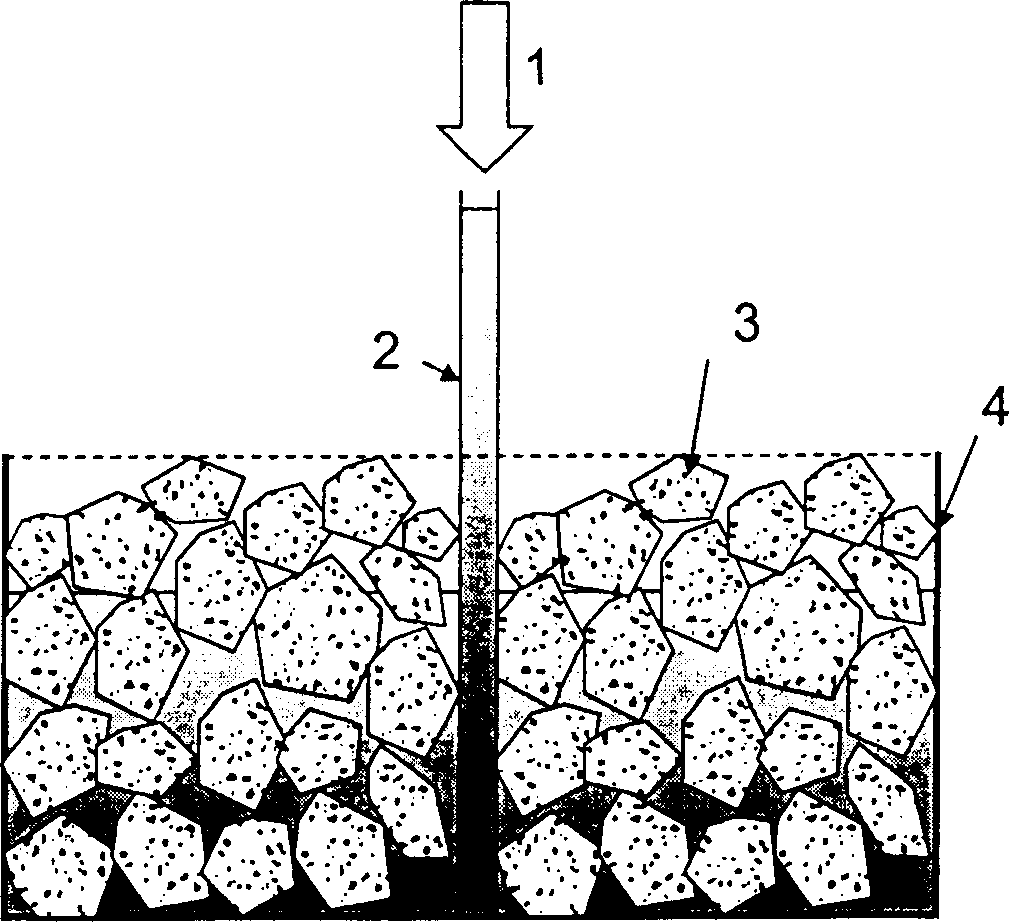

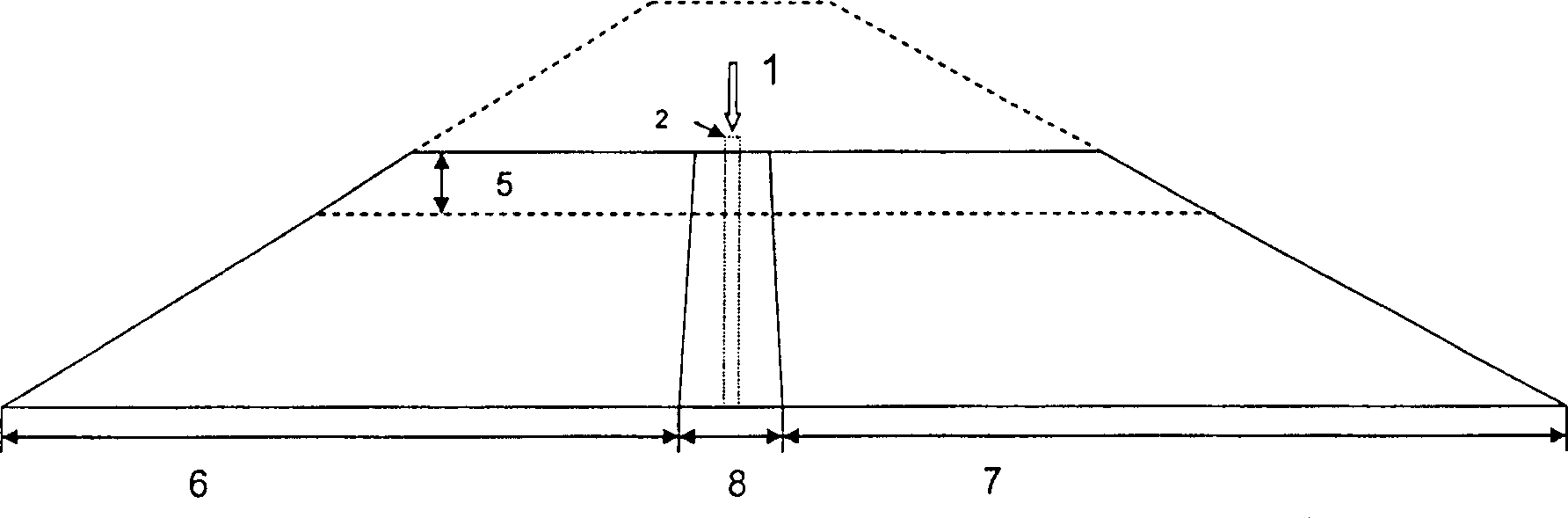

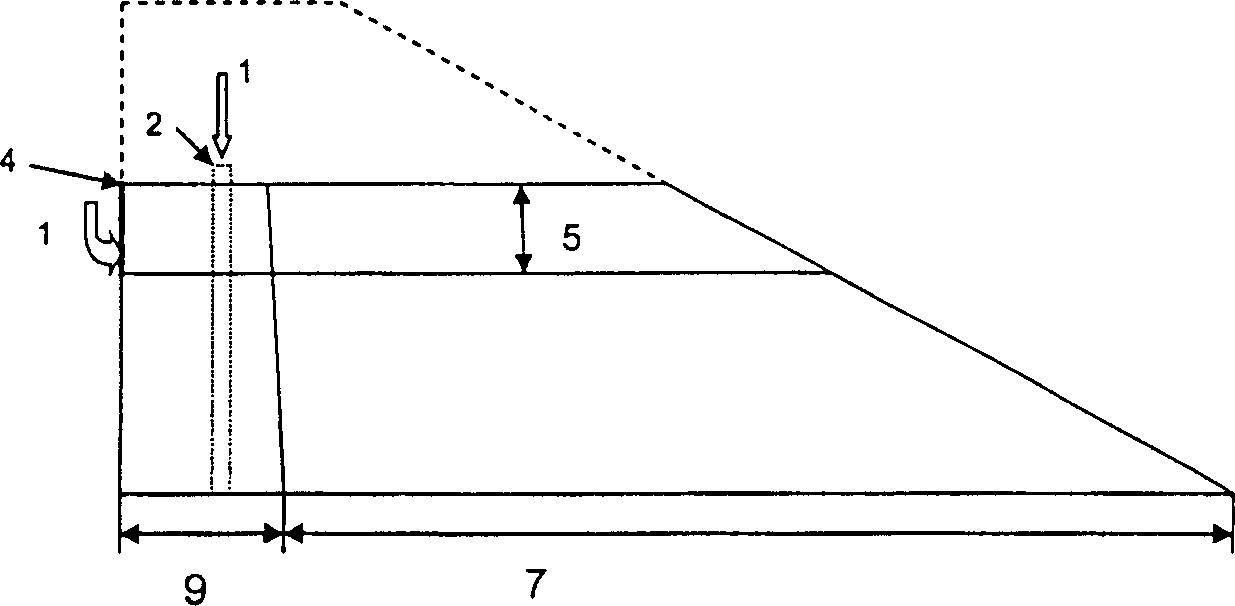

Construction method for rock-fill concrete dam

InactiveCN1238609CReduce adiabatic temperature riseLarge particle sizeBarrages/weirsFoundation engineeringPre embeddingConstruction aggregate

The construction method of rockfill-concrete dam is one dam constructing method as the combination of concrete construction technology and rockfill dam construction technology and adopting one kind of concrete material with good flowability and high material separating resistance. The construction method of the present invention includes using un-sieved or initially sieved rockfill, introducing coarse aggregate in rockfill dam constructing process, pre-embedding grouting pipes to parts to form concrete, grouting concrete via the grouting pipes to void in rockfill to from the rockfill-concrete dam. With rockfill as aggregate can reduce cement consumption, lower cost, speed construction, lower the hydration heat of concrete, simplify process and reduce construction links.

Owner:TSINGHUA UNIV

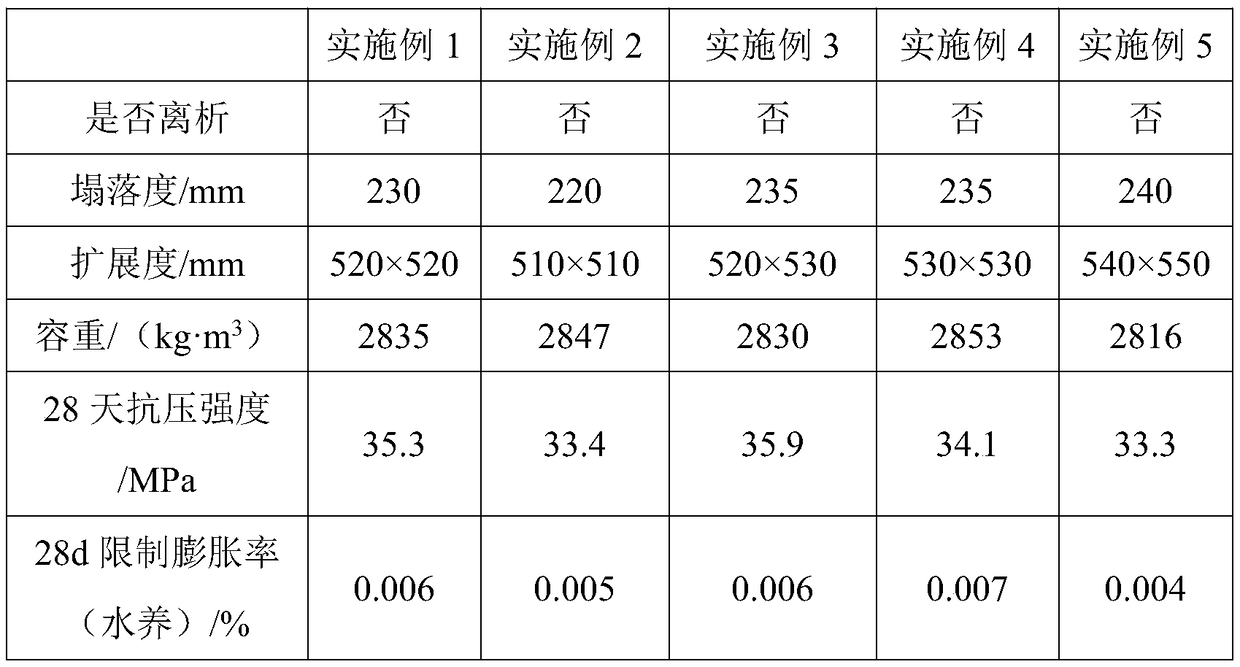

Low thermal micro-expansive cement based radiation shielding concrete and preparation method thereof

InactiveCN109320159AReduce the chance of segregationImprove homogeneityUltimate tensile strengthLarge size

The invention belongs to the field of concrete and particularly discloses low thermal micro-expansive cement based radiation shielding concrete and a preparation method thereof. The low thermal micro-expansive cement based radiation shielding concrete is prepared from the following materials in parts by weight: 280-320 parts of cement, 900-1200 parts of fine aggregates, 1200-1500 parts of coarse aggregates, 10-20 parts of a neutron absorber, 0.4-0.6 part of a water reducer and 140-160 parts of water. The concrete accords with the strength requirements for C30 concrete without the segregation phenomenon, is good in slump and divergence, has the bulk density ranging from 2800 kg.m<3> to 2900 kg.m<3>, has the 28d restrained expansion rate ranging from 0.004 percent to 0.007 percent under thewater cultivation condition, has the characteristics of excellent working performance, good radiation shielding performance, low cost and the like at the same time, solves the problems of easiness insegregation, poor homogeneity, poor construction performance and the like of the traditional radiation shielding concrete, is further beneficial to meeting the requirements for the special performanceincluding non shrinkage, micro expansion, low hydration heat and the like of the radiation shielding concrete and is very suitable for large-size radiation shielding concrete engineering.

Owner:成都宏基建材股份有限公司

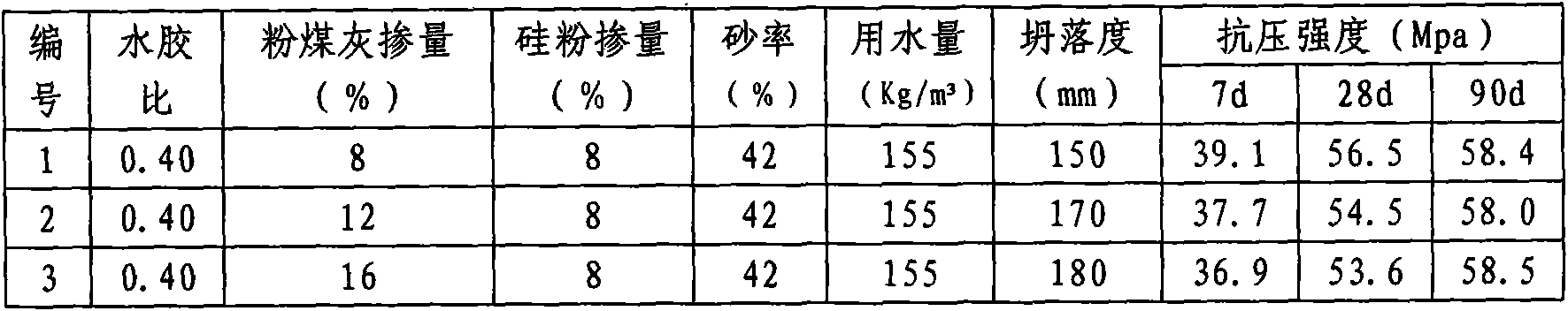

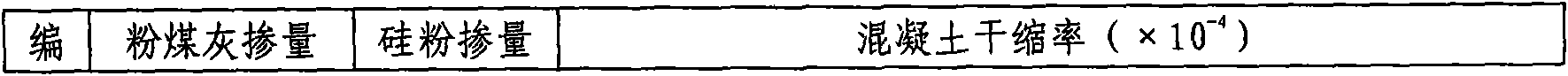

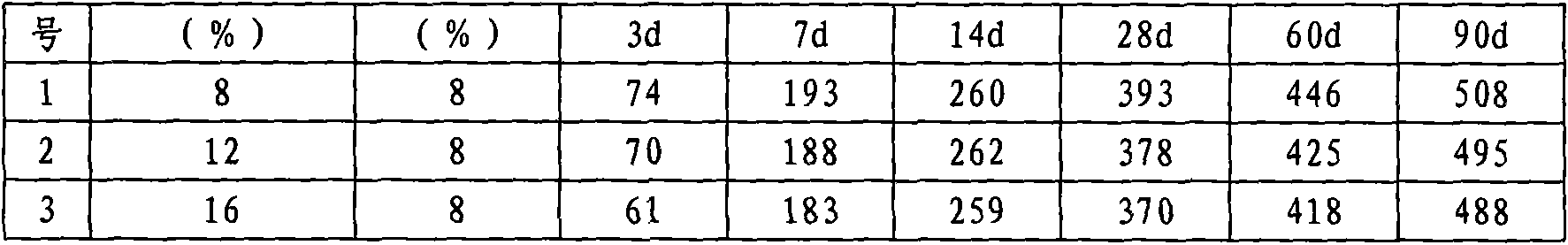

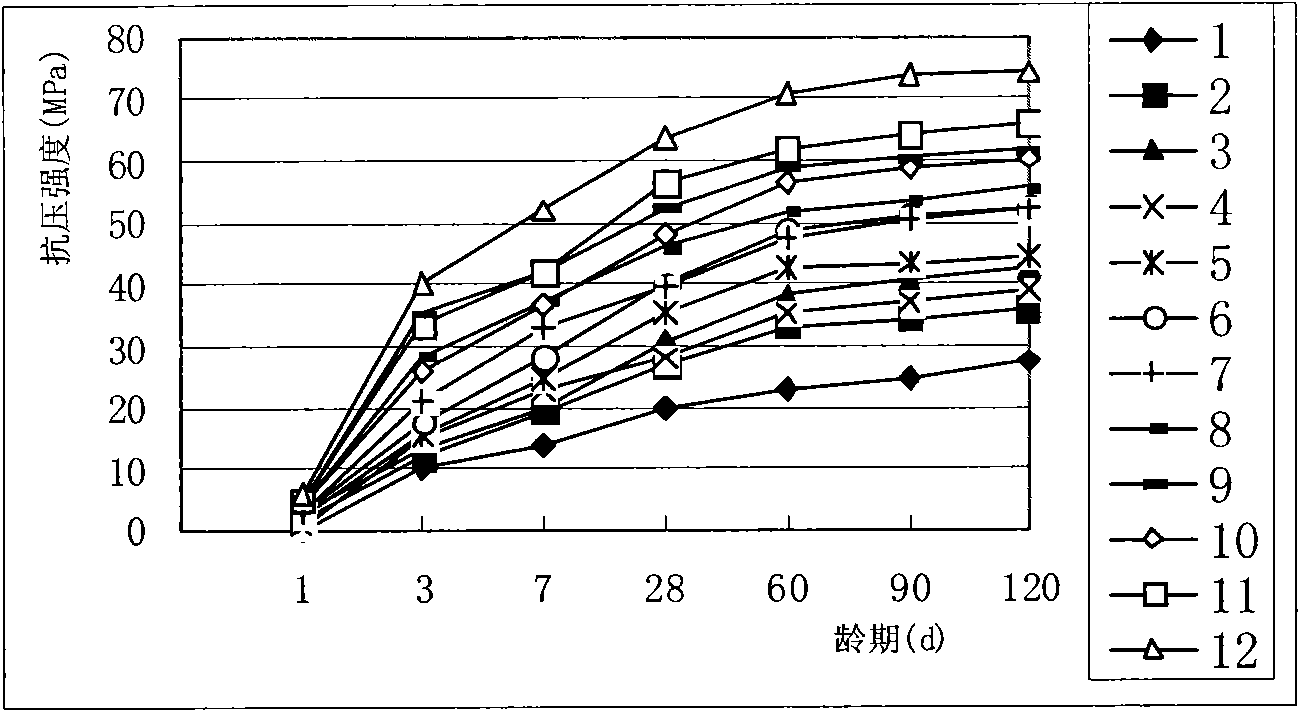

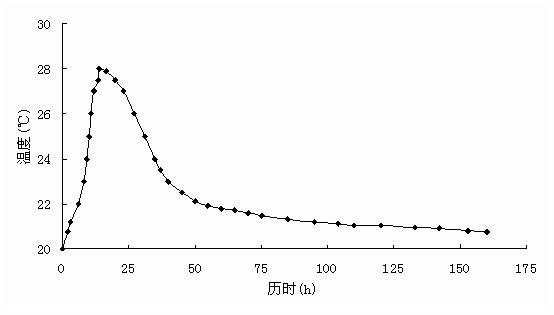

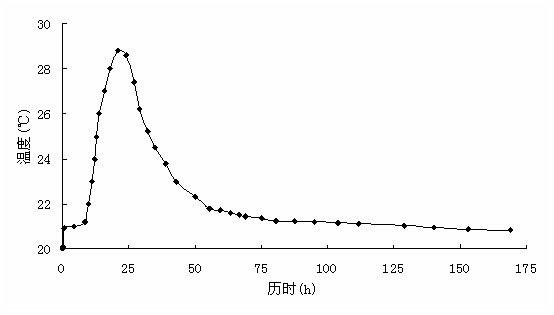

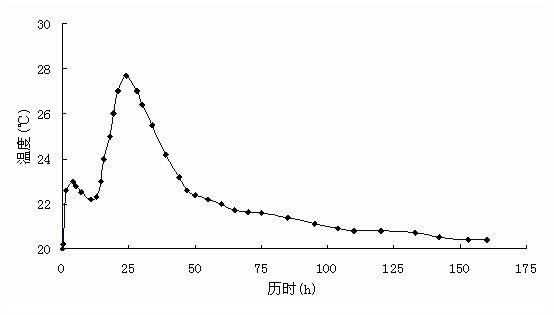

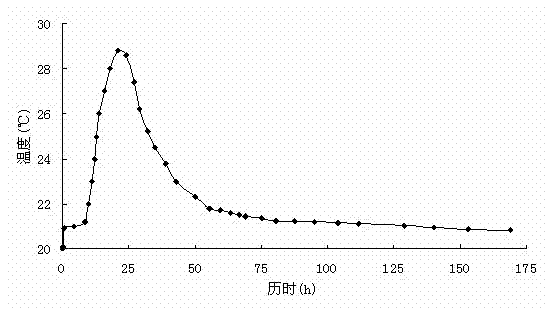

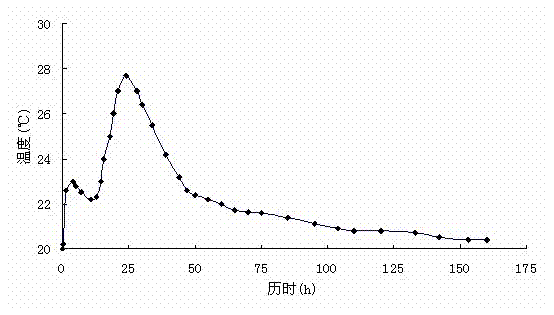

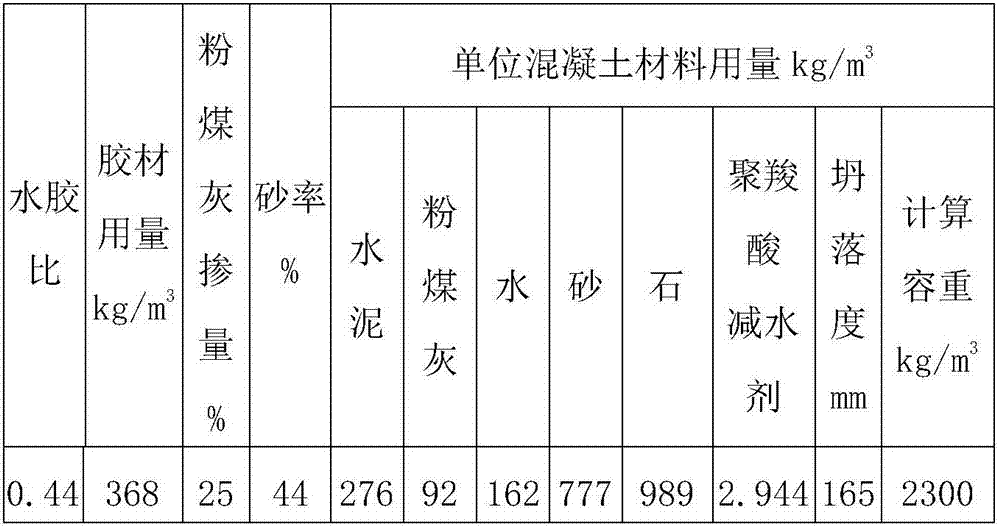

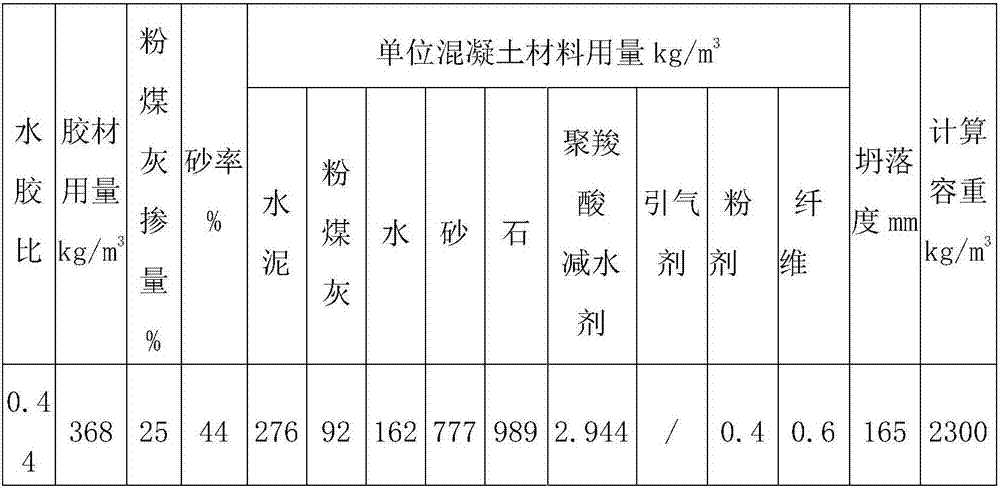

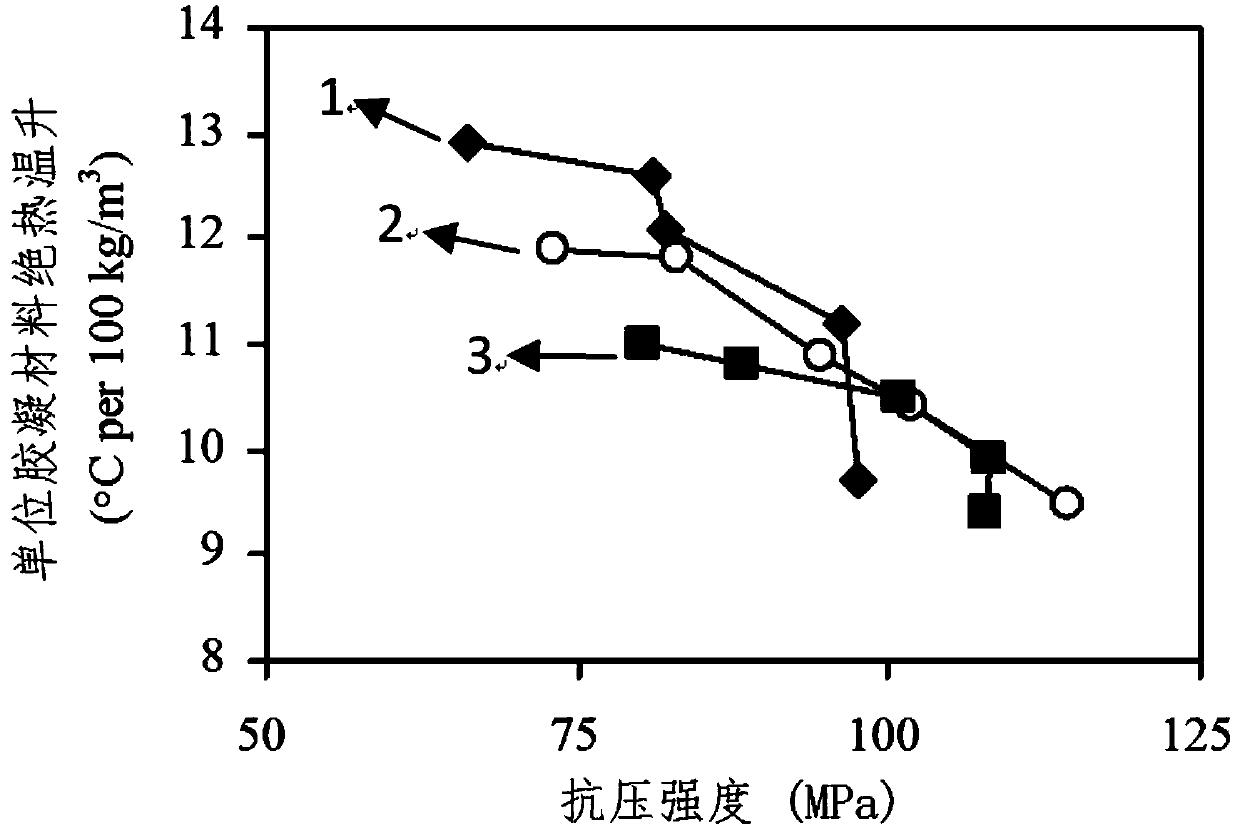

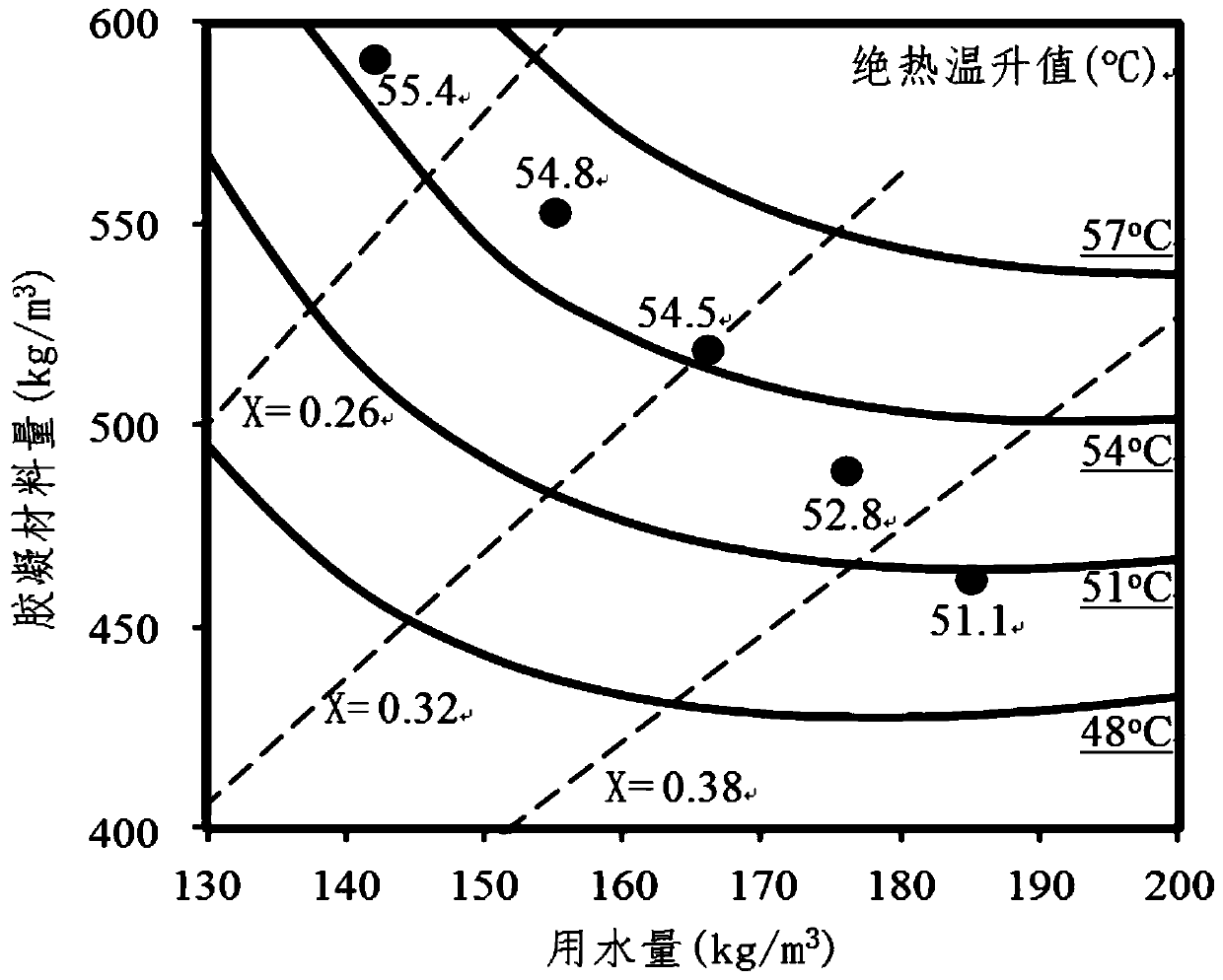

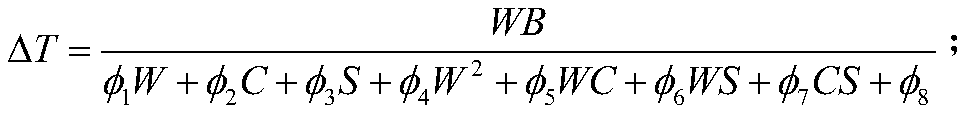

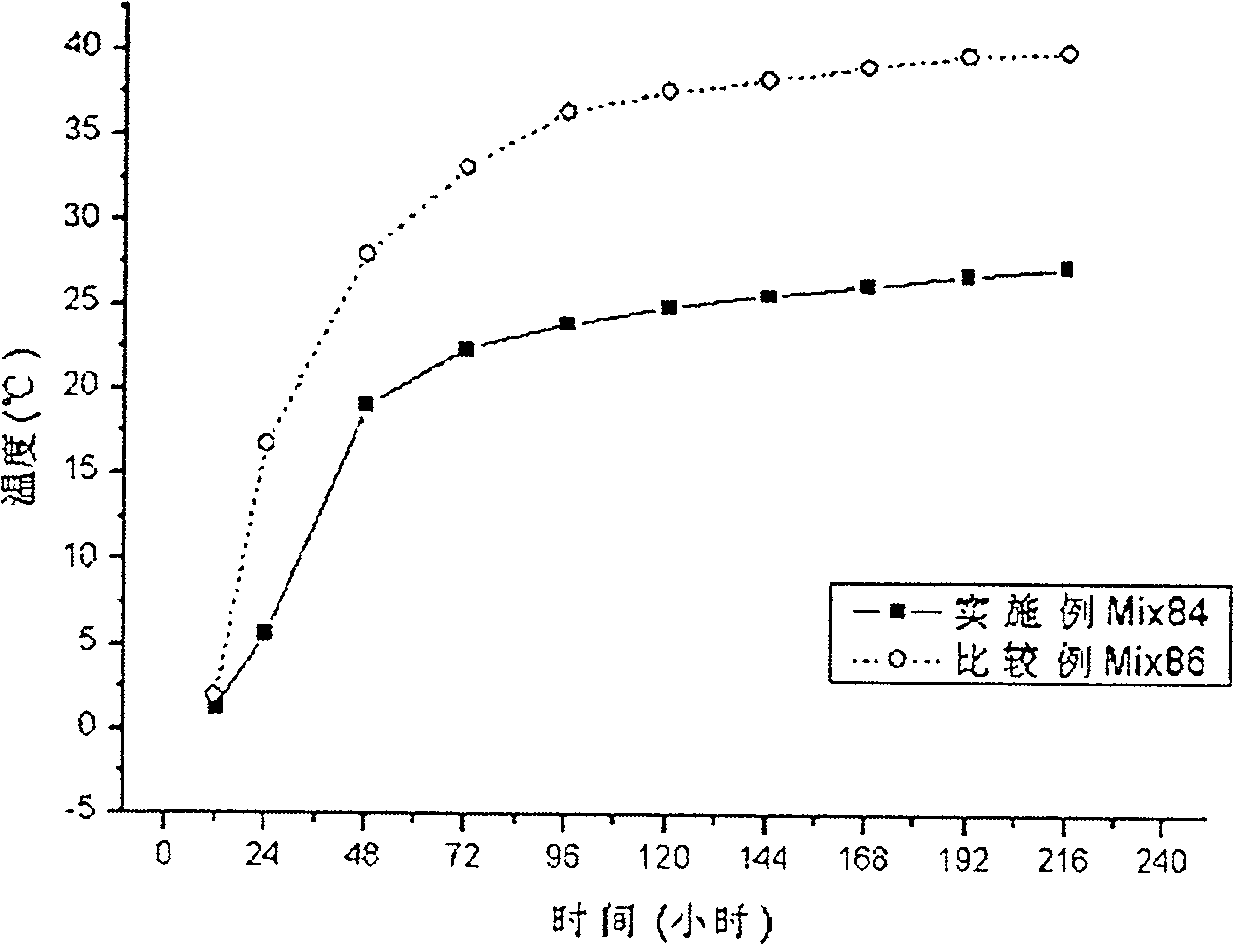

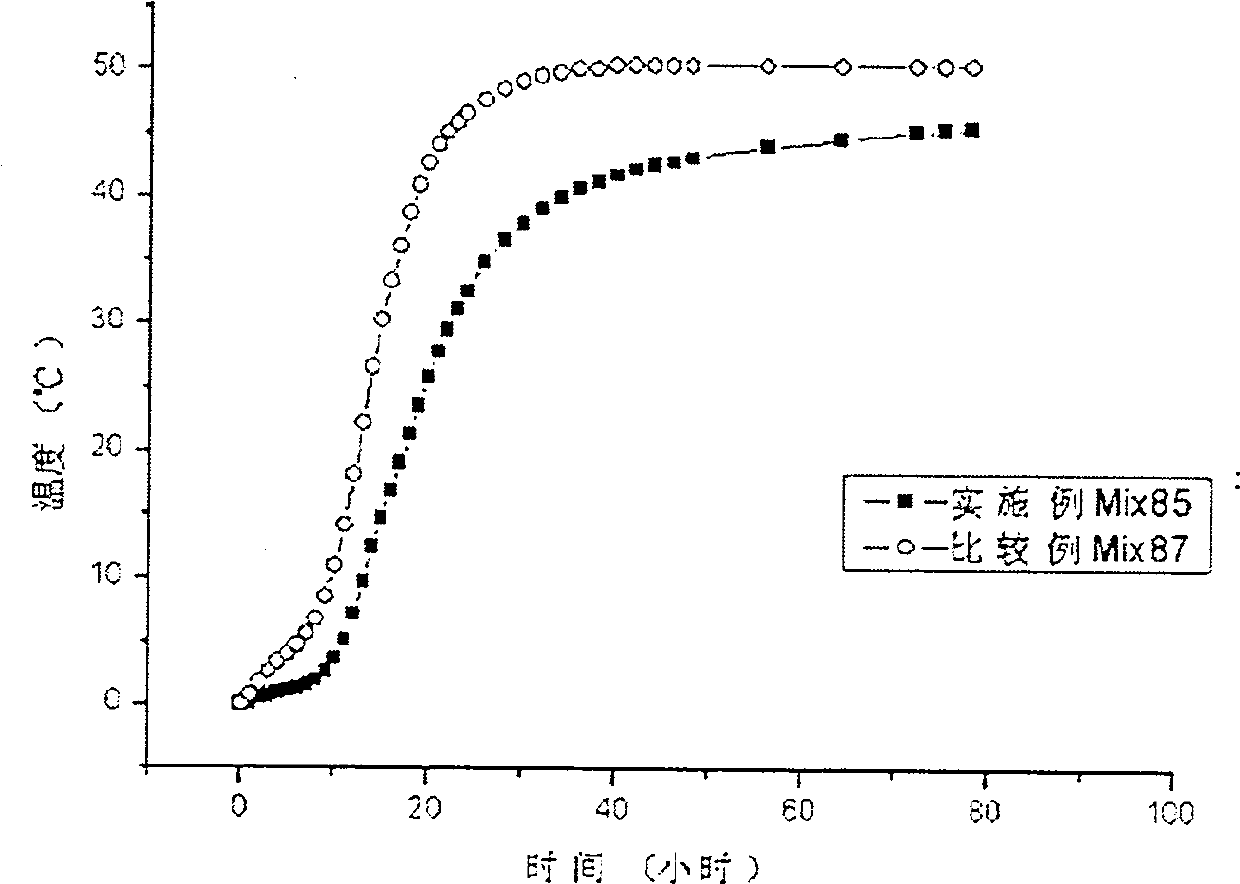

High-intensity low adiabatic temperature rise concrete and analysis method for adiabatic temperature rise value of same

InactiveCN110186954AReduce adiabatic temperature riseHigh strengthMaterial heat developmentRegression analysisHigh intensity

The invention relates to the technical field of concrete, and in particular relates to high-intensity low adiabatic temperature rise concrete and an analysis method for the adiabatic temperature risevalue of the same. Silicon powder can improve performance such as concrete intensity, durability and the like, but the influence of the silicon powder to the adiabatic temperature rise of the concreteis not clear, pertinent literature even summarizes opposite conclusions on the influence of the silicon powder on the heat of the concrete. In order to discuss the influence, the research prepares 15silicon powder concrete proportioned samples with different water-binder ratios, different silicon powder aiming amount to measure half adiabatic temperature rise values, and acquires the adiabatic temperature rise value via a thermal compensation method. The result proves that the adiabatic temperature rise of the concrete can be reduced by silicon powder, and the adiabatic temperature rise value can be significantly reduced under the same intensity requirement. Based on the silicon powder concrete adiabatic temperature rise result, the research acquires the adiabatic temperature rise prediction formula via regression analysis, and the silicon powder concrete adiabatic temperature rise value design drawing is drawn.

Owner:FOSHAN UNIVERSITY

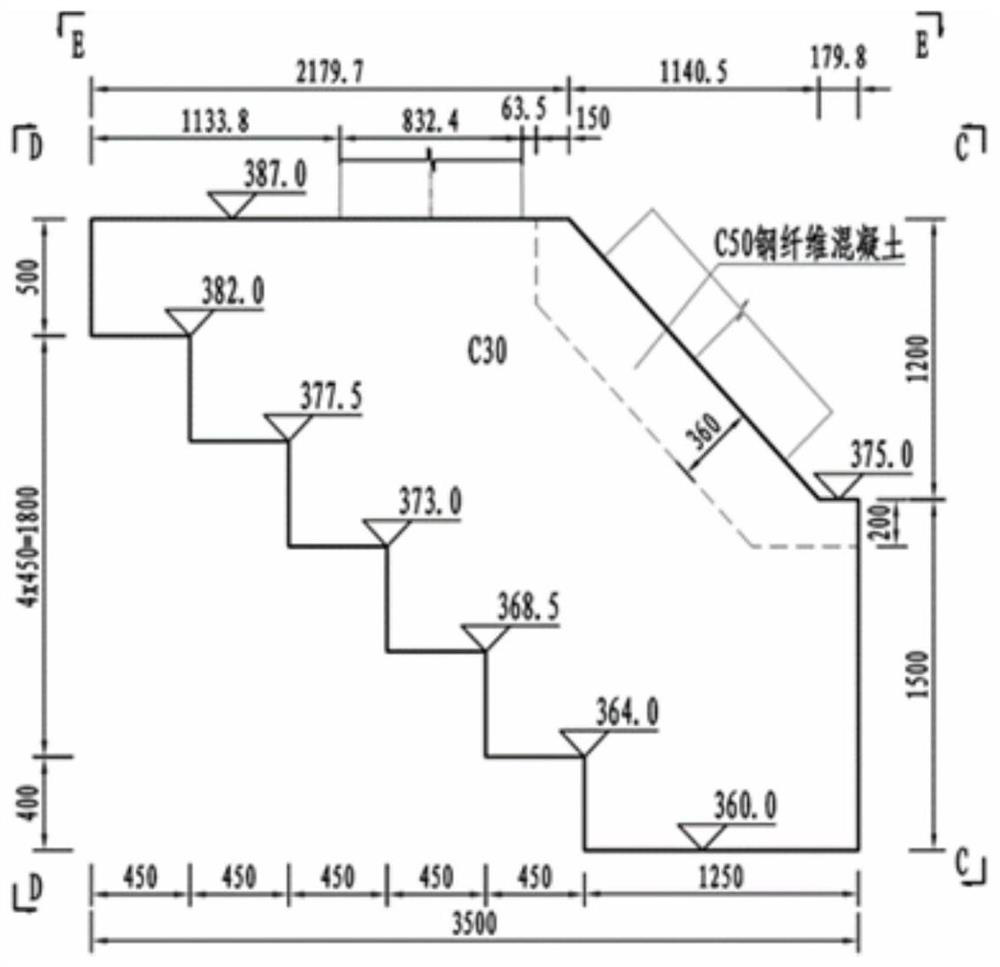

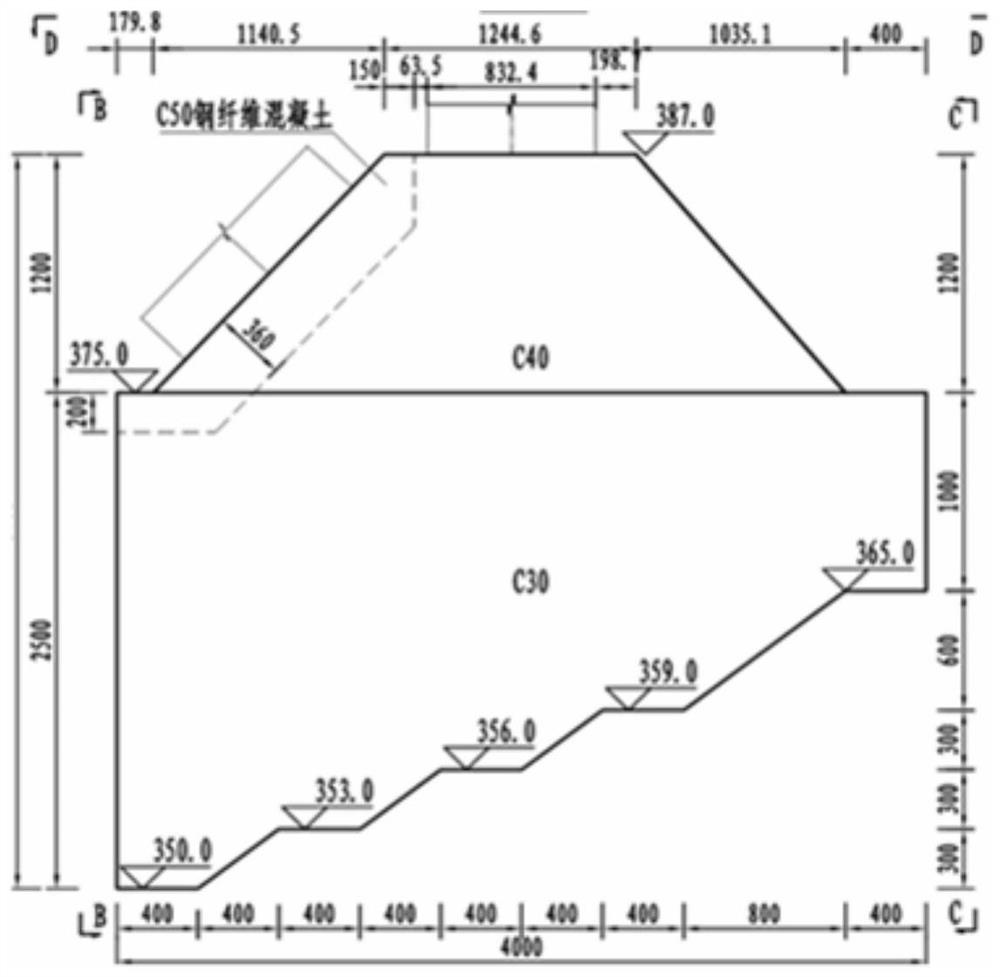

Large-span prestressed bealock beam, bealock structure, maritime work pool and construction method

PendingCN114108949AReduce adiabatic temperature riseImprove crack resistanceGeometric CADForms/shuttering/falseworksStructural deformationPre stress

The invention relates to the technical field of buildings, and provides a large-span prestressed bealock beam, a bealock structure, a maritime work pool and a construction method. The large-span pre-stress bealock beam comprises a pre-stress supporting structure which is arranged in the first direction and connected with an environment structure, and the pre-stress supporting structure is a pre-stress beam; the coping beam is connected with the prestress supporting structure, and at least one plane of the coping beam is arranged to be an assembling face of the bealock beam. The large-span pre-stress bealock beam has the beneficial effects that the large-span pre-stress bealock beam is divided into the pre-stress supporting structure and the coping beam, so that the influence of deformation of the pre-stress supporting structure on the coping beam is reduced to the greatest extent, and the flatness of the assembly surface of the coping beam is improved; therefore, the high-precision requirement of the maritime work pool large-span bealock beam is met.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

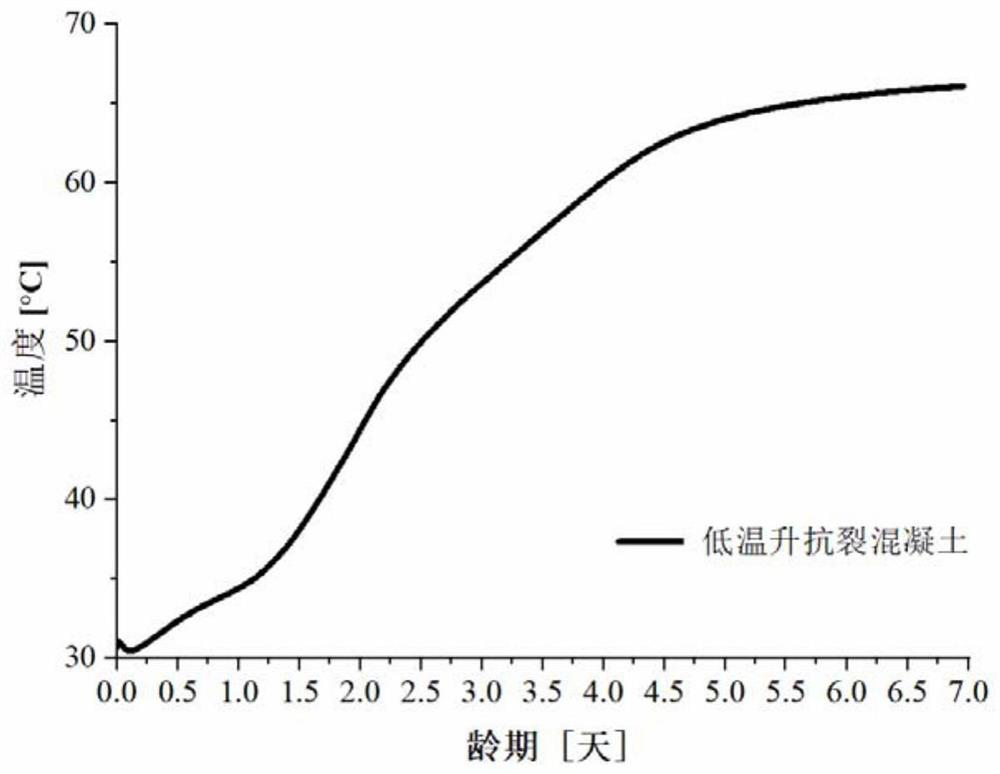

Control method for crack of large-volume concrete of arch support foundation of large-span stiff framework arch bridge

InactiveCN112538861AReduced risk of crackingImprove securityFoundation engineeringArch-type bridgeContinuous useArchitectural engineering

The invention discloses a control method for a crack of large-volume concrete of an arch support foundation of a large-span stiff framework arch bridge. The method comprises the following measures sequentially implemented according to construction steps of 1) determining that the maximum layered pouring thickness of the concrete of the arch support foundation is less than or equal to 4 m accordingto the environment of the concrete of the arch support foundation, the total pouring volume and the different construction seasons; 2) determining a low-temperature-rise anti-crack concrete raw material and a storage mode thereof; 3) determining the mix proportion of the low-temperature-rise anti-crack concrete; 4) transporting and vibrating the concrete; and 5) determining a heat preservation and moisture preservation maintenance process. The control method for the crack of the large-volume concrete of the arch support foundation of the large-span stiff framework arch bridge has the advantages that operation and implementation are easy, the concrete cracking risk in the construction period of the arch support foundation can be remarkably reduced, the safety and durability of an arch support foundation structure are improved, safe, stable and continuous use is guaranteed, and remarkable social and economic benefits are achieved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Low cementitious material self-compacting concrete

InactiveCN102060481BImprove volume stabilityIncreased durabilityHigh strength concreteHigh intensity

The invention discloses low cementitious material self-compacting concrete. Cement is a main raw material in a cementitious material of the self-compacting concrete; and if the cement consumption is high, overhigh concrete shrinkage is easily caused due to overhigh hydration heat of the cement, which is unfavorable for concrete crack control and concrete durability improvement, and problems such as disintegration, bleeding and the like easily occur. An additive XAMC is added into the concrete formula and can adsorb onto surfaces of particles to form a close adsorption layer so as to prevent the particles from flocculating and aggregating to realize the dispersion and stabilization function. Water-washing superfine sand which is rich in resources replaces partial mineral admixture, the lowcementitious material self-compacting concrete can meet the basic requirement of high strength concrete by adding the XAMC under the condition of reducing cement consumption, and has obvious thickening and water retaining functions; concrete mixtures do not bleed or disintegrate, the homogenization and workability of the concrete are improved, and the concrete has important significance for saving energy and reducing emission.

Owner:北京元泰达环保科技有限公司

Modified phosphorus slag powder, concrete prepared by using the phosphorus slag powder, and method for making concrete

ActiveCN103755186BReduce dosageReduce the effect of hydration reaction rateSolid waste managementPhysical chemistryMaterials science

The invention provides a modified phosphorous slag powder, a concrete prepared from the modified phosphorous slag powder and a preparation method of the concrete, and belongs to the technical field of concrete preparation. The modified phosphorous slag powder comprises a phosphorous slag powder, an organic salt and cationic starch. The organic salt and the cationic starch are used for modifying the phosphorous slag powder in stead of common chemical excitation carried out on the phosphorous slag by using an inorganic alkali activator in the prior art; when the modified phosphorous slag powder is used for preparing the concrete, the dosage of the modified phosphorous slag powder accounts for 38-70wt% of the total amount of the cementing material; the 3d compressive strength of the concrete ranges from 14.5 to 33.5MPa, and the 28d compressive strength of the concrete ranges from 30.6 to 77.3MPa, and the stability of the concrete is good; the utilization rate of the phosphorous slag powder is greatly reduced while the cost of the concrete is reduced, and therefore, the environmental pollution problem caused by the phosphorous slag can be reduced.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Method for manufacturing steel pipe phosphor slag concrete member

InactiveCN108331255AHigh compressive strengthOvercome the defect of low early strengthStrutsPillarsPhosphorSlag

The invention discloses a method for manufacturing a steel pipe phosphorous slag concrete member. The method for manufacturing the steel pipe phosphorous slag concrete member comprises the following steps that a, phosphorus slag used as a byproduct for producing yellow phosphorus is crushed, the particle size of the phosphorus slag meets the requirements of fine aggregate and coarse aggregate concrete in a specification, and the phosphorus slag is used directly as concrete aggregate, that is to say, an A product; b, the A product is mixed into concrete for uniform mixing, phosphorous slag concrete is obtained, that is to say, a B product, and the incorporation amount of the A product is 30%-60% of the weight of sand and gravel in the concrete; c, the B product is poured into a steel pipe with a closed end until the product B solidifies, after solidification, gaps of the B product during contraction are grinded, filled and leveled up using high-strength mortar, and after filling, the other end of the steel pipe is closed to obtain a semi-finished member; and d, the semi-finished member is maintained for 28d, and a finished product is obtained.

Owner:GUIZHOU UNIV

Method for producing low heat expansive cement

ActiveCN102515583BThe physical properties meet the requirements of GB2938 cement standardReduce manufacturing costCement productionSlagBlast furnace

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

Self-compacting concrete

InactiveCN102060482BImprove volume stabilityIncreased durabilitySolid waste managementSuperplasticizerCoal

The invention relates to self-compacting concrete which is used for overcoming the contradiction between flowability and stability, early strength and delayed coagulation, contraction and expansion and the like of the self-compacting concrete in the prior art. In the invention, by means of combination of an aliphatic (hydroxyl) sulfonate superplasticizer and a polycarboxylic acid superplasticizer, selection and collocation of a cementing material and coarse and fine aggregates as well as specific mix design, the self-compacting concrete (more than C40) with low consumption of the cementing material is prepared from coal ash, mineral powder and tailings, wherein, a ketoaldehyde condensate is taken as the main component of the aliphatic (hydroxyl) sulfonate superplasticizer; and when the superplasticizer is added to cement paste, the mixed concrete has the advantages of good construction workability, less possibility of bleeding and segregation, no crystallization precipitate at low temperature and the like. Compared with the prior art, the self-compacting concrete prepared by the method provided by the invention has the advantages of lowering cement consumption by at least 70kg / m<3>, reducing consumption of the cementing material by at least 70kg / m<3>, comprehensively utilizing at least 470kg / m<3> of solid waste, and lowering concrete cost by at least **yuan / m<3>.

Owner:北京中联新航建材有限公司 +1

Special grinding aid for maritime work cement and preparation method thereof

The invention discloses a special grinding aid for maritime work cement and a preparation method of the special grinding aid. The special grinding aid for maritime work cement is prepared from the following raw materials: 5-9% of grinding aid mother liquor, 13-18% of an industrial salt, 3-9% of a superplasticizer, 7-15% of slag powder, 3-5% of limestone powder, 3-8% of silica fume and 36-66% of fly ash; specifically, the percentages are mass percentages. By using the superplasticizer with high dispersion performance, cement particles can be highly dispersed, and in addition, through dispersionpermeation, charges carried by the cement particles are neutralized, so that the agglomeration phenomenon is reduced. Slag powder, limestone powder and fly ash are used, so that hydration heat of marine cement can be remarkably reduced, adiabatic temperature rise in concrete is reduced, temperature stress caused by internal and external temperature difference is reduced, generation of concrete temperature cracks is prevented, the overall integrity of a concrete structure is guaranteed, therefore, the corrosion resistance and the durability of the concrete structure are effectively improved.

Owner:NANJING YONGNENG MATERIALS

A low-shrinkage, low-creep, crack-resistant, high-performance mass concrete

The invention relates to a low-shrinkage, low-creep, anti-crack, high-performance, large-volume concrete, which belongs to the technical field of concrete. A concrete apparent density ≥ 2400kg / m was achieved with the addition of fly ash alone 3 , 28d compressive strength ≥ 70MPa, 28d tensile strength ≥ 4.7MPa requirements, 365d dry shrinkage rate ≤ 519×10 ‑6 , 365d compression creep degree ≤ 28.0×10 ‑6 / MPa, 365d pressure creep coefficient ≤0.72. The remarkable feature of the present invention is that there is no special mixing process for mixing concrete with the concrete mixing ratio, the mixing is simple and convenient, and the order of mixing and feeding can be changed. The concrete mixture has moderate viscosity, good cohesion, low pump pressure during construction, easy to pump and pour, good concrete crack resistance, low shrinkage and creep, good volume stability, and is suitable for high-strength stress complex mass concrete construction Reduce the chance of cracks. Concrete mixed with fly ash can reduce the silo configuration of the mixing station and rationally use the stone powder in the machine-made sand, avoid waste of resources, reduce energy consumption, and greatly reduce costs, which is in line with the green development of concrete. The abstract should not exceed 300 words, so it will be deleted.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

Concrete composition containing ultra-fine carbonate rock powder and preparation method thereof

The invention relates to a concrete composition containing superfine carbonate rock powder and a preparation method thereof. The concrete composition is prepared by mixing multi-element powder, admixture, coarse aggregate, fine aggregate and water, and each cubic meter The dosage range of multi-component powder in concrete is 300kg / m3-550kg / m3, the multi-component powder contains 70kg / m3-150kg / m3 ultra-fine carbonate rock powder, and the rest is cement and mineral admixture, which is composed of cement and mineral The aggregate forms the cementing material, and the weight percentage of cement in the cementing material is 20%-100%. The invention can reduce the water consumption of concrete, greatly reduce the cement consumption, and prepare high-strength concrete. The concrete has the characteristics of saving energy, resources and protecting the environment. The invention can prepare concrete suitable for various purposes.

Owner:北京恒坤混凝土有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com