Shrinkage-reducing anti-cracking pavement cement concrete and preparing method thereof

A technology of cement concrete and cement, which is applied in the field of concrete, can solve the problems of broken or pulled out fibers, weak bonding between fibers and cement paste, and reduction of concrete fatigue tensile strength, so as to reduce drying shrinkage and deformation and creep deformation, improving fatigue resistance and tensile strength, and tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

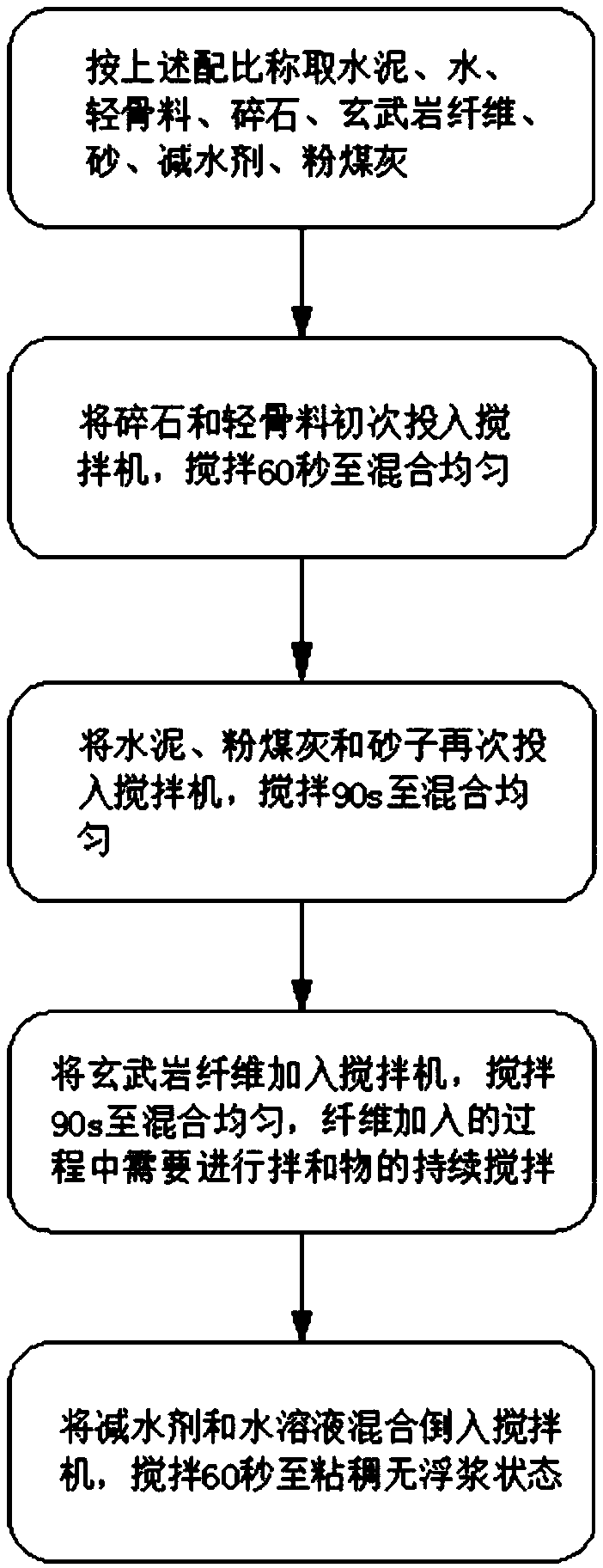

Method used

Image

Examples

Embodiment 1

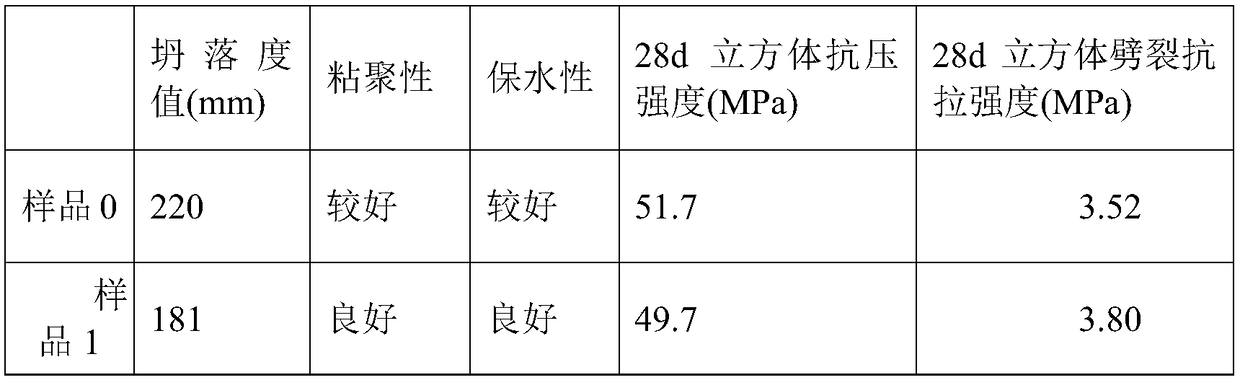

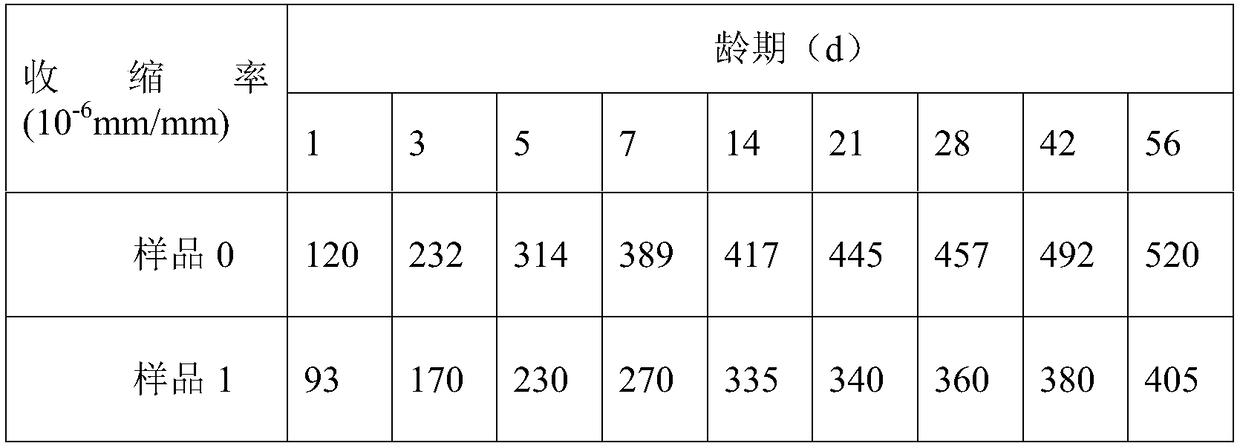

[0025] The shrinkage-reducing and anti-cracking pavement cement concrete of the present invention is prepared from water, cement, fly ash, basalt fiber, lightweight aggregate, gravel, sand and water reducing agent, wherein water, cement, fly ash, basalt The mass ratio of fiber, lightweight aggregate, gravel, sand and water reducer is 180:405:45:2.65:286:465:846:4.3.

[0026] The cement is P·O 42.5 ordinary Portland cement.

[0027] The fly ash is Class II fly ash, the fineness of the fly ash is 14%, the loss on ignition of the fly ash is 3.4%, the water demand ratio of the fly ash is 98%, and the 28d activity index of the fly ash is 82%.

[0028] Basalt fiber is chopped basalt fiber, the diameter of basalt fiber is 13μm, the length is 20mm, the tensile strength is 4100-4800MPa, the elastic modulus is 93-110GPa, the elongation at break is 3.0-3.2%, and the retention rate of monofilament breaking strength is 75%.

[0029] The lightweight aggregate is gravel-type high-strength...

Embodiment 2

[0056] The shrinkage-reducing and anti-cracking pavement cement concrete of the present invention is prepared from water, cement, fly ash, basalt fiber, lightweight aggregate, gravel, sand and water reducing agent, wherein water, cement, fly ash, basalt The mass ratio of fiber, lightweight aggregate, gravel, sand and water reducer is 180:410:40:5.3:229:559:830:4.5.

[0057] The cement is P·O 42.5 ordinary Portland cement.

[0058] The fly ash is Class II fly ash, the fineness of the fly ash is 14%, the loss on ignition of the fly ash is 3.4%, the water demand ratio of the fly ash is 98%, and the 28d activity index of the fly ash is 82%.

[0059] Basalt fiber is chopped basalt fiber, the diameter of basalt fiber is 13μm, the length is 20mm, the tensile strength is 4100-4800MPa, the elastic modulus is 93-110GPa, the elongation at break is 3.0-3.2%, and the retention rate of monofilament breaking strength is 75%.

[0060] The lightweight aggregate is gravel-type high-strength ...

Embodiment 3

[0067] The shrinkage-reducing and anti-cracking pavement cement concrete of the present invention is prepared from water, cement, fly ash, basalt fiber, lightweight aggregate, gravel, sand and water reducing agent, wherein water, cement, fly ash, basalt The mass ratio of fiber, lightweight aggregate, gravel, sand and water reducer is 200:400:50:2.65:286:465:850:4.1.

[0068] The cement is P·O 42.5 ordinary Portland cement.

[0069] The fly ash is Class II fly ash, the fineness of the fly ash is 14%, the loss on ignition of the fly ash is 3.4%, the water demand ratio of the fly ash is 98%, and the 28d activity index of the fly ash is 82%.

[0070] Basalt fiber is chopped basalt fiber, the diameter of basalt fiber is 13μm, the length is 20mm, the tensile strength is 4100-4800MPa, the elastic modulus is 93-110GPa, the elongation at break is 3.0-3.2%, and the retention rate of monofilament breaking strength is 75%.

[0071] The lightweight aggregate is gravel-type high-strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com