Rubber powder modified asphalt with high fatigue resistance and cracking resistance and preparation method of rubber powder modified asphalt

A modified asphalt, anti-cracking technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of fatigue cracking, poor bonding force, easy to break, etc. , the effect of increasing the winding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

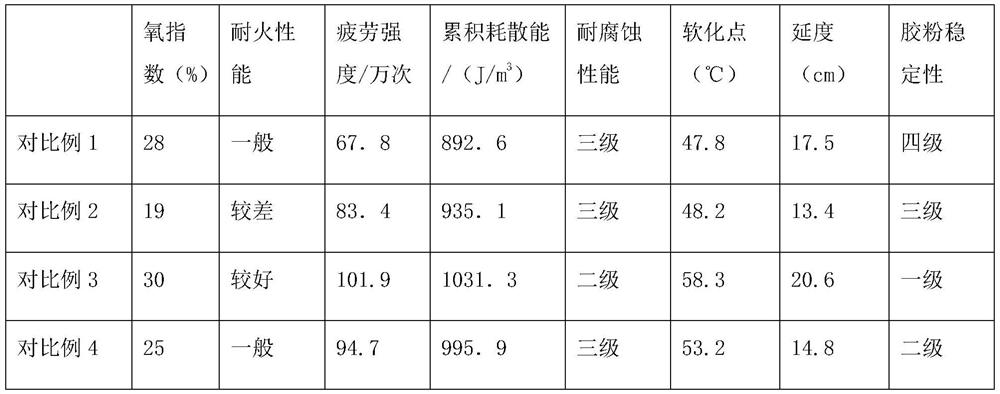

Examples

Embodiment 1

[0042] S1. Preparation of modified white carbon black: at 35°C, add nanocellulose into dimethylacetamide solution for ultrasonic dispersion for 1 h, then add N,N-carbonyldiimidazole and epichlorohydrin in turn, and stir for 8 h , adding white carbon black, ultrasonically dispersed for 7h, taken out, and freeze-dried to obtain modified white carbon black powder.

[0043] S2, preparing rubber powder:

[0044] a. Grinding: Recycling waste rubber tires for cleaning and grinding to make waste rubber powder with a fineness of 80 mesh;

[0045] b. Mix waste rubber powder, benzoyl peroxide, styrene, and deionized water, stir and react at 100°C for 4h, filter and wash with cyclohexane, and dry at 55°C for 1h to obtain material A.

[0046] c. Mix isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, liquid paraffin, decabromodiphenylethane, and antimony trioxide evenly. Min speed stirring reaction 20min, add material A and mix evenly to obtain material B;

[0047] d. M...

Embodiment 2

[0055] S1. Preparation of modified white carbon black: at 40°C, add nanocellulose into dimethylacetamide solution for ultrasonic dispersion for 1.5h, then add N,N-carbonyldiimidazole and epichlorohydrin in sequence, and stir to react After 9 hours, white carbon black was added, ultrasonically dispersed for 8 hours, taken out, and freeze-dried to obtain modified white carbon black powder.

[0056] S2, preparing rubber powder:

[0057] a. Grinding: Recycling waste rubber tires for cleaning and grinding to make waste rubber powder with a fineness of 90 mesh;

[0058] b. Mix waste rubber powder, benzoyl peroxide, styrene, and deionized water, stir and react at 130°C for 6h, filter and wash with cyclohexane, and dry at 60°C for 1.5h to obtain material A.

[0059] c. Mix isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, liquid paraffin, decabromodiphenylethane, and antimony trioxide evenly. Min speed stirring reaction 25min, add material A and mix evenly to obta...

Embodiment 3

[0068] S1. Preparation of modified white carbon black: at 45°C, add nanocellulose into dimethylacetamide solution for ultrasonic dispersion for 2 hours, then add N,N-carbonyldiimidazole and epichlorohydrin in turn, and stir for 10 hours , adding white carbon black, ultrasonically dispersed for 9h, taken out, and freeze-dried to obtain modified white carbon black powder.

[0069] S2, preparing rubber powder:

[0070] a. Grinding: Recycling waste rubber tires for cleaning and grinding to make waste rubber powder with a fineness of 100 mesh;

[0071] b. Mix waste rubber powder, benzoyl peroxide, styrene, and deionized water, stir and react at 140°C for 8 hours, filter and wash with cyclohexane, and dry at 65°C for 2 hours to obtain material A.

[0072] c. Mix isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, liquid paraffin, decabromodiphenylethane, and antimony trioxide evenly, and heat at 2000 r / h at 75°C Min speed stirring reaction 30min, add material A an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com