Cement-base quick repairing material and preparation method thereof

A repair material, cement-based technology, applied in the field of building materials, can solve the problems of environmental pollution, land occupation, waste of resources, etc., and achieve the effect of promoting development, compact structure, and promoting early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

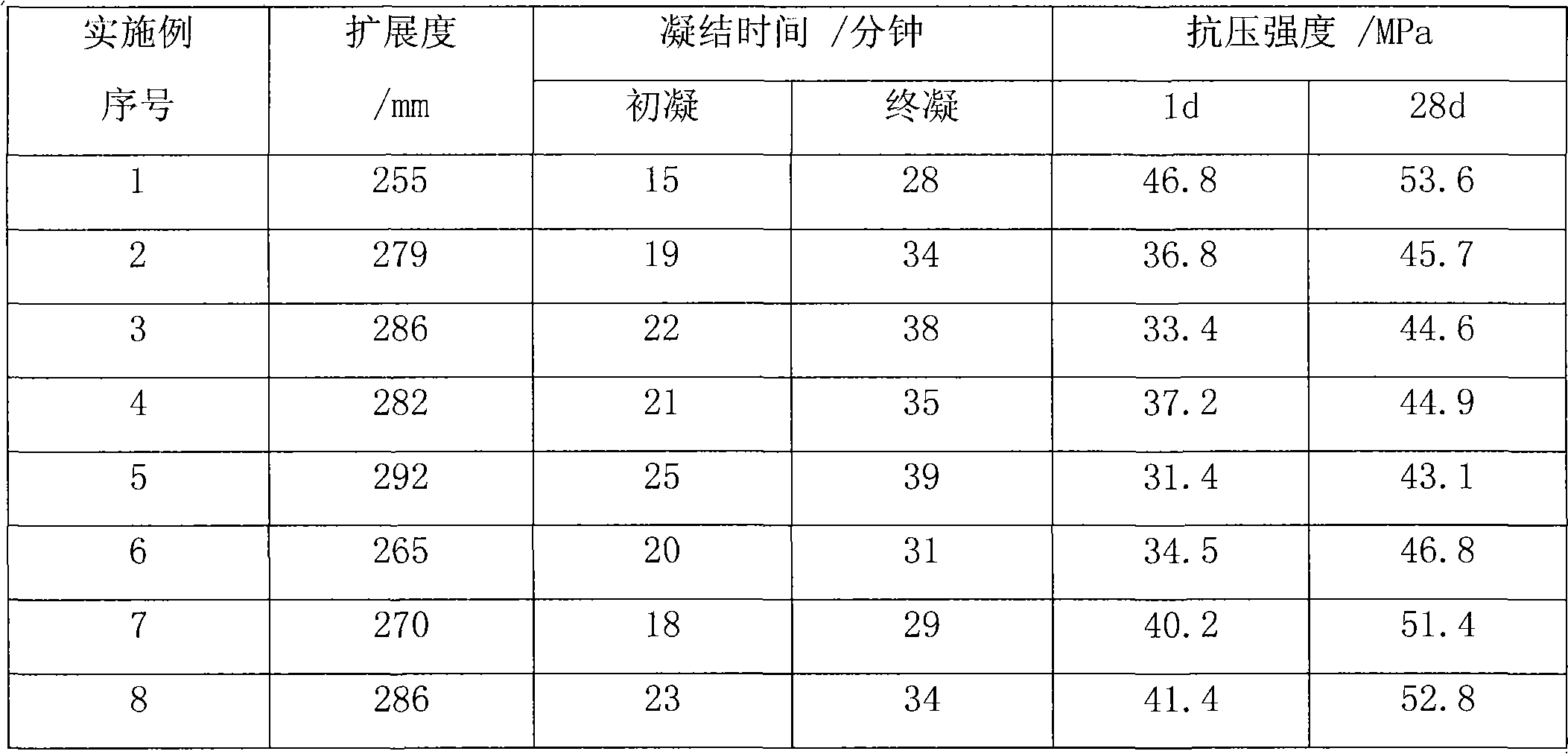

[0022] A cement-based rapid repair material, which is prepared from sulphoaluminate cement, cement slurry dehydrated phase, metakaolin, water glass, water reducer, water, composite early strength agent raw materials, the weight ratio of each raw material is shown in the table 1.

[0023] Each raw material weight ratio of table 1

[0024] Example

serial number

Aluminosulfate

salt cement

body dehydrated phase

water glass

water

complex

early strength agent

1

1

0.2

0.3

0.25

0.06

0.3

0.008

2

1

0.05

0.1

0.3

0.07

0.5

0.001

3

1

0.5

0.5

0.2

0.02

0.4

0.009

4

1

0.1

0.05

0.02

0.01

0.6

0.0006

5

1

0.3

0.4

0.1

0.09

0.3

0.01

6

1

0....

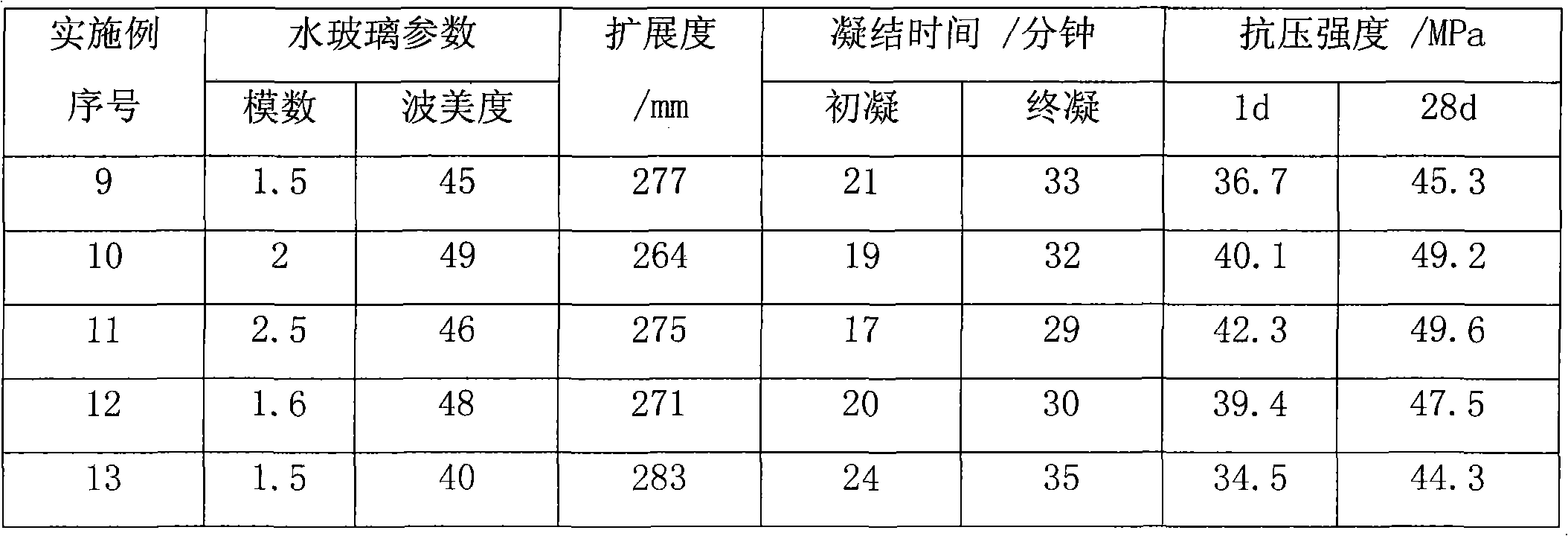

Embodiment 9-13

[0039] A cement-based rapid repair material, which is prepared from sulphoaluminate cement, cement slurry dehydrated phase, metakaolin, water glass, water reducer, water, and composite early strength agent raw materials, and each raw material is prepared according to the raw materials in Example 1. The first weight ratio (serial number is 1) is batched, see Table 1.

[0040]The dehydrated phase of the cement slurry is obtained by calcining waste cement slurry powder with a particle size of less than 0.075mm at 500°C for 4 hours; the metakaolin is obtained by calcining at 550°C for 6 hours, and its specific surface area is 15000m 2 / kg; the composite early strengthening agent is a mixture of sodium nitrite, anhydrous calcium chloride and triethanolamine, and the weight ratio of sodium nitrite, anhydrous calcium chloride and triethanolamine is 1.5:1.5:1.5. Change the modulus and Baume degree of water glass, see Table 3.

[0041] The preparation method is the same as in Example...

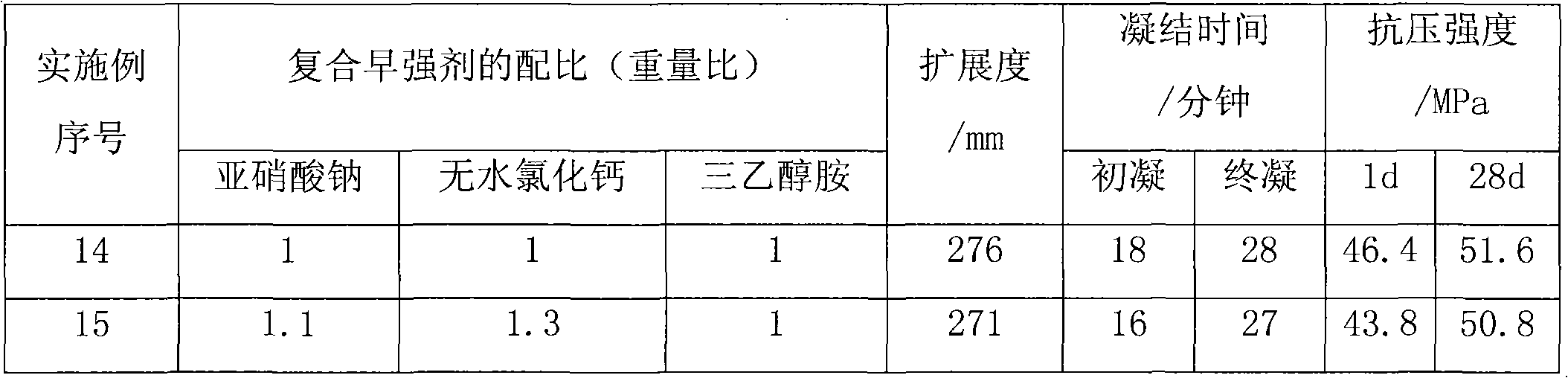

Embodiment 14-15

[0045] A cement-based rapid repair material, which is prepared from sulphoaluminate cement, cement slurry dehydrated phase, metakaolin, water glass, water reducer, water, and composite early strength agent raw materials, and each raw material is prepared according to the raw materials in Example 1. The first weight ratio (serial number is 1) is batched, see Table 1.

[0046] The dehydrated phase of the cement slurry is obtained by calcining waste cement slurry powder with a particle size of less than 0.075mm at 1000°C for 2 hours; the metakaolin is obtained by calcining kaolin at 1000°C for 4 hours, and its specific surface area is 13000m 2 / kg; The modulus of described water glass is 2.2, and Baume degree is 41. Change the composition of the compound accelerator, see Table 4.

[0047] The preparation method is the same as that of Example 1, and the properties of each group of products prepared are shown in Table 4.

[0048] Table 4 The ratio and product performance of comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com