Spray coating material for preventing air leakage in roadway, use method thereof and special spray gun

A technology for spraying materials and roadways, which is applied in the field of spraying roadway wall materials, and can solve problems such as low efficiency, high spraying costs, and affecting the effect of wind isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

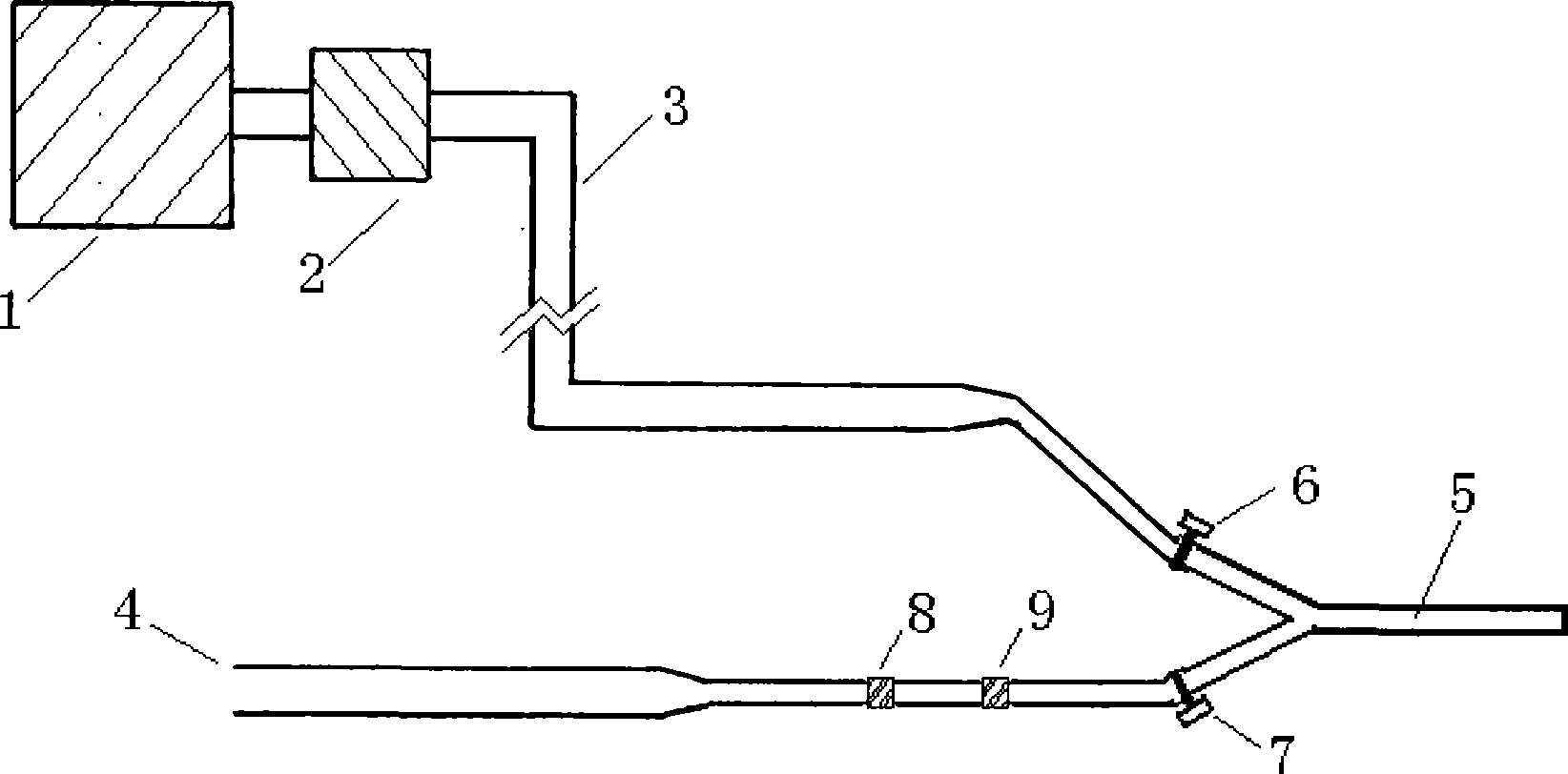

Image

Examples

Embodiment 1

[0014] Embodiment 1. Take 0.55t of clay, 0.37t of cement, 5L of water glass, 1kg of glass fiber, and the balance is water. Mix and stir through the pulping system to prepare a volume of 1m 3 clay grout.

Embodiment 2

[0015] Embodiment 2, take 0.5t of clay, 0.4t of cement, 4L of water glass, 1kg of glass fiber, and the balance is water, mix and stir through the pulping system, and prepare a volume of 1m 3 clay grout.

Embodiment 3

[0016] Embodiment 3, take 0.65t of clay, 0.5t of cement, 6L of water glass, 2kg of glass fiber, and the balance is water, and mix and stir through the pulping system to prepare a volume of 1m 3 clay grout.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com