Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve coagulation tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

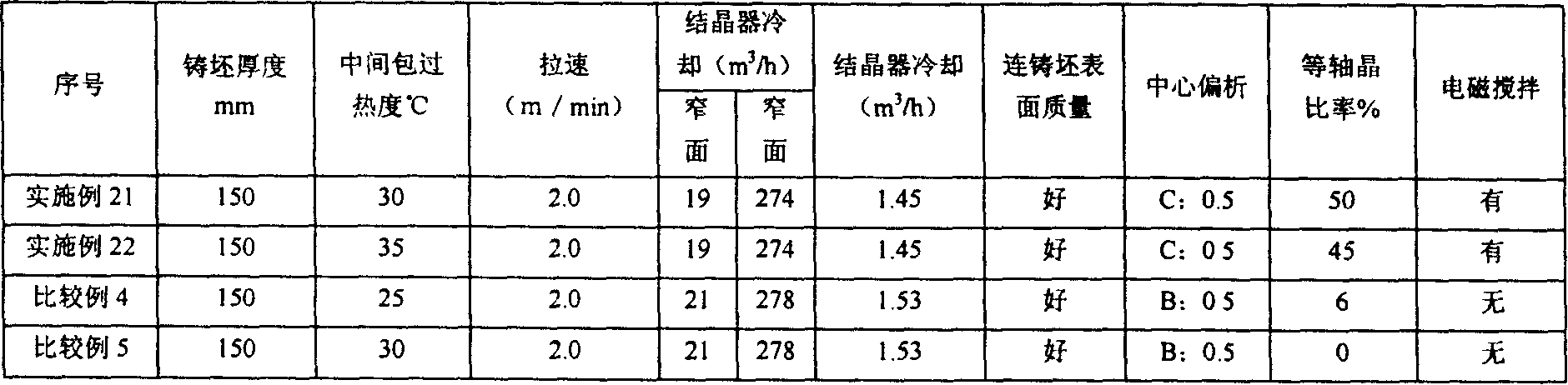

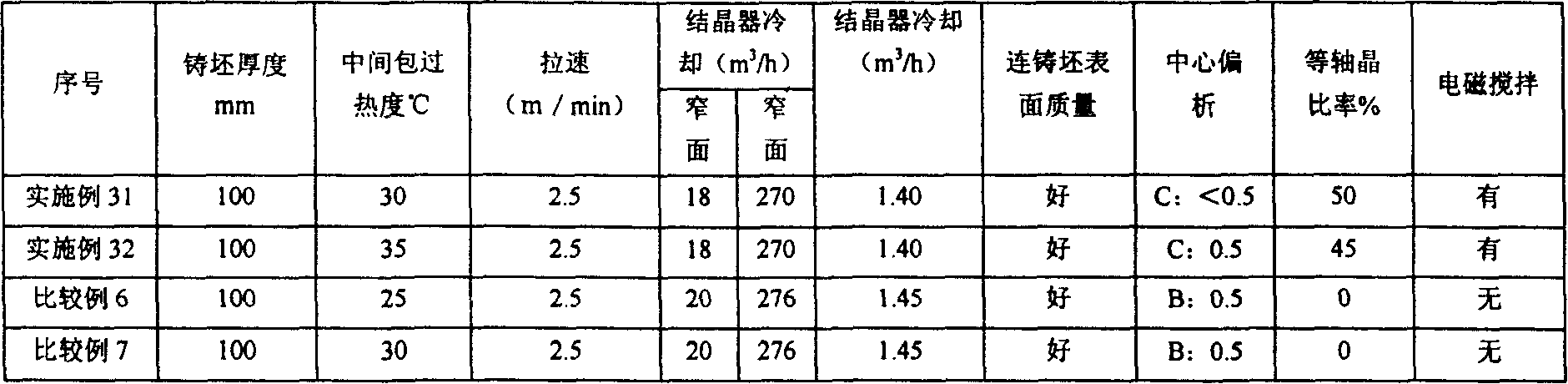

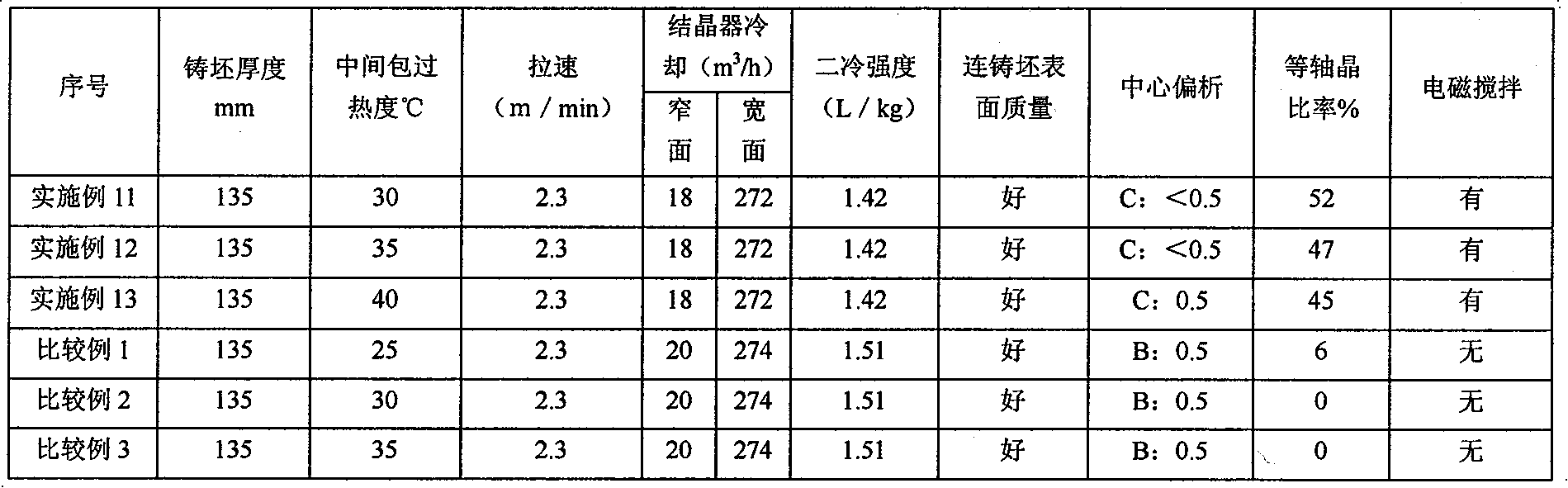

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

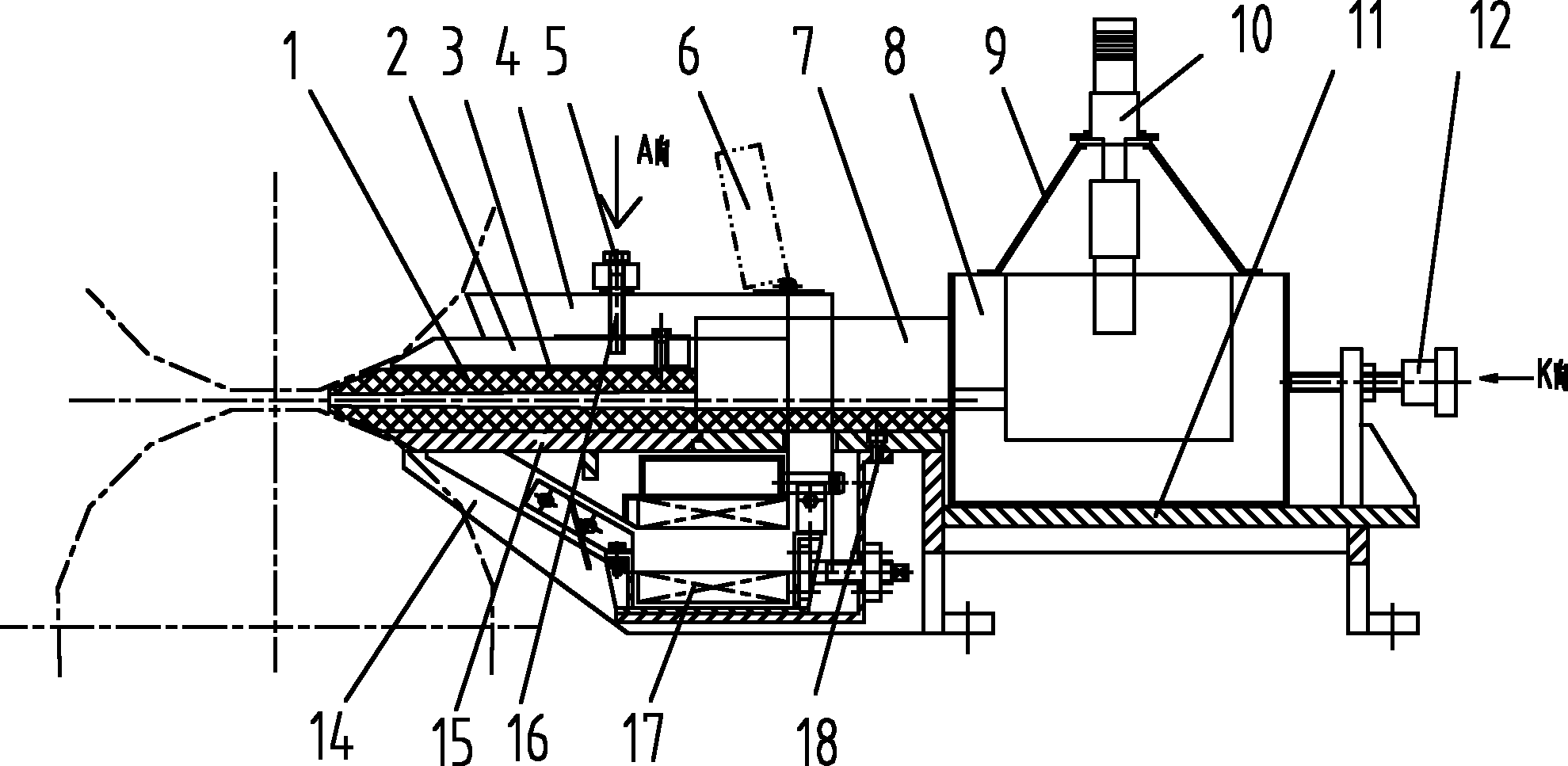

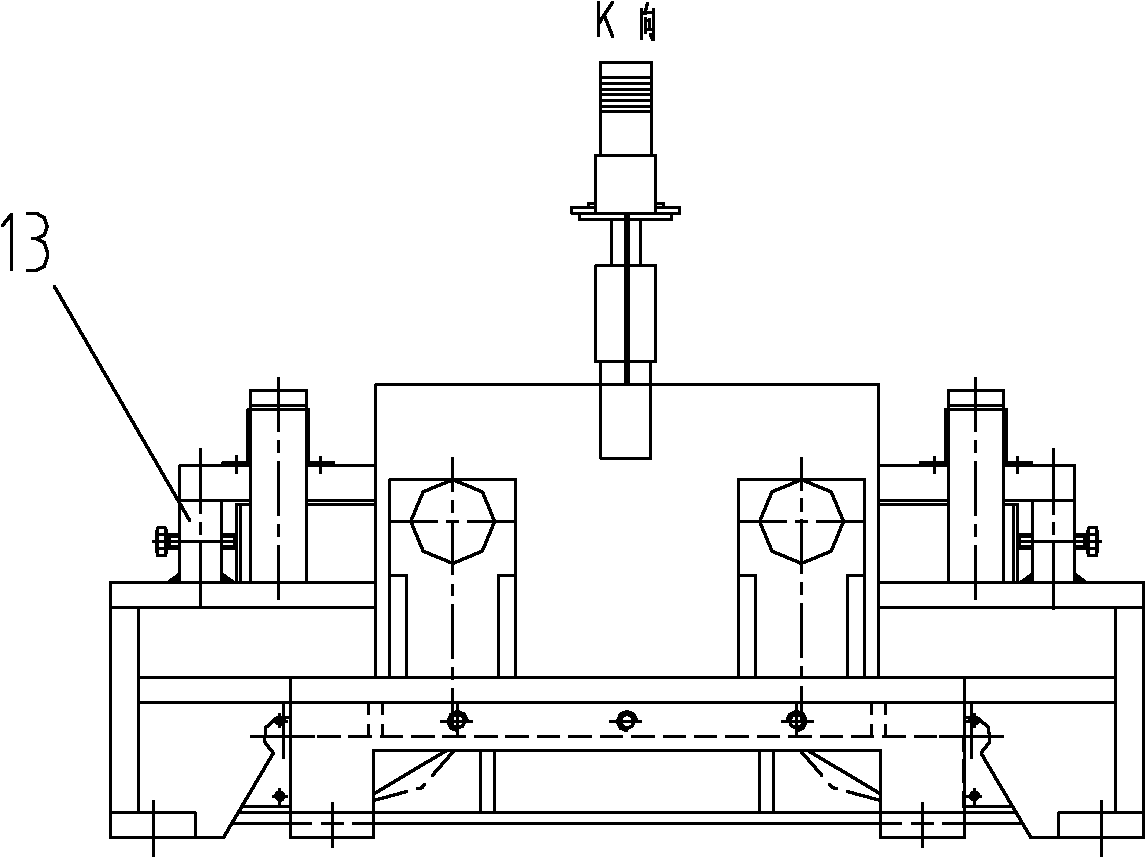

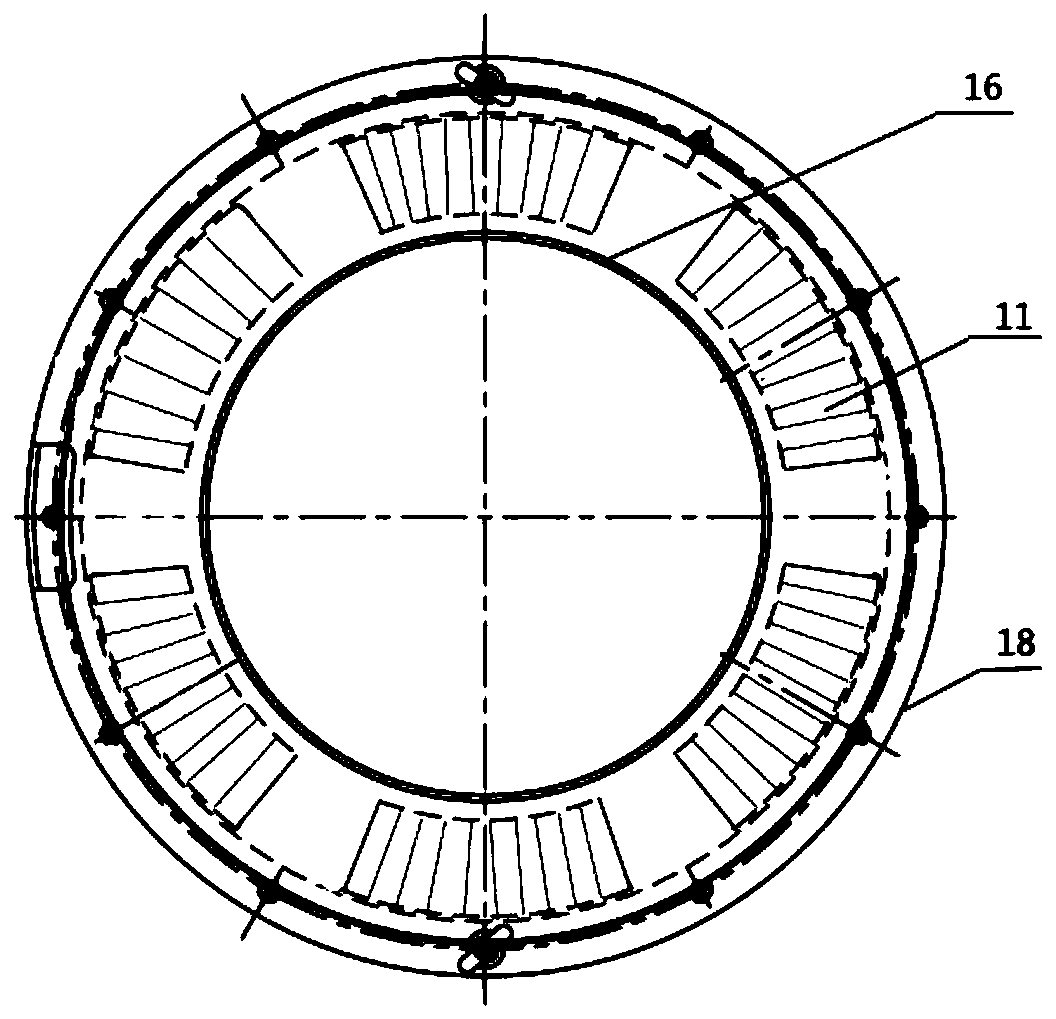

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

Middle-chromium rare earth-containing high-purity ferrite wrinkle-resistant stainless steel and manufacturing method thereof

InactiveCN101148739AImprove wrinkle resistanceImprove wrinkle defectsRoll mill control devicesHeat treatment process controlChemical compositionRare earth

The RE-containing medium Cr wrinkling resistant ferritic stainless steel has the chemical components including C not more than 0.02 wt%, N not more than 0.02 wt%, Si not more than 0.50 wt%, Mn not more than 0.50 wt%, P not more than 0.03 wt%, S not more than 0.02 wt%, Cr 16-20 wt%, Ni not more than 1.00 wt%, Mo not more than 2.00 wt%, Ti not more than 0.30 wt%, Nb not more than 0.40 wt%, O not more than 0.015 wt%, RE 0.01-0.20 wt%, and Fe and inevitable impurity for the rest. The ferritic stainless steel features low C and N contents, medium Cr content, containing RE, high wrinkling resistance, etc. It is suitable for punching formation to make product.

Owner:BAOSHAN IRON & STEEL CO LTD

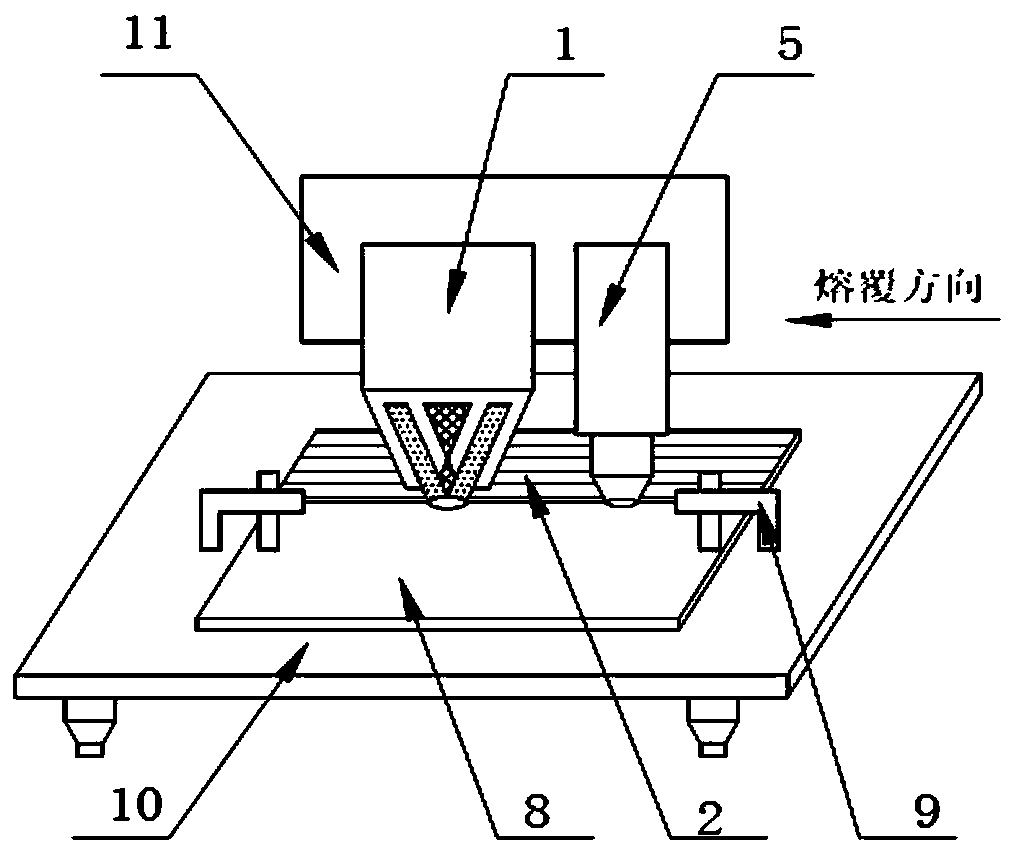

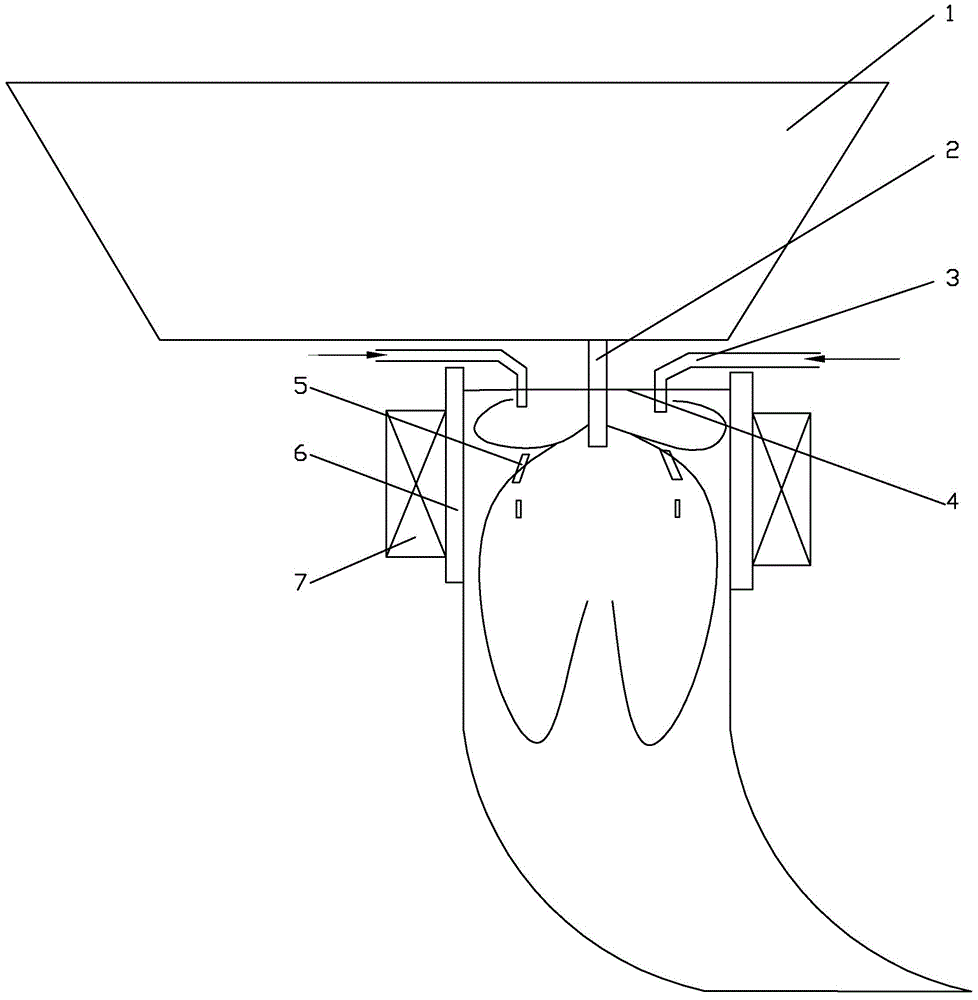

Electromagnetic/ultrasound compound outfield continuous casting and rolling device

InactiveCN101844212AEnhanced convective heat transferUniform temperature fieldEngineeringMicroscopic scale

The invention discloses an electromagnetic / ultrasound compound outfield continuous casting and rolling device. A frame body (14) is fixedly provided with a magnetic field generator (17) distributed along the axial direction of a roller; a vibration-proof bar (23) is connected with and arranged on the frame body (14); at least one upper iron core (4) distributed along the axial line of the roller is connected to the vibration-proof bar (23) through a first bolt (5); the upper iron core (4) is connected with a movable iron core (6) through a hinge; an upper press plate (2) and an upper liner plate (3) are arranged between the upper iron core (4) and a casting nozzle (1); a supporting rod (9) is connected to a front box (8) and is provided with an ultrasound generator (10); and an ultrasound toolhead of the ultrasound generator (10) extends into the front box (8). The invention relates to the electromagnetic / ultrasound compound outfield continuous casting and rolling device which can refine a casting and rolling texture, increase the mechanical property, improve the anisotropy, reduce or eliminate segregation, macro and micro flaws and achieve long service life of the casting nozzle in the continuous casting and rolling process of an aluminum alloy casting and rolling plate billet.

Owner:CENT SOUTH UNIV

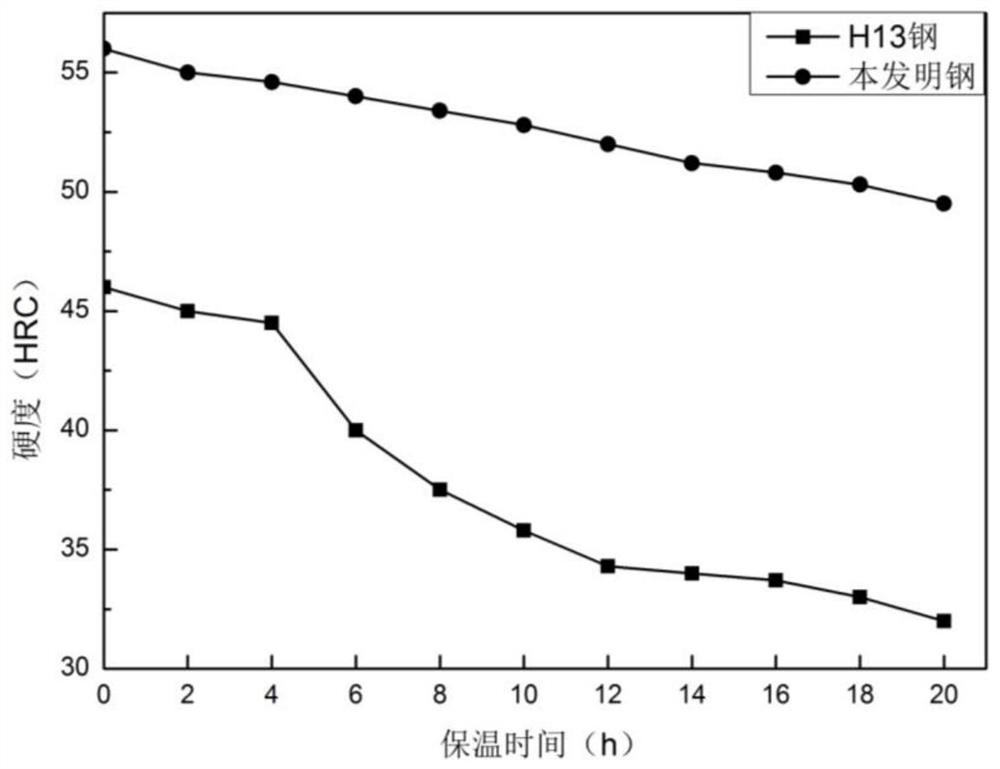

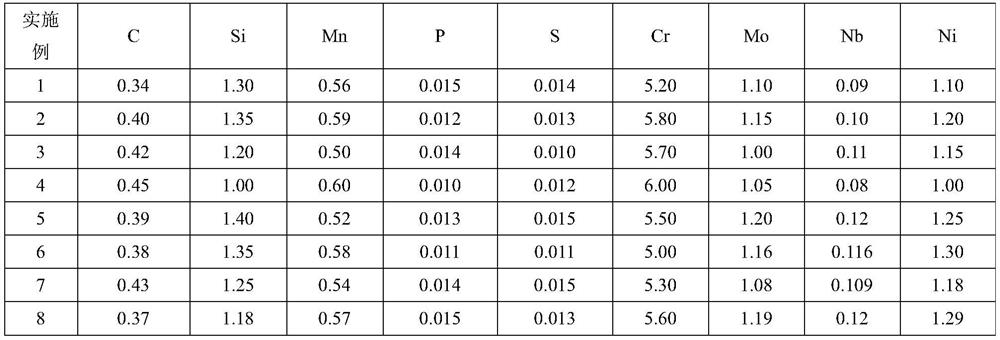

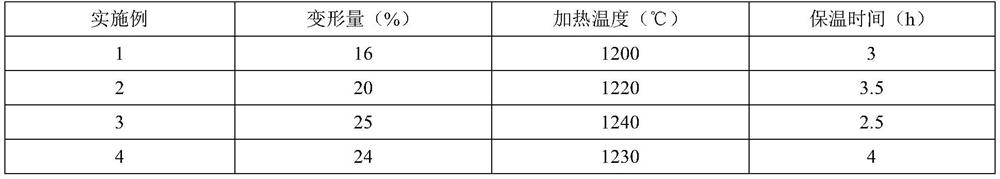

Hot-working die steel and efficient preparation method thereof

The invention relates to hot-working die steel and an efficient preparation method thereof. The hot-working die steel comprises, by weight, 0.34%-0.45% of C, 1.00%-1.40% of Si, 0.50%-0.60% of Mn, lessthan or equal to 0.015% of P, less than or equal to 0.015% of S, 5.00%-6.00% of Cr, 1.00%-1.20% of Mo, 0.08%-0.12% of Nb, 1.00%-1.30% of Ni, and the balance Fe and inevitable impurities. The preparation method has the advantages that the alloy components are optimized, and mechanical diffusion and thermal diffusion are adopted to jointly act, so that the components of the hot-working die steel are homogenized, the time required for homogenization of the alloy elements is shortened, the production efficiency is improved, the production cost is reduced, the produced hot-working die has the Rockwell hardness of 55-57 HRC, the isotropic performance is good, and the thermal stability is good.

Owner:ANGANG STEEL CO LTD

Continuous casting production control method for super-large section heavy rail steel

InactiveCN107790666AImprove segregationImprove densification performanceMelt-holding vesselsPower flowCurrent range

The invention discloses a continuous casting production control method for a super-large section heavy rail steel, and particularly relates to the continuous casting production control method in the field of ferrous metallurgy for the super-large section heavy rail steel. According to the continuous casting production control method for the large-section heavy rail steel, a parabolic taper curve type tubular mold is adopted, a cooling water pipeline is provided with two cooling water inlets and two cooling water outlets, a super-large section heavy rail steel mold adopts an immersion type water port, a double-side hole mode is adopted in the immersion type water port, the intensity of stirring currents ranges from 300-400A, the current frequency is 2.4Hz, the specific water flow of secondary cooling water is matched with the pulling rate at mold subsequent solidification section, and the solidification tail end is pressed down. According to the method, molten steel flow fields and solidification cooling of the mold are effectively controlled, a secondary cooling system is reasonably controlled on the basis, a force field is externally applied to a casting blank, the casting blank solidification structure is optimized, the segregation of solute elements is improved, and the compactness of the center of the casting blank is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method and apparatus for preparing aluminium base composite materials under high magnetic field

A process for preparing the Al-base composition under strong magnetic field includes such steps as heating Al to 850 deg.C, holding the temp for 30 min, adding reinforcing Al2O3 particles (or short fibres), stirring, pouring in mould, solidifying for 20 min strong magnetic field system and cooling in air. Its equipment is composed of metallic ladle, heating system, thermoelectric couple, reinforcing material delivering pipe, stirring coil, casting mould, supporter, slide sprue, vacuum chamber or protecting gas chamber, and the strong magnetic field control system consisting of strong magnetic field genrator, cooling water pipe, alarm and temp control unit and insulating layer.

Owner:NORTHEASTERN UNIV

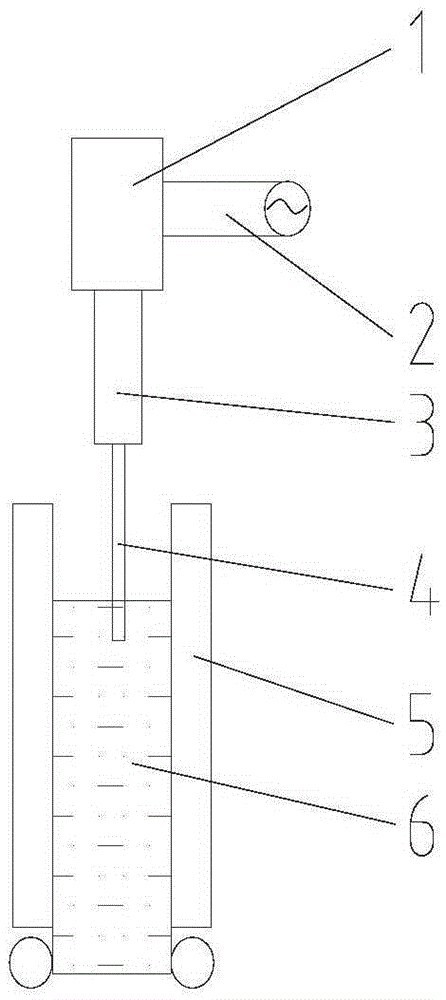

Method for direct intervening of internal quality of casting blank

InactiveCN1876274AImprove coagulation tissueReduces center segregation and porosityDuctilityProduction rate

The invention relates to a method for direct interfering casting blank quality, belonging to field of continuous cast steel production technology. The method employs feeding apparatus to insert metallic band into mould liquid steel, and said band can vibrate according to applicable frequency and amplitude. The method interferes internal coagulation and crystallization directly by controlling band inserting mode and speed, the degree of superheat of crystallizer liquid steel is reduced, depth of liquid core is shortened, columnar crystal is decreased, equiax crystal proportion is increased, coagulation tissue of cast blank is improved, central aliquation is released, zigzag plasticity, dynamic ductility of steel products are improved, and fault localization percent of pass is increased. Furthermore, the pulling rate and production rate can be increased on condition of guaranteeing cast blank quality. The invention is characterized by low investment, reduced energy consumption, low operation cost, convenient device maintenance, and eligibility for various cast blank production.

Owner:SHANDONG IRON & STEEL CO LTD

Method of manufacturing clad layer on basis of vibration-assistant ultrahigh-speed laser cladding technology

InactiveCN109913869AHigh hardnessReduce residual stressMetallic material coating processesUltrasoundHigh frequency

The invention discloses a method of manufacturing a clad layer on the basis of a vibration-assistant ultrahigh-speed laser cladding technology. The method specifically comprises the steps that a workpiece is fixed to a workbench, the surface of the workpiece is cleaned, ultrahigh-speed laser cladding powder is preheated, screened and then fed into a powder feeder, a laser spot and a powder focusing spot are adjusted to be located on the same straight line, coaxial powder feeding is adopted, powder feeding is adjusted, and then an ultrasonic high-frequency impact head is adjusted to make contact with the workpiece; and an ultrasonic high-frequency impact facility is started, an ultrahigh-speed laser cladding facility is started to conduct cladding operation on the workpiece, the impact headcan conduct violent reciprocating vibration through the high frequency of the ultrasonic high-frequency impact facility, and the purpose that the impact is immediately conducted on a coating which isjust subjected to the cladding operation can be achieved. The vibration is applied to the clad layer in the ultrahigh-speed laser cladding process, and therefore the effects that the residual stressof the clad layer is reduced, the crystal grain is refined, and the organization is uniform can be achieved, the crack sensitivity of the clad layer can be reduced, the metal solidification structurecan be improved, and the mechanical property can be improved.

Owner:西安中科光机投资控股有限公司

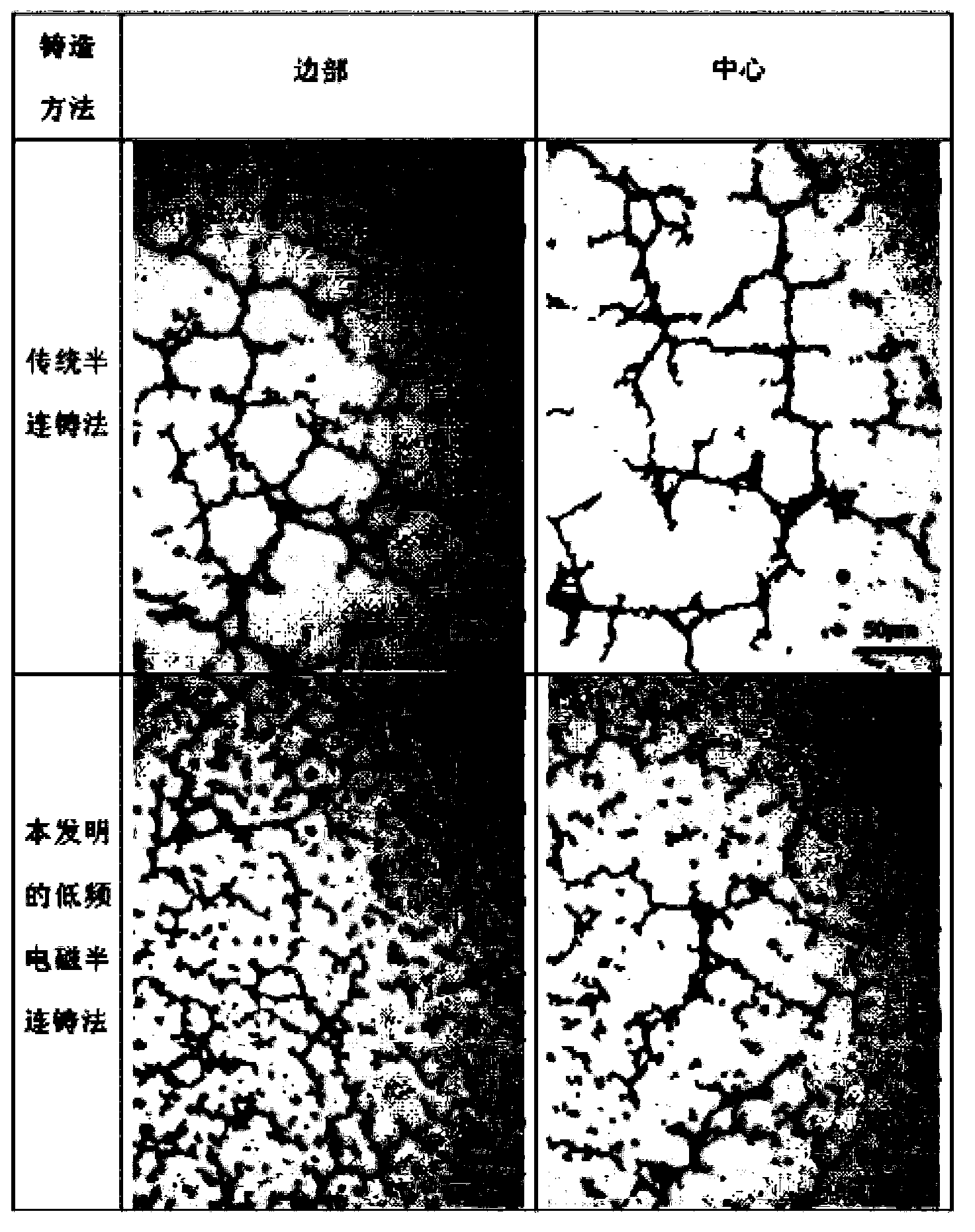

Electromagnetic semi-continuous casting method for preparing high-strength heat-resistant rare-earth magnesium alloy ingot blank

The invention discloses an electromagnetic semi-continuous casting method for preparing a high-strength heat-resistant rare-earth magnesium alloy ingot blank. The method is characterized by comprising the following steps: batching, smelting and casting molding, namely by adopting a mold provided with an excitation coil, allowing melt to flow into the mold, and applying a low-frequency electromagnetic field of specified frequency and strength; starting a casting machine and performing throwing casting when the metal liquid level in the mold reaches the liquid level height which is 30-40mm away from the horizontal position on the top of the mold, wherein the casting speed is 50-90mm / min, the casting temperature is 740-750DEG C; and the applied low-frequency electromagnetic frequency ranges from 1 to 90Hz, and the strength is 2000-4000AT. According to the method, the transverse temperature gradient in the process of solidifying the casting blank can be greatly reduced, the liquid pool shape is changed, the solidification uniformity of the casting blank is improved, the size effect of the casting blank casting defects is reduced, the internal metallurgical quality and surface quality of a large vertical semi-continuous casting rare-earth magnesium alloy ingot blank are improved, and a high-quality rare-earth magnesium alloy ingot blank which does not have cracks and is even and smooth in surface, stable in components, obviously low in macrosegregation and fine and uniform in texture can be obtained.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Method for improving internal quality of continuous casting and submerged nozzle for implementing method

The invention relates to a method for improving the internal quality of a continuous casting and a submerged nozzle for implementing the method. The submerged nozzle mainly comprises a long-barrel flat annular body submerged nozzle body with the bottom sealed, two arc surfaces at the upper end of the bottom of the nozzle are provided with symmetrical side holes; the two opposite side surfaces and hollow surfaces respectively arranged at the periphery are connected in a closing way to form an integrated feeding guide pipe; each hollow surface is inclined downward and extends while a certain distance is kept with each side surface of the nozzle body, thus all the feeding guide pipe are communicated at the bottom and form an exit section at the bottom of the nozzle body. In a continuous casting process, granular or bead-like, piece-like and strap-like part steel or iron product is continuously fed from the feeding guide pipes of the submerged nozzle and creeps down to the center of a molten pool of a crystallizer, degree of superheat of molten steel can be reduced, the cooling speed at the center is increased, formation of a central isometric crystal is promoted, enrichment and segregation of solute element at the center of a cast blank are prevented, solidification structure at the center of the cast blank is effectively optimized, and the density at the center of the cast blank is strengthened.

Owner:WISDRI ENG & RES INC LTD

Low-cost, ultra-pure, high-strength and high-toughness low-carbon stainless bearing steel and preparation method thereof

The invention discloses low-cost, ultra-pure, high-strength and high-toughness low-carbon stainless bearing steel and a preparation method thereof. The bearing steel is prepared from the components including 0.13%-0.30% of C, 0.05%-0.2% of Si, 0.02%-0.1% of Mn, 13.6%-16.80% of Cr, 2.1%-4.0% of Ni, 12.5%-17% of Co, 5%-6% of Mo, 0.7%-2.5% of W, 0.7%-1.2% of Nb + V, less than or equal to 0.025% of P+S+Ti, less than or equal to 0.0012% of Ti, less than or equal to 0.0007% of O, less than or equal to 0.0015% of N+H, less than or equal to 0.0014% of N, 0.05%-0.08% of Al, 0.005%-0.015% of Ce, 0.005%-0.02% of La, 0.01%-0.03% of Y, and the other element of Fe. The preparation process route comprises the steps of molten steel primary smelting, AOD refining, LF refining, IC casting, VIM smelting, ESR electroslag remelting and VAR vacuum consumable remelting. Compared with the prior art, the low-carbon stainless bearing steel is lower in production cost, higher in strength and toughness, longer in fatigue life and extremely low in oxygen and nitrogen impurity content.

Owner:ANHUI FUKAI STAINLESS STEEL

Electroslag remelting method for Hastelloy

ActiveCN110331301AUniform coagulation tissueWell-organized ingredientsFurnace typesHeat treatment furnacesSlagFilling ratio

The invention discloses an electroslag remelting method for Hastelloy, wherein an adopted consumable electrode is subjected to high-temperature diffusion annealing at 1100-1150 DEG C, after which theelectroslag remelting is performed under the protection of argon; and the smelting rate during the electroslag remelting is 3 kg / min-3.5 kg / min. According to the electroslag remelting method, the adopted consumable electrode is subjected to high-temperature diffusion annealing firstly, the electroslag remelting is performed after homogenization is finished, low smelting speed control is adopted, and thus a uniform solidification structure of a cast ingot can be effectively guaranteed, and a Hastelloy steel ingot with uniform and excellent component structure is obtained. According to the electroslag remelting method, the matching of an electroslag slag system is guaranteed, the liquidus temperature of Hastelloy is relatively low, a shallow and flat molten pool can be obtained by adopting higher voltage and lower current in the smelting period, and therefore good surface quality can be guaranteed at a low smelting speed; and by properly increasing the filling ratio, the electroslag process is improved, the direct current component of the crystallizer in the electroslag process is increased, the lower slag temperature and the smaller molten pool volume are kept, the width of a two-phase region is reduced, the local solidification time is shortened, and a better solidification structure is obtained.

Owner:HEBEI IRON AND STEEL

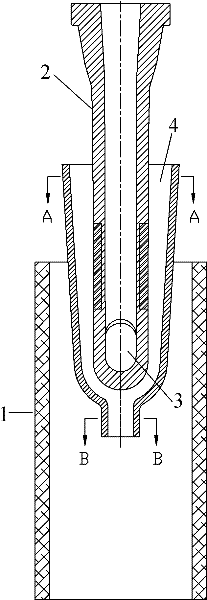

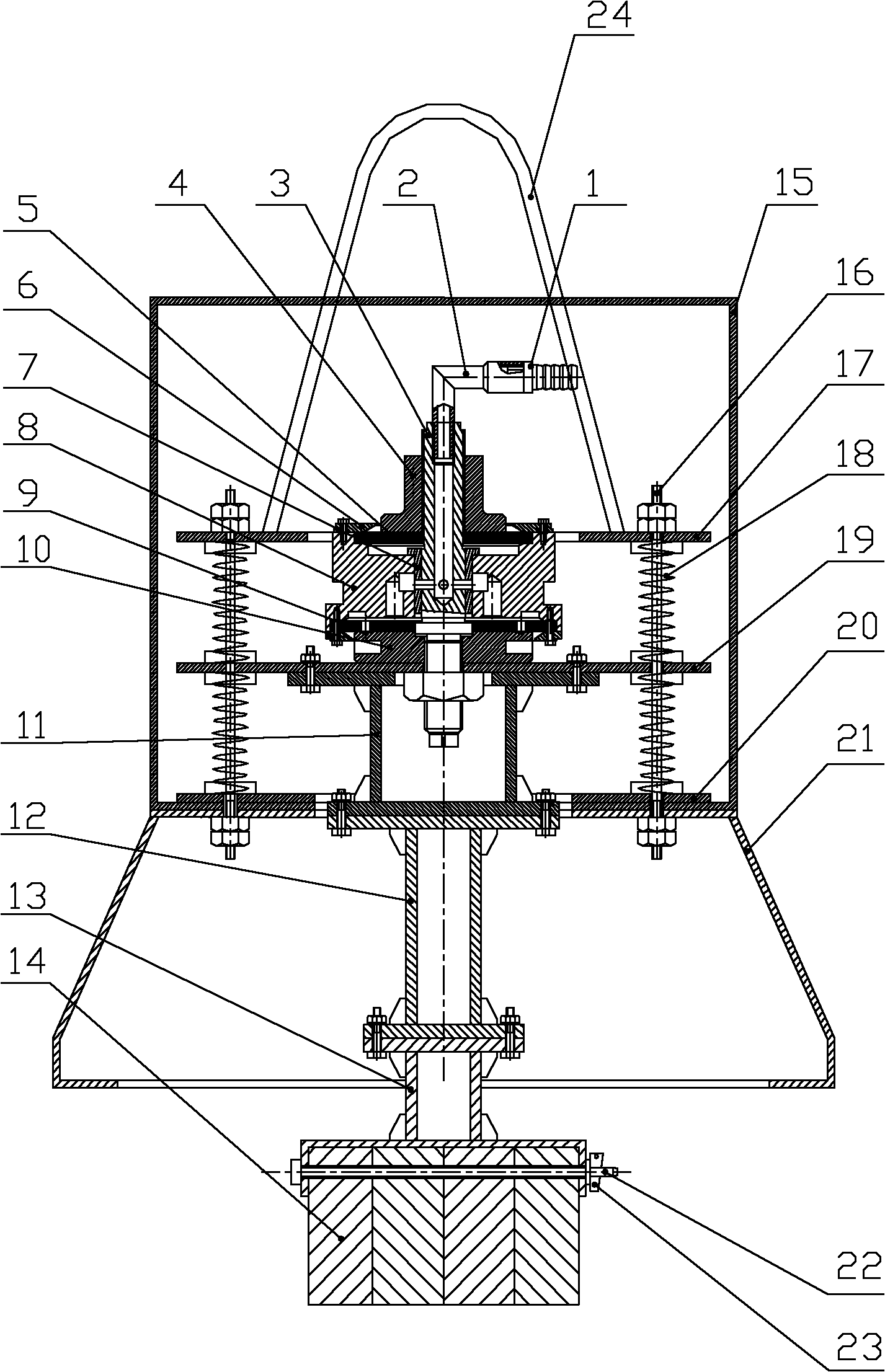

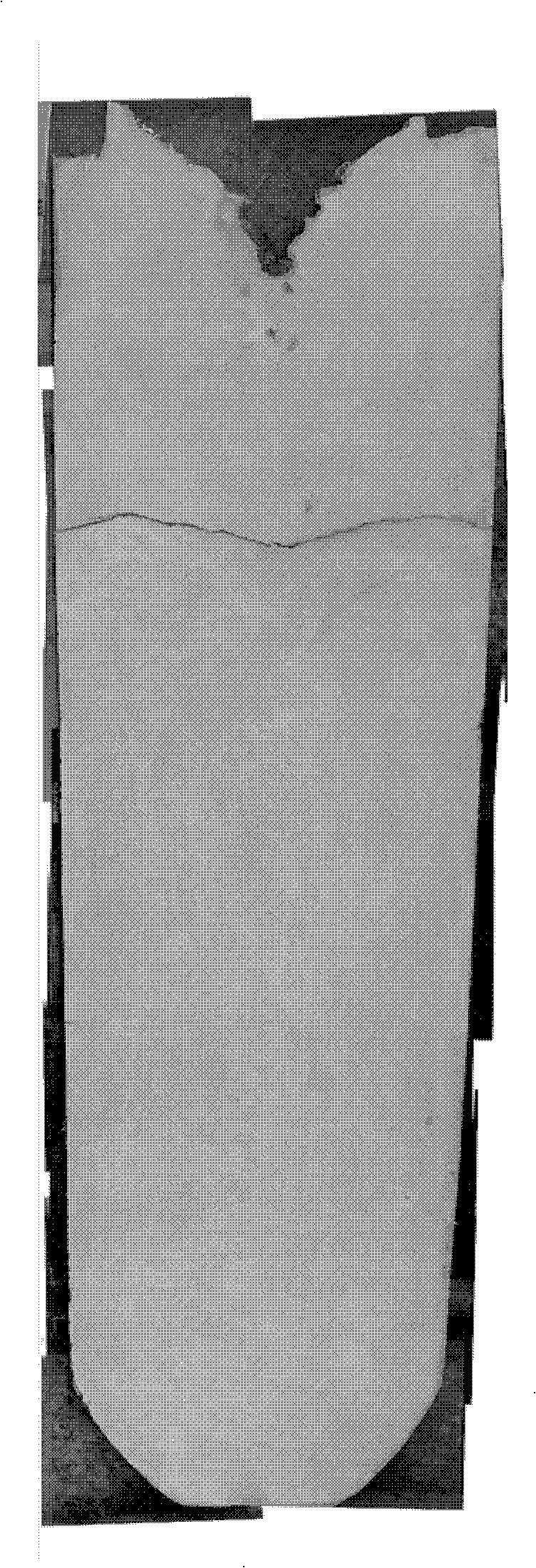

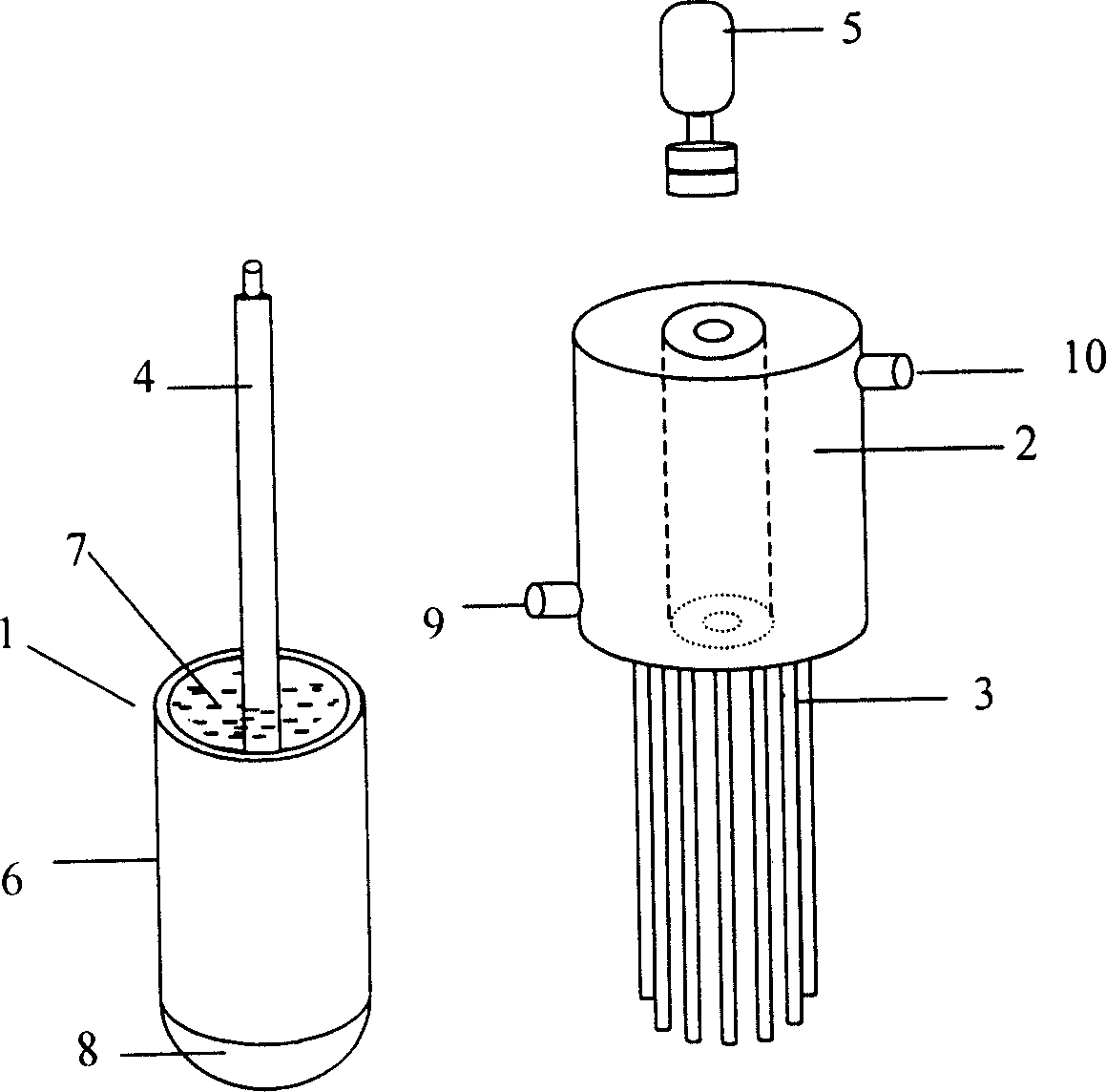

Melting-type ultrasonic vibration device of continuous casting crystallizer

The invention discloses a melting-type ultrasonic vibration device of a continuous casting crystallizer. The melting-type ultrasonic vibration device comprises an ultrasonic transducer, an ultrasonic generator connected onto the side surface of the ultrasonic transducer and an amplitude-change pole connected onto the lower end of the ultrasonic transducer, wherein the lower end of the amplitude-change pole is provided with an ultrasonic vibration transmission rod which is inserted into molten steel of crystallizer; the ultrasonic vibration transmission rod is manufactured by adopting a cast steel material which is similar to a cast steel type and additionally contains trace alloy elements; and the ultrasonic vibration transmission rod is allowed to be melted in the molten steel during a casting process. According to the melting-type ultrasonic vibration device, on one hand, the industrial long-time application of ultrasonic metallurgy in continuous casting can be realized; and on the other hand, the superheat degree and temperature gradient of the molten steel can be greatly lowered by the molten tool head, and the aim of improving a casting blank solidification structure is realized by controlling the melting speed of the tool head.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for improving internal quality of casting blank by composite intervention

Provided is a method for improving internal quality of casting blank by composite intervention. The method comprises following steps: 1), machining pure iron or steel with the approximate content of steel grades to be an easily-melted cold bodies moving with molten steel and then drying; 2), baking feeding guide pipes which are made by refractory material and immersing them into a crystallizer below the molten steel surface; aligning feeding guide pipe openings to the center of steel streams as for round and square billets; utilizing two guide pipes for plate blank and distributing them on two sides of a wide surface of the crystallizer; 3), continuously injecting the dried cold bodies into a high-temperature region of a molten pool of the crystallizer, adding the cold bodies in the amount of 0.8-1.3% of casting blank; adopting the crystallizer to electromagnetically stir during the continuous casting process. The method for improving internal quality of casting blank by composite intervention has following beneficial effects: cold bodies are fed into the crystallizer such that superheat and temperature gradient of molten steel during mass production of continuous casting; the solidification structure of casting blank is improved; quality flaws of the internal quality of the casting blank is reduced; the temperature field of the crystallizer is improved; and therefore the purposes of increasing equiaxial crystal ratio and improving internal quality of the casting blank are fulfilled.

Owner:BAOSHAN IRON & STEEL CO LTD

A Method for Effectively Eliminating Center Defects of Solidified Billet and Refining Solidified Structure

The invention discloses a method for effectively eliminating the central defect of a solidification blank and refining a solidification structure. The method relates to preparation of various castings with dead heads, round continuous casting blanks with the diameter of between phi 100 and phi 2,000 millimeters, square continuous casting blanks with the thickness of between 100 and 1,500 millimeters, 5-700-ton mould casting steel ingots, casting blanks and hollow blanks, is applied to preparation of carbon steel, alloy steel and non-ferrous metal under conditions of vacuum and non vacuum, andhas an inhibitory action on cavity shrinkage and loosen of various casting which are provided with the dead heads and made of black alloy material, the steel ingots and casting blanks. For the steel ingot and the casting, a vibration device is arranged in a steel ingot dead head after completion of pouring, and for the continuous casting blank, the vibration device is arranged in a crystallizer during pouring; the vibration device is connected with a refractory material; the refractory material is immersed in metal liquid and used for vibrating the metal liquid to increase the number of primary crystallization of the metal liquid; and a crystal nucleus is triggered to fall under the action of vibration to increase nucleation particles inside the steel ingot, eliminate cavity shrinkage andloosen inside the steel ingot, the casting and the casting blanks and refine the solidification structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

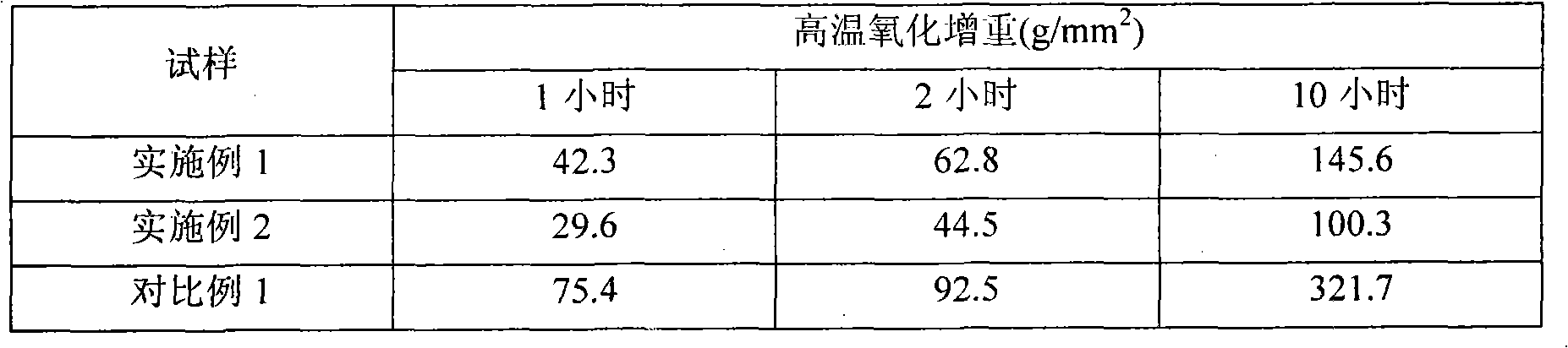

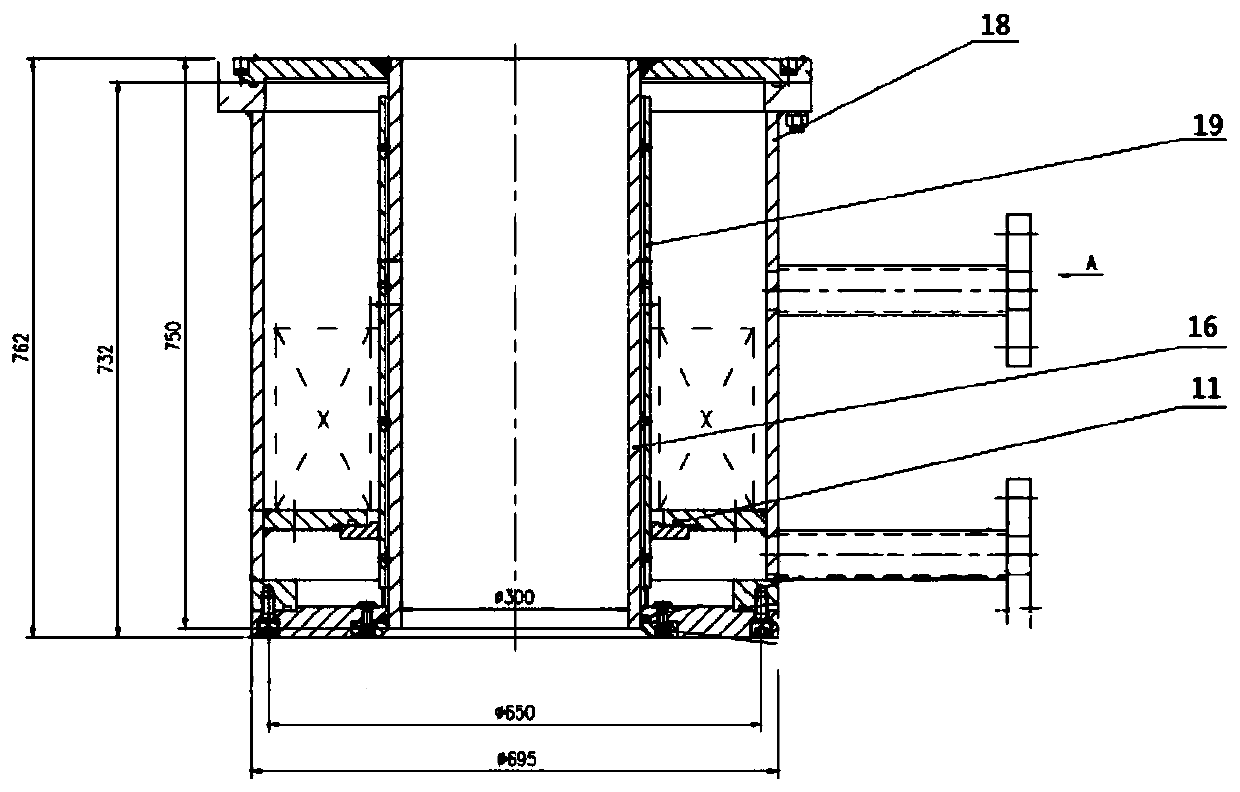

Austenitic stainless steel containing rare-earth element

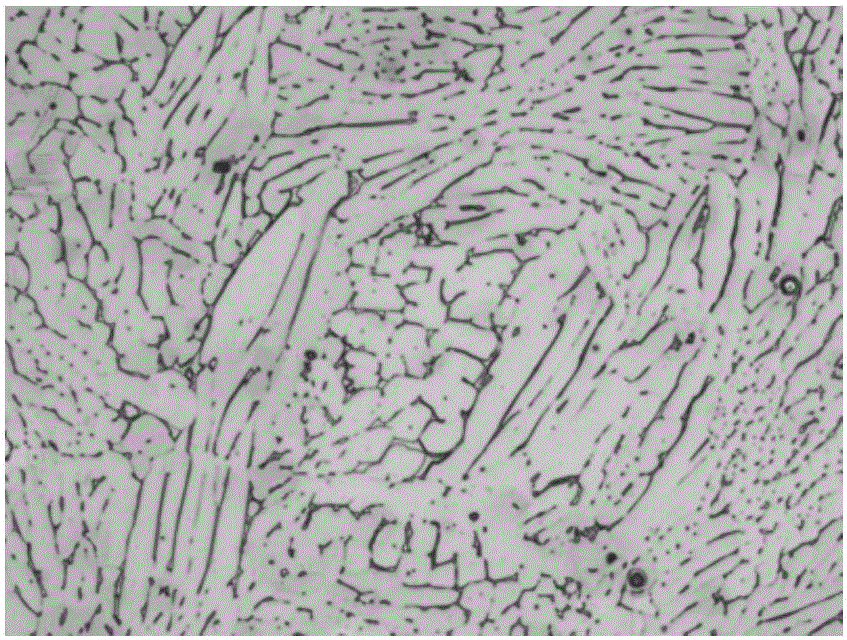

InactiveCN102312171AImprove coagulation tissueImprove sheet formabilityRare-earth elementSimple component

The invention provides an austenitic stainless steel containing a rare-earth element, which comprises the chemical components in weight percent: not greater than 0.06 percent of carbon (C), 17.0-19.0 percent of chromium (Cr), 0.5-0.7 percent of manganese (Mn), 8.5-10.5 percent of nickel (Ni), 0.04-0.06 percent of rare-earth element, not greater than 1 percent of silicon (Si), not greater than 0.02 percent of phosphorus (P), not greater than 0.02 percent of sulfur (S) and the balance of ferrum (Fe). The austenitic stainless steel containing the rare-earth element has fewer elements, simple components and the conventional performance of common austenitic stainless steel. Moreover, columnar crystals and equiaxed crystals can be obviously refined by the addition of mischmetal, and the sheet moldability of the austenitic stainless steel is improved. Moreover, the impact performance of the austenitic stainless steel is also greatly improved, and the high-temperature oxidation resistance is also improved to a certain extent.

Owner:INNER MONGOLIA HUAYE SPECIAL STEEL

Method and apparatus for preparing aluminium base composite materials under high magnetic field

InactiveCN1261612CImprove acceleration performanceImprove coagulation tissueMetallic aluminumInsulation layer

A process for preparing the Al-base composition under strong magnetic field includes such steps as heating Al to 850 deg.C, holding the temp for 30 min, adding reinforcing Al2O3 particles (or short fibres), stirring, pouring in mould, solidifying for 20 min strong magnetic field system and cooling in air. Its equipment is composed of metallic ladle, heating system, thermoelectric couple, reinforcing material delivering pipe, stirring coil, casting mould, supporter, slide sprue, vacuum chamber or protecting gas chamber, and the strong magnetic field control system consisting of strong magnetic field genrator, cooling water pipe, alarm and temp control unit and insulating layer.

Owner:NORTHEASTERN UNIV LIAONING

Semi-continuous casting method for light alloy and dedicated apparatus for implementing the same

The invention discloses a method of light alloy semi-continuous casting and relative special device. Wherein, said method comprises: using upright semi-continuous device to guide out the heat of metallic liquid hole with inorganic heat pipe, while the liquid hole is formed by flowing metal into crystallizer. And said special device comprises a mixer driven by motor, several heat pipes, and a cooling water tank, while the mixer has one mandrel whose upper end is through the water tank and driven by motor and lower end is connected to a mixing cylinder; said mixing cylinder is filled with alloy whose fusion point is lower; said heat pipes are mounted at the bottom of cooling water tank and inserted into said alloy. The invention can effectively improve the nucleation rate of light alloy liquid, reduce the non-uniform crystallized range, and improve the solidified organize of light alloy.

Owner:HUNAN INT ECONOMICS UNIV

Device and method for refining high-end bearing steel by electromagnetically controlling electroslag

ActiveCN110499426AImprove heat transfer efficiencyEnhanced convection coolingIncreasing energy efficiencyMelting tankConcentration gradient

The invention relates to a device and method for refining high-end bearing steel by electromagnetically controlling electroslag, and belongs to the technical field of metallurgy. According to the technical scheme, electromagnetic energy is converted into molten steel kinetic energy, a rotating magnetic field is applied into an electromagnetic crystallizer, so that convection cooling between metaland the crystallizer is strengthened; and an induction coil and a liquid level monitoring device are arranged inside the electromagnetic crystallizer. The device and method for refining the high-end bearing steel by electromagnetically controlling the electroslag has the beneficial effects that convection movement around a metal molten pool before solidification is effectively improved, solute enriched liquids between the molten pool and solid dendritic crystals are mutually scoured and mixed so as to reduce the concentration gradient, so that element segregation is reduced; and meanwhile, through convection heat transfer generated by molten steel flowing, convection cooling and heat transfer conditions of metal molten steel and the crystallizer are reinforced, heat transfer efficiency ofmolten steel to a crystallizer water cooling copper pipe is greatly improved so that segregation can be reduced, net carbide precipitation can be eliminated, formation of coarse columnar crystals in the molten steel solidification process can be inhibited, and production of the high-end bearing steel through an electroslag furnace is achieved.

Owner:HEBEI IRON AND STEEL

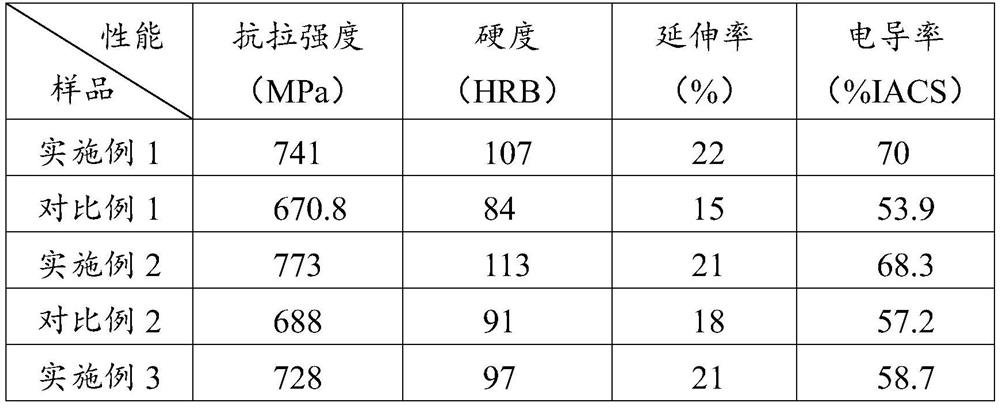

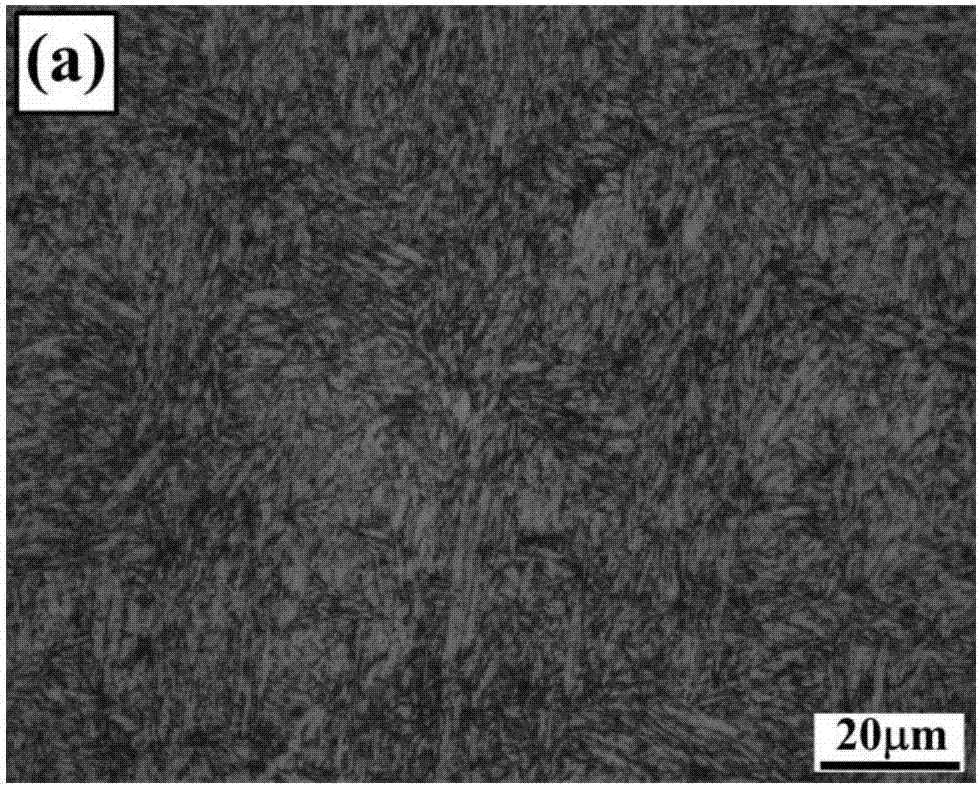

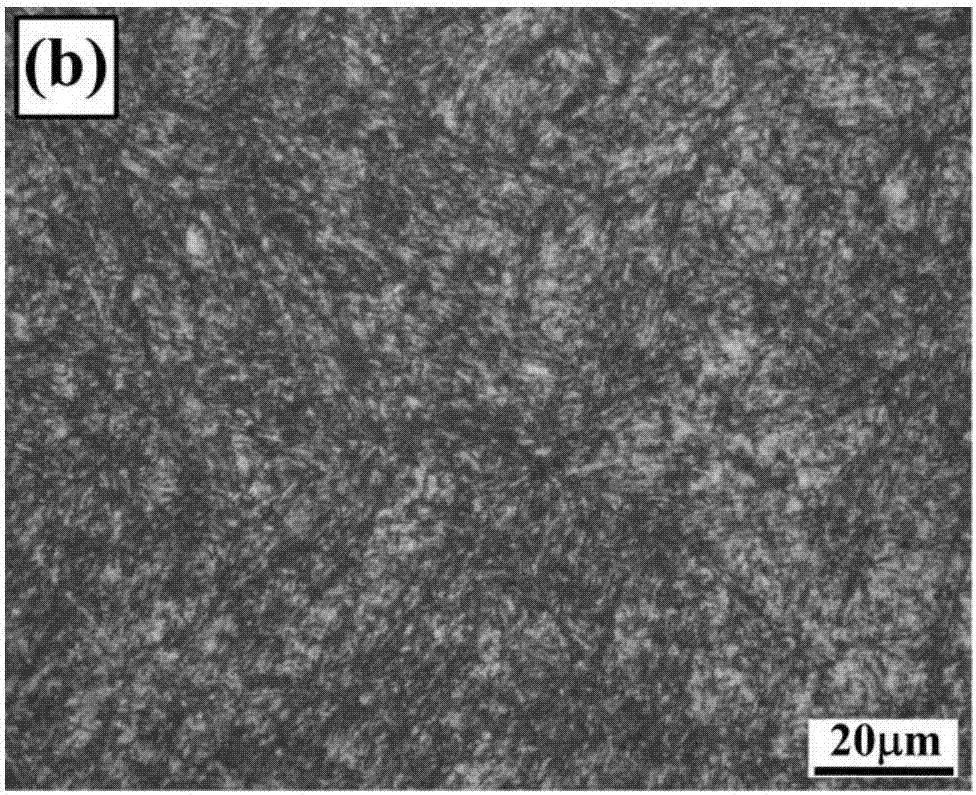

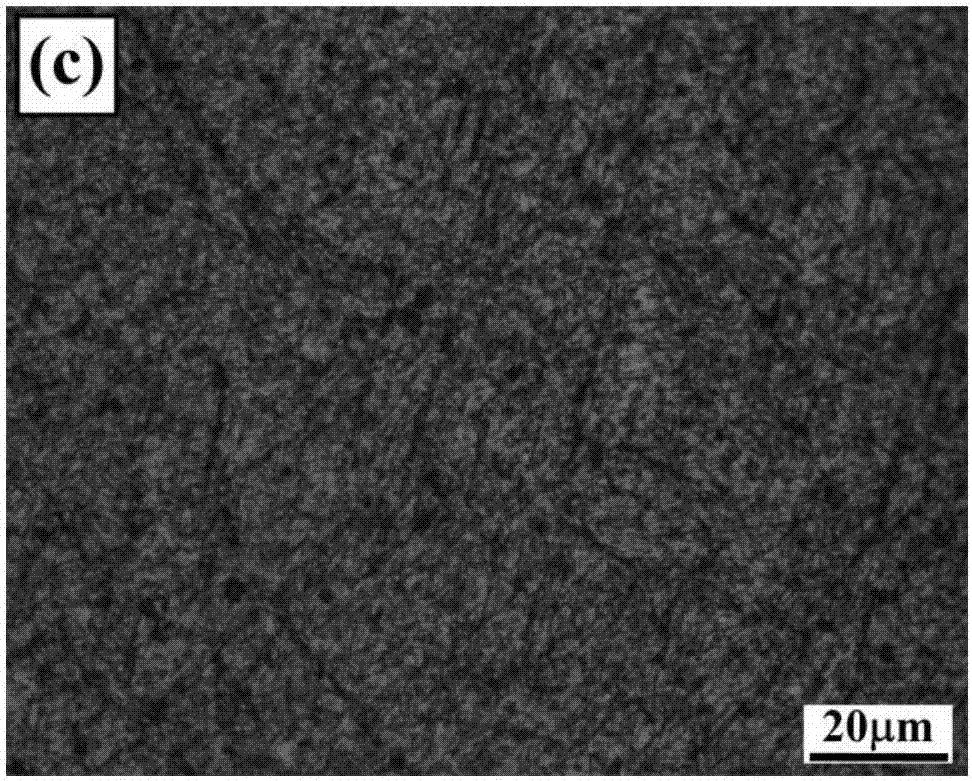

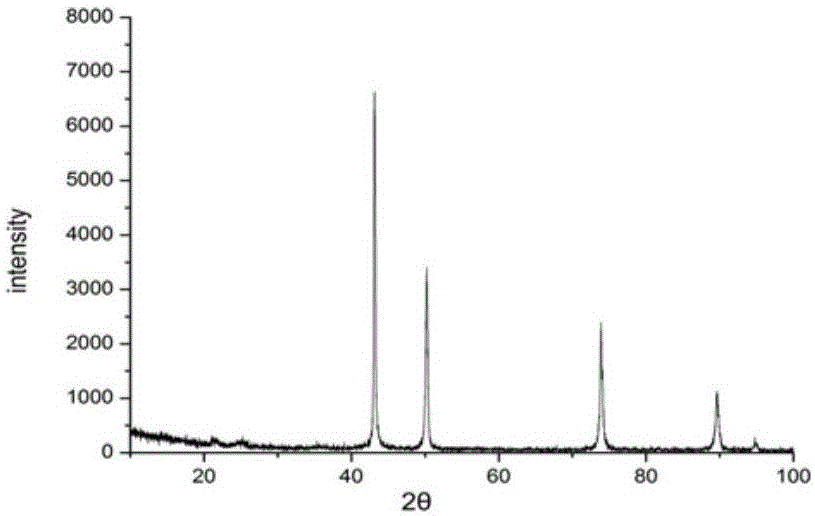

Method for preparing high-performance beryllium-copper alloy through mechanical vibration treatment and high-performance beryllium-copper alloy

The invention provides a method for preparing a high-performance beryllium-copper alloy through mechanical vibration treatment and the high-performance beryllium-copper alloy, and belongs to the field of metal material machining. The method comprises the following steps that (1) alloy raw materials are smelted, and melt is obtained; (2) the melt obtained in the step (1) is poured into a mold in mechanical vibration, and mechanical vibration is kept until the melt is completely solidified to obtain a beryllium copper alloy cast ingot; the amplitude of mechanical vibration is 1-4 mm, and the frequency of the mechanical vibration is 25-75 Hz; and (3) the beryllium-copper alloy ingot obtained in the step (2) is sequentially subjected to solution treatment and graded aging treatment, and the high-performance beryllium-copper alloy is obtained; the temperature of the solution treatment is 920-950 DEG C, and the time of the solution treatment is 0.8-1.2 h. The method is simple in technology, low in production cost and relatively low in requirements on smelting equipment, and the beryllium-copper alloy prepared by the method is excellent in mechanical property and high in conductivity.

Owner:NANCHANG HANGKONG UNIVERSITY +1

High-Cr-content cast heading machine cutter steel and manufacturing technique thereof

ActiveCN107881435AImprove thermal fatigue crack levelImprove oxidation and corrosion resistanceFurnace typesHeat treatment furnacesThermal fatigueNear net shape

The invention relates to high-Cr-content cast heading machine cutter steel. The cutter steel comprises the chemical components of, by weight, 0.30%-0.55% of C, 8.0%-12.0% of Cr, 1.2%-3.0% of Mo, 0.5%-1.8% of Ni, 0.6%-1.0% of V, 0.1%-0.4% of Mn, 0.6%-0.8% of Si, 0.04%-0.30% of N, no more than 0.005% of S, no more than 0.03% of P and the balance Fe. The cutter steel manufacturing technique comprisesthe following steps that a near-net shape blank of a cutter is obtained through precise casting, then heat treatment is conducted, and a finished product is obtained directly after fine machining. Yield strength and tensile strength are improved while the hardness, impact toughness and elongation of the cutter steel all can reach the level of domestic forged heading machine cutter steel; the oxidation corrosion resistant capability, thermal fatigue resistant performance and abrasive grain abrasion resistance are improved; and the production period is shortened, and the production cost is reduced.

Owner:JILIN UNIV

Preparation method of ultra-pure G102Cr18Mo stainless bearing steel

ActiveCN113088623AImprove purityReduce oxygen contentElectric furnaceDie castingSS - Stainless steel

The invention discloses a preparation method of ultra-pure G102Cr18Mo stainless bearing steel, and belongs to the technical field of metal smelting. According to the method, firstly, base metal needed for preparing the ultra-pure G102Cr18Mo stainless bearing steel is obtained through intermediate frequency furnace smelting, LF furnace refining, sedation treatment and die casting, the oxygen content ranges from 20 ppm to 30 ppm, and conditions are created for ultra-pure stainless steel bearing steel smelting; then, the base metal is subjected to forging and scaling treatment and then is put into a vacuum induction furnace to be melted and refined, and no alloy element is added in the vacuum induction treatment process; a consumable electrode subjected to vacuum induction melting is subjected to vacuum consumable remelting twice, and the G102Cr18Mo stainless bearing steel with extremely high purity can be obtained.

Owner:ANHUI FUKAI STAINLESS STEEL

Novel automobile body structural member die-casting die steel and preparation process thereof

InactiveCN110241358AImprove hardenabilityImprove red hardnessProcess efficiency improvementThermal fatigueDie casting

The invention provides novel automobile body structural member die-casting die steel and a preparation process thereof. The die steel comprises the following components of, by mass, 0.25%-0.35% of C, 0.20%-0.40% of Si, 0.20%-0.60% of Mn, less than or equal to 0.002% of P, less than or equal to 0.001% of S, 7%-9% of Cr, 2.5%-3.5% of Mo, 0.30%-0.50% of V, 0.40%-0.60% of W, 0.10%-0.30% of Nb, 0.005%-0.10% of N, 0.05%-0.20% of Ti and the balance Fe and inevitable impurities. Therefore, the novel automobile body structural member die-casting die steel has good hardenability, wear resistance and thermal fatigue resistance.

Owner:NINGBO HELI TECH CO LTD

Method for improving inner quality of continuous casting billet with thick and large section

The invention relates to the filed of the manufacture of continuous casting billets, in particular to a method for improving inner quality of a continuous casting billet with a thick and large section, which can solve the problems of the centerline shrinkage, porosity and segregation of the continuous casting billet with the thick and large section in the prior art. In the invention, through controlling degree of purity of molten steel and degree of superheat of pouring, and cooperatively adopting the micro-region oscillation technology and the solidification self-feeding technology, the inner quality of the continuous casting billet can be improved. The micro-region oscillation technology can effectively eliminate the defects of segregation in the continuous casting billet, can also effectively reduce solidification tissues, and decreases the centerline shrinkageand porosity; and the solidification self-feeding technology can realize simultaneous solidification and plastic movement of solid metal in the subsequent solidification shrinkage process, so that the purpose of radial self-feeding of high-temperature deformable metal can be achieved, further, the centerline shrinkage in the continuous casting billet can be eliminated, and the porosity in the continuous casting billet can be remarkably improved and is even eliminated. The invention is suitable for carbon steel, alloy steel and nonferrous metal casting billets with the thick and large sections, particularly for continuous casting sheet billets with the thickness being over 300mm, square billets, and round casting billets with the section phi being over 500mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser therapeutic system

ActiveCN100349554CEffective Vaporization CuttingImprove coagulation tissueSurgical instrument detailsRadiation therapyOptical fiber couplerEndoscope

The invention relates to a laser therapy system comprising: a first laser generator for generating vaporized slicing laser; a first light-combine mirror which has an angle of 45 degrees to said vaporized slicing laser; a second laser generator for generating coagulated hemostasis laser which has an angle of 45 degrees to the first light-combine mirror and vertical to the vaporized slicing laser; a first reflection mirror with a angle of 45 degrees to the vaporized slicing laser; a third laser generator for generating the guiding laser with an angle of 45 degrees to the first laser reflection mirror and vertical to the vaporized slicing laser; a optical fiber coupler vertical to the guide laser; a optical fiber connected to the optical fiber coupler; a endoscope connected to the optical fiber; and a optical filter connected to the endoscope. Wherein, the first light-combine mirror is plated a layer which is high transparent to the vaporized slicing laser and high reflective to the coagulated hemostasis laser; the first reflection mirror is plated a layer which is high reflective to the vaporized slicing laser and the coagulated hemostasis laser; and the input end of optical fiber coupler is plated a layer which is high transparent to the vaporized slicing laser and the coagulated hemostasis laser.

Owner:BEIJING INST OF OPTO-ELECTRONIC TECH

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

A kind of hot working die steel and its efficient preparation method

The invention relates to hot-working die steel and an efficient preparation method thereof. The hot-working die steel comprises, by weight, 0.34%-0.45% of C, 1.00%-1.40% of Si, 0.50%-0.60% of Mn, lessthan or equal to 0.015% of P, less than or equal to 0.015% of S, 5.00%-6.00% of Cr, 1.00%-1.20% of Mo, 0.08%-0.12% of Nb, 1.00%-1.30% of Ni, and the balance Fe and inevitable impurities. The preparation method has the advantages that the alloy components are optimized, and mechanical diffusion and thermal diffusion are adopted to jointly act, so that the components of the hot-working die steel are homogenized, the time required for homogenization of the alloy elements is shortened, the production efficiency is improved, the production cost is reduced, the produced hot-working die has the Rockwell hardness of 55-57 HRC, the isotropic performance is good, and the thermal stability is good.

Owner:ANGANG STEEL CO LTD

Continuous casting method for big round billet of medium-high-carbon medium-high-alloy tool steel

ActiveCN106563780AImprove performanceAvoid secondary oxidationMelt-holding vesselsPower flowHardness

The invention discloses a continuous casting method for big round billet of medium-high-carbon medium-high-alloy tool steel. The method comprises the following steps of: in a casting process, controlling degree of superheat of molten steel to 10 DEG C to 30 DEG C, controlling electromagnetic stirring current of a crystallizer to 250 A to 350 A, controlling frequency to 1.0 Hz to 2.0 Hz, controlling electromagnetic stirring current of a solidification end to 300 A to 400 A, and controlling frequency to 5.0 Hz to 8.0 Hz. The molten steel consists of the following components in percentage by weight: greater than or equal to 0.30% of C, greater than or equal to 3.0% of Cr and greater than or equal to 5% of total alloys. According to the continuous casting method disclosed by the invention, the defects that high-alloy tool steel is high in hardness and is not liable to straighten can be overcome by setting and optimizing technological parameters; and meanwhile, secondary oxidization of molten steel is avoided, product quality is guaranteed, the production process is simple, and the yield is high. The produced alloy tool steel has the characteristics of good structure uniformity and excellent comprehensive mechanical property.

Owner:SHANDONG IRON & STEEL CO LTD

Electrode for applying pulse current to continuous casting tundish

InactiveCN101885042BImprove high temperature oxidation resistanceEasy to replaceRefractoryPulse power supply

The invention discloses an electrode for applying pulse current to a continuous casting tundish. The electrode is characterized by comprising a cone frustum shaped fireproof material (2) and an electrode distribution plate (3) embedded into the fireproof material (2); a plurality of rod-like small electrodes (4) are vertically distributed on the surface of the electrode distribution plate (3); the rod-like small electrodes (4) pass through the cone frustum shaped fireproof material (2), and the ends of the rod-like small electrodes (4) are naked on the surface of the cone frustum shaped fireproof material (2) and connected with molten steel; the bottom end of the electrode distribution plate (3) is provided with a pulse current connecting end (1); and the pulse current connecting end (1) passes out of the bottom end face of the cone frustum shaped fireproof material (2) and is connected with a pulse power supply. The electrode has the advantages of strong high-temperature oxidation resistance and molten steel melting resistance, long service life, good conductivity, simple and feasible operation in a pulse processing process, safety and reliability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A production method of electroslag remelting of high-strength and high-plasticity twip steel

The invention provides a production method of high-strength high-plasticity TWIP (Twinning Induced Plasticity) steel, and belongs to the technical field of metallurgy. The TWIP steel comprises 0.03%-0.08% of C, 2.0%-3.0% of Si, 20%-30% of Mn, 2.5%-3.5% of Al, the balance of Fe and a small amount of other alloying elements. The TWIP steel is smelted by adopting a slag system comprising 60-70% of CaF2, 20-30% of Al2O3 and 5-15% of CaO; a right amount of manganese metal or electrolytic manganese and aluminium powder are added to slag so as to solve the problems of easy oxidization and burning loss of volatile elements in the TWIP steel. Argon is used for protecting remelting at a flow rate of 20-40Nm<3> / h, so that the burning loss of aluminium is reduced; the refinement is carried out at a low melting rate, and the melting rate is controlled at 700-950kg steel / hour. In a feeding period, electric currents gradually decline, and the feeding time is greater than 1.5 hours. The production method has the advantages that by adopting the electroslag remelting method, cracks are prevented from occurring in a TWIP solidification process, the solidification structure and the segregation condition of the TWIP steel can be improved, and meanwhile, the cleanliness of the TWIP steel can also be obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com