Device and method for refining high-end bearing steel by electromagnetically controlling electroslag

A technology of electroslag refining and electromagnetic control, which is applied in the field of metallurgy, can solve the problems of reducing the surface quality of ingots and affecting production efficiency, and can improve the solidification structure of ingots, inhibit the formation of coarse columnar crystals, and strengthen convective cooling and heat transfer conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

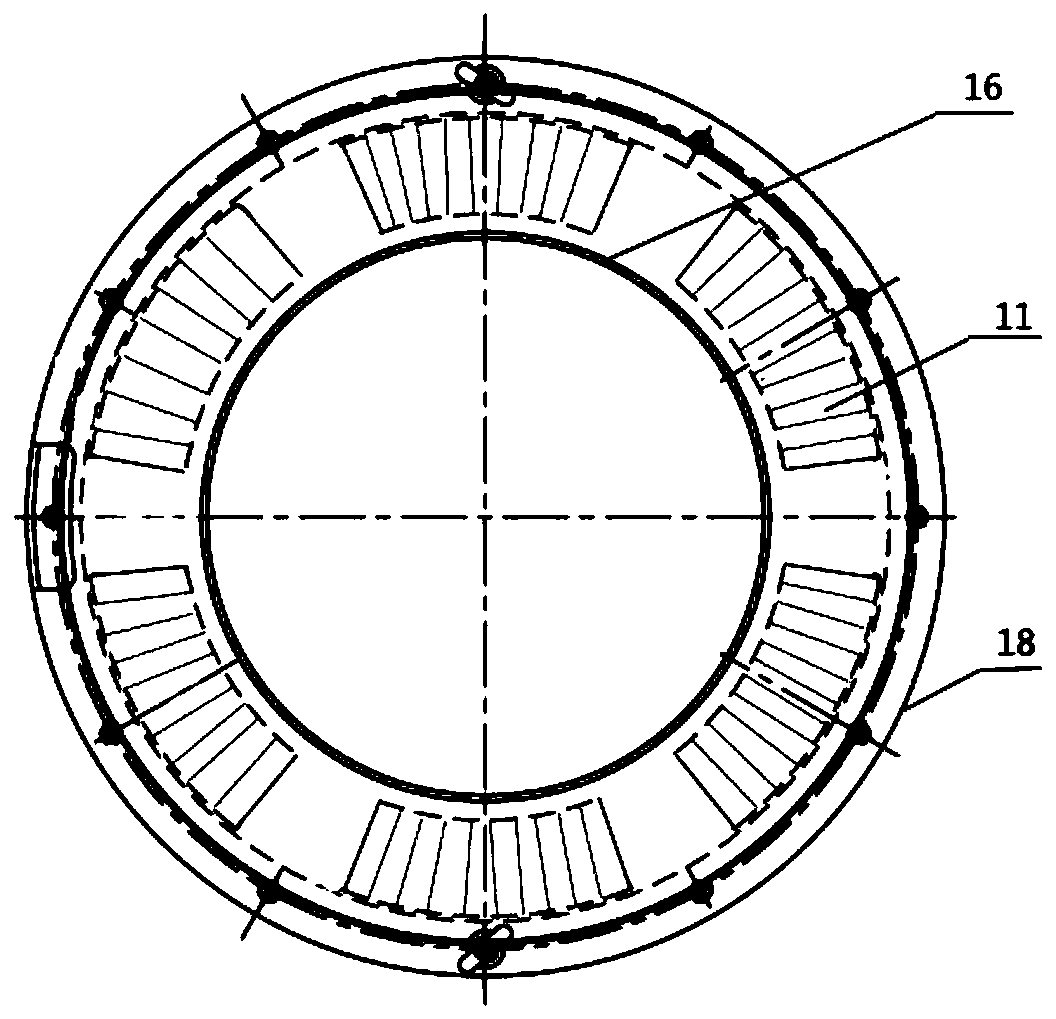

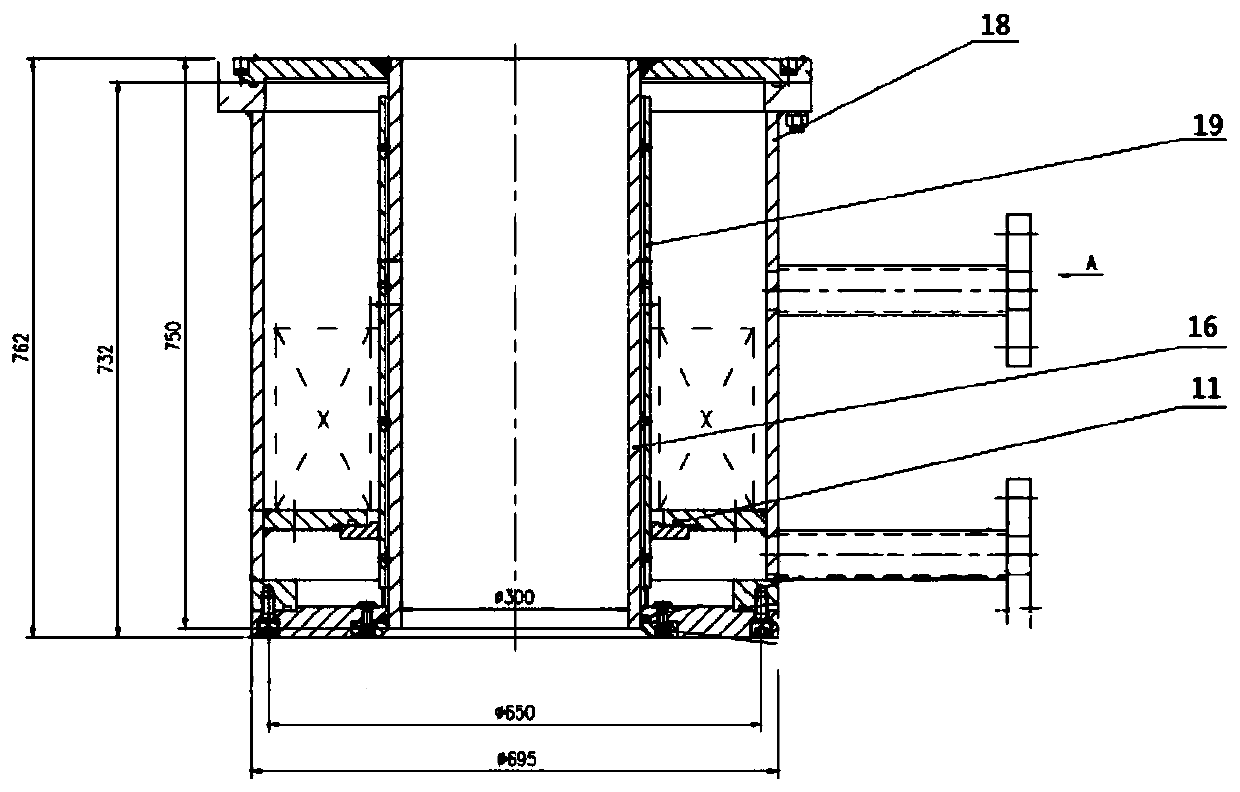

[0042] Electroslag refining consumable electrode is φ200×2000mm bearing steel, with 60%CaF 2 , 20%CaO, 18%Al 2 o 3 , 2% MgO slag material is used as the electroslag component, the refining melting rate is controlled by a constant melting rate of 240kg / h, the lifting speed of the electromagnetic crystallizer is X=7.26mm / min, and the crystallizer is a φ300×750mm electromagnetic crystallizer. Electroslag is carried out under the conditions of 2Hz-100A, 4Hz-150A, and 6Hz-300A. The specific process is that after the slag is melted, the electromagnetic control system is turned on, and the constant melting rate electroslag is automatically controlled by the PLC, and the mold lifting method is adopted to ensure that the metal molten pool is always located at the center of the electromagnetic stirring of the mold. The smelting is carried out under the slag pool, and the oxygen content in the upper part of the slag pool is less than 80ppm. See Table 1 for details.

[0043] Table 1 E...

Embodiment 2

[0047] Electroslag refining consumable electrode is φ220×1800mm bearing steel, with 55%CaF 2 , 25%CaO, 17%Al 2 o 3 , 3% MgO slag material is used as the electroslag component, the refining melting rate is controlled by constant melting rate 210kg / h, the lifting speed of the electromagnetic crystallizer is X=6.35mm / min, and the crystallizer is φ300×750mm electromagnetic crystallizer, respectively in the absence of magnetic field, Electroslag is carried out under the conditions of 1Hz-50A, 3Hz-150A and 6Hz-200A. The specific process is that after the slag is melted, the electromagnetic control system is turned on, and the constant melting rate electroslag is automatically controlled by the PLC, and the mold lifting method is adopted to ensure that the metal molten pool is always located at the center of the electromagnetic stirring of the mold. The smelting is carried out under the slag pool, and the oxygen content in the upper part of the slag pool is less than 100ppm. See T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com