Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve oxidation and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

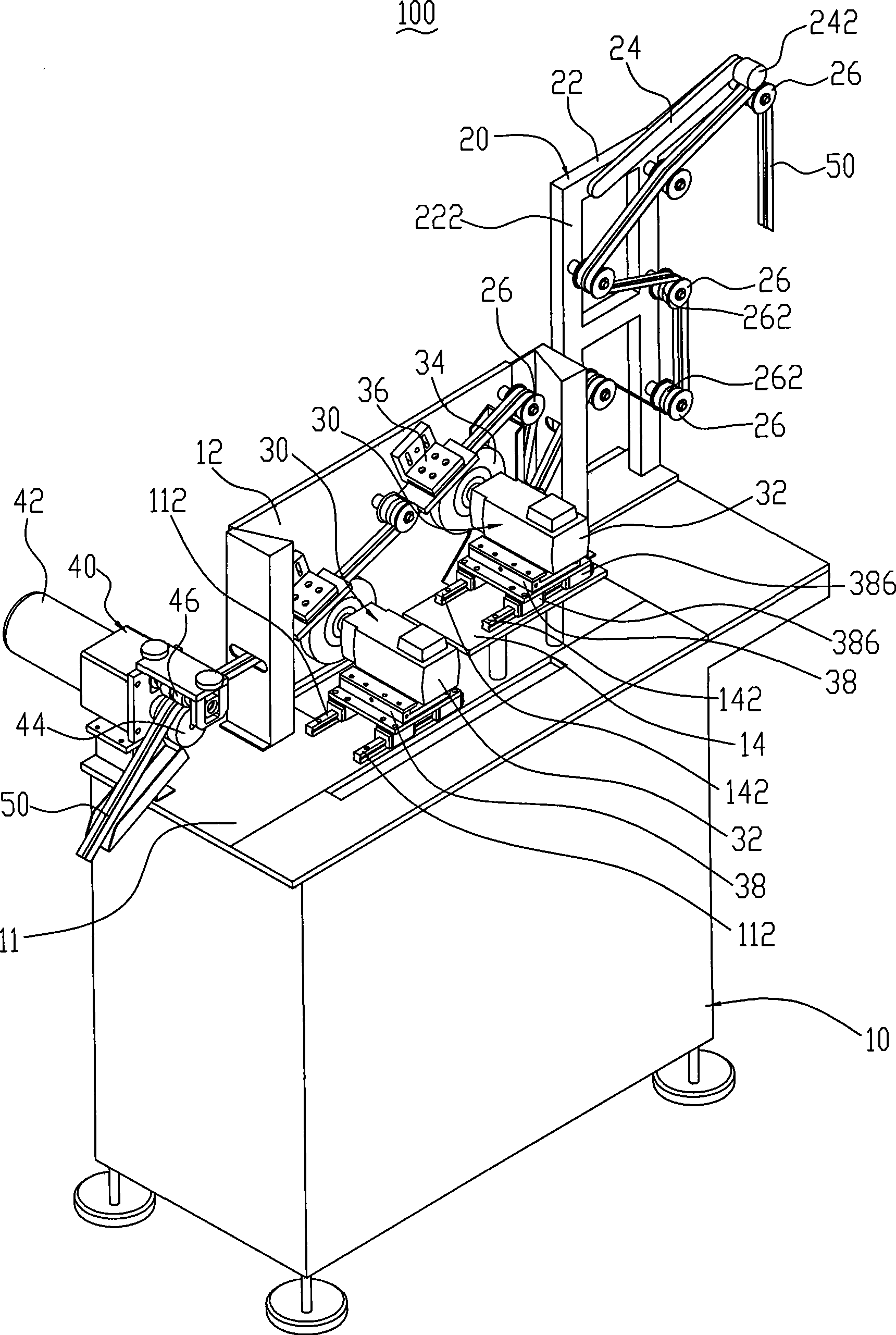

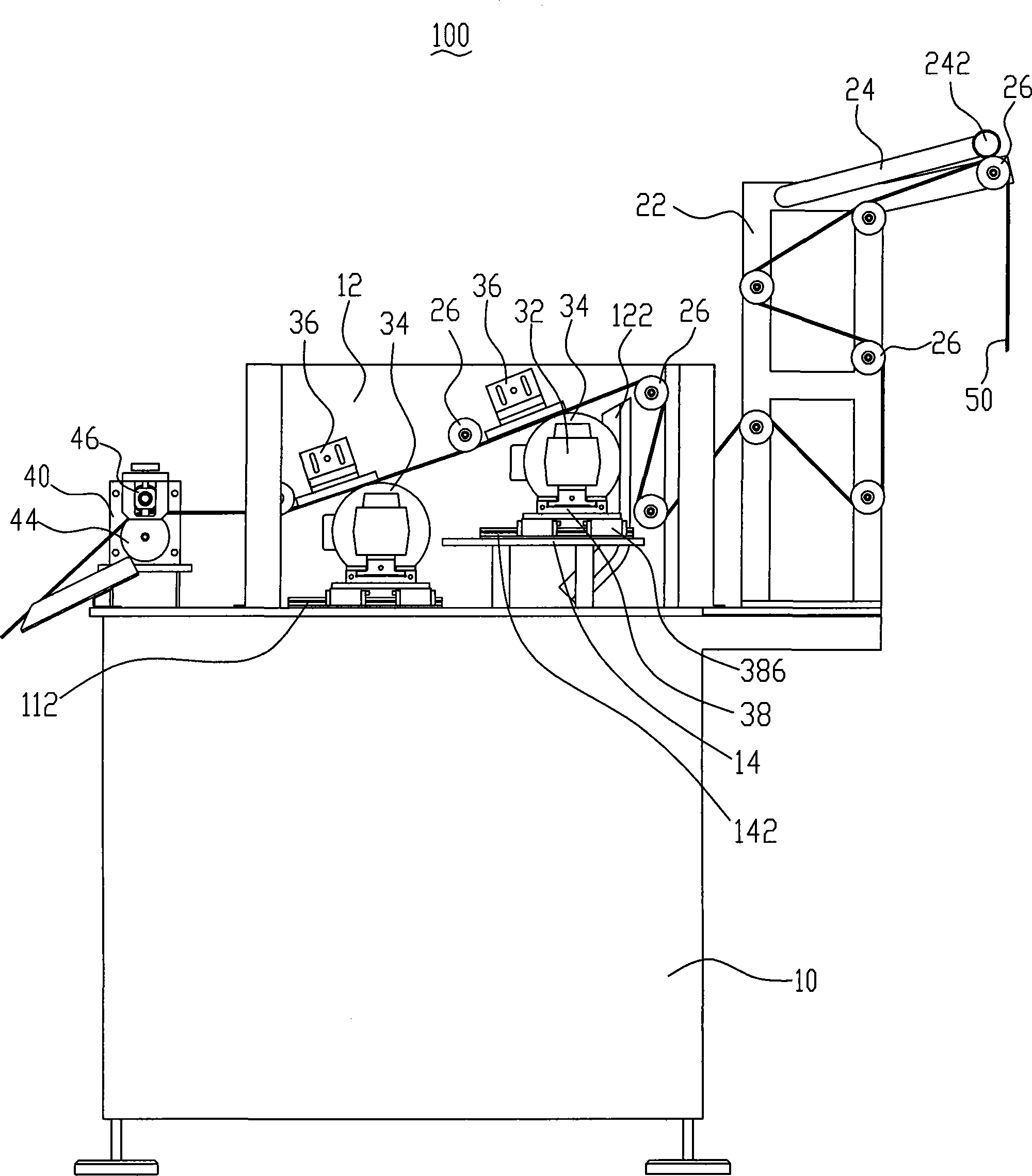

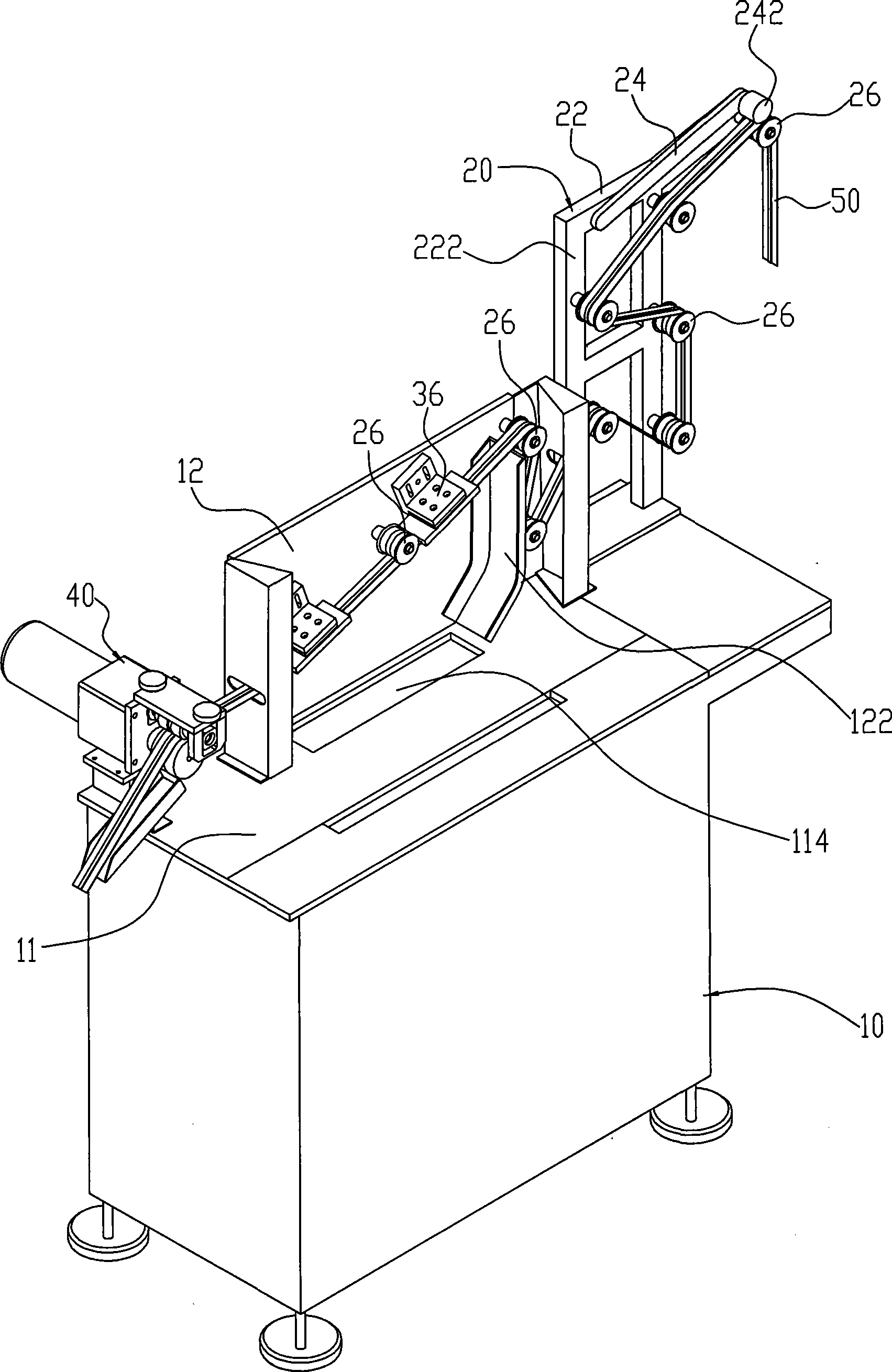

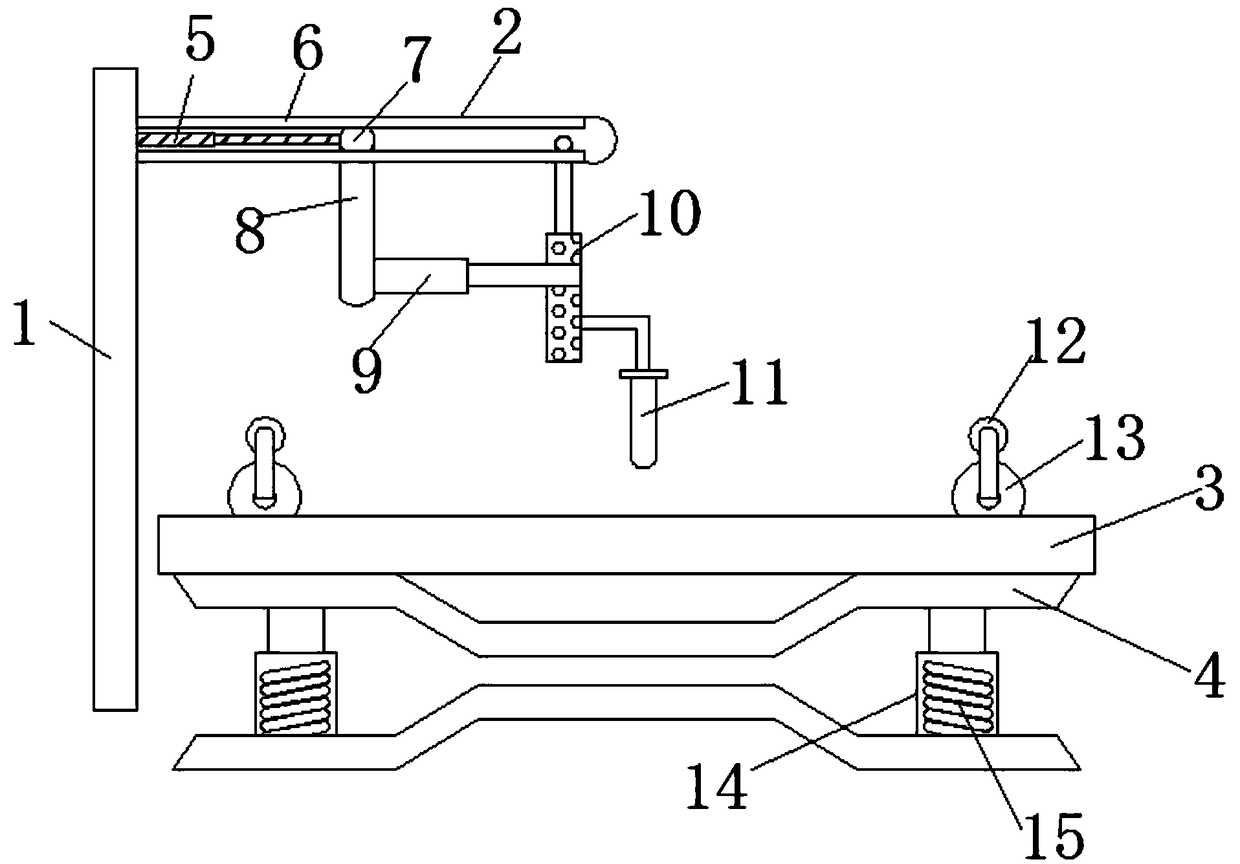

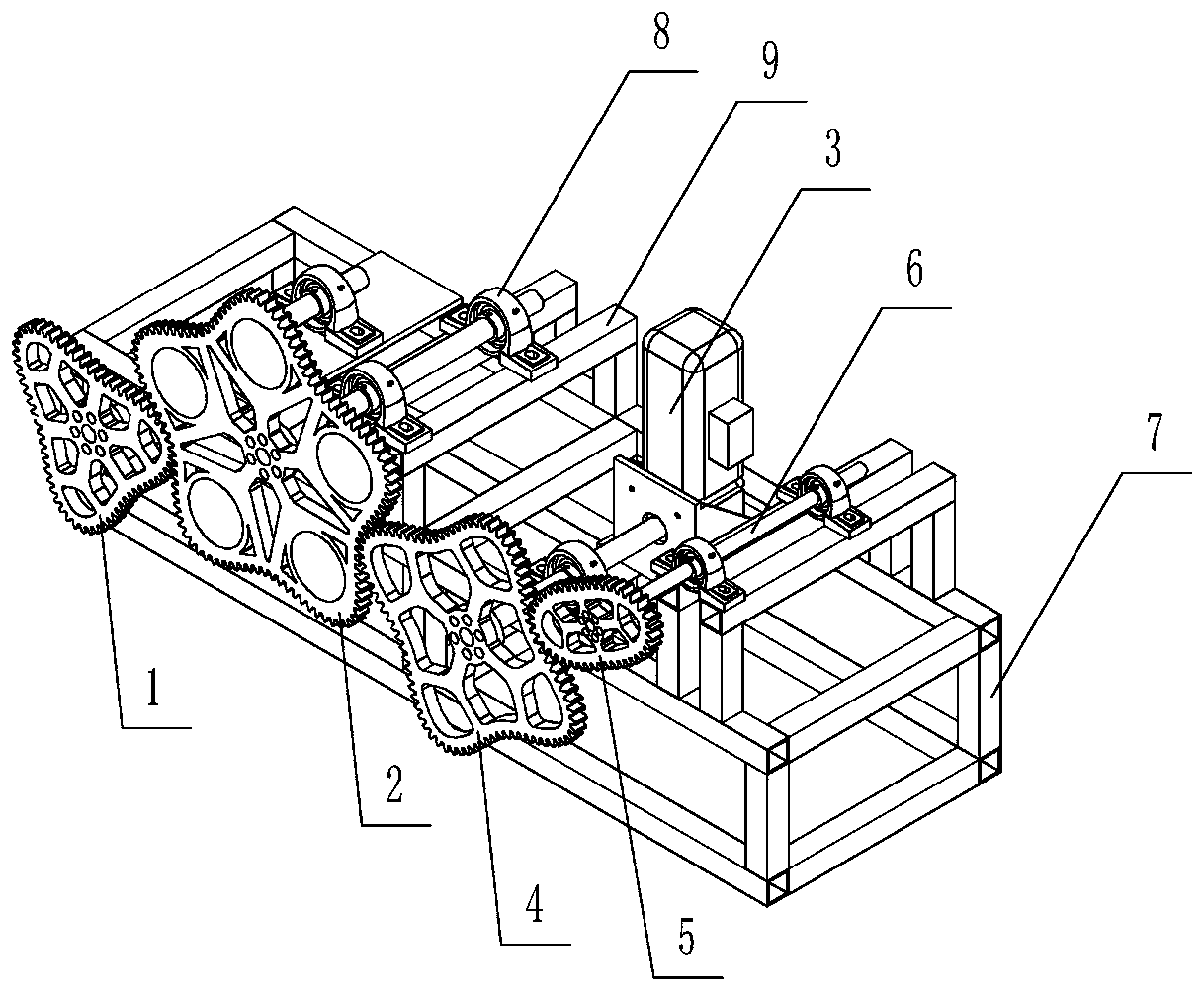

Metal slide fastener as well as surface working apparatus and surface working method thereof

InactiveCN101461589AImprove oxidation and corrosion resistanceImprove lightnessSlide fastenersGrinding machinesMotor driveEngineering

The invention relates to a metal zipper, surface processing equipment and surface processing method thereof. The metal zipper surface processing equipment is used for surface processing zipper tooth of the metal zipper belt, which comprises a machine body, a transporting mechanism and a traction mechanism. The transporting mechanism and the traction mechanism are disposed on the machine body, which are used for transporting and tracting the metal zipper belt. A milling mechanism disposed on the machine body between the transporting mechanism and the traction mechanism is further included, which comprises a motor, a milling wheel, and a clip. The clip abuts the zipper tooth of the metal zipper belt against the milling wheel. The motor drives the milling wheel to rotate for milling the zipper tooth on the metal zipper belt. The metal zipper surface processing equipment is capable of effectively controlling milling depth of the milling, eliminating deep mark on the zipper tooth surface, and making the metal zipper tooth surface smooth and bright.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Sn-Ag-Cu-Cr-X lead-free soldering material and its preparation

ActiveCN1895838AEasy to useGood anti-oxidation and anti-corrosion propertiesWelding/cutting media/materialsSoldering mediaAlloySoldering

A lead-free Sn-Ag-Cu-Cr-X solder is proportionally prepared from Cu, Cr, alloy of one or more of Ga, Bi, In, Ni, Ge, La, Ce, Sb, Mn and Zn, Ag, P and / or Al and Sn through smelting in vacuum or protecting atmosphere to preparing intermediate alloys Sn-Cu, Sn-Cr, Sn-Ag, Sn-P and Sn-Al, and proportional smelting.

Owner:BEIJING COMPO ADVANCED TECH

Wear-resistant and corrosion-resistant surfacing material

InactiveCN104942477AGuaranteed wear and corrosion resistanceGuaranteed welding effectWelding/cutting media/materialsSoldering mediaFerrosiliconCorrosion resistant

The invention discloses a wear-resistant and corrosion-resistant surfacing material. The wear-resistant and corrosion-resistant surfacing material for a flux-cored wire comprises a steel strip and powder; the wear-resistant and corrosion-resistant surfacing material for a welding electrode comprises a core wire and the powder; the powder is prepared from the following components by weight: 4-8 parts of marble, 0-15 parts of feldspar, 4-14 parts of rutile, 0-4 parts of titanium dioxide, 0-10 parts of fluorite, 0.5-5 parts of mid-carbon ferromanganese, 3-6 parts of atomized ferrosilicon, 42-55 parts of chromium metal, 7-12 parts of molybdenum powder, 12-18 parts of nickel powder, 5.5-8 parts of ferroniobium, 0-8 parts of iron powder, 1-2.5 parts of ferrotitanium, and 0.5-2 parts of rare earth; the thickness of the steel strip is 0.3-0.61 mm; the filling amount of the powder is 28-35 percent of the total amount; the core wire is made from any one of H08A, H0Cr24Ni13 and 0Cr18Ni9Ti; the weight part ratio of the core wire to the powder is (40-65) to (35-60).

Owner:宋焯

Composite permanent-magnetic material of motor and preparation method of composite permanent-magnetic material

ActiveCN106409458AImprove remanenceImprove coercive forceInorganic material magnetismMagnetic circuit characterised by magnetic materialsNanoparticleMagnetic energy

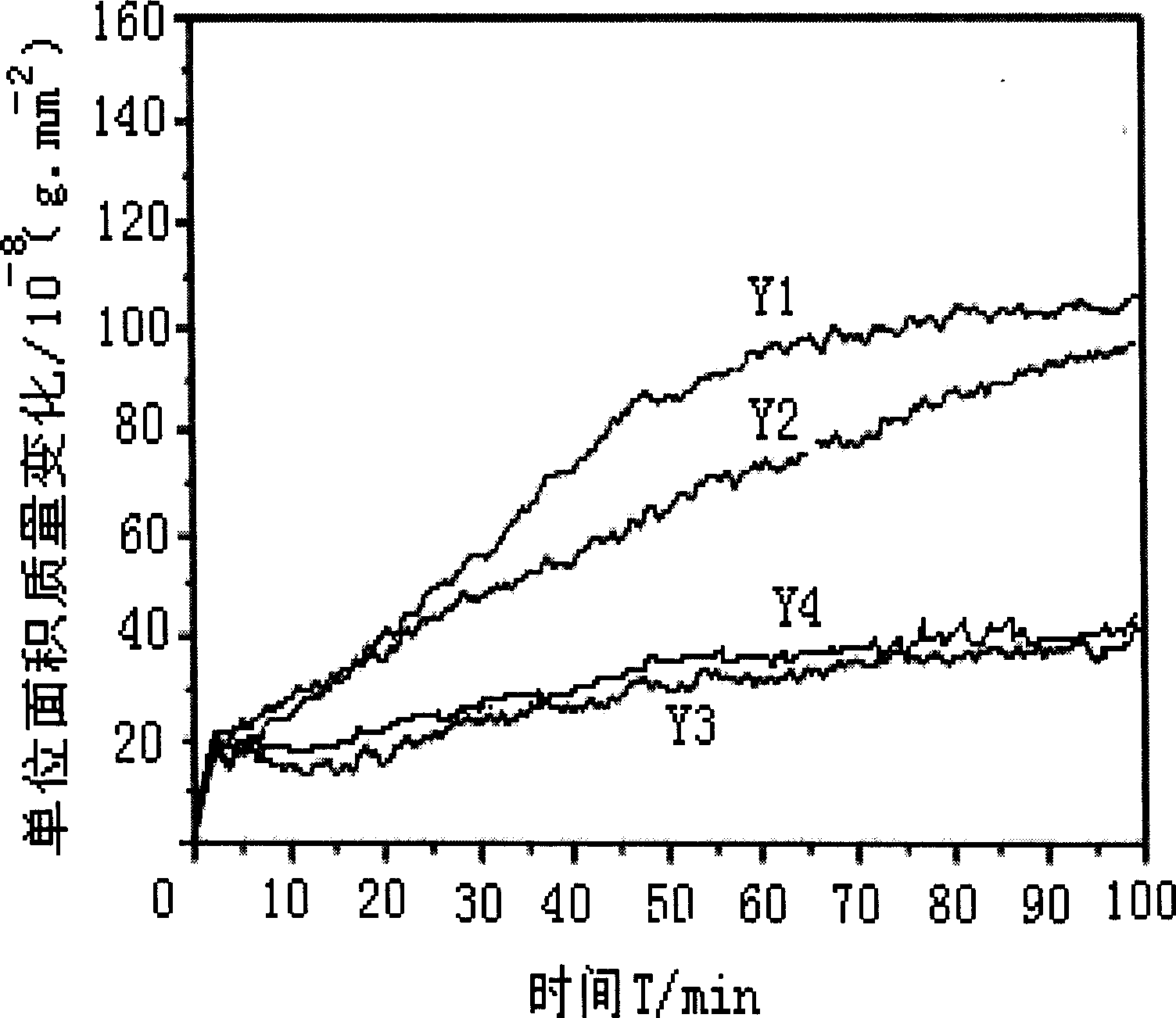

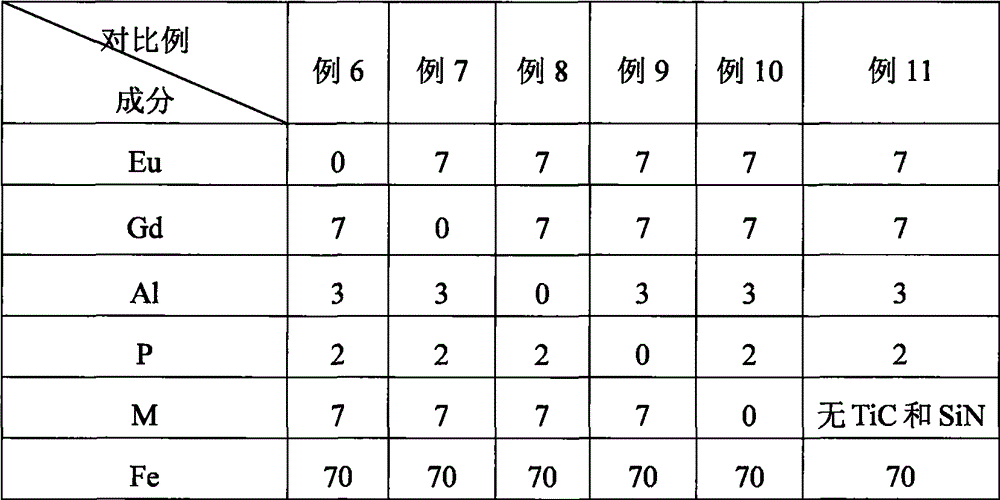

The invention provides a composite permanent-magnetic material of a motor and a preparation method of the composite permanent-magnetic material. The composite permanent-magnetic material of the motor is formed by a system of Eu, Gd, Fe, Al, P and M, wherein the M is formed by mixing nanoparticles of Fe2O3, Fe3O4, TiC and SiN; the mass ratio of Eu to Gd to Fe to Al to P to M in the system is (5-7) to (5-7) to (60-70) to (2-3) to (1-2) to (5-7); and the mass ratio of the Fe2O3 to the Fe3O4 to the TiC to the SiN in the M is 10 to 5 to 2 to 1. Therefore, the residual magnetism and the magnetic energy product are kept while the coercive force and the high-temperature stability of the permanent-magnetic material are improved, and the cost is effectively reduced.

Owner:慈溪市华夏电器实业有限公司

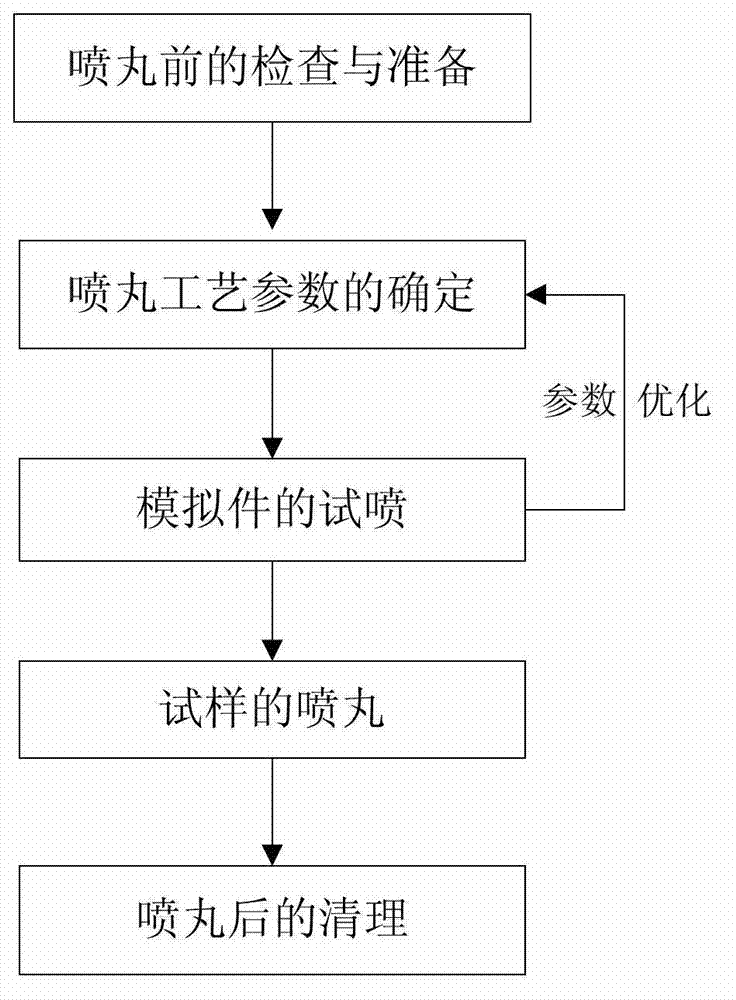

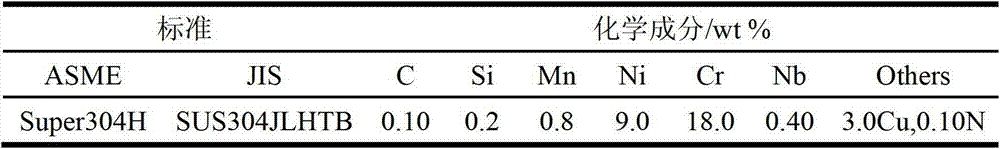

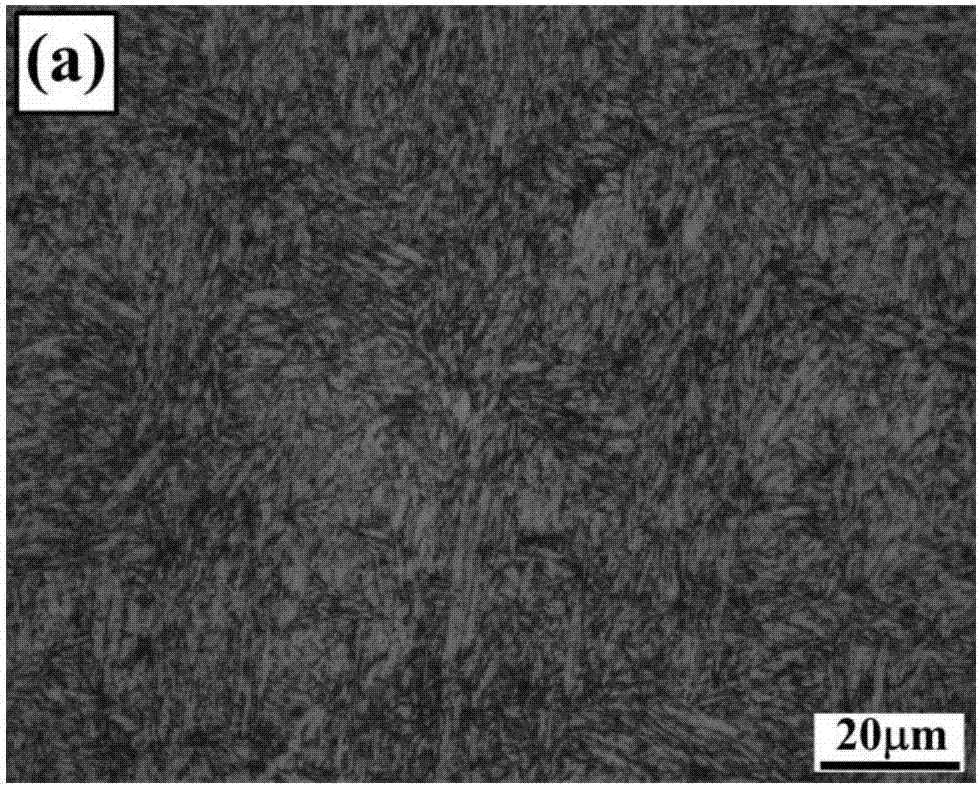

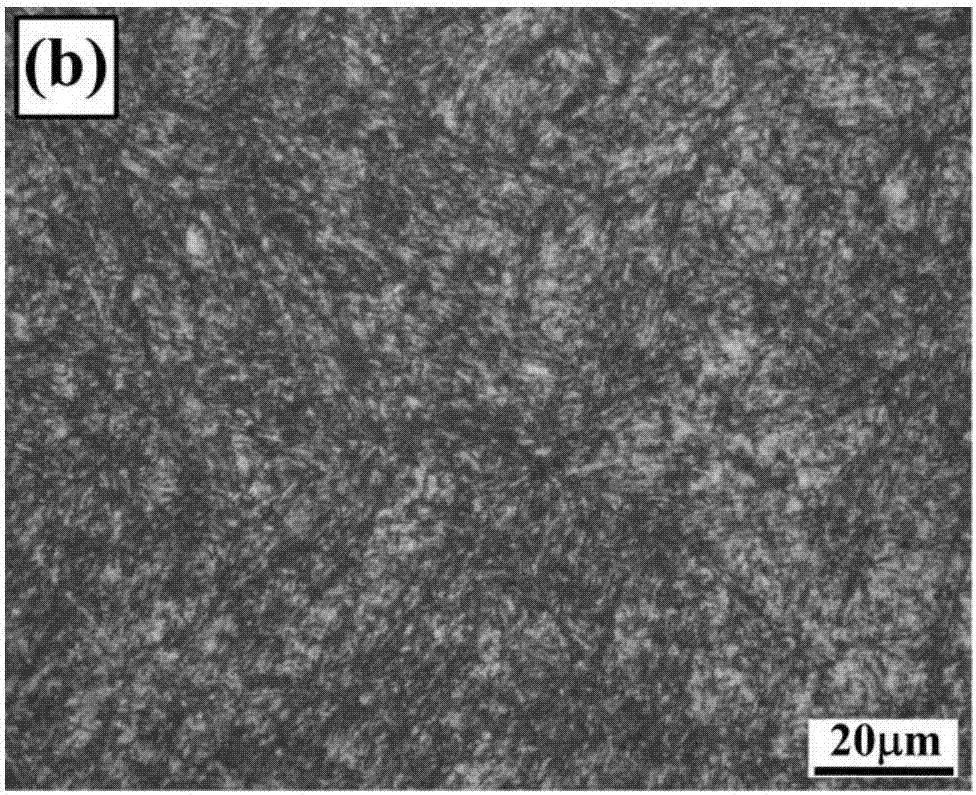

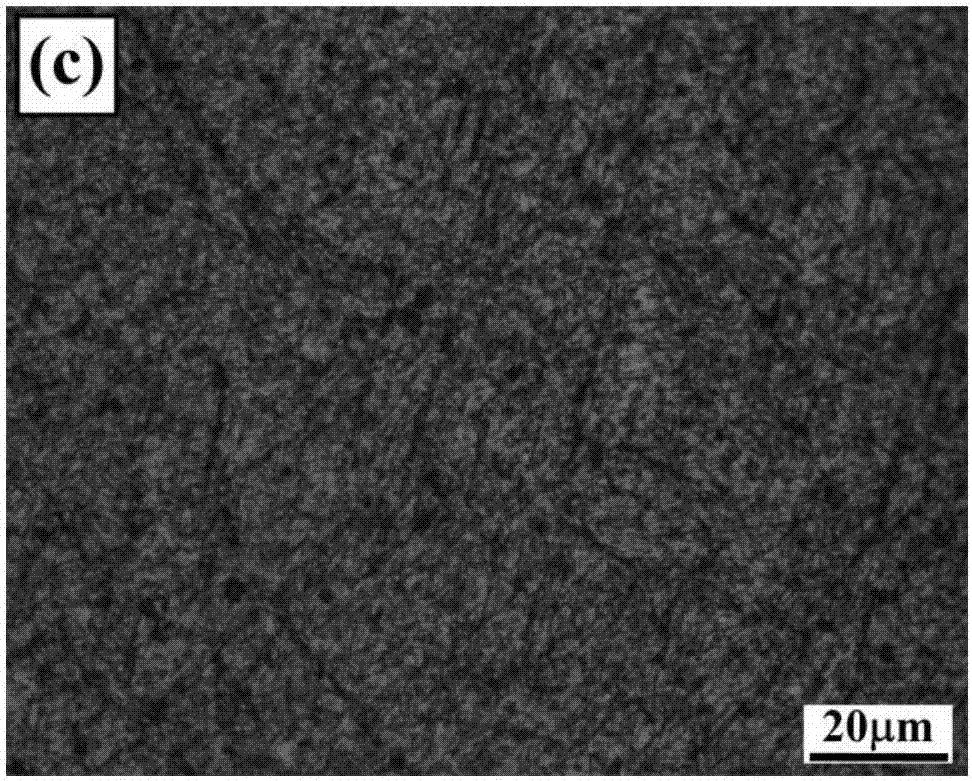

Surface shot blasting process for improving high temperature steam oxidization resistance of high-chromium austenite steel

InactiveCN103045830AStrong plastic deformationIncrease the dislocation densityTest sampleOxidation resistant

The invention discloses a surface shot blasting process for improving a high temperature steam oxidization resistance of a high-chromium austenite steel, wherein mechanical centrifugal shot blasting equipment is used for shot blasting; the shot is made of ceramic; microhardness of the shot is 660-750HV, shot diameter is 0.25-0.75mm, a distance from a nozzle to the surface of a test sample is 150-190mm, shot blasting flow is 1.0-2.5kg / min, shot blasting duration is 2-4min and shot blasting angle theta is 40-65 degrees. According to the process disclosed by the invention, a shot blasting strength of 0.25-0.35A and a surface coverage of 200% of the high-chromium austenite steel can be guaranteed; and meanwhile, the oxidizing corrosion resistance of the high-chromium austenite steel in the high-temperature steam is effectively improved, so that the development of high-temperature steam oxidizing protection methods of supercritical and ultra supercritical units is greatly promoted.

Owner:XI AN JIAOTONG UNIV

Anti-oxidative refractory brick and preparation method thereof

InactiveCN106699202AImprove oxidation and corrosion resistanceImproved thermal stabilityCeramic materials productionClaywaresCoal waterCorrosion

The invention discloses an anti-oxidative refractory brick and a preparation method thereof. The anti-oxidative refractory brick is prepared from raw materials in parts by weight as follows: 12-19 parts of quartzite, 10-15 parts of topaz, 11-17 parts of coal water slurry slag, 5-10 parts of silicon oxynitride, 18-27 parts of dolomite, 7-13 parts of zirconium diboride, 8-16 parts of forsterite, 9-18 parts of dolomite, 22-29 parts of marine dredged sludge, 16-24 parts of anthracite, 14-22 parts of granite stones, 15-20 parts of kaolin, 10-15 parts of porous powder quartz, 5-10 parts of pyrophyllite and 13-19 parts of industrial aluminum oxide. The effects of promoting sintering and improving the oxidation resistance and the corrosion resistance of the refractory brick are realized by introducing silicon oxynitride and zirconium diboride; the added raw materials such as porous powder quartz, coal water slurry slag and the like can improve the heat stability, the corrosion resistance and the wear resistance of the refractory brick. The refractory brick has excellent properties of excellent oxidation resistance, thermal shock resistance, corrosion resistance, wear resistance, high high-temperature strength, low expansion coefficients and the like.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

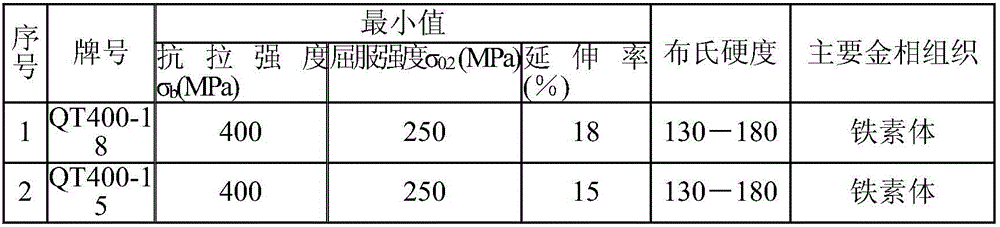

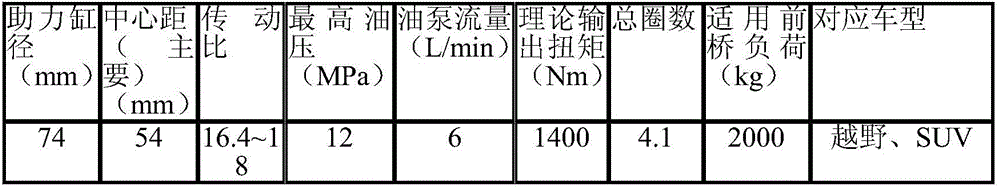

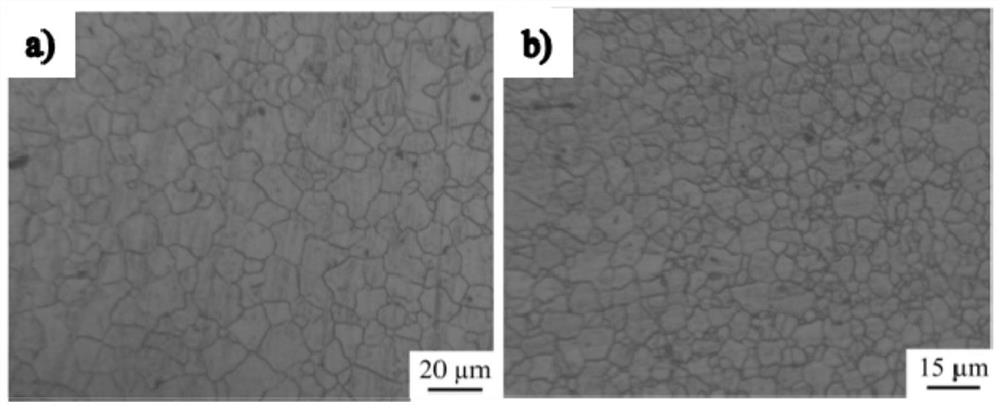

Light automobile steering gear aluminum alloy material replacing QT400 and gravity casting method of aluminum alloy material

The invention discloses a light automobile steering gear aluminum alloy material replacing a QT400. The light automobile steering gear aluminum alloy material replacing the QT400 is characterized in that main components comprise, by weight percentage, 0.08%-0.25% of titanium Ti, smaller than or equal to 2% of manganese Mn, 0.05%-0.5% of cadmium Cd, 4.2%-8.0% of copper Cu, 1%x10<-4>-2.0% of Lewis acid-base pairs and the balance aluminum, wherein Cu>=0.8Mn+4.05%, and the alloy mean grain size is smaller than 120 microns.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Flawless high-temperature-oxidation-resistant wearproof multilayer surfacing welding electrode

ActiveCN103722308AThe formula is scientific and reasonableLow costArc welding apparatusWelding/cutting media/materialsCrazingNiobium

The invention discloses a flawless high-temperature-oxidation-resistant wearproof multilayer surfacing welding electrode. The welding electrode comprises a core wire and a coating. The core wire, namely a core wire H08A, is 4.0 in diameter. The weight factor of the coating is 0.90-1.2. The coating comprises, by weight, 10-20 parts of marble, 20-40 parts of rutile, 10-15 parts of titanium dioxide powder; 2-6 parts of ferrotitanium, 12-20 parts of mid-carbon ferromanganese, 1-4 parts of ferrosilicon, 20-40 parts of chromium metal, 1-5 parts of molybdenum powder, 5-10 parts of nickel powder, 1-5 parts of ferrocolumbium, 1-3 parts of sodium carbonate, 2-8 parts of mica, 0.2-1.5 parts of rare-earth ferrosilicon and 20-25% of potassium-sodium water glass. The welding electrode is scientific and reasonable in formula, low in cost, flawless in welding surface, high in high-temperature-oxidation resistance and wear resistance and simple in operation process; by the welding electrode, common welding operators can complete welding independently, and productivity and acceptability are improved; the welding electrode has good promotion value.

Owner:SHENGYANG HAWEIER SURFACE ENG TECH

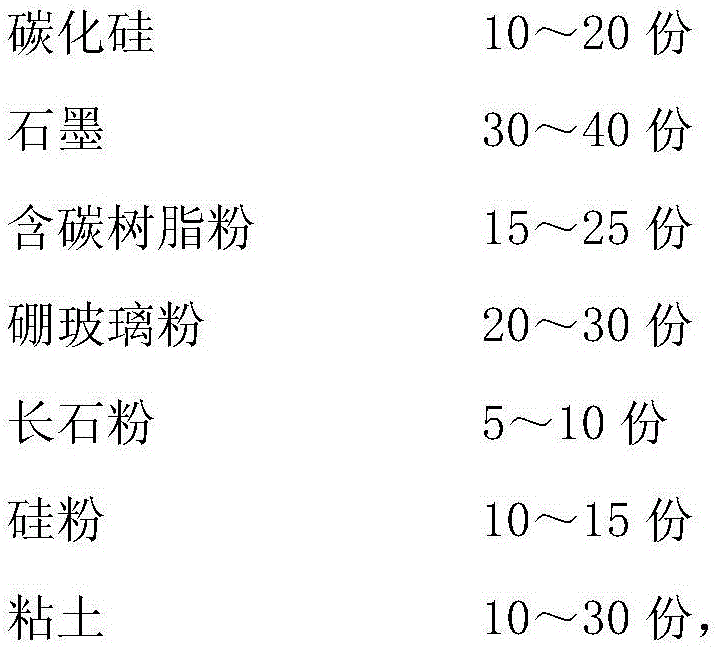

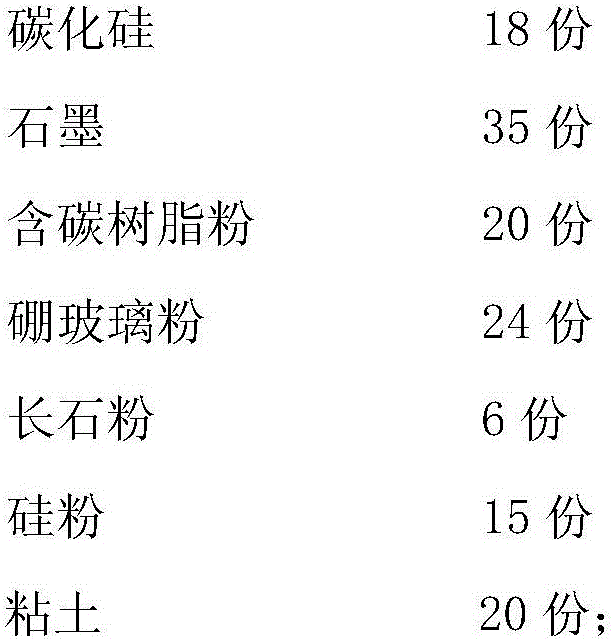

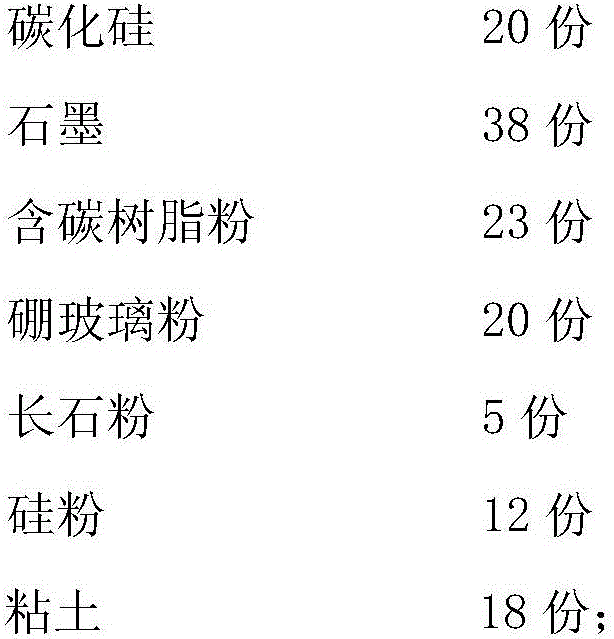

Protective casing with oxidation corrosion resistance and thermal shock resistance and a preparation method thereof

ActiveCN105924171AImprove oxidation and corrosion resistanceGuaranteed long-term useMaterials preparationOxidation resistant

The invention belongs to the field of heat resistant material preparation, and in particular relates to a protective casing with oxidation corrosion resistance and thermal shock resistance and a preparation method thereof. The synergistic effect of silicon carbide, graphite, carbon-containing resin powder, boron glass powder, feldspar powder, silicon powder and clay, the casing has improved oxidation corrosion resistance and greatly increased impact resistant performance, and doubled service life, so as to ensure the long-term use in high temperature environment.

Owner:常州英诺新材料有限公司

High-Cr-content cast heading machine cutter steel and manufacturing technique thereof

ActiveCN107881435AImprove thermal fatigue crack levelImprove oxidation and corrosion resistanceFurnace typesHeat treatment furnacesThermal fatigueNear net shape

The invention relates to high-Cr-content cast heading machine cutter steel. The cutter steel comprises the chemical components of, by weight, 0.30%-0.55% of C, 8.0%-12.0% of Cr, 1.2%-3.0% of Mo, 0.5%-1.8% of Ni, 0.6%-1.0% of V, 0.1%-0.4% of Mn, 0.6%-0.8% of Si, 0.04%-0.30% of N, no more than 0.005% of S, no more than 0.03% of P and the balance Fe. The cutter steel manufacturing technique comprisesthe following steps that a near-net shape blank of a cutter is obtained through precise casting, then heat treatment is conducted, and a finished product is obtained directly after fine machining. Yield strength and tensile strength are improved while the hardness, impact toughness and elongation of the cutter steel all can reach the level of domestic forged heading machine cutter steel; the oxidation corrosion resistant capability, thermal fatigue resistant performance and abrasive grain abrasion resistance are improved; and the production period is shortened, and the production cost is reduced.

Owner:JILIN UNIV

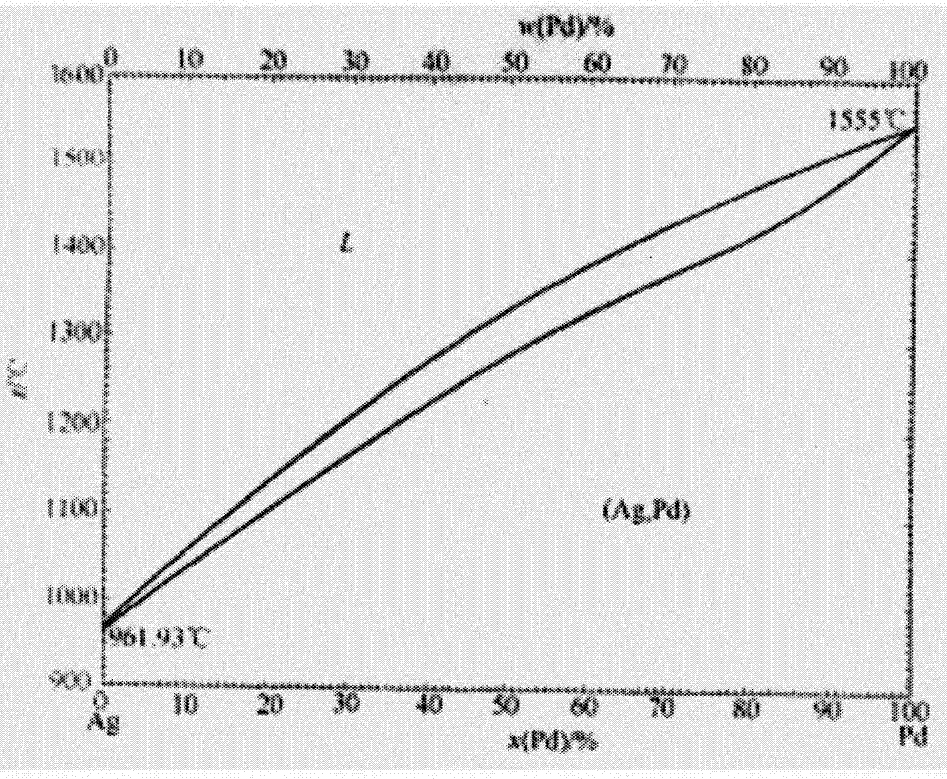

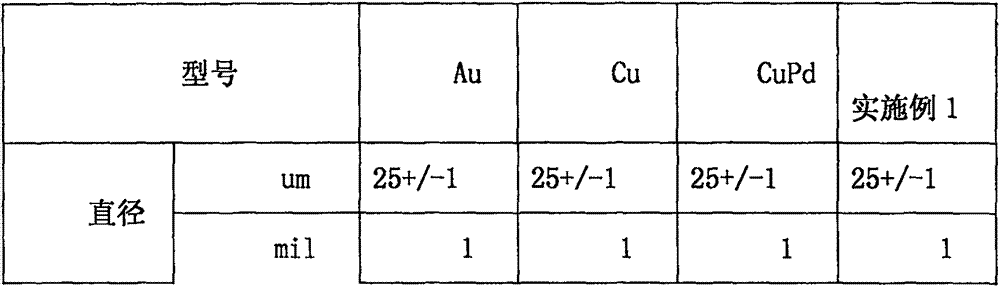

Alloy bonding wire of gold, silver and palladium and preparation method thereof

InactiveCN107316854AImprove processing performanceImprove oxidation and corrosion resistanceSemiconductor/solid-state device detailsSolid-state devicesOxidation resistantCorrosion

The invention discloses an alloy bonding wire of gold, silver and palladium. The alloy bonding wire comprises gold element, silver element, palladium element and impurities, wherein the mass percentage of the gold element is 1% to 5%; the mass percentage of the palladium element is 1% to 15%; the mass percentage of the silver element is 80% or greater than 80%; and the balance is the impurities. A preparation method of the bonding wire comprises the following steps: step one, weighing raw materials; step two, preparing alloy; step three, casting; step four, wire drawing; step five, cleaning; step six, annealing; and step seven, compound winding. Silver and palladium are pre-alloyed, gold and pure silver are cast into a rod material, and then wire drawing, annealing, cleaning and compound winding are carried out to complete product preparation; in the preparation process, various technological parameters are reasonably used, the processing performance of the silver-based alloy bonding wire is improved, and the oxidation resistance and corrosion resistance are greatly improved; and moreover, the bonding wire disclosed by the invention is extremely good and stable in using performance, and can meet the requirement on the performance quality of the bonding wire in the field of semiconductor high-end packaging.

Owner:山东赢耐鑫电子科技有限公司

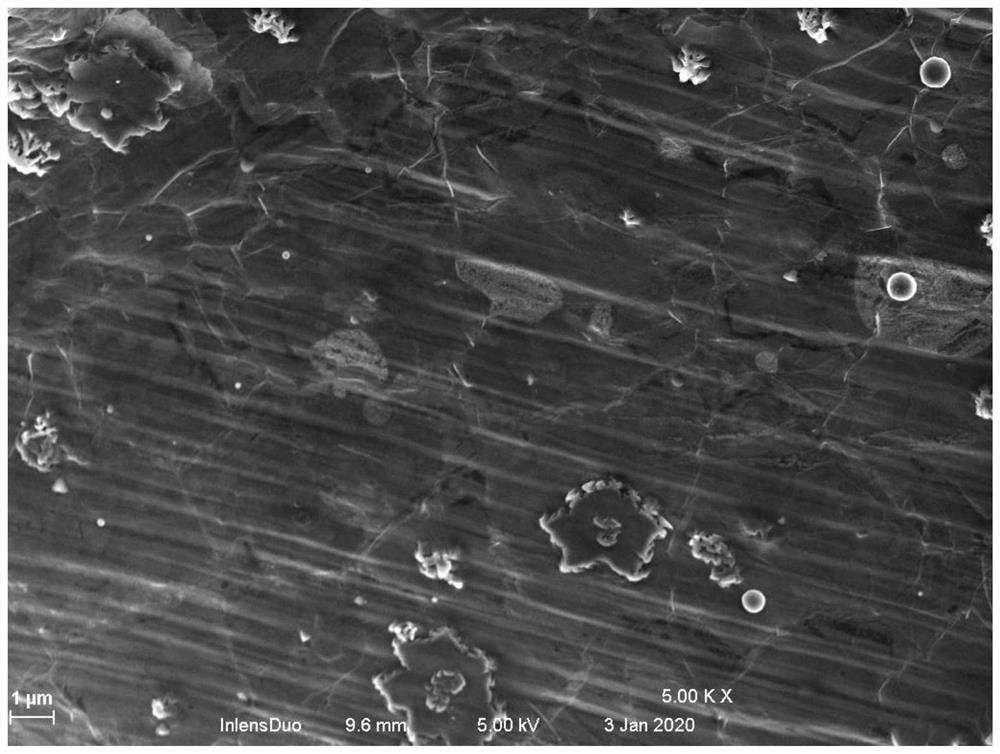

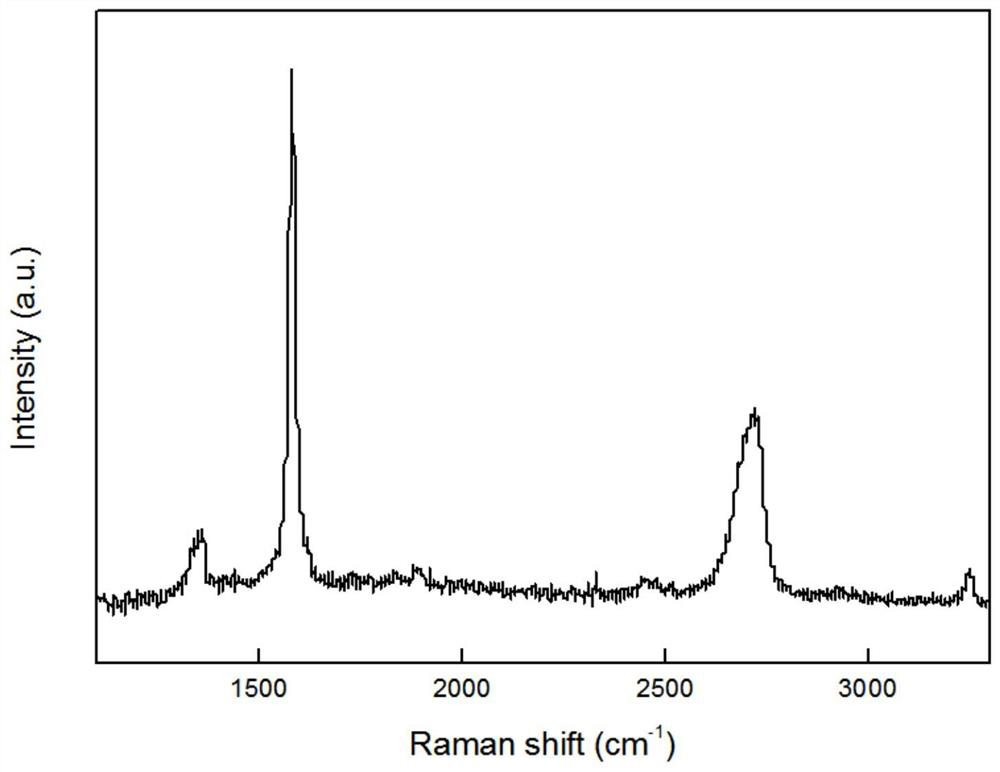

Method for growing graphene on structured copper base, cable core material and preparation method of cable core material

PendingCN113909476AImprove oxidation and corrosion resistanceGood electrical propertiesApparatus for heat treatmentConductive materialCopper foilGraphene

The invention discloses a method for growing graphene on a structured copper base, a cable core material and a preparation method of the cable core material. The method for growing the graphene on the structured copper base comprises the following steps of S1, alternately stacking copper powder and copper foil into a mold, and carrying out isostatic pressing treatment molding to form an ingot; and S2, growing the graphene on the ingot through a chemical vapor deposition method to form the copper-based graphene. The formed copper-based graphene is subjected to re-pressing, sintering and hot sintering wire drawing forming in sequence, and the cable core material is prepared; and the prepared cable core material comprises a copper material and the graphene, wherein the copper material comprises the copper foil and the copper powder, and the copper foil and the copper powder are coated with the graphene. The copper powder and the copper foil are alternately stacked to carry out structural treatment on the copper base, so that the service life of a copper-based graphene material is prolonged, and the performance of the copper-based graphene material is improved; and the cable core material formed by further processing generates obvious anisotropy, and the phenomena of non-uniform current distribution and equivalent resistance increase caused by alternating current in the use of the cable core material are improved.

Owner:SHANGHAI SIMBATT ENERGY TECH CO LTD +1

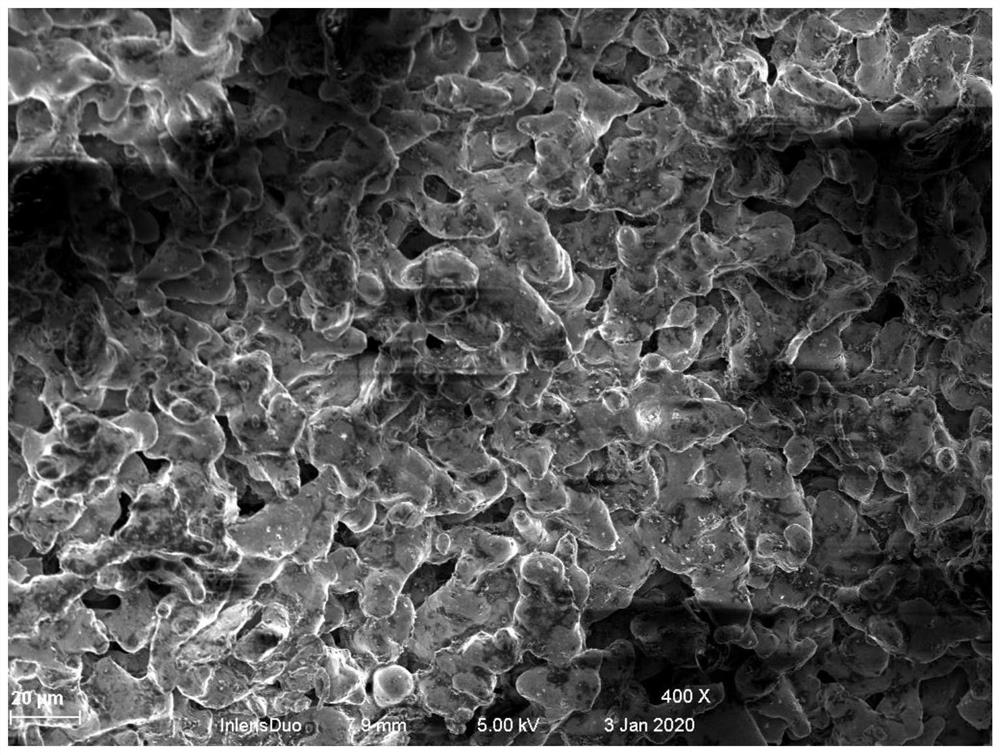

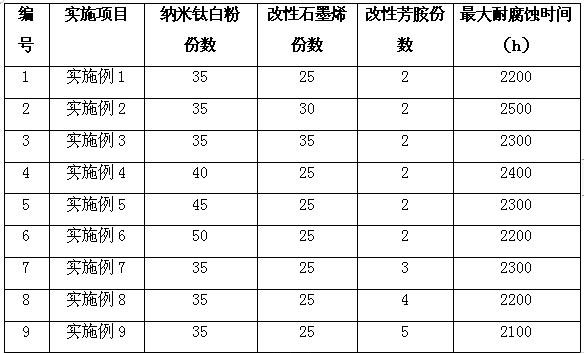

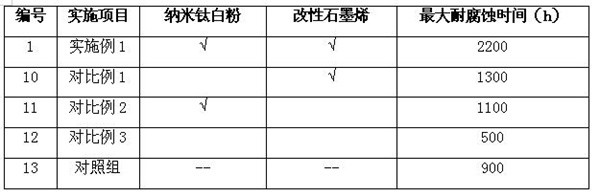

Nano titanium-doped modified graphene high-performance anticorrosive coating and preparation method thereof

InactiveCN112375464AGood chemical stabilityStrong adhesionAnti-corrosive paintsEpoxy resin coatingsOxidation resistantTitanium dioxide

The invention is applicable to the technical field of anticorrosive coatings, and provides a nano titanium-doped modified graphene high-performance anticorrosive coating which comprises the followingraw materials in parts by weight: 35-50 parts of nano titanium dioxide, 25-35 parts of modified graphene, 200-300 parts of epoxy resin, 1-5 parts of a cosolvent, 1-5 parts of a coupling agent, 2-5 parts of a curing agent and 30-50 parts of water. The invention also provides a preparation method of the nano titanium-doped modified graphene high-performance anticorrosive coating, graphene is modified, excellent chemical stability, strong adhesive force and film-forming property of graphene are considered, and meanwhile, the hydrophobicity of graphene is reduced, so that graphene is uniformly dispersed in the anticorrosive coating, and a protection effect of layer-by-layer overlapping is realized; the nano titanium dioxide is doped with the curing agent to form a coating layer firmly bonded with the substrate, thereby enhancing the compactness and integrity of the anticorrosive coating and greatly enhancing the oxidation corrosion resistance of the anticorrosive coating.

Owner:山东金芝麻环保工程有限公司

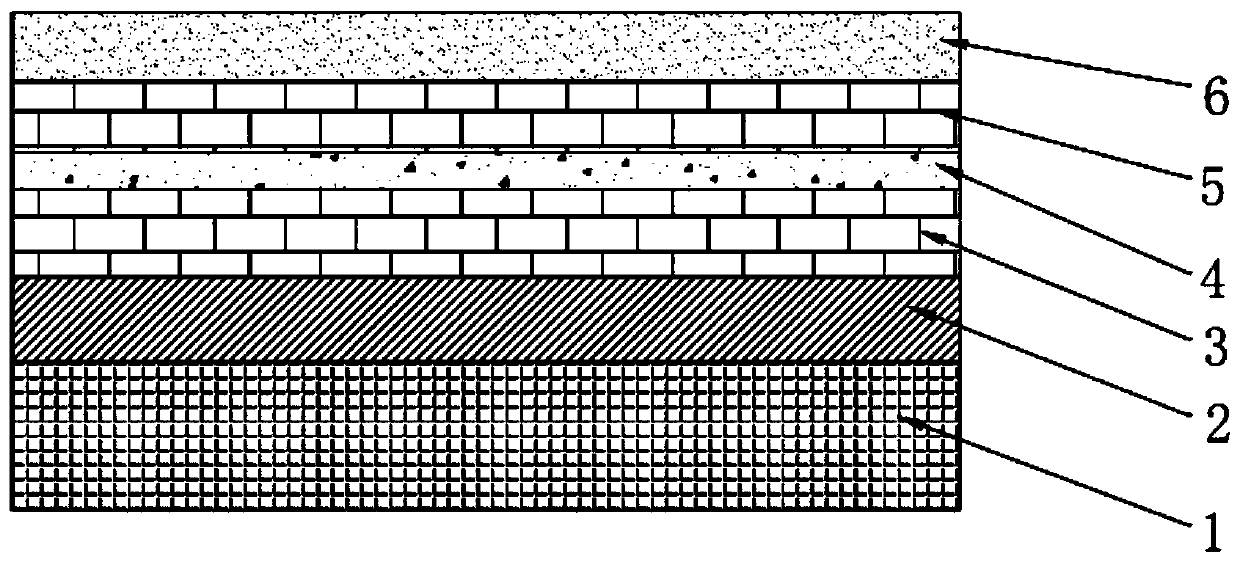

Seamless steel pipe for high-pressure boiler

InactiveCN104180088AHigh durabilityImprove oxidation and corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationOxidation resistantHigh pressure

The invention discloses a seamless steel pipe for a high-pressure boiler. The seamless steel pipe comprises a steel pipe main body, a first endurance strength protection layer, a second endurance strength protection layer, a first oxidation corrosion resisting layer, a second oxidation corrosion resisting layer, a first tissue stable layer and a second tissue stable layer, wherein the first tissue stable layer, the first endurance strength protection layer, the first oxidation corrosion resisting layer and the second oxidation corrosion resisting layer are arranged on the inner wall of the steel pipe main body in sequence; the second tissue stable layer and the second endurance strength protection layer are arranged on the outer wall of the steel pipe main body in sequence. Through adopting the method, the seamless steel pipe is high in endurance strength, high in oxidation corrosion resistant property and good in tissue stability, and can be used under high-temperature and high-pressure conditions in long-term.

Owner:WUXI HAOHAO STEEL PIPE

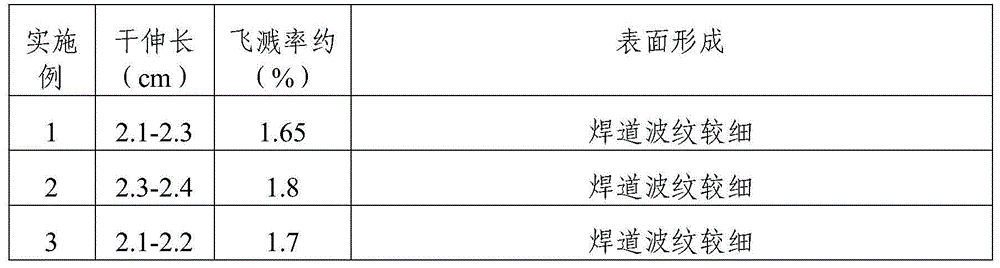

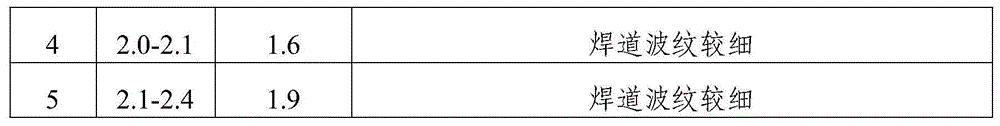

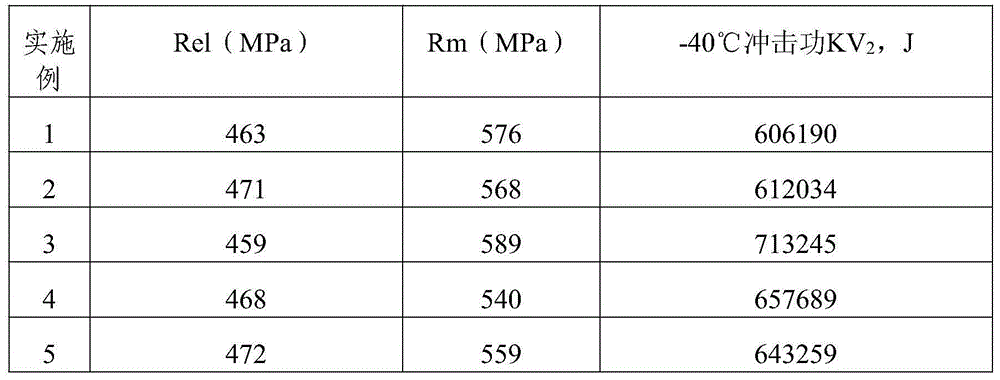

Shielding welding wire and production method thereof

InactiveCN104923963AImprove corrosion resistanceImprove oxidation and corrosion resistanceWelding/cutting media/materialsSoldering mediaBoronSulfur

The invention relates to the technical field of shielding welding wire, in particular to a shielding welding wire and a production method thereof. The mass percentages of chemical components of raw materials of the shielding welding wire are 0.01 to 0.04 percent of carbon, 1.2 to 1 percents of silicon, 1.1 to 2.1 percents of manganese, 1.0 to 2.1 percents of titanium, 0.009 to 0.013 percent of sulfur, 0.23 to 0.31 percent of aluminum, no more than 0.013 percent of phosphorus, 0.003 to 0.01 percent of boron, 0.0005 to 0.001 percent of vanadium, and the remains are iron ad unnecessary impurities. Through reasonable element match design, the prepared welding wire is high in splitting strength, the splitting strength reaches 540 MPa, the shock-resistance work of the welding wire reaches 606190 KV 2 J under the environment of 40 DEG C below zero, and the spatter lose rate in the welding process is reduced to below 2 percents.

Owner:贵州凯宏汇达冷却系统有限公司

Preparation methods of corrosion-resisting aluminum honeycomb core and aluminum honeycomb plate

ActiveCN108385896AGood weather resistanceExtended service lifeConstruction materialLamination ancillary operationsWeather resistanceAluminum honeycomb

The invention provides preparation methods of a corrosion-resisting aluminum honeycomb core and an aluminum honeycomb plate. In a process of preparing the aluminum honeycomb core, a through hole and athrough groove are formed, so that when a honeycomb core is welded with an aluminum plate, residual air in the honeycomb core can be sufficiently discharged, and a condition that an aluminum foil ofthe aluminum core in a high-temperature welding process is oxidized is avoided; meanwhile, an exposed surface of the aluminum foil is coated with a corrosion-resisting layer, so that the oxidization-resisting and corrosion-resisting capability of the aluminum foil is improved, the weather resistance of the aluminum honeycomb core is improved and the service life of the aluminum honeycomb core is prolonged.

Owner:合肥普飞精密工业有限公司

Corrosion resistant coating of silver combined coating

The invention relates to the technical field of electroplating, in particular to a corrosion resistant coating of a silver combined coating. The corrosion resistant coating comprises a base coating, afirst silver coating, a first gold coating and a rhodium ruthenium coating which are sequentially electroplated on the surface of a base material, the base coating is used for adjusting the surface flatness of the base material, the first silver coating is used for improving the conductivity of the base material, the first gold coating is used for improving the adhesion of the adjacent coating, and the rhodium ruthenium coating is used for improving the corrosion resistance and wear resistance of the base material. The coating structure prepared from the coating has good wear resistance, oxidation resistance, conductivity and corrosion resistance, and the adhesiveness between the electroplating coating and the base material is good.

Owner:东莞市合航精密科技有限公司

Material for casting exhaust manifold

InactiveCN107939501AImproved and increased wear resistanceImprove and enhance oxidation corrosion resistanceExhaust apparatusSilencing apparatusChemical compositionNitrogen

The invention provides a material for casting an exhaust manifold. The material for casting the exhaust manifold is composed of the following chemical ingredients of, in percentage by mass, 0.2-0.6% of C, 1.2-2.6% of Si, 0.1-0.5% of Al, 0.1-0.3% of Mn, 20-24% of Cr, 22-26% of Ni, 0.6-0.8% of Mo, 0.7-1.1% of Ba, 4-7% of Ce, 0.9-1.6% of N, 1.5-1.9% of Nb, 0.02-0.05% of P, 0.11-0.16% of S, 5-7% of Ti, 6-8% of V and the balance ferrum. The material for casting the exhaust manifold has the beneficial effects that (1), an appropriate amount of alloying elements of chromium, nickel, molybdenum, nitrogen, aluminum and silicon and the like are added in the exhaust manifold material, and the abrasive resistance and oxidation corrosion resistance of final exhaust manifold products are improved and enhanced to a certain extent; (2), automobile exhaust manifolds fabricated by the material for casting the exhaust manifold have higher temperature bearing capacity and durability, the quality of products is improved, the service life of products is prolonged, and to some extent, the cost is also saved.

Owner:绩溪县徽洋车桥有限责任公司

Additive for improving anti-oxidation and anti-corrosion performance of lubricating oil

The invention discloses an additive for improving the anti-oxidation and anti-corrosion performance of lubricating oil. The additive is prepared from methacrylic acid, tertiary butylhydroquinone, phytic acid, diethylamine, boric acid, propyl-octyl secondary-primary alkyl zinc dithiophosphate, double-octyl primary alkyl zinc dithiophosphate, sulfurized olefin, lupenyl palmitate, polysiloxane, camellia seed husk extract and a nano-particle mixture. All ingredients of the lubricating oil have a mutual effect and cooperate with one another, so that the anti-oxidation and anti-corrosion effects of the lubricating oil are significantly improved, and the stability, wear resistance, dispersity, lubricating property and the like of the lubricating oil are all well improved; the lubricating oil can be widely applied to lubricating of various mechanical equipment and significantly improve the anti-oxidation and anti-corrosion effects of the mechanical equipment, and has high market competitiveness.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

Corrosion-resistant coating for interface of electronic device

InactiveCN110401056AImprove wear resistanceImprove antioxidant capacityCoupling contact membersSolderabilityWear resistance

The invention relates to the technical field of electroplating, in particular to a corrosion-resistant coating for an interface of an electronic device. The corrosion-resistant coating comprises a substrate plating layer plated on a surface of a substrate, the substrate plating layer is a nickel-plated tungsten layer for improving corrosion resistance of the substrate, the surface of the nickel-plated tungsten layer is plated with a pre-plating layer for improving the adhesion of adjacent plating layers, a first silver plating layer for improving corrosion resistance and the electrical conductivity of the substrate, and a second gold plating layer for improving adhesion of adjacent plating layers. a third rhodium layer for improving corrosion resistance and wear resistance of the substrateand a fourth gold plating layer for improving the solderability of the substrate. The coating structure combined by the above plating layers has the better wear resistance, oxidation resistance, electrical conductivity and corrosion, and the adhesion between the plating layer and the substrate material is good, and the welding property of the substrate is also improved.

Owner:东莞市合航精密科技有限公司

Low-temperature composite calcium sulfonate-based lubricating grease and preparation method thereof

InactiveCN110982583AImprove low temperature resistanceImprove oxidation and corrosion resistanceLubricant compositionCyclohexylaminesActive agent

The invention discloses low-temperature composite calcium sulfonate-based lubricating grease and a preparation method thereof, and belongs to the technical field of lubricating grease, wherein the low-temperature composite calcium sulfonate-based lubricating grease comprises the following raw materials in parts by weight: 35-40 parts of low-temperature base oil, 1.1-1.5 parts of a converting agent, 3.5-5.5 parts of a composite thickening agent, 25-30 parts of ultrahigh-base-number synthetic calcium sulfonate, 3.5-5.5 parts of monoalkyl titanate, 1.5-2.5 parts of micro-nano borate, 1.5-2.0 parts of glacial acetic acid, 1.2-1.8 parts of cyclohexylamine, 0.5-1.5 parts of a high-temperature antioxidant, 1.0-2.0 parts of an oxidation and corrosion-resistant additive and 0.1-3.5 parts of a surfactant. By blending the low-temperature base oil, the low-temperature resistance of the lubricating grease can be improved from the raw materials, and by adding the oxidation and corrosion-resistant additive, the oxidation resistance and the corrosion resistance of the lubricating grease can be improved, so that the service life of the lubricating grease is prolonged, and the lubricating grease issuitable for popularization and application.

Owner:江苏澳润新材料有限公司

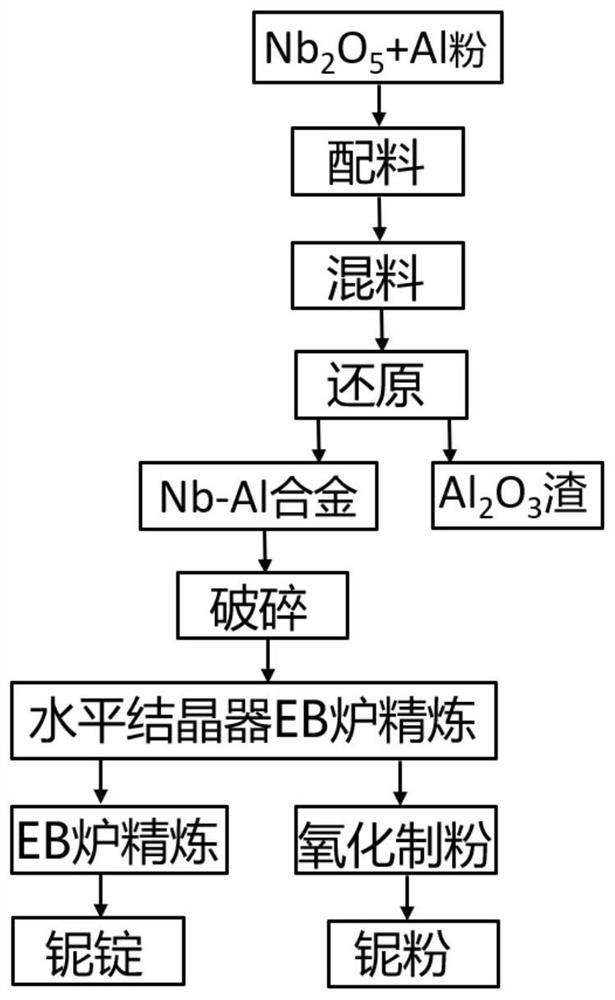

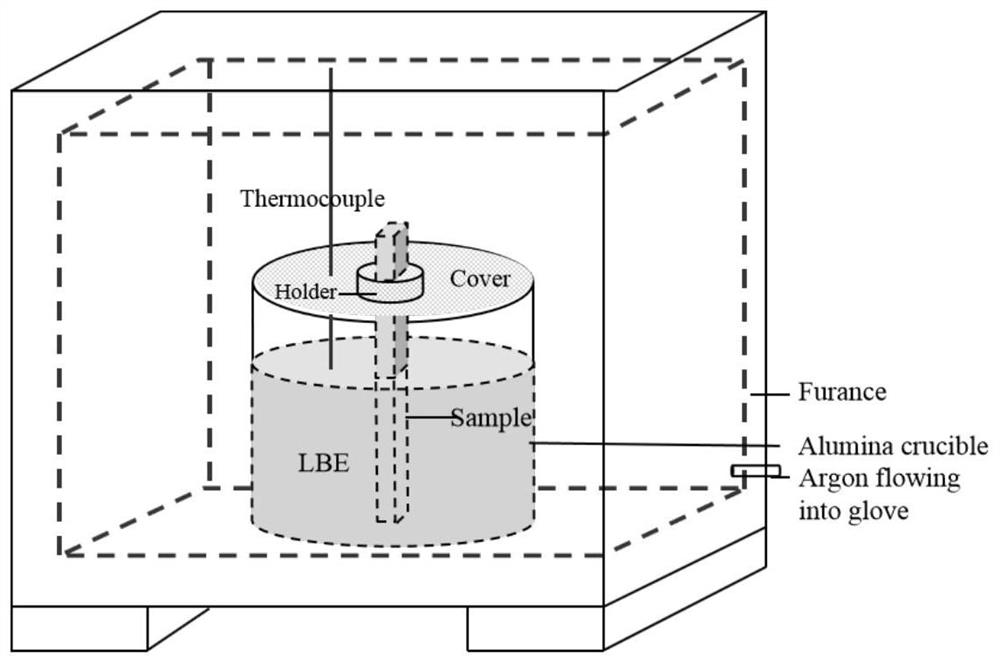

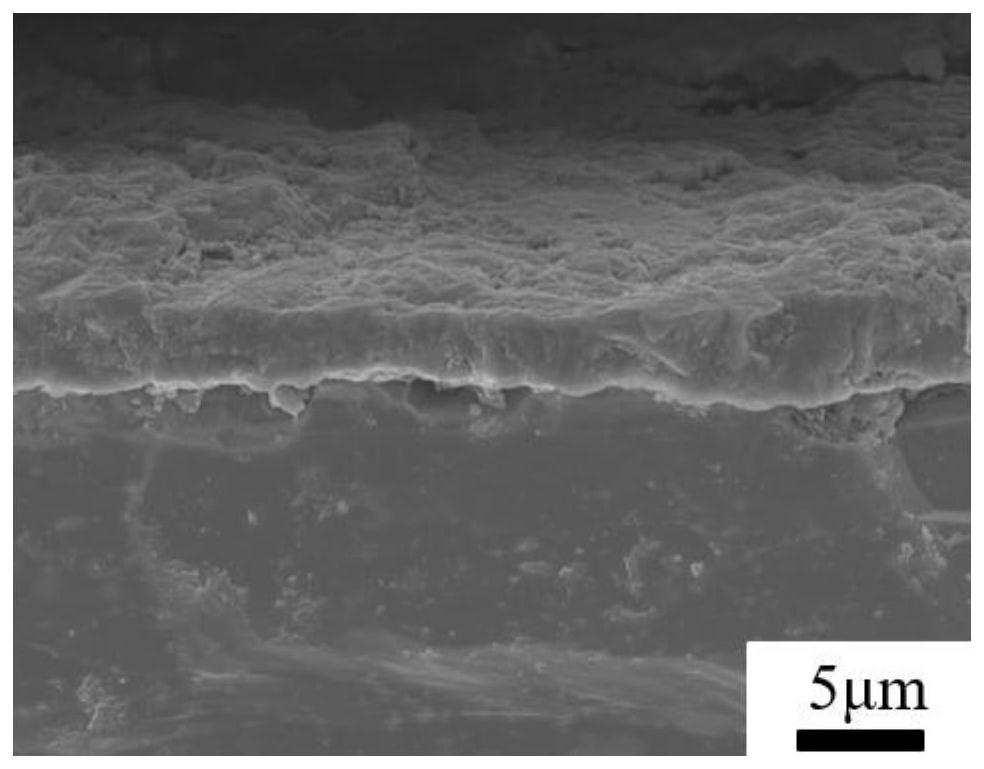

Protective film for corrosion resistance of metal niobium at high temperature and preparation method of protective film

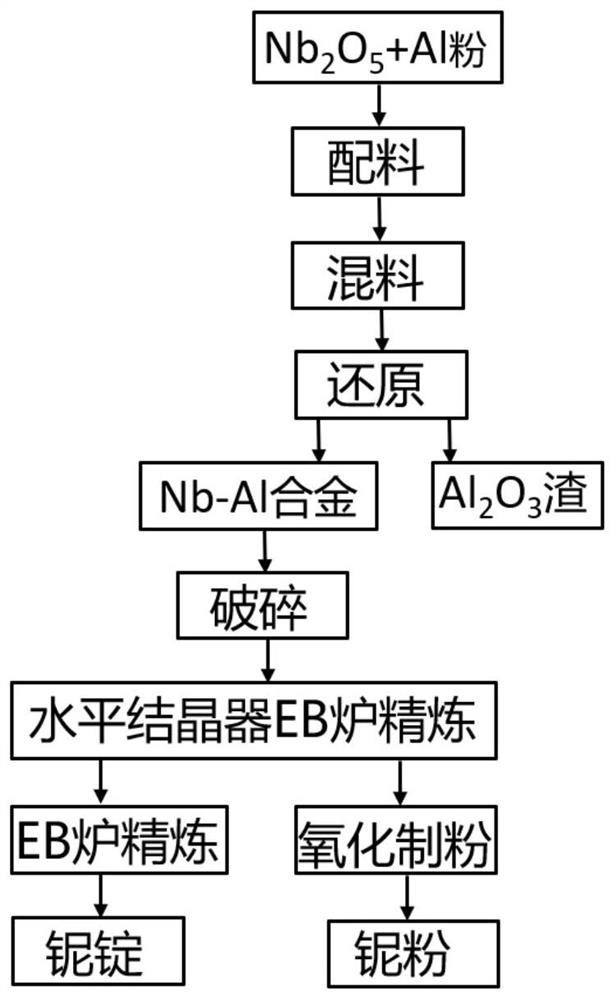

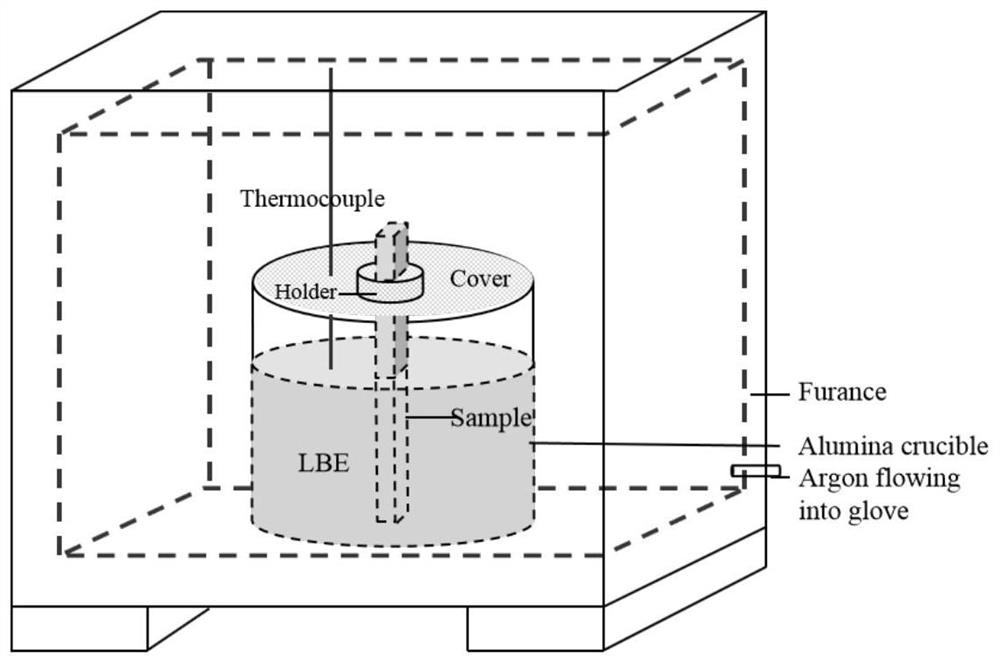

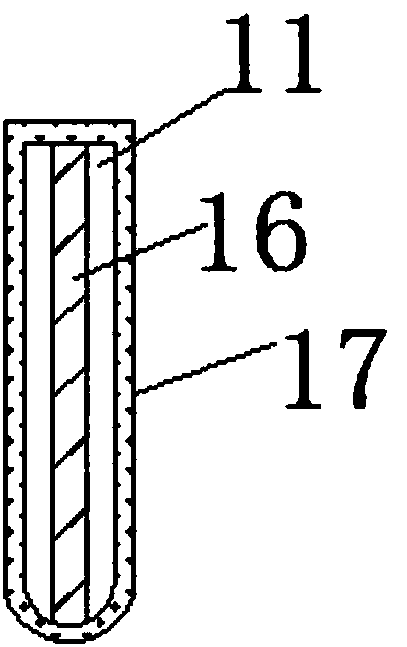

ActiveCN113718193AImprove corrosion resistanceMelted completelyNuclear energy generationSolid state diffusion coatingInterfacial reactionLead bismuth

The invention discloses a protective film for corrosion resistance of metal niobium at a high temperature and a preparation method of the protective film. The preparation method comprises the following steps of sequentially carrying out vacuum melting, rolling and annealing treatment on a niobium bar, and then cutting the niobium bar into an experimental sample; melting a lead-bismuth alloy to obtain liquid lead bismuth; putting the treated experimental sample into the liquid lead bismuth, fixing the sample, and carrying out interface reaction and diffusion reaction on Nb in the experimental sample and oxygen dissolved in the liquid lead bismuth to generate a layer of NbO surface film at first; the NbO surface film further reacts with oxygen dissolved in the liquid lead bismuth to generate a layer of NbO2 protective film; and the experimental sample is taken out and placed on a stainless steel sheet, and metal niobium with the protective film is obtained after the experimental sample is cooled. The protective film lays a foundation for expanding the application of the refractory metal in the industry.

Owner:XI AN JIAOTONG UNIV

Tailoring device for producing and processing sail cloth

PendingCN108189141AEasy cutting workConvenient for different locationsNon-rotating vibration suppressionSevering textilesEngineeringBronze

The invention discloses a tailoring device for producing and processing sail cloth. The tailoring device comprises a support, a transverse column and a tailoring table, wherein the upper part of the support is fixedly connected to the transverse column; the tailoring table is located on one side of the support; a chute is formed in the inner wall of the transverse column; an electric telescopic rod is connected in the chute; a pulley is arranged at one end of the electric telescopic rod; the bottom of the pulley is fixedly connected to a connecting column; an air pressure rod is arranged on one side of the outer side of the connecting column; one end of the air pressure rod is connected to a bearing; and one end of the bearing is movably connected to the chute. By arranging the electric telescopic rod and the bearing, the sail cloth is tailored effectively and conveniently, and people operate a tailoring blade flexibly and conveniently. By arranging a hydraulic column and a shock absorbing spring, the tailoring table is conveniently lifted and lowered effectively. Meanwhile, the tailoring device has a function of reducing shock. By arranging a beryllium bronze layer and an antioxidant layer, the hardness of the tailoring blade is enhanced effectively, and the resistance to oxidation of the tailoring blade is enhanced effectively.

Owner:海宁泰威新材料有限公司

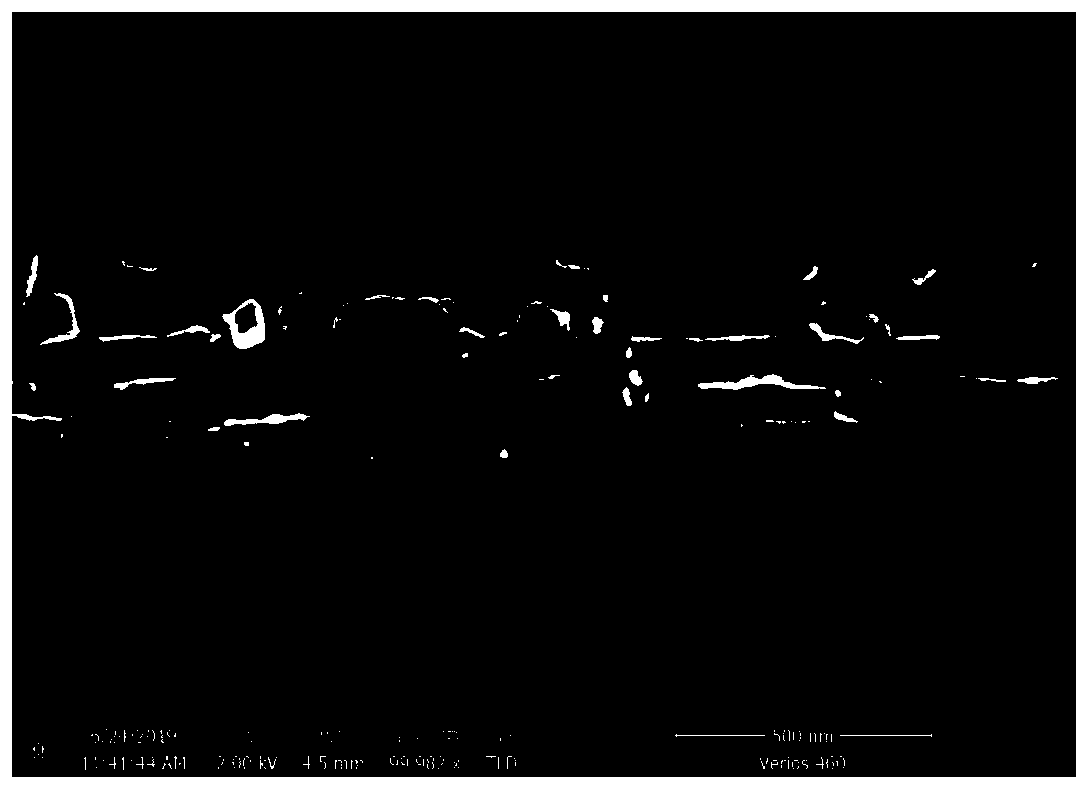

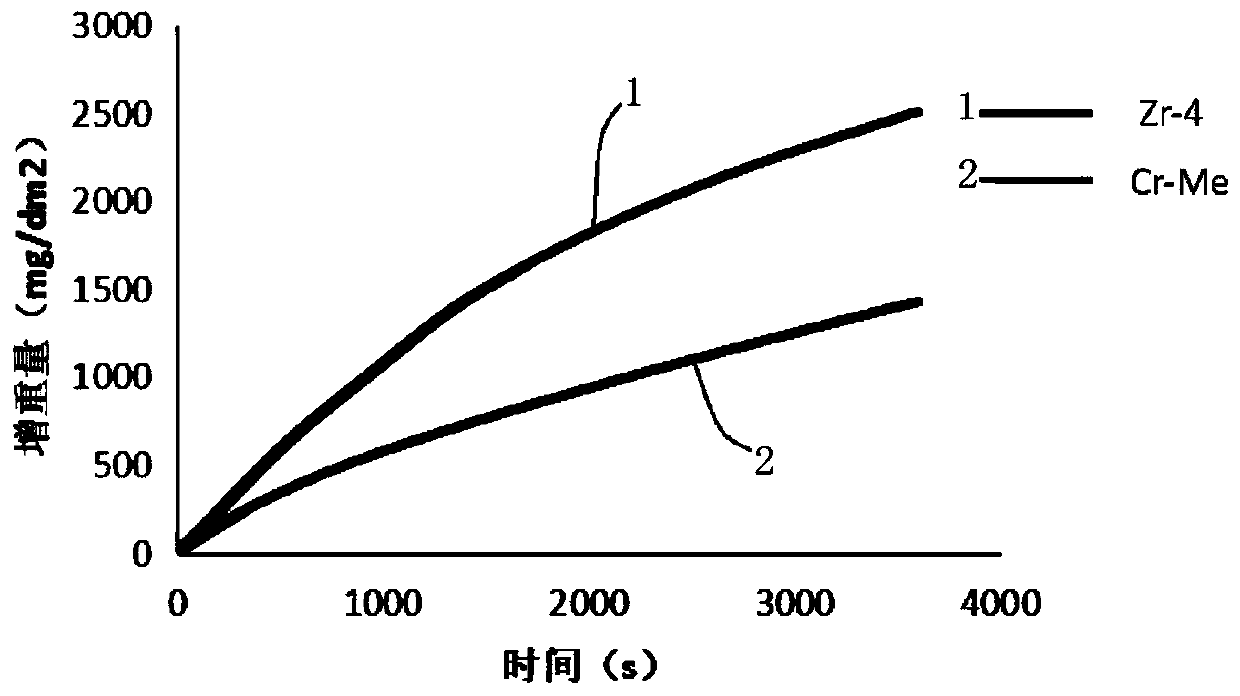

Cr-Me multilayer film based on Zr as substrate and preparation method thereof

PendingCN110499495AImprove efficiencyImprove securityOptical rangefindersNuclear energy generationGas phaseWater vapor

The invention discloses a Cr-Me multilayer film based on Zr as a substrate and a preparation method thereof and belongs to the field of plating of physical vapor deposition. By taking a Zr-4 alloy (prepared from 1.20-1.70% of Sn, 0.18-0.24% of Fe, 0.07-0.13% of Cr and 0.03-0.08% of Ni) as the substrate, the Cr-Me multilayer film is coated to the surface of Zr by means of a magnetron sputtering method. The modulation ratio of the Cr-Me multilayer film (Zr, Al, Mg and Nb) is 1: (0.1-10). The total number of layers of the Cr-Me multilayer film based on Zr as the substrate is 2-100 and the thickness is 0.5-50 [mu]m. The plated Cr-Me multilayer film can improve high-temperature water vapor corrosion resistance and oxidizing performance of a zirconium alloy tubular product, so that the service life of a zirconium alloy pressure pipe is prolonged, the nuclear leakage accident is reduced, and the economical benefit and the safety guarantee of nuclear industry are further improved.

Owner:XI AN JIAOTONG UNIV

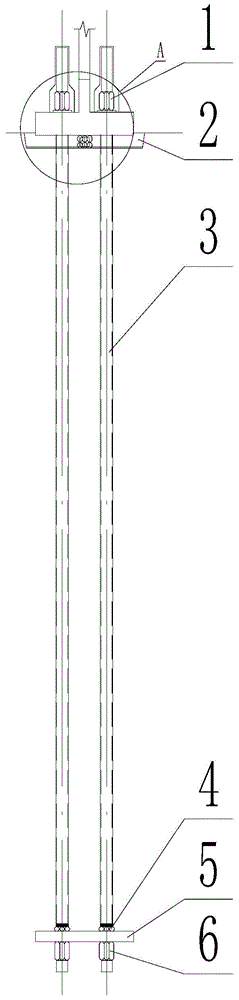

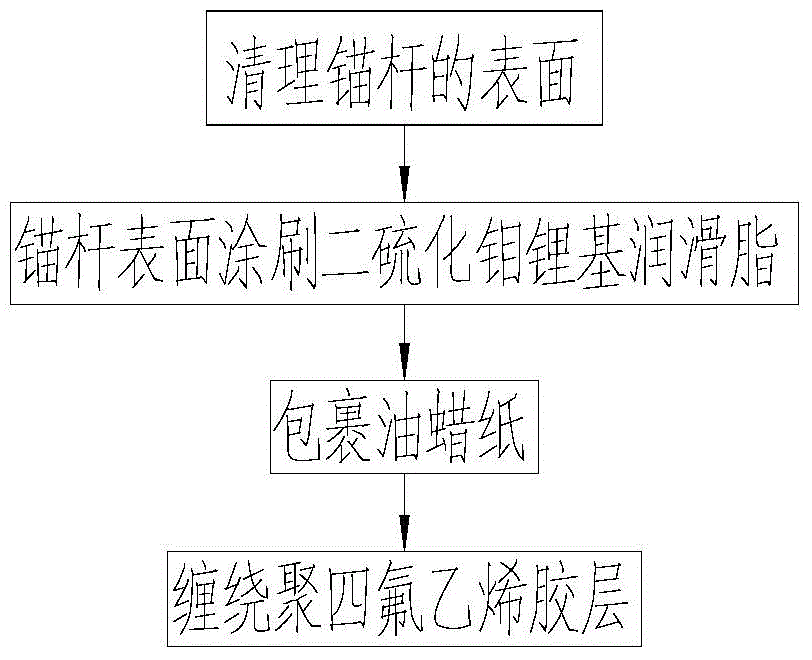

Anchor rod corrosion prevention method

InactiveCN104612149AImprove oxidation and corrosion resistanceExtended service lifeProtective foundationBulkheads/pilesCorrosion preventionEngineering

The invention relates to the field of construction engineering, in particular to an anchor rod corrosion prevention method. The method comprises the steps that the parts inside a base and outside the base of an anchor rod are both subjected to corrosion prevention processing; according to the steps for corrosion prevention processing of the part inside the base of the anchor rod, flexible corrosion prevention surface treatment is conducted, a flexible corrosion prevention coating is covered with a waterproof material, and a rubber layer is wound and fixed outside the waterproof material; according to the steps for corrosion prevention processing of the part outside the base of the anchor rod, flexible corrosion prevention surface treatment is conducted, and the anchor rod is sleeved with a protection cap. According to the anchor rod corrosion prevention method, the two parts inside and outside the base of the anchor rod are subjected to different corrosion prevention processing, the outer part exposed out of the base and the inner part extending into the base are subjected to different corrosion prevention processing, particularly, the part inside the base is subjected to flexible corrosion prevention, the phenomenon that a corrosion prevention layer on the surface of the anchor rod is damaged when the anchor rod is deformed due to stress is avoided, the corrosion prevention capacity is improved, and the service life of the anchor rod is prolonged.

Owner:北京中水新能工程技术有限公司

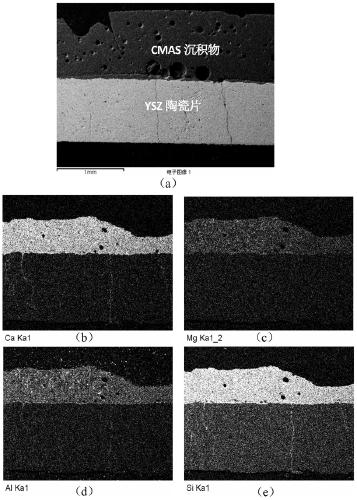

Anti-environmental sediment corrosion thermal barrier coating and preparation method thereof

ActiveCN108118190BImprove reliabilityExtended service lifeGas turbine plantsSuperimposed coating processElectron beam physical vapor depositionSuperalloy

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

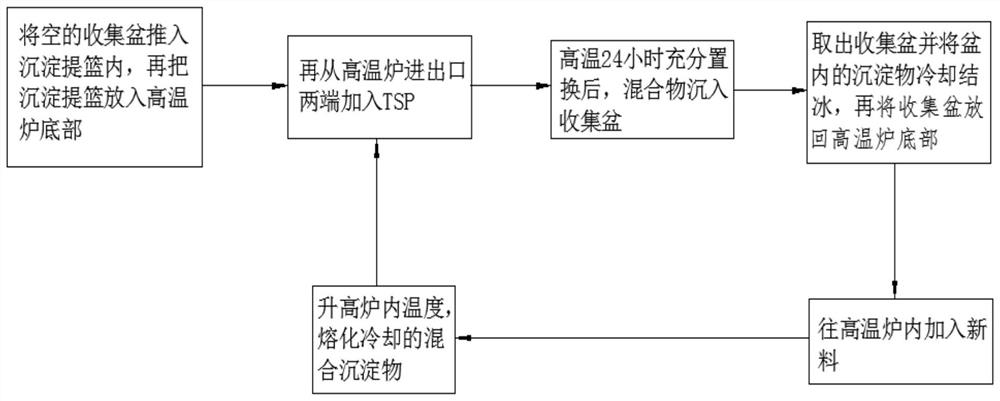

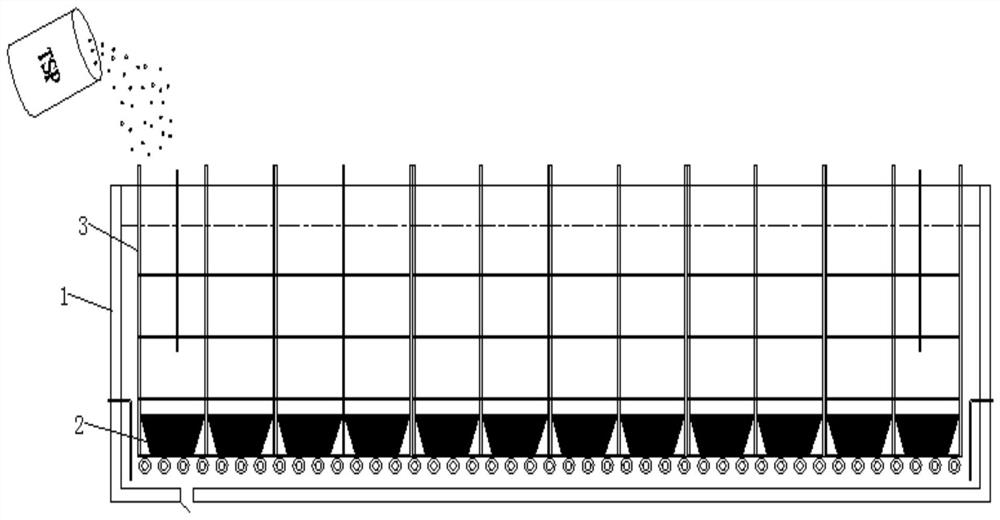

Boiler water high-utilization-rate method

InactiveCN112624629AExtend your lifeEvenly distributedCharge manipulationThermodynamicsPhosphoric acid

The invention relates to a boiler water high-utilization-rate method, which comprises the following steps of: putting a collection basin into the bottom of a high-temperature furnace, adding 3 per thousand to 8 per thousand of anhydrous trisodium phosphate into a high-temperature furnace, heating the high-temperature furnace to 400-500DEG C for processing, taking out the collection basin, cooling and icing collected precipitates, and putting the collection basin back to the bottom of the high-temperature furnace; adding a new material into the high-temperature furnace in proportion, raising the temperature to melt the cooled mixed precipitate, and then reducing the temperature and testing the furnace to produce glass; and raising the temperature in the high-temperature furnace to 450DEG C for processing for 24h. The method further involves a precipitation basket, the collection basin is pushed into the precipitation basket, and then the precipitation basket is placed at the bottom of the high-temperature furnace; the collection basin and the precipitation basket are made of nickel-based alloy; according to the boiler water high-utilization-rate method, a large amount of time and cost are saved, and the production efficiency is remarkably improved.

Owner:伯恩创盛技术研发(惠州)有限公司

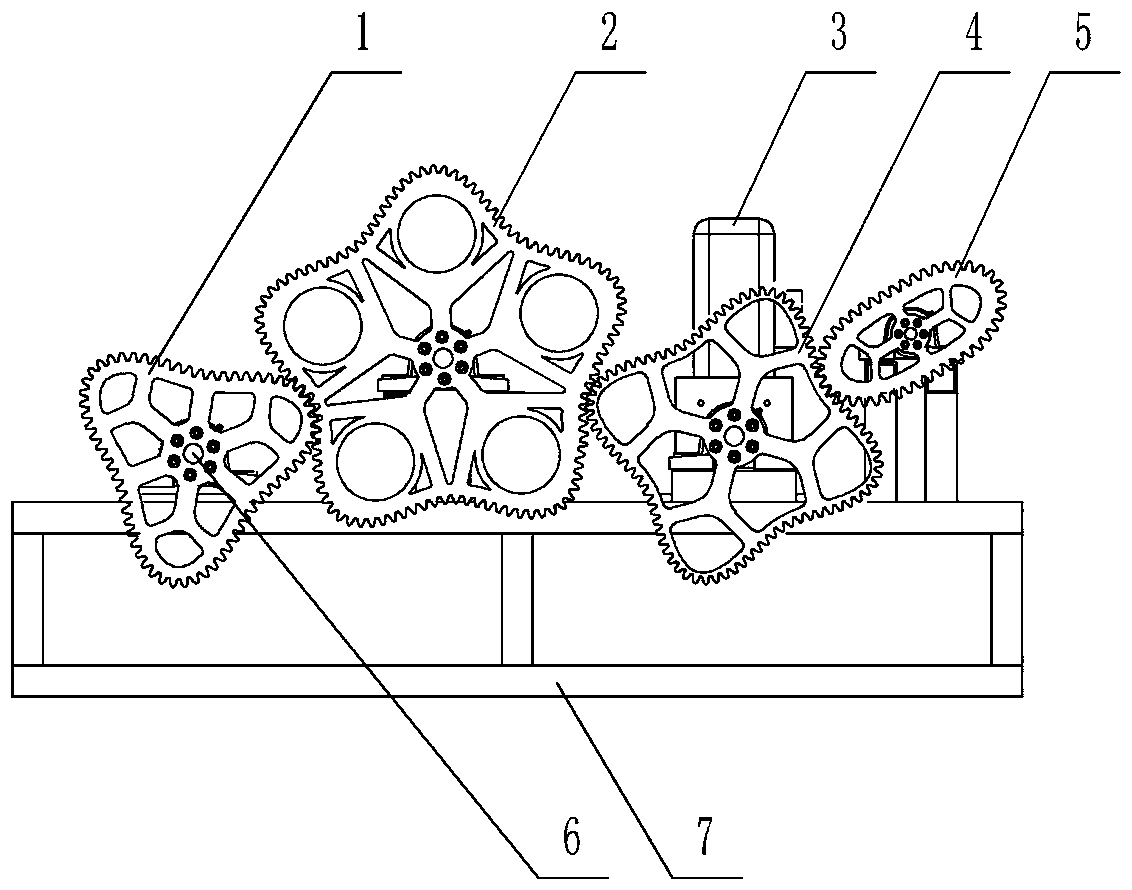

A special-shaped gear transmission display device

ActiveCN106151793BImprove plastic processing performanceImprove toughnessPortable liftingStands/trestlesDisplay deviceGear transmission

The invention belongs to the technical field of mechanical transmission, and discloses a hydraulic feeding device of a special-shaped gear transmission exhibition device. The hydraulic feeding device comprises a base which is provided with multiple sets of supports; each support is provided with a bearing block where a center shaft is fixed, and one end of the center shaft is provided with a triangular gear, a pentagonal gear, a quadrangular gear and an elliptic gear which are meshed; and the other end of any center shaft is in transmission connection with a motor. The included angles of the triangular gear, the pentagonal gear and the quadrangular gear are in cambered surface, a side line between the included angles of two arc faces is in a concave surface; and the number of teeth on the arc faces is equal to the number of the teeth on the concave surface. Center shafts of the triangular gear, the pentagonal gear, the quadrangular gear and the elliptic gear are located on different horizontal planes. The hydraulic feeding device is simple in structure and novel in design, the condition of transmission through a noncircular gear and transmission under the same linear velocity and the same angle is exhibited, and the technical problem that the transmission manner in the prior art is excessively single is effectively solved.

Owner:临沂市新天力机械有限公司

A protective film based on the corrosion resistance of metal niobium at high temperature and its preparation method

ActiveCN113718193BImprove corrosion resistanceMelted completelyNuclear energy generationSolid state diffusion coatingInterfacial reactionNiobium

Owner:XI AN JIAOTONG UNIV

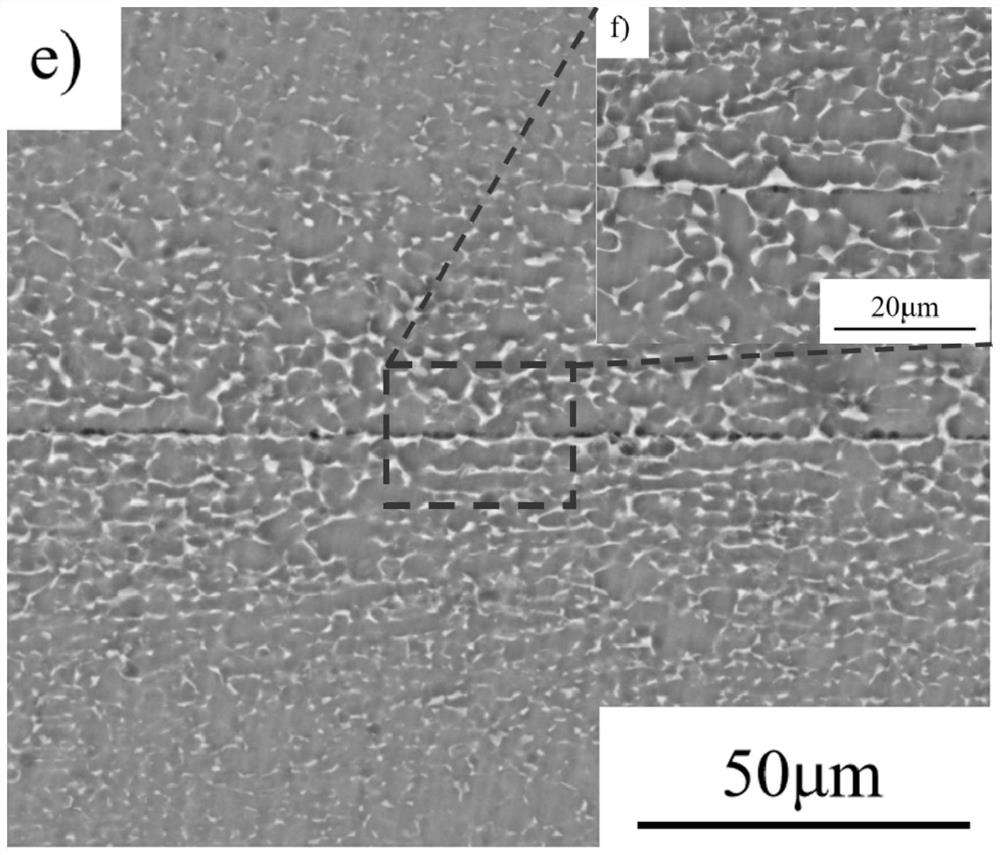

Process method for reducing diffusion bonding temperature of titanium alloy through electro-deposition of Ni-Co nanocrystalline layer

ActiveCN114427106AImprove oxidation and corrosion resistanceMeet the intensityNon-electric welding apparatusBonding processOxidation resistant

The invention relates to a process method for reducing titanium alloy diffusion bonding temperature through electro-deposition of a Ni-Co nanocrystalline layer, belongs to the technical field of titanium alloy low-temperature diffusion bonding, and aims to solve the technical problems that in the prior art, when titanium alloy is subjected to diffusion bonding, due to long-time heating, heat preservation and cooling, the diffusion bonding temperature of the titanium alloy is reduced; the titanium alloy low-temperature diffusion bonding process based on the titanium alloy surface nanocrystallization solves the problems that a plate subjected to diffusion bonding often has certain loss in the aspect of mechanical property compared with an original plate, and high energy consumption and long production period are also caused by the high diffusion bonding temperature, and the titanium alloy low-temperature diffusion bonding process based on the titanium alloy surface nanocrystallization is provided. Nanocrystallization of the surface of the titanium alloy is achieved through electro-deposition of a nanocrystalline coating, so that the oxidation corrosion resistance of an atomic diffusion channel and the alloy surface in the diffusion bonding process of the titanium alloy is improved, and diffusion bonding is conducted at the low temperature and the low vacuum degree to obtain the diffusion bonding joint strength meeting the use requirement. And an effective reference is provided for diffusion bonding of large-size parts under low-temperature and low-vacuum conditions.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com