Corrosion-resistant coating for interface of electronic device

An electronic equipment, corrosion-resistant technology, applied in the direction of contact parts, etc., can solve the problems of reduced electrical conductivity, peeling off of the electroplating layer, poor adhesion between the electroplating layer and the substrate material, etc., to achieve good wear resistance, adhesion and welding. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

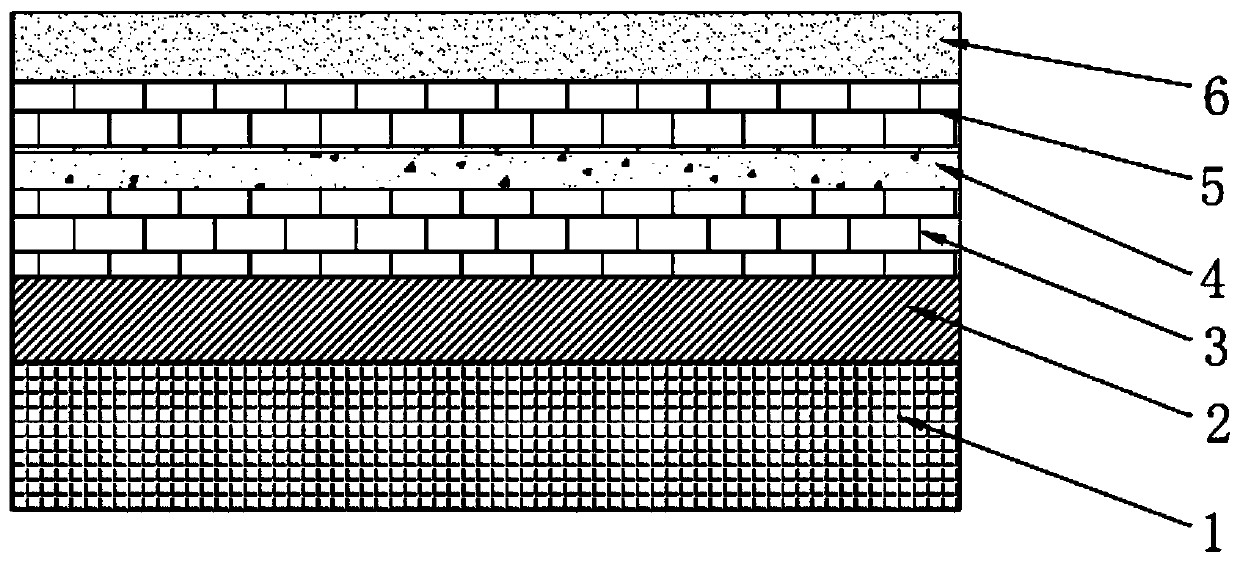

[0025] This embodiment provides a corrosion-resistant coating for an interface of an electronic device, comprising a nickel-tungsten coating layer 1, a gold coating layer, a first silver coating layer 3, a second gold coating layer 4, a third coating layer, and Rhodium ruthenium layer 5 and the fourth gold-plated layer 6, the thickness of described nickel-tungsten layer 1 is 0.5 micron, the thickness of described gold-plated layer is 0.025 micron, the thickness of described first silver-plated layer 3 is 0.5 micron, described The thickness of the second gold-plated layer 4 is 0.025 microns, the thickness of the third rhodium-plated ruthenium layer 5 is 0.25 microns, and the thickness of the fourth gold-plated layer 6 is 0.025 microns.

Embodiment 2

[0027] This embodiment provides a corrosion-resistant coating for an interface of an electronic device, comprising a nickel-tungsten coating layer 1, a gold coating layer, a first silver coating layer 3, a second gold coating layer 4, a third coating layer, and Rhodium ruthenium layer 5 and the fourth gold-plated layer 6, the thickness of described nickel-tungsten layer 1 is 5 microns, the thickness of described gold-plated layer is 0.25 microns, the thickness of described first silver-plated layer 3 is 6 microns, described The thickness of the second gold-plated layer 4 is 0.5 microns, the thickness of the third rhodium-plated ruthenium layer 5 is 4 microns, and the thickness of the fourth gold-plated layer 6 is 0.25 microns.

[0028] The pre-plating layer 2 of embodiment 1 and embodiment 2 selects the gold-plated layer to ensure the bonding force of the gold-plated layer and enhance the wear resistance and anti-corrosion ability. Compared with the silver-plated layer, althoug...

Embodiment 3

[0030] This embodiment provides a corrosion-resistant coating for an interface of an electronic device, comprising a nickel-tungsten coating 1, a silver coating, a first silver coating 3, a second gold coating 4, a third Rhodium-plated ruthenium layer 5 and the fourth gold-plated layer 6, the thickness of described nickel-tungsten layer 1 is 0.5 micron, the thickness of described silver-plated layer is 0.025 micron, the thickness of described first silver-plated layer 3 is 0.5 micron, The thickness of the second gold-plated layer 4 is 0.025 microns, the thickness of the third rhodium-plated ruthenium layer 5 is 0.25 microns, and the thickness of the fourth gold-plated layer 6 is 0.025 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com