Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

790 results about "Diffusion bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

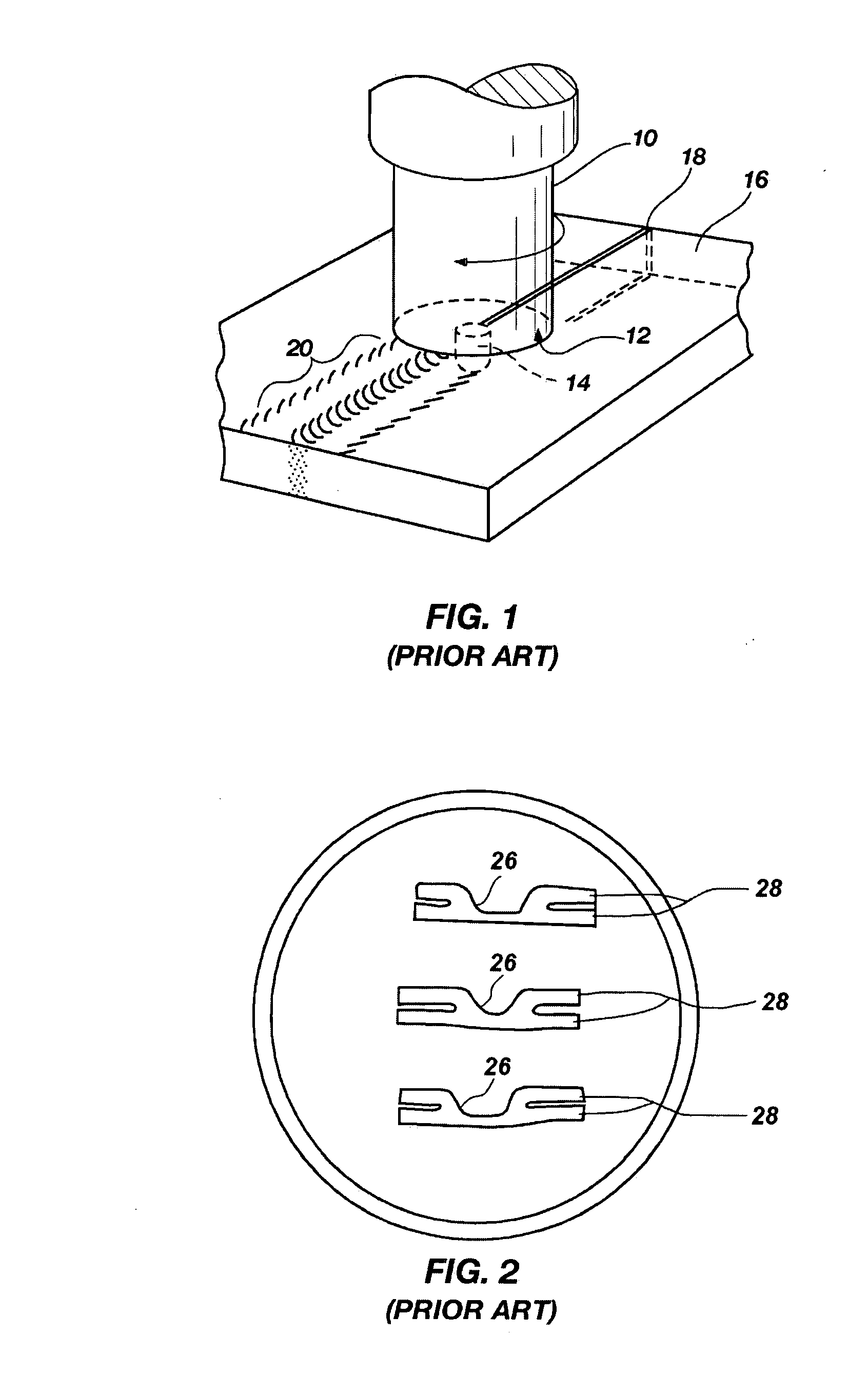

Diffusion bonding or diffusion welding is a solid-state welding technique used in metalworking, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves over time. This is typically accomplished at an elevated temperature, approximately 50-70% of the absolute melting temperature of the materials. Diffusion bonding is usually implemented by applying high pressure, in conjunction with necessarily high temperature, to the materials to be welded; the technique is most commonly used to weld "sandwiches" of alternating layers of thin metal foil, and metal wires or filaments. Currently, the diffusion bonding method is widely used in the joining of high-strength and refractory metals within the aerospace and nuclear industries.

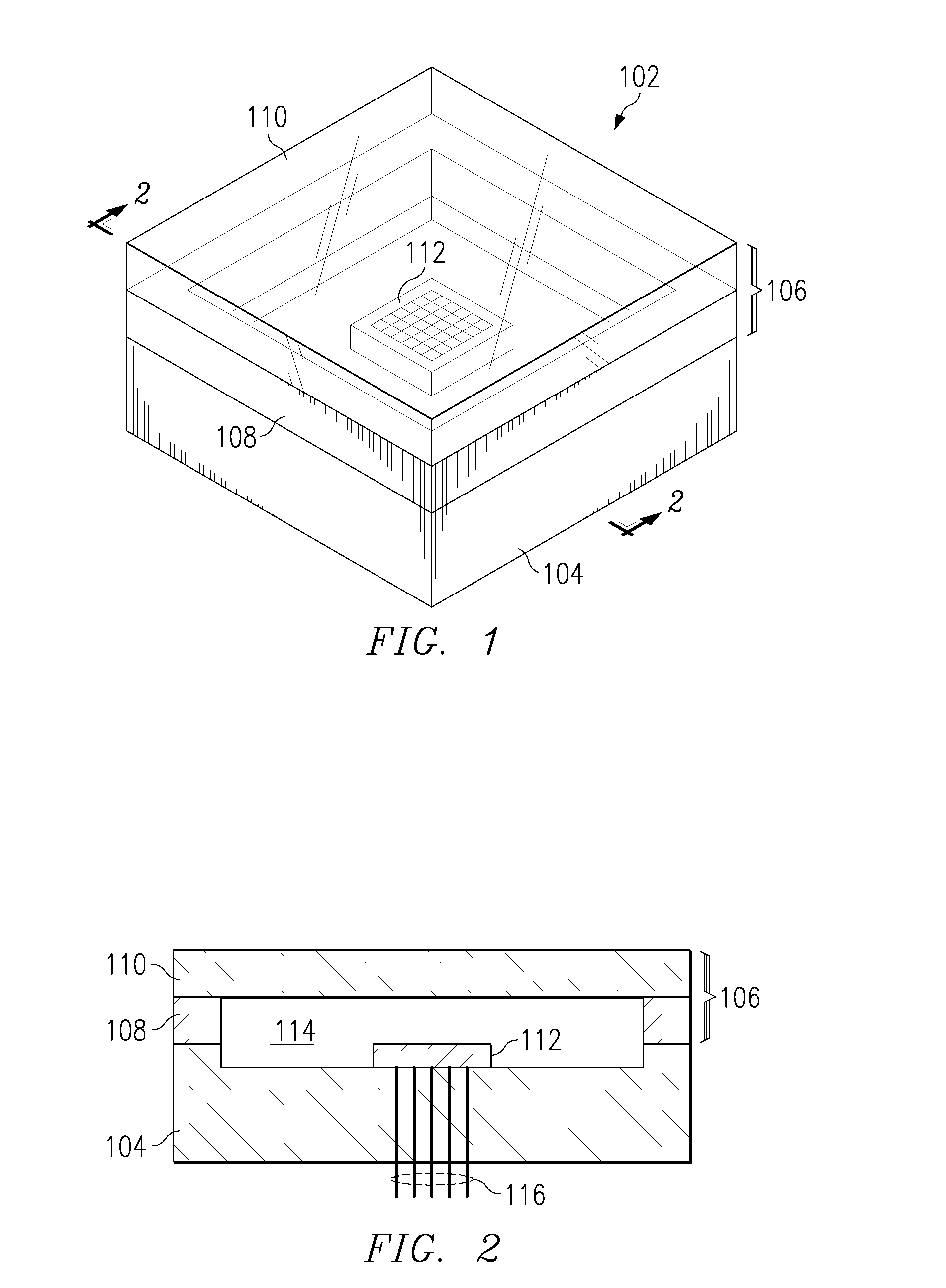

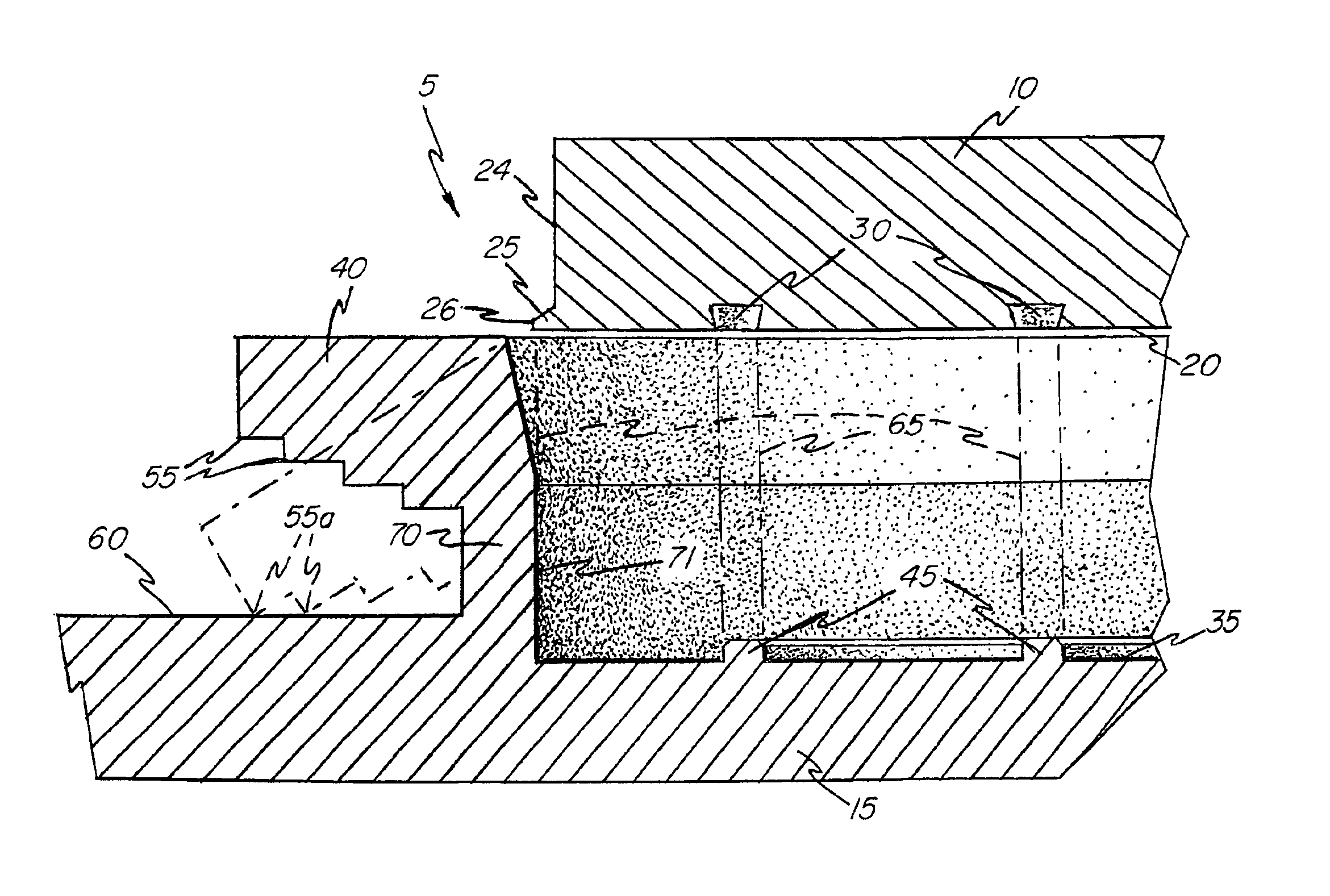

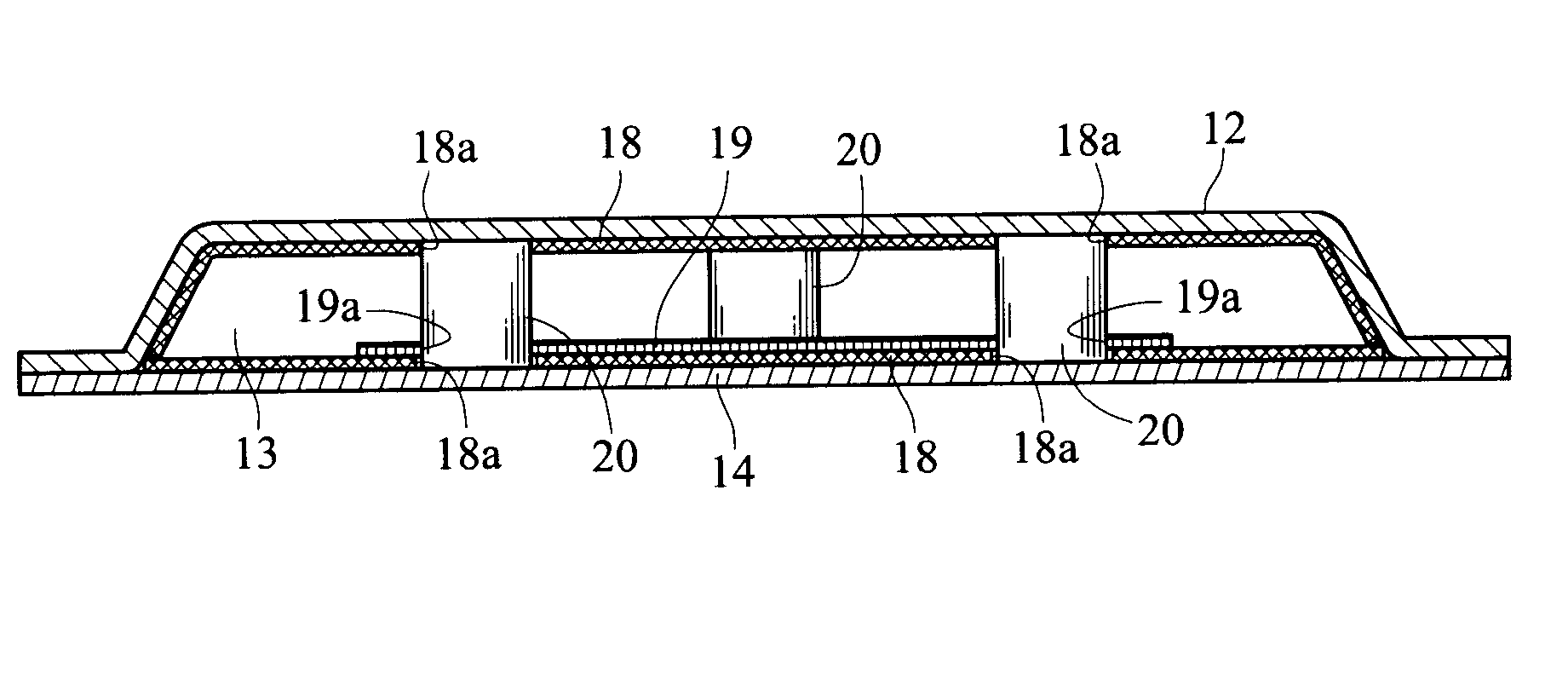

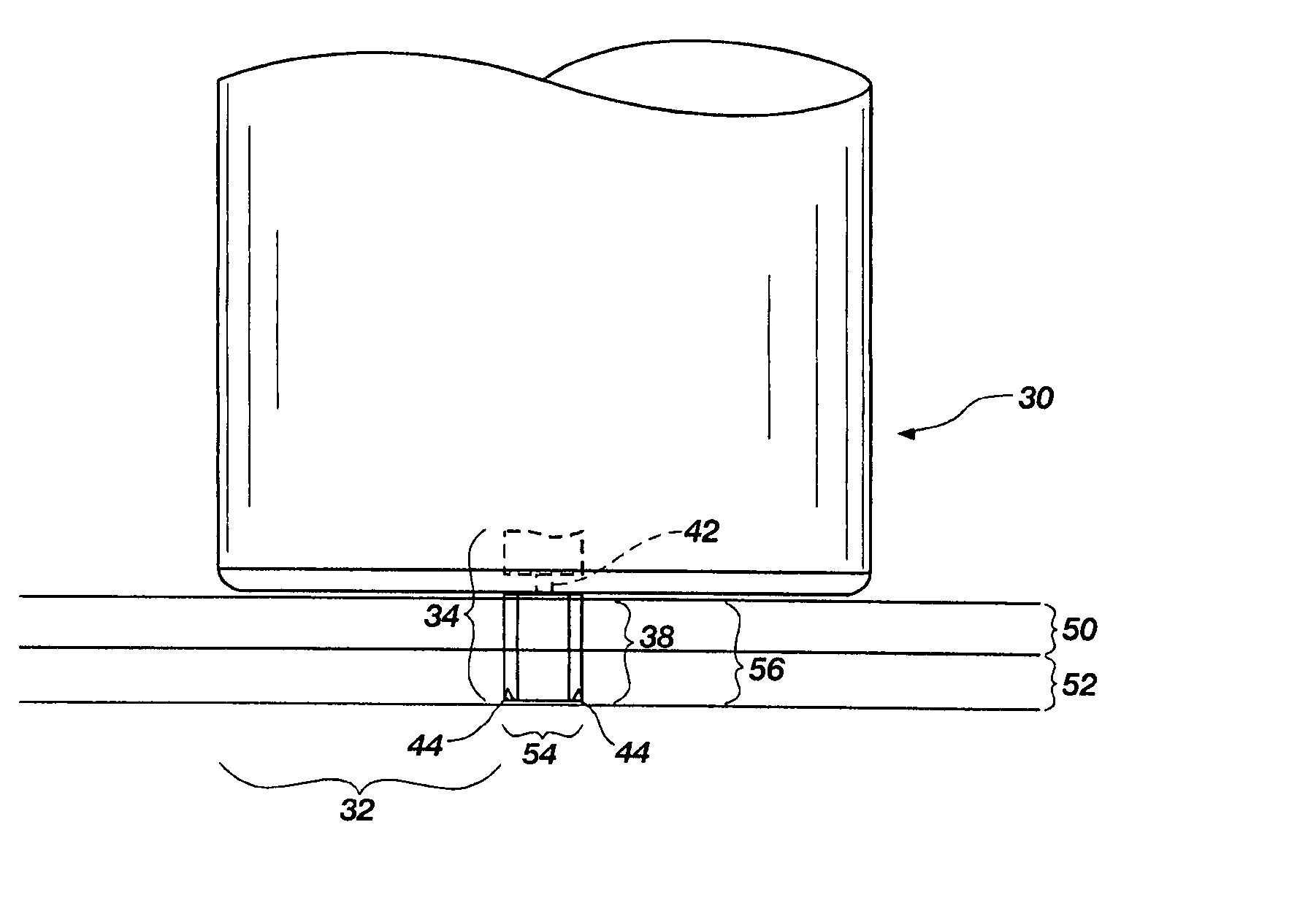

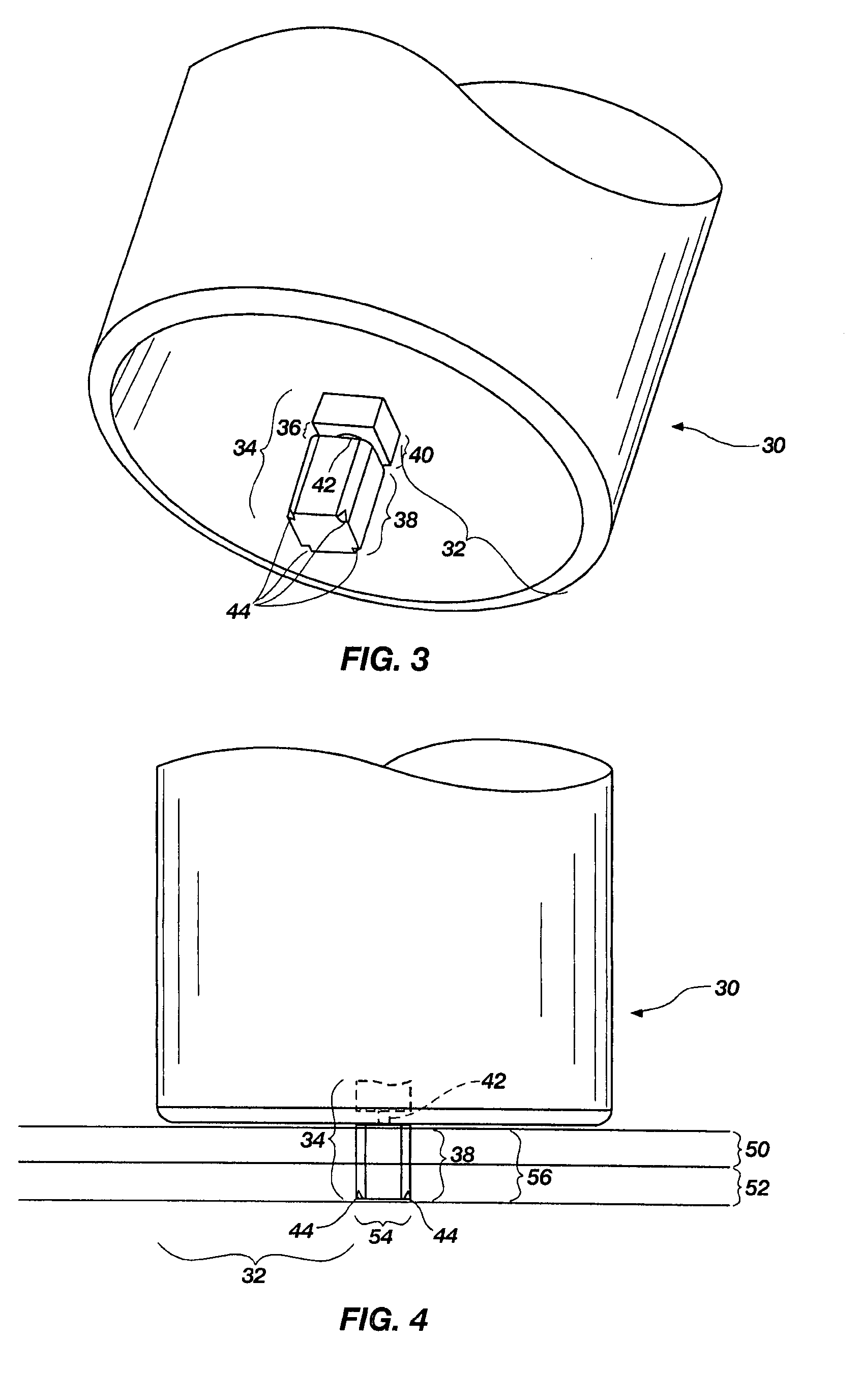

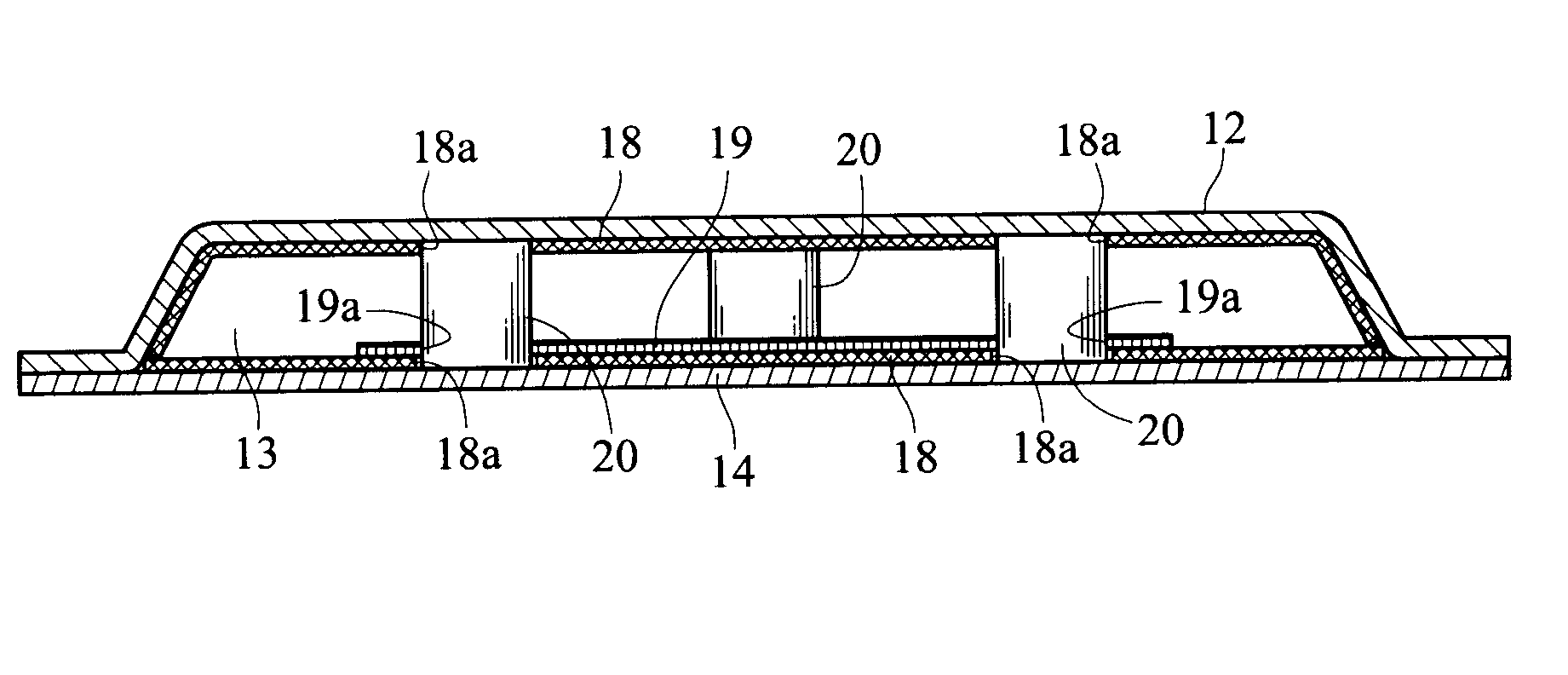

Insulated glazing units

InactiveUS20060187608A1Improve heat resistanceReduce weight and depthDoors/windowsSemiconductor/solid-state device detailsInsulated glazingEngineering

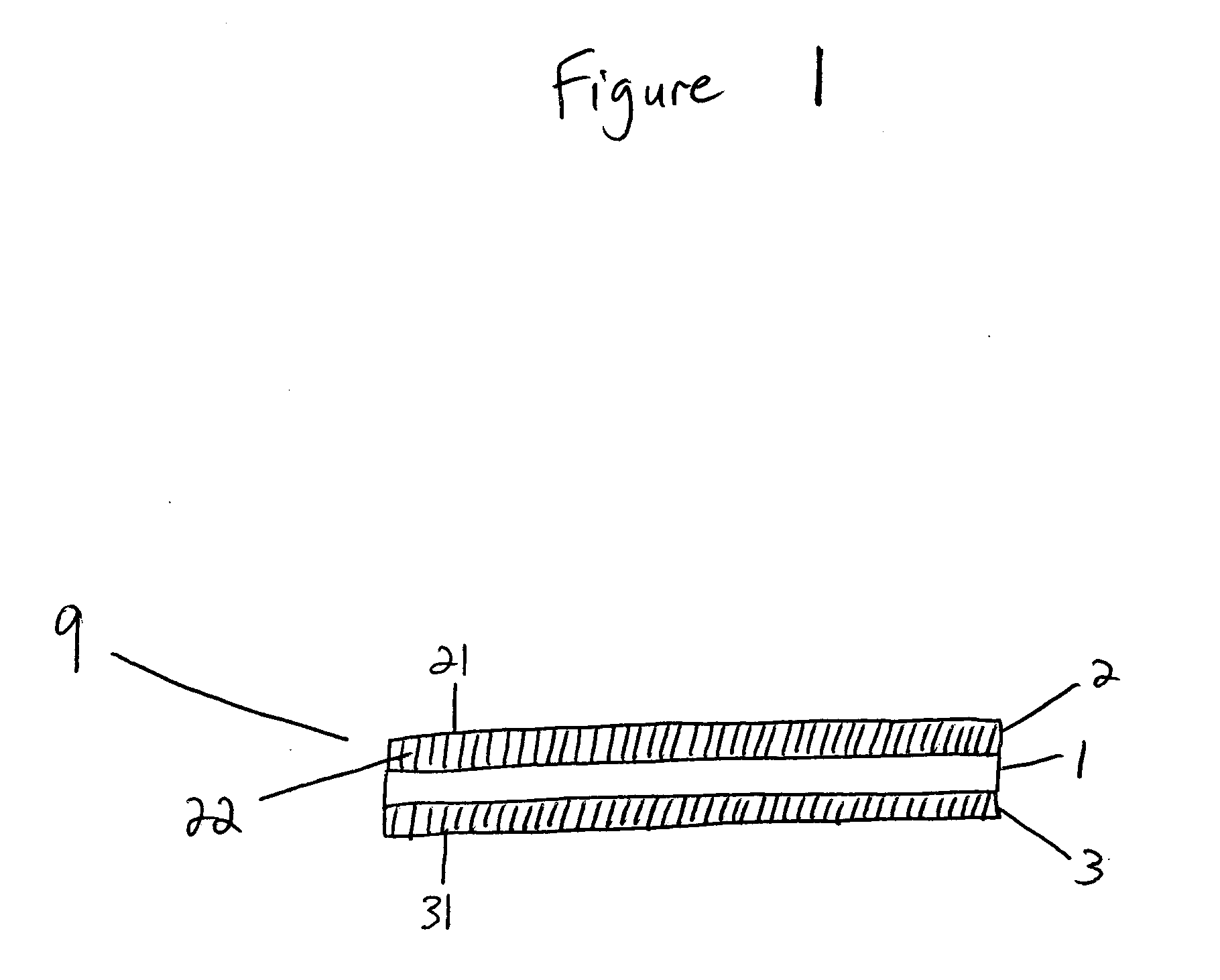

A hermetically sealed multi-pane window assembly comprises first and second windowpane sheets formed of transparent materials. A first sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the first windowpane sheet by diffusion bonding. A second sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the second windowpane sheet by diffusion bonding and the outer edge being hermetically attached to the outer edge of the first sealing member. A spacer assembly is disposed between the first and the second windowpane sheets for maintaining a gap therebetween, whereby a hermetically sealed cavity is defined between the first and the second windowpanes.

Owner:ASTRAVAC GLASS INC

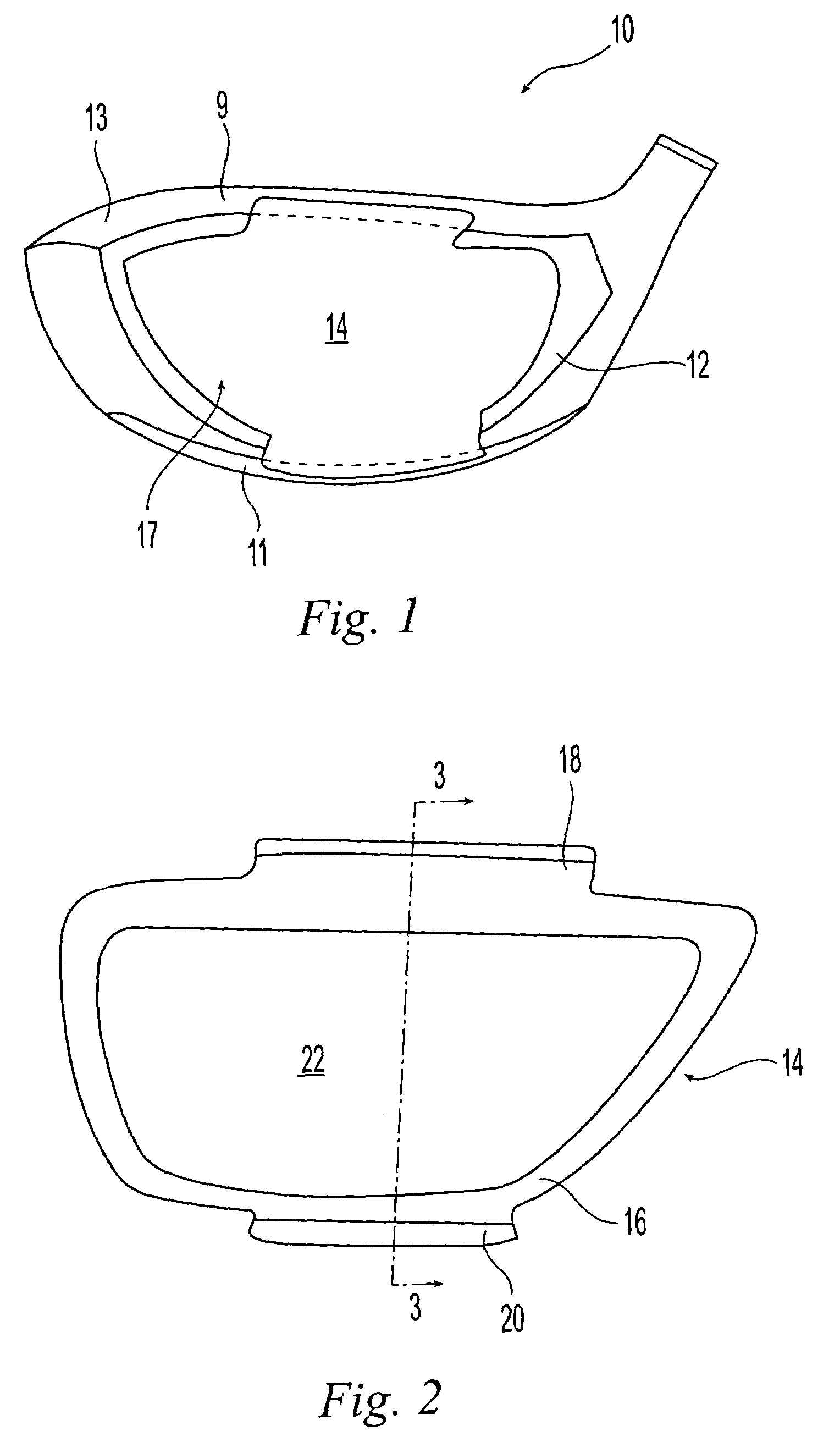

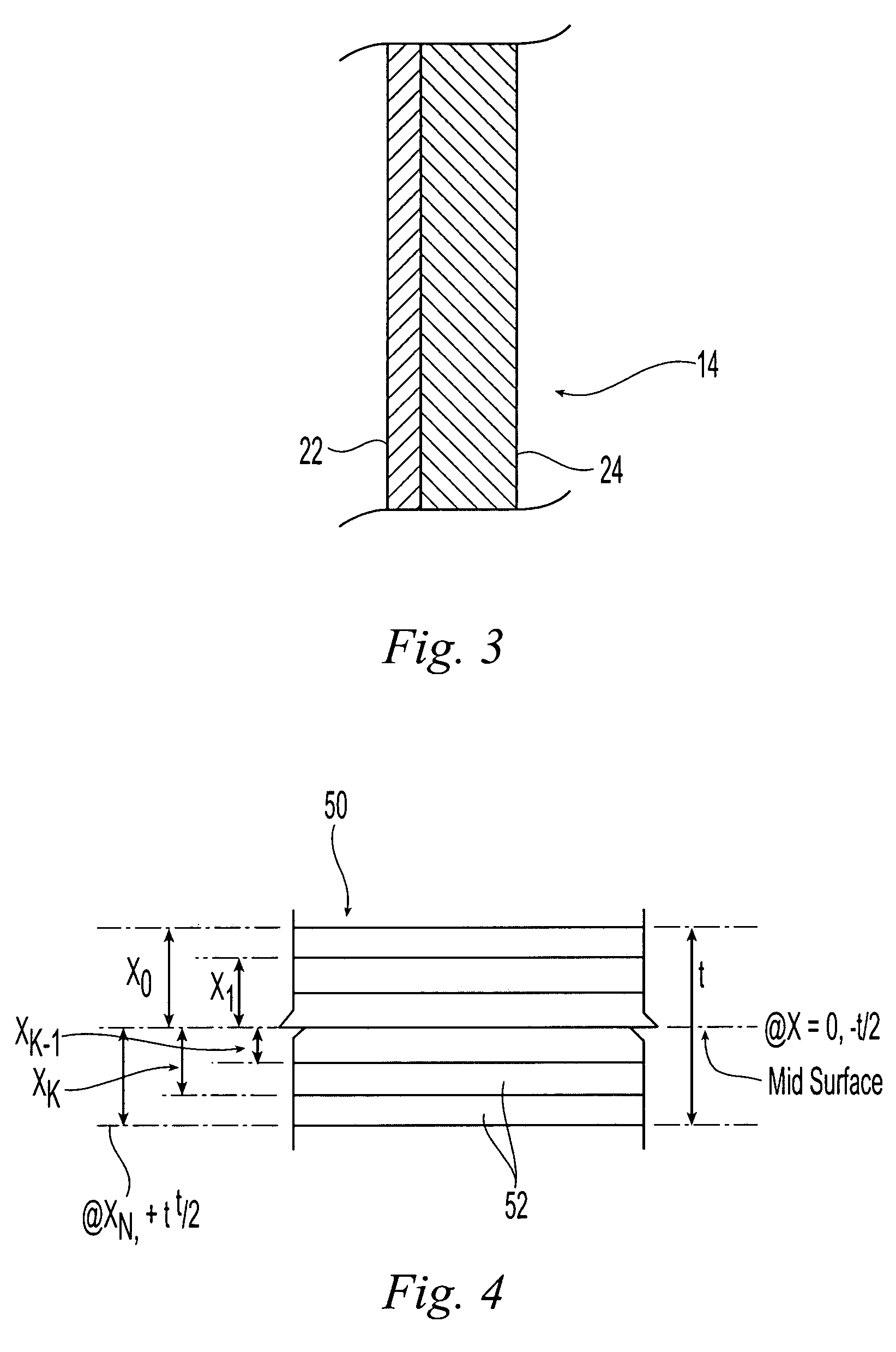

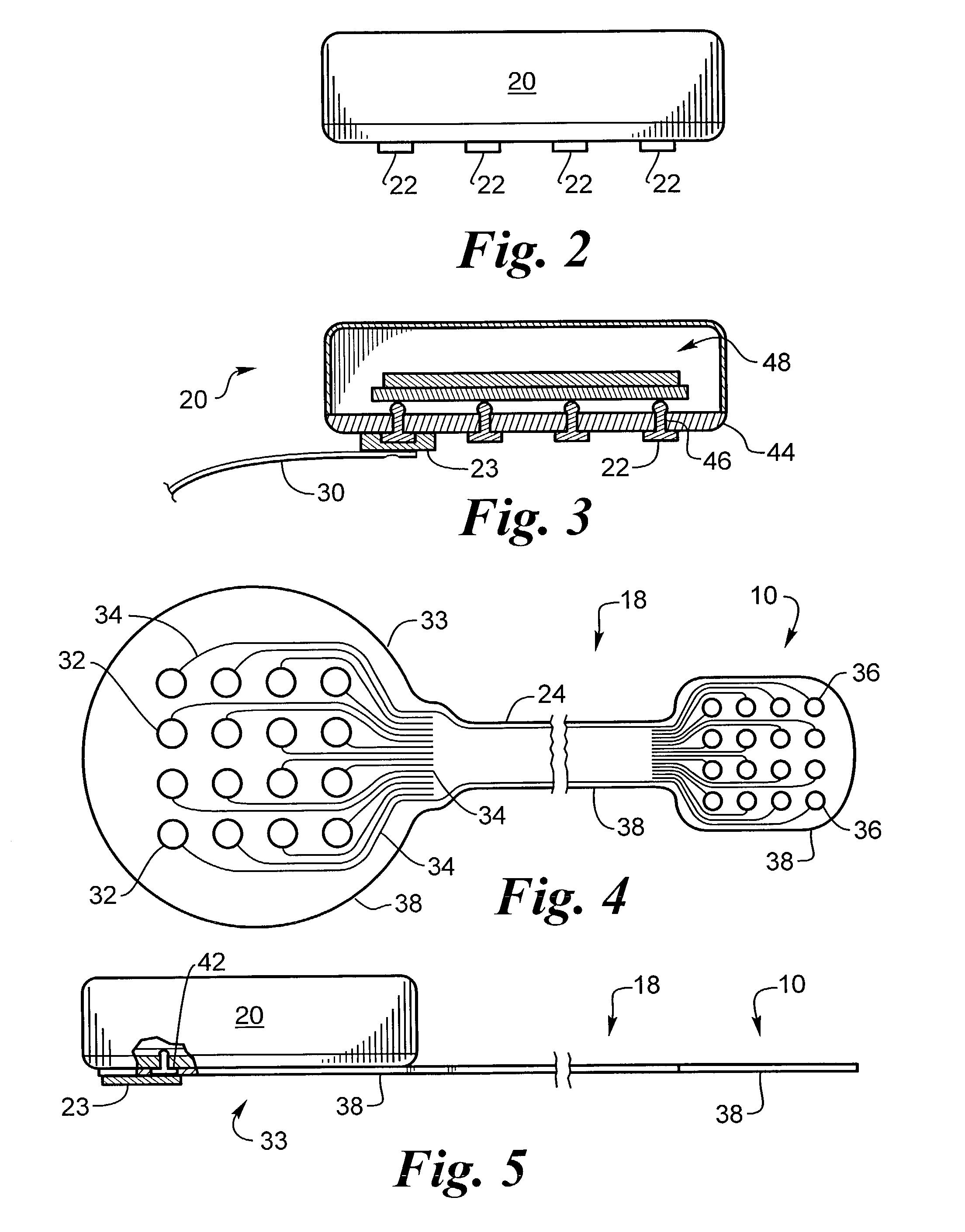

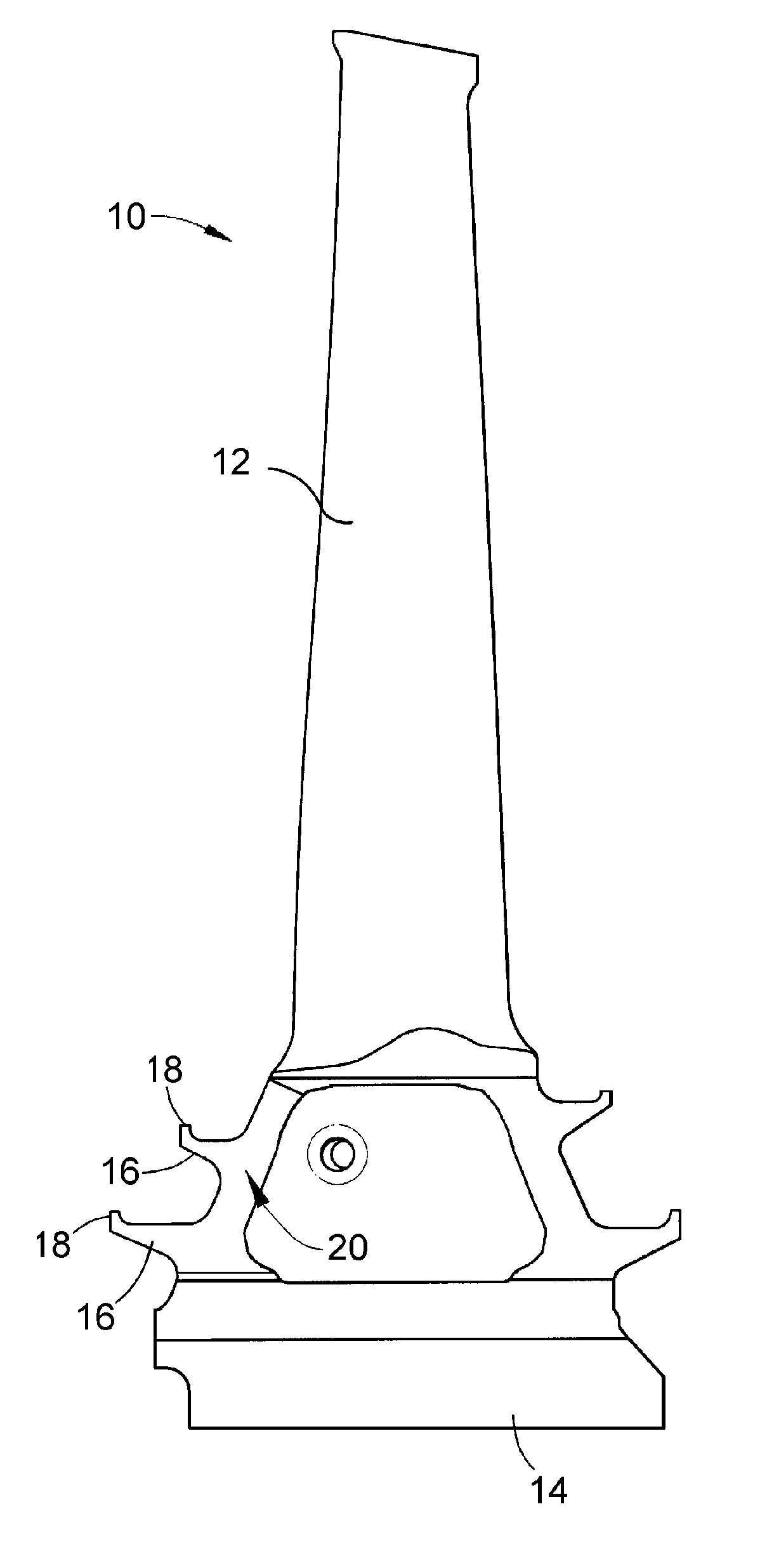

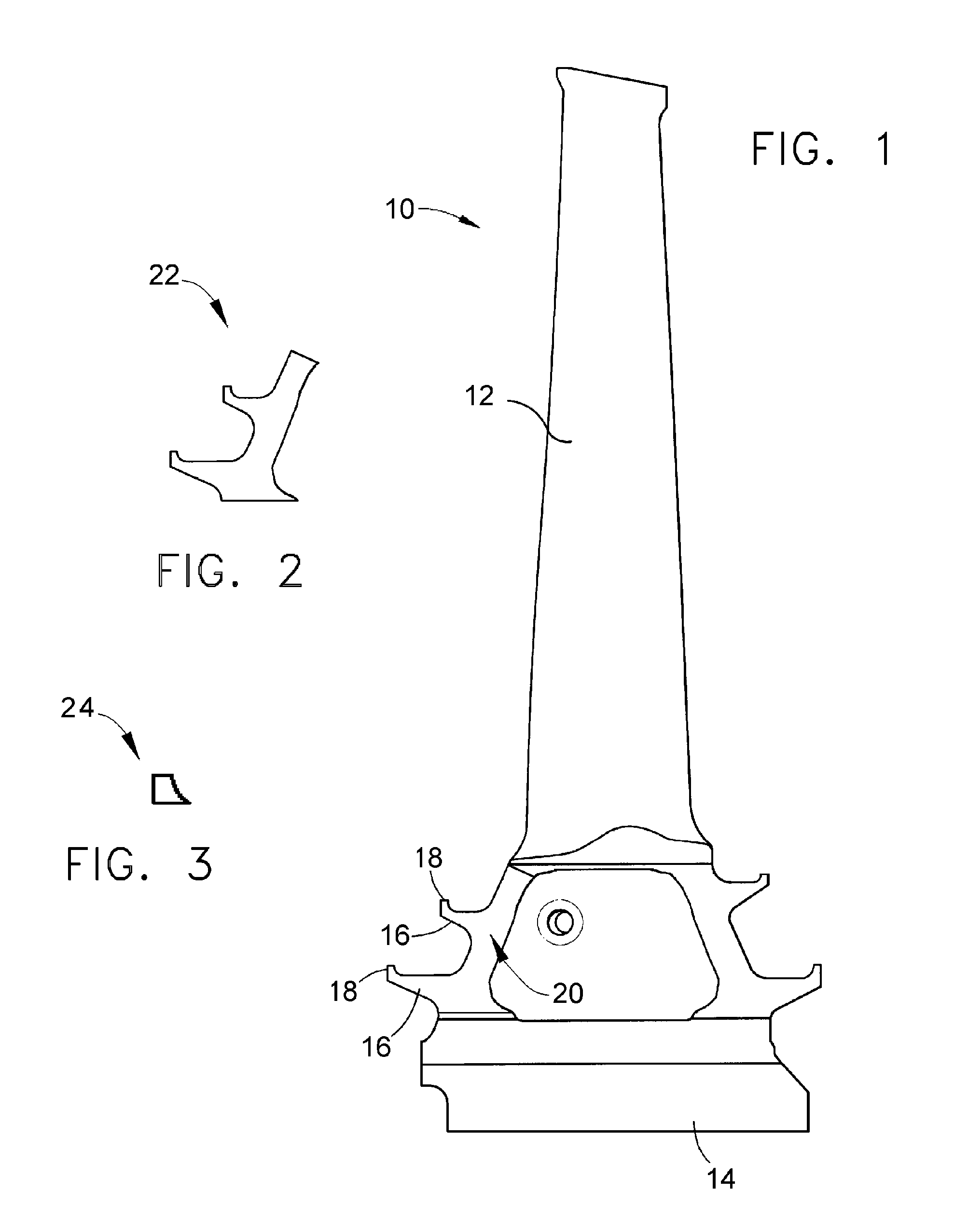

Metal wood club with improved hitting face

Owner:ACUSHNET CO

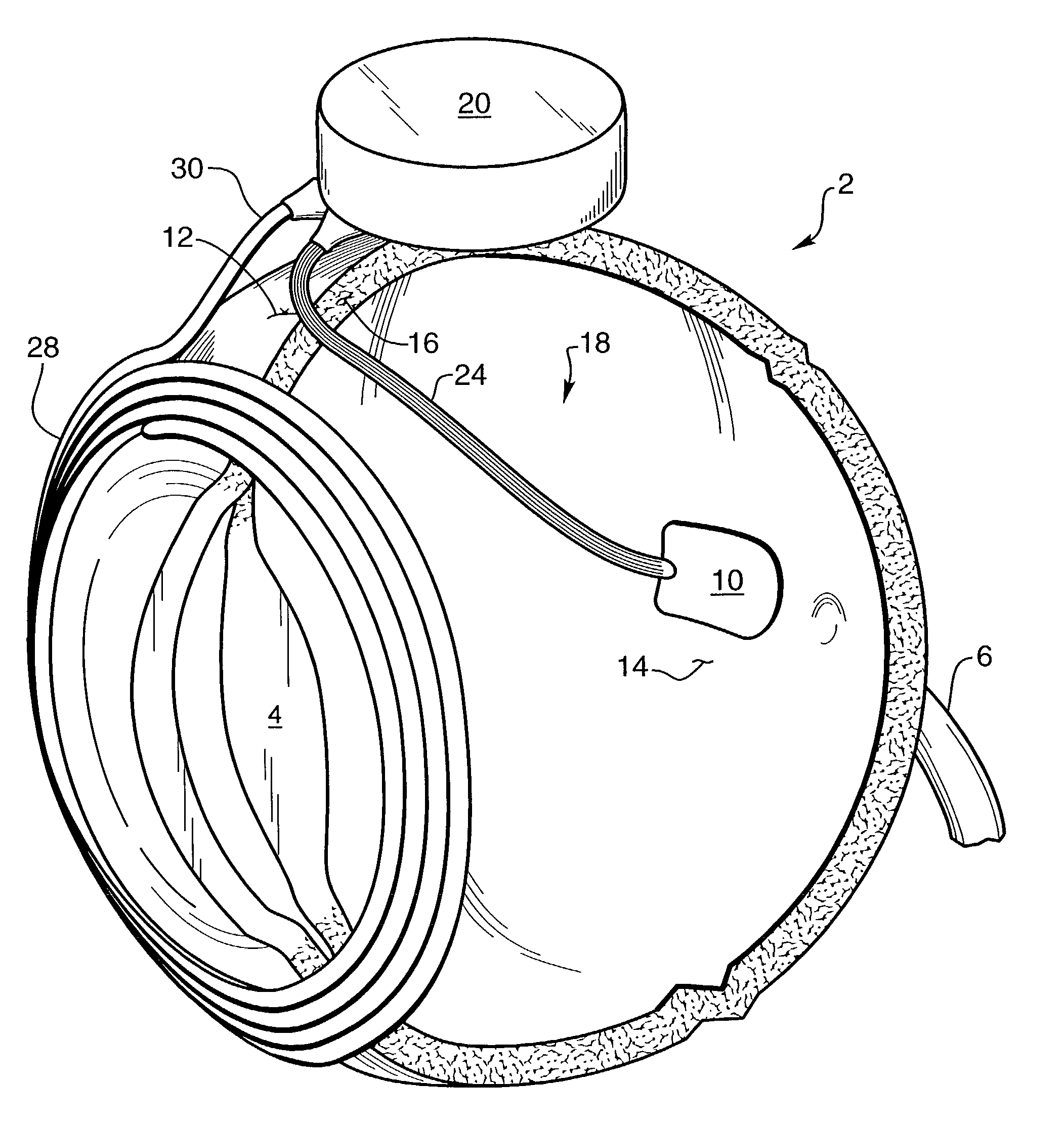

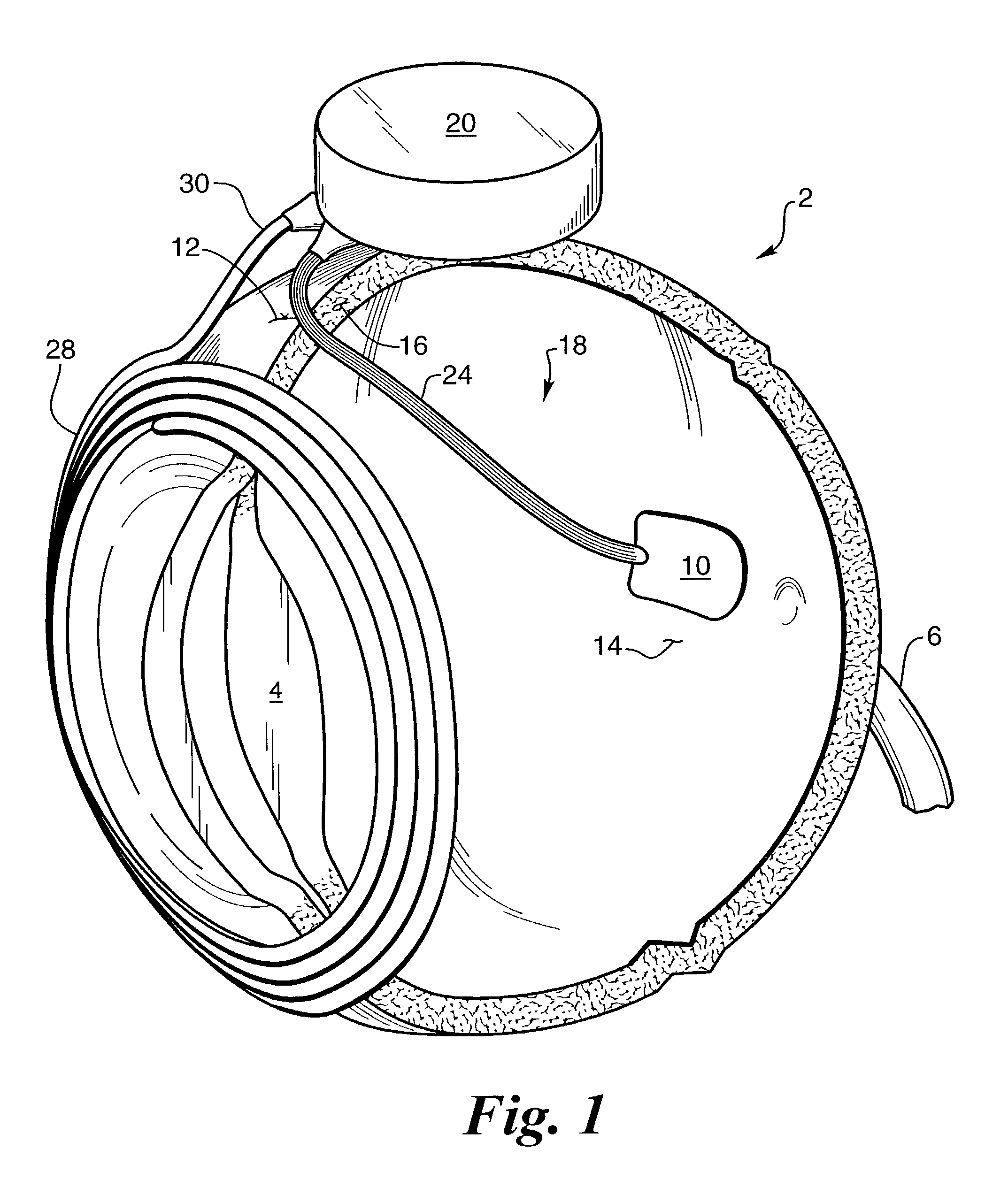

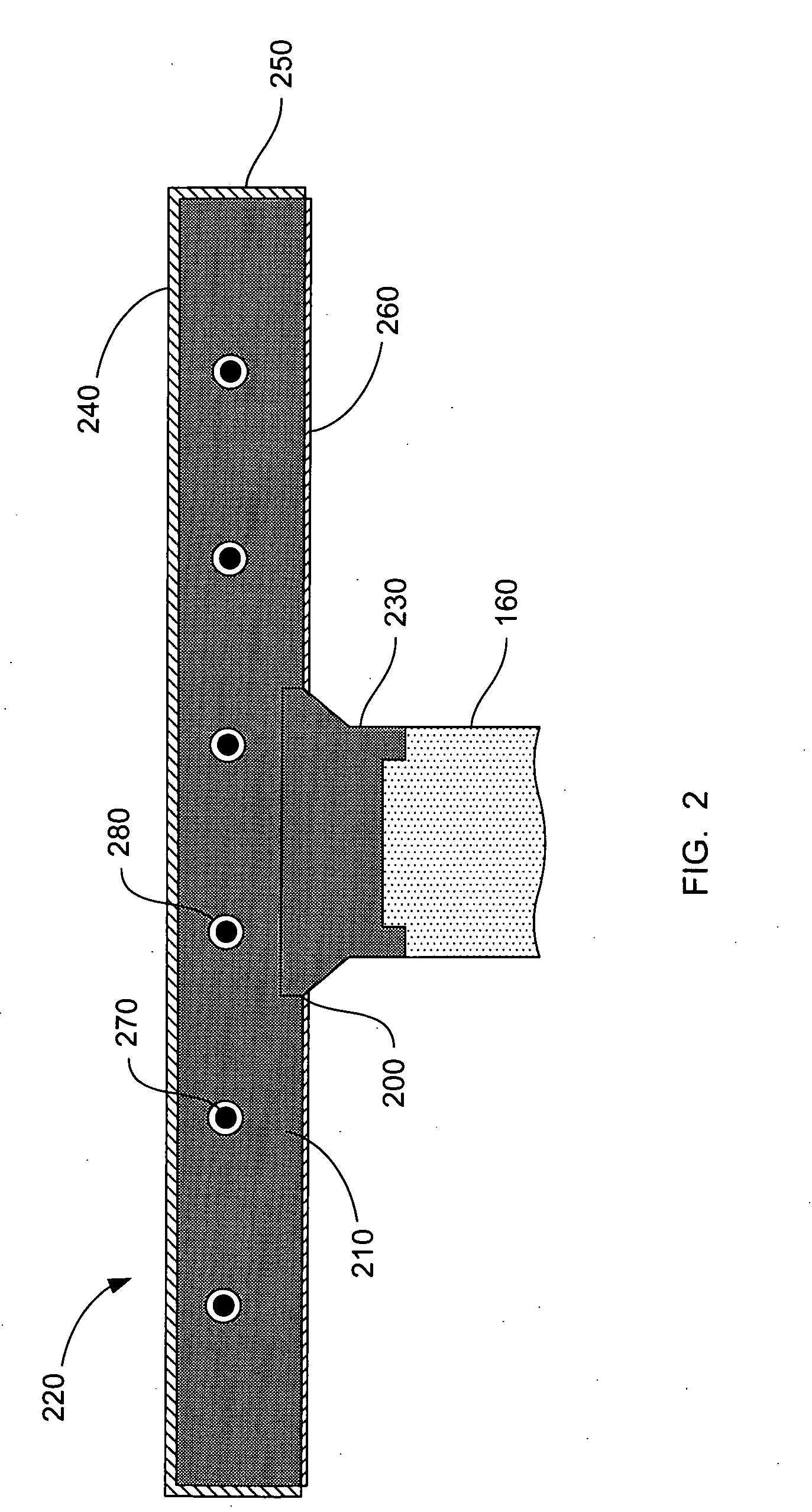

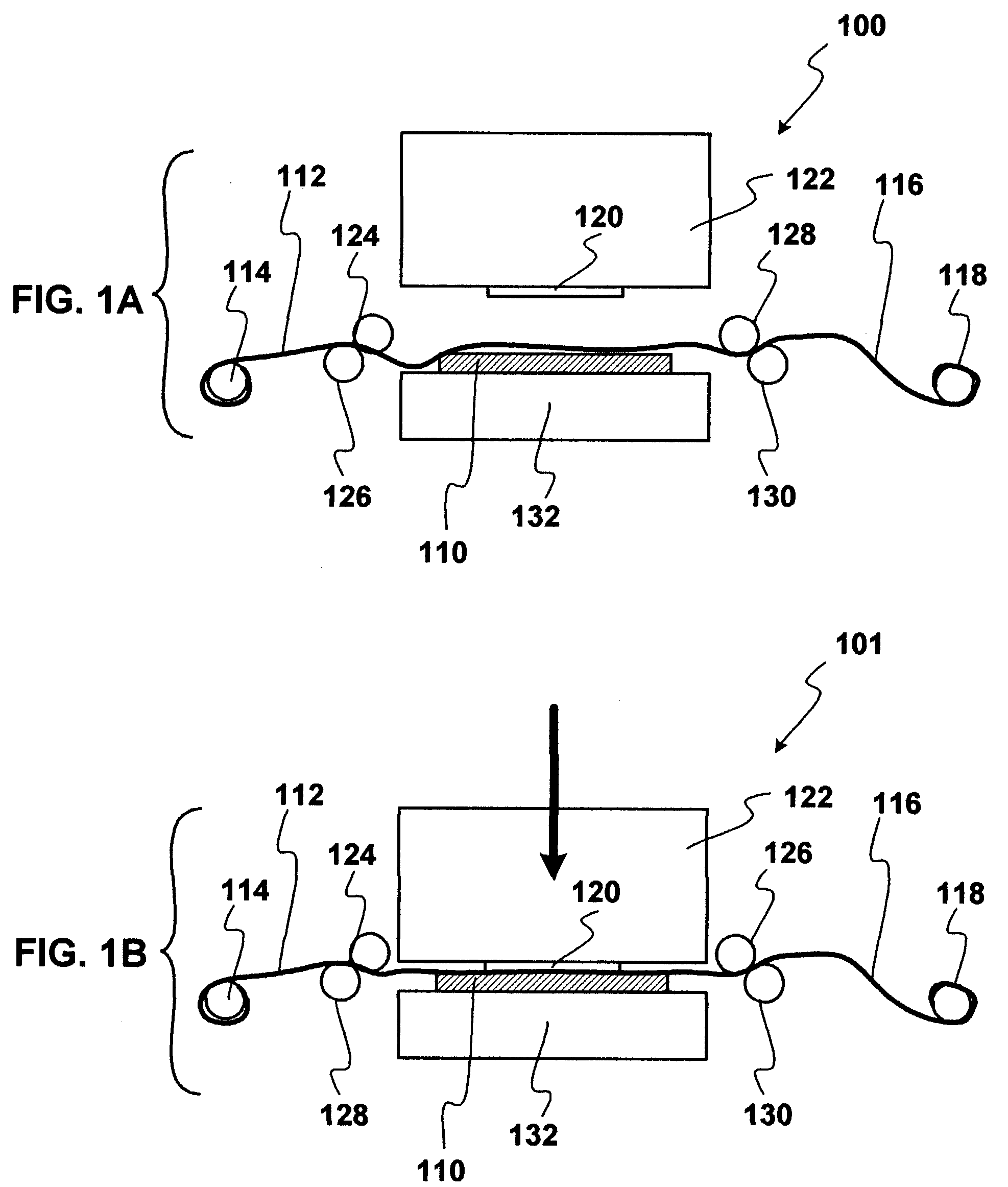

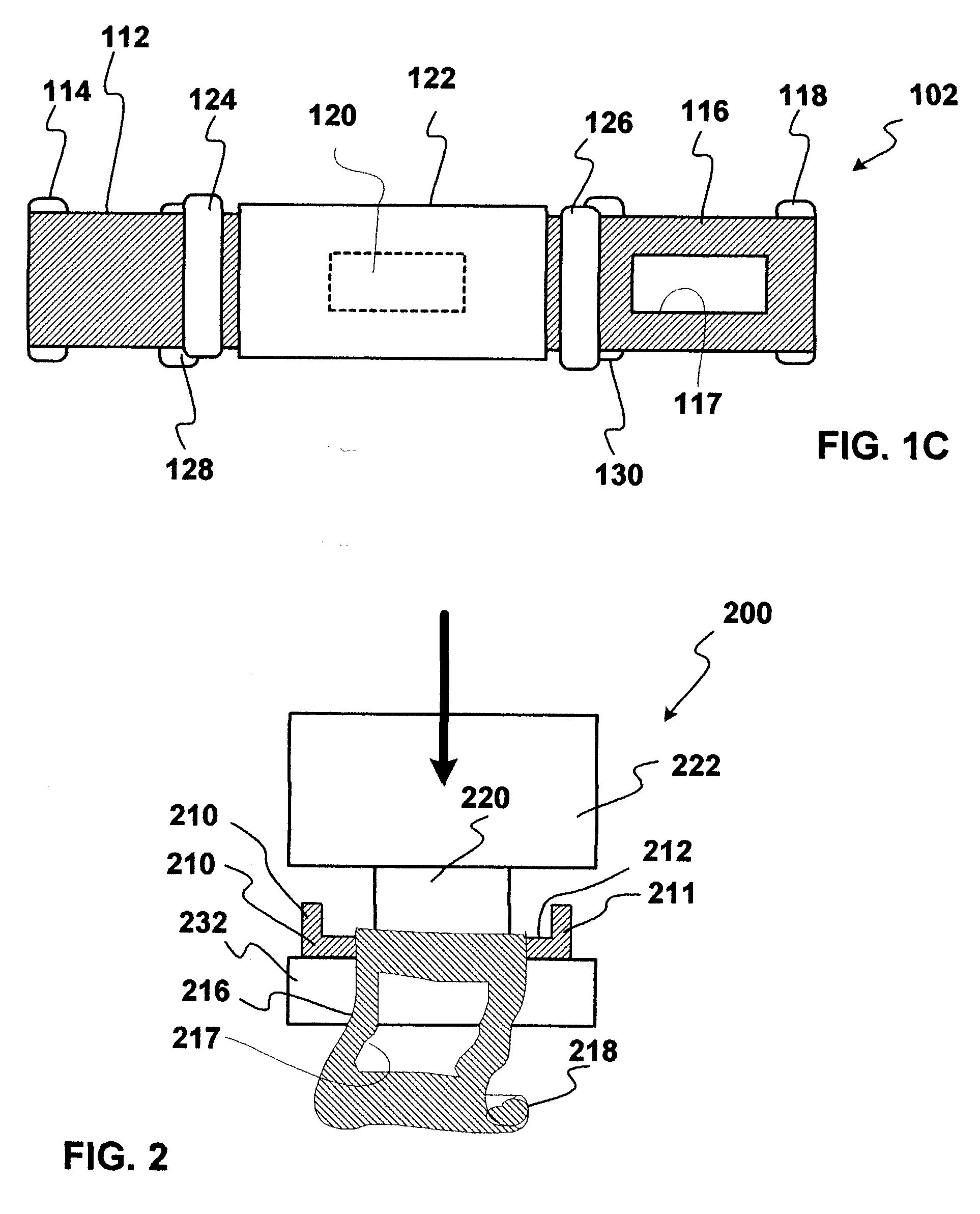

Biocompatible bonding method and electronics package suitable for implantation

The invention is directed to a method of bonding a hermetically sealed electronics package to an electrode or a flexible circuit and the resulting electronics package, that is suitable for implantation in living tissue, such as for a retinal or cortical electrode array to enable restoration of sight to certain non-sighted individuals. The hermetically sealed electronics package is directly bonded to the flex circuit or electrode by one of several methods, including attachment by an electrically conductive adhesive, such as epoxy or polyimide, containing platinum metal flake in biocompatible glue; diffusion bonding of platinum bumps covered by an insulating layer; thermal welding of wire staples; or an integrated interconnect fabrication. The resulting electronic device is biocompatible and is suitable for long-term implantation in living tissue.

Owner:SECOND SIGHT MEDICAL PRODS +1

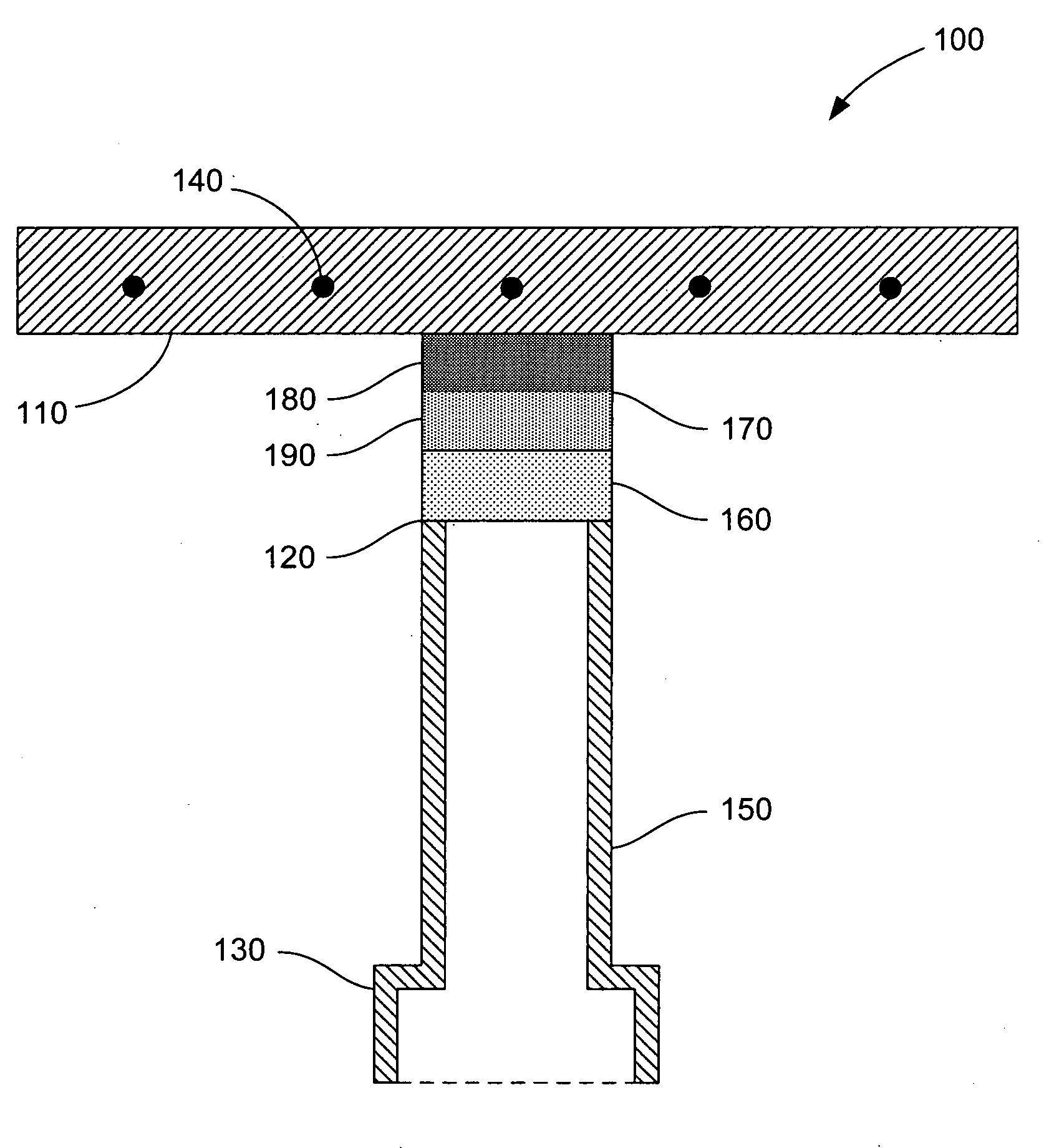

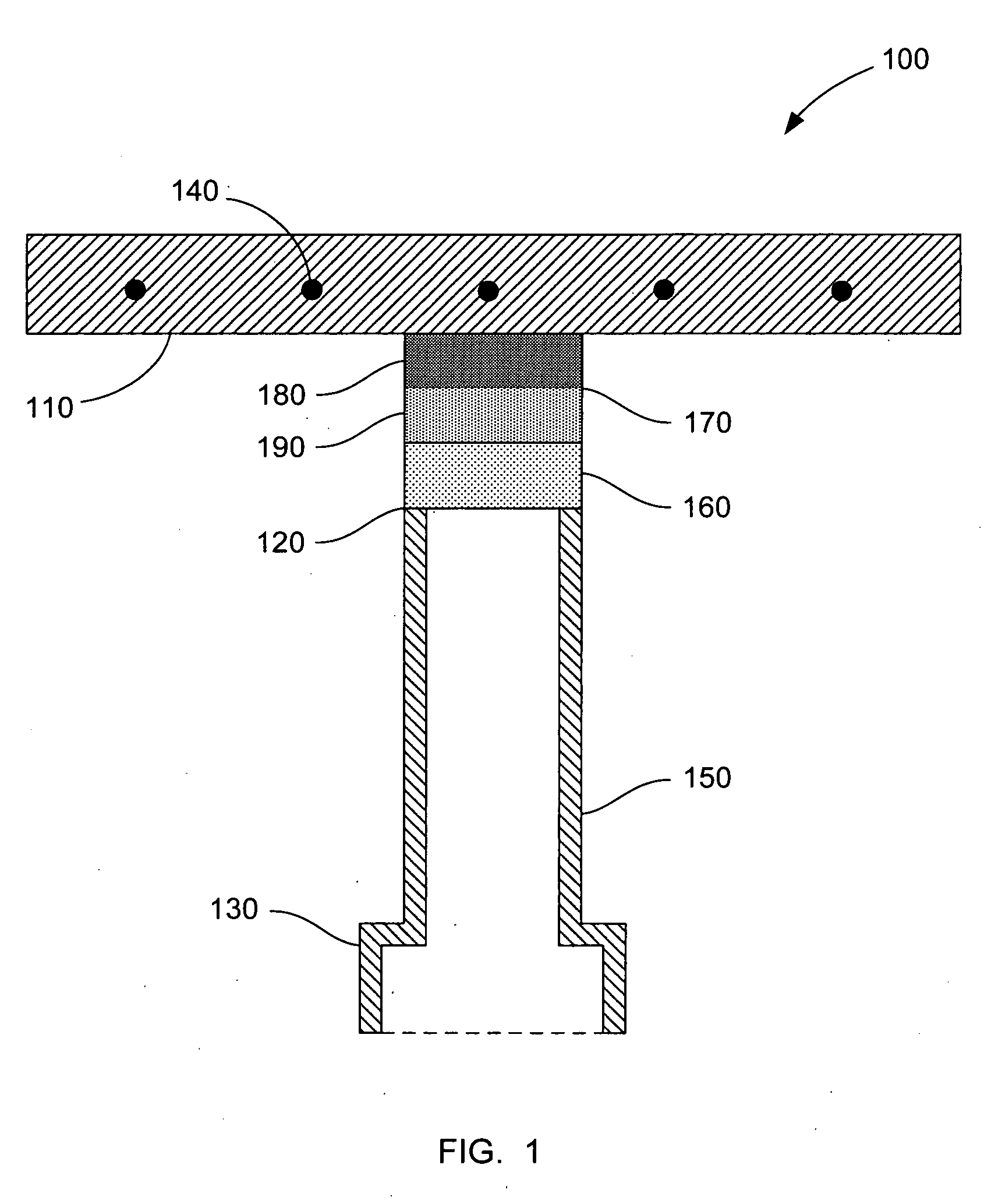

Advanced ceramic heater for substrate processing

InactiveUS20070169703A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetal alloy

Susceptors are provided that employ layers of CTE-matching materials to reduce the stresses that otherwise lead to cracking and failure. Exemplary CTE-matching materials include metal alloys of aluminum and silicon that can be tailored to specific CTE values by adjusting the ratio of the elements. An exemplary susceptor comprises a CTE-matching material that accommodates the differences in the CTEs of a ceramic material and a thermal barrier layer disposed on opposite sides of the CTE-matching material. Methods are also provided for forming susceptors. These methods comprise assembling the components and bonding the assembly together, such as by diffusion bonding, to produce a susceptor that is a monolithic body.

Owner:COMPONENT RE ENGINEERING COMPANY INC +1

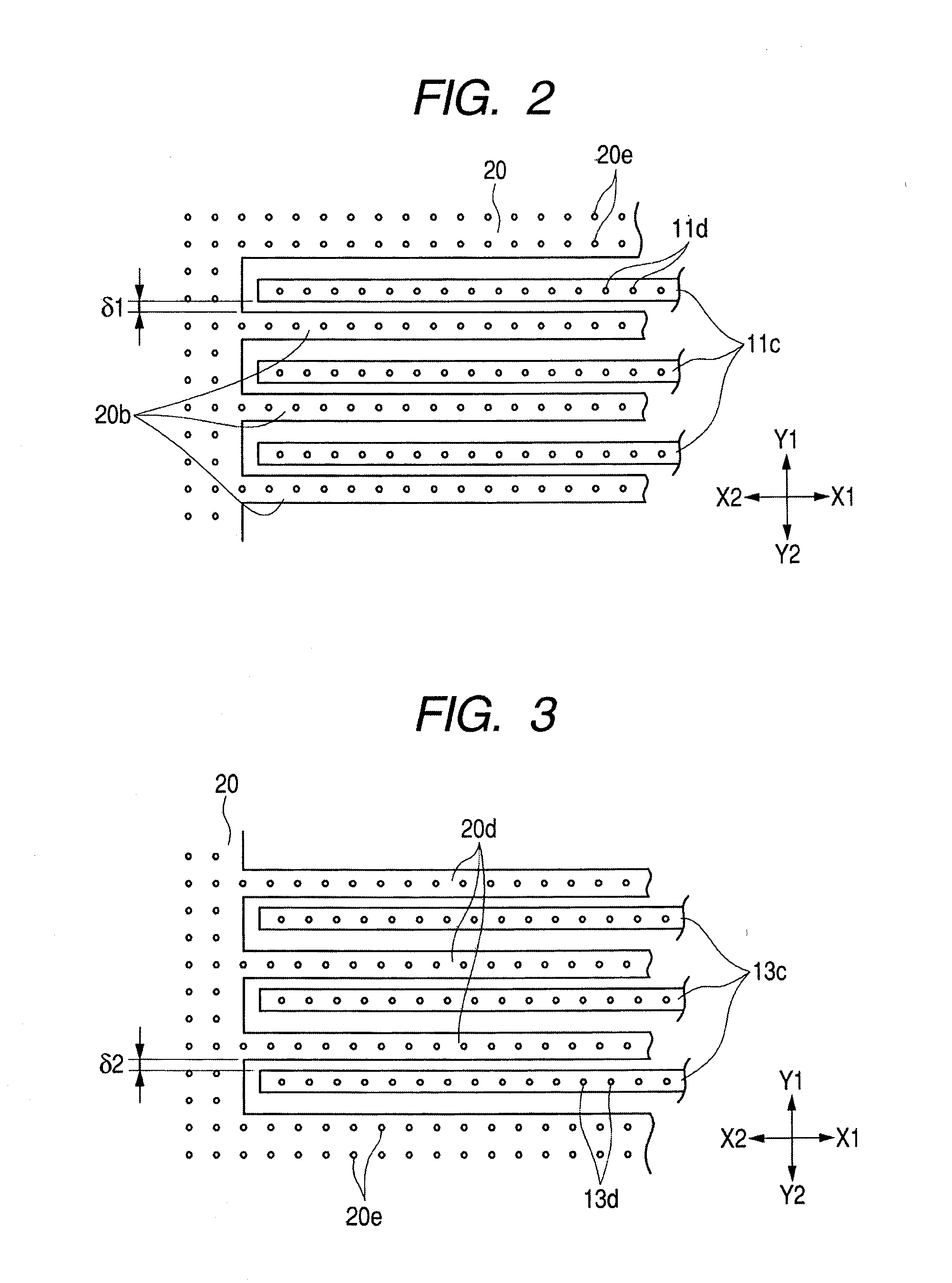

Hydrogen extraction unit

A hydrogen extraction unit has reformed gas flow channel plates, hydrogen separation plates, and purge gas flow channel plates, which are designed as thin metal plate members. The hydrogen extraction unit is constructed by laminating these thin plate members and then bonding them together by diffusion bonding. Each of reformed gas flow channel holes formed in the reformed gas flow channel plates constitutes a flow channel for reformed gas together with a correspondingly adjacent one of the hydrogen separation plates. Each of purge gas flow channel holes formed in the purge gas flow channel plates constitutes, together with a correspondingly adjacent one of the hydrogen separation plates, a flow channel for purge gas with which hydrogen extracted from reformed gas is mixed.

Owner:TOYOTA JIDOSHA KK

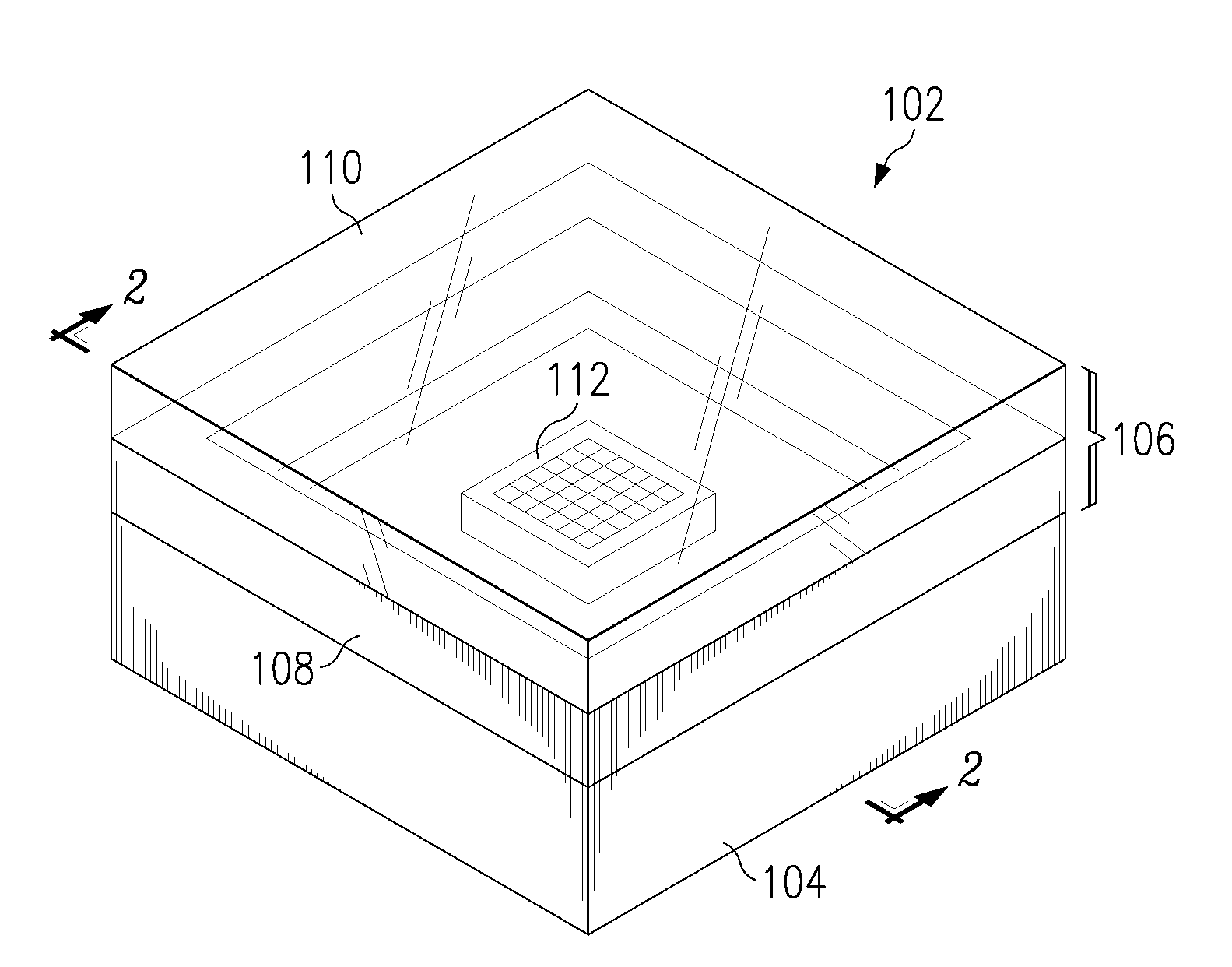

Heat sink with preattached thermal interface material and method of making same

InactiveUS20040188814A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A process of making an integrated heat spreader is disclosed. The integrated heat spreader is stamped with a thermal interface material under conditions to form a diffusion bonding zone between the integrated heat spreader and the thermal interface material. The thermal interface material can have one of several cross-sectional profiles to facilitate reflow thereof against a die during a method of assembling a packaged microelectronic device. The thermal interface material can also have one of several footprints to further facilitate reflow thereof against the die.

Owner:INTEL CORP

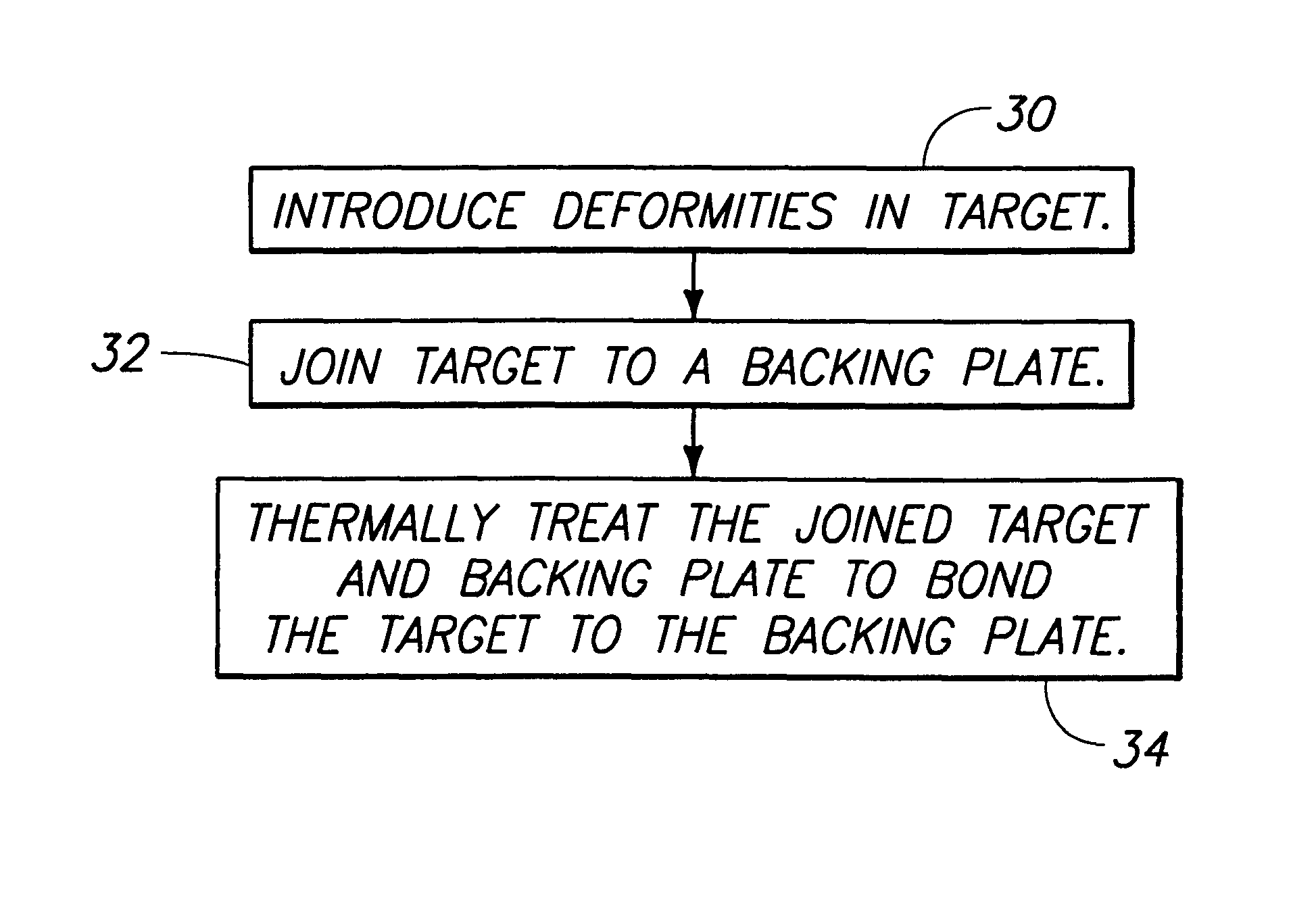

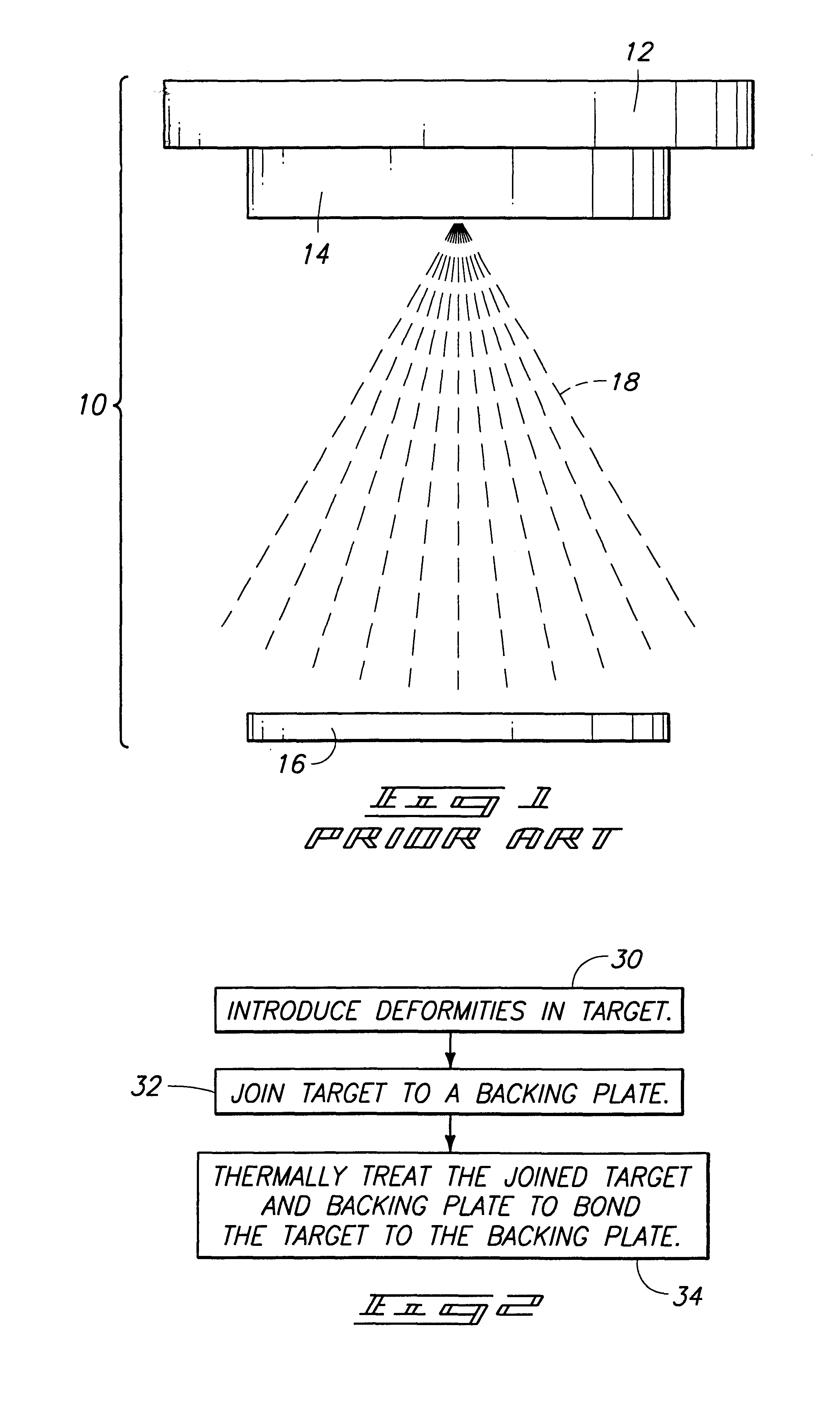

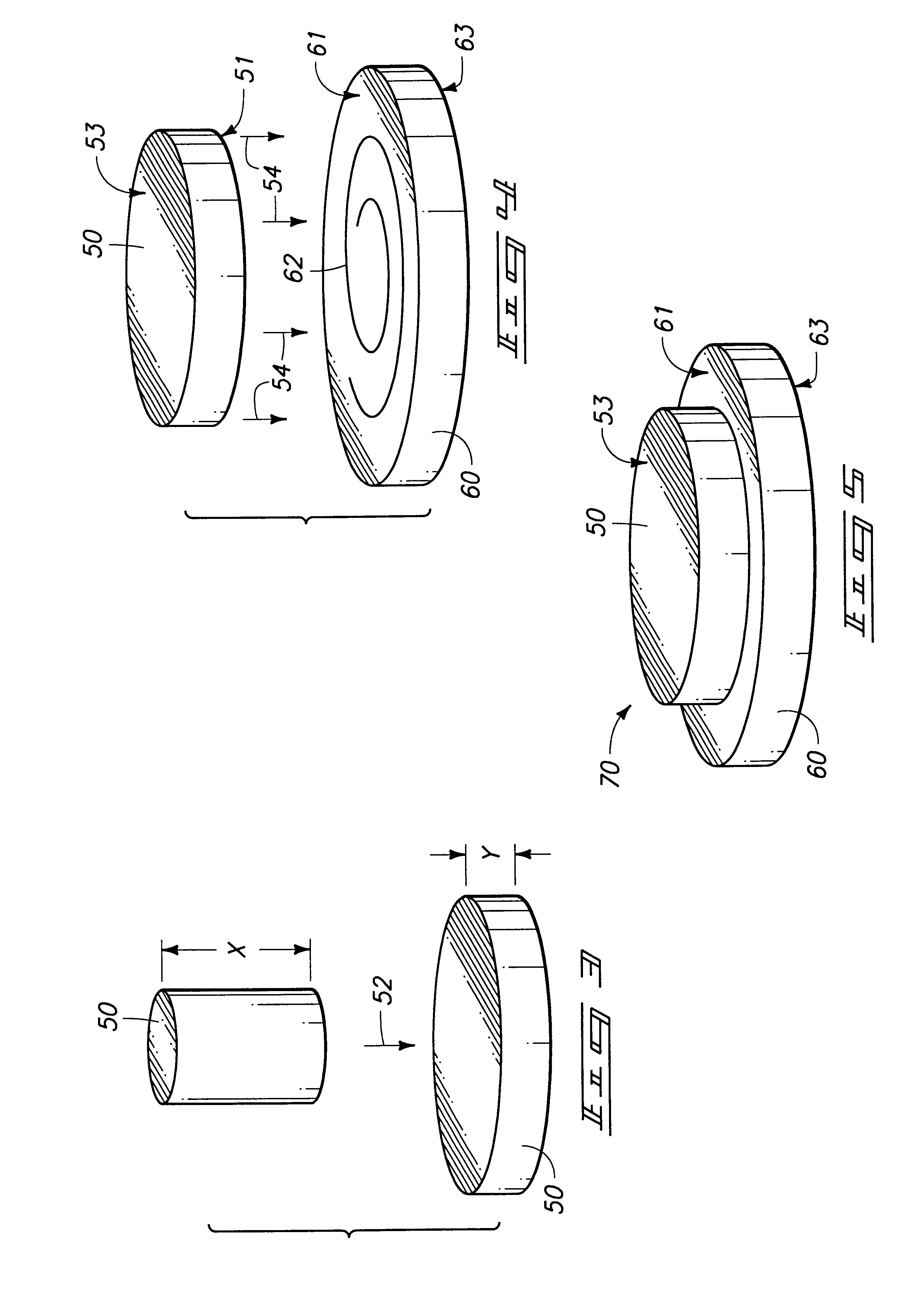

Low temperature sputter target/backing plate method and assembly

InactiveUS7146703B2Firmly connectedSolve the lack of resistanceCellsElectric discharge tubesBond interfaceBond strength

A sputtering target and a backing plate are diffusion-bonded with or without an insert or inserts interposed there-between so as to have a solid phase diffusion-bonded interface. The sputtering target substantially maintains its metallurgical characteristic and properties even though it has been diffusion-bonded to the backing plate. The solid-diffusion bonding of the target and backing plate, is achieved at a low temperature and pressure and results in interdiffusion of constituent atoms to attain high adhesion and bond strength without attendant deterioration or large deformation of the target material, while inhibiting the crystal growth in the target material. The bond undergoes no abrupt decrease in bond strength upon elevation of the service temperature. One hundred percent bonding is achieved with non-bonded portions such as pores left along the interface.

Owner:TOSOH SMD

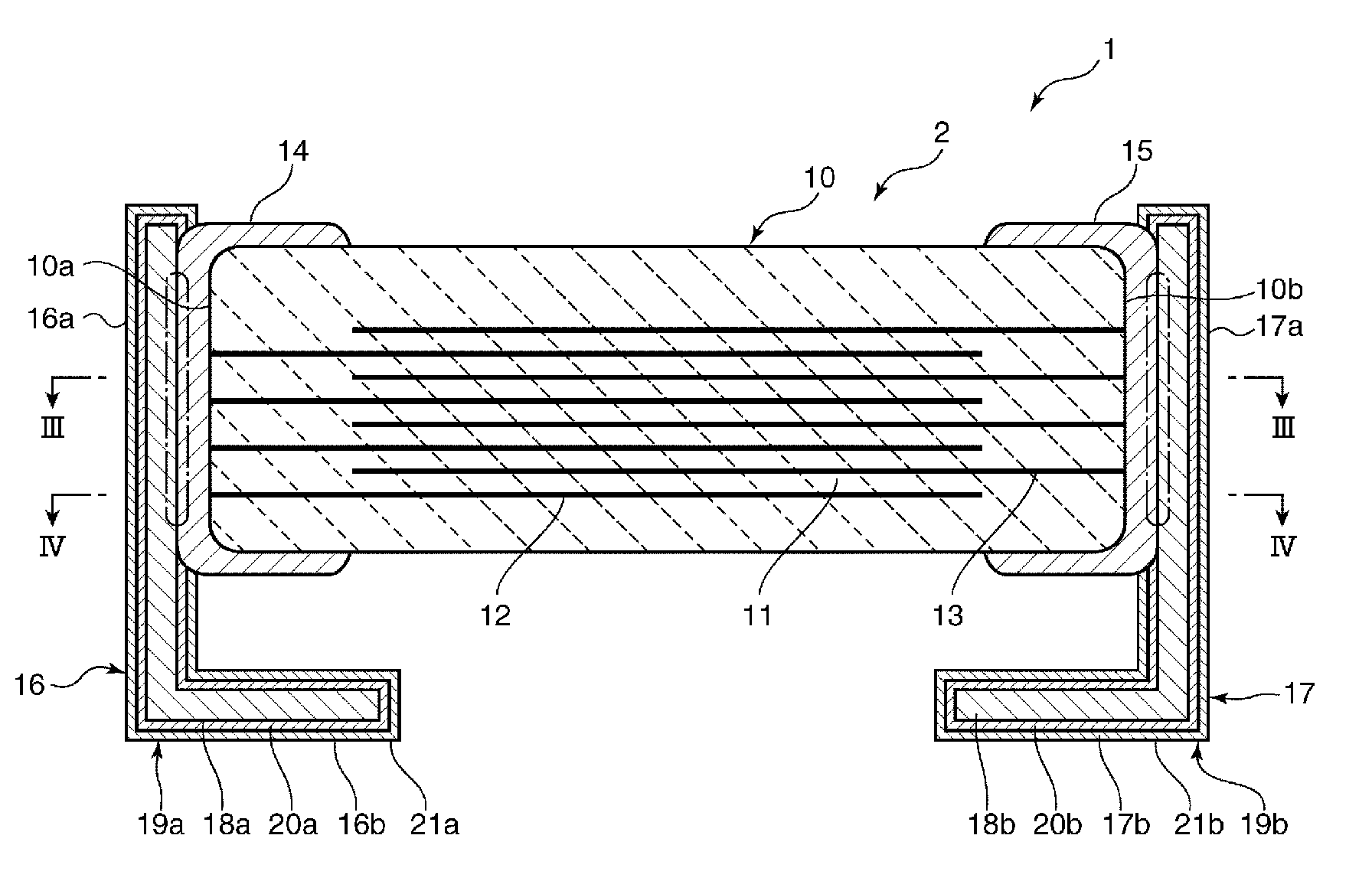

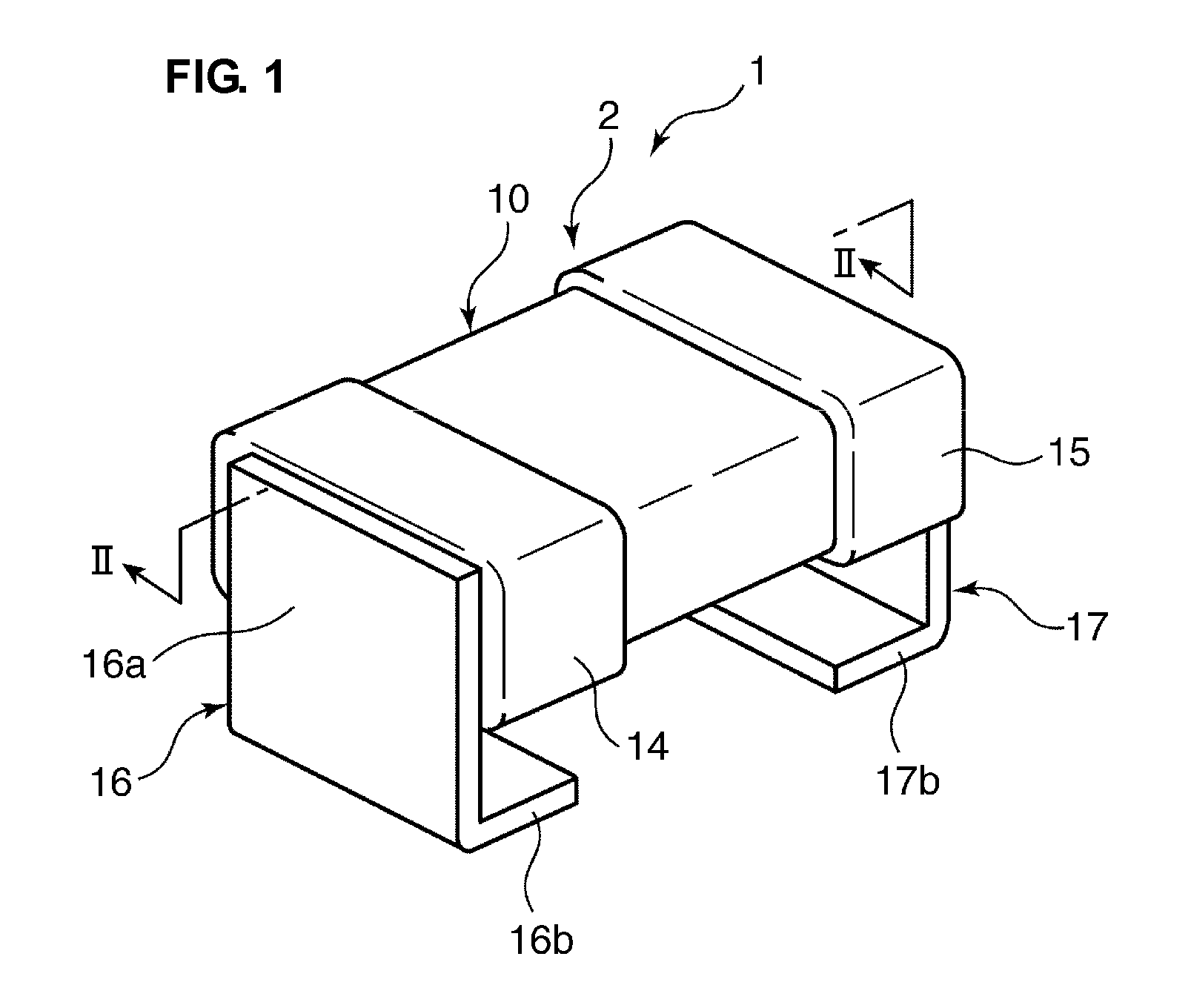

Ceramic electronic component and method for manufacturing the same

ActiveUS20090296311A1Improve reliabilityIncrease resistanceMultiple fixed capacitorsFixed capacitor dielectricMetal particleElectronic component

A ceramic electronic component has a ceramic element assembly, external electrodes, and metal terminals. The external electrodes are arranged on the surface of the ceramic element assembly. The external electrodes contain a sintered metal. The metal terminals are electrically connected to the external electrodes, respectively. The external electrode and the metal terminal are directly diffusion-bonded by diffusion of metal in the metal terminals into the external electrodes. The above arrangement provides a ceramic electronic component having highly reliable metal particle bonding and a method for manufacturing the same.

Owner:MURATA MFG CO LTD

Method of joining ceramics: reaction diffusion-bonding

InactiveUS20060162849A1Suitable characteristicMaintain structural integrityAfter-treatment detailsLamination ancillary operationsBond interfaceSolid solution

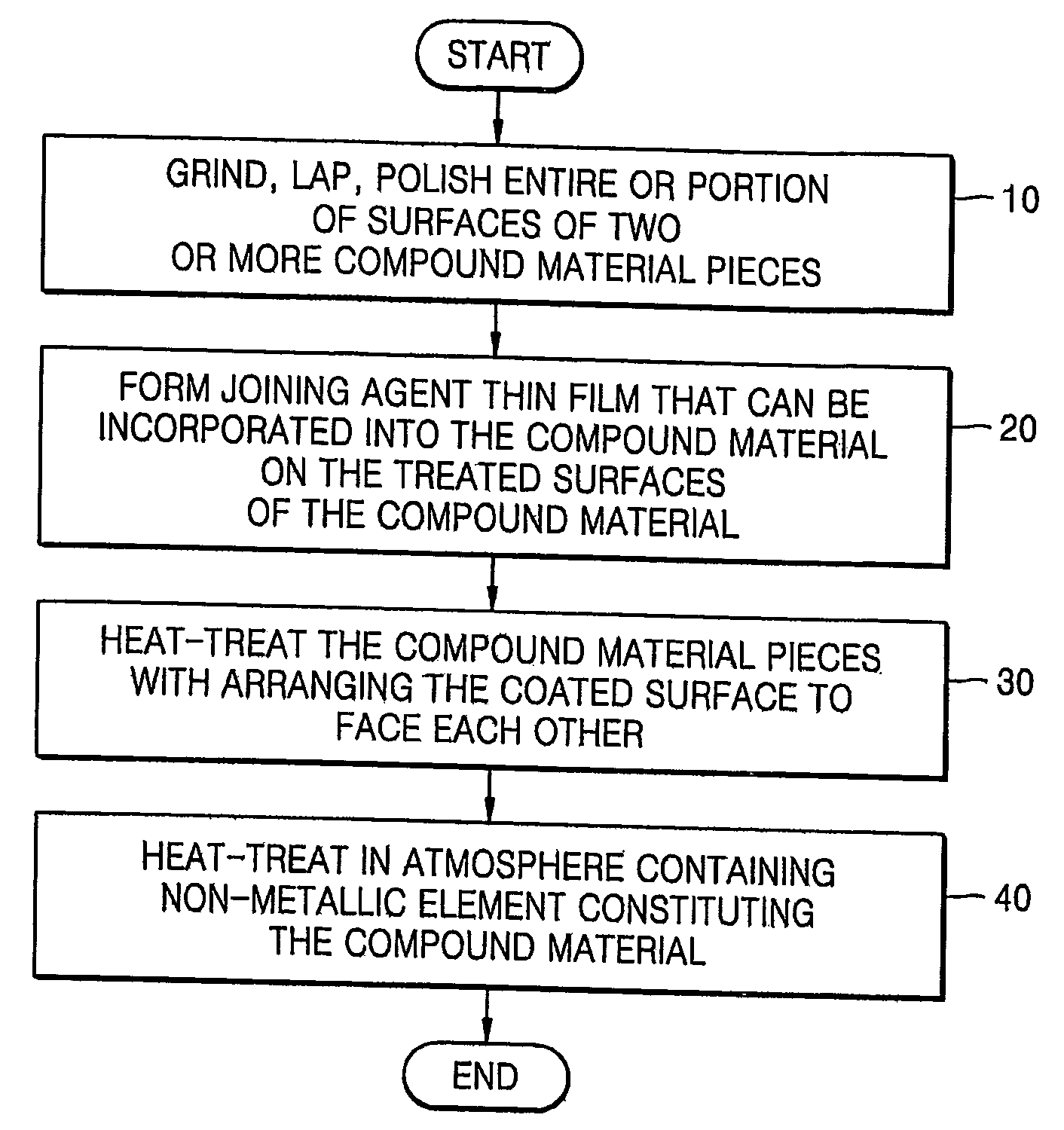

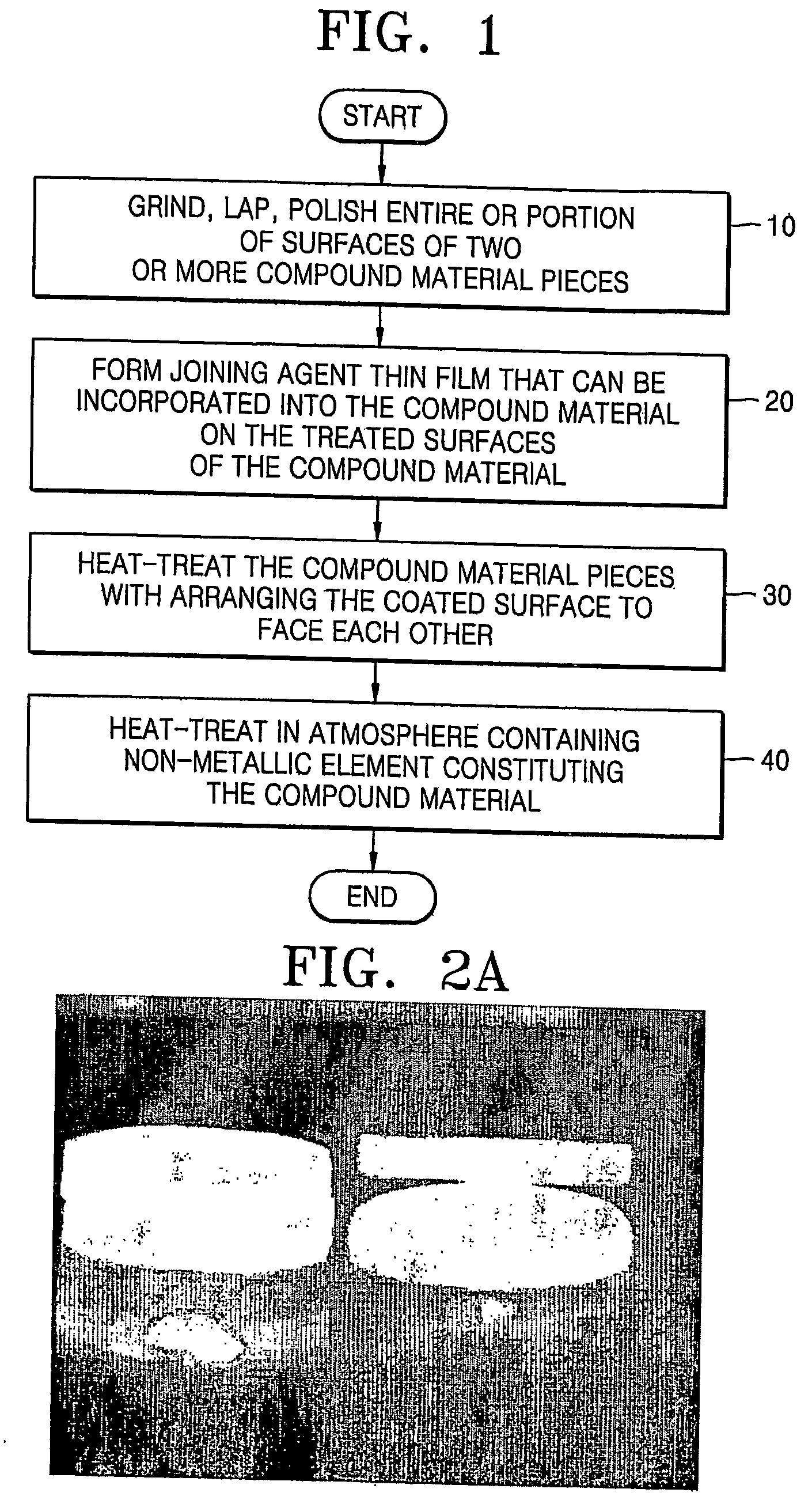

Provided is a method of joining compound materials such as ceramics. The method is a combination of diffusion bonding and reaction bonding, which is called reaction diffusion bonding (RDB). The method includes: grinding, lapping, or polishing entire or portions of surfaces to be joined of two or more pieces of a compound material; forming a thin film of a joining agent on one or more of the ground, lapped, or polished surfaces by one of inserting, spreading, depositing, plating, and coating, the joining agent being able to transform into the compound material by being incorporated into the compound material or by forming a solid solution with the compound material upon heat treating; and forming a directly bonded interface without a second phase by heat treating the pieces of the compound material with the to-be-joined surfaces on which the joining agent film is formed arranged to face each other, wherein the joining agent thin film is composed of a material selected from the group consisting of metals, metal organics, and metal compounds.

Owner:CERAWEL

Method for realizing gallium nitride ELD vertical structure using metal bounding process

InactiveCN101005110AImprove yieldAchieve preparationSemiconductor devicesOhmic contactGallium nitride

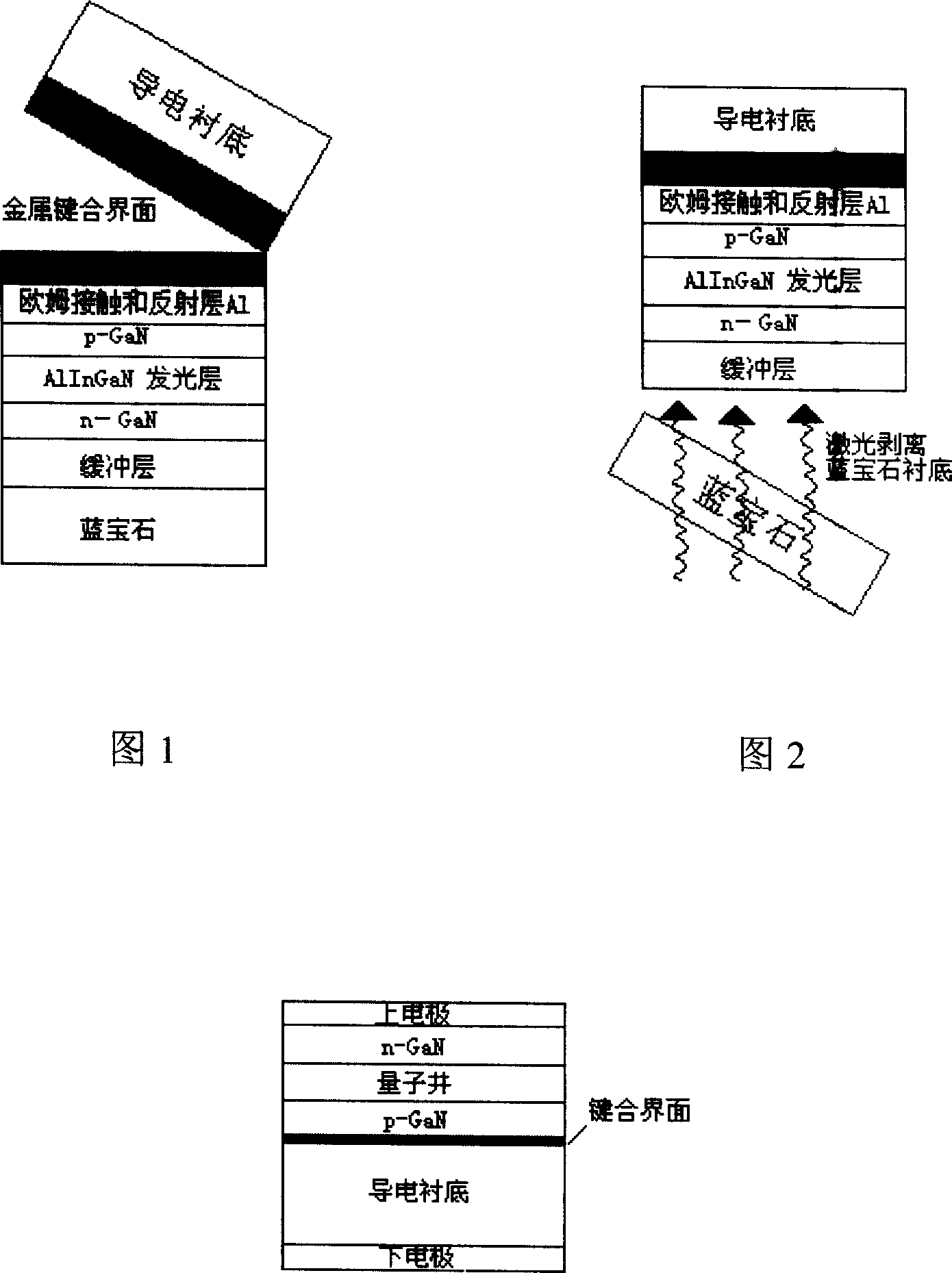

Using metal bonding technique in diffusion bonding form, the method bonds gallium nitride LED developed and prepared on sapphire and silicon chip in low resistance together, and realizes ohmic contact. Advantages are: stable bonding technique, high ratio of good produced parts, small area, using material of luminous layer fully, as well as good conductivity and heat conductivity of substrate.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

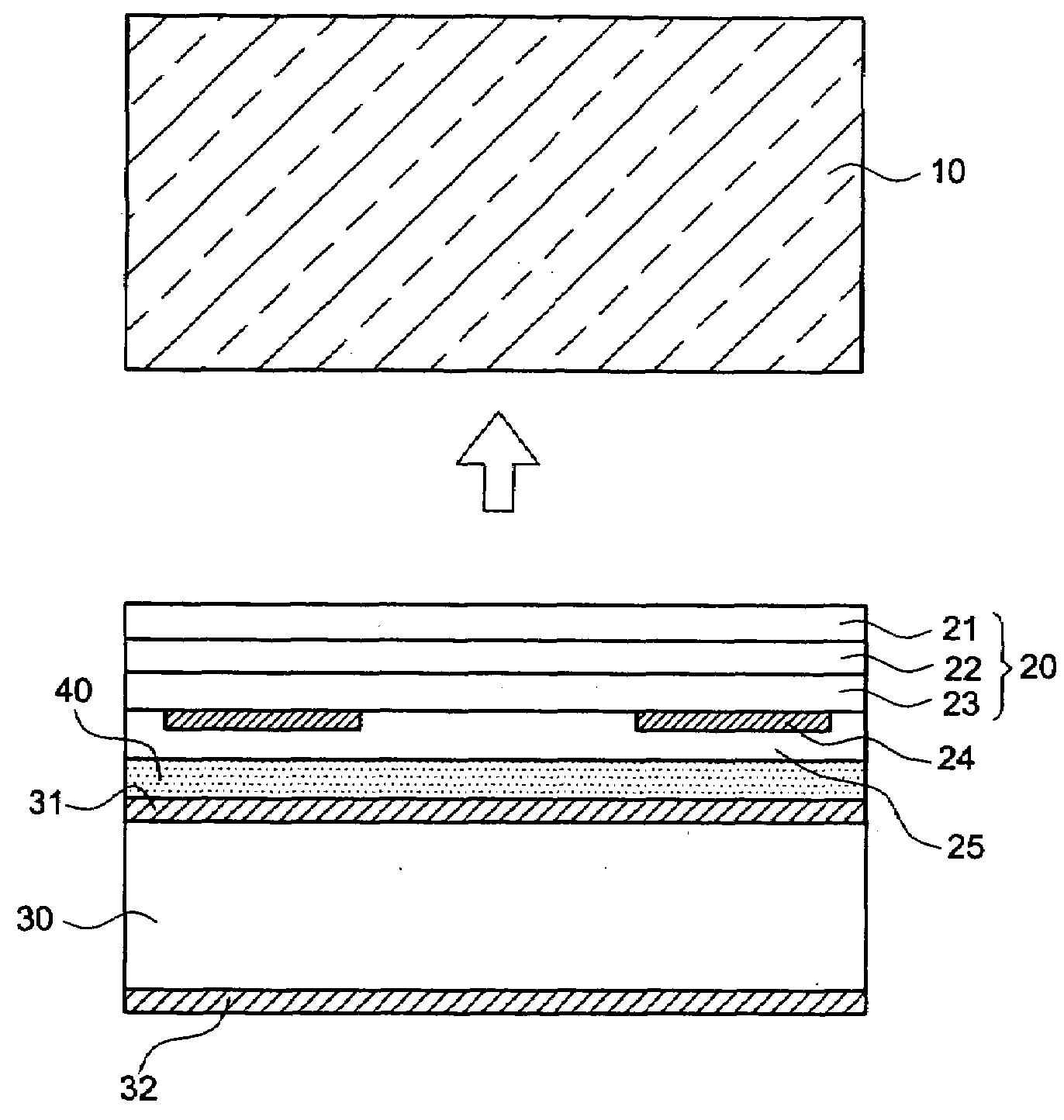

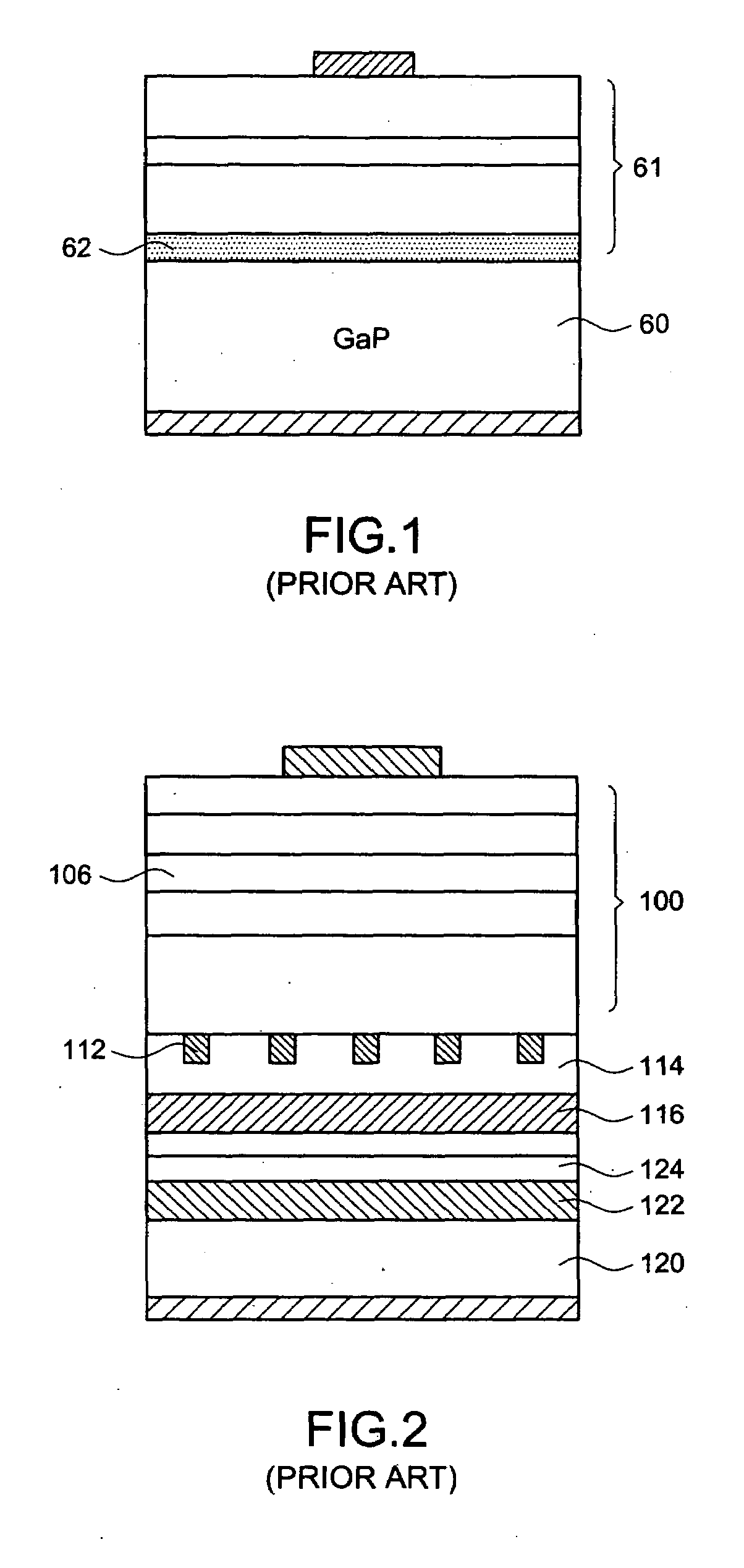

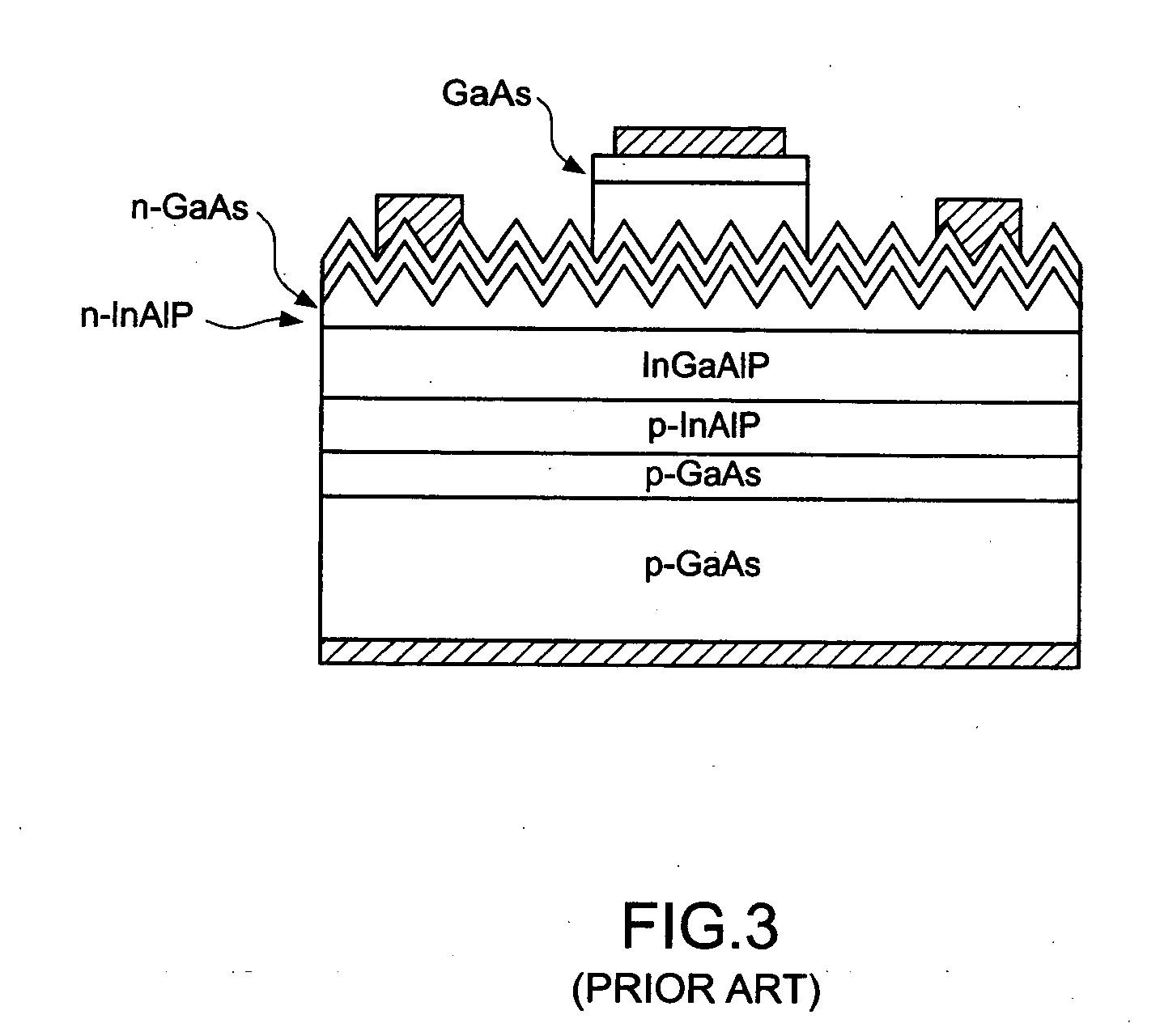

Light emitting diode by use of metal diffusion bonding technology and method of producing light emitting diode

InactiveUS20070194325A1Improve performanceSolid-state devicesSemiconductor/solid-state device manufacturingCompound (substance)Thermal expansion

The main objective of present invention is to provide a manufacturing method of light emitting diode that utilizes metal diffusion bonding technology. AlInGaP light emitting diode epitaxial structure on a temporary substrate is bonded to a permanent substrate having a thermal expansion coefficient similar to that of the epitaxial structure, and then the temporary substrate is removed to produce an LED having a vertical structure and better performance. The other objective of the present invention is to provide a high performance LED that uses metal diffusion technology and wet chemical etching technology to roughen the LED surface in order to improve light extraction efficiency.

Owner:ARIMA OPTOELECTRONICS

Electrochemical fuel cell component materials and methods of bonding electrochemical fuel cell components

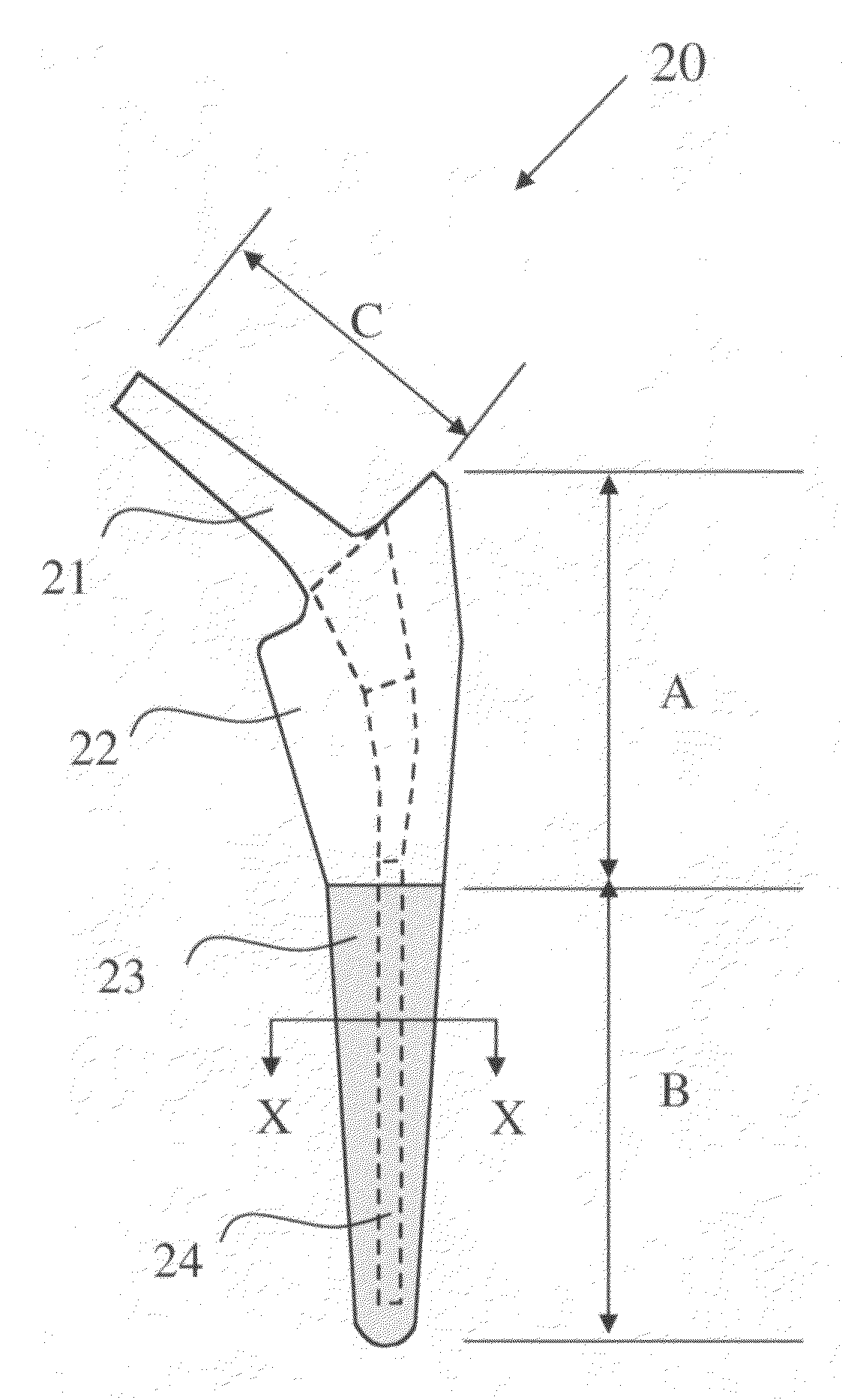

A method of producing a porous flow field material for a bipolar separator plate is provided. The method includes bonding a single layer of wire mesh or bonding together at least two layers of wire mesh to form a porous flow field material, wherein the bonding is achieved by diffusion bonding, continuous resistance welding, continuous sintering, or a combination thereof. Such porous flow filed materials may function as, for example, fluid flow fields, current collectors, gas distribution layers, and / or coolant layers. A method of producing a bipolar separator plate including such porous flow field materials is also provided, wherein the component layers are bonded together by diffusion bonding, continuous resistance welding, continuous sintering, or a combination thereof, thereby forming a bipolar separator plate.

Owner:MARTIN KURZ & CO

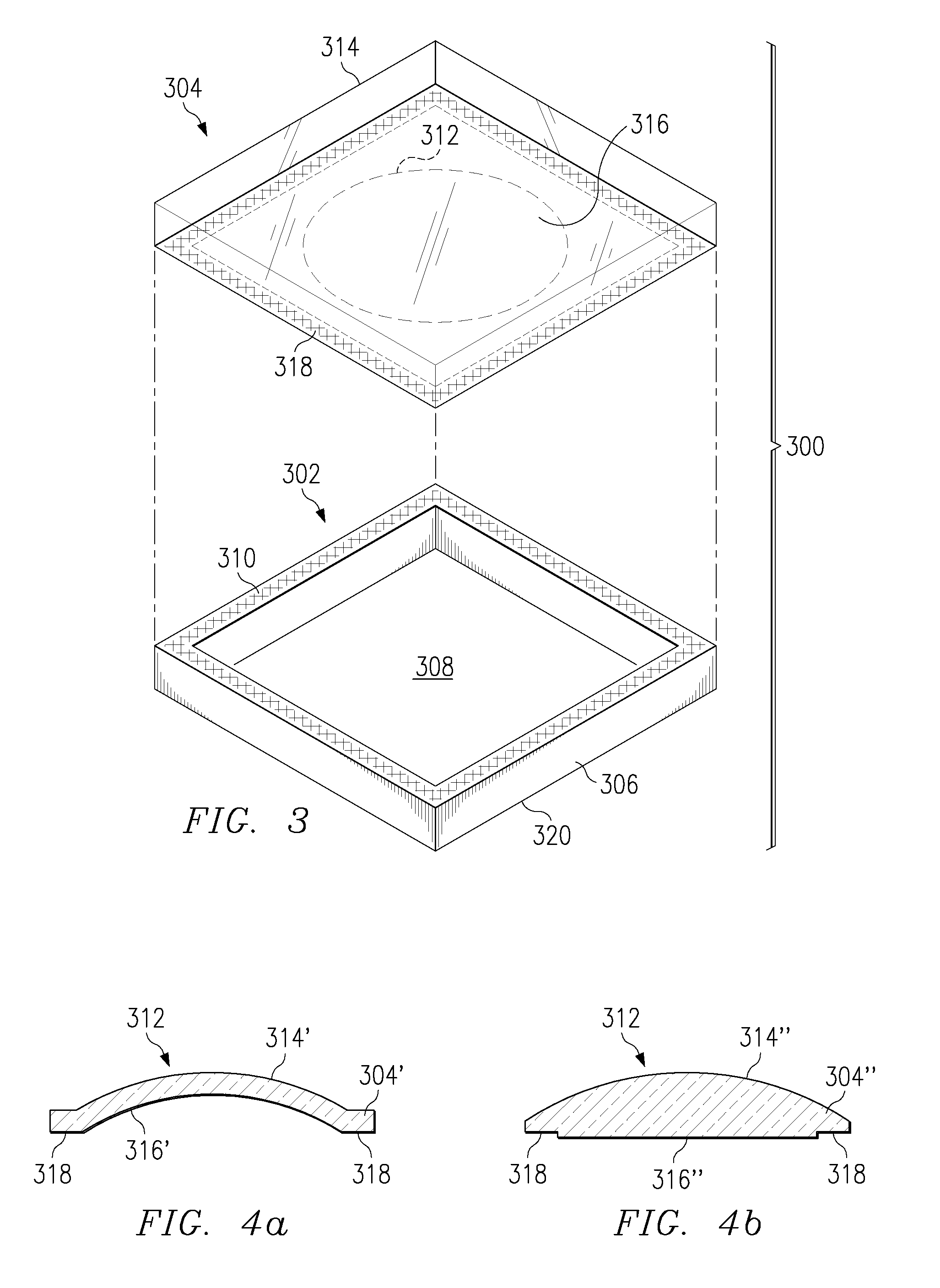

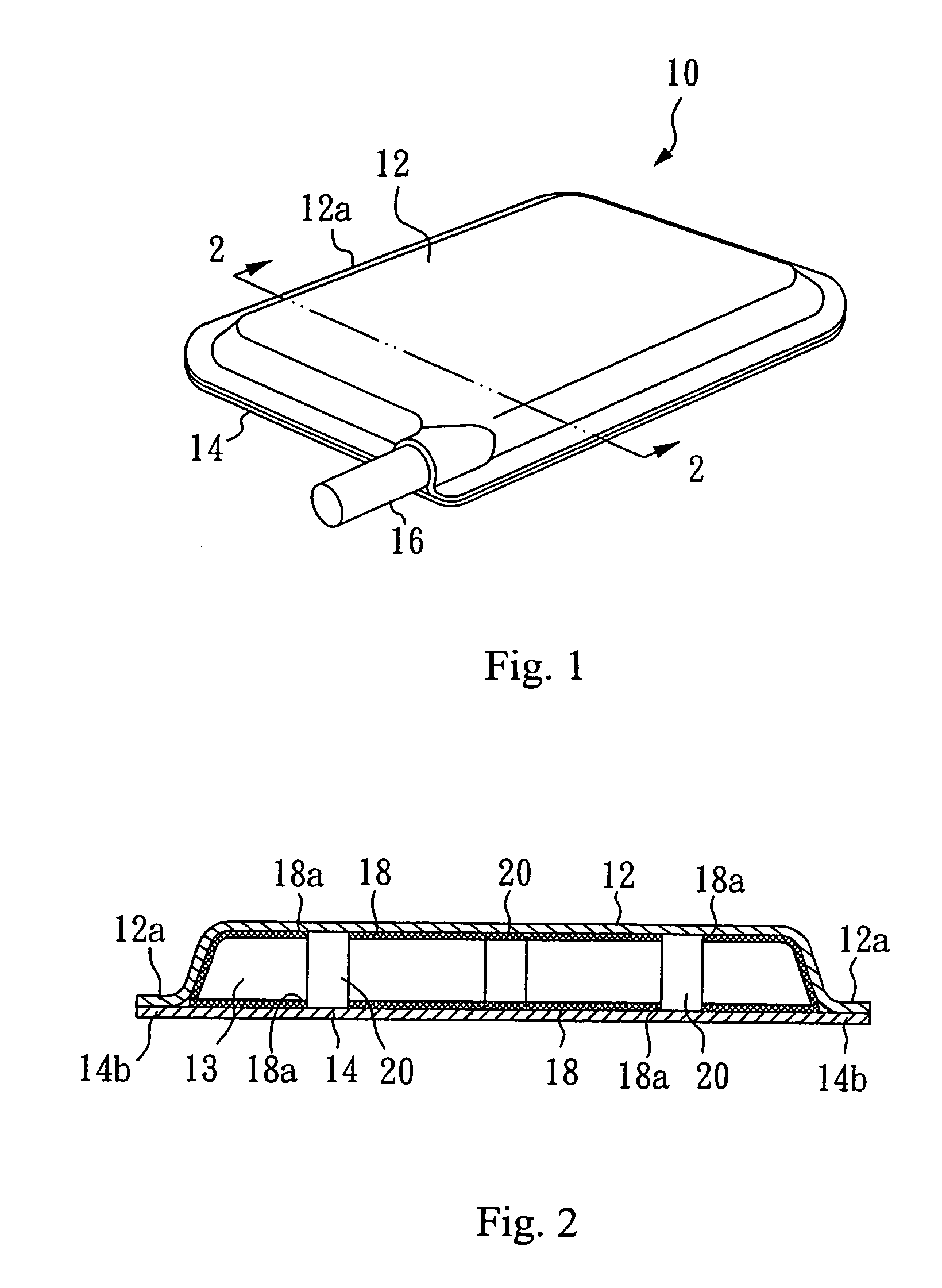

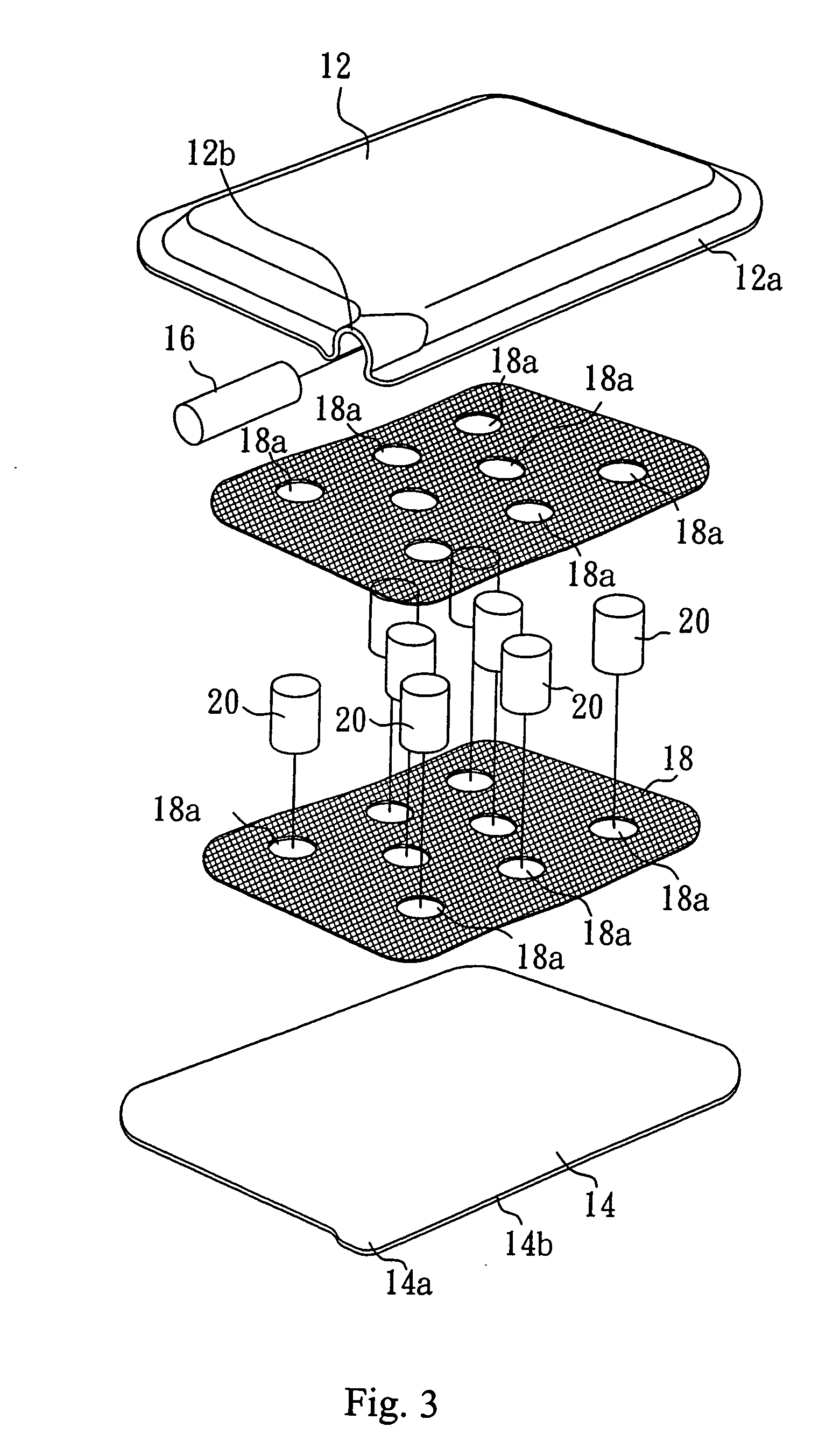

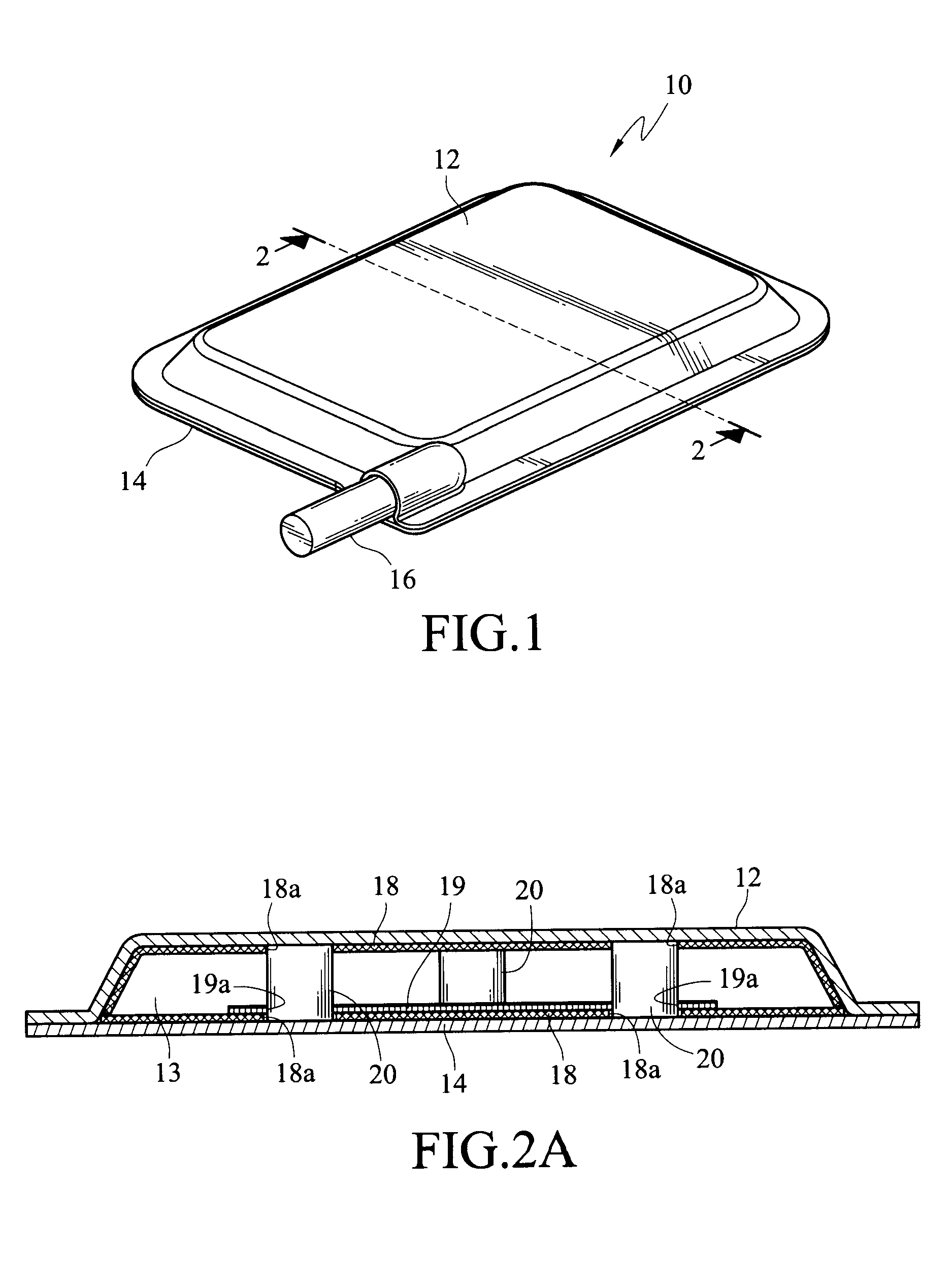

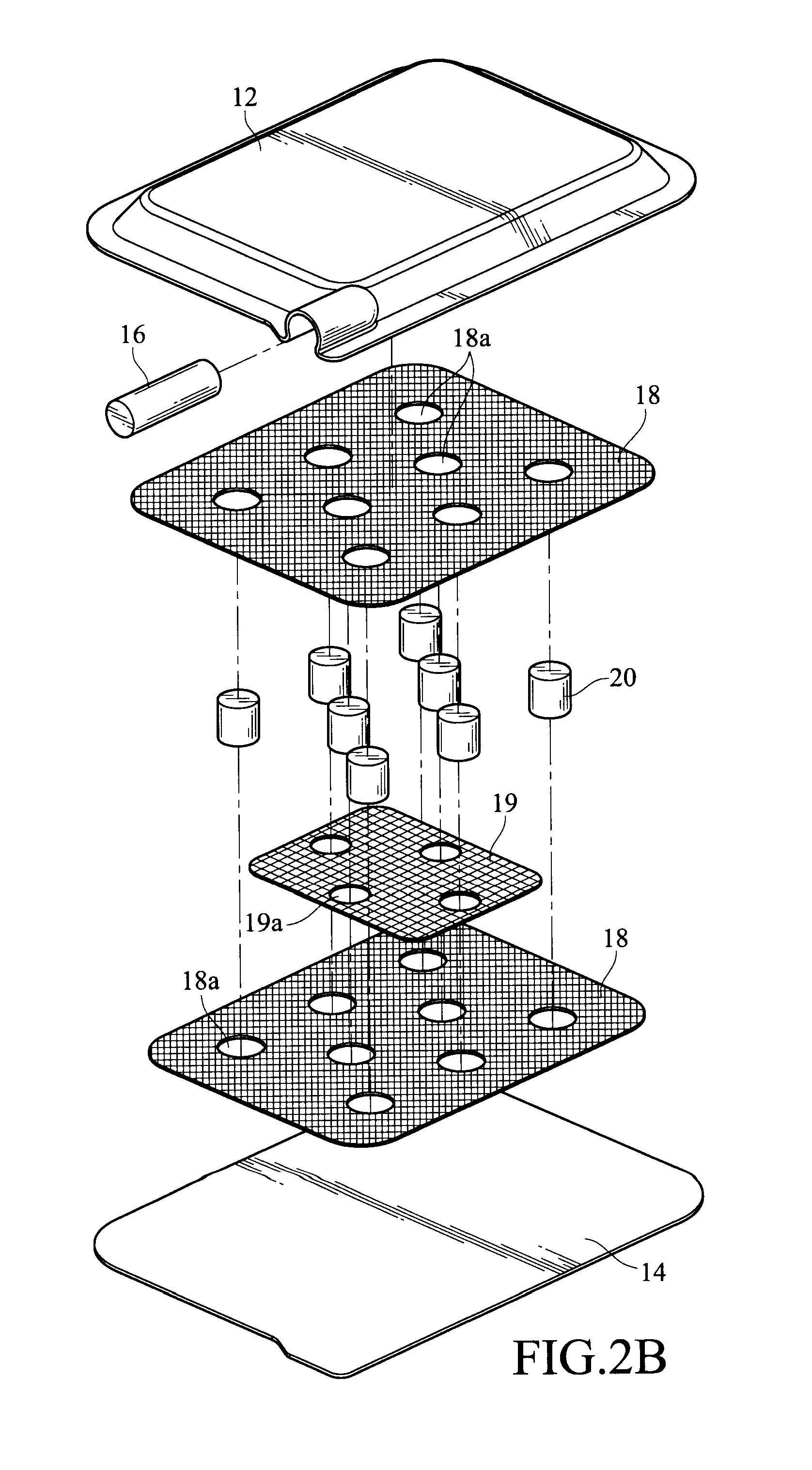

Bendable heat spreader with metallic wire mesh-based microstructure and method for fabricating same

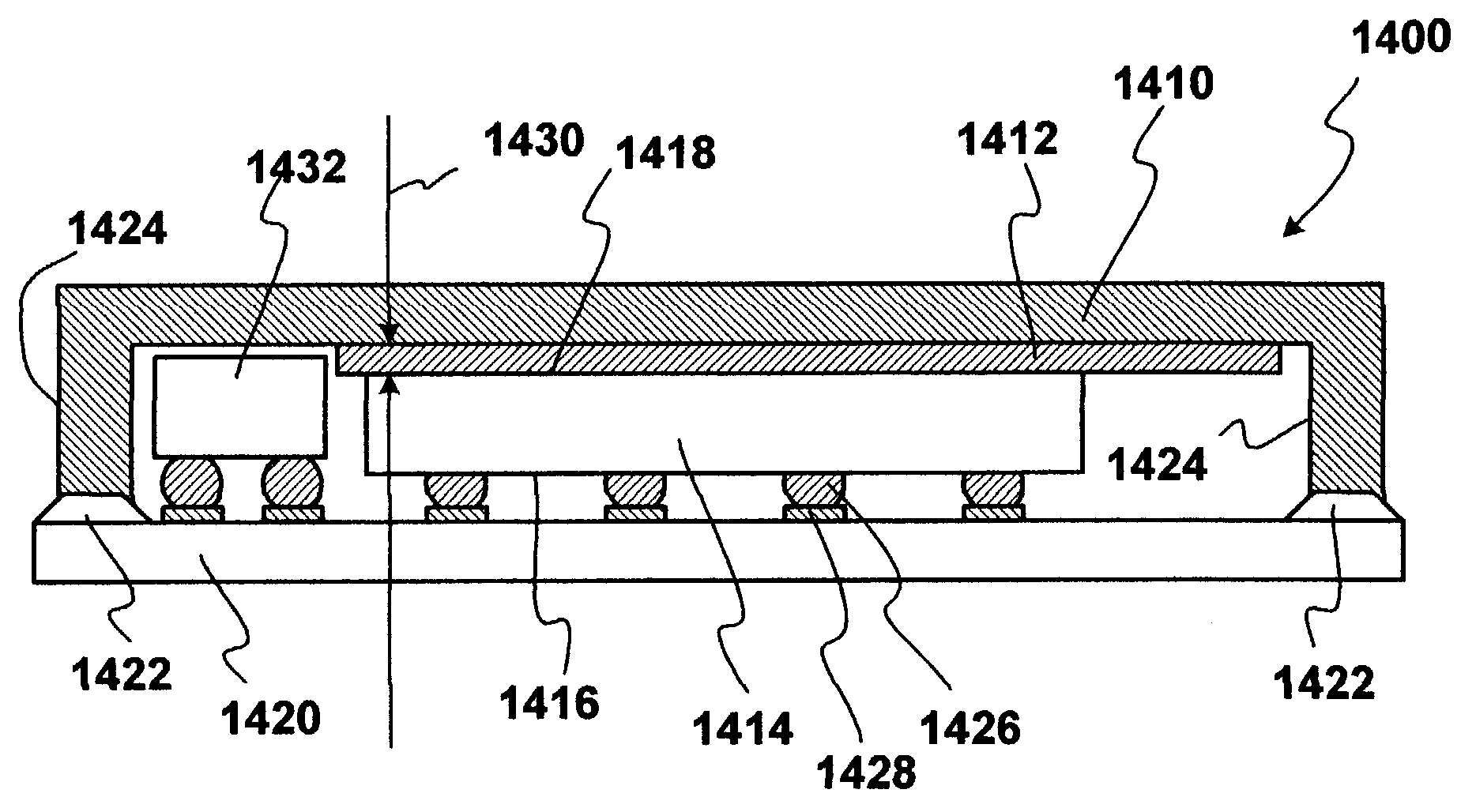

InactiveUS20060098411A1Semiconductor/solid-state device detailsMetal-working apparatusBond interfaceWorking fluid

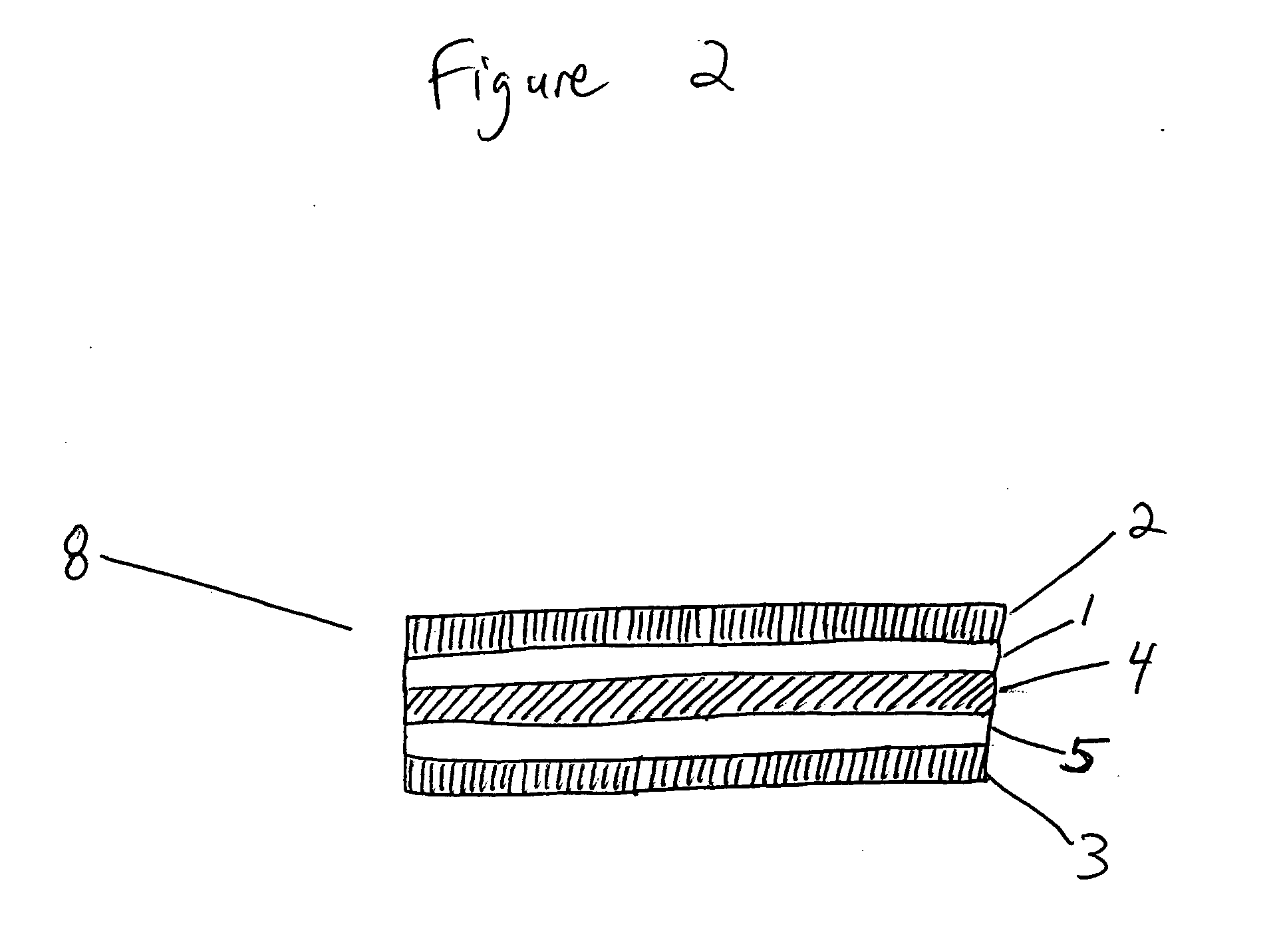

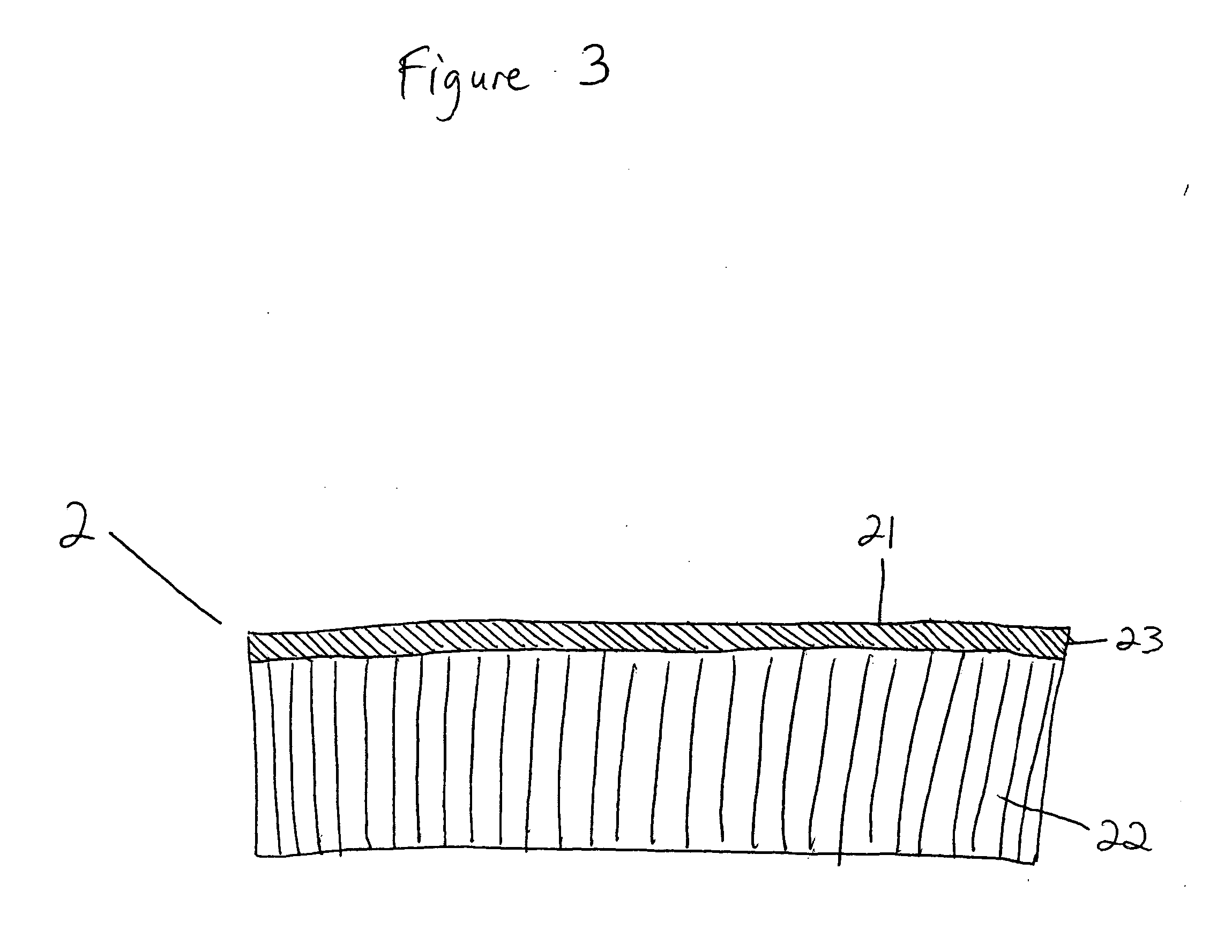

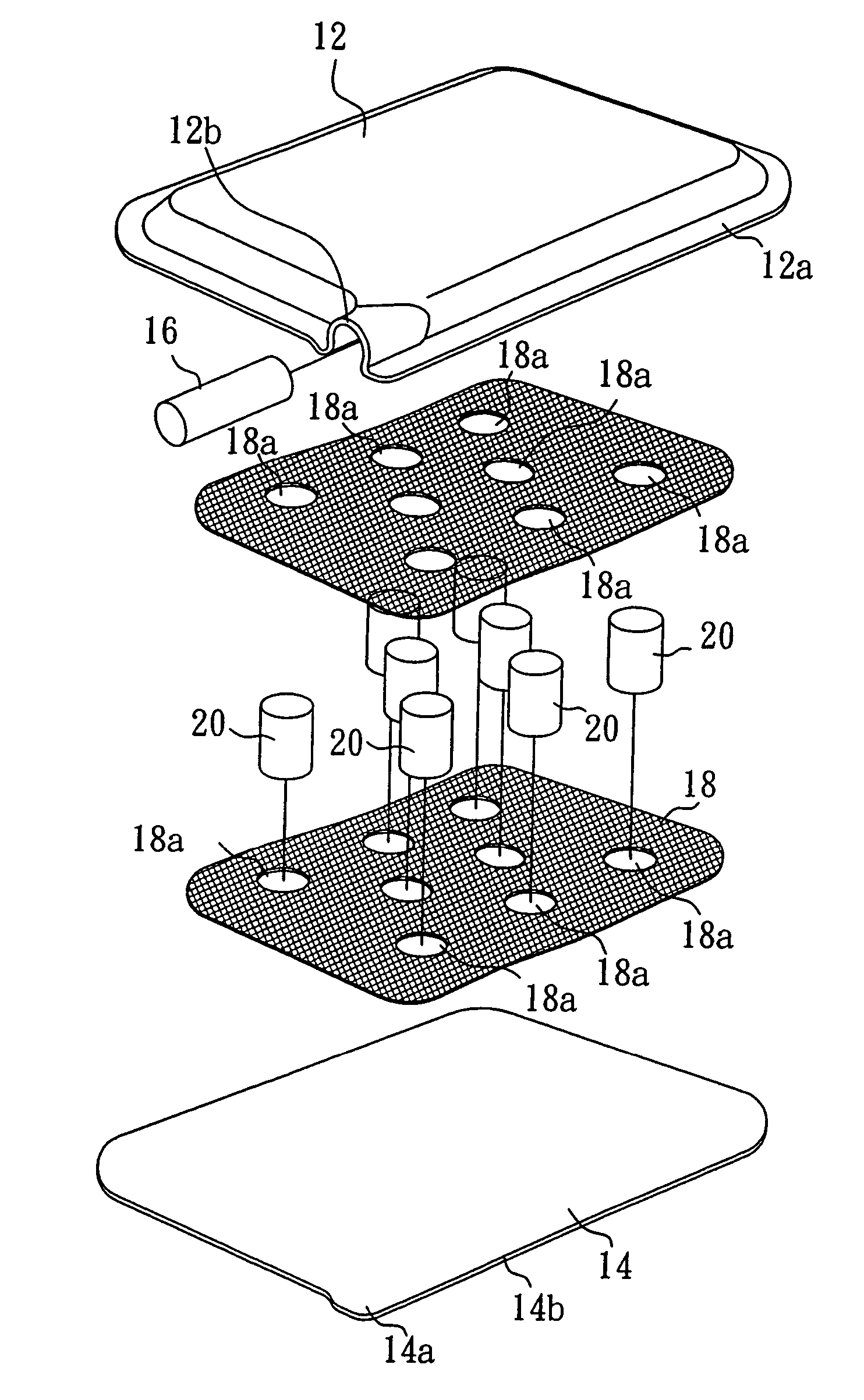

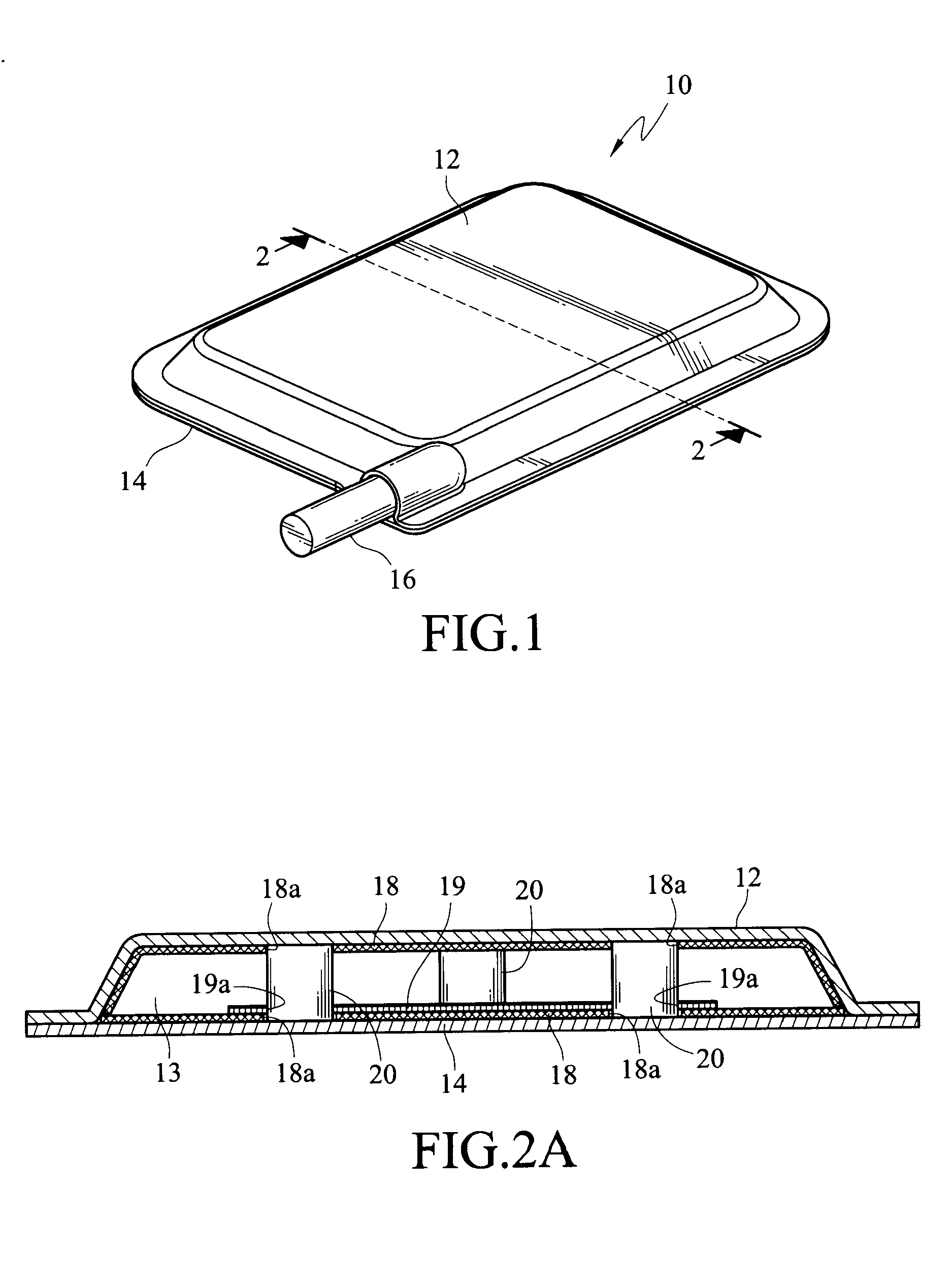

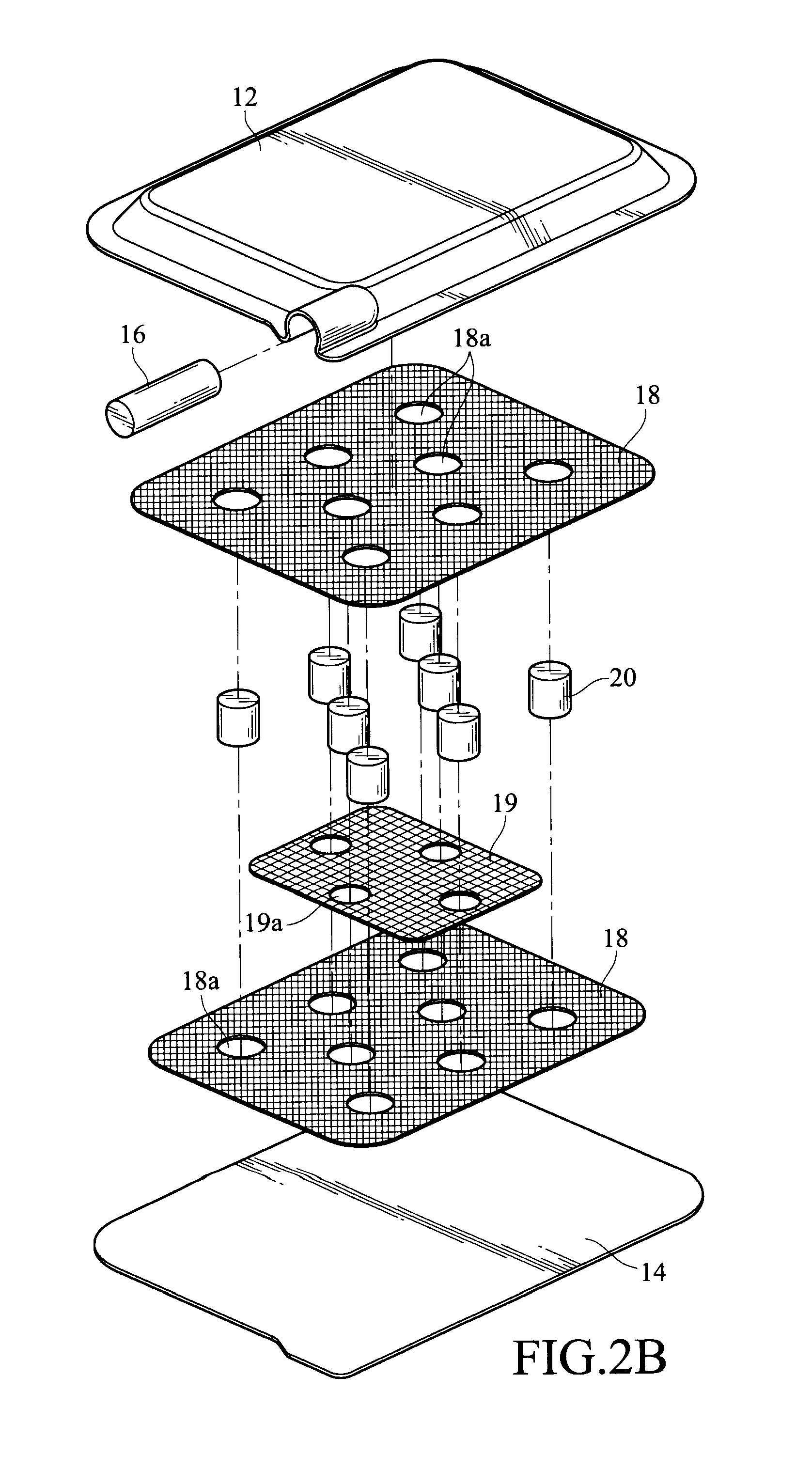

The present invention discloses a heat spreader and method for making the heat spreader. The heat spreader comprises: a hollow metallic housing including an upper cover having an inner surface and a lower cover having an inner surface, the upper and lower covers being bonded together along their perimeters defining a cavity; a capillary structure in a form of metallic meshes bonded to the inner surfaces of the upper and lower covers of the metallic housing; a plurality of reinforcing members disposed in the cavity and bonded between the inner surfaces of the upper and lower covers of the metallic housing; and a working fluid receive in the cavity; wherein bonded surfaces between the metallic meshes and the inner surfaces of the metallic housing, the upper cover and the lower cover, and the reinforcing members and the inner surfaces of the metallic housing all are diffusion-bonded interfaces.

Owner:TAIWAN MICROLOOPS CORP

Preform and method of repairing nickel-base superalloys and components repaired thereby

InactiveUS20060134454A1Minimize distortionEasy to crackBlade accessoriesSolid state diffusion coatingPowder mixtureWear resistant

A process for repairing a turbine component of a turbomachine, as well as a sintered preform used in the process and a high gamma-prime nickel-base superalloy component repaired thereby. The sintered preform contains a sintered mixture of powders of a cobalt-base braze alloy and a cobalt-base wear-resistant alloy. The braze alloy constitutes at least about 10 up to about 35 weight percent of the sintered preform and contains a melting point depressant such as boron. The preform is formed by mixing powders of the braze and wear-resistant alloys to form a powder mixture, and then sintering the powder mixture. To use the preform, a surface portion of the turbine component is removed to expose a subsurface portion, followed by diffusion bonding of the preform to the subsurface portion to form a wear-resistant repair material containing the braze alloy dispersed in a matrix of the wear-resistant alloy.

Owner:GENERAL ELECTRIC CO

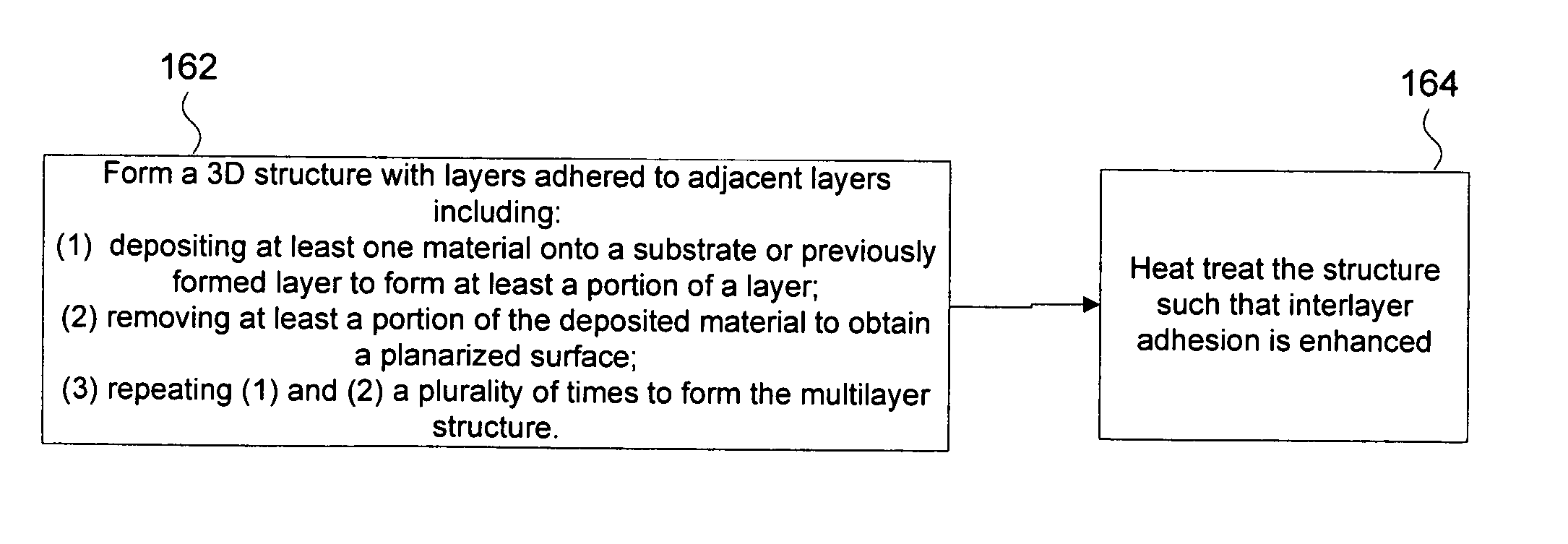

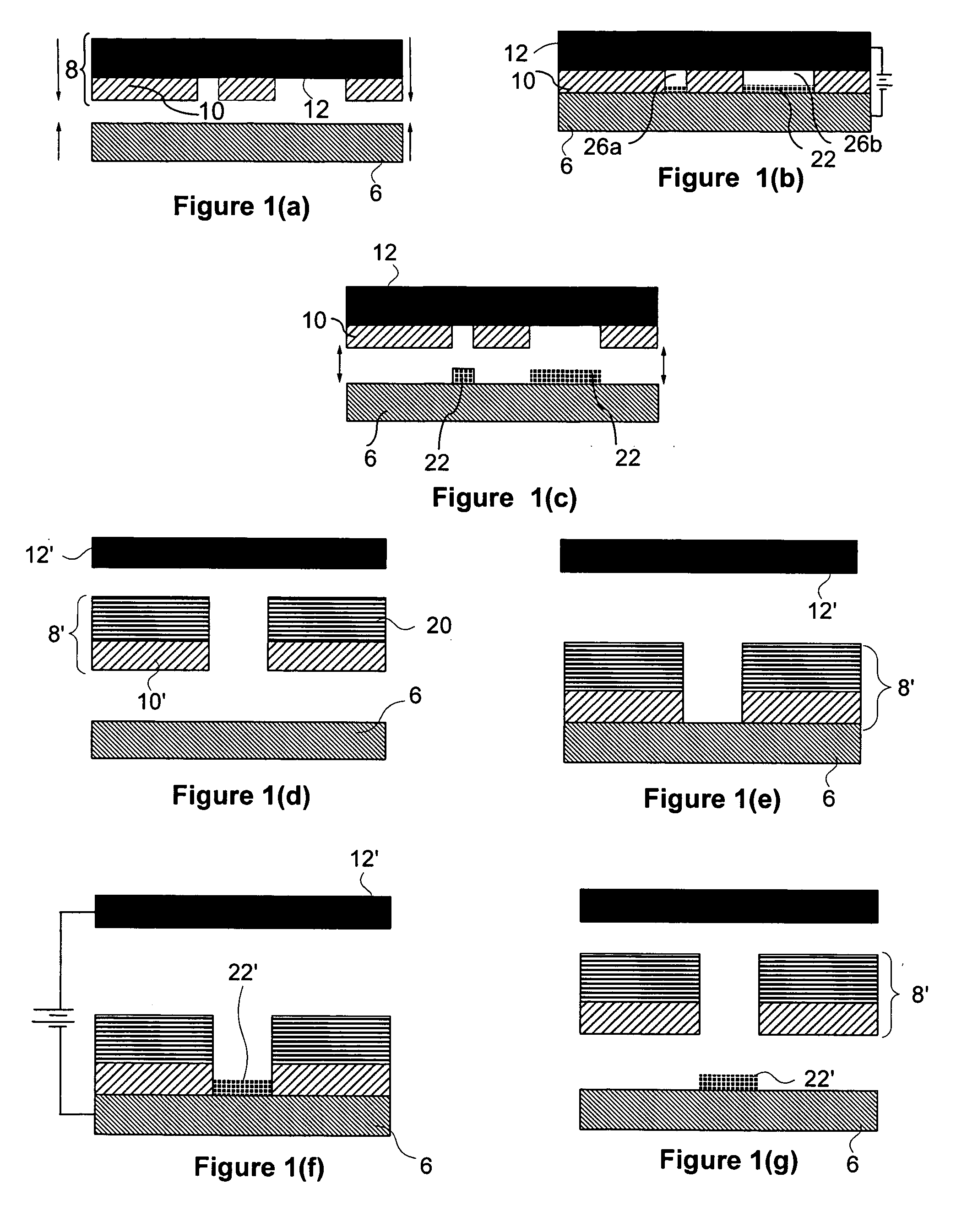

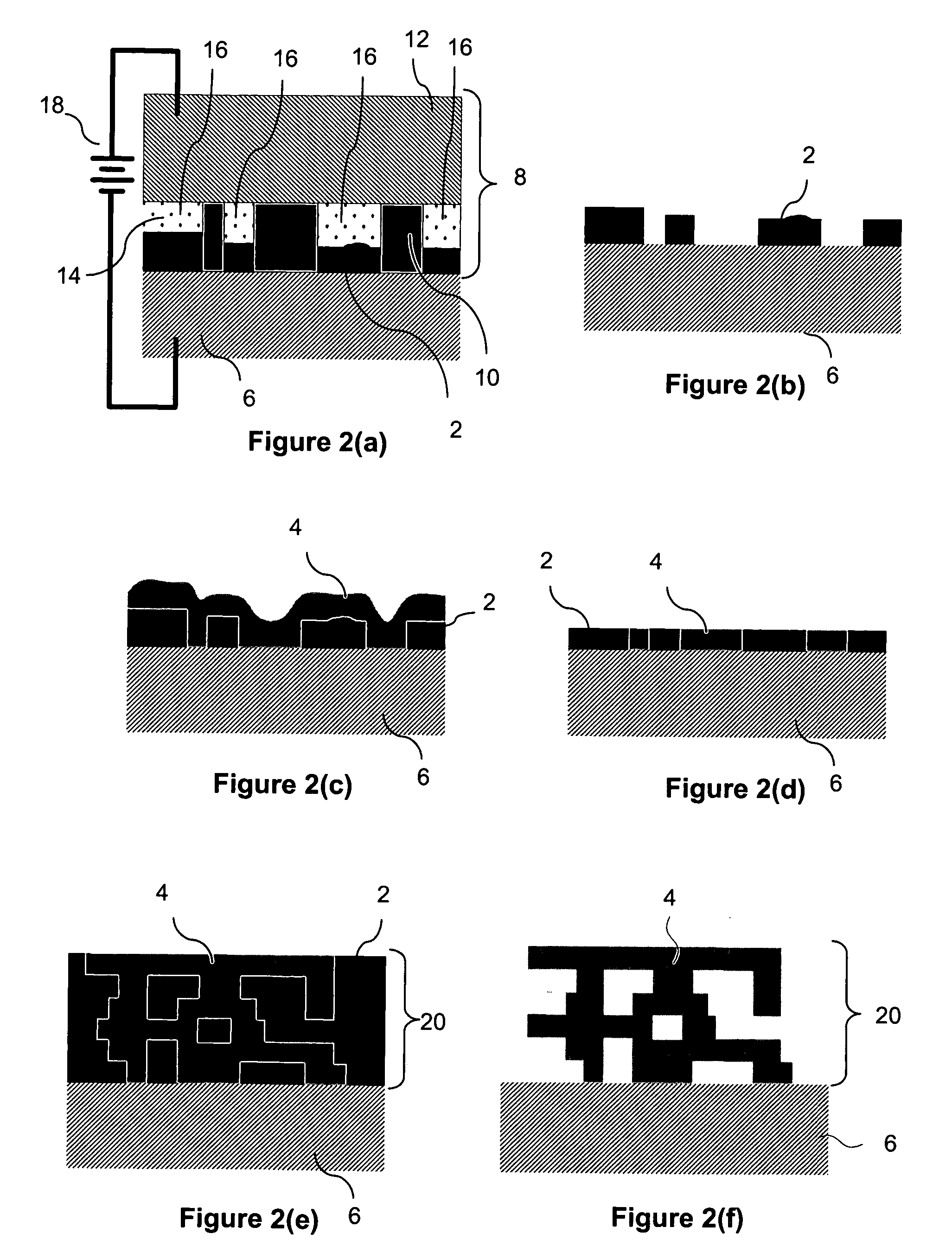

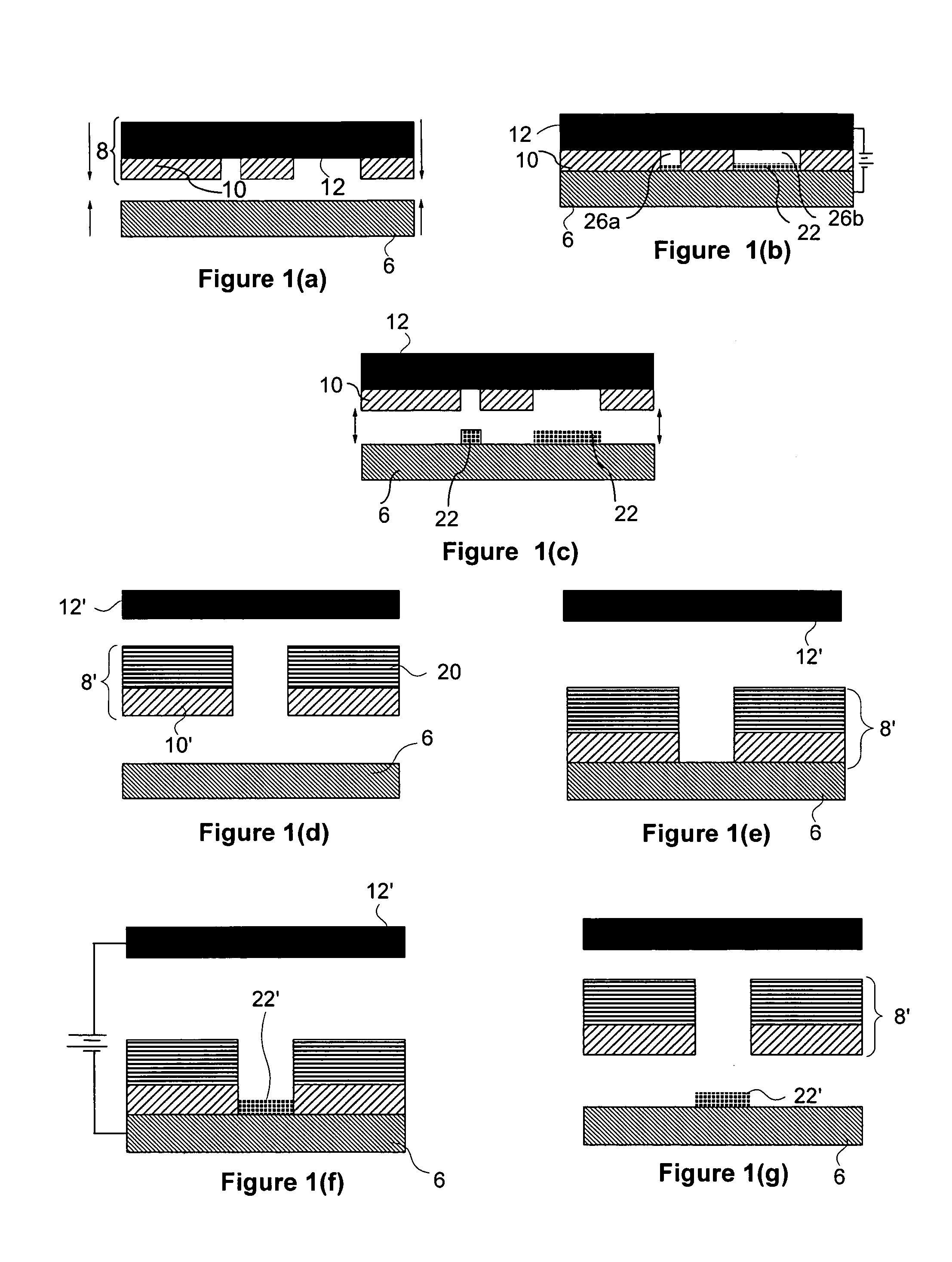

Method of electrochemically fabricating multilayer structures having improved interlayer adhesion

InactiveUS20050029109A1Improve propertiesImprove interlayer adhesionSemiconductor/solid-state device manufacturingConductive pattern reinforcementReducing atmosphereHeat treating

Multi-layer microscale or mesoscale structures are fabricated with adhered layers (e.g. layers that are bonded together upon deposition of successive layers to previous layers) and are then subjected to a heat treatment operation that enhances the interlayer adhesion significantly. The heat treatment operation is believed to result in diffusion of material across the layer boundaries and associated enhancement in adhesion (i.e. diffusion bonding). Interlayer adhesion and maybe intra-layer cohesion may be enhanced by heat treating in the presence of a reducing atmosphere that may help remove weaker oxides from surfaces or even from internal portions of layers.

Owner:UNIV OF SOUTHERN CALIFORNIA

Heat spreader with composite micro-structure

InactiveUS20070295486A1Capillarity is enhancedLow flow resistanceIndirect heat exchangersHeat exchange apparatusMicro structureWorking fluid

A heat spreader comprising a casing, a micro-structure layer, a support device, and a working fluid is provided. The casing has an inner surface and is defined by a sealed chamber where the working fluid circulates therein. The micro-structure layer is formed on the inner surface of the casing, wherein the micro-structure layer comprises a first structure layer which is formed by the first metallic mesh. Specifically, the first metallic mesh forms the first structure layer on the inner surface through diffusion bonding so that the working fluid can circulate within the micro-structure layer by capillary action. In addition, the support device is disposed in the sealed chamber for supporting the casing. Thus, a heat spreader with a composite micro-structure can not only enhance the capillarity but also reduce the flowing resistance during operation.

Owner:TAIWAN MICROLOOPS CORP

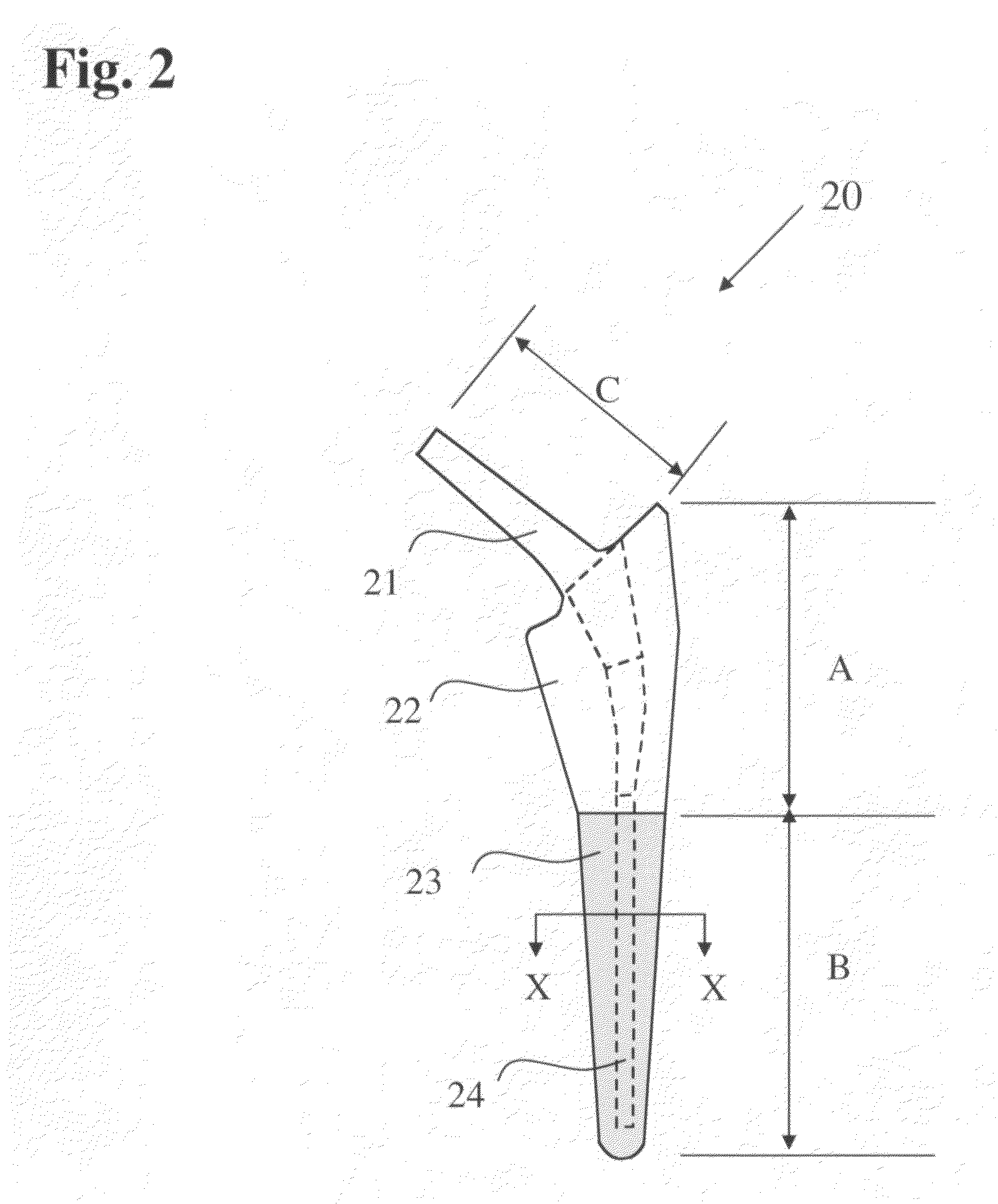

Bone-compliant femoral stem

A femoral stem for canines or humans is made bone-compliant by use of a thick sintered titanium body in a proximal bone contacting region and a polymeric or ceramic body in a distal bone contacting region of the femoral stem. An elastic modulus is thereby engineered to match that of bone tissue. The porous sintered titanium body is created by sintering spheres of titanium. It is bonded to a central solid biocompatible metallic body by diffusion bonding. The distal region has a biocompatible polymeric body or biocompatible cement body. When compression molded the distal region develops an elastic modulus matching that of bone tissue. The proximal region has a porosity designed to encourage bone ingrowth.

Owner:SIDEBOTHAM CHRISTOPHER G

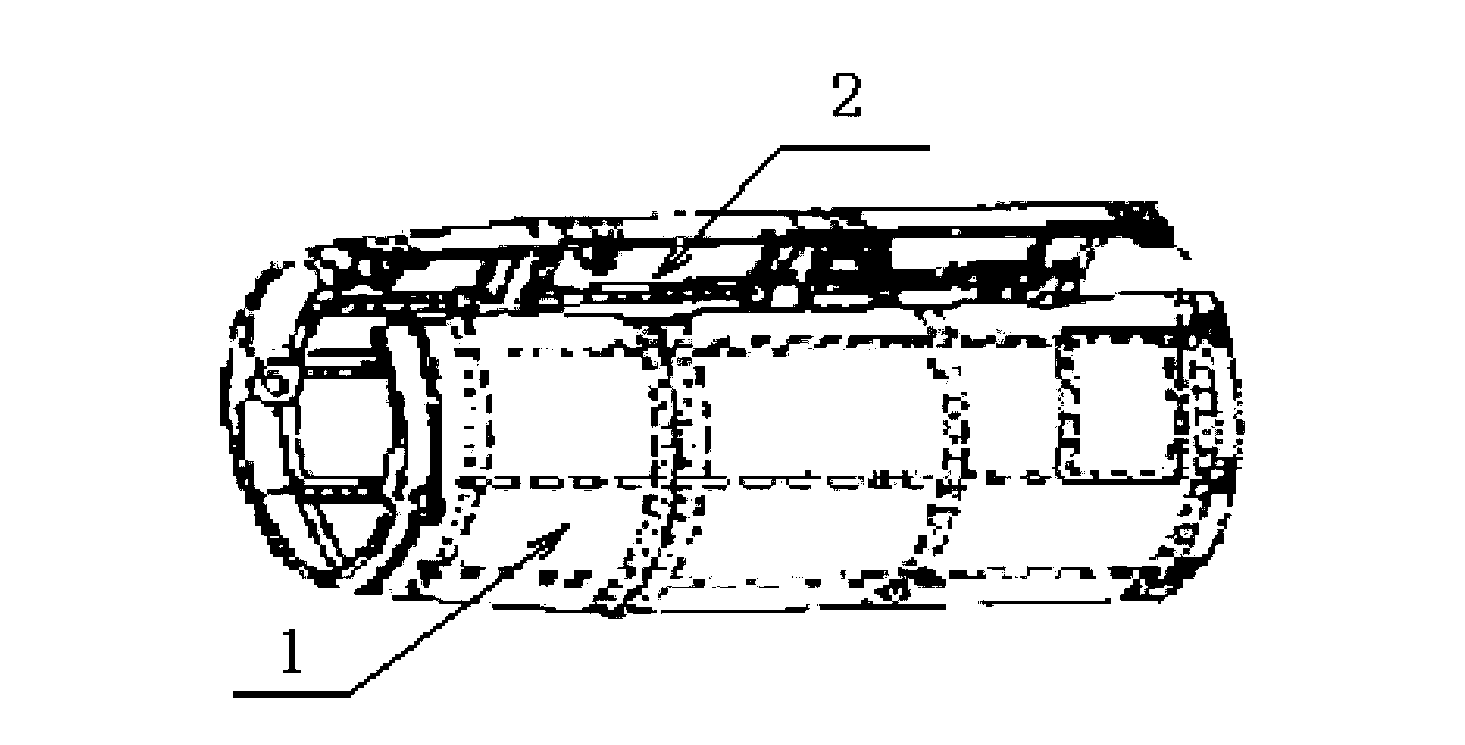

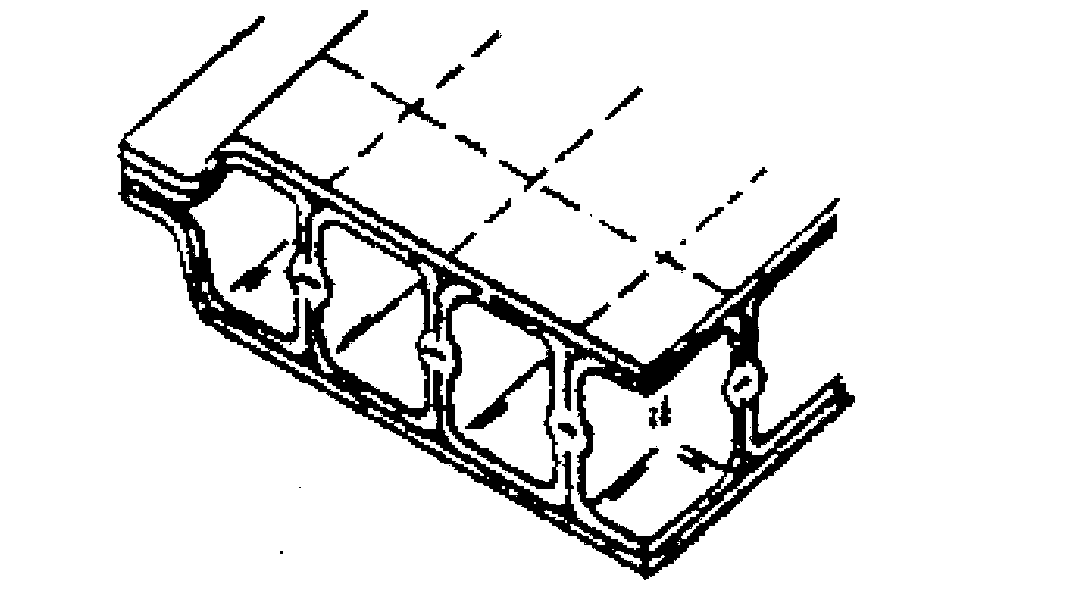

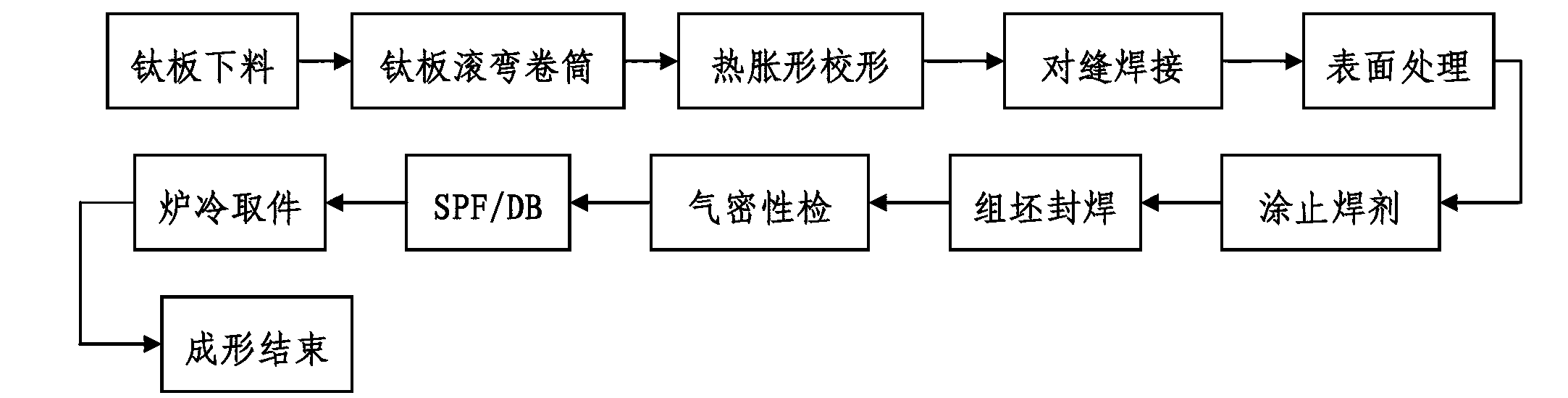

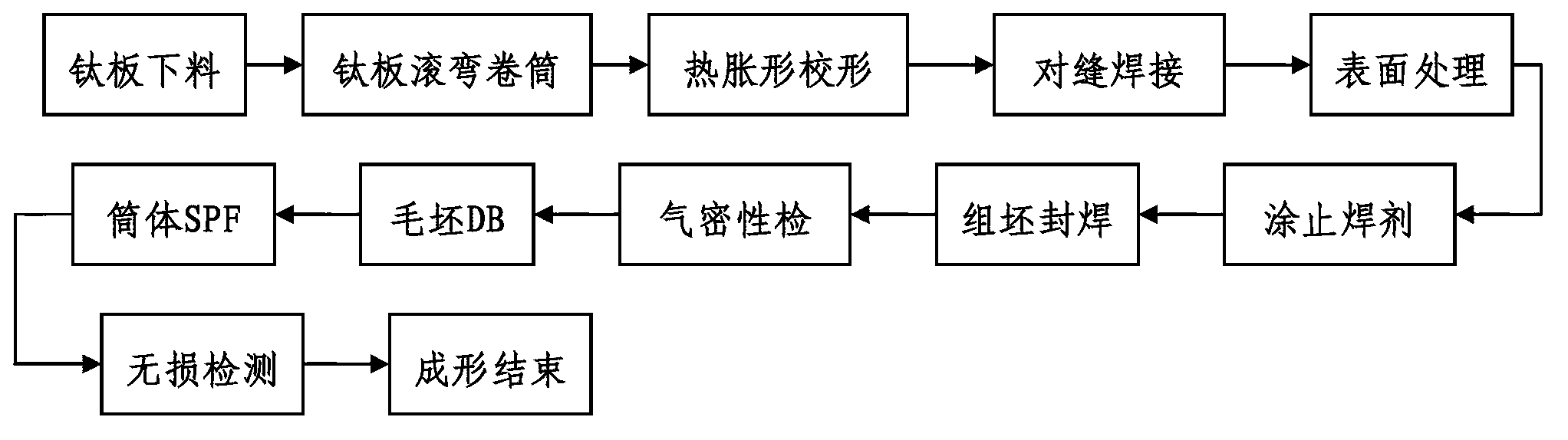

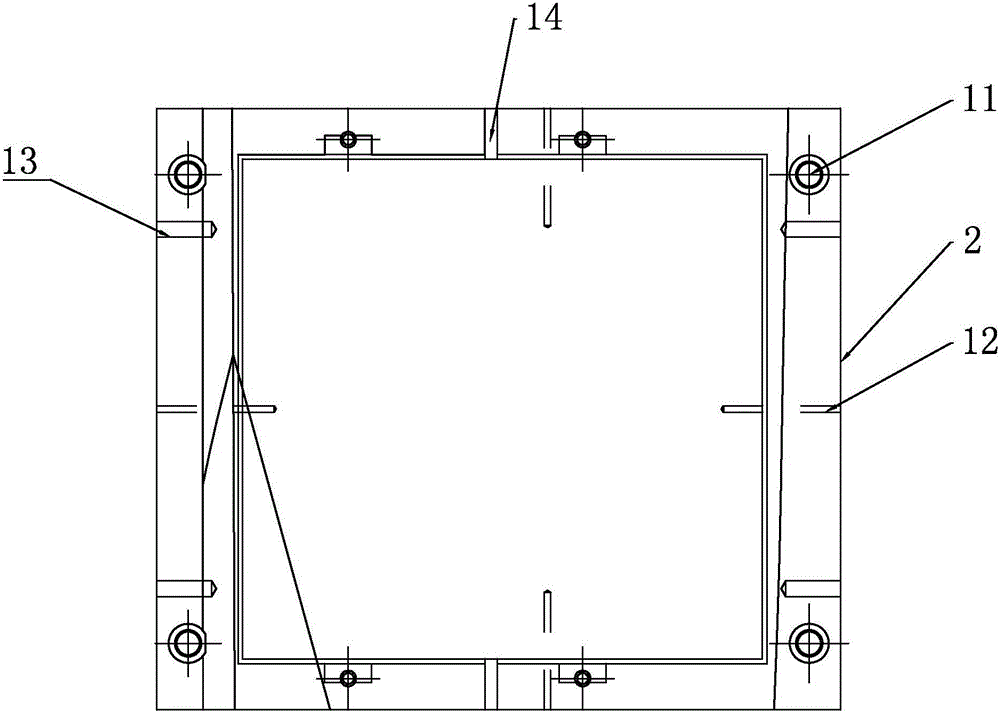

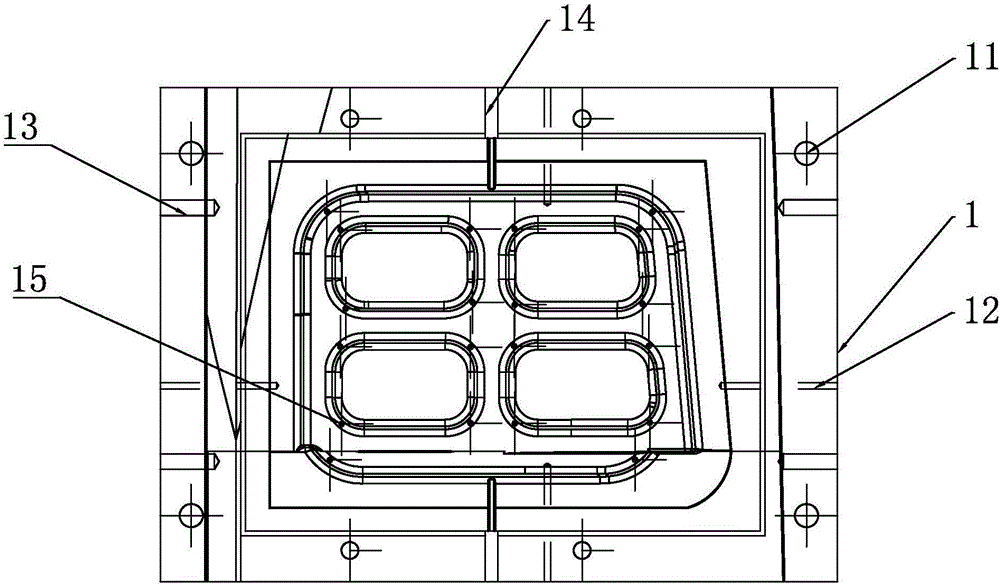

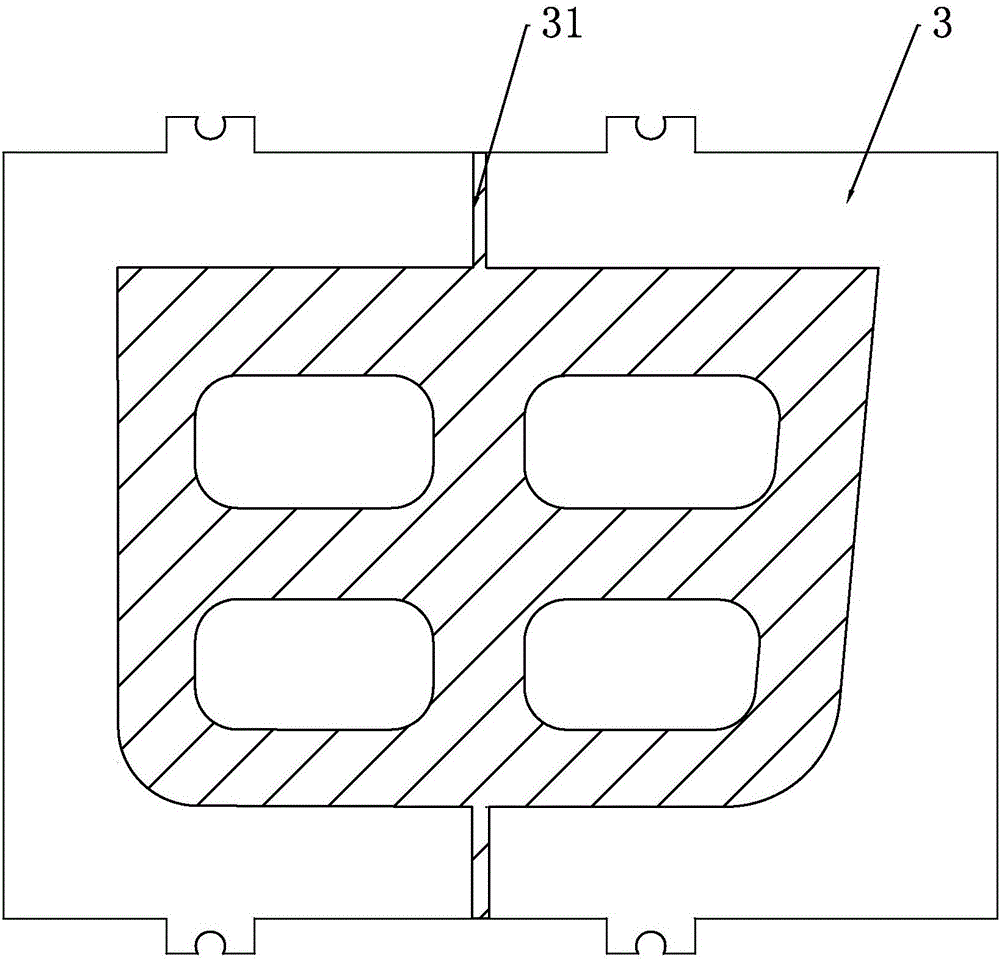

Superplastic forming (SPF)/diffusion bonding (DB) forming method of titanium alloy cylindrical four-layer structure

ActiveCN103008997AThe overall structure is light in weightImprove integrityShaping toolsMetal formingApplication areas

The invention belongs to a sheet-metal forming technology, and relates to a superplastic forming / diffusion connection forming method of a titanium alloy cylindrical four-layer structure. By adopting a novel blank structural form and a blank production method, the requirements on coating welding stopping agent and positioning a cylinder on the four-layer structure can be met, and the formation quality and the technological stability can be improved, the difficulty and complexity of a technological tool can be reduced, the SPF / DB formation of the titanium alloy cylindrical four-layer structure can be stably and reliably realized, and the formation quality and the technological stability can be improved. The SPF / DB technological method is enlarged from the formation of a flat sandwich structure to the formation of a cylindrical rotation sandwich structure, so that the application field of the process is enlarged, and good economic and technical benefit can be realized.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

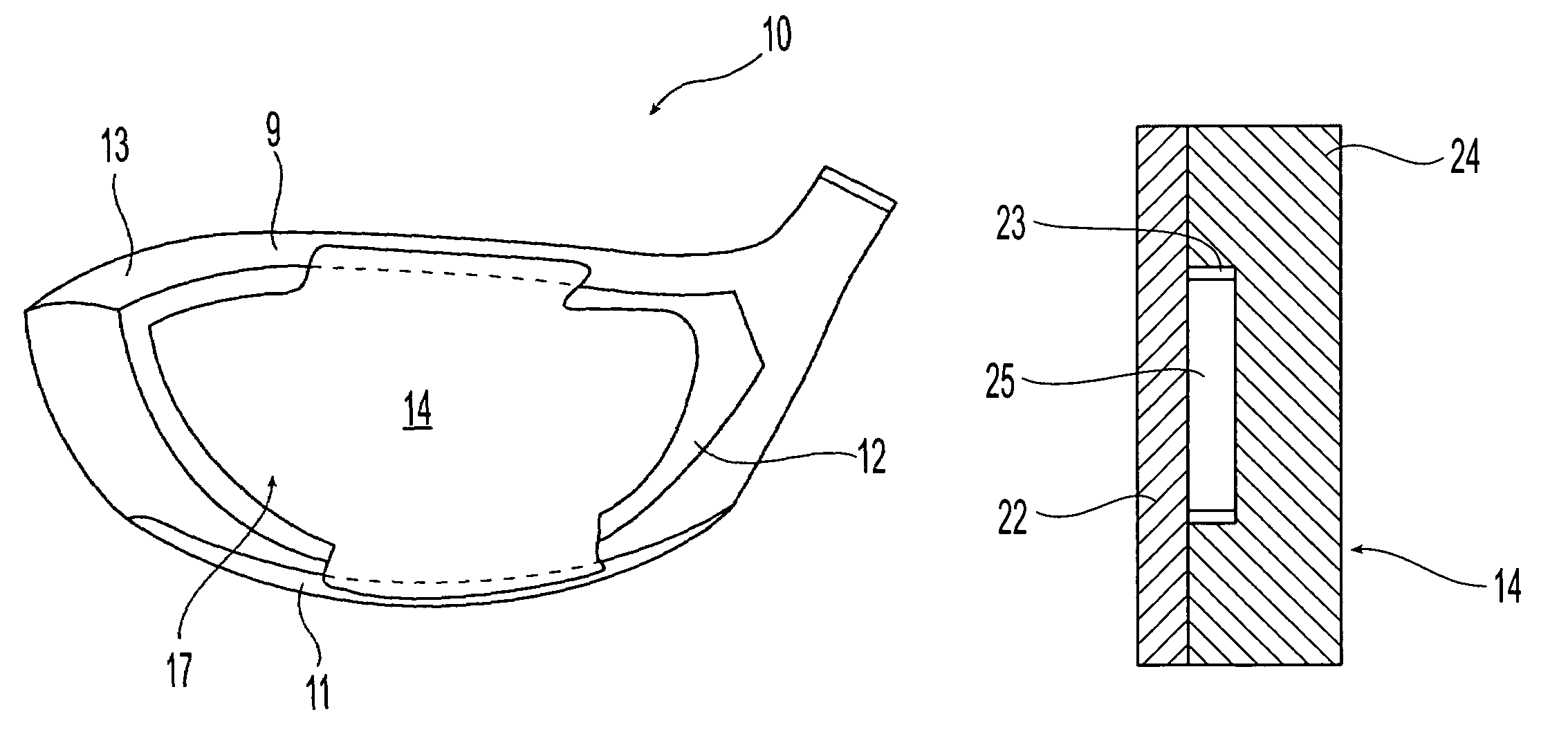

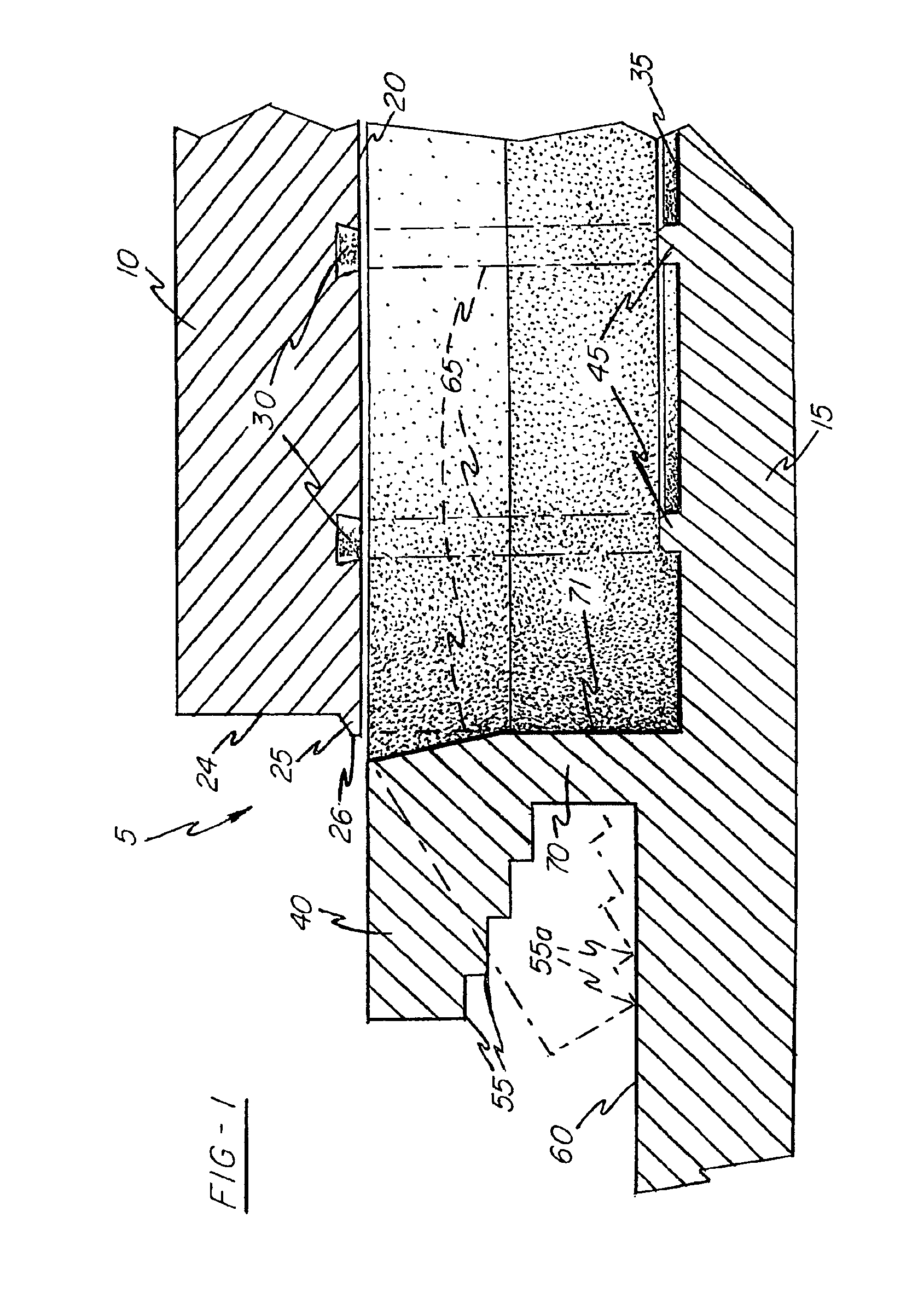

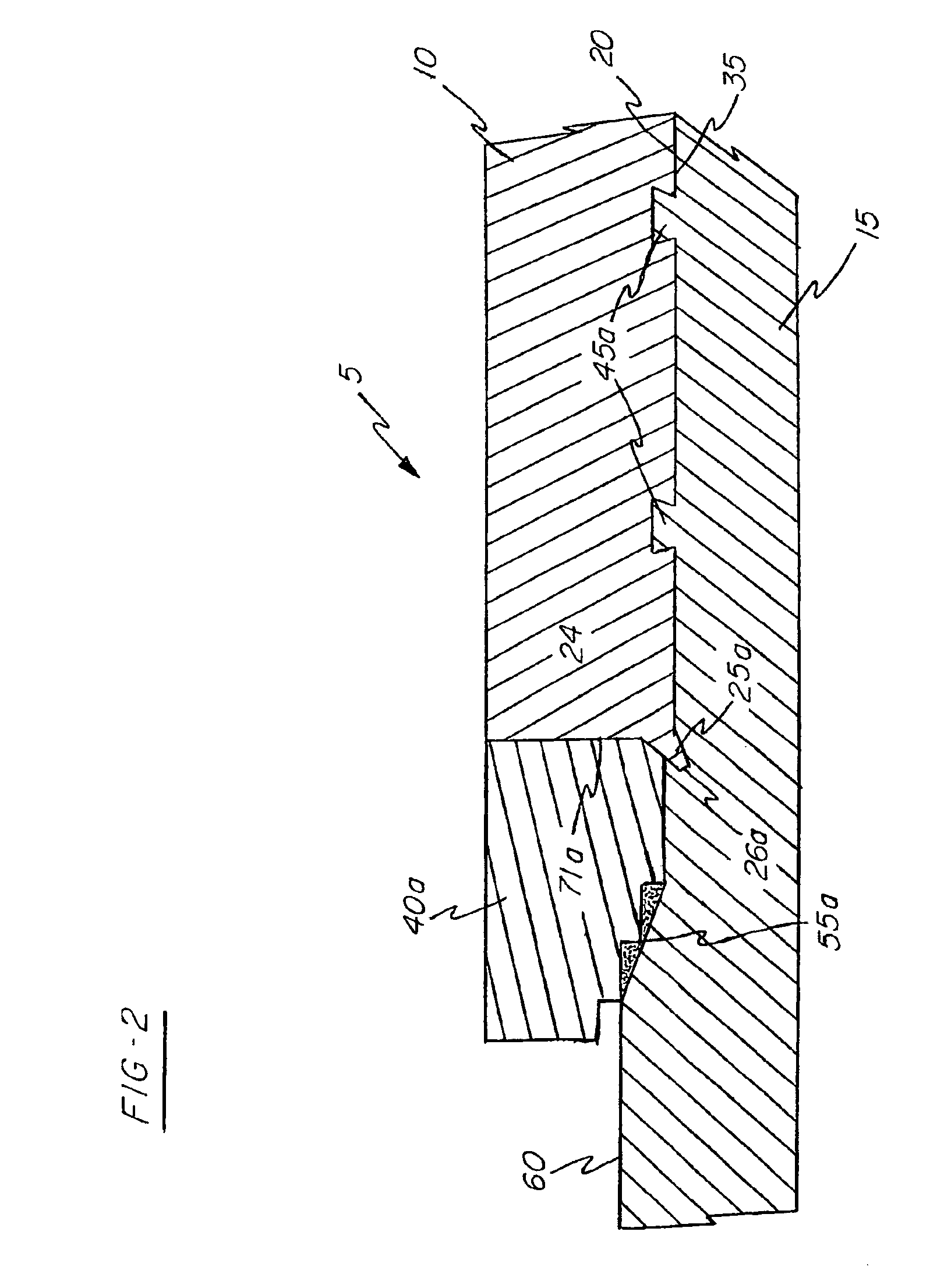

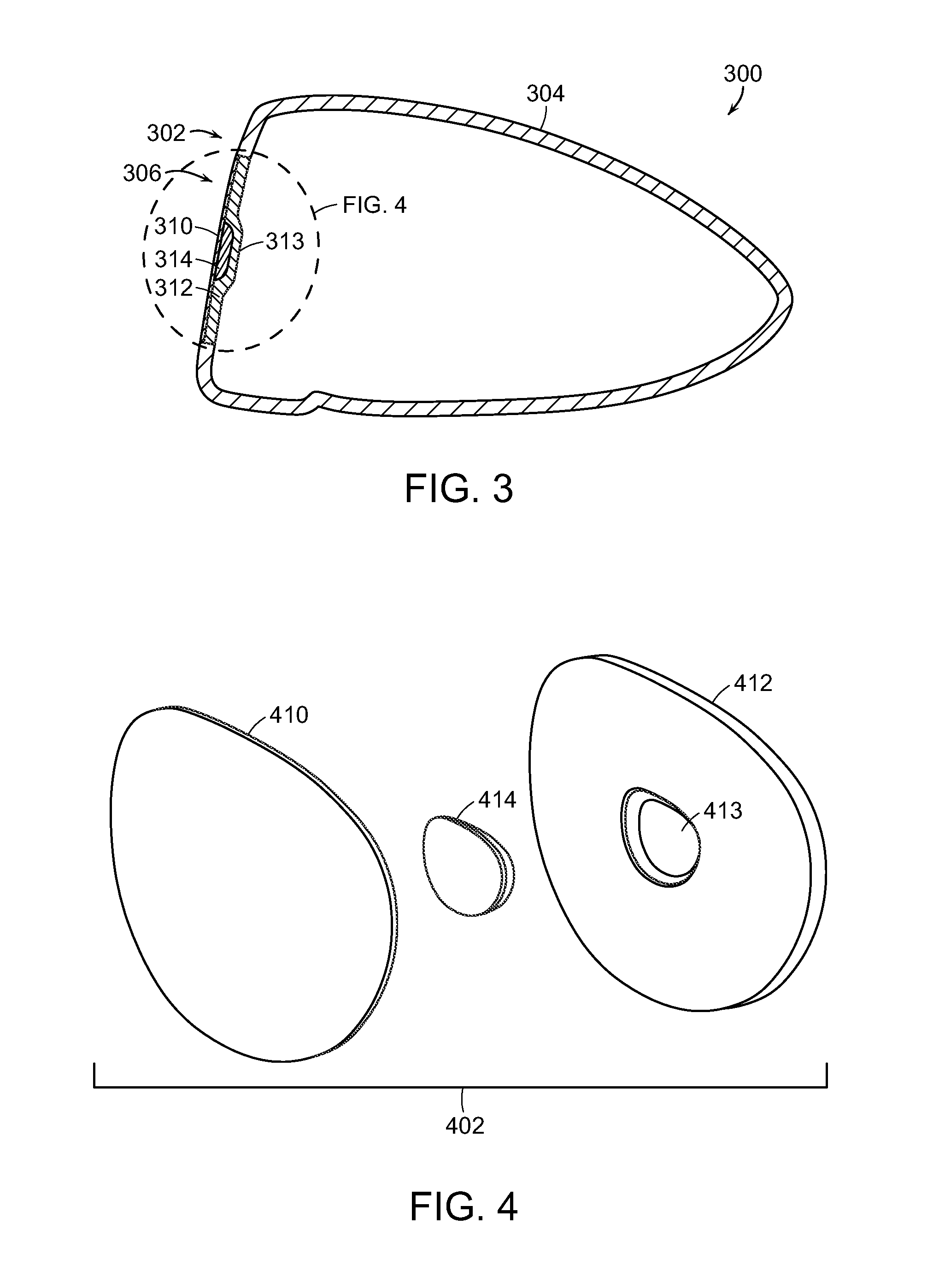

Golf club head with multi-material face

A metal wood golf club with a striking face portion made from more than one material is disclosed. More specifically, due to the unique construction of the striking face portion having multiple materials, the present invention utilizes diffusion bonding, liquid interface diffusion, or even super plastic forming techniques to achieve the desirable bond between the more than one material used to form the striking face. The striking face portion is formed by adding a chip insert made from a secondary material that is different from the remainder of the striking face portion substantially near a geometric center of the striking face portion; wherein the secondary material has a higher Young's modulus than the remainder of the striking face portion.

Owner:ACUSHNET CO

Three-body joining using friction stir processing techniques

ActiveUS20080006678A1Increase rotation speedRotational speedWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringFriction stir processing

A friction stir tool is provided to perform friction stir riveting using a partially consumable pin, wherein the pin includes a cutting edge on a bottom surface thereof, wherein the tool is rotated at a first speed to enable cutting by the pin into a first material that is overlapping a second material, wherein after the pin has cut to a sufficient depth, the rotational speed of the tool is increased to thereby enable plasticization of the consumable pin, the first material, and the second material, wherein the tool is then rapidly decelerated until stopped, enabling diffusion bonding between the pin, the first material and the second material.

Owner:MAZAK CORP +1

Method of electrochemically fabricating multilayer structures having improved interlayer adhesion

InactiveUS20050045585A1Improve propertiesImprove interlayer adhesionDecorative surface effectsSemiconductor/solid-state device manufacturingReducing atmosphereHeat treating

Multi-layer microscale or mesoscale structures are fabricated with adhered layers (e.g. layers that are bonded together upon deposition of successive layers to previous layers) and are then subjected to a heat treatment operation that enhances the interlayer adhesion significantly. The heat treatment operation is believed to result in diffusion of material across the layer boundaries and associated enhancement in adhesion (i.e. diffusion bonding). Interlayer adhesion and maybe intra-layer cohesion may be enhanced by heat treating in the presence of a reducing atmosphere that may help remove weaker oxides from surfaces or even from internal portions of layers.

Owner:UNIV OF SOUTHERN CALIFORNIA

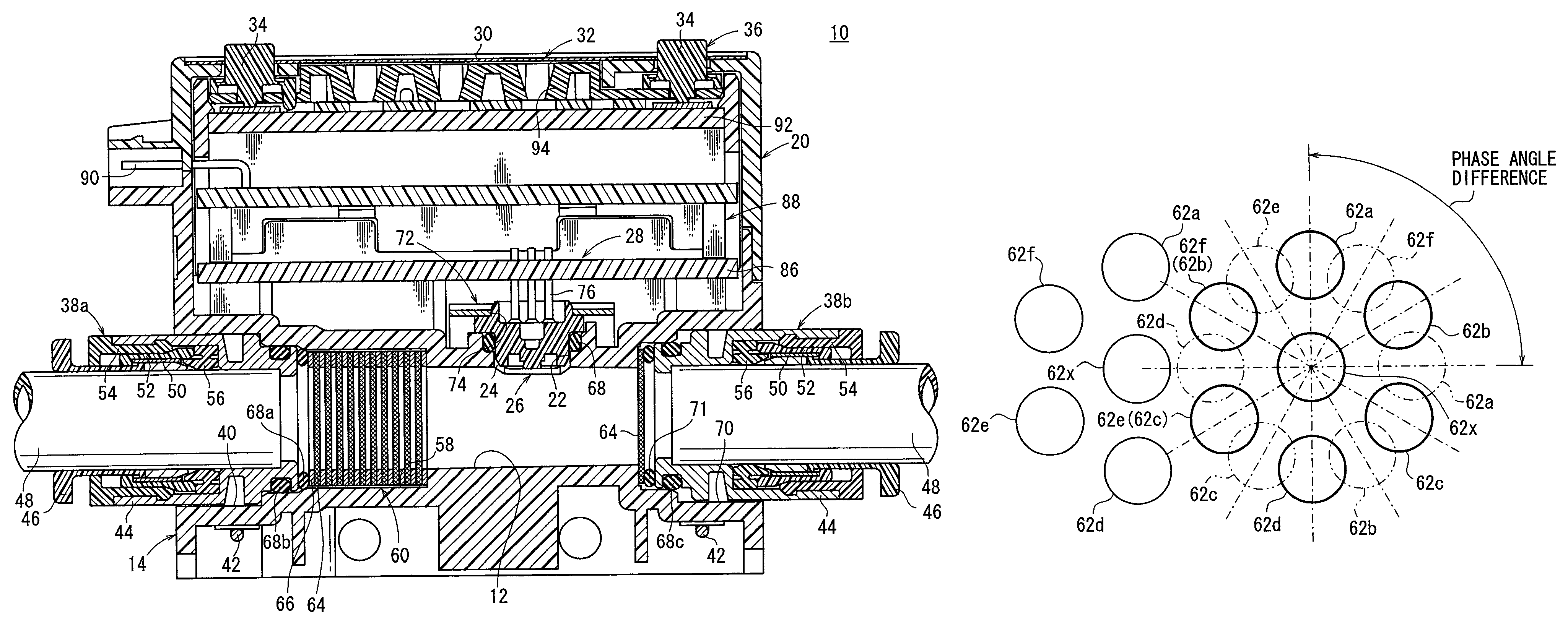

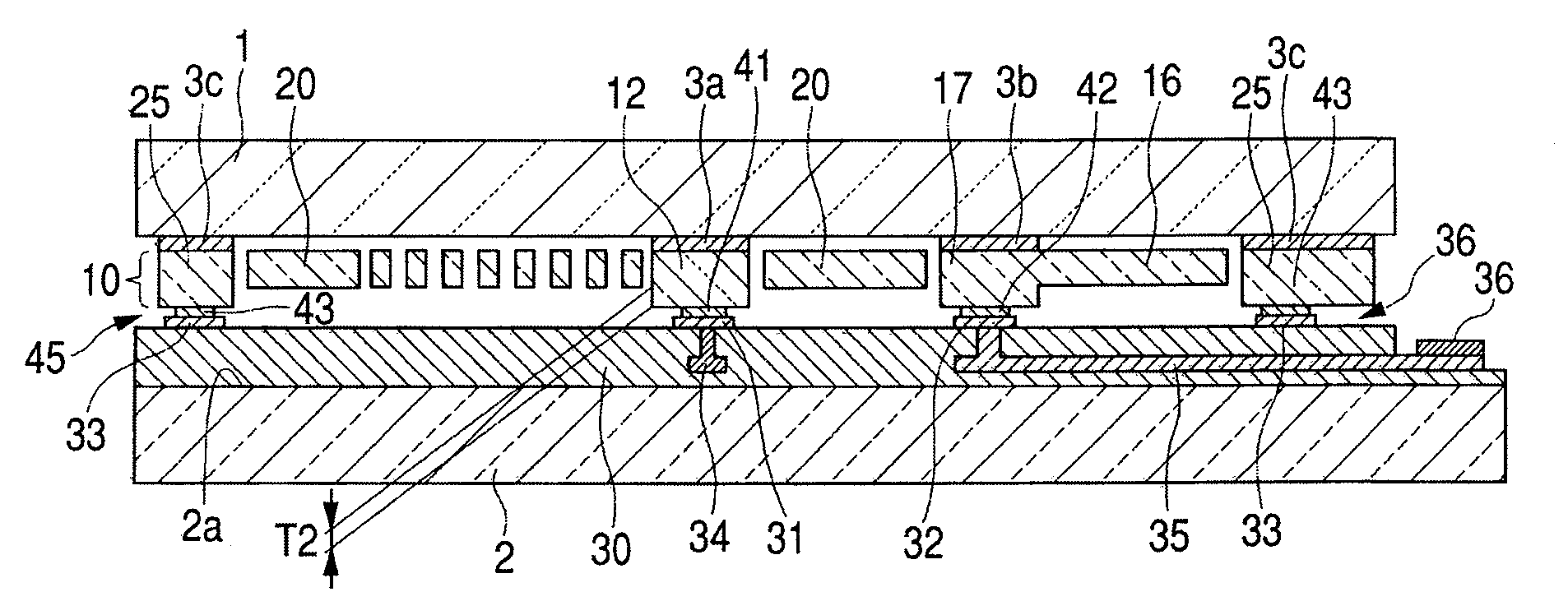

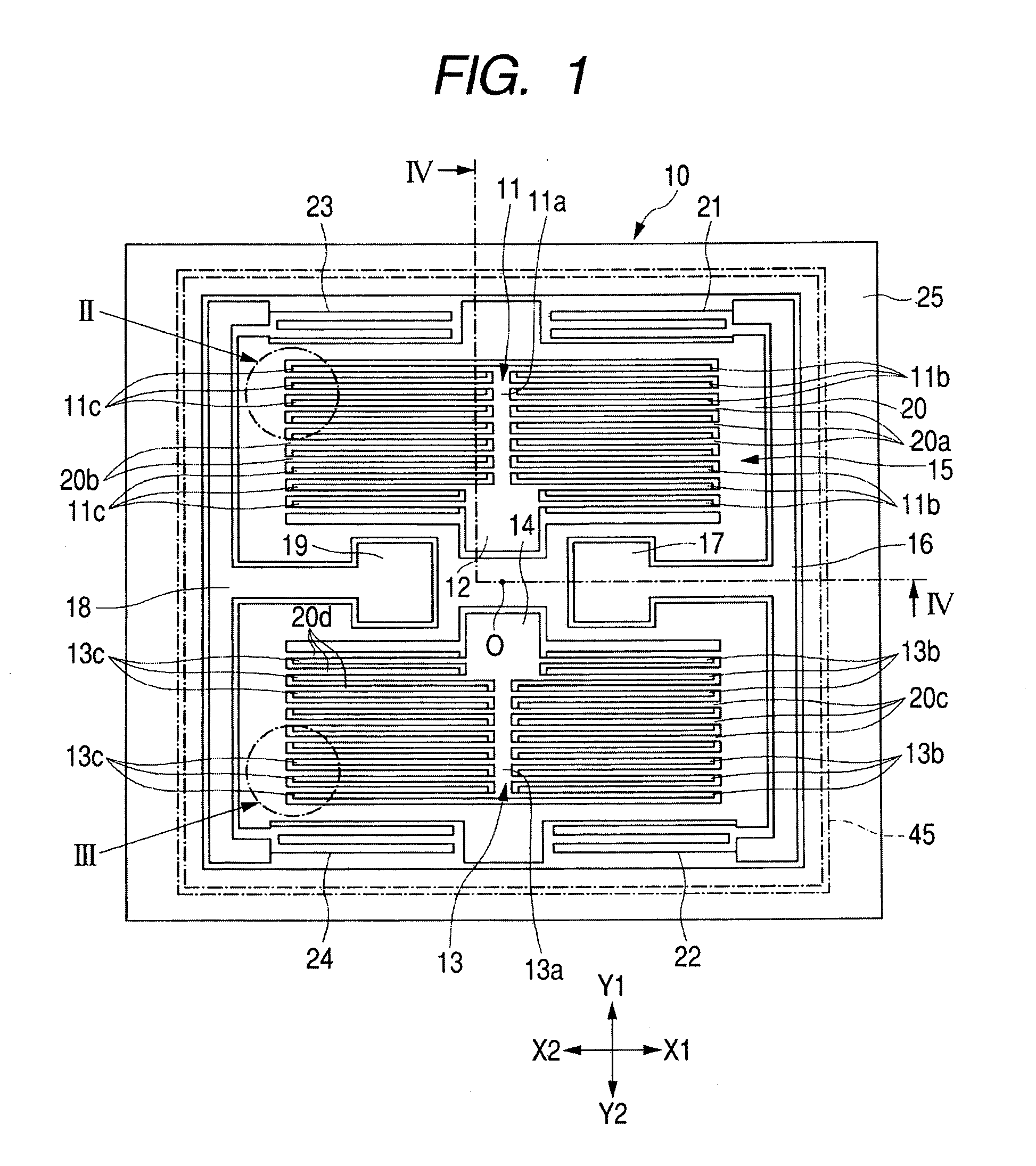

Flow meter with a rectifying module having a plurality of mesh members

ActiveUS7415895B2Conveniently performedThe effect is accurateFluid dynamicsVolume meteringPhase angle differenceSmall hole

A rectifying module is arranged on an upstream side of a flow passage containing a flow velocity sensor. The rectifying module includes mesh members each having a plurality of circular small holes and ring-shaped spacers, wherein the mesh members and the spacers are alternately stacked in an axial direction and integrally joined to one another by means of thermal diffusion bonding. The mesh members have identical structures, in which the plurality of small holes are arranged concentrically at angles of separation of 60 degrees in the circumferential direction about the center of a reference small hole. The small holes are formed over the entire surface of the mesh member continuous with adjoining other small holes. The small holes of one mesh member and another mesh member adjacent thereto in the axial direction are arranged so as to have a phase angle difference of 90 degrees in the circumferential direction.

Owner:SMC CORP

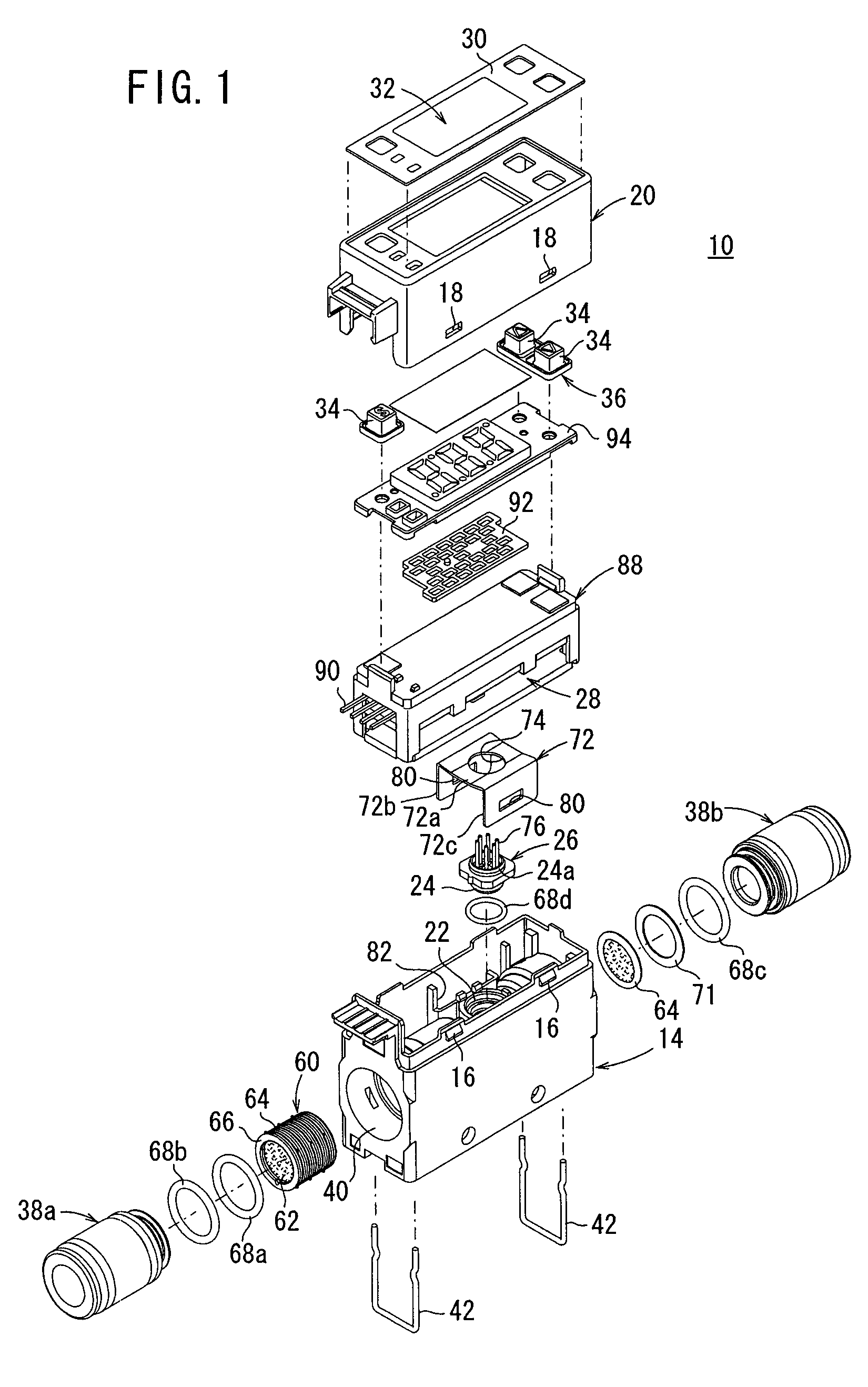

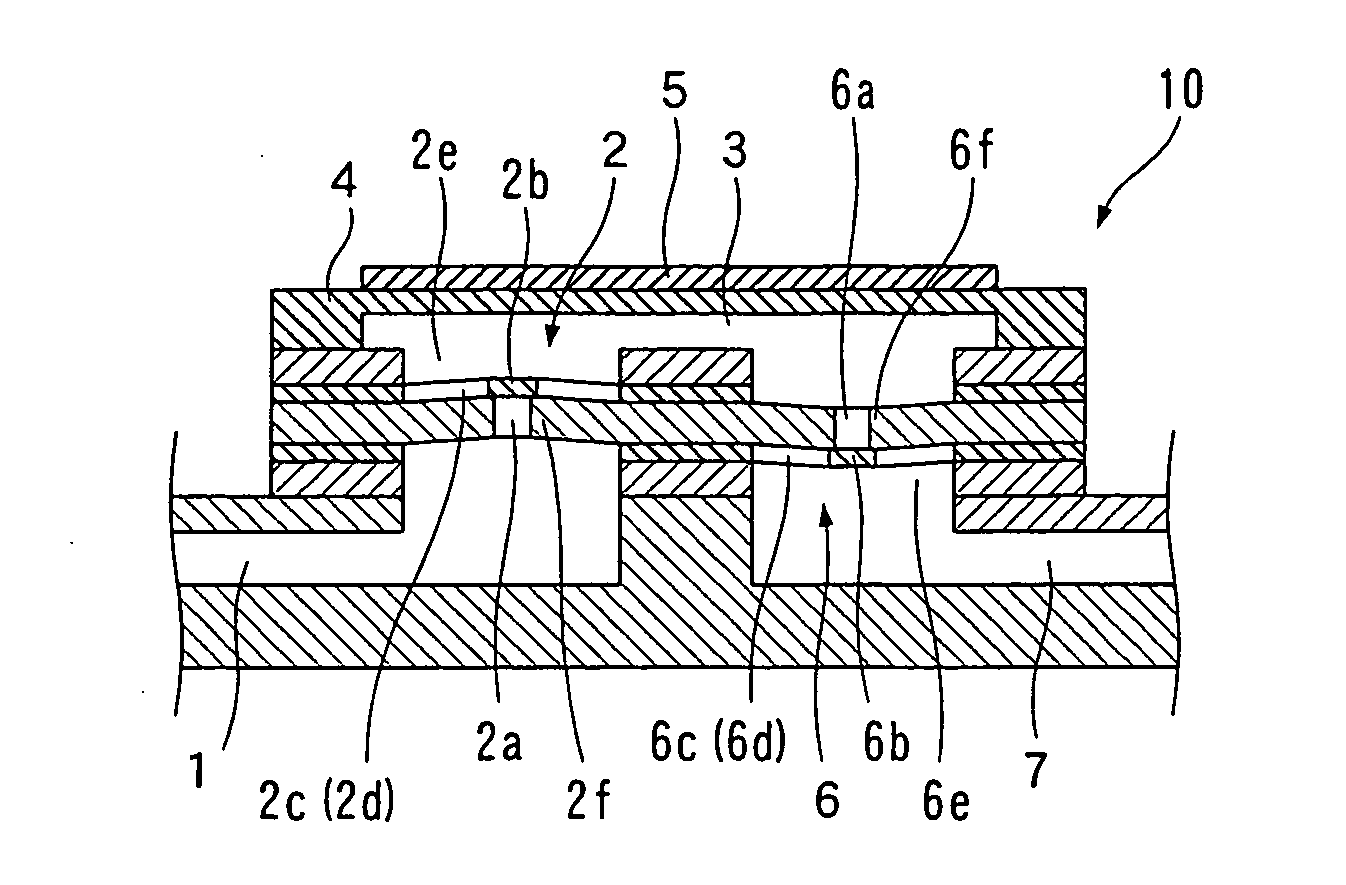

Micropump check valve and method of manufacturing the same

InactiveUS20050158188A1Satisfactory bondingImprove reliabilityFlexible member pumpsCheck valvesAdhesiveEngineering

The invention provides a method capable of manufacturing a micropump check valve, inexpensively and without much trouble or time, which does not cause disadvantages even if a material that dissolves an adhesive is contained in the fluid, and which allows bonding with high accuracy. After a valve forming member and a valve receiving member are bonded, a valve receptor is projected towards a valve part and pretension is applied. Thus, the valve forming member and the valve receiving member can be satisfactorily bonded through a solid phase diffusion bonding method and the like using a relatively inexpensive material, such as stainless steel, without using an adhesive, and the pretension is not reduced when in the annealing state.

Owner:PANASONIC CORP

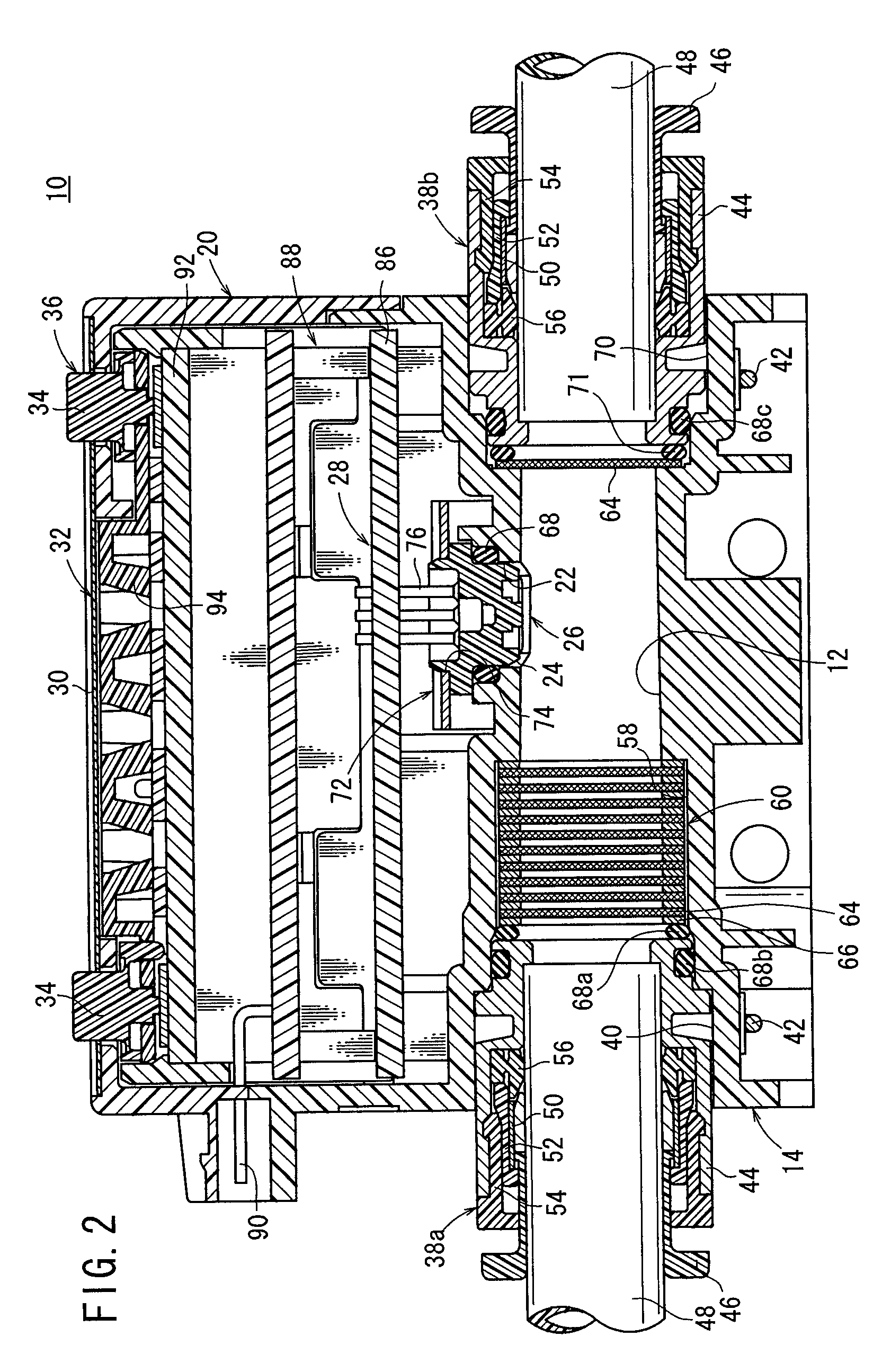

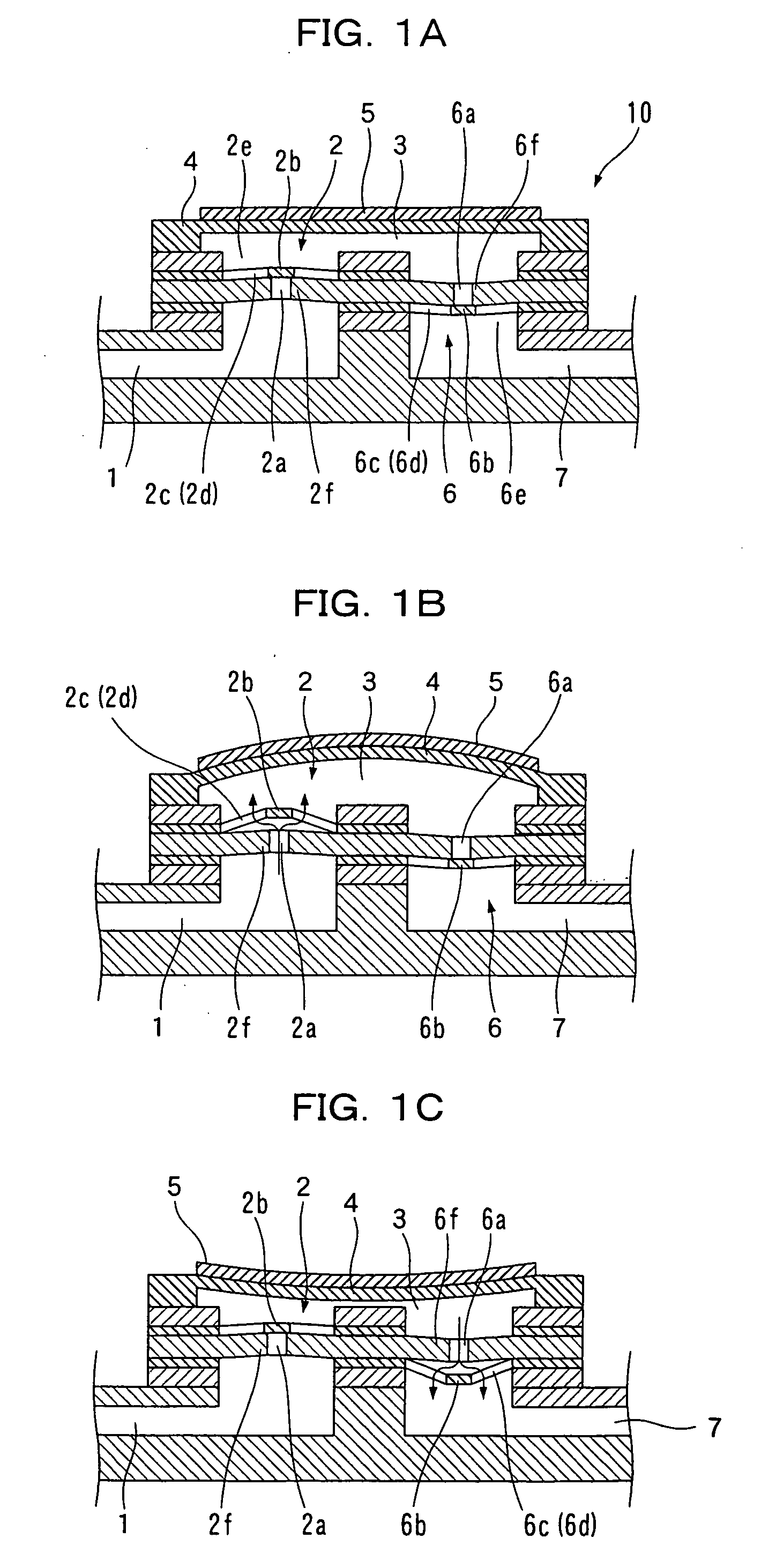

Substrate bonded MEMS sensor

InactiveUS20100072563A1Acceleration measurement using interia forcesTransducer detailsMems sensorsElectrical and Electronics engineering

A MEMS sensor includes a first substrate; a second substrate; a movable electrode portion and a fixed electrode portion which are arranged between the first substrate and the second substrate, wherein: conductive supporting portions of the movable electrode portion and the fixed electrode portion are, respectively, fixedly secured to a surface of the first substrate via a first insulating layer; a second insulating layer, a lead layer buried into the second insulating layer, and connection electrode portions that are electrically connected to the lead layer to be individually connected to the conductive supporting portions are provided on a surface of the second substrate; a metallic connection layer is formed on the surface of one of the respective conductive supporting portions; one of the respective connection electrode portions and the metallic connection layer are bonded together by eutectic bonding or diffusion bonding; and, at least each of the connection electrode portions has a thickness of about 4 μm or smaller.

Owner:ALPS ALPINE CO LTD

Superplastic forming (SPF)/diffusion bonding (DB) forming method of titanium alloy cylindrical three-layer structure

ActiveCN103008998AThe overall structure is light in weightImprove integrityMetal formingTitanium alloy

The invention belongs to a sheet-metal forming technology, and relates to a superplastic forming (SPF) / diffusion bonding (DB) forming method of a titanium alloy cylindrical three-layer structure. A novel blank structural form and a blank production method are adopted, the requirements on coating welding stopping agent and positioning a cylinder on a three-layer structure can be met, and a hot isostatic pressure DB and cylinder SPF step-by-step formation method is adopted for the cylinder blank, so that the technical difficulty and complexity can be reduced, and the structural flexibility can be improved. A partition ring is creatively additionally arranged among the cylinders, the dropping of the welding stopping agent, caused by the collision of the cylinders, can be avoided, an air inlet passage and an exhaust passage are directly machined and formed on the blank, no air passage needs to be machined on a mold, and the structural complexity of a tool can be reduced. The SPF / DB formation of the titanium alloy cylindrical three-layer structure can be stably and reliably realized, and the formation quality and the technological stability can be improved. The SPF / DB technological method is enlarged from the formation of a flat sandwich structure to the formation of the cylindrical rotation sandwich structure, so that the application field of the process can be enlarged, and good economic and technical benefit can be realized.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Methods of bonding two aluminum-comprising masses to one another

The invention encompasses a method of bonding a first mass to a second mass. A first mass of first material and a second mass of second material are provided and joined in physical contact with one another. The first and second masses are then diffusion bonded to one another simultaneously with the development of grains of the second material in the second mass. The diffusion bonding comprises solid state diffusion between the first mass and the second mass. A predominate portion of the developed grains in the second material have a maximum dimension of less than 100 microns. The invention also encompasses methods of forming a physical vapor deposition target bonded to a backing plate.

Owner:HONEYWELL INT INC

Heat spreader with composite micro-structure

InactiveUS8074706B2Capillarity is enhancedReduce the flowing resistance during operationIndirect heat exchangersHeat exchange apparatusMicro structureWorking fluid

A heat spreader comprising a casing, a micro-structure layer, a support device, and a working fluid is provided. The casing has an inner surface and is defined by a sealed chamber where the working fluid circulates therein. The micro-structure layer is formed on the inner surface of the casing, wherein the micro-structure layer comprises a first structure layer which is formed by the first metallic mesh. Specifically, the first metallic mesh forms the first structure layer on the inner surface through diffusion bonding so that the working fluid can circulate within the micro-structure layer by capillary action. In addition, the support device is disposed in the sealed chamber for supporting the casing. Thus, a heat spreader with a composite micro-structure can not only enhance the capillarity but also reduce the flowing resistance during operation.

Owner:TAIWAN MICROLOOPS CORP

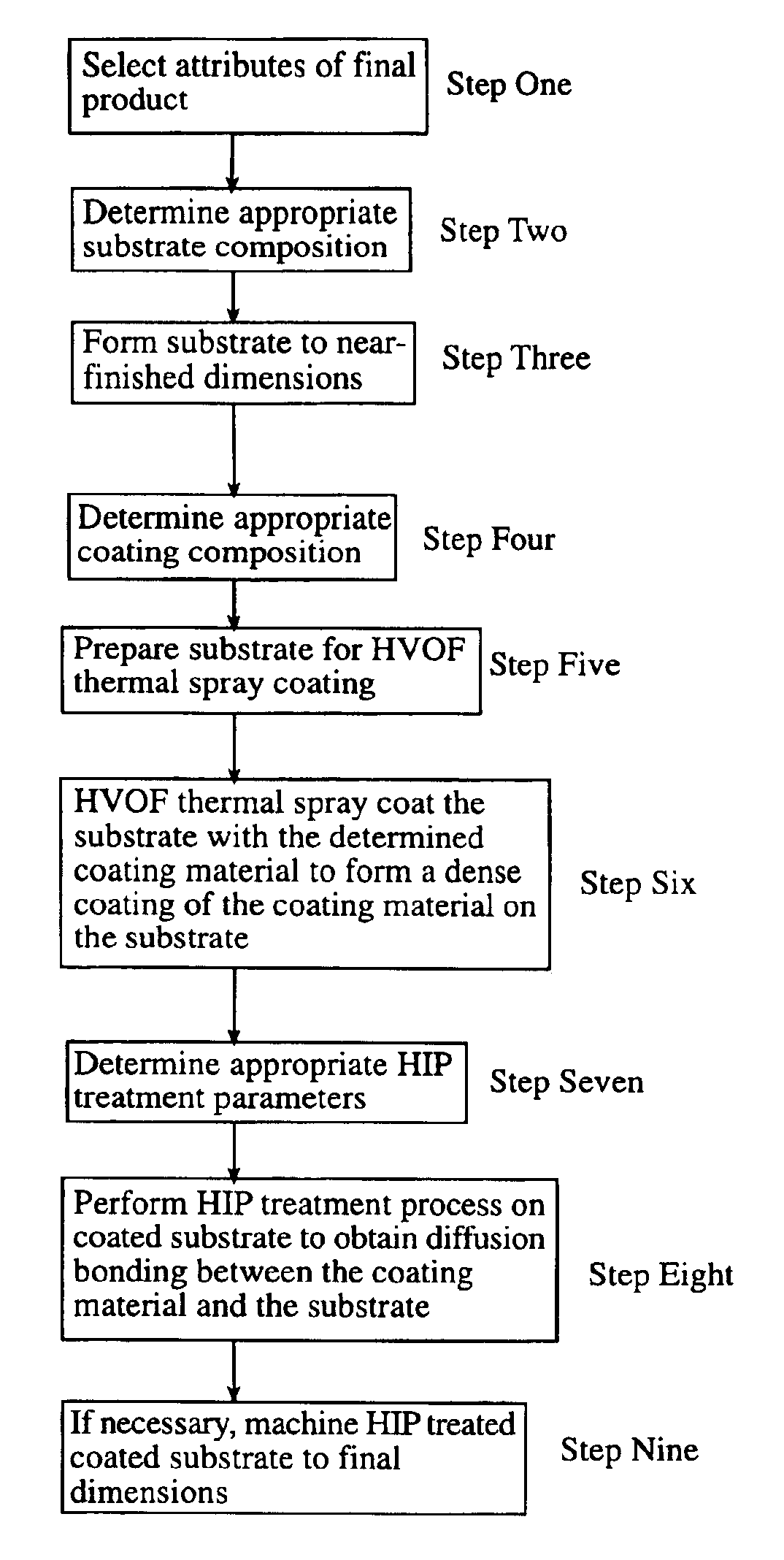

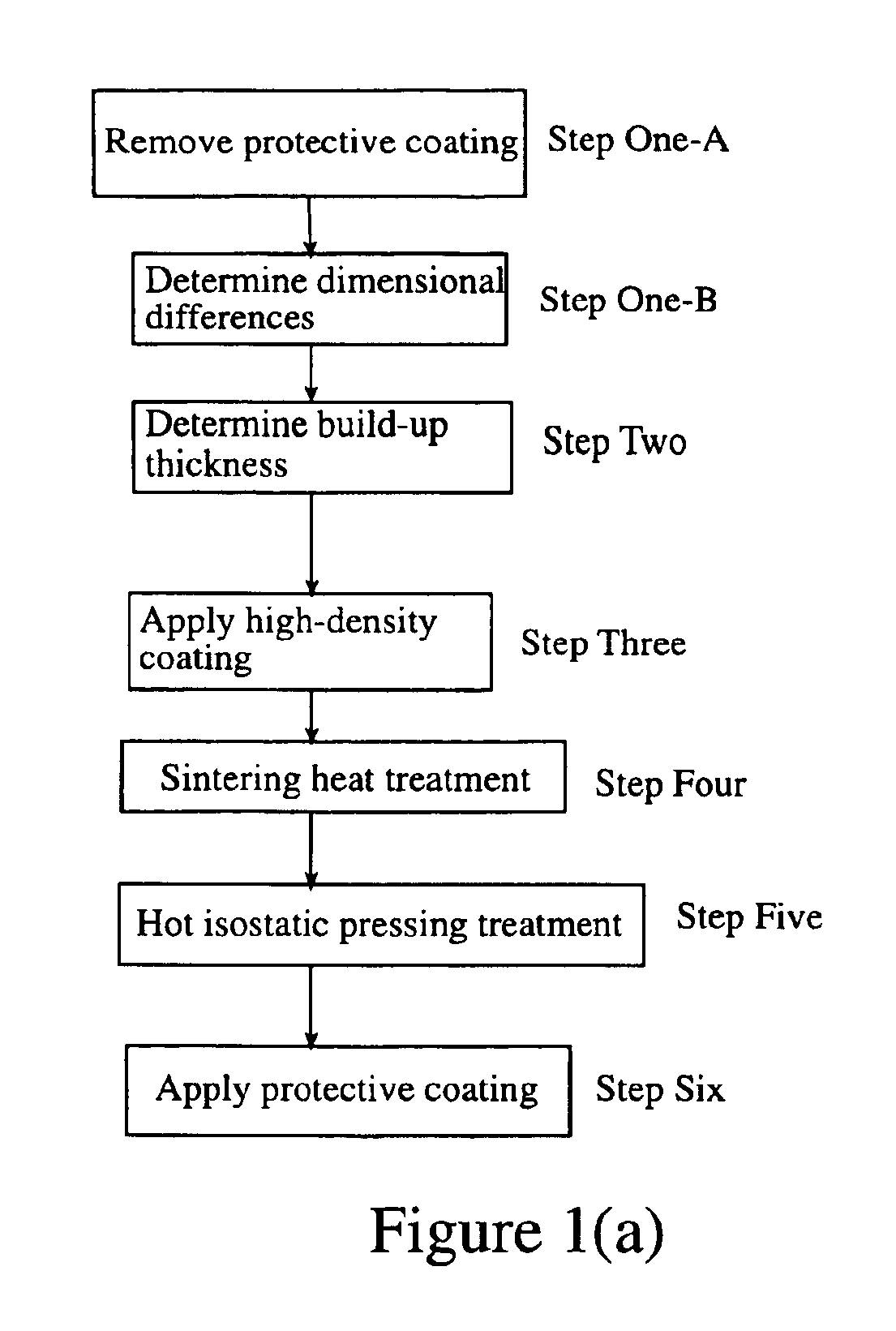

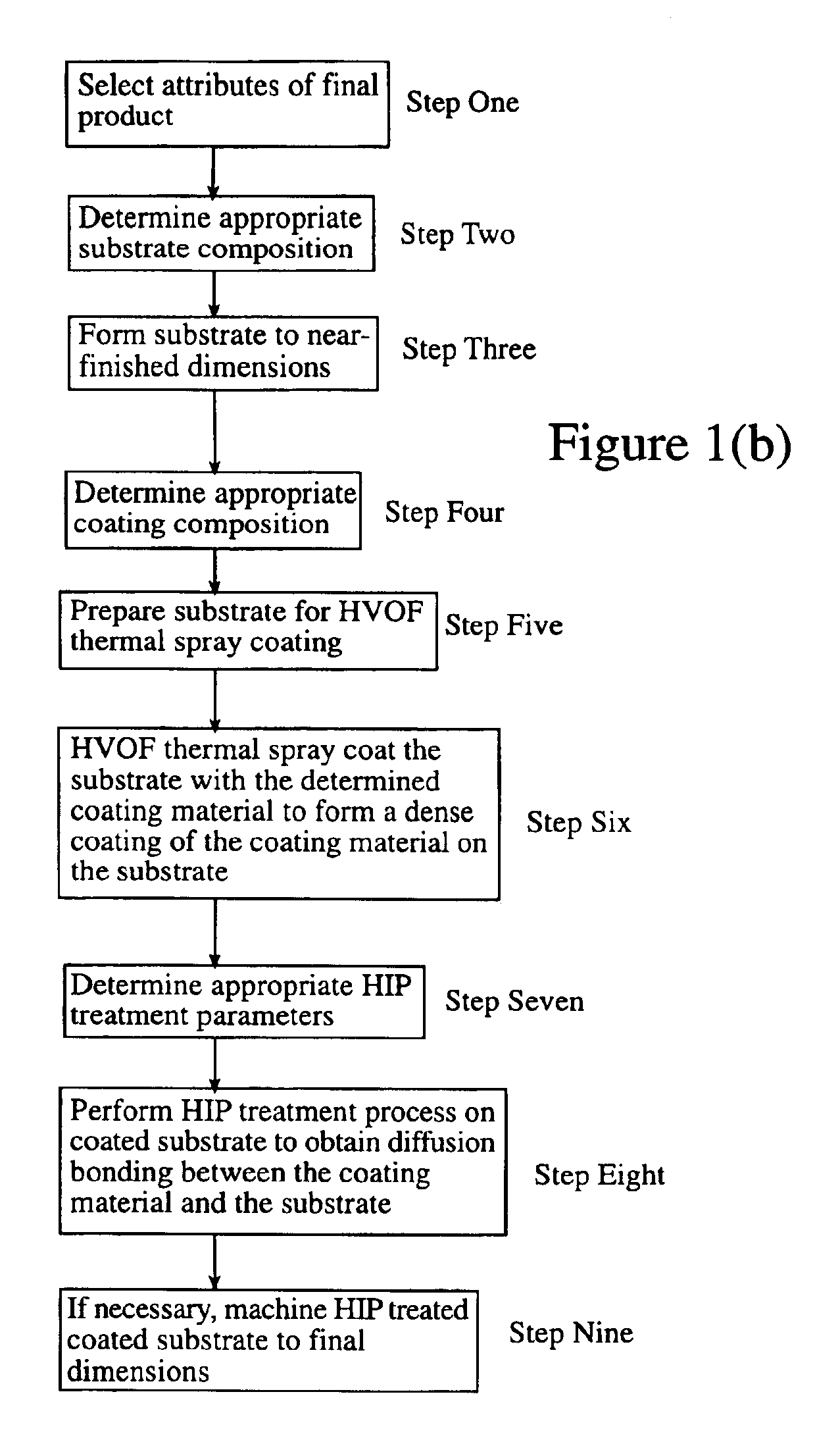

Methods for forming metal parts having superior surface characteristics

InactiveUS7043819B1Improve surface propertiesOvercomes drawbackMolten spray coatingMetal rolling stand detailsHigh densityMetal alloy

A method of forming a metal product. A metal alloy workpiece substrate is provided have pre-process dimensions. The dimensional differences are determined between the pre-process dimensions of the workpiece substrate and desired post-process dimensions of a post-process metal product formed from the workpiece substrate. A build-up thickness is determined of coating material required to obtain the desired post-process dimensions of the post-process metal product. A high-density coating process is performed to coat the workpiece substrate with a coating material to build-up a thickness of coating material effective to obtain desired finished dimensions after performing a sintering heat treatment process and / or a hot isostatic pressing treatment. The sintering heat treatment is performed on the coated workpiece substrate to densify the coating material. Then, the hot isostatic pressing treatment is performed to obtain the post-process metal product having the desired post-process dimensions and having diffusion bonding between the coating material and the workpiece substrate.

Owner:RECAST AIRFOIL GROUP

Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

ActiveCN106271439AHigh strengthIncrease stiffnessWelding apparatusTitanium alloyUltimate tensile strength

The invention belongs to the technical field of metal plastic processing, and aims at providing a superplastic forming / diffusion bonding forming method for a heat-resistant titanium alloy envelope with high material utilization ratio, high dimension control precision and high product performance. As a mould is adopted to control the appearance and dimension of a workpiece, the forming of a titanium alloy workpiece provided with a complex profile is completed, the production process of the heat-resistant envelope workpiece is shortened, and production cost is lowered; as the process of diffusion bonding followed by superplastic forming is adopted, the diffusion bonding is realized at the contact part of an inner envelope and an outer envelope, and the superplastic forming is realized at a separated part, the once-formed heat-resistant envelope with the complex profile and a hollow structure has the advantages of greatly improved structural integrity of a component, enhanced specific strength and specific stiffness of the component and increased welding rate of the diffusion bonding; the processed workpiece has the advantages of high dimension accuracy, high integral performance, light weight and the like; and the method disclosed by the invention has the advantages of shortened processing period, high material utilization ratio and lowered production cost.

Owner:北京普惠三航科技有限公司

Tantalum or tungsten target-copper alloy backing plate assembly and production method therefor

InactiveUS6759143B2Small overall deformationSurviving high power sputteringVacuum evaporation coatingSputtering coatingSputteringBond interface

A tantalum or tungsten target-backing plate assembly which comprises a tantalum or tungsten target and a copper alloy backing plate that are subject to diffusion bonding via an aluminum- or aluminum alloy-sheet insert material at least 0.5 mm thick, and which is provided with diffusion bonded interfaces between the respective materials, wherein the assembly suffers only a small deformation after diffusion bonding and is free from separation between the target and the backing plate or from cracking even when the target material and the backing plate differ greatly in thermal expansion, and can survive high power sputtering; and a production method therefor.

Owner:JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com