Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

A technology of superplastic forming and diffusion bonding, which is applied in the field of metal plastic processing to achieve high overall performance, improved welding rate, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A superplastic forming / diffusion bonding forming method of a titanium alloy heat-resistant skin, comprising the following steps:

[0051] (1) Mold making

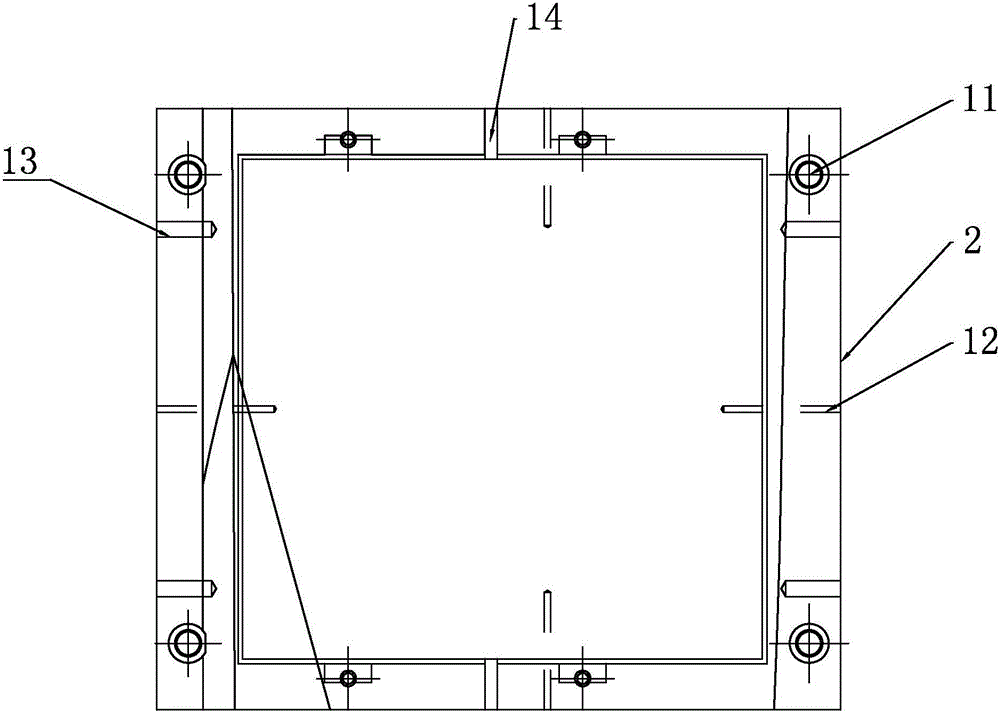

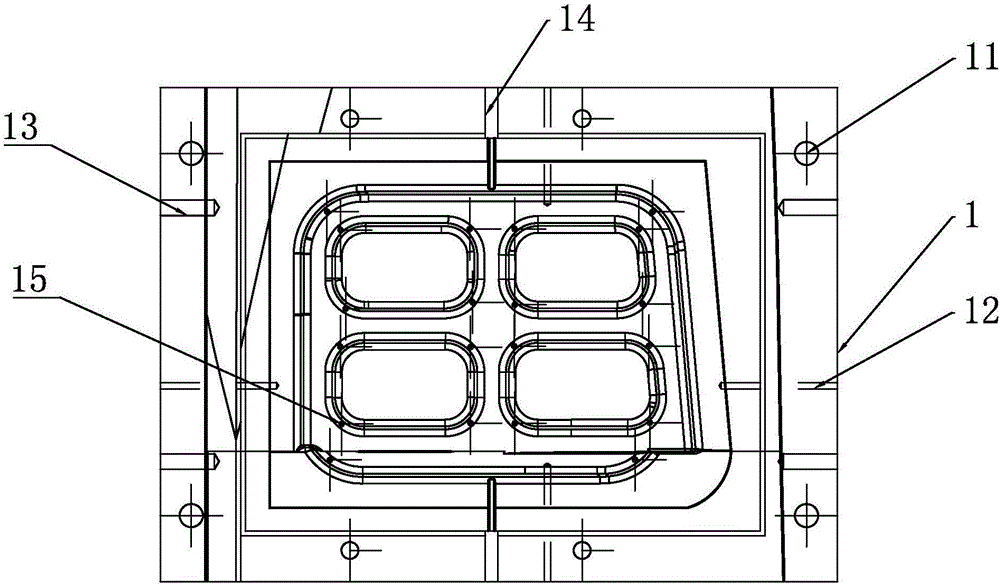

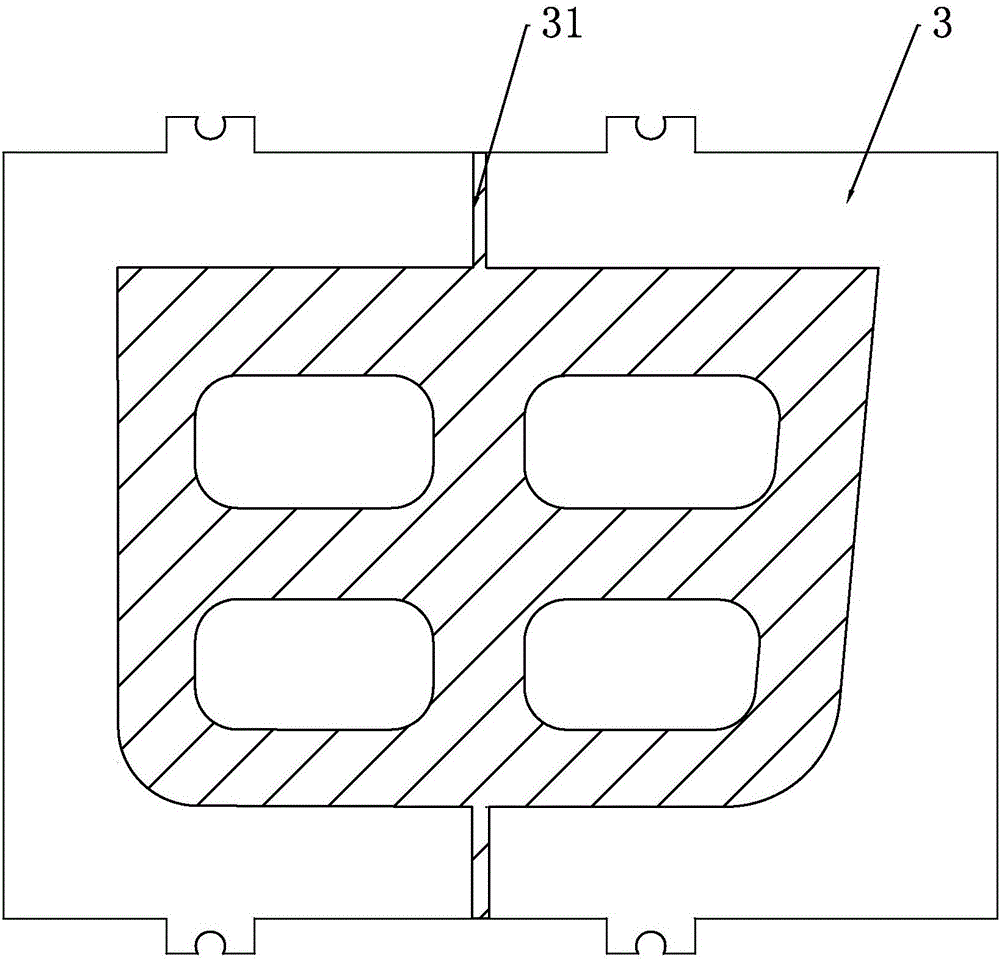

[0052] In the process of superplastic forming / diffusion connection of heat-resistant skin, molds are needed to control the shape and size of the workpiece. The mold includes an upper mold and a lower mold. The cavities of the upper mold and the lower mold are designed according to the outline of the workpiece. Make the cavity surface of the upper mold and the lower mold consistent with the appearance of the heat-resistant skin, and process the positioning holes, temperature measuring holes, hoisting holes, ventilation grooves, upper mold and lower mold upper mold respectively on the upper mold and the lower mold Corresponding to the position of the upper mold, and set a number of vent holes on the cavity surface of the upper mold;

[0053] (2) Blank processing

[0054] Both the inner and outer skins are made of 0.8...

Embodiment 2

[0070] A superplastic forming / diffusion bonding forming method of a titanium alloy heat-resistant skin, comprising the following steps:

[0071] (1) Mold making

[0072] In the process of superplastic forming / diffusion connection of heat-resistant skin, molds are needed to control the shape and size of the workpiece. The mold includes an upper mold and a lower mold. The cavities of the upper mold and the lower mold are designed according to the outline of the workpiece. Make the cavity surface of the upper mold and the lower mold consistent with the appearance of the heat-resistant skin, and process the positioning holes, temperature measuring holes, hoisting holes, ventilation grooves, upper mold and lower mold upper mold respectively on the upper mold and the lower mold Corresponding to the position of the upper mold, and set a number of vent holes on the cavity surface of the upper mold;

[0073] (2) Blank processing

[0074] Both the inner and outer skins are made of 0.8...

Embodiment 3

[0089] A superplastic forming / diffusion bonding forming method of a titanium alloy heat-resistant skin, comprising the following steps:

[0090] (1) Mold making

[0091] In the process of superplastic forming / diffusion connection of heat-resistant skin, molds are needed to control the shape and size of the workpiece. The mold includes an upper mold and a lower mold. The cavities of the upper mold and the lower mold are designed according to the outline of the workpiece. Make the cavity surface of the upper mold and the lower mold consistent with the appearance of the heat-resistant skin, and process the positioning holes, temperature measuring holes, hoisting holes, ventilation grooves, upper mold and lower mold upper mold respectively on the upper mold and the lower mold Corresponding to the position of the upper mold, and set a number of vent holes on the cavity surface of the upper mold;

[0092] (2) Blank processing

[0093] Both the inner and outer skins are made of 0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com