Surface shot blasting process for improving high temperature steam oxidization resistance of high-chromium austenite steel

A technology of austenitic steel and high temperature resistance, applied in the field of shot peening technology, can solve problems such as limited scope of application, difficulty in obtaining grain structure, unfavorable steam oxidation resistance, etc., to improve dislocation density and high temperature oxidation resistance , Improve the effect of oxidation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

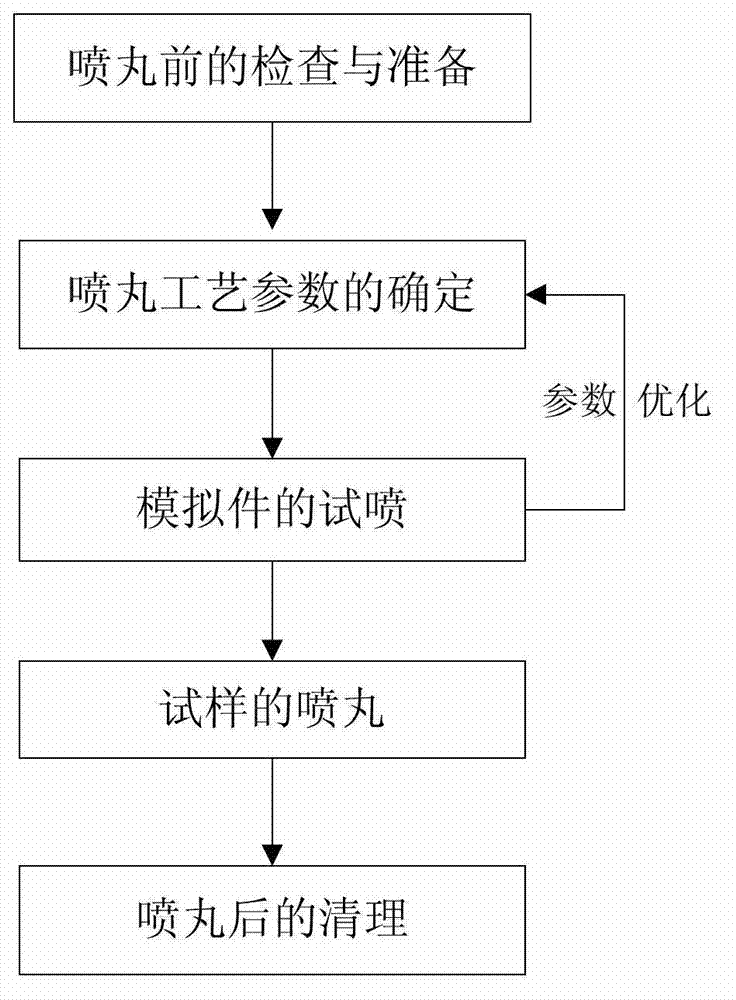

[0026] see figure 1 Shown, a kind of surface shot peening process of improving high-chromium austenitic steel anti-high temperature steam oxidation of the present invention is:

[0027] (1) Adopt mechanical centrifugal shot blasting equipment, which has a projectile size screening and crushing projectile device, and a ventilation and dust removal device.

[0028] (2) Ceramic projectiles are used as shot blasting materials, with a microhardness of 700HV and a diameter of 0.6mm.

[0029] (3) When shot peening is in progress, the distance from the nozzle to the sample surface is 150 mm, the shot peening flow rate is 1.8 kg / min, the shot peening time is 3 min, and the spray angle θ=50°.

[0030] (4) The rotational speed of the centrifugal shot blasting machine is 3500r / min.

[0031] The main organization of the above ceramic projectiles is dense ZrO 2 Crystal phase and SiO 2 Amorphous phase, ZrO 2 The mass percentage of crystal phase is 60%~70%, SiO 2 The mass percentage of ...

Embodiment 2

[0042] A surface shot peening process for improving the high-chromium austenitic steel anti-high temperature steam oxidation of the present invention is as follows:

[0043] (1) Adopt mechanical centrifugal shot blasting equipment, which has a projectile size screening and crushing projectile device, and a ventilation and dust removal device.

[0044] (2) Ceramic projectiles are used as shot blasting materials, with a microhardness of 660HV and a diameter of 0.75mm.

[0045] (3) When shot peening is in progress, the distance from the nozzle to the sample surface is 170 mm, the shot peening flow rate is 2.5 kg / min, the shot peening time is 2 min, and the spray angle θ=40°.

[0046] (4) The rotational speed of the centrifugal shot blasting machine is 4500r / min.

[0047] The main organization of the above ceramic projectiles is dense ZrO 2 Crystal phase and SiO 2 Amorphous phase, ZrO 2 The mass percentage of crystal phase is 60%~70%, SiO 2 The mass percentage of amorphous ph...

Embodiment 3

[0050] A surface shot peening process for improving the high-chromium austenitic steel anti-high temperature steam oxidation of the present invention is as follows:

[0051] (1) Adopt mechanical centrifugal shot blasting equipment, which has a projectile size screening and crushing projectile device, and a ventilation and dust removal device.

[0052] (2) Ceramic projectiles are used as shot blasting materials, with a microhardness of 750HV and a diameter of 0.25mm.

[0053] (3) When shot peening is in progress, the distance from the nozzle to the sample surface is 190 mm, the shot peening flow rate is 1.0 kg / min, the shot peening time is 4 min, and the spray angle θ=65°.

[0054] (4) The rotational speed of the centrifugal shot blasting machine is 2500r / min.

[0055] The main organization of the above ceramic projectiles is dense ZrO 2 Crystal phase and SiO 2 Amorphous phase, ZrO 2 The mass percentage of crystal phase is 60%~70%, SiO 2 The mass percentage of amorphous ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com