High-Cr-content cast heading machine cutter steel and manufacturing technique thereof

A manufacturing process and tool steel technology, which is applied in the field of new high-Cr casting roadheader tool steel and its manufacturing process, can solve the problems of difficult to obtain imported tools, save processing hours, improve thermal fatigue crack level, and improve oxidation and corrosion resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) The chemical composition of the new high-Cr cast roadheader tool steel is by weight percentage:

[0045] C: 0.307; Cr: 8.151; Mo: 1.272; Ni: 0.564; V: 0.665; Mn: 0.131; Si: 0.648;

[0046] (2) The heat treatment process scheme and mechanical properties of this embodiment are shown in Table 4.

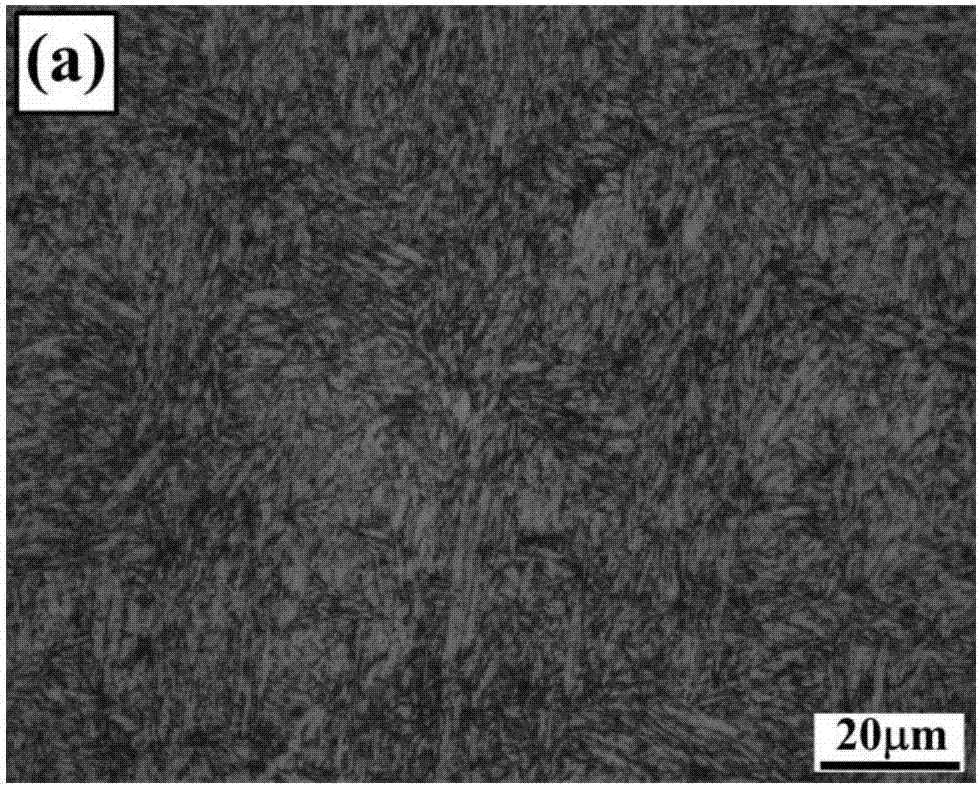

[0047] The high-Cr cast roadheader tool steel is mainly composed of lath martensite and retained austenite after heat treatment in schemes 2 to 4, and its mechanical properties have reached or exceeded that of forged high-carbon H13 roadheader tool steel. Among them, after process plan 3 heat treatment, the impact toughness increased by 19.4%, the tensile strength increased by 6.8%, the yield strength increased by 12.7%, and the elongation increased by 18.0%; the oxidation weight was increased by oxidation at 550°C for 60 hours in the air environment. 42.4% of H13 steel; after 10,000 thermal cycles at 550°C → 25°C, the length and number of thermal fatigue cracks were signifi...

Embodiment 2

[0055] (1) The chemical composition of high-Cr cast roadheader tool steel is by weight percentage:

[0056] C: 0.415; Cr: 10.163; Mo: 2.171; Ni: 1.233; V: 0.804; Mn: 0.235; Si: 0.706;

[0057] (2) The heat treatment process characteristics of the new high-Cr cast roadheader tool steel are shown in Table 6.

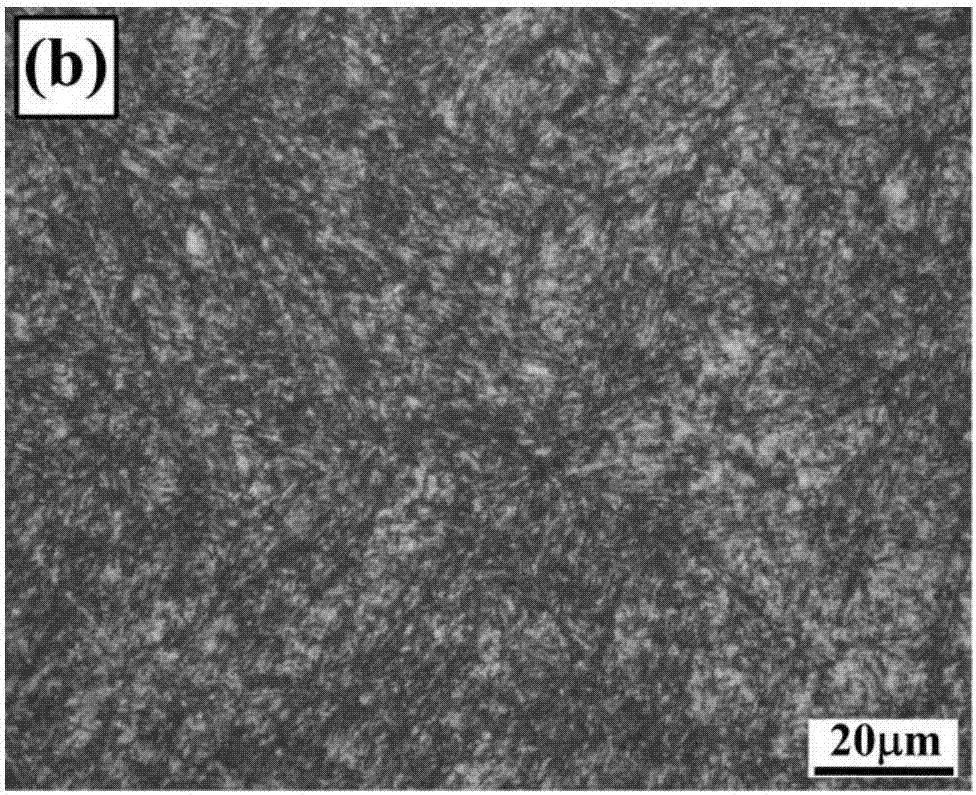

[0058] The new high-Cr cast roadheader tool steel is mainly composed of lath martensite and retained austenite after heat treatment in schemes 2 to 4, and its mechanical properties have met or exceeded that of forged high-carbon H13 roadheader tool steel. Among them, after the heat treatment process scheme 3, the hardness increased by 1.5HRC, the impact toughness increased by 17.8%, the tensile strength increased by 13.5%, the yield strength increased by 19.5%, and the elongation increased by 13.8%. Oxidation at 550°C in the air environment 60-hour oxidation weight gain is 40.5% of that of forged H13 steel; after 10,000 thermal cycles at 550°C → 25°C, the oxidation corros...

Embodiment 3

[0065] (1) The chemical composition of the new high-Cr cast roadheader tool steel is by weight percentage:

[0066] C: 0.547; Cr: 11.89; Mo: 2.880; Ni: 1.692; V: 0.947; Mn: 0.384; Si: 0.771;

[0067] (2) The heat treatment process characteristics of the new high-Cr cast roadheader tool steel are shown in Table 8.

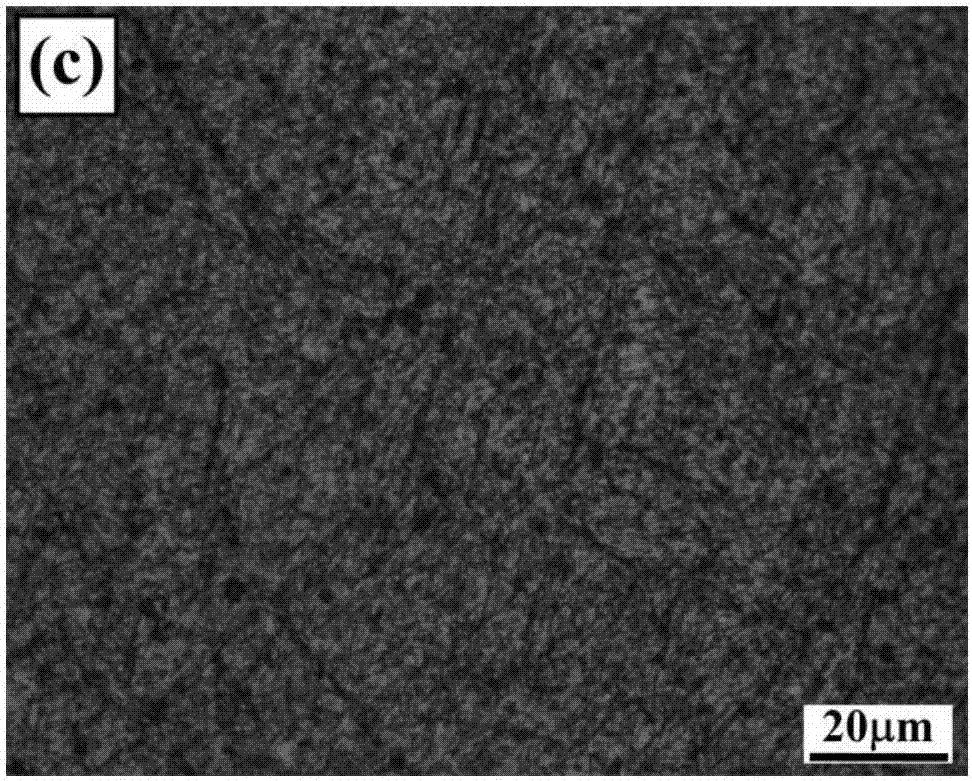

[0068] After the heat treatment of the new high-Cr cast roadheader tool steel through heat treatment schemes 1 to 3, the structure is mainly lath martensite, and at the same time, high-carbon acicular martensite appears in different degrees, and the plasticity and toughness decrease. Compared with forged high-carbon H13 roadheader tool steel, the hardness is increased by 2-3HRC, the tensile strength is increased by 8.3%-11.5%, and the yield strength is increased by 13.2%-19.5%. When the quenching temperature is higher than 1100 °C, quenching cracks on the surface of the sample are more obvious. Oxidation at 550°C for 60 hours in the air environment, oxidation weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com