Patents

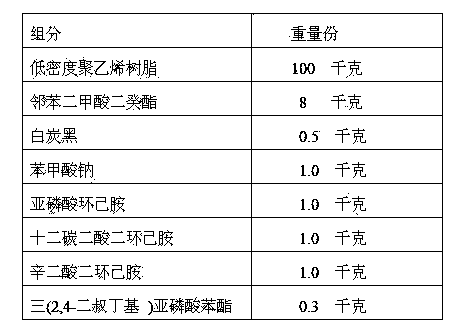

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473 results about "Cyclohexylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexylamine is an organic compound, belonging to the aliphatic amine class. It is a colorless liquid, although, like many amines, samples are often colored due to contaminants. It has a fishy odor and is miscible with water. Like other amines, it is a weak base, compared to strong bases such as NaOH, but it is a stronger base than its aromatic analog, aniline.

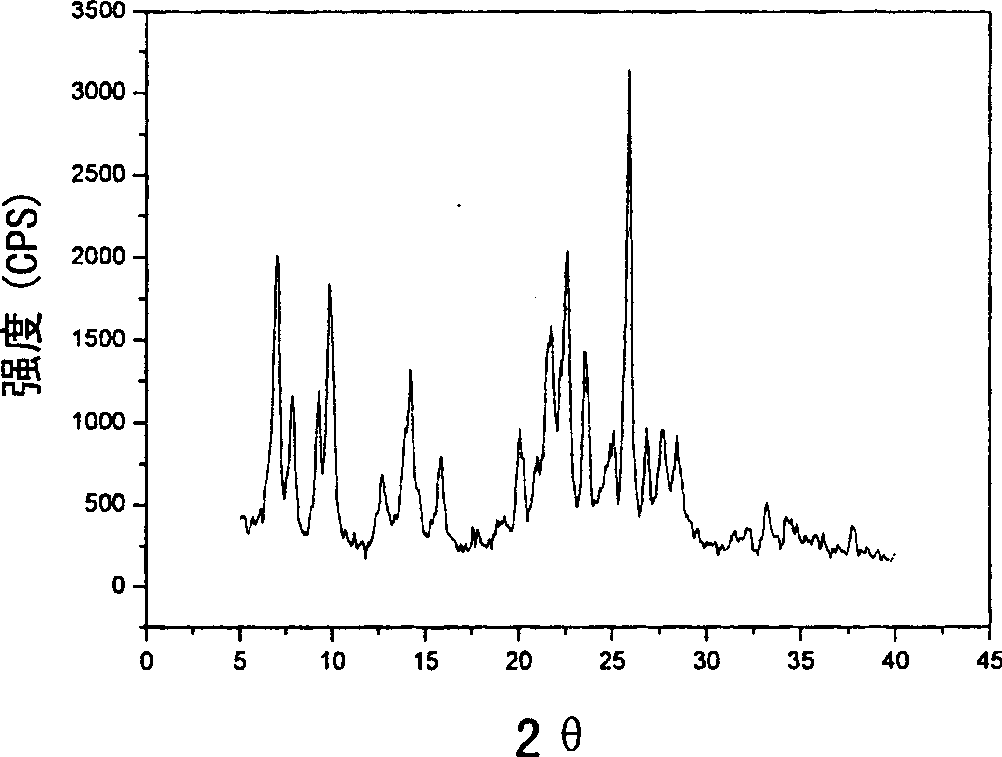

Synthetic method for MCM-22 molecular sieve

InactiveCN1789126AReduce dosageLower synthesis costMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCyclohexylamine

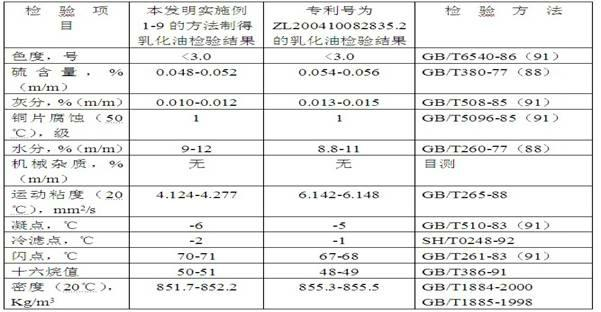

A method for synthesizing MCM-22 molecular screen, which possesses MWW topological structure, employing silicon, aluminium, alkali, mould agent and deionized water as reacting raw material, blooming under the temperature of 135-185 Deg C for some time, hydrothermal synthesizing the needed molecular screen; the invention is characterized by using diamin liquid mixture (BA) as mould agent to prepare molecular screen, one (SDAI) is hexamethylene amine (HMI), another (SDA2) is any one of the followings: cyclohexylamine (CHA)or buta (BuA) or isopropyl amine (IPA).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

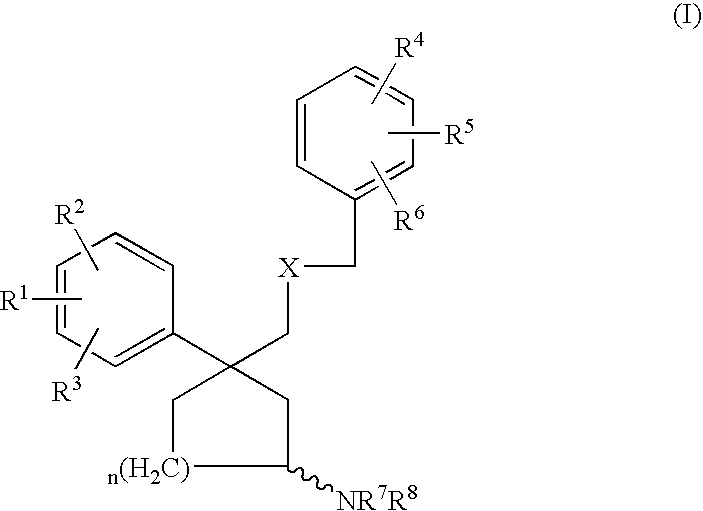

Cyclopentylamine and cyclohexylamine derivatives as NK-1/SSRI antagonists

The present disclosure relates to chemical compounds and their use in human therapy. A specific embodiment of the disclosure relates to compounds of Formula (I); or an isomer, a pharmaceutically acceptable salt or solvate thereof or a pharmaceutically acceptable formulation comprising said compounds are useful for the useful for the treatment or prevention of conditions mediated by tachykinins and / or selective inhibition of serotonin reuptake transporter protein. The compounds act as dual NK-1 antagonists and selective serotonin reuptake inhibitors.

Owner:BRISTOL MYERS SQUIBB CO

Method for preparing rare earth-containing MCM-49 molecular sieve

InactiveCN101468800ACrystalline aluminosilicate zeolitesMolecular-sieve compoundsRare-earth elementMolecular sieve

The invention provides a method for preparing an MCM-49 molecular sieve containing rare earth. The molecular sieve comprises the following raw materials: an aluminum source, a base source, a silicon source, hexamethylene imine, cyclohexane, deionized water and salts of the rare earth, wherein the molar ratios of the raw materials comprise: SiO2:Al2O3 is 12-50, OH:SiO2 is 0.05-0.7, (HMI+CHA):SiO2 is 0.08-1.2, H2O:SiO2 is 10-70, and Re2O3:Al2O3 is 0.01- 0.5. The method comprises the following steps: putting the raw materials into a synthesizing kettle according to the ratios, and sealing the kettle; raising programming temperature to a crystallization temperature of between 135 and 180 DEG C; and then crystallizing and cooling the raw materials in self-generated pressure; and obtaining the MCM-49 molecular sieve containing the rare earth after a crystallized product is subjected to filtering, washing and drying. The method can improve the stability of a molecular sieve catalyst by introducing the rare earth into the molecular sieve in synthesizing, and obviously reduce the synthesizing cost by replacing partial or most of the hexamethylene imine by the cyclohexane in organic amine; meanwhile, the preparation method has the characteristics of good repeatability and high degree of crystallinity of the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing o-chloroaniline

InactiveCN101333169AHigh yieldLow costOrganic compound preparationAmino compound preparationEthylenediamineO-nitrochlorobenzene

An o-chloroaniline production method takes o-nitrochlorobenzene as raw material and is characterized in that the o-nitrochlorobenzene is dissolved in alcohol solvent in the presence of catalyst and additive and reacted with hydrogen at 10-120 DEG C and under 0.3-4.0 MPa; the reaction process is continuous reaction; after the completion of the reaction, the o-chloroaniline is obtained through treatment, wherein, the catalyst can be selected from one of the following: Ni / Al2O3, Raney Ni, Pt / C and Pd / C; while the additive can be selected from one, or two, or three of the following compounds: cyclohexylamine, ethylenediamine, ethanolamine, diethanolamine, triethanolamine, pyridine, liquid ammonia, ammonium bicarbonate, ammonium carbonate, sodium carbonate, sodium bicarbonate, potassium bicarbonate, potassium carbonate, potassium hydrogen phosphate, potassium dihydrogen phosphate, sodium hydrogen phosphate and sodium dihydrogen phosphate; the dosage of the catalyst takes up 0.05% to 20% of the mass of the o-nitrochlorobenzene; the dosage of the additive takes up 0. 5% to 20% of the mass of the o-nitrochlorobenzene; the alcohol can be methanol or ethanol; the dosage of alcohol takes up 30% to 150% of the dosage of the o-nitrochlorobenzene; the continuous reaction is realized through 1 to 6 tank reactors which are connected in series.

Owner:淮安嘉诚高新化工股份有限公司

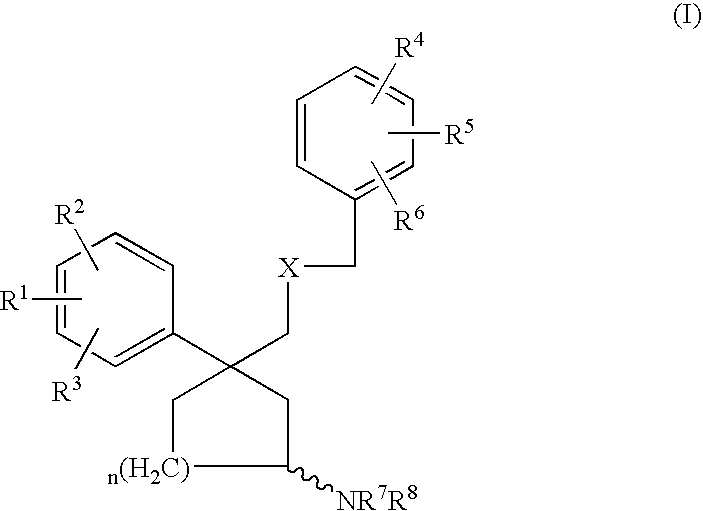

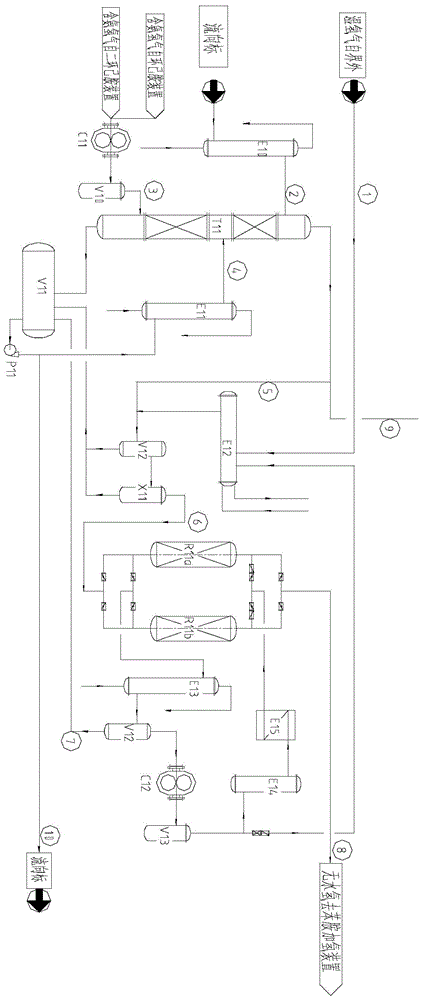

Method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation

ActiveCN102633649AExtended service lifeHigh yieldOrganic compound preparationAmino compound preparationGas phaseFixed bed

The invention discloses a method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation, which includes the steps: 1) mixing fresh hydrogen with circulating hydrogen; 2) mixing mixed hydrogen with the aniline according to the molar ratio of 15:1-19:1 in an aniline evaporator to enable vaporization of the aniline; 3) carrying out a hydrogenation reaction of vaporized mixed gas in a fixed bed hydrogenation reactor prefilled with cobalt-ruthenium catalyst or nickel-ruthenium catalyst at the reaction temperature of 165-179 DEG C and under the reaction pressureof 0.2-0.3MPa; and 4) materials which are subjected to the hydrogenation reaction enter a separator by means of heat exchange, condensation and cooling, performing gas separation to obtain crude cyclohexylamine, and then rectifying so that a cyclohexylamine product is prepared. By the aid of the method, production cost is effectively reduced, product yield is increased, and the service life of the catalyst is prolonged.

Owner:SHANDONG WEIJIAO GRP

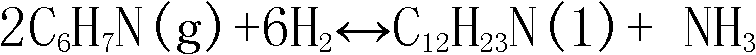

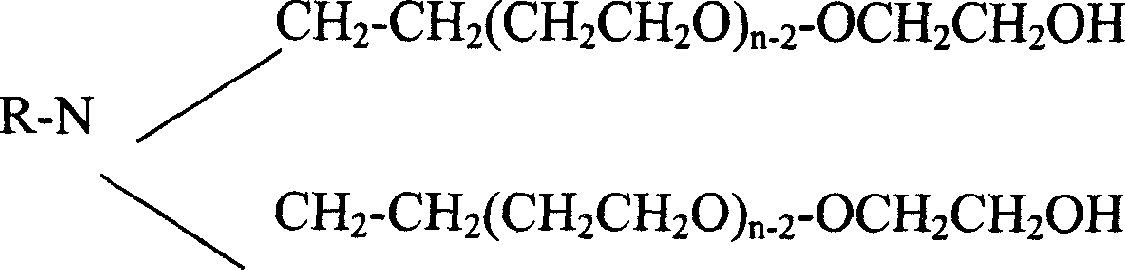

Solder paste

InactiveUS6159304AImprove solderabilityEasy to corrodeWelding/cutting media/materialsSoldering mediaEthylene oxideAlloy

In order to prevent aging of an Sn-Zn system alloy solder paste, 0.5-5% by weight of a compound obtained by adding an ethylene oxide to cyclohexylamine, preferably together with 0.5-5% by weight of a polyoxyethylene alkylamine is added to a flux of said solder paste.

Owner:PANASONIC CORP +1

Method for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine

ActiveCN101386579ASimple methodReduce construction costsPreparation by reductive alkylationCyclohexanonePolymer science

The present invention discloses a method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine(isophorone diamine, IPDA) from 3-cyan-3,5,5-trimethyl cyclohexanone(IPN). The method comprises the following steps 3-cyan-3,5,5-trimethyl cyclohexanone, ammonia, an alcohol and / or ether solvent, a hydrogenation catalyst and a promoter are reacted at a temperature of between 50 and 120 DEG C and a hydrogen pressure of between 5 and 15 MPa so as to obtain 3-aminomethyl-3,3,3-trimethyl cyclohexylamine. The method simplifies the prior process for preparing IPDA from IPN, is low in equipment cost, mild in reaction conditions and high in offspring yield.

Owner:WANHUA CHEM GRP CO LTD +1

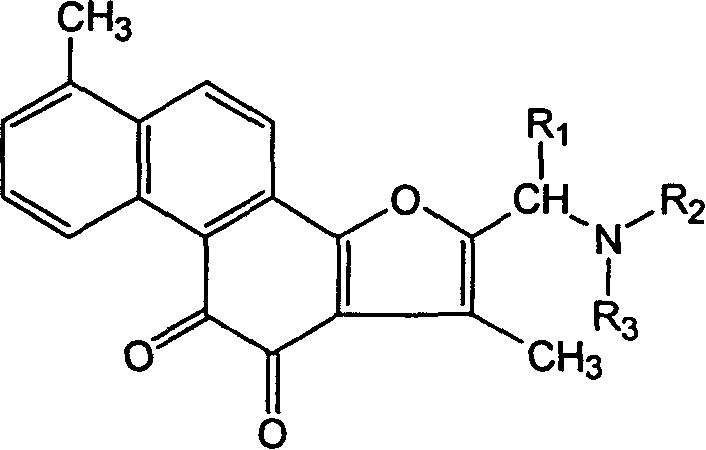

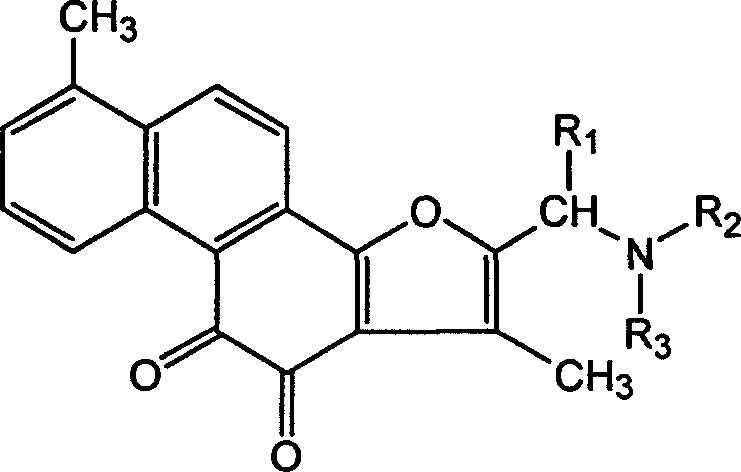

Tanshinone I derivatives and pharmaceutical application thereof

InactiveCN1837200AGood water solubilityImprove bioavailabilityPowder deliveryOrganic active ingredientsMorpholineCyclohexylamine

Owner:秦引林

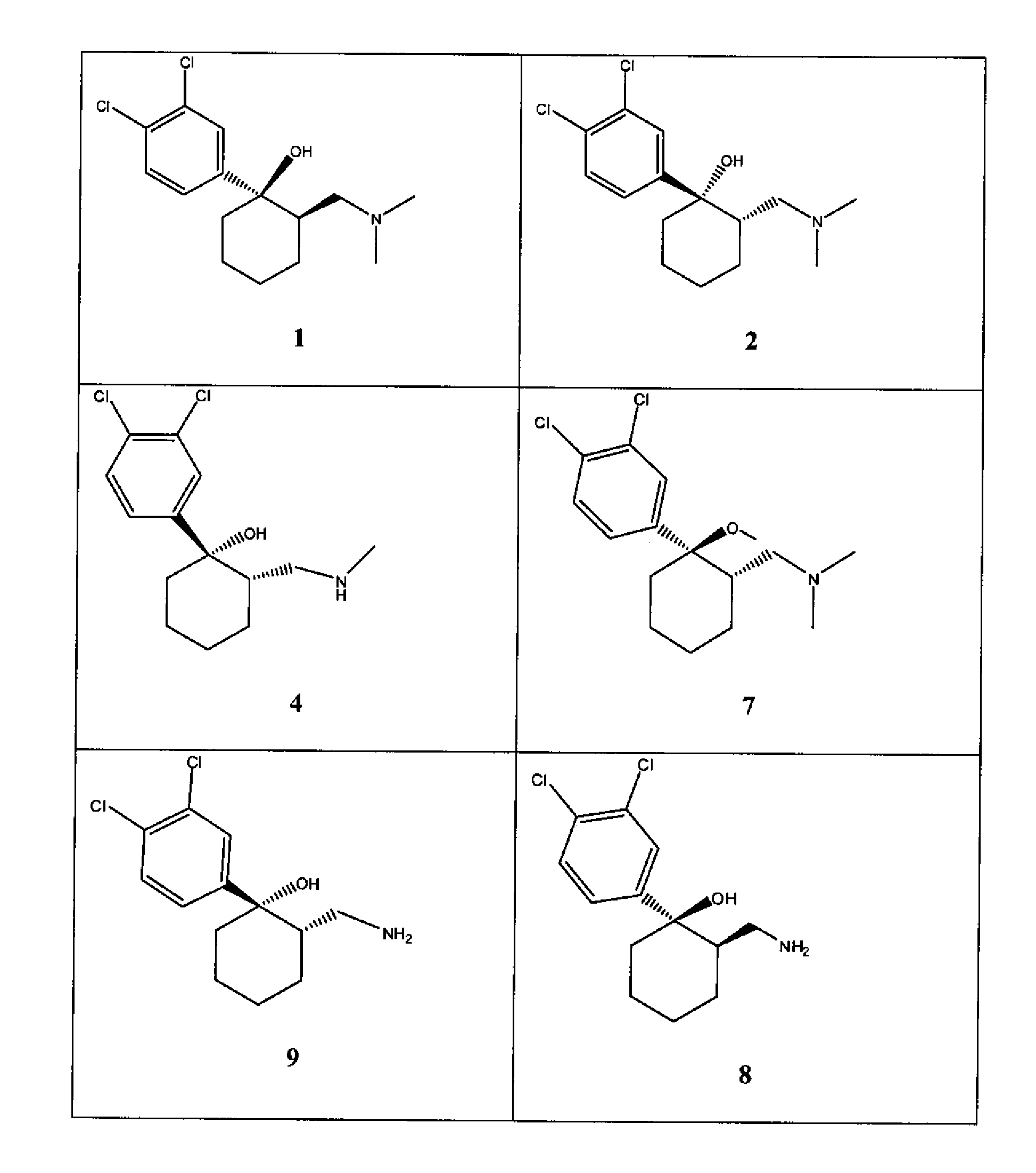

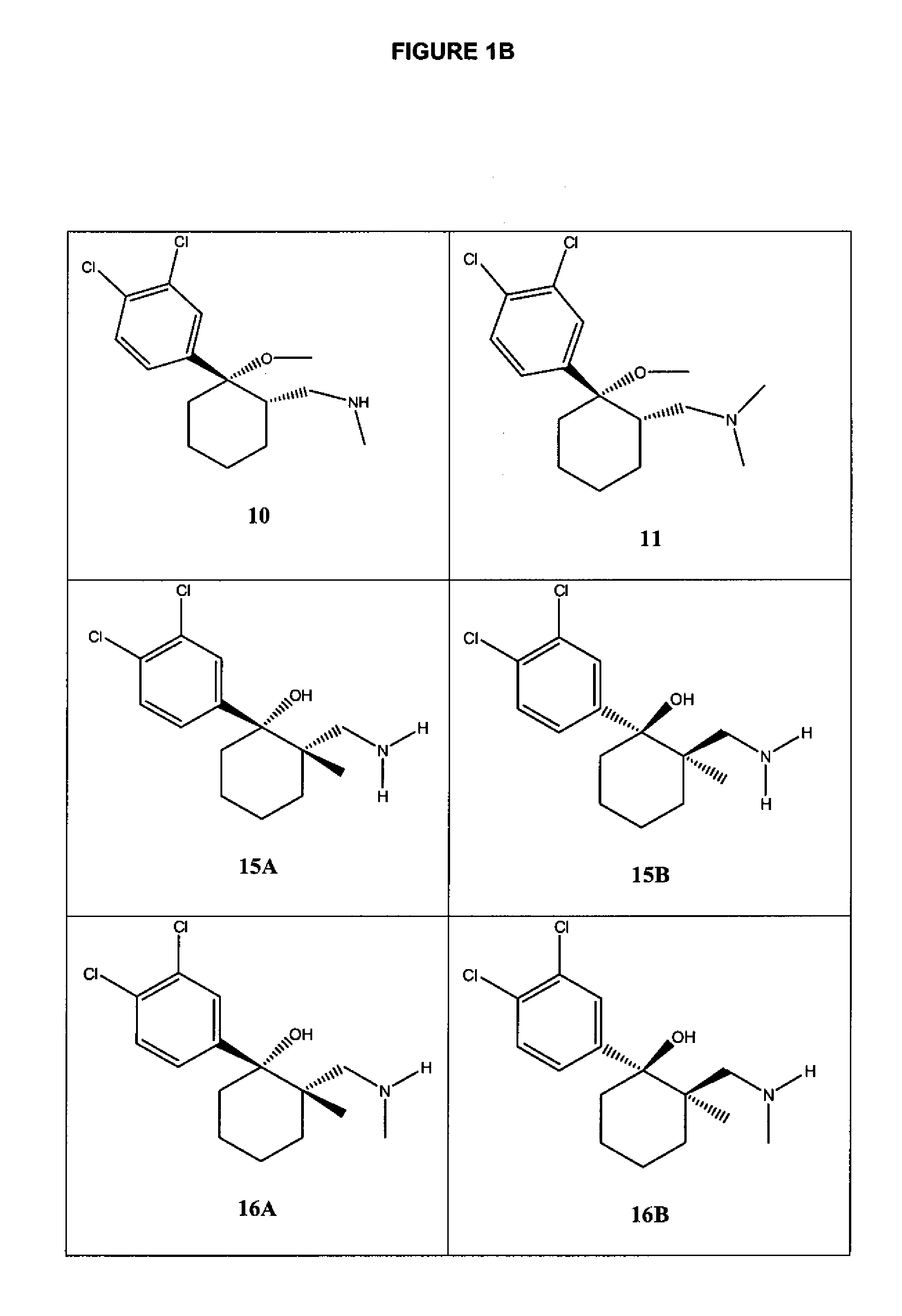

Phenyl substituted cycloalkylamines as monoamine reuptake inhibitors

ActiveUS20090005456A1Improve usabilityOrganic active ingredientsBiocideSynaptic cleftPharmaceutical formulation

Phenyl-substituted cyclohexylamine derivatives and method for their synthesis and characterization are disclosed. Use of these compounds to treat / prevent neurological disorders as well as methods for their synthesis are set forth herein. Exemplary compounds of the invention inhibit reuptake of endogenous monoamines, such as dopamine, serotonin and norepinephrine (e.g., from the synaptic cleft) and modulate one or more monoamine transporter. Pharmaceutical formulations incorporating compounds of the invention are also provided.

Owner:SUNOVION PHARMA INC

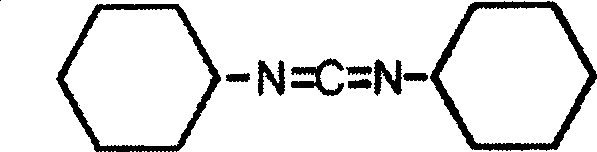

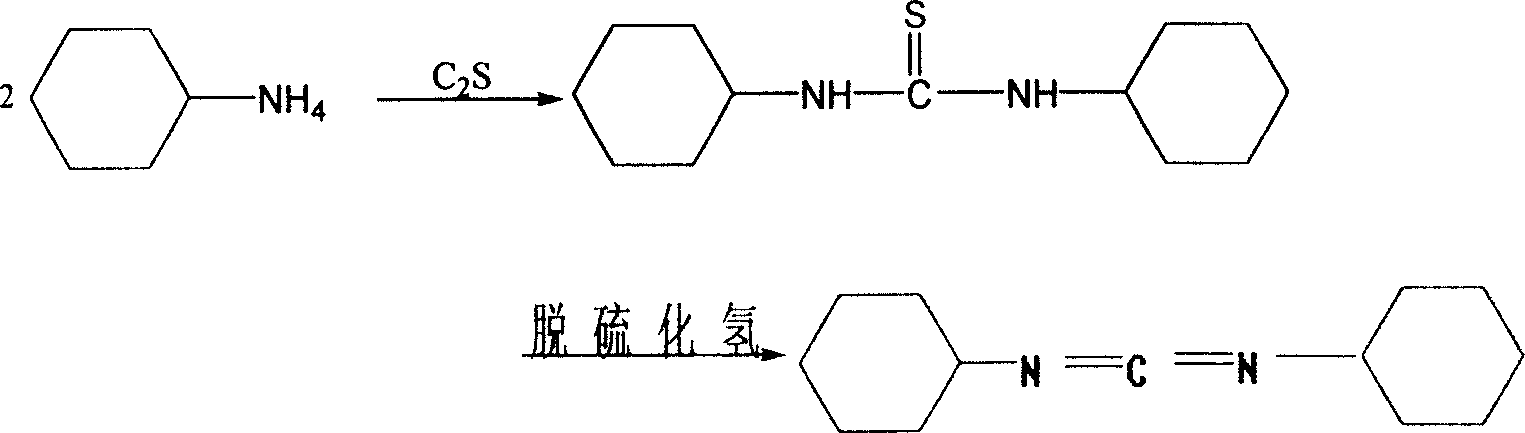

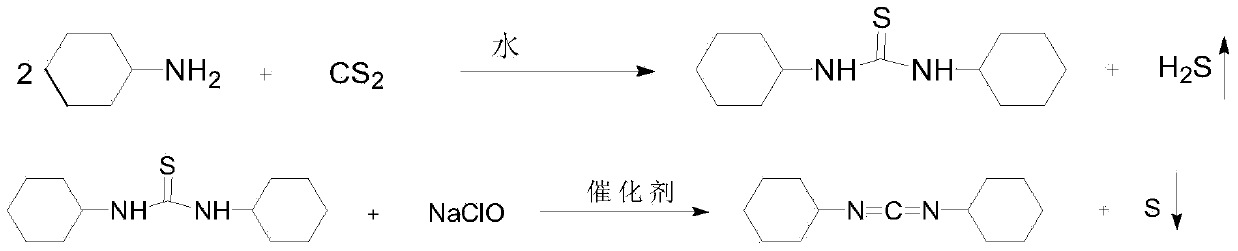

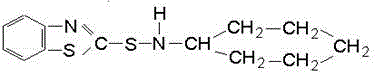

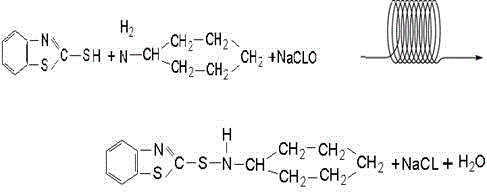

Production technique of N,N'-dicyclo hexylcar bodiimide

ActiveCN101096349AComplete oxidation reactionReduce manufacturing costImino compound preparationPolyethylene glycolCyclohexylamine

The invention discloses a production technology of N, N'-dicyclo hexylcar bodiimide, which comprises the following steps: generating dicyclohexyl sulfourea and sodium sulfide with cyclohexylamine and carbon bisulphide; generating N, N'-dicyclo hexylcar bodiimide by oxygenizing dicyclohexyl sulfourea twice with sodium hypochlorite and removing hydrogen sulfide. The invention is characterized by the following: adding the accelerant when dicyclohexyl sulfourea is oxygenized by sodium hypochlorite; applying triethyl benzyl ammonium chloride(TEBA)or carbowax as the accelerant; adding sodium sulfide which is generated in the first step reaction in order to removing sulfur by reacting with sulfur in the organic phase after oxygenizing twice. The invention guarantees the sufficient oxidation reaction, which reduces the production cost, and improves the product quality.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

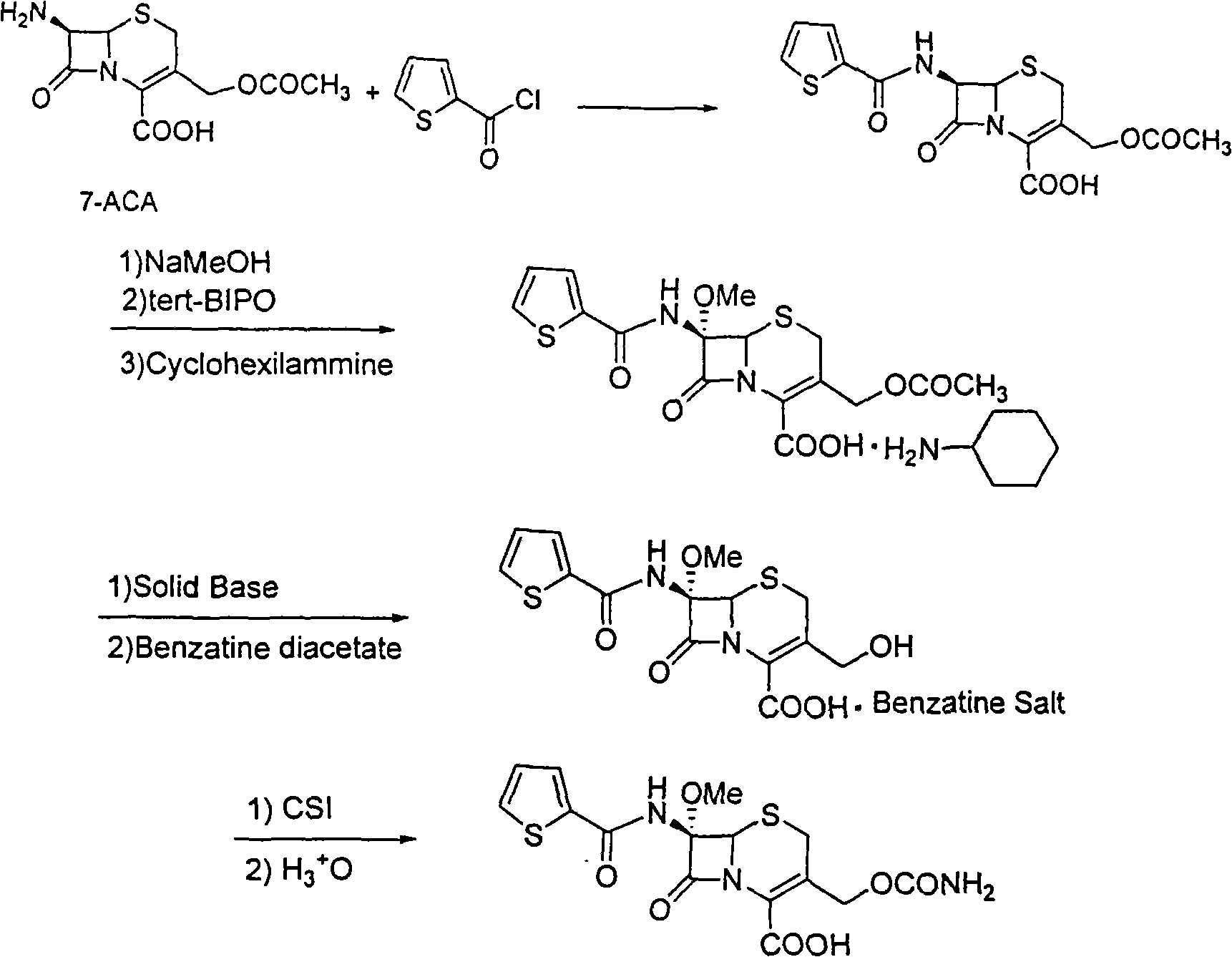

Synthetic method of antibiotic cefoxitin

ActiveCN101555252AEmission reductionEliminate emissionsAntibacterial agentsOrganic chemistryCefoxitinAlkaloid

The invention relates to a synthetic method of antibiotic cefoxitin. 7-ACA is taken as a starting material and firstly reacts with thiopheneacetyl chloride, cephalothin acid is obtained by separation; the cephalothin acid is not purified, and the methoxylation is directly carried out on the cephalothin acid to obtain an intermediate A which introduces methoxy on the position of 7, the intermediate A obtains 7-alpha-methoxy cephalothin cyclohexylamine salt under the action of cyclohexylamine; the 7-alpha-methoxy cephalothin cyclohexylamine salt reacts with benzathine diacetate under the catalysation of solid alkaloid to obtain 7-alpha-methoxy-3-deacetoxy cephalothin benzathine salt; and the carbamylation is carried out under the action of chlorosulfonyl isocyanate to obtain the cefoxitin. The synthetic method has the advantages that compared with the prior art, the synthetic method simplifies the operation process, has high product yield, reduces the production cycle, eliminates the discharge of waste water containing organic solvent and reduces the production cost. The product quality is stable, and the synthetic method is applicable to the large-scale industrial production.

Owner:国药集团致君(苏州)制药有限公司

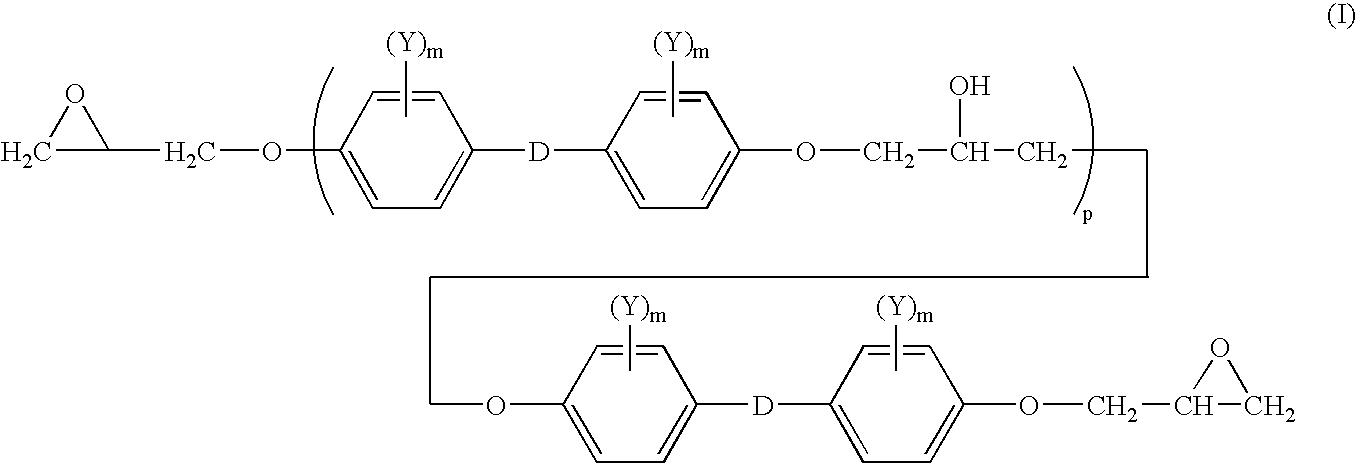

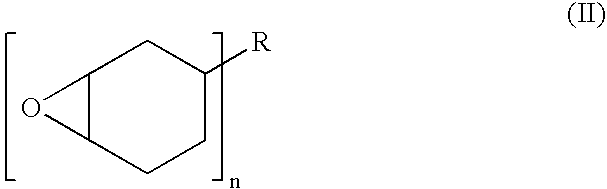

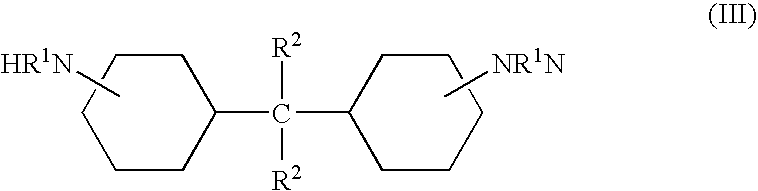

Process for Preparing Composites Using Epoxy Resin Formulations

InactiveUS20080308972A1High distinctness of imageImprove surface qualityCeramic shaping apparatusCoatingsEpoxyAlkane

The invention is a process for making reinforced composites using an epoxy resin composition. The epoxy resin compositions are hardened using a gem-di(cyclohexylamine)-substituted alkane as a hardener and a tertiary amine compound, a heat-activated catalyst, or a mixture thereof as an accelerator. This epoxy resin composition has a long open time, and then cures rapidly in a mold in the presence of a reinforcement. These cure characteristics make the composition well suited for use in manufacturing processes such as resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), Seeman Composites Resin Infusion Molding Process (SCRIMP) and reaction injection molding (RIM).

Owner:DOW GLOBAL TECH LLC

Therapeutic application of a thienycyclohexylamine derivative

A method of inhibiting effects of neurotoxic products in warm-blooded animals comprising administering to warm-blooded animals an amount of 2-methyl-1-(1-piperidinyl)-1-(2-thienyl)-cyclohexane in substantially pure racemic, diastereoisomeric or enantiomeric form effect to inhibit effects of neurotropic products and mixtures of thienyl cyclohexylamine and at least one member of the group consisting of anticholinergic, anticonvulsant or cholinesterase-reactivating substances.

Owner:IPSEN PHARMA SAS

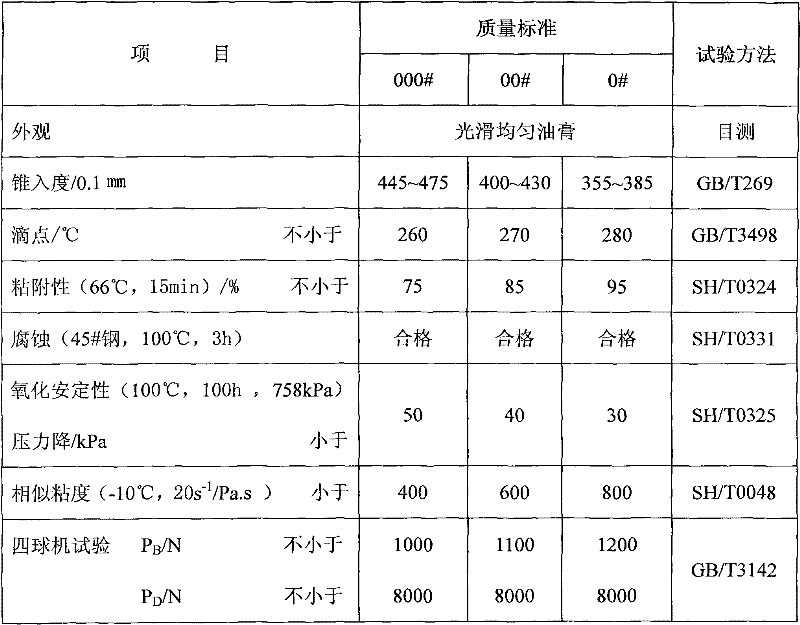

Grease specially used for heavy-load open-type gear and preparation method thereof

ActiveCN102311850AAvoid direct contactStrong extreme pressure and wear resistanceLubricant compositionDiphenylmethaneEngineering

The invention discloses grease specially used for a heavy-load open-type gear and a preparation method. The grease of the invention comprises the following raw materials by weight percentage: 1-2% of MDI (diphenylmethane-4,4'-diisocyanate), 0.2-1% of octadecylamine, 0.5-2% of cyclohexylamine, 35-50% of base oil A, 30-45% of base oil B, 0.5-1.0% of anti-oxidant A, 1.5-3.0% of anti-oxidant B, 0.5% of antirust agent, 0.5-1.5% of extreme pressure antiwear additive A, 4-8% of extreme pressure antiwear additive B, 2-5% of oiliness agent A, 0.1-0.3% of oiliness agent B, 10-15% of adhesive compound and 4-8% of solid lubricant. Various raw materials are stirred and mixed under certain sequence according to different temperature while preparing, the grease of the present invention has ultra-strong extreme pressure and antiwear property, and excellent adhesiveness, anticorrosion and antirust performance, good anti-oxidizability and water resistance performance and spray characteristic, and has good adaptability with routine seal elements. The grease has no heavy metal lead or a volatile solvent, and belongs to the energy saving and environment-friendly product.

Owner:安徽中天石化股份有限公司

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Vapor phase antirust blown polyethylene film and making method thereof

The invention discloses a vapor phase antirust blown polyethylene film and a making method thereof. The vapor phase antirust blown polyethylene film comprises low density polyethylene resin, a plasticizer, an auxiliary filler, sodium benzoate, cyclohexylamine phosphate, amine salt of aliphatic dibasic acid, and an antioxidant. Polyethylene materials comprising vapor phase antirust agents are utilized to make the vapor phase antirust blown polyethylene film through a blowing production process in order to realize convenient production and vapor phase antirust effects. The vapor phase antirust agents adopted in the invention are different from traditional nitrite vapor phase antirust agents, are in favor of realizing environmental protection and benefiting the health of human bodies. The film made in the invention has the advantages of composite structure, obstruction of the outward penetration of the vapor phase antirust agents, antirust effect increase and antirust time prolongation.

Owner:YANTAI HENGDIKE ENERGY TECH

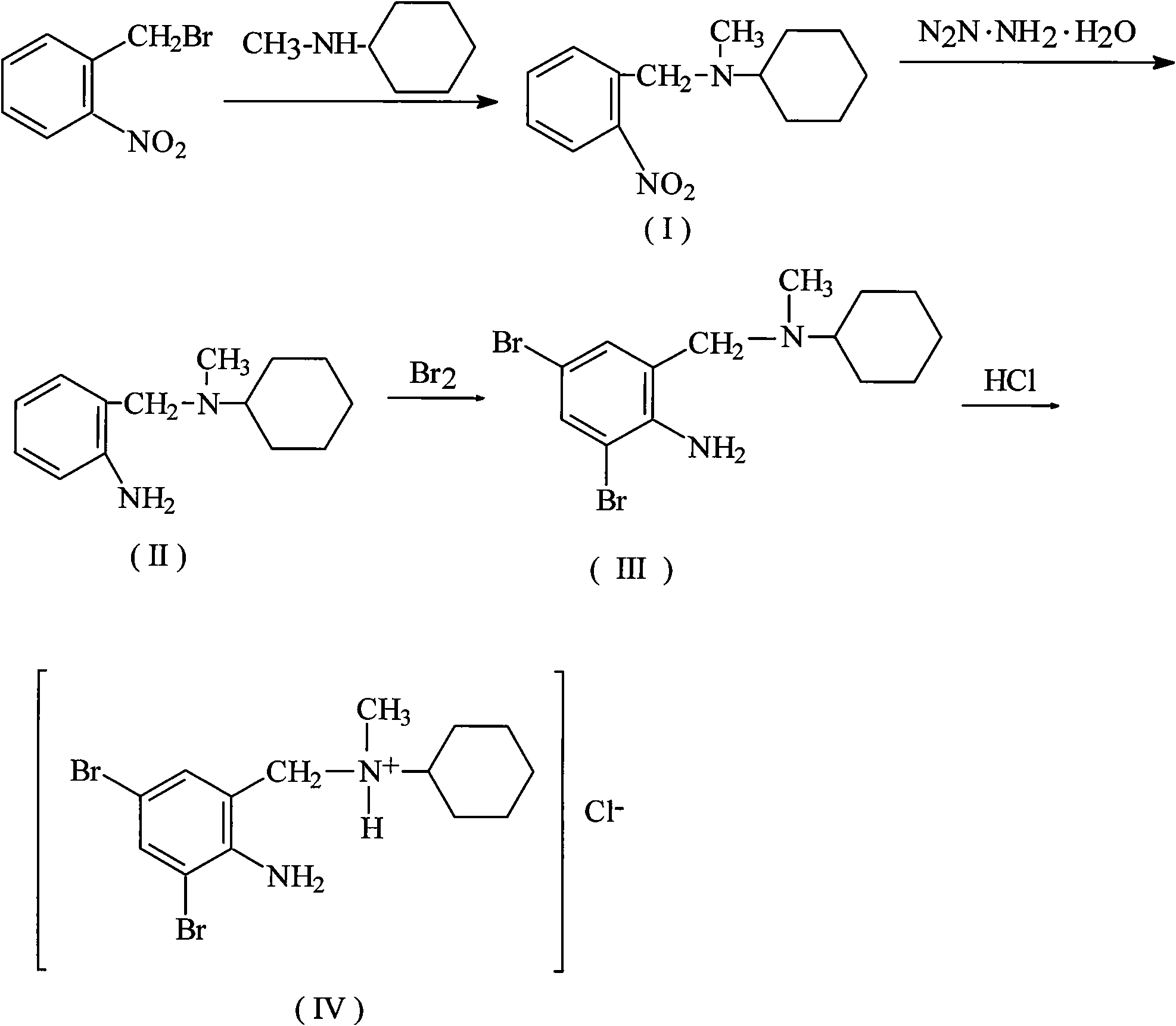

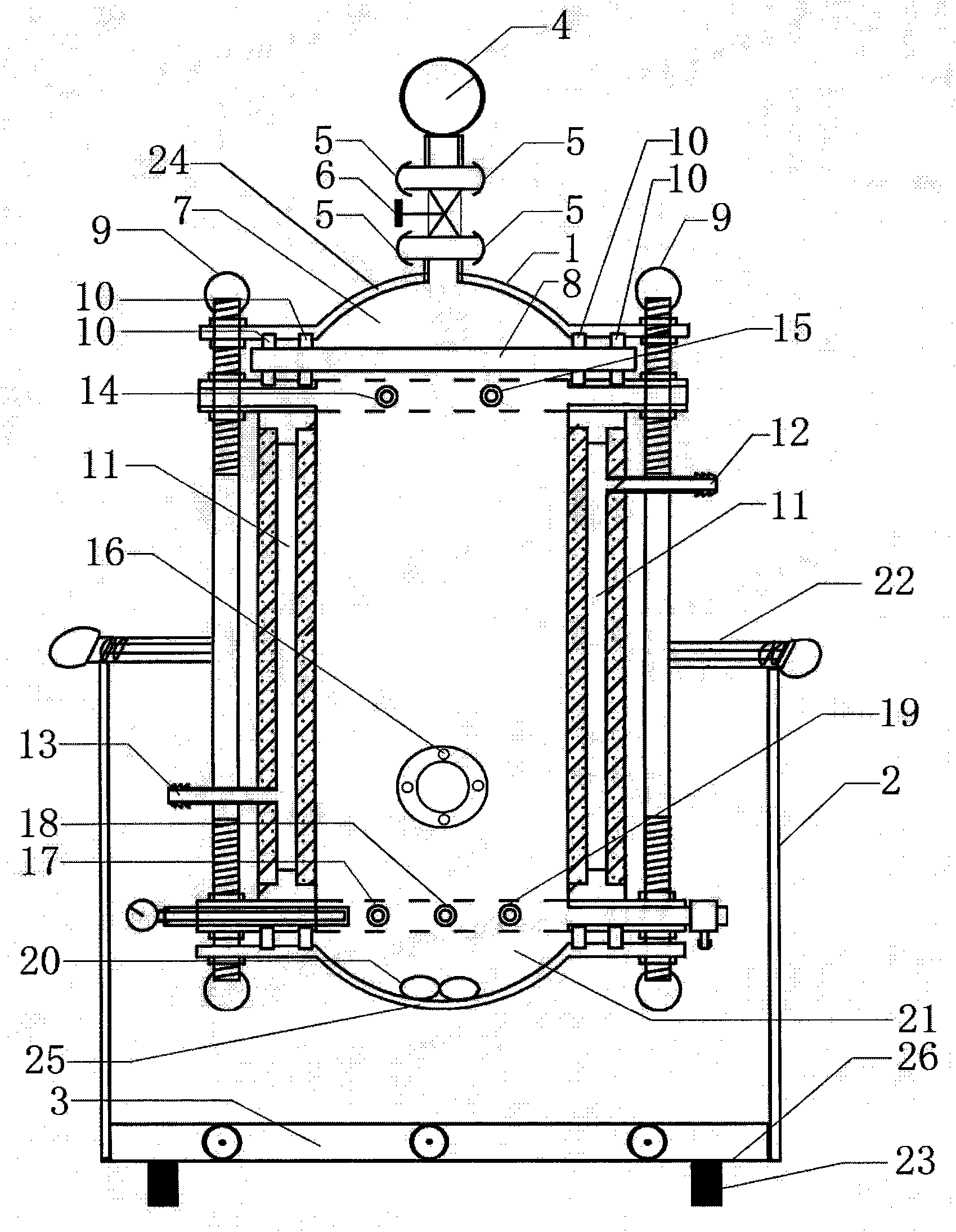

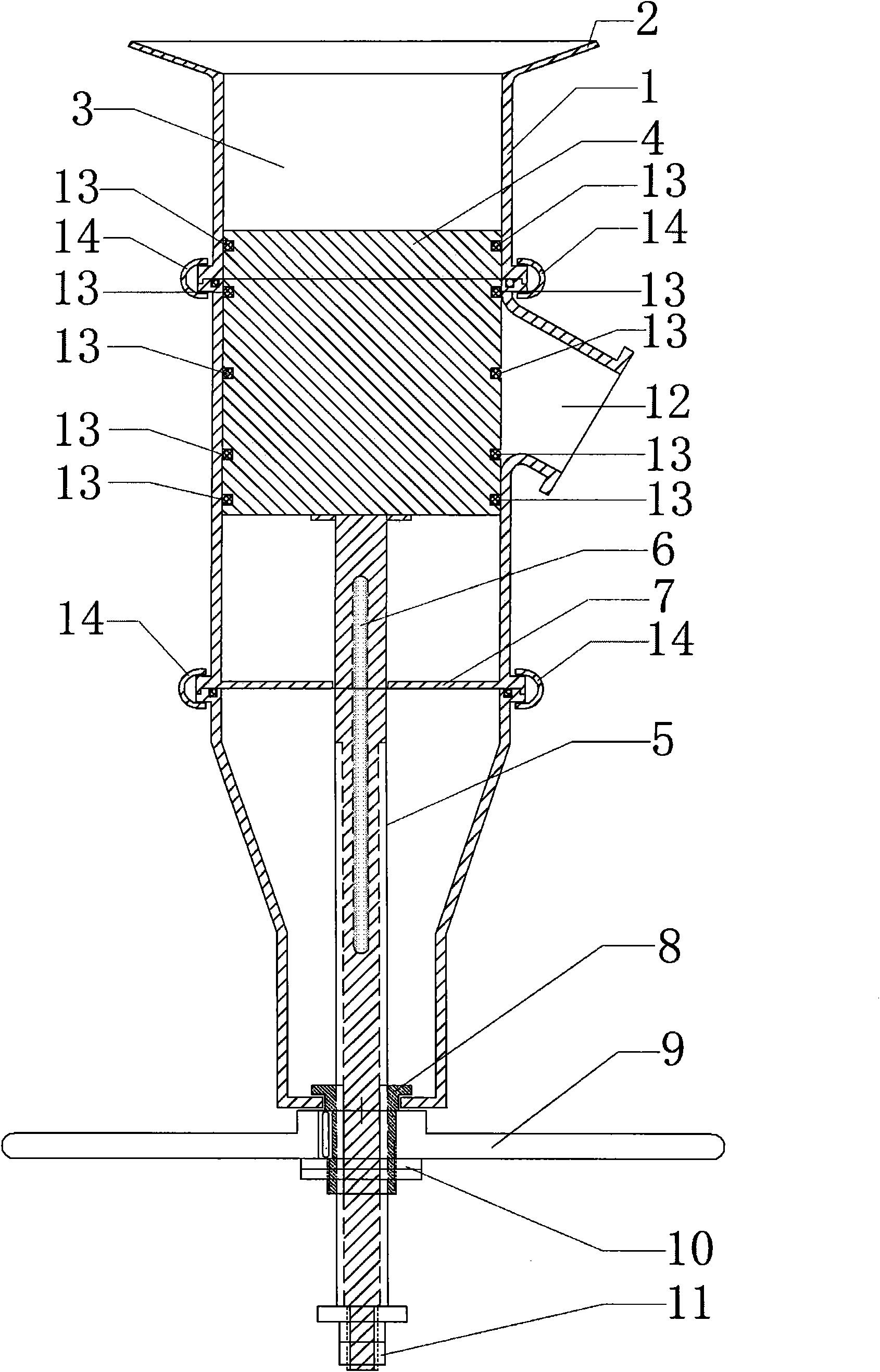

Production method of bromhexine hydrochloride

InactiveCN101817754AFewer synthetic stepsMild reaction conditionsAmino preparation from aminesMixersHydrazine compoundAir tightness

The invention discloses a production method of bromhexine hydrochloride, which uses a multi-function reaction kettle with a special kettle bottom valve as the reaction vessel, uses a special filter as the purifier, uses 2-nitrobenzyl bromide and N-methyl cyclohexylamine as the starting materials, enables the product generated by the reaction under the condition of normal temperature and pressure to the react with hydrazine hydrate under the catalysis of Raney's nickel, and produces the bromhexine hydrochloride by brominating substitution reaction, chlorine hydride salification reaction, purification and drying. Compared with the disclosed production process of bromhexine hydrochloride and the bromhexine hydrochloride produced by the current synthesis device, the production method of the invention has the advantages of less reaction steps, moderate reaction condition, convenient purification and simple operation; the used special device has the advantages of good heat insulation, oxidation resistance, air tightness and environmental protection effects and thorough reaction; and the reaction device has the advantages of simple structure, convenient operation, easy disassembly / assembly and cleaning, high filter efficiency, reaction quality and yield, and stable product quality.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

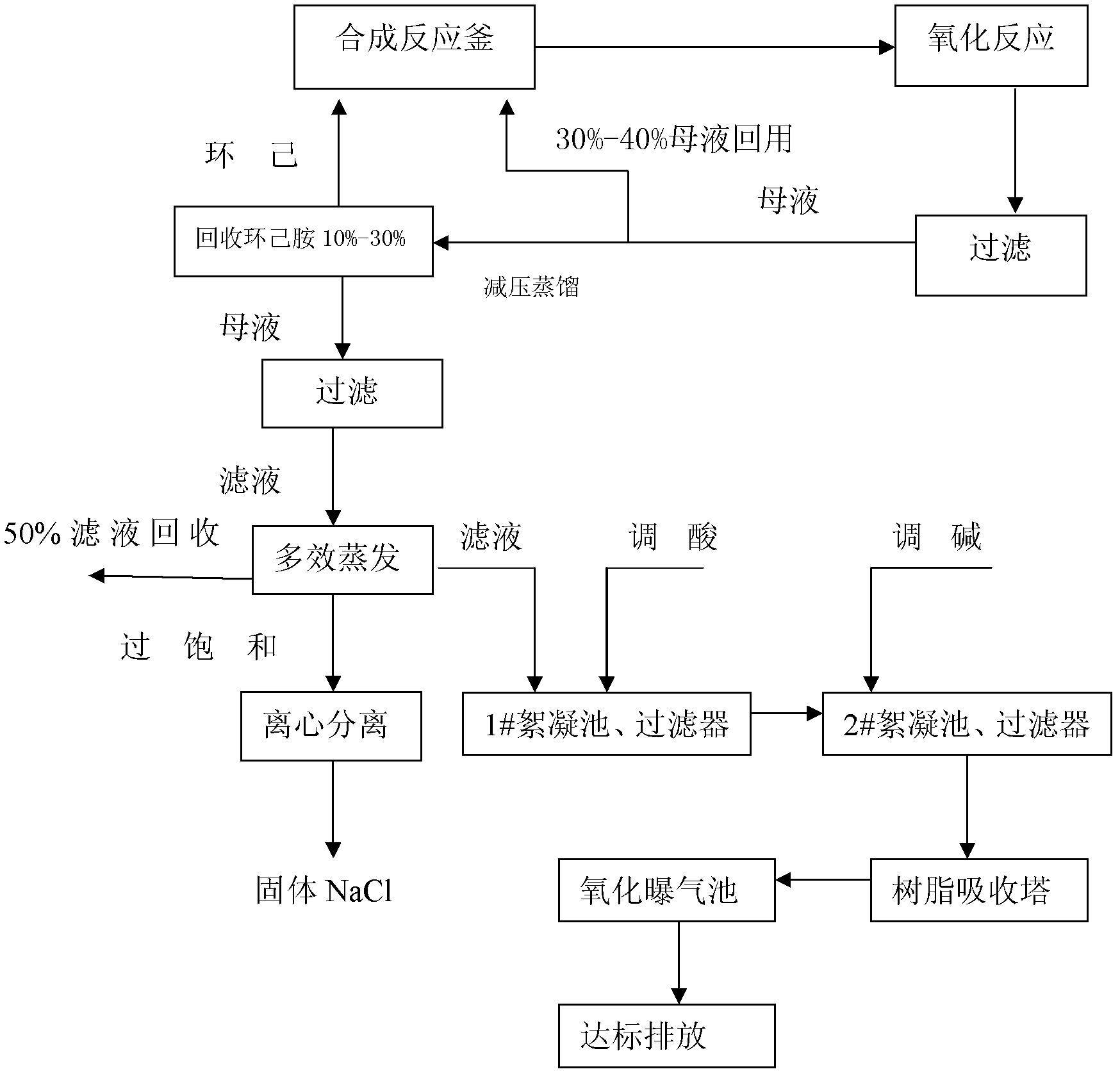

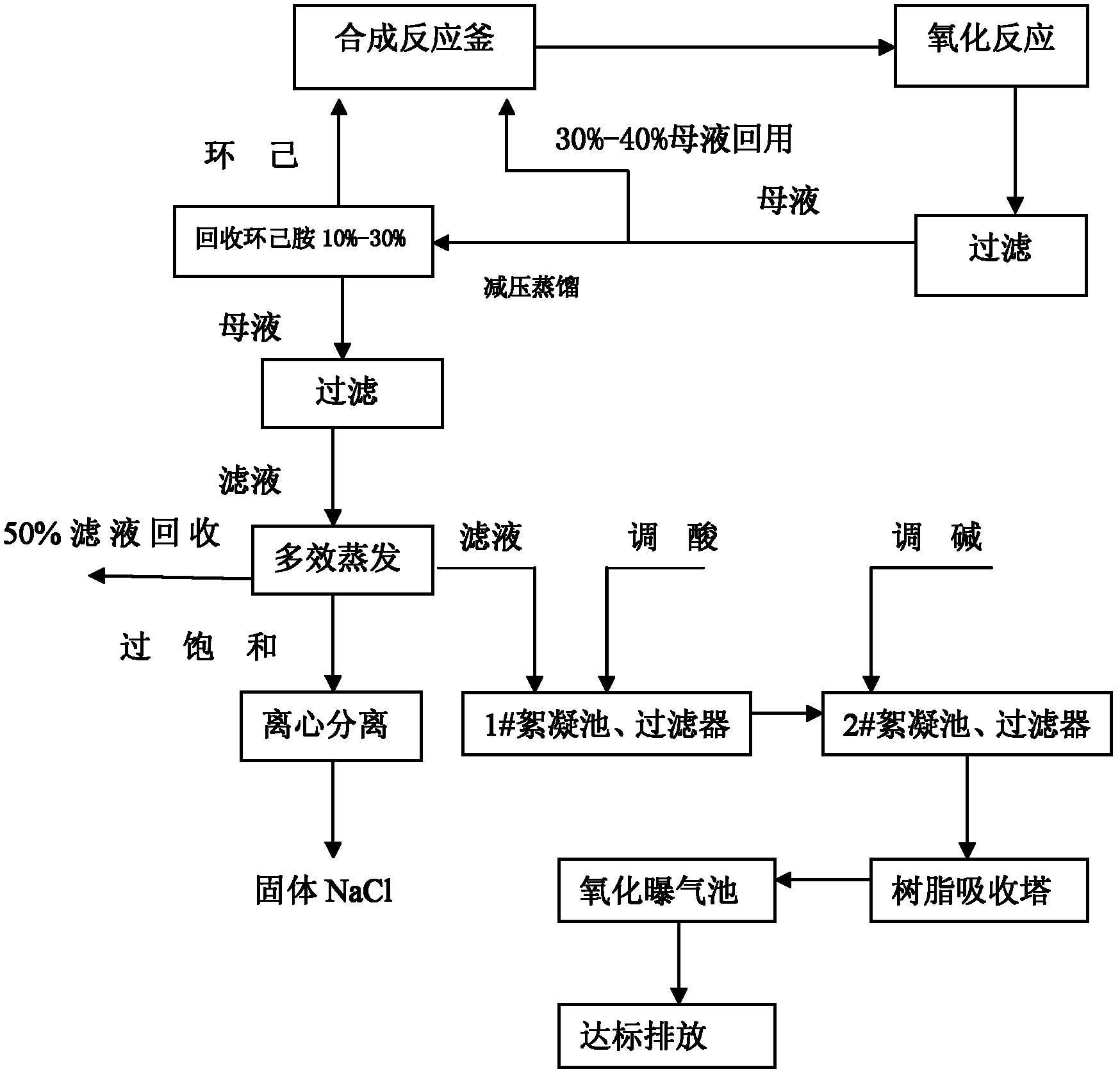

Method for treating wastewater of rubber vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfonamide

InactiveCN102432136AEfficient extractionEfficient removalAmino compound purification/separationMultistage water/sewage treatmentVulcanizationEvaporation

The invention belongs to a method for treating wastewater of a rubber vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfonamide (CZ). The method comprises: returning 30%-40% of generated wastewater into a CZ synthesis reaction vessel for indiscriminate application, subjecting the rest part to vacuum distillation, recovering cyclohexylamine; precipitating organic components dissolved in cyclohexylamine, filtering the recovered mother liquid, and putting the precipitated organic matter into the synthesis reaction vessel for continuous reaction, and leading the filtrate to multiple-effect evaporation so as to obtain a sodium chloride saturated solution, conducting concentration so as to obtain a supersaturated solution of sodium chloride, and carrying out centrifugation, thus obtaining sodium chloride; returning part of the evaporated water to the device for reuse, and leaving the left part to biochemical treatment. In order to make the raw material M completely reacted during production, excess cyclohexylamine is added, so that a great amount of cyclohexylamine is contained in the wastewater. By adopting a mother liquid indiscriminate application technology, the mother liquid can be recycled, the primary utilization rate of cyclohexylamine can be enhanced, simultaneously the mother liquid treatment cost can be reduced, and the CZ yield can be improved. After mother liquid indiscriminate application, the CZ product has no abnormal change in appearance, and no obvious change in melting point as well as ash content.

Owner:KEMAI CHEM

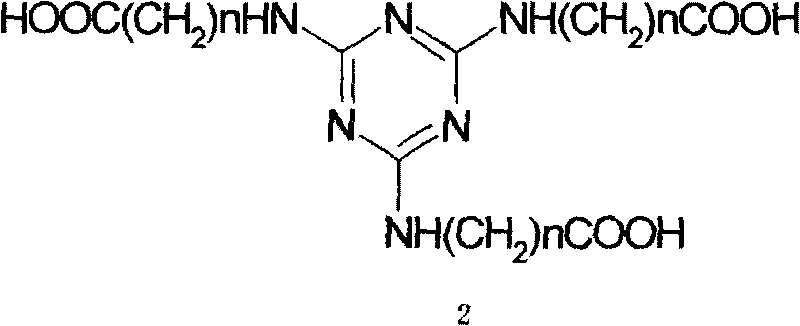

Thermal test solution for engine

The invention discloses a thermal test solution for an engine, which consists of the following components in weight percent: 70-80 percent of ethylene glycol, 0.1-5.0 percent of aliphatic monocarbocylic, 1.0-5.0 percent of straight-chain aliphatic dicarboxylic acid, 0.1-1.0 percent of triazine skeleton tricarboxylic acid, 0.1-4.5 percent of aromatic acid, 0.1-1.0 percent of composite inhibitor, 0.1-0.5 percent of hydrolytic polymaleic anhydride, 0.2-4.0 percent of alkenyl amines, 0.2-2.0 percent of cyclohexylamine carbonate, 0.001-0.2 percent of antifoaming agent and the balance of deionized water. The invention can inhibit and prevent the corrosion during the thermal test process of the engine, has a unique gaseous phase corrosion inhibition technology, can be used for preventing the corrosion generated by potential corrosion which is formed by the contacting of the residual liquid and the air during the placing process after the thermal test of the engine, and has both a fully organic acid type engine coolant corrosion inhibition technology and a gaseous phase corrosion inhibition technology as well as good stability.

Owner:北京蓝星清洗有限公司

Gas-phase anti-corrosion paint

InactiveCN101245218ADry fastHigh hardnessAnti-corrosive paintsPolyester coatingsBenzoic acidOctanoic Acids

The invention relates to a gas phase antirust coating, the components of the combination account according to parts by weight, and the scope is as follows: 8 to 25 parts of acrylate modified alkyd resin, 5 to 20 parts of 2402 phenolic resin, 0 to 15 parts of petroleum sulfonate barium, 0 to 25 parts of oxidized malthenes magnesium soap, 0 to 5 parts of dodecatylene base succinic acid imidazoline, 0 to 6 parts of sebacic acid morpholine, 0 to 6 parts of octanoic acid two cyclohexylamines, 0 to 6 parts of octanoic acid tributyl amine, 0 to 6 parts of capric acid tributyl amine, 0 to 15 parts of benzoic acid monoethanolamine, 0.1 to 1.0 part of drier, 0 to 5 parts of thixotropic agent, 1 to 5 parts of dibutyl phthalate, 0 to 5 parts of black paste, and the rest of xylene / 200 model solvent (1:1). The gas phase antirust coating of the invention has the advantages of fast table-drying speed, long antirust time, high rigidity, high brightness, good temperature resistance, etc., and can satisfy the requirements of the automatic pipeline production and long time open storage antirust need of oil steel pipes and other large pipes or profiles.

Owner:DALIAN YATAI SCI & TECH NEW MATERIAL

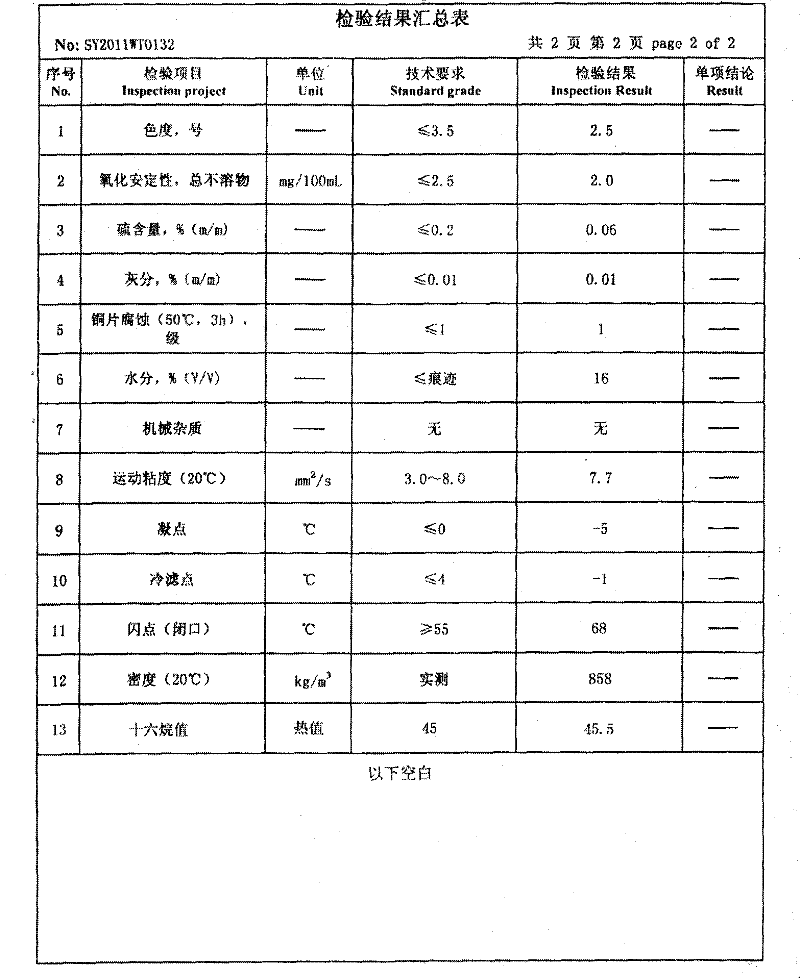

Method for preparing micro-emulsified procetane

InactiveCN102250656AImprove physical and chemical propertiesEasy to useLiquid carbonaceous fuelsAlkylphenolPolyethylene glycol

The invention provides a method for preparing a micro-emulsified procetane. The method comprises the following steps of: selecting the following components in percentage by weight: 60% of oleic acid, 10% of naphthenic acid, 6% of ethanolamine, 2% of triethanolamine, 7% of cyclohexylamine, 3% of n-butyl alcohol, 3% of isopropanol, 2% of Span-80, 0.5% of Span-20, 0.5% of polyethylene glycol, 2% of alkylphenol polyoxyethylene ether OP4, 0.5% of alkylphenol polyoxyethylene ether OP10 and 3.5% of conditioning agent; agitating the mixture at room temperature and normal pressure for 40-60 minutes toprepare the micro-emulsified procetane. By using the method provided by the invention, the physicochemical performance and use effects of the emulsified fuel gas are improved and energy is saved by more than 30%; the exhaust gas purification rate is more than 30-60%, the cost is reduced by more than 15-20% and the dynamic performance and the oil consumption of the micro-emulsified procetane have little difference from those of pure diesel oil.

Owner:QUANZHOU XINRAN ENVIRONMENTAL PROTECTION ENERGY

Concentrated emulsified diesel fuel and preparation method thereof

The invention relates to concentrated emulsified diesel fuel and a preparation method thereof, wherein the concentrated emulsified diesel fuel is long in shelf life and low in cost and is prepared by the following raw materials by weight parts: 50-80 of diesel, 0.5-1 of cyclohexylamine, 0.5-2 of ethanolamine, 0.03-0.08 of water and hydrazine, 8-17 of oleic acid or fatty acid, 0.01-0.08 of ferrocene, 0.1-1 of isooctyl nitrate or amyl nitrate, 5-10 of ethanol, 4-15 of solvent oil and 10-30 of water. The concentrated emulsified diesel fuel is long in service life which is 6 years, has no emulsion breaking, is good in stability, can be used directly, also can be used by being mixed with national-standard diesel in any proportion, and further has the advantages of being simple in production process, easy to control, low in sulphur content and good in flowability, and the quality of the diesel is free of influence caused by secondary water adding.

Owner:易信三农(沈阳)石化有限公司

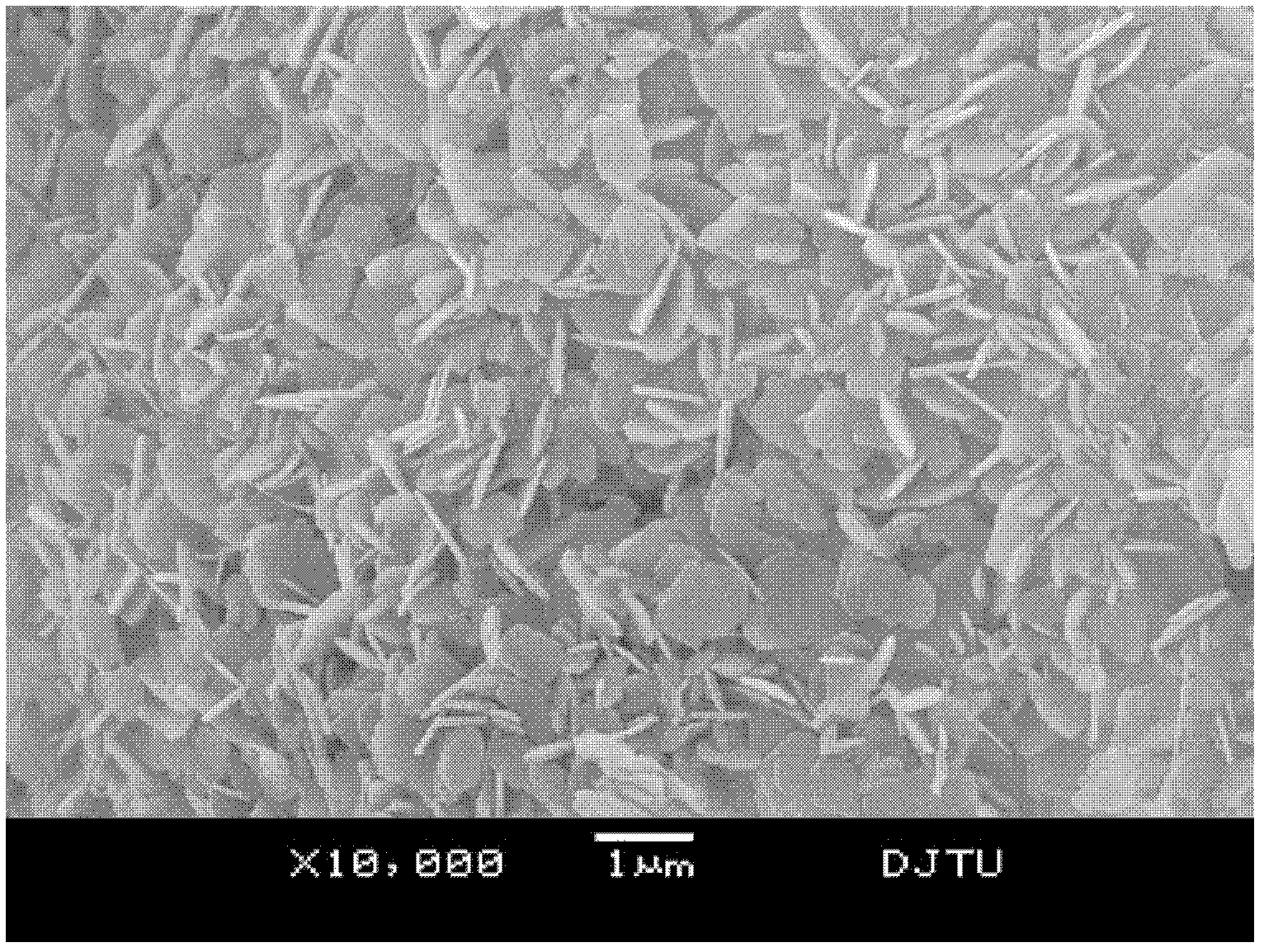

Preparation method of ZSM-35 molecular sieve

The invention provides a preparation method of a ZSM-35 molecular sieve. The preparation method comprises the following steps of: firstly, with cyclohexane as a reaction medium and a template agent, adding a precursor compound of aluminum, a precursor compound of silicon, an alkali source, water and a homogeneous molecular sieve crystal seed with ZSM-35 into the cyclohexane by violent stirring to obtain a precursor mixer of the molecular sieve; crystallizing the precursor mixer prepared in the first step at the reaction temperature of 130-220DEG C for 10-240 hours; and thirdly, cooling the mixture crystallized in the second step to room temperature and filtering to obtain solid and carrying out vacuum drying on the obtained solid to obtain the ZSM-35 molecular sieve. According to the preparation method disclosed by the invention, after the synthesis is finished, the cyclohexane can be directly separated and recycled; and meanwhile, the washing of the molecular sieve is avoided and no waste water generates in the reaction. The preparation method is an environment-friendly production process for the molecular sieve.

Owner:CHINA CATALYST HLDG CO LTD

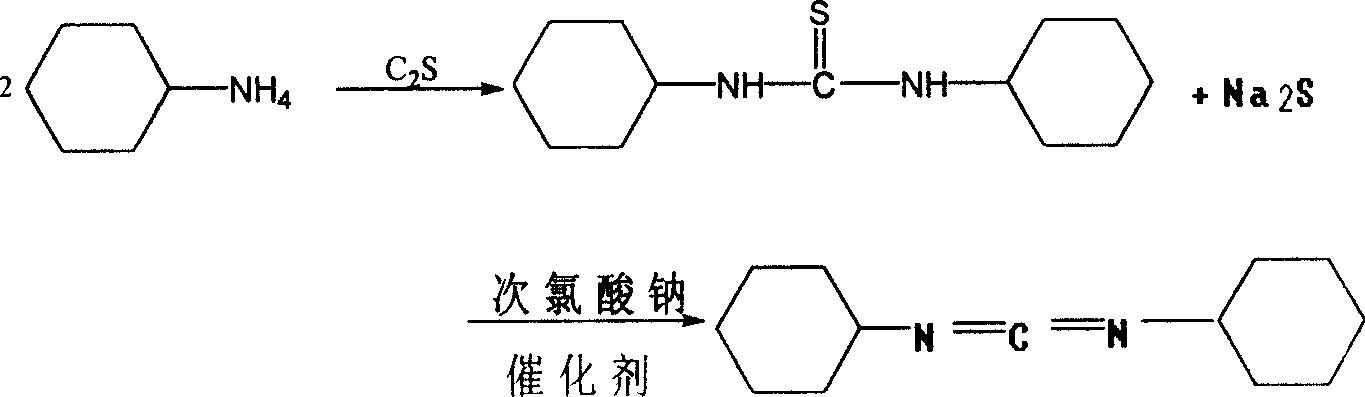

Novel synthesis method of N, N'-dicyclohexylcarbo-diimide

The invention discloses a novel synthesis method of N, N'-dicyclohexylcarbo-diimide. The novel synthesis method comprises the steps of adding water and cyclohexylamine, starting to stir; dropwise adding carbon disulfide, controlling temperature and pressure, and filtering after cooling to obtain N, N'-dicyclohyxylthiourea; after mixing N, N'-dicyclohyxylthiourea and an adjuvant, adding the mixture into a sodium hypochlorite solution, separating the liquid by heating, adding an organic phase into a hot sodium sulfide solution, separating the liquid while heating, extracting the organic phase, washing the organic phase twice by using a hot sodium hydroxide solution to obtain a crude product, wherein each washing time is 15 minutes; and rectifying to obtain a finished product, namely N, N'-dicyclohexylcarbo-diimide. By using the synthesis method, no organic solvents are used, and the dangers that the organic solvents are flammable and combustible are eliminated; the solvent does not need to be evaporated before N, N'-dicyclohexylcarbo-diimide is rectified, so that the energy waste, the cost and the product loss are reduced, and no solvent residues are left; the novel synthesis method is wide in application range; and the yield and purity of N, N'-dicyclohexylcarbo-diimide are increased, the yield is not lower than 93.5%, and the purity is not lower than 99.3%.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Corrosion inhibitor for steam condensate system of industrial boiler and process for manufacturing same

InactiveCN1557746AWith corrosion inhibitor concentration indication functionWith concentration indication functionScale removal and water softeningMorpholineAlkyl amine

The corrosion inhibitor for industrial boiler steam condensating water system includes alkyl amine with 12-18 carbon atoms or epoxy alkyl amine, Tween-60, Span-60, morpholine, cyclohexylamine and / or ammonia, and water. The corrosion inhibitor is emulsified liquid, and has functions of filming and neutralizing, reasonable steam-liquid distribution ratio, lower consumption, concentration indication, corrosion inhibiting efficiency over 98 %, obvious energy saving function and simple use, and may be used widely in various industrial boiler steam condensating water systems.

Owner:张文利 +4

Method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation

InactiveCN104445067AHigh purityAchieving zero emissionsHydrogen separationAmmonia preparation/separationWater vaporGas phase

The invention relates to a tail gas refining method, and in particular relates to a method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation, belonging to the technical field of chemical engineering. The method comprises the following steps: allowing tail gas discharged by a cyclohexylamine device and a dicyclohexylamine device to enter an ammonia absorption tower by virtue of a Roche hydrogen compressor and a degreaser, wherein most of ammonia is absorbed by water to be converted into ammonia water to be output from the tower bottom in the tower, and the gas output from the tower top is water-containing hydrogen; allowing the water-containing hydrogen to pass through a water segregator, a fiber filter and a water adsorption tower so as to further remove water vapor, thereby obtaining the refined hydrogen. The concentration of the refined hydrogen can be 98.0-99.8 percent, the material and energy consumption is reduced, and the aims of energy conservation and emission reduction are achieved. The refined hydrogen can serve as recycling gas to be used for an aniline hydrogenation reaction, and gas phase zero emission is realized.

Owner:NANJING UNIV OF TECH

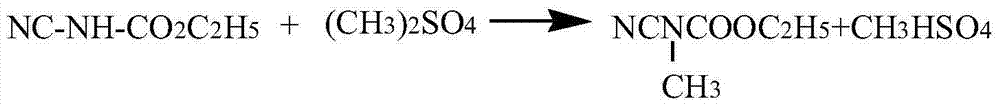

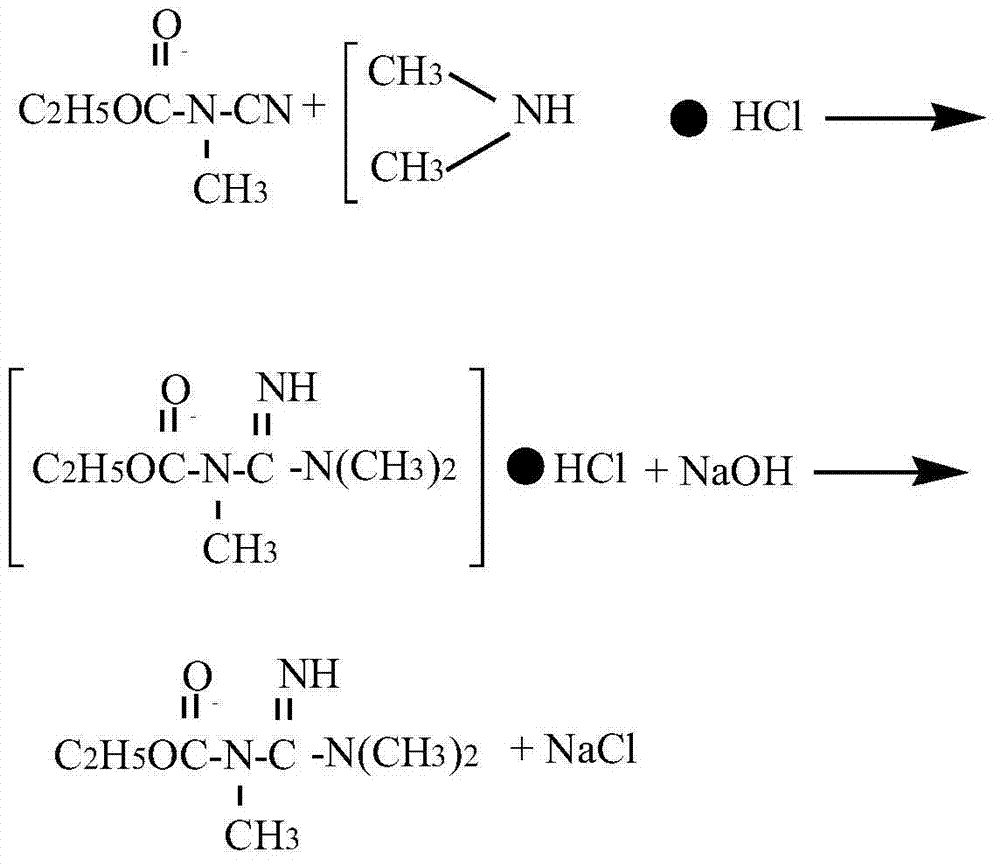

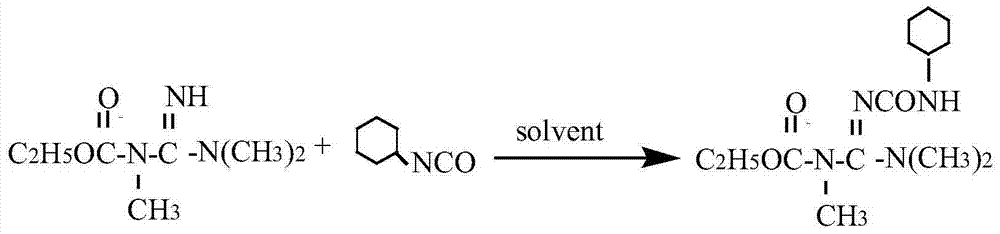

Synthetic process of hexazinone

ActiveCN103755654AOmit extractionReduce extractionOrganic chemistrySodium methoxideChemical reaction

The invention provides a synthetic process of hexazinone. The synthetic process comprises the steps of: by taking ethanol, lime nitrogen, cyclohexylamine, dimethylamine, dimethyl sulfate, sodium methoxide and phosgene as main active ingredients, generating a series of chemical reactions in solvent, and carrying out desolventizing and concentration, crystallizing and separating and drying to obtain a finished hexazinone product. According to the synthetic process, the solvent extraction can be omitted, the reaction procedures can be reduced, the efficiency can be improved, the energy consumption can be saved by 10%, and the conversion rate can also be improved by 5%; while the amount of waste water can be greatly decreased, dimethylamine can be recycled, and the quality of solvent can be guaranteed; a great amount of water can be saved, therefore, the production cost can be greatly lowered.

Owner:ANHUI GUANGXIN AGROCHEM

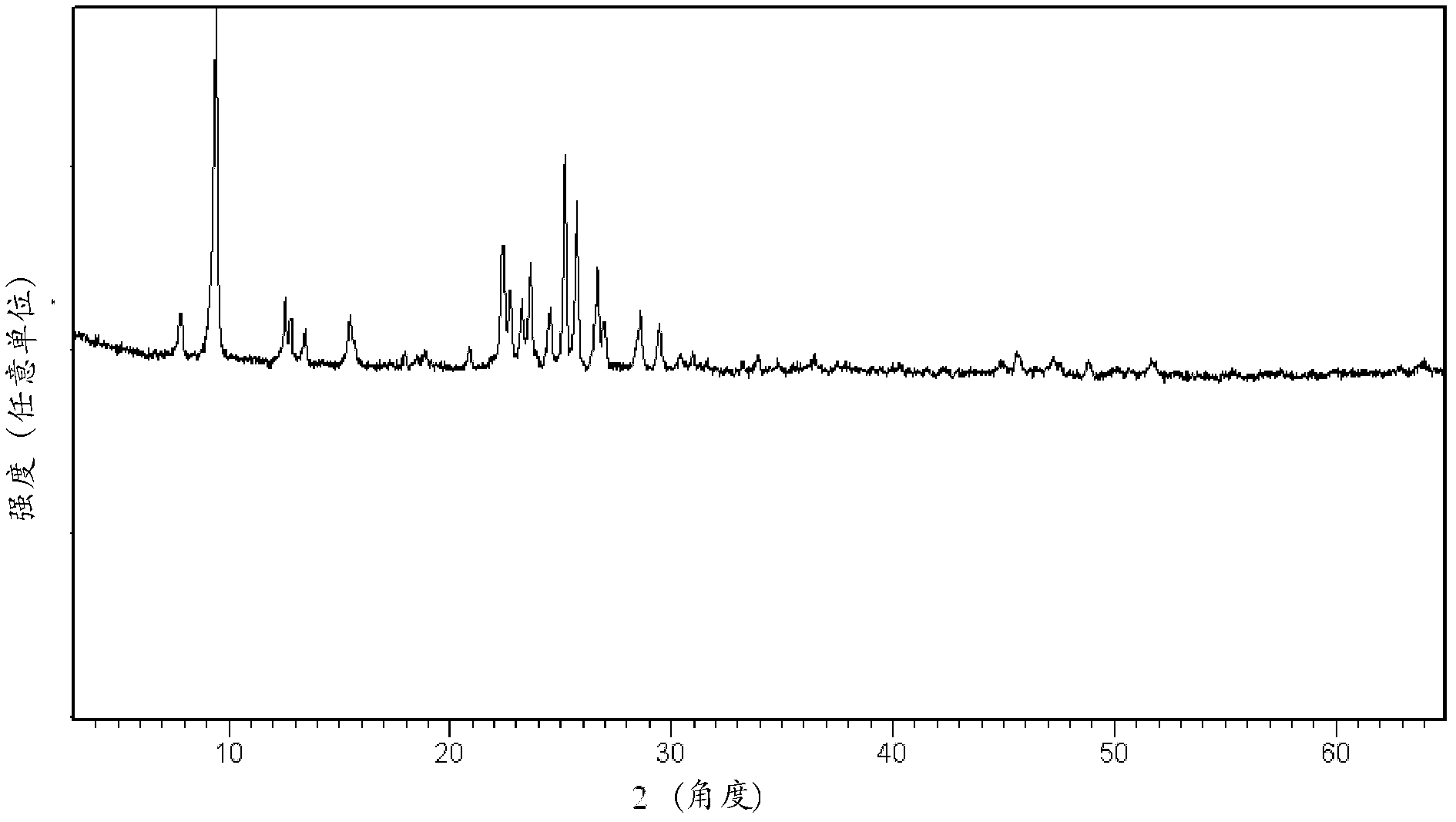

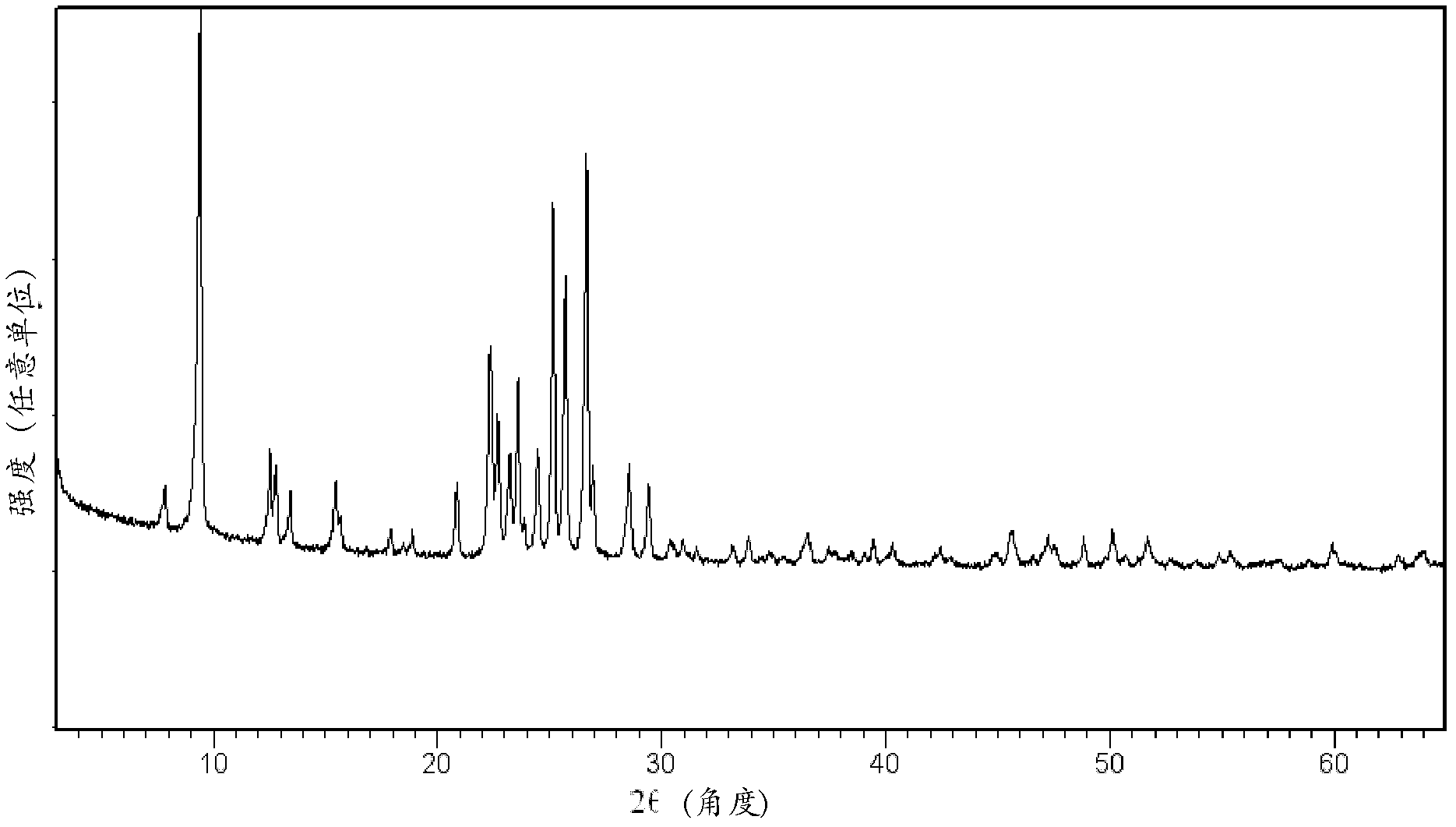

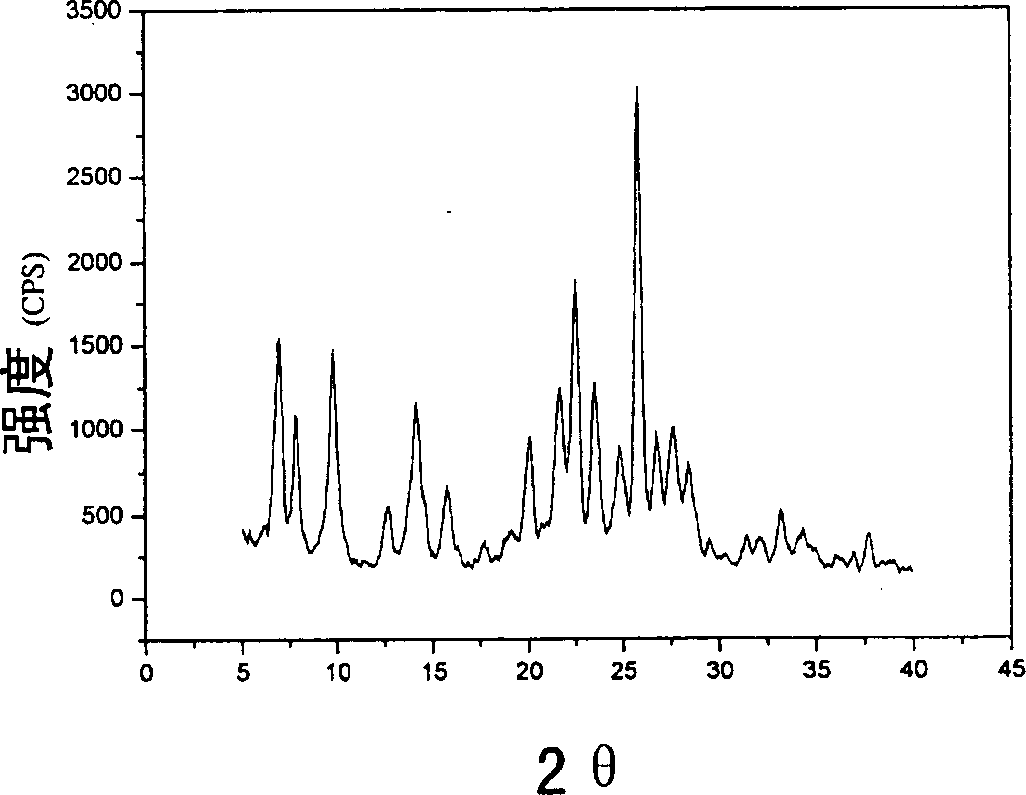

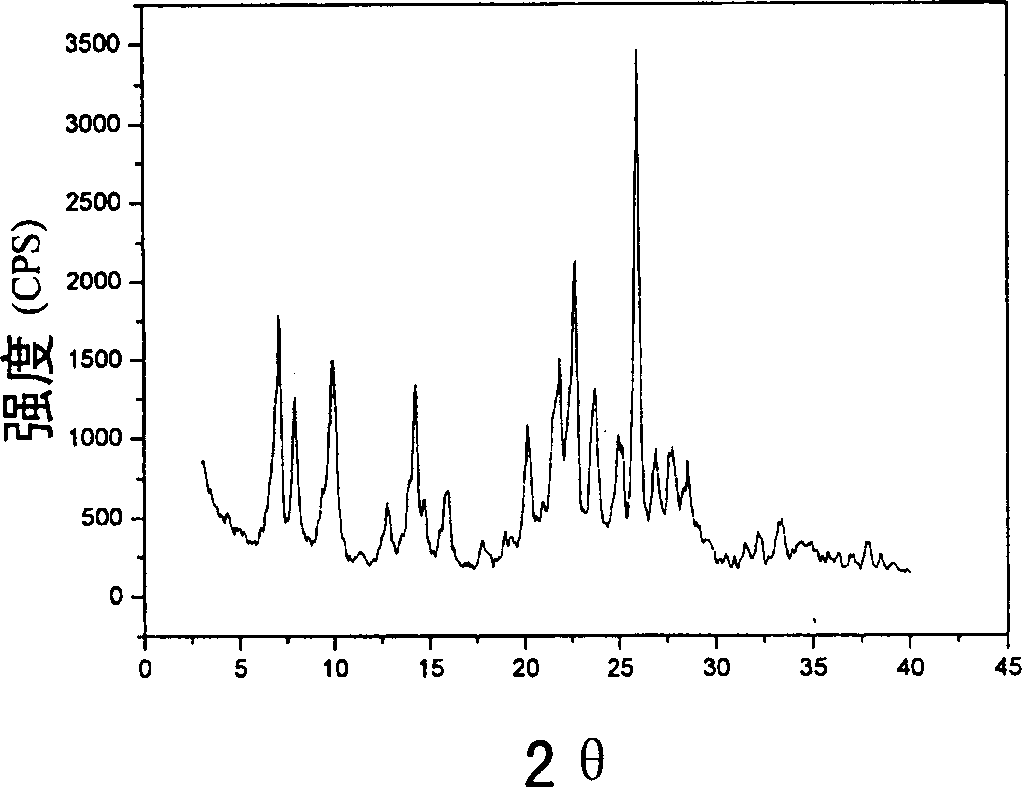

Co-crystallization molecular screen and preparation method and application thereof

InactiveCN1689972ALow priceHigh crystallinityMolecular-sieve and base-exchange compoundsIsomerizationAlkali metal

The process of preparing cocrystallized molecular sieve of ZSM-35 accounting for 0-100 wt% and MCM-22 adopts the mixture of hexamethylene imine and cyclohexylamine as template agent. Compound of silicon and aluminum, hydroxide of alkali metal, hexamethylene imine, cyclohexylamine and deionized water as materials are crystallized at 90-200 deg.c for some period and reacted completely to synthesize the molecular sieve hydrothermally. The synthesized molecular sieve is catalyst used widely in the catalytic reaction of converting hydrocarbons, such as hydrocarbon isomerization and aromatization, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

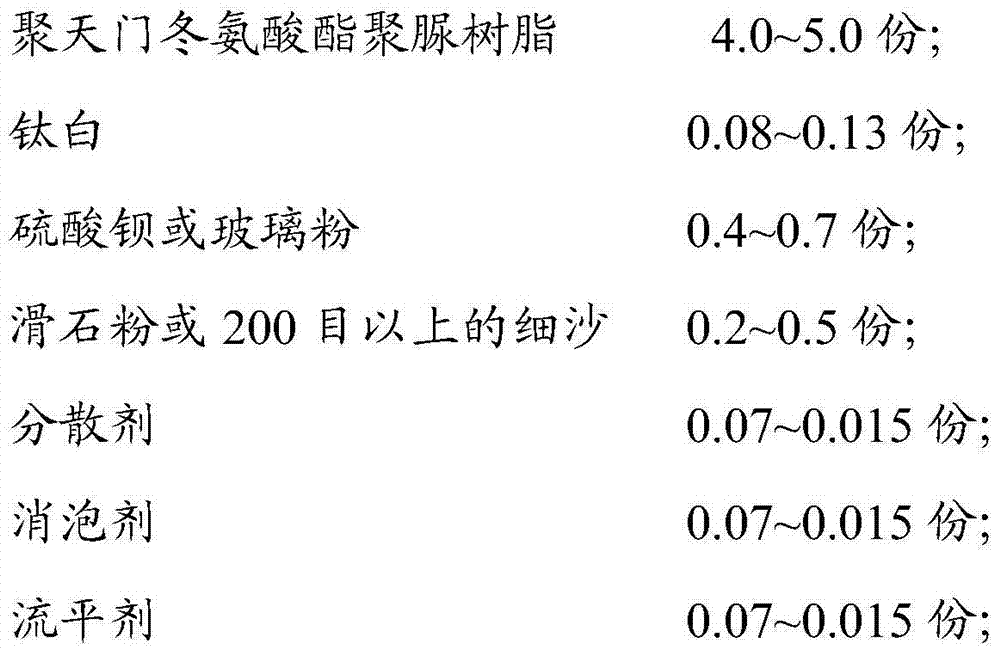

Polyurea floor coating and preparation and application methods thereof as well as carbamide resin

InactiveCN104497824AImprove wear resistanceImprove aging resistancePolyurea/polyurethane coatingsPolyaspartic acidAging resistance

The invention discloses a polyurea floor coating and preparation and application methods thereof as well as carbamide resin. The carbamide resin is polyaspartic acid ester carbamide resin; the polyaspartic acid ester carbamide resin is prepared by reacting diethyl maleate and 3,3-dimethyl-4,4-methylenebis(cyclohexylamine) as raw materials at 60-80 DEG C for 70-74 DEG C, with the weight ratio of the diethyl maleate to the 3,3-dimethyl-4,4-methylenebis(cyclohexylamine) is 1.0 to (1.55-1.60). The polyaspartic acid ester carbamide resin can stably exist at a room temperature; the polyaspartic acid ester carbamide resin is taken as a base component; and packing, an assistant and the like are added, so as to prepare the polyurea floor coating disclosed by the invention. The polyurea floor coating and an HDI curing agent are mixed to use at a certain ratio, so that the polyurea floor coating has the advantages of good abrasive resistance, ageing resistance, waterproofness, controllable elasticity and high-strength shock resistance.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

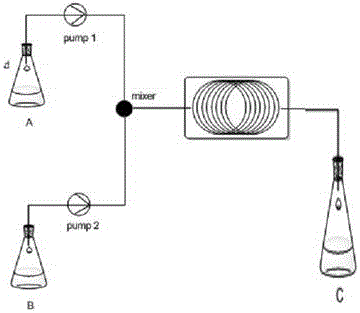

Method for preparing rubber vulcanization accelerator CBS by using microchannel reactor

InactiveCN106800540AQuality improvementImprove conversion rateOrganic chemistryMicroreactorVulcanization

The invention relates to the field of fine chemical product production, in particular to a method for preparing a rubber vulcanization accelerator CBS by using a microchannel reactor. In the method for preparing the rubber vulcanization accelerator CBS by using the microchannel reactor, the microchannel reactor consisting of a micro mixer and a micro reactor which are connected together is included. The method is characterized by comprising the following steps: dissolving an accelerator M into excessive cyclohexylamine to form a solution, introducing cyclohexylamine together with an oxidant into a micro mixer for mixing, and feeding into the micro reactor for an oxidation reaction; and after the reaction is completed, performing suction filtration, washing filter cakes with water, and drying, thereby obtaining the rubber vulcanization accelerator CBS. As the microchannel reactor is adopted to prepare the rubber vulcanization accelerator CBS, the reaction time and the reaction temperature can be precisely controlled, the reaction time can be shortened, the reaction conversion rate can be increased, high throughput can be achieved, the product quality can be stable, production can be enlarged, high security can be achieved, and defects of a conventional reaction kettle can be effectively overcome.

Owner:山东斯递尔化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com