Thermal test solution for engine

A heat test and engine technology, applied in the chemical industry, can solve problems such as poor engine coolant compatibility, solder corrosion, precipitation, etc., and achieve good overall synergy, corrosion prevention, and good corrosion inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0036] Embodiments 1-8 Preparation of engine heat test fluid of the present invention.

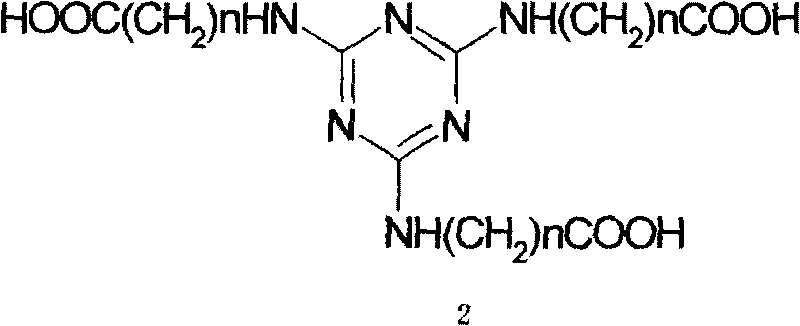

[0037] Put ethylene glycol and deionized water into the reactor according to the ratio shown in Table 1, stir at room temperature for 10 minutes, and then add aliphatic monocarboxylic acid, straight-chain aliphatic dicarboxylic acid, triazine Skeleton tribasic carboxylic acid, aromatic acid, composite corrosion inhibitor, alkenyl amines are put into the reaction kettle, stirred at room temperature for 40 minutes, added hydrolyzed polymaleic anhydride, cyclohexylamine carbonate, defoamer, stirred until completely dissolved That's it.

[0038] Table 1 Components and proportions of engine hot test fluid

[0039] composition

[0040] composition

Embodiment 9

[0041] Embodiment 9 The engine heat test fluid of the present invention inhibits and protects performance tests on various metals

[0042] Glassware corrosion test and simulated use corrosion test are the test methods to evaluate the performance of automobile engine coolant to multi-metal corrosion inhibition. The test solution was tested, and the results are shown in Table 2

[0043] Table 2 Engine heat test fluid performance inspection result table of the present invention

[0044] serial number

[0045] From the data in Table 2, it can be seen that the engine heat test fluid of the present invention has excellent corrosion inhibition and protection properties for various metals such as solder, brass, red copper, carbon steel, cast iron, and cast aluminum.

Embodiment 10

[0046] Example 10 Comparative experiment on corrosion performance of engine heat test fluid of the present invention

[0047] The engine heat test liquid of the present invention prepared in embodiment 4 and the P113 engine test protection liquid of German BASF Company are compared with reference to the SH / T 0085 standard glassware corrosion test, and the corrosion contrast test results are shown in Table 3

[0048] Table 3 Corrosion performance comparison test results

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com