Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Amyl nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amyl nitrate is the chemical compound with the formula CH₃(CH₂)₄ONO₂. This molecule consists of the 5-carbon amyl group attached to a nitrate functional group. It is the ester of amyl alcohol and nitric acid.

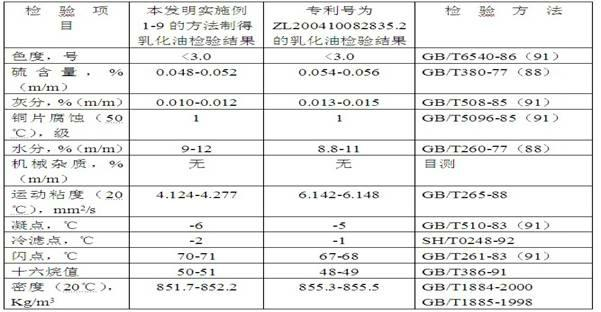

Concentrated emulsified diesel fuel and preparation method thereof

The invention relates to concentrated emulsified diesel fuel and a preparation method thereof, wherein the concentrated emulsified diesel fuel is long in shelf life and low in cost and is prepared by the following raw materials by weight parts: 50-80 of diesel, 0.5-1 of cyclohexylamine, 0.5-2 of ethanolamine, 0.03-0.08 of water and hydrazine, 8-17 of oleic acid or fatty acid, 0.01-0.08 of ferrocene, 0.1-1 of isooctyl nitrate or amyl nitrate, 5-10 of ethanol, 4-15 of solvent oil and 10-30 of water. The concentrated emulsified diesel fuel is long in service life which is 6 years, has no emulsion breaking, is good in stability, can be used directly, also can be used by being mixed with national-standard diesel in any proportion, and further has the advantages of being simple in production process, easy to control, low in sulphur content and good in flowability, and the quality of the diesel is free of influence caused by secondary water adding.

Owner:易信三农(沈阳)石化有限公司

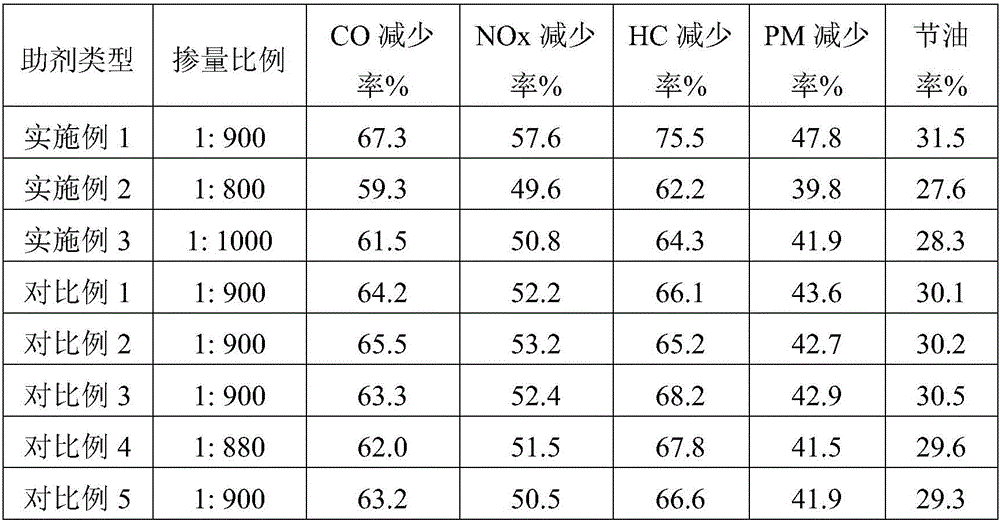

Diesel motor fuel additive and method for preparing same

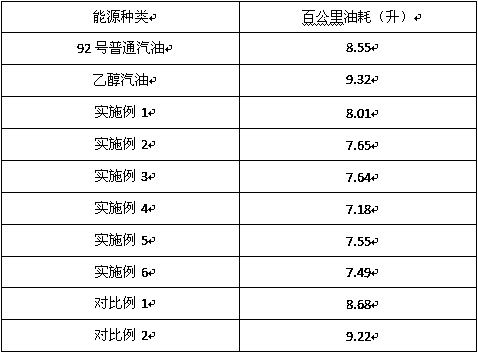

InactiveCN101250448AReduce surface tensionReduce fuel consumptionLiquid carbonaceous fuelsParticulatesMass ratio

The invention relates to a diesel engine fuel additive and the process for preparation, which is formed by the components whose mass ratio as following: amyl nitrate 10-40 parts, isooctyl nitrate 10-40 parts, manganese naphthenate 100-500 parts, iron naphthenate 50-802 parts, barium naphthenate 60-90 parts, naphthenates cerium 60-90 parts, barium dinonyl naphthalene sulphonate 100-150 parts, dicyclopentadienyl iron 20-60 parts, alkyl alcohol polyoxyethylene ether 100-150 parts, alkylphenol polyoxyethylene ether 150-250 parts and dimethylbenzene 80-150 parts. The invention provides a diesel engine fuel additive which can obtain synergistic effects of two types of additives, has the advantages of excellent chemical stability, lowering secondary discharge pollution, saving fuel oil, and can promote a particulate trap to regenerate and he process for preparation.

Owner:ZHEJIANG INST OF COMM

Additive for synthetic water-diesel oil fuel and its prepn and application

The additive for synthetic water-diesel oil fuel consists of fatty alcohol polyoxyethyleneether 6.8 wt%, alkylene phenol polyvinyl ether 5.2 wt%, amyl nitrate 7.4 wt%, high-alkali barium sulfonate 5.6 wt%, ethylene-acrylate copolymer 5.5 wt%, sorbitan monostearate polyoxyethyleneether 40 wt%, Span-60 10 wt%, sorbitan trioleate polyoxyethyleneether 10.3 wt% and ferrocene 9.2 wt%. It is produced through mixing while stirring at high speed to react and letting stand to eliminate bubble and become emulsion. The additive is used in producing mixed water-diesel oil fuel, which has the same performance as diesel oil and can save oil by 20-30 %.

Owner:石生玉

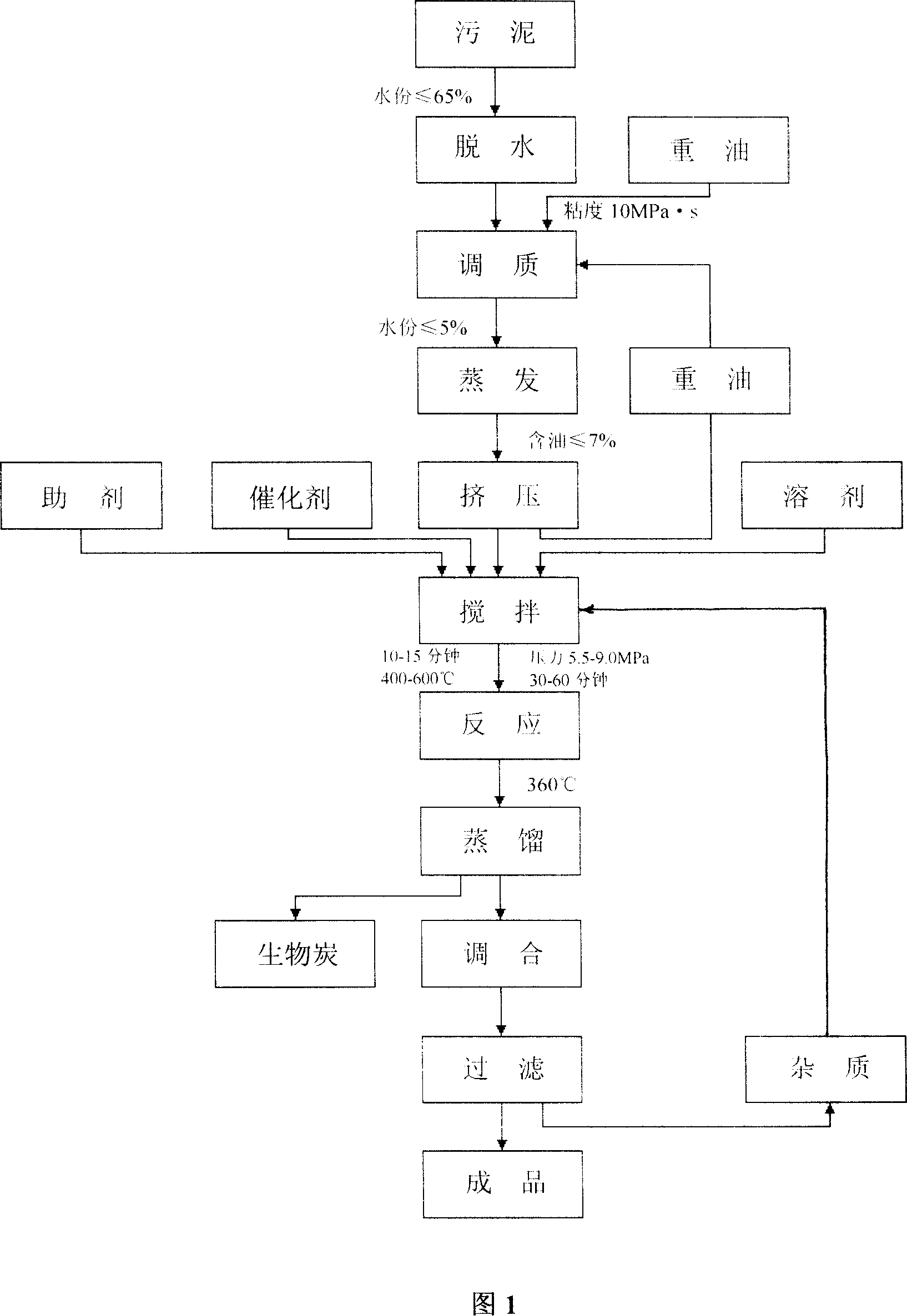

Process for making bio-diesel oil by using municipal sludge

The invention discloses a new technique of biological diesel through urban sludge in the energy domain, which comprises the following steps: allocating the component formula with 70.5-56.5% sludge, 20.0-40.0% solvent, 0.5-2.5% adjuvant and 1.0% catalyst; adopting urban sludge or living effluent mud as sludge; selecting the solvent form rape oil, soyabean oil, waste kitchen oil and arachis oil; setting carbinol as adjuvant and aluminium chloride as catalyst; stirring these materials completely for 10-15min; reacting under 400-600 Deg C at 5.5-9.0Mpa for 30-60min; heating to 360 Deg C to obtain the distillate oil (gas oil); transmitting to blending procedure; adding 0.2-1.0% amyl nitrate to generate the diesel.

Owner:任春山

Composite fuel additive

InactiveCN106433819AEmission reductionIncrease surface activation energyLiquid carbonaceous fuelsFuel additivesOctanolEthyl acetate

The invention discloses a composite fuel additive. The composite fuel additive is prepared from the following components in parts by weight: 3 to 5 parts of isopropyl alcohol, 2 to 4 parts of tert butyl alcohol, 1 to 3 parts of octanol, 1 to 3 parts of tertiary amyl methyl ether, 2 to 5 parts of dimethyl malonate, 1 to 4 parts of amyl nitrate, 10 to 15 parts of butyl acetate, 0.6 to 0.8 part of dibutyl phthalate, 1 to 3 parts of strontium peroxide, 0.4 to 0.6 part of ethyl acetate, 2 to 6 parts of fatty alcohol polyoxyethylene ether, 0.2 to 0.6 part of nonylphenol polyoxyethylene ether, 0.3 to 0.7 part of a fluorocarbon surfactant, 0.2 to 0.5 part of sodium carboxymethyl cellulose, 1 to 4 parts of polytetrafluoroethylene, 0.5 to 0.9 part of a catalyst, 0.1 to 0.3 part of attapulgite powder, 1 to 3 parts of nano-ceria and 0.2 to 0.4 part of nanometer magnesium powder.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

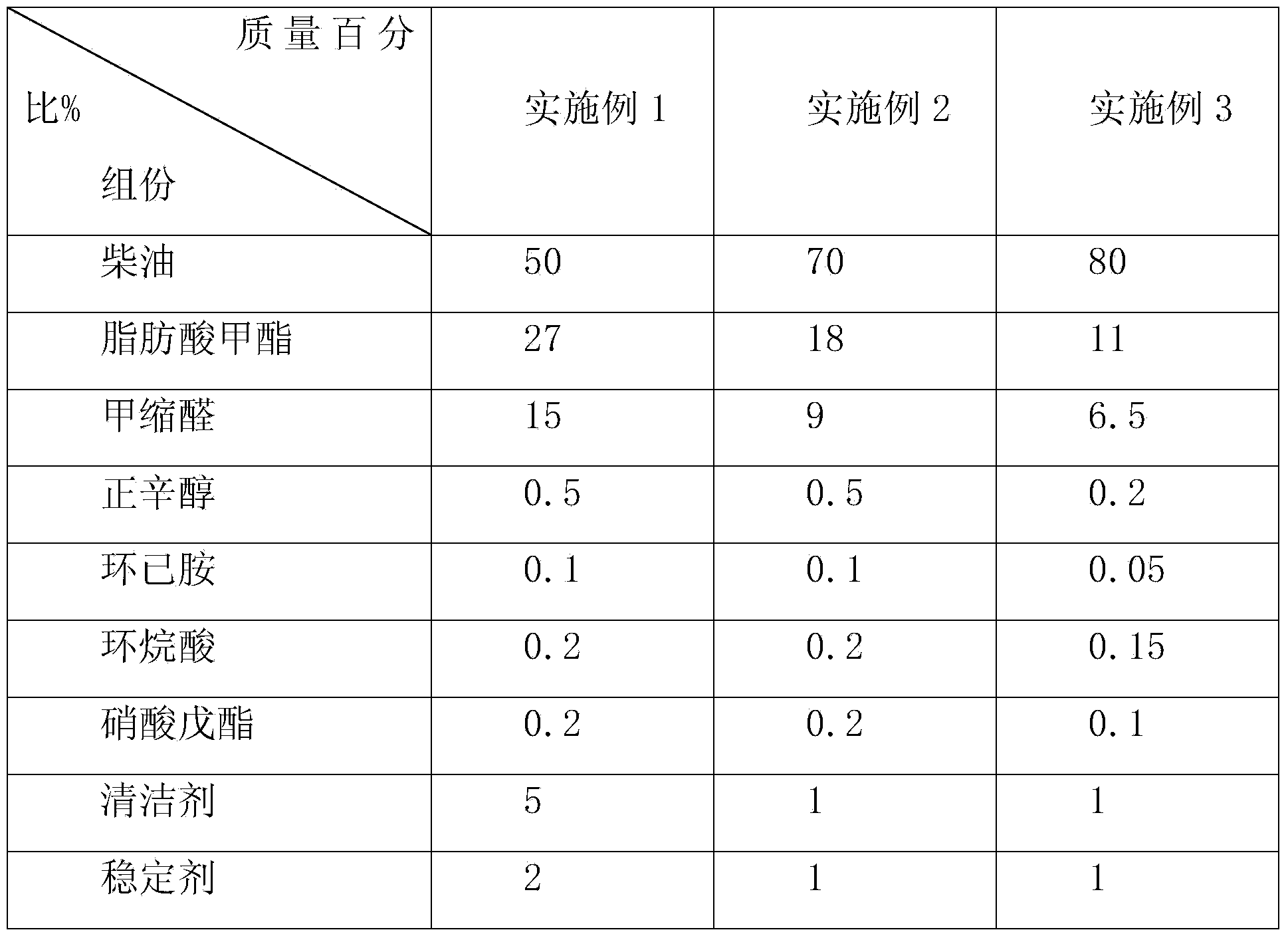

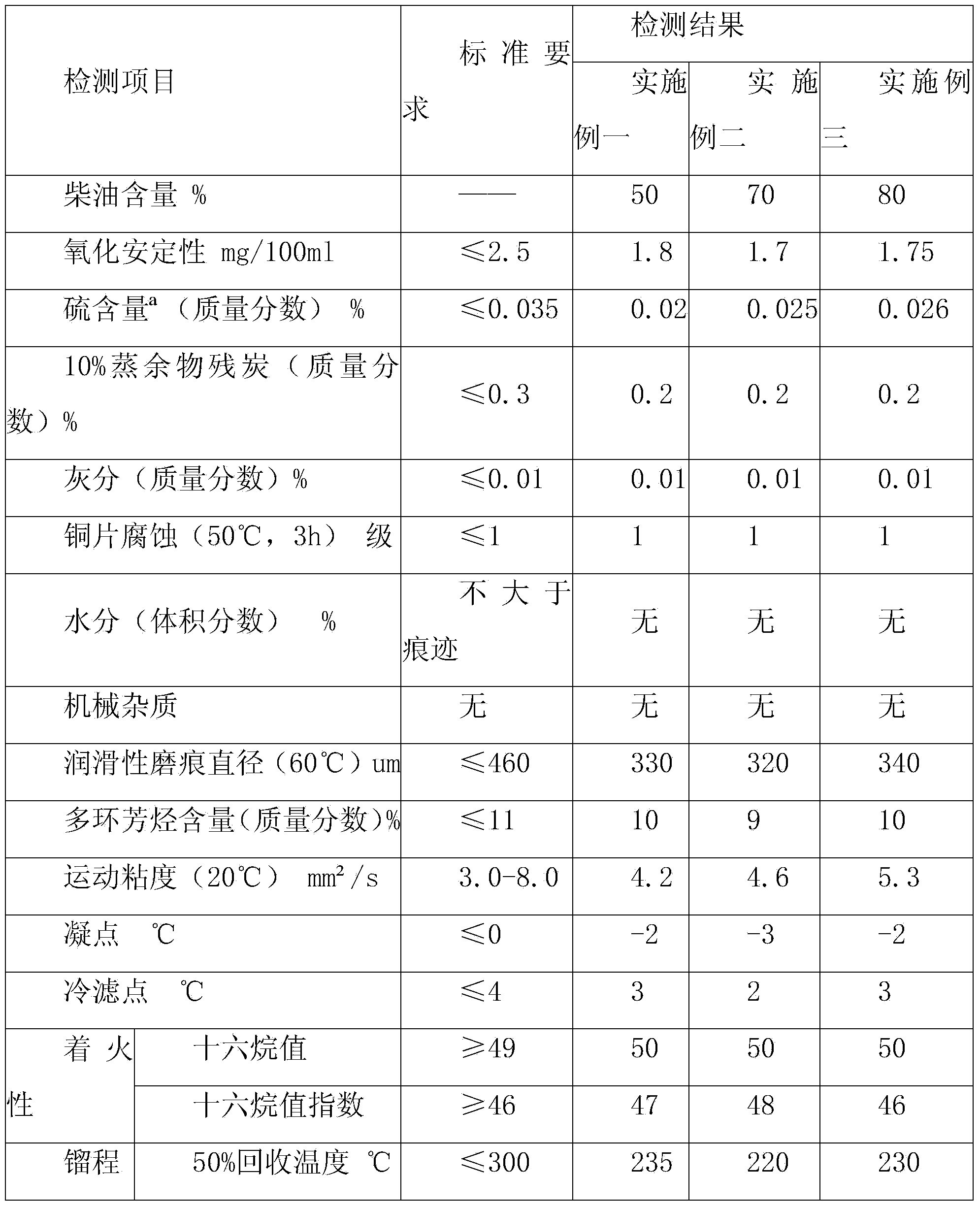

Methyl diesel

ActiveCN103865593ARich sourcesImprove performanceLiquid carbonaceous fuelsFuel additivesSulfurOctanol

The present invention discloses a methyl diesel. The methyl diesel comprises the components by mass percent of 50-80% of diesel, 11-27% of fatty acid methyl ester, 6-15% of methylal, 0.2-0.6 % of n-octanol, 0.05-0.2% of cyclohexylamine, 0.1-0.3% of naphthenic acid, 0.1-0.2% of amyl nitrate, 0.8-5% of detergent and 1-2% of stabilizer. The methyl diesel disclosed by the invention has good protective effect on the power system and fuel supply system of the vehicle; and dynamic performance, carbon deposits reduction, corrosion resistance, storage period, fuel consumption, micro metal emissions, sulfur emissions, miscibility, diesel air resistance meet or exceed the standard after the actual test is carried out.

Owner:常胜 +1

A production device and preparation method of clean dimethoxymethane diesel oil

InactiveCN102268304ALow costLow ignition pointLiquid carbonaceous fuelsFuel additivesBenzotriazoleProcess engineering

The invention discloses clean dimethoxymethane diesel oil, which is characterized in that the diesel oil is prepared by the following raw materials: dimethoxymethane, diesel oil and dimethoxymethane solution I, wherein the dimethoxymethane solution I is prepared by dissolving benzotriazole, dilinoleic acid, 2,6-tert-butyl-4-methylphenol, LD-r01 diesel lubricity improver, isooctyl nitrate(amyl nitrate) in the dimethoxymethane. A preparation method of the clean dimethoxymethane diesel oil comprises the following steps: A, mixing the dimethoxymethane, the diesel oil and the dimethoxymethane diesel oil solution I according to a ratio of 14.00:85.00:1.00, preparing D15 dimethoxymethane diesel oil; B, mixing the dimethoxymethane, the diesel oil and the dimethoxymethane diesel oil solution I according to the ratio of 29.00:70.00:1.00, and preparing the D30 dimethoxymethane diesel oil. Compared with the methanol diesel oil, the unique dimethoxymethane diesel oil in the invention has the advantages that the fire point of dimethoxymethane is low, cetane number is high and the like, and the dimethoxymethane diesel oil can be miscible with diesel oil in any proportion and has low cost and strong competitiveness.

Owner:HENAN COAL CHEM IND GROUP INST

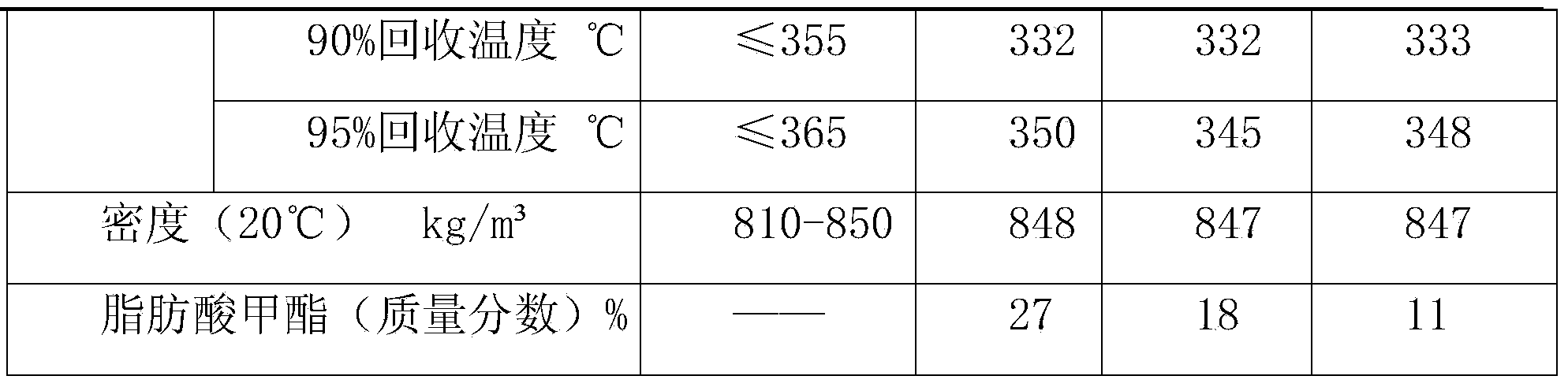

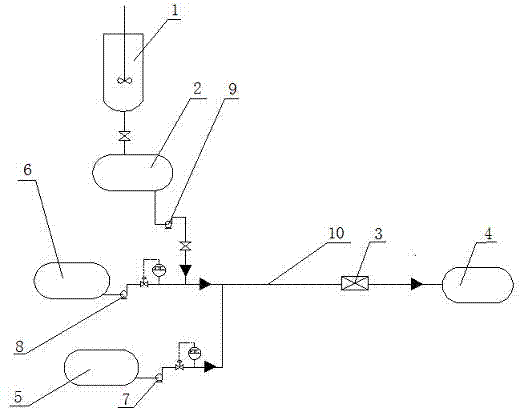

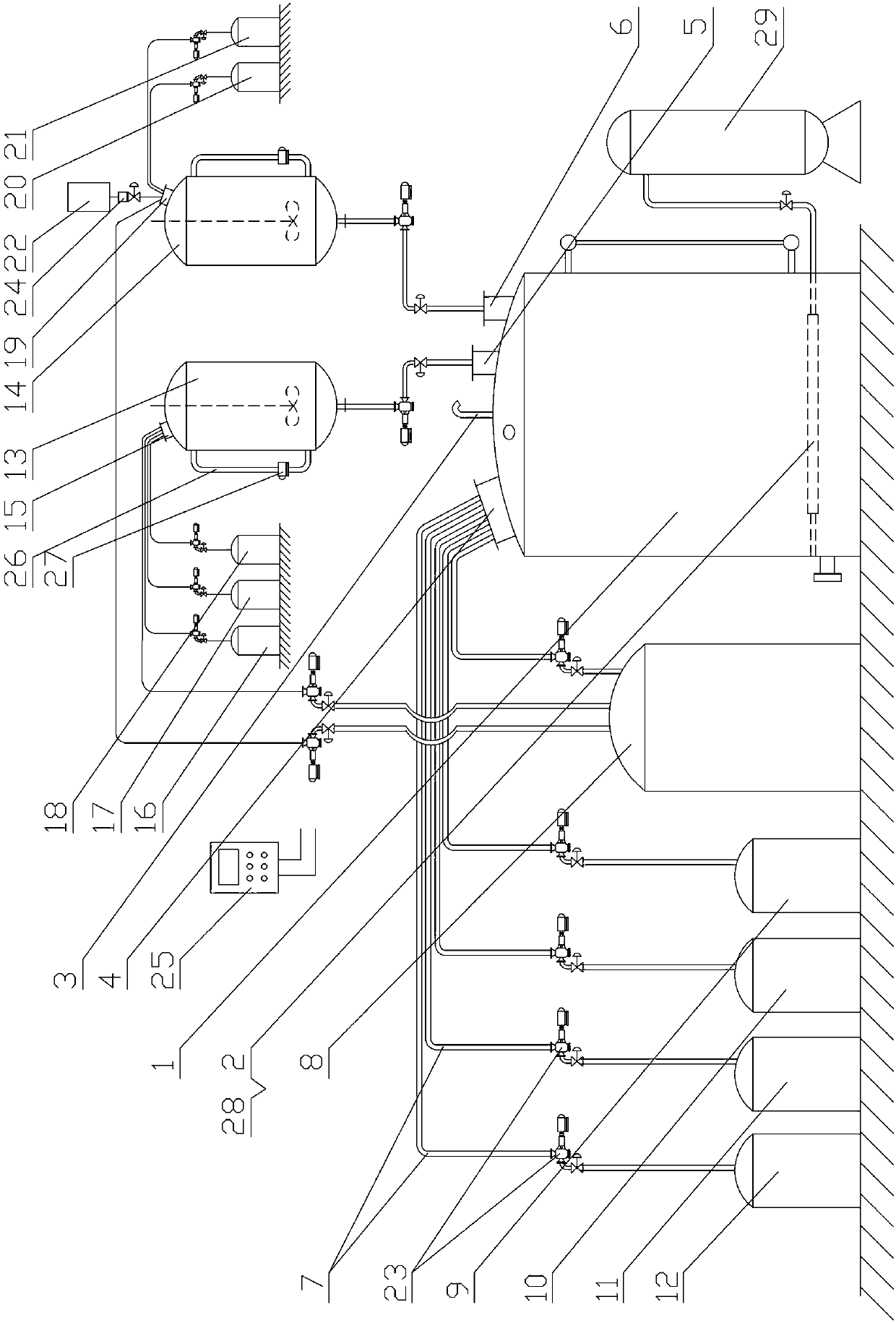

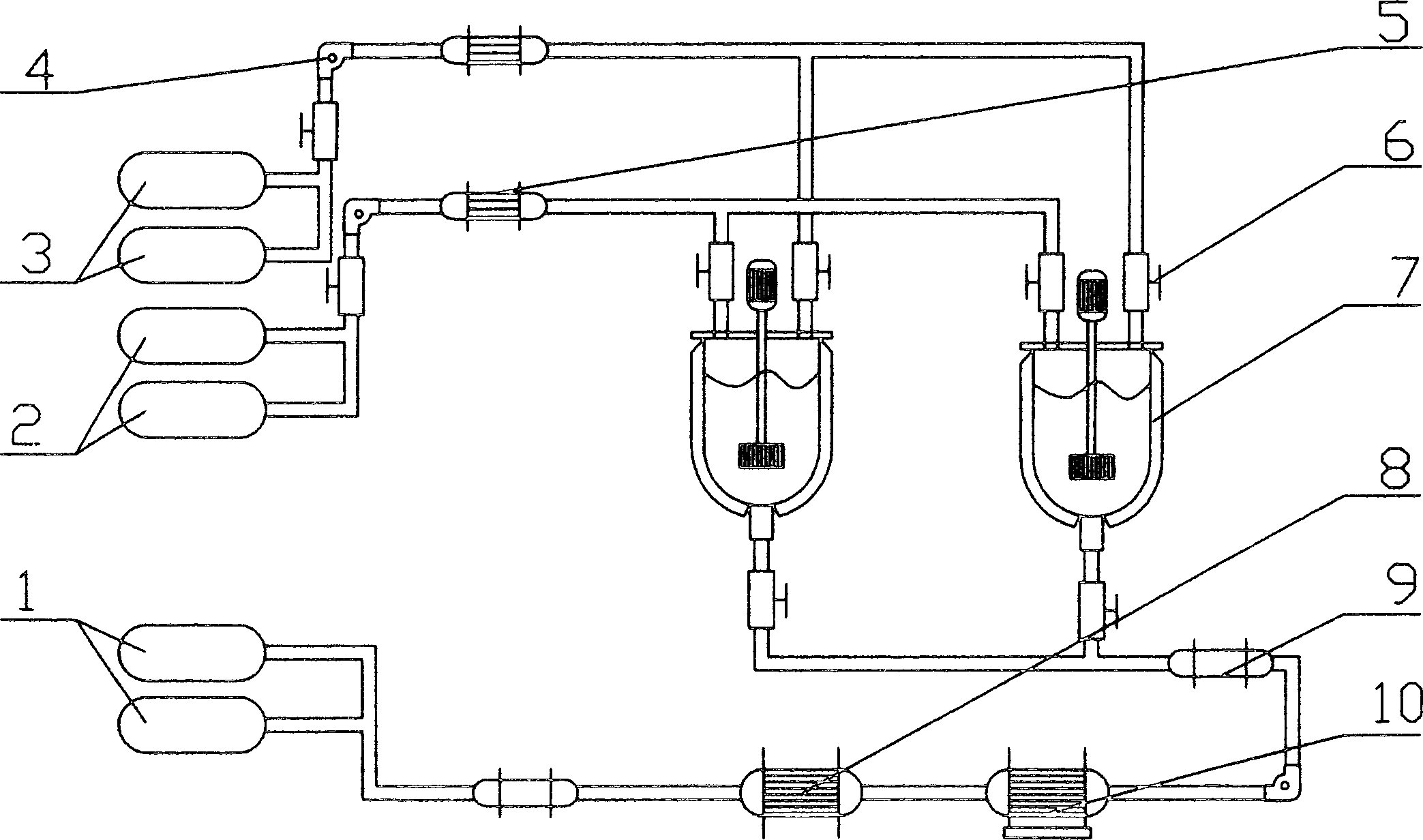

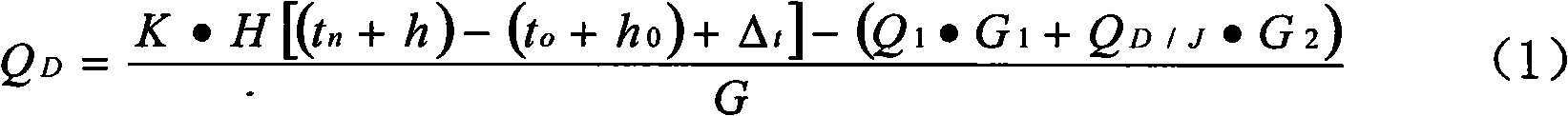

Efficient and clean alcohol-containing fuel oil and preparation method and device thereof

PendingCN107653009ANo pollutionRaw materials are easy to getTransportation and packagingMixer accessoriesMethyl carbonateFuel oil

The invention discloses an efficient and clean alcohol-containing fuel oil and a preparation method and a device thereof. The fuel oil is composed of the following raw materials of methanol, ethanol,methylal, xylene, ferrocene, acetone, C12, naphtha / gas condensate, diesel oil, amyl nitrate, hydrogen peroxide and dimethyl carbonate. The preparation method includes the following steps that (1) the methylal and the C12 are added to a reaction tank with a gas flow stirring device, stirring and mixing are started, then the ethanol, the naphtha / gas condensate and the methanol are sequentially added, and the stirring and mixing are started; (2) the amyl nitrate, the hydrogen peroxide and the dimethyl carbonate are added to a first auxiliary tank and uniformly diluted with the methanol to obtain an additive A, and the additive A is added to the reaction tank for mixing; and (3) the diesel and the methanol are added on a second auxiliary tank for mixing, then the xylene, the ferrocene andthe acetone are mixed to obtain an additive B, and the additive B is added to the reaction tank for mixing to obtain the efficient and clean alcohol-containing fuel oil. The efficient and clean alcohol-containing fuel oil and the preparation method and the device thereof have the advantages of being low in cost, simple in method and device, high in product calorific value, less in impurities, andhigh in safety and environmental friendliness and having no pollution of tail gas.

Owner:湖北恒泰新能源开发有限公司

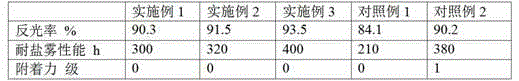

Preparation method of water-based light-reflective coating used on solar mirror surface

InactiveCN104356906AGood resistance to salt sprayImprove reflectivityReflecting/signal paintsPolyester coatingsSilicic acidActive agent

The invention relates to a preparation method of a water-based light-reflective coating used on a solar mirror surface, and belongs to the technical field of solar devices. The method comprises the following steps: adding tetrabutyl titanate and tetraethyl orthosilicate into water, then adding ethyl alcohol and silver nitrate, evenly stirring, heating, dropwise adding a hydrochloric acid aqueous solution, cooling to a room temperature after the adding of the hydrochloric acid aqueous solution and aging so as to obtain an aged sol; and evenly stirring the sol, water-based alkyd resin, glycerin, sorbitol, ethyl alcohol, amyl nitrate, pentaerythritol, sodium borate, a thickening agent, celluloses and a surfactant so as to obtain the water-based light-reflective coating. According to the method, the sol containing inorganic particles is prepared via a sol-gel method, and the sol and the water-based resin materials are prepared into the coating used on the mirror surface. The coating has the characteristic of excellent salt spray resistance and is capable of improving the light reflectivity at the same time.

Owner:WUXI SUNOCEAN

Diesel oil additive

InactiveCN105001927AIncrease profitReduce accumulationLiquid carbonaceous fuelsEthyleneglycol monobutyl etherTetralin

The invention provides a diesel oil additive. The diesel oil additive is prepared from the following raw materials by weight: 9 to 11 parts of potassium permanganate, 6 to 8 parts of sodium nitrate, 6 to 10 parts of manganese carbonate, 2 to 6 parts of a stabilizing agent, 8 to 12 parts of N,N-bis(salicylidene)propane diamine, 1.3 to 6 parts of tetralin, 4 to 8 parts of triethanolamine, 6 to 11 parts of methyl tert-butyl ether, 7 to 10 parts of isobutanol, 1.2 to 2 parts of amyl nitrate, 7 to 10 parts of glycol monobutyl ether, 2 to 4 parts of barium sulfonate, 7 to 12 parts of 5-methyl-2-hepten-4-one, 5 to 8 parts of methylbenzotriazol and 4 to 6 parts of glycol monobutyl ether. The invention has the following beneficial effects: the diesel oil additive can perfectly improve the utilization rate of fuel oil, reduces accumulation of carbon deposit and decreases discharge of toxic substances.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Purified diesel and its preparation process

InactiveCN1632065AWith cleanEnergy savingRefining by water treatmentLiquid carbonaceous fuelsDemulsifierHigh pressure

The invention relates to a diesel oil purified by water and its preparing technique, belonging to the fuel field. The purified diesel oil is comprised of diesel oil, water, compound additive, and the compound additive is comprised of amyl nitrate, alkene, demulsifier, tetraethyllead, saponifiable oil, Italian red oil, auxiliary diesel oil, cyclanes, methylnaphthalene and aromatic hydrocarbon ect, through the techniques of synthesis, atomization, and mixing, make water disperse averagely and stably in nm to form oil-covering water. It has remarkable characteristics that its transparent as the general diesel oil, can be mixed with the general diesel oil willingly with good stability, and saving-oil rate is 18-30%, it has simple productive technique which does not relate to high temperature and high pressure, without 'three waste' is clean, energy-saving, economic and safe.

Owner:高扬飞

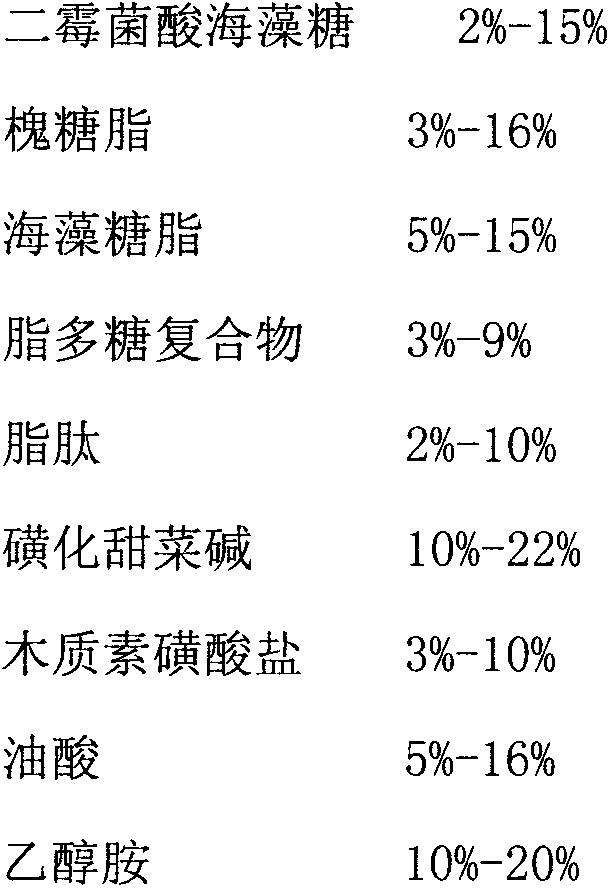

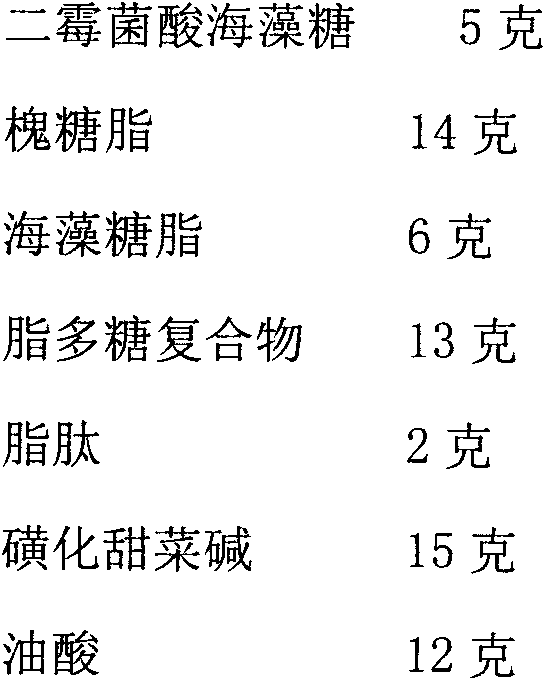

Microemulsion diesel oil with good thermodynamic stability

InactiveCN103409182AEasy to gatherHigh thermodynamic stabilityLiquid carbonaceous fuelsBetaineMycolic acid

The invention discloses microemulsion diesel oil with good thermodynamic stability and belongs to the field of energy chemistry. The formula is characterized by consisting of diesel oil, water and a total assistant, wherein the total assistant is composed of di-mycolic acid fungal acid trehalose, sophorolipid, trehalose glycolipid, lipopolysaccharide complex, lipopeptide, sulfonated betaine, lignin sulfonate, oleic acid, cholamine and amyl nitrate. The microemulsion diesel oil disclosed by the invention is good in thermodynamic stability, good in combustion effect, small in viscosity and free of oil-water stratification phenomenon after long-term storage. Moreover, the microemulsion diesel oil disclosed by the invention can be used for stably improving the vaporization rate of diesel fuel, and the secondary atomization effect of the microemulsion diesel oil ensures more full contact between the diesel fuel and the oxygen, so that the combustion of the diesel fuel is more full; compared with common diesel oil, the oil saving rate of the microemulsion diesel oil disclosed by the invention is larger than 10%, and the tail gas emission is excellent superior than that of national standard diesel oil.

Owner:朱光银

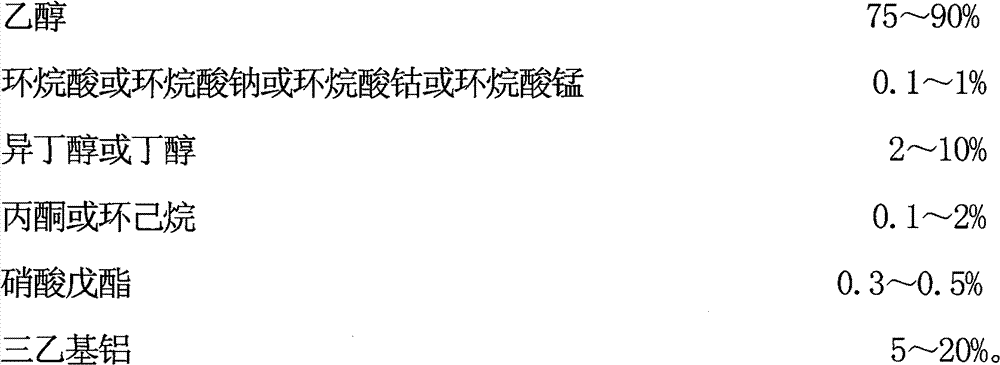

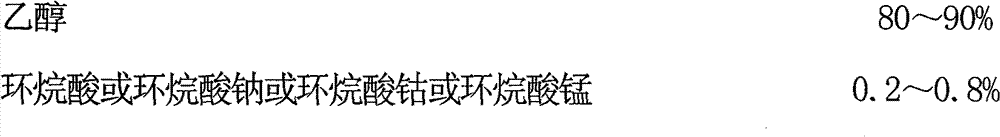

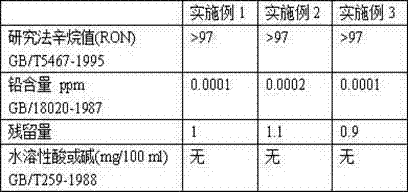

Low-temperature resistant ethyl alcohol diesel oil and method of producing the same

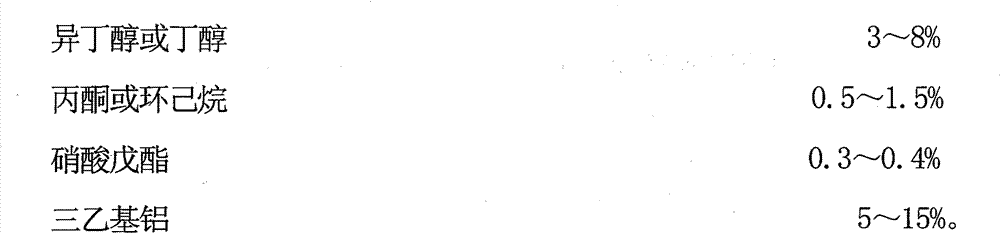

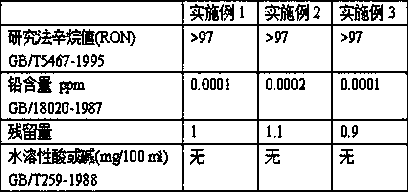

InactiveCN101402887AExtended service lifeReduce Exhaust PollutantsLiquid carbonaceous fuelsManganeseTemperature resistance

The invention discloses a low-temperature resistance ethanol diesel oil which is prepared by materials of 75 to 90 percent of ethanol, 0.1 to 1 percent of naphthenic acid or sodium naphthenate or cobalt naphthenate or manganese naphthenate, 2 to 10 percent of isobutyl alcohol or butanol, 0.1 to 2 percent of acetone or cyclohexane, 0.3 to 0.5 percent of cetane number improver or amyl nitrate as well as 5 to 20 percent of triethylaluminium according to a volume percentage. Laboratory hot value detection and running experiment are carried out on the low-temperature resistance ethanol diesel oil prepared by the method and a testing unit is consigned for carrying out a physicochemical analysis experiment and an engine frame experiment. The running experiment result shows that the speed and therotation speed of the engine when using the low-temperature resistance ethanol diesel oil do not have remarkable differences with that of using the diesel oil of a contrast experiment; the physicochemical analysis experiment shows that each index of the low-temperature resistance ethanol diesel oil is better or approaches to that of commercial diesel oil; the solidifying point is less than 48 DEGC below zero; and the frame experiment result shows that the smoke degree of the demarcated rotation speed of an exhaust emission diesel engine is reduced by 22 percent; and the CO is reduced by 34.6percent. The low-temperature resistance ethanol diesel oil is used for a diesel oil engine and can remarkably reduce the exhaust contaminations of CO2 and CO.

Owner:SHAANXI LVDI INVESTMENT HLDG GROUP

Oil-saving additive of fuel oil and preparation method thereof

InactiveCN101824342AQuality improvementImprove mass burn rateLiquid carbonaceous fuelsAntioxidantOil additive

The invention relates to an oil-saving additive of fuel oil, which comprises the following ingredients in parts by weight: 0.2 to 0.7 part of biological lipase, 6 to 9 parts of sodium hydroxide, 3 to 7 parts of xylenol, 1 to 3 parts of sorbitan, 1 to 5 parts of carbinol, 1 to 5 parts of fatty alcohol-polyoxyethylene ether, 0.05 to 0.09 part of tertiary butyl ferrocene, 1 to 5 parts of methyl ethyl ketone, 5 to 7 parts of high-grade lubricating grease, 1 to 4 parts of quadrol, 0.003 to 0.009 part of 2, 6-Di-tert-butyl-methyl phenol and 3 to 7 parts of amyl nitrate, wherein the biological lipase is used as a catalyst, the fatty alcohol-polyoxyethylene ether is used as a surface active agent, the 2, 6-Di-tert-butyl-methyl phenol is used as an antioxidant, the quadrol is used as a decarbonizer, the high-grade lubricating grease is used as a lubricating agent, the tertiary butyl ferrocene is used as a smoke suppressor, the sodium hydroxide, the xylenol, the sorbitan and the carbinol are used as an emulsifier, the methyl ethyl ketone is used as a cleaning agent, and the amyl nitrate is used as an improving agent. The oil saving rate can reach more than 13.4 percent, the exhaust amount of harmful gas in tail gas reaches more than 30 percent, the noise is reduced by more than 14 percent, in addition, the accumulated carbon in an engine can be effectively cleared, and the motive power can be obviously improved.

Owner:山东国弘能源科技有限公司

Multifunctional alcohol-based fuel

InactiveCN106244257AIncrease cetane numberImprove ignition characteristicsLiquid carbonaceous fuelsN-MethylanilineIsoamyl alcohol

The invention belongs to the technical field of fuels, and particularly relates to a multifunctional alcohol-based fuel. The multifunctional alcohol-based fuel is prepared from the following raw materials in parts by weight: 68 to 92 parts of methyl alcohol, 16 to 34 parts of diesel oil, 0.7 to 1.9 parts of amyl nitrate, 0.2 to 1.4 parts of poly-methoxyl dimethyl ether, 0.02 to 0.14 part of 5-amino-o-cresol, 0.3 to 1.5 parts of N-methylaniline, 0.1 to 1.3 parts of ferricinium, 0.01 to 0.07 part of tetrahydrocyclopentadiene, 0.03 to 0.15 part of isoamyl alcohol and 0.1 to 1.3 parts of a clearing agent. The multifunctional alcohol-based fuel disclosed by the invention has various functions of cleaning, oxidization prevention, combustion supporting, corrosion resisting, freezing resisting, smoke elimination and increase of a cetane number.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Alcohol-based fuel for lowering particulate matter emission

InactiveCN106221822AImprove ignition characteristicsImprove cold start problemLiquid carbonaceous fuelsFuel additivesParticulatesDiisononyl adipate

The invention belongs to the technical field of fuel and particularly relates to alcohol-based fuel for lowering particulate matter emission. The alcohol-based fuel is prepared from, by weight, 68-92 parts of methyl alcohol, 16-34 parts of diesel oil, 0.7-1.9 parts of amyl nitrate, 0.2-1.4 parts of diisononyl adipate, 0.02-0.14 part of succinimide, 0.3-1.5 parts of dimethylformamide, 0.1-1.3 parts of 2,6-butylated hydroxytoluene, 0.01-0.07 part of ethylene glycol, 0.03-0.15 part of glycerin monostearate and 0.1-1.3 parts of combustion improver. The alcohol-based fuel for lowering particulate matter emission has the advantages of being clean, resistant to oxidation, capable of helping to combust, disperse, capable of improving the effect of the cetane number, good in combustion performance, capable of remarkably lowering particulate matter emission and saving energy and environmentally friendly.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Micro-emulsified diesel oil for diesel engines

The invention discloses a micro-emulsified diesel oil for diesel engines. The micro-emulsified diesel oil is prepared from the following raw materials by mass and volume percentage: 65-85% of diesel oil, 5-35% of H2O, 1-20% of oleic acid, 0.001-0.3% of NaOH (weight ratio), 0.1%-1% of amyl nitrate, 0.001-0.05% of Na2CO3 (weight ratio), 0.1%-1% of NaCl, 1-6% of n-butanol, 0.2-2% of ethanolamine, and 1-10% of kerosene. Compared with pure diesel oil, under the circumstance of no obvious change in power, the micro-emulsified diesel oil provided by the invention can save nonrenewable and increasingly exhausted fossil fuel sources by 10-25%; renewable energy sources are applied in diesel engines to replace nonrenewable and increasingly exhausted fossil energy diesel oil; and the harmful ingredients CO2, SO2, CO, black smoke, HC and the like of diesel engine exhaust emissions can be reduced.

Owner:河南省恒双节能技术服务有限公司

Low-temperature resistant ethyl alcohol diesel oil and method of producing the same

InactiveCN101402887BExtended service lifeReduce Exhaust PollutantsLiquid carbonaceous fuelsCyclohexanesAmyl nitrate

Owner:SHAANXI LVDI INVESTMENT HLDG GROUP

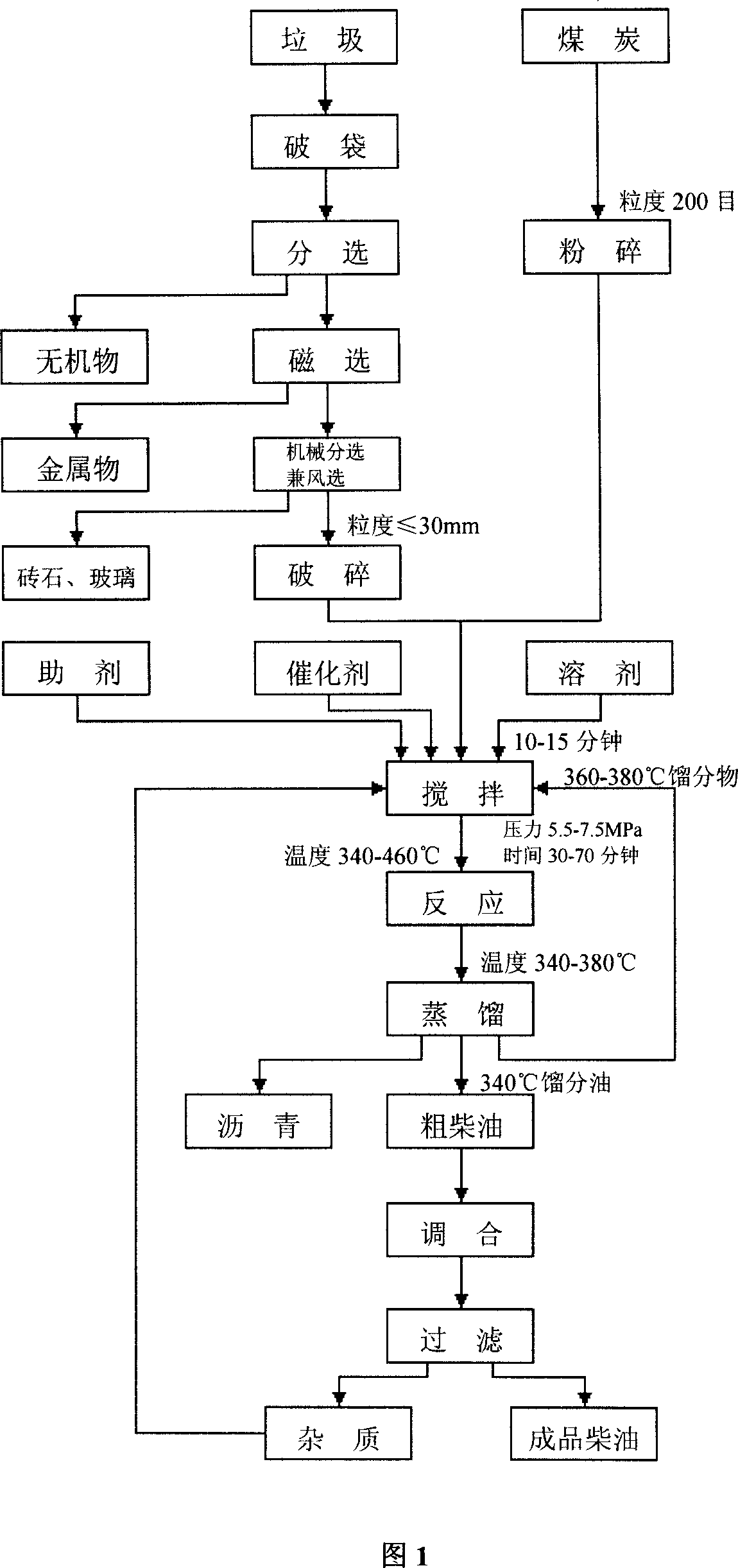

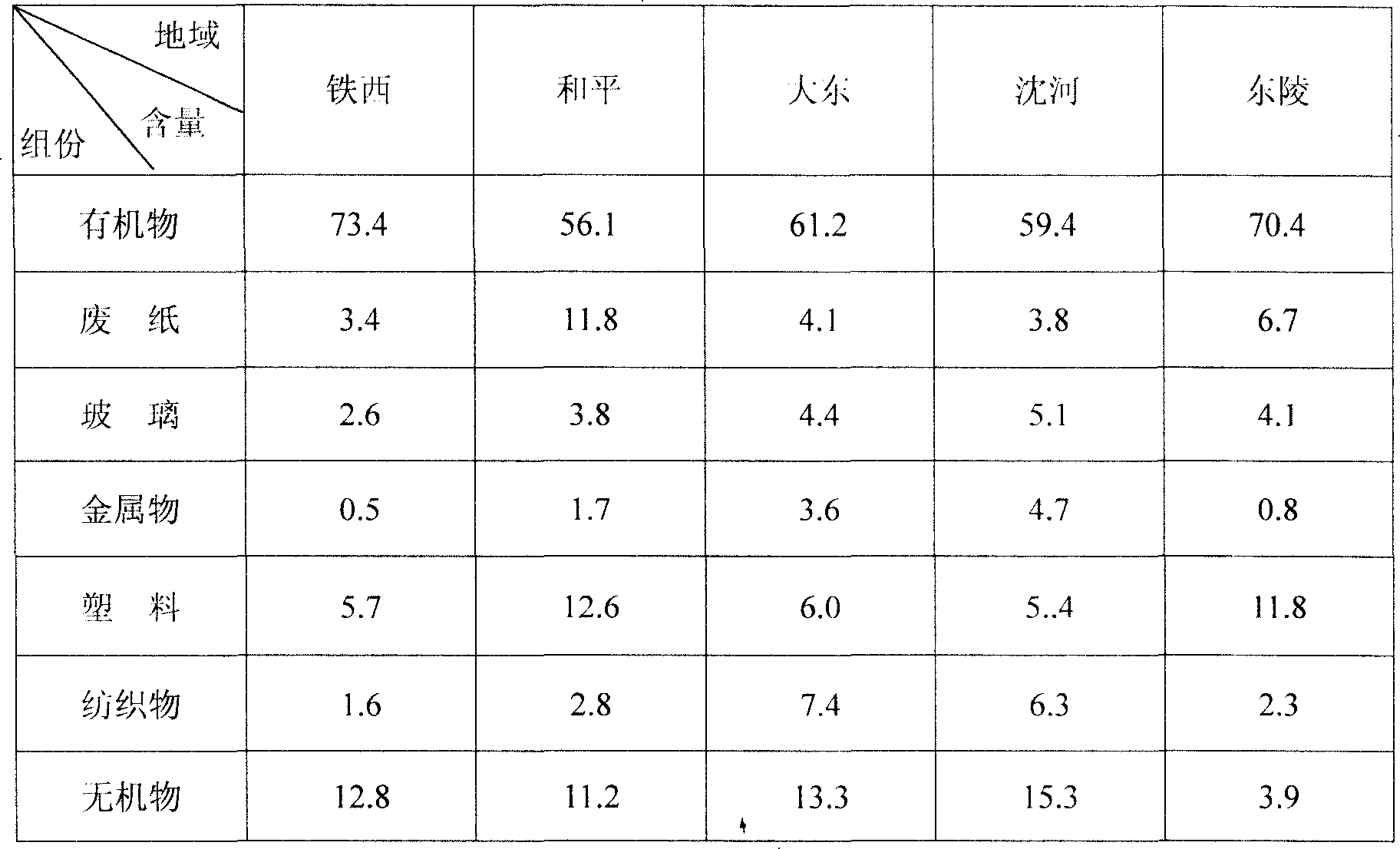

Process of preparing diesel oil substitute with domestic garbage and coal

InactiveCN1986736AConvenient sourceAlleviate shortagesLiquid hydrocarbon mixture productionPre treatmentSolvent

The present invention relates to energy source technology, and is especially process of preparing diesel oil substitute with domestic garbage and coal. The present invention features that the material consists of domestic garbage 25-45 wt%, coal 15-35 wt%, solvent 30 wt%, assistant 5 wt% and catalyst 5 wt%. The coal is lignite, subbituminous coal, oil shale or turf; the solvent is anthracene oil in the initial operation stage and the 340-380 deg.c distillate oil after the equipment is in continuous operation; the assistant is methanol and the catalyst is industrial hydrochloric acid. Pre-treated garbage and coal as well as other materials are first mixed through stirring for 10-15 min, then reacted at 340-460 deg.c and 5.5-7.5 MPa for 30-70 min and finally distilled to obtain the 340 deg.c below distillate oil as the coarse diesel oil. The coarse diesel oil is blended with amyl nitrate to obtain the diesel oil substitute.

Owner:任春山

Preparation method for methanol gasoline with good stability

The invention provides a preparation method for methanol gasoline with good stability, and belongs to the technical field of synthetic fuels. The preparation method comprises the following steps: steps one, putting heavy benzol, alkyl naphthalene, amyl nitrate, sodium biphosphate, ethylene-vinyl acetate copolymer, light diesel oil, tebutate peroxide, 70# gasoline, a dispersing agent, and a metal deactivator into a reactor and stirring to obtain a mixture; adding methanol into the mixture, cooling down, stirring continuously, and standing to obtain the methanol gasoline. The methanol gasoline provide by the invention has good burning performance, and is not changed in performance and has no sediments after being placed for a long time.

Owner:南通市通州区五接农业机电管理站有限公司

Diesel fuel additive, and preparation method and application method thereof

InactiveCN103965975AEmission reductionSolve the problem of carbon accumulationLiquid carbonaceous fuelsCombustionExhaust gas emissions

The invention provides a diesel fuel additive and a preparation method and an application method thereof. The additive comprises the following raw materials by mass: 780 parts of n-butanol, 10 parts of acetone, 14 parts of isopropyl-ketone, 42 parts of triethanolamine, 43 parts of amyl nitrate, 26 parts of ferrocene and 45 parts of camphor. The diesel fuel additive provided by the invention can improve the combustion rate of diesel oil, promote full combustion of fuel oil, reduce emission of exhaust gas and protect the environment.

Owner:SHANDONG HUAFU ENERGY TECH

Ethanol gasoline combustion enhancer and preparation method thereof

InactiveCN107916149ALow calorific valueAddress lack of motivationLiquid carbonaceous fuelsNitrocelluloseFreeze-drying

The invention relates to an ethanol gasoline combustion enhancer and a preparation method, belonging to the technical field of fuel additives. The technical problem solved by the invention is to provide a preparation method of an ethanol gasoline combustion enhancer. The method comprises: a. dissolving xanthan gum in water to form a wall material solution; dissolving nitrocellulose and Tween 80 in ethyl acetate to form a core material solution; b. Add the material solution into the wall material solution, and stir at a high speed to obtain an emulsion; c, freeze-dry the emulsion to obtain nitrocellulose capsules; d, mix nitrocellulose capsules, castor oil, dicyclopentadienyl iron, n-hexane, and amyl nitrate Mix evenly with surfactant to obtain ethanol gasoline combustion enhancer. The preparation method of the present invention has a simple process and low cost, and the prepared ethanol gasoline combustion enhancer has good stability, strong power and good mutual solubility, can increase the combustion value of ethanol gasoline during combustion, and solve the problem of low calorific value and power consumption of ethanol gasoline. The problem of insufficiency.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Composite diesel

InactiveCN101691505AAbundant resourcesStable and renewable supplyLiquid carbonaceous fuelsSolventN-propyl nitrate

The invention relates to composite diesel, which is mainly characterized by comprising the following components in percentage by weight: 64 to 75 percent of dimethyl ether (1), 22 to 30 percent of diesel No.0 (2), 2 to 4 percent of solvent oil No.100 (3) and 1 to 2 percent of diesel modifier (4). The composite diesel is obtained by stirring the components in percentage by weight uniformly at normal temperature and normal pressure. In an embodiment, the composite diesel comprises the following components in percentage by weight: 69.5 percent of dimethyl ether (1), 26 percent of diesel No.0 (2), 3 percent of solvent oil No.100 (3) and 1.5 percent of diesel modifier (4). The diesel modifier comprises amyl nitrate (1), propyl nitrate (2) and 2,2,5-trimethyl ethane (3) in a weight ratio of 1:1:2. The composite diesel has simple process and low cost, passes the detection, and is favorable for the promotion and development.

Owner:祝民

Alcohol-based fuel for high-calorific-value boiler

InactiveCN111286373ASatisfy daily consumptionHigh calorific valueLiquid carbonaceous fuelsXylyleneNaphtha

The invention discloses an alcohol-based fuel for a high-calorific-value boiler. The alcohol-based fuel comprises the following raw materials in percentage by mass: 22-30% of methanol, 3-5% of ethanol, 25-30% of diesel oil, 15-20% of naphtha, 10-15% of xylene, 10-15% of ferrocene, 0.3-0.5% of amyl nitrate and 0.4-0.8% of dimethyl carbonate. According to the invention, methanol and ethanol are usedas main fuels and main solvents, naphtha and diesel oil are added to increase the heat value, xylene and amyl nitrate are used as combustion improvers, dimethyl carbonate and ferrocene are used as stabilizers, and the alcohol-based fuel oil for the high-heat-value industrial boiler is obtained through accurate proportioning and scientific mixing; and the heat value of the product reaches 7500 kilocalories or above, daily consumption and use of a conventional boiler can be completely met, the product does not contain harmful substances, the impurity content after combustion is small, and the product belongs to high-heat-value and high-cleanness alcohol-based fuel.

Owner:黄石仁泰新能源开发有限公司

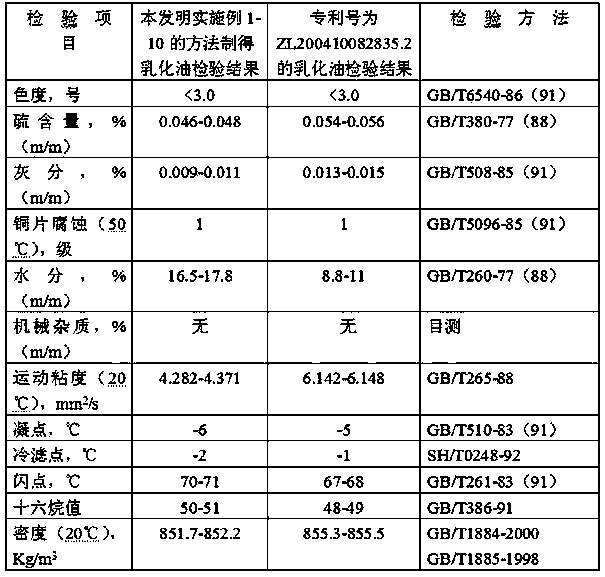

Concentration emulsified diesel fuel and preparation method thereof

ActiveCN102585942BExtended shelf lifeBurn fullyLiquid carbonaceous fuelsEthanolaminesEnvironmental engineering

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY

Alcohol-based fuel and preparation method thereof

The invention belongs to alcohol-based fuel which comprises, by weight, 88-98 parts of methanol, 3-9 parts of alcohol, 0.2-2.5 parts of water, 0.05-2 parts of hydroxyethylidene diphosphonate, 0.04-0.08 part of pine oil, 0.006-0.009 part of camphor oil, 0.003-0.008 part of mint oil, 0.01-0.04 part of edible pigment, 5-8 parts of methyl methacrylate, 6-12 parts of isobutyl acetate, 6-7 parts of cinmethylin, 0.3-1.6 parts of tributyl citrate and 10-15 parts of iso-amyl nitrate. The alcohol-based fuel has the advantages of being more sufficient in burning and dissolving.

Owner:段刘伟

Alcohol-based fuel for high-calorific-value kiln

InactiveCN111286372AImprove environmental friendlinessHigh calorific valueLiquid carbonaceous fuelsEngineeringTert butyl

The invention discloses an alcohol-based fuel for a high-calorific-value kiln. The alcohol-based fuel comprises the following raw materials in percentage by mass: 20-25% of methanol, 5-10% of ethanol,3-5% of propyl alcohol, 30-40% of light oil, 5-10% of methyl formate, 10-15% of triethanolamine, 5-10% of methyl tert-butyl ether, 0.5-1% of ferrocene and 1-3% of amyl nitrate. According to the invention, methanol, ethanol and light oil are used as main fuels and main solvents, a proper amount of methyl formate, triethanolamine, methyl tert-butyl ether, ferrocene and amyl nitrate are added to serve as auxiliary agents, the prepared finished product is high in heat value and can be directly used for fuel of various industrial kilns, few impurities are left after the product is combusted, the waste gas emission of a combustor can be reduced, and the environmental friendliness of the fuel is improved.

Owner:黄石仁泰新能源开发有限公司

A kind of preparation method of methanol gasoline with good stability

The invention provides a preparation method for methanol gasoline with good stability, and belongs to the technical field of synthetic fuels. The preparation method comprises the following steps: steps one, putting heavy benzol, alkyl naphthalene, amyl nitrate, sodium biphosphate, ethylene-vinyl acetate copolymer, light diesel oil, tebutate peroxide, 70# gasoline, a dispersing agent, and a metal deactivator into a reactor and stirring to obtain a mixture; adding methanol into the mixture, cooling down, stirring continuously, and standing to obtain the methanol gasoline. The methanol gasoline provide by the invention has good burning performance, and is not changed in performance and has no sediments after being placed for a long time.

Owner:南通市通州区五接农业机电管理站有限公司

High cleaning diesel oil stablizer

InactiveCN1737089ATo achieve the purpose of useLong stable periodLiquid carbonaceous fuelsStationary phaseMethyl aldehyde

The invention relates to a highly clean diesel oil stabilizer, wherein the stabilizer comprises methyl aldehyde, isopropyl alcohol, dialkyl hydroquinone and amyl nitrate. The stationary phase of the catalytic cracked diesel fuel can be extended by 45 days.

Owner:李宇翔

High cleaning diesel oil stablizer

InactiveCN100335598CTo achieve the purpose of useLong stable periodLiquid carbonaceous fuelsStationary phaseMethyl aldehyde

The invention relates to a highly clean diesel oil stabilizer, wherein the stabilizer comprises methyl aldehyde, isopropyl alcohol, dialkyl hydroquinone and amyl nitrate. The stationary phase of the catalytic cracked diesel fuel can be extended by 45 days.

Owner:李宇翔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com