A production device and preparation method of clean dimethoxymethane diesel oil

A dimethoxymethane, production device technology, applied in the production device of clean dimethoxymethane diesel oil and its preparation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Benzotriazole 0.5%

[0038] Dimerized linoleic acid 1.0%

[0039] 2,6-tert-butyl-p-cresol 0.3%

[0040] LD-r01 diesel lubricity improver 0.5%

[0041] Isooctyl nitrate (amyl nitrate) 4.5%

[0042] Dimethoxymethane 93.2%

[0043] 2. Mix dimethoxymethane, diesel oil, and dimethoxymethane solution I at a ratio of 14.0:85.00:1.0 to prepare D15 dimethoxymethane diesel oil.

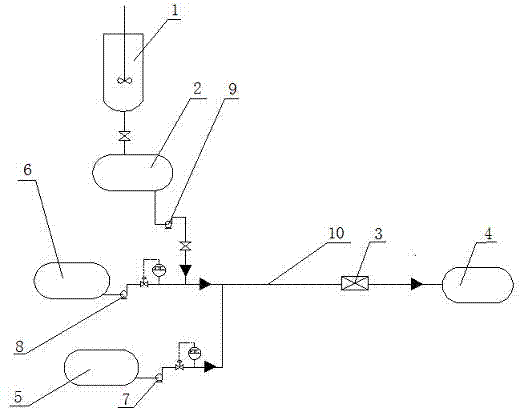

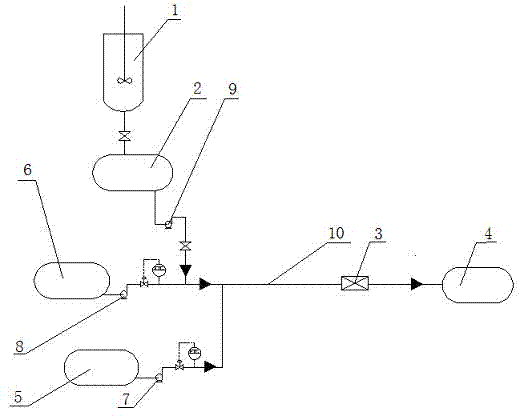

[0044] like figure 1 Shown: Dimethoxymethane is sent out from the dimethoxymethane raw material tank 5 through the dimethoxymethane feed pump 7, and is sent into the mixing pipeline 10 after the flow is adjusted by the flow regulating valve;

[0045] The diesel oil in the diesel raw material tank 6 is sent in and out through the diesel feed pump 8, and then sent into the mixing pipeline 10 after adjusting the flow rate through the flow regulating valve;

[0046] Add dimethoxymethane to dimethoxymethane solution I preparation kettle 1, and then add benzotriazole, dimer linoleic acid, 2,6-tert-butyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com