Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

300 results about "Solar mirror" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solar mirror contains a substrate with a reflective layer for reflecting the solar energy, and in most cases an interference layer. This may be a planar mirror or parabolic arrays of solar mirrors used to achieve a substantially concentrated reflection factor for solar energy systems.

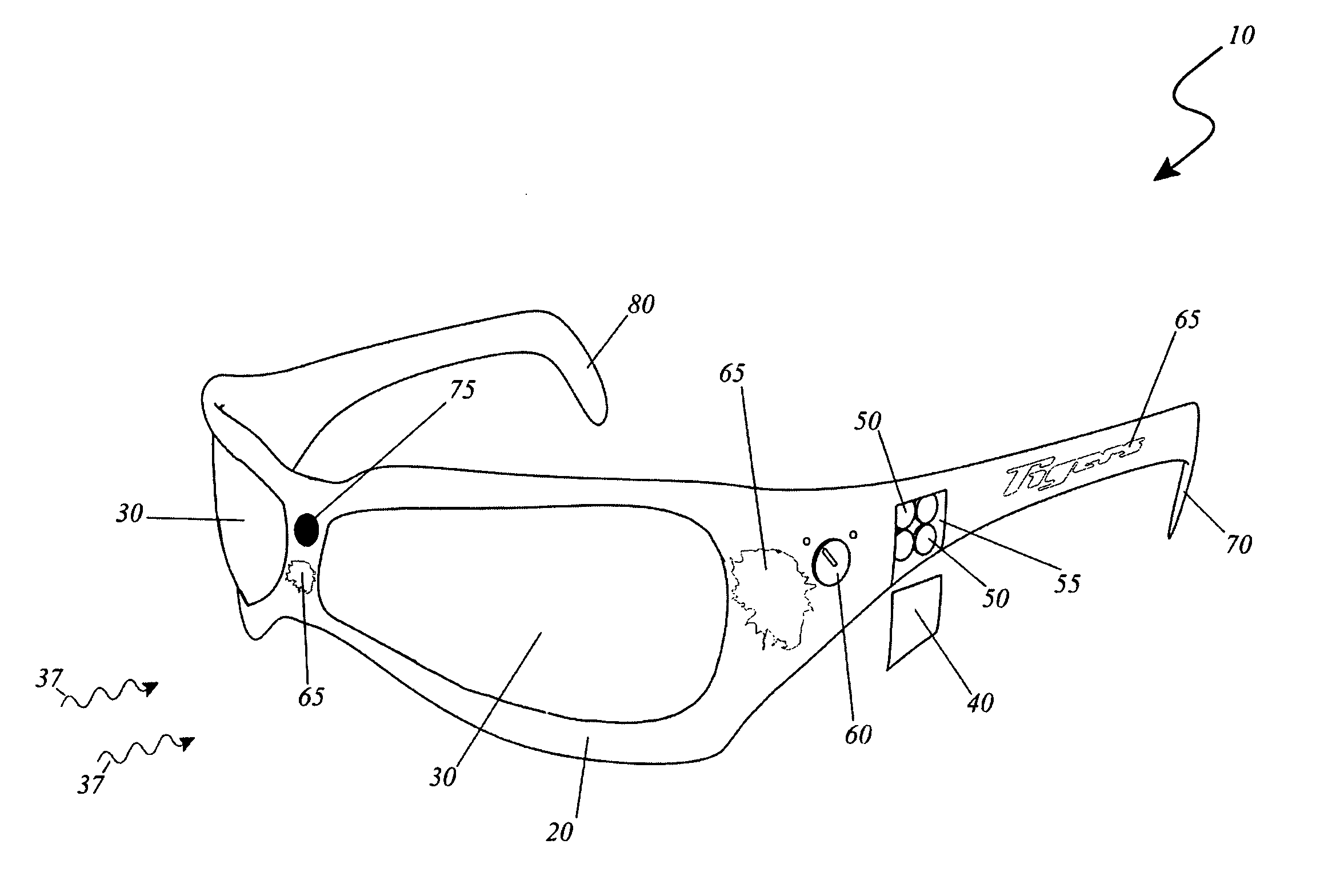

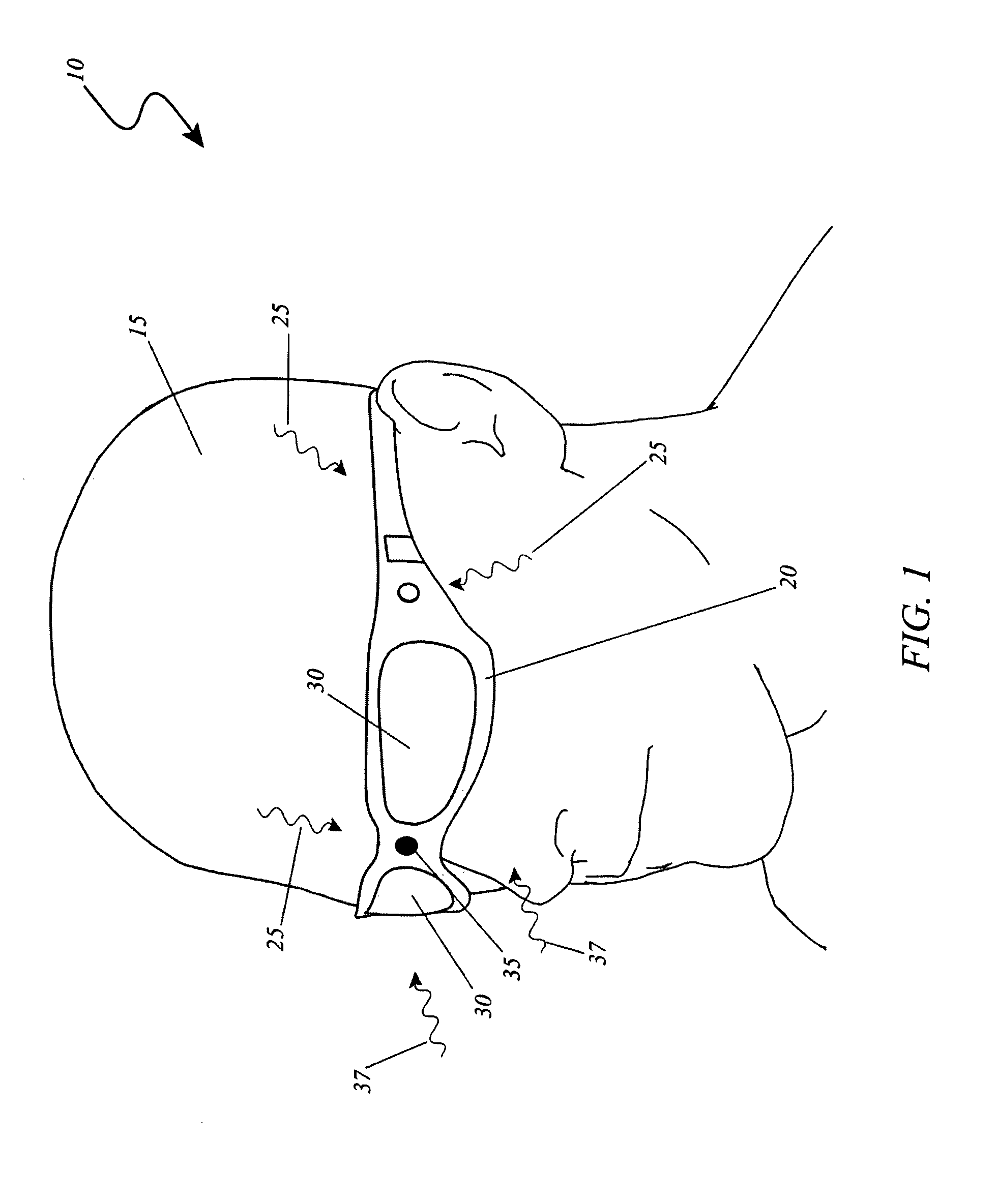

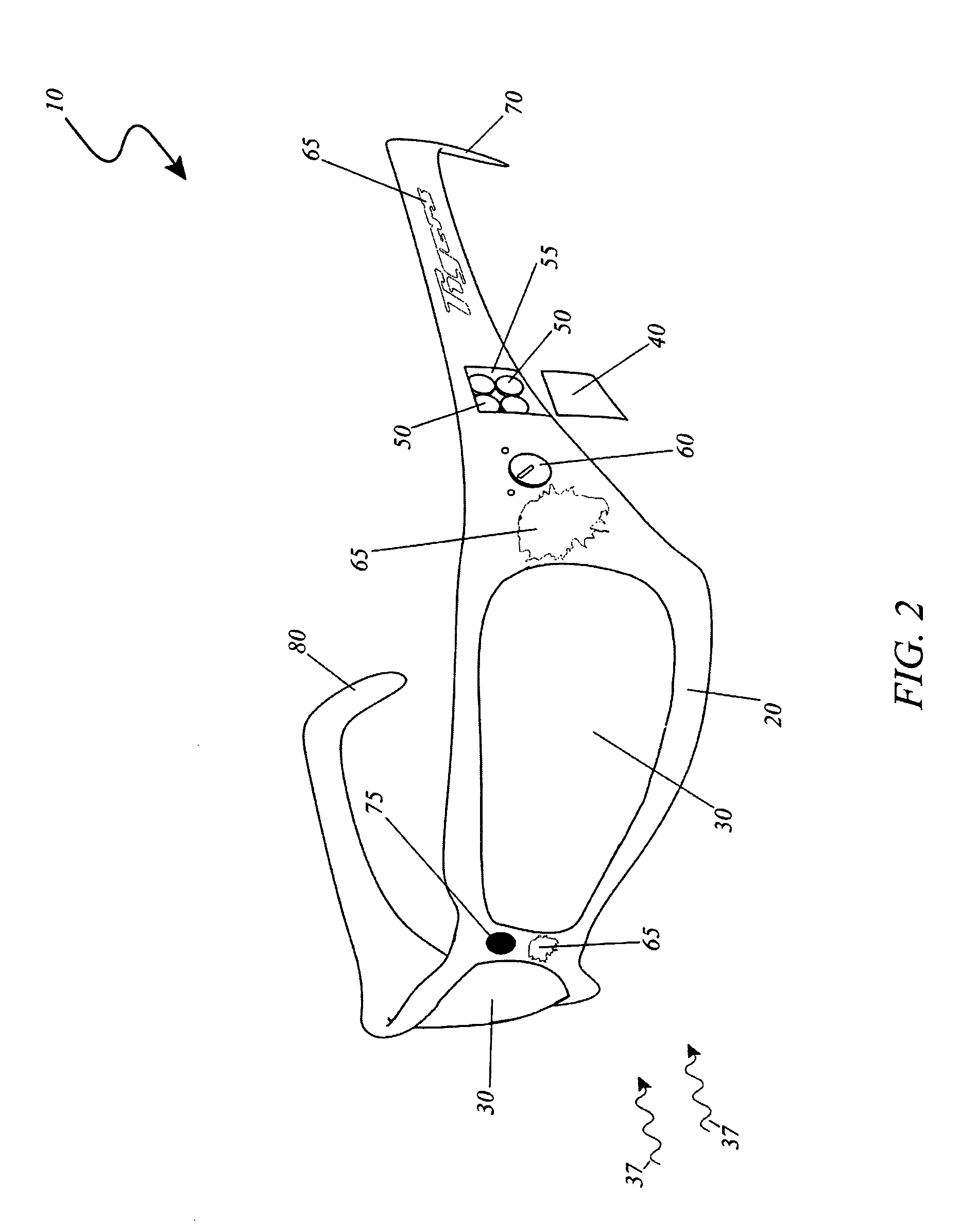

Electrically controlled optical shield for eye protection against bright light

InactiveUS7970172B1Reduce decreaseLower Level RequirementsAntiglare equipmentPedestrian/occupant safety arrangementPupilElectron

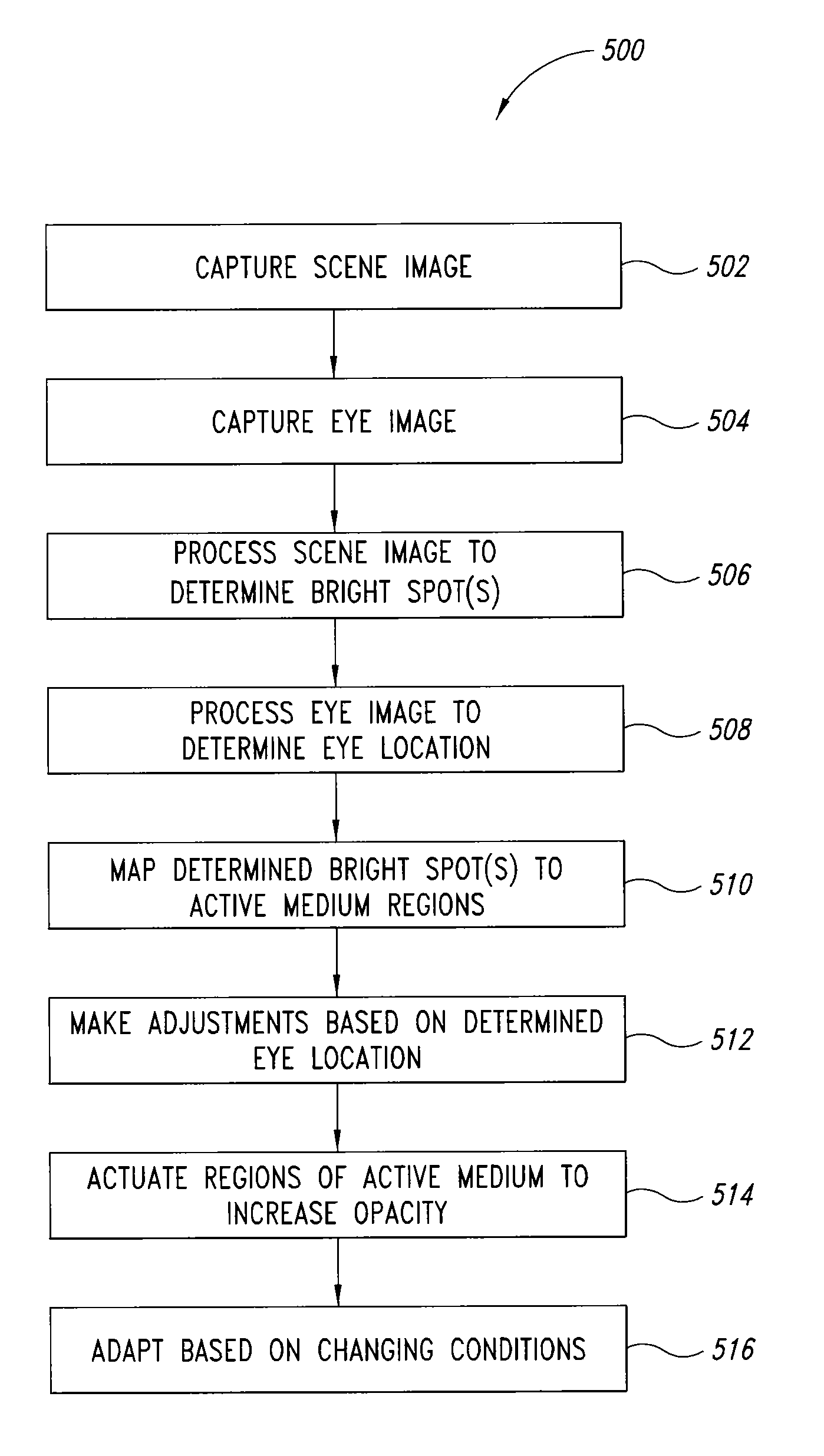

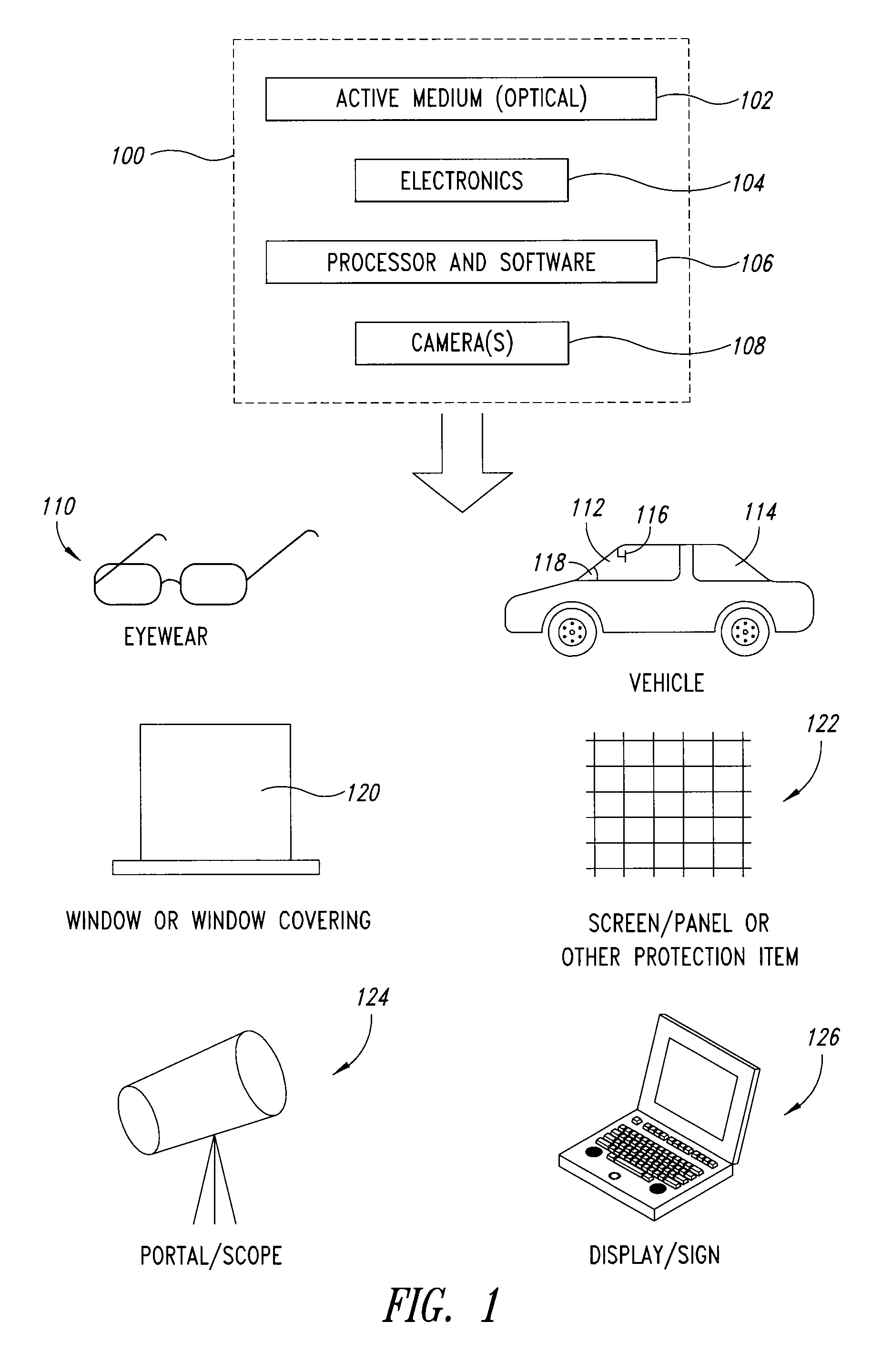

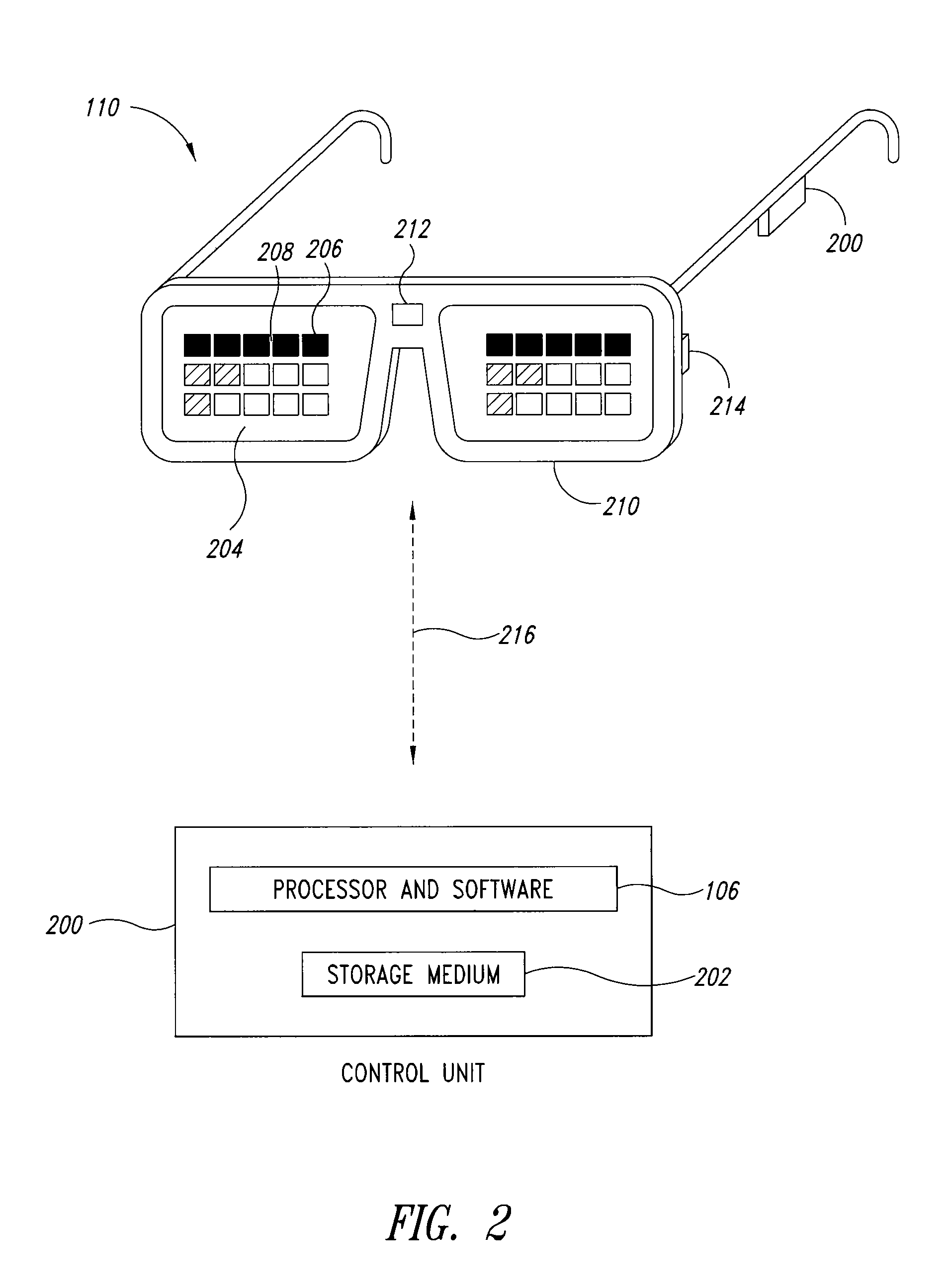

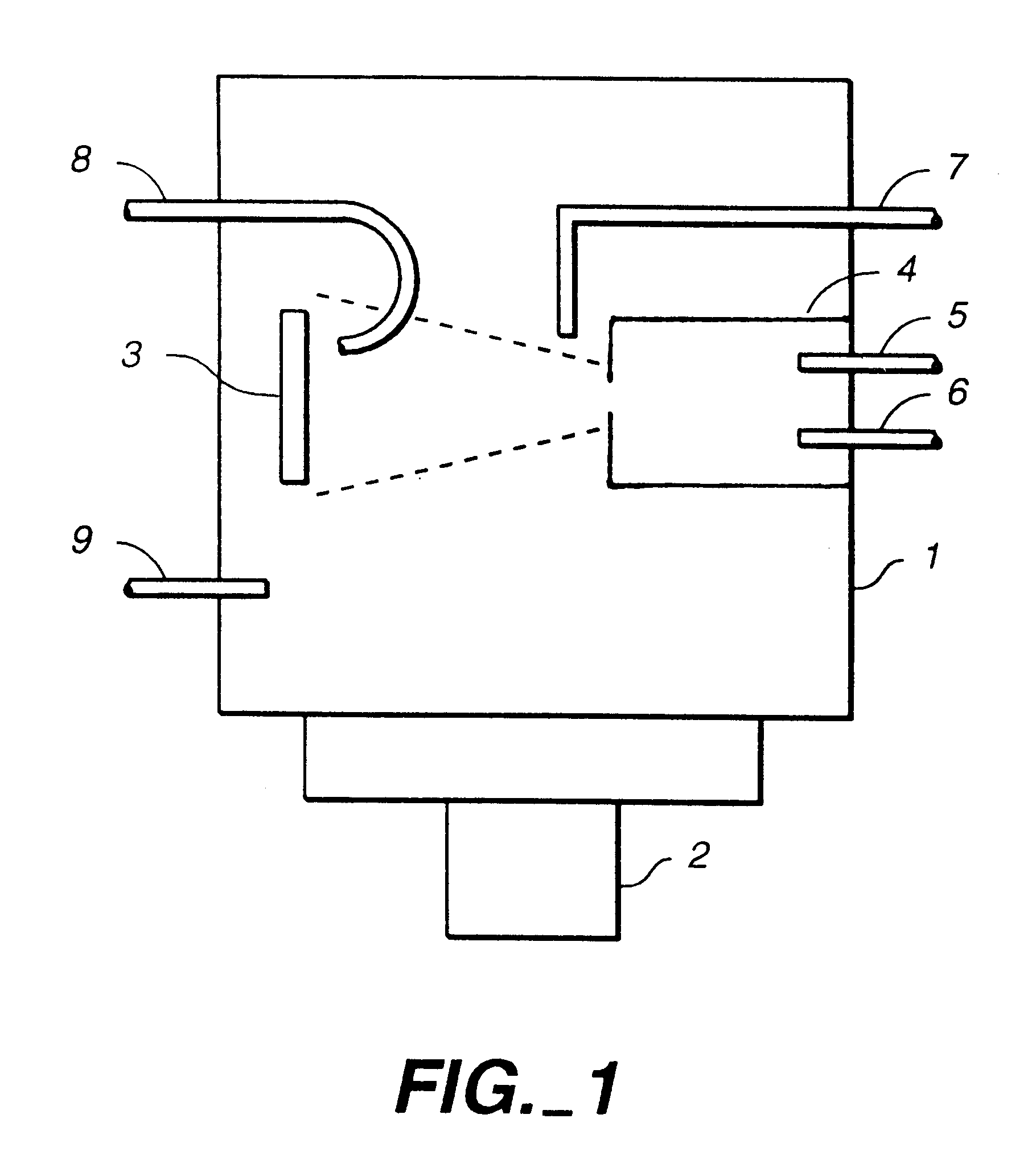

An active device provides protection from the sun or other bright light source for improved vision, using a variable opacity medium that is electronically controlled to cast a shadow on an eye of a user and / or to otherwise reduce the amount of the light incident on the eye, thereby reducing glare. Miniature cameras monitor the user's eye movements and the scene in front of the user. If a bright light is detected, one or more dark spots is created in the variable opacity medium that acts as a shade or light filter for a pupil of the eye. The variable opacity medium, cameras, and associated electronics can be used in connection with eyeglasses (including sunglasses), as part of a device worn by the user (such as a helmet), a windshield, mirror, or other optical element having a view port through which light can be seen by the user.

Owner:HENDRICKSON JAMES ANTHONY

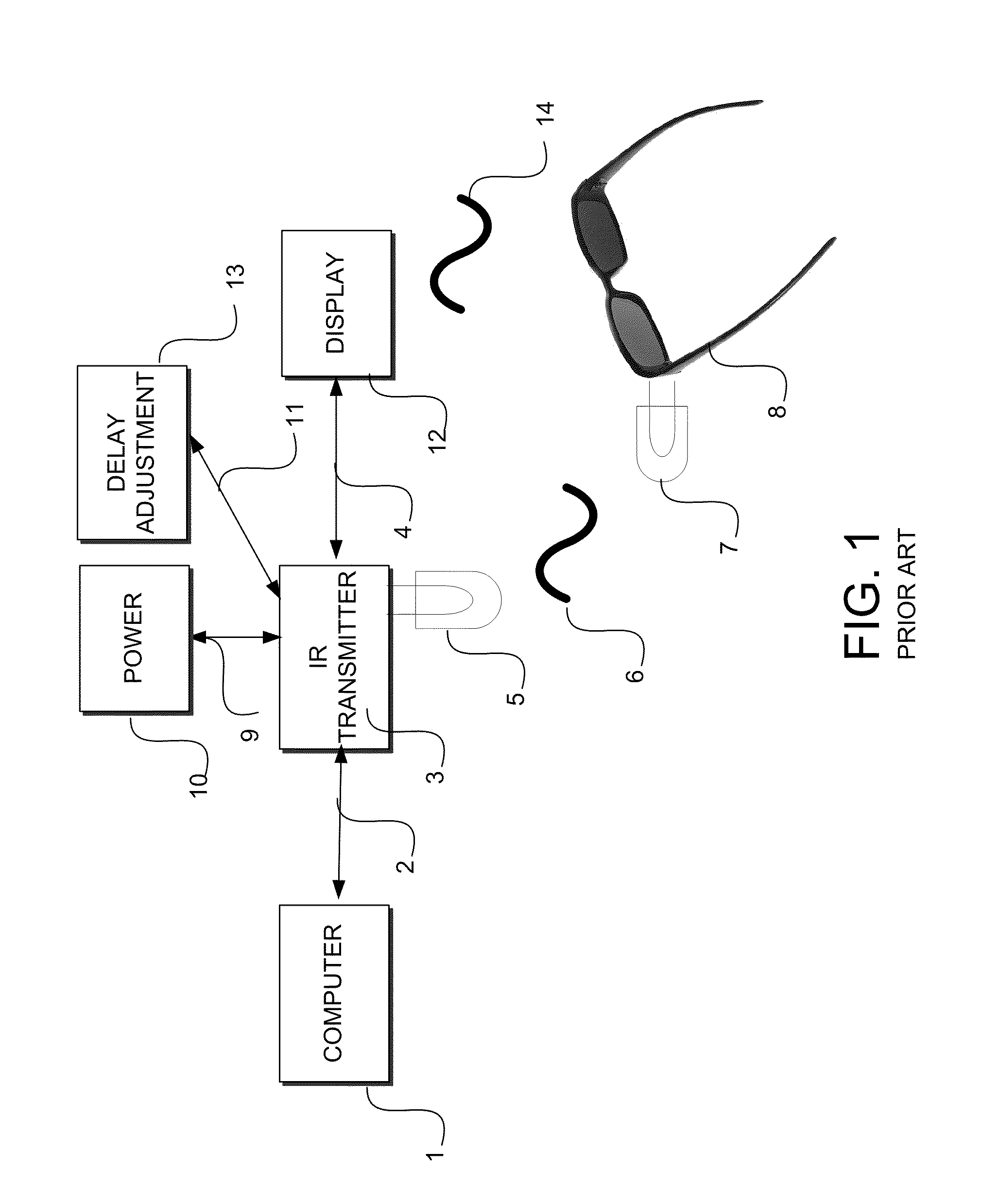

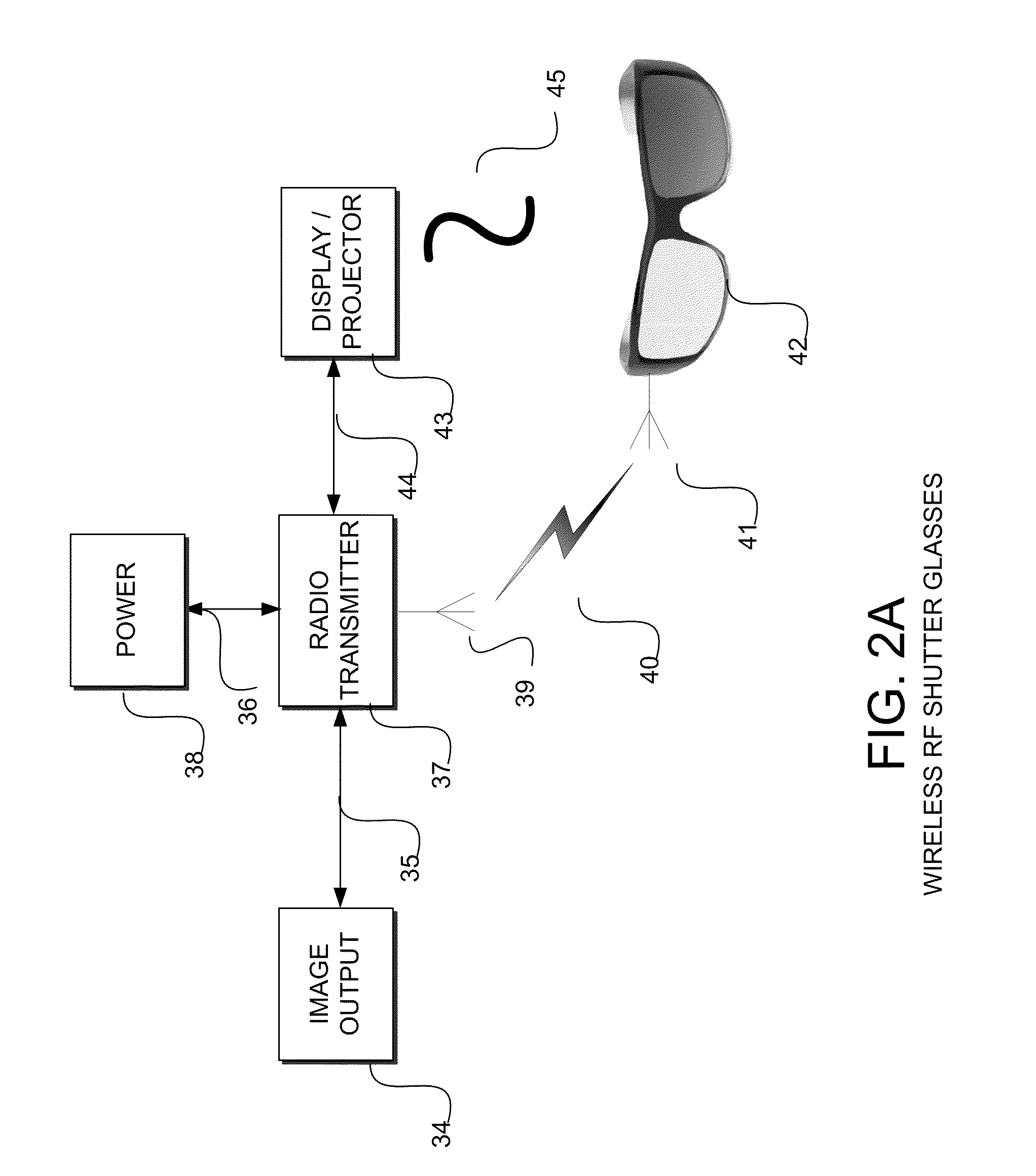

Method of stereoscopic 3D viewing using wireless or multiple protocol capable shutter glasses

InactiveUS20100194857A1Increase level of synchronizationImprove the level ofStatic indicating devicesColor television detailsComputer graphics (images)Display device

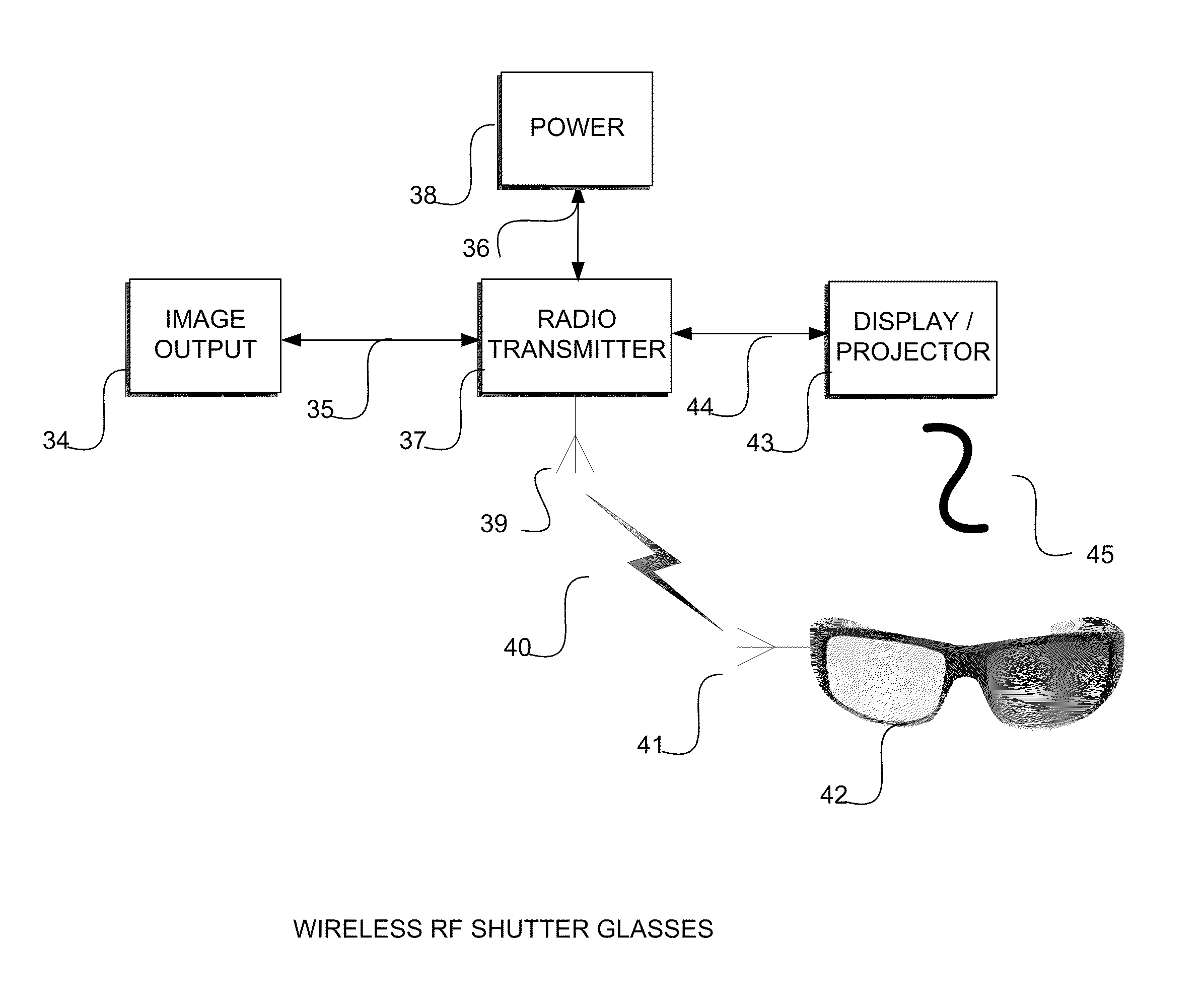

A system, apparatus, method, and computer-readable media are provided for the viewing of stereoscopic three dimensional (3D) images using shutter glasses. According to one method, a wireless protocol is used to communicate stereoscopic synchronization information. The glasses may scan wireless, infrared, and visible light signals to deduce the timing necessary for stereoscopic synchronization with the display. The necessary synchronization information is then determined from the information in these signals. Other methods incorporate this technology into a mobile device, a cradle or dongle that attaches to the mobile device, or an otherwise ordinary pair of sunglasses.

Owner:BIT CAULDRON CORP

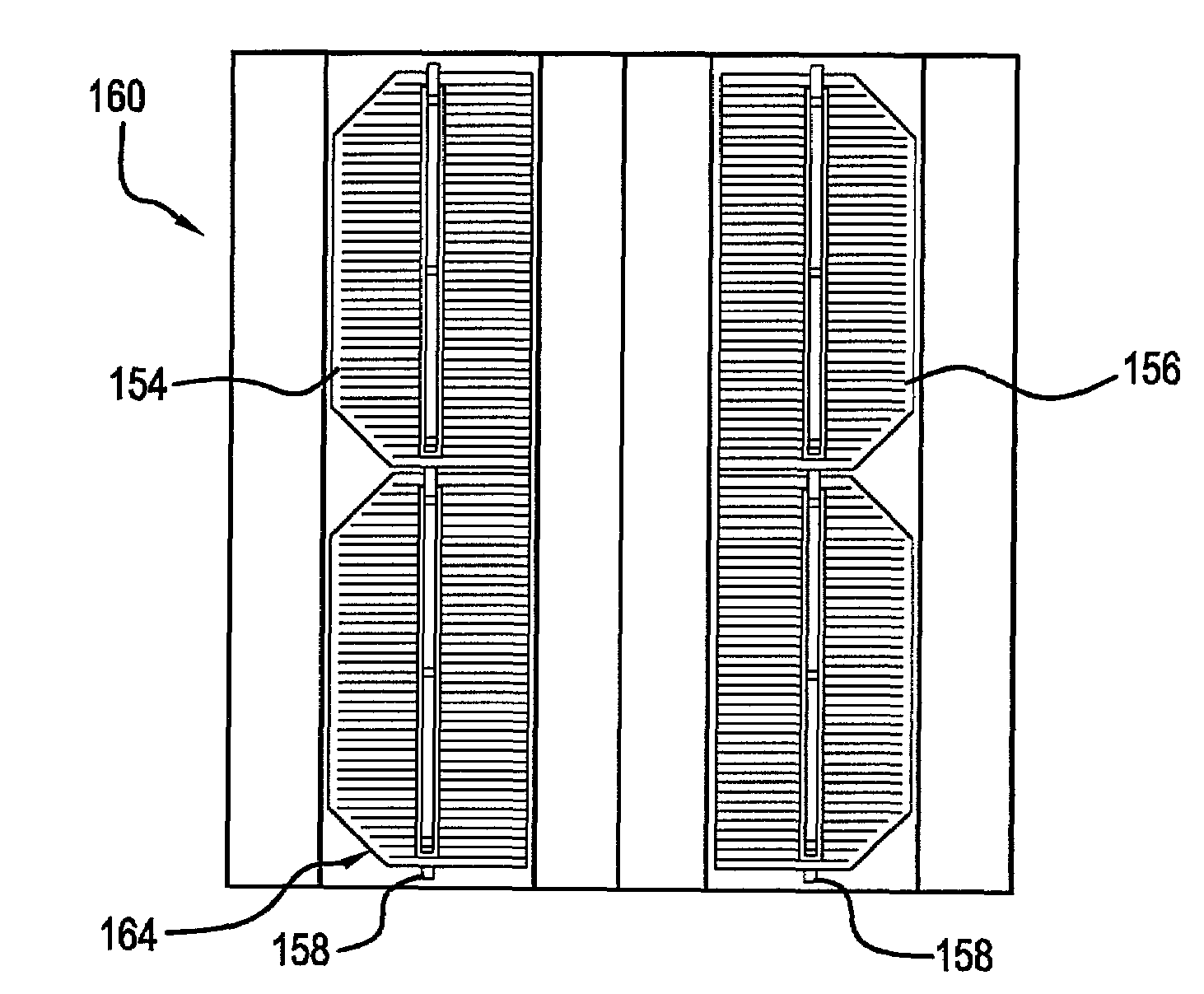

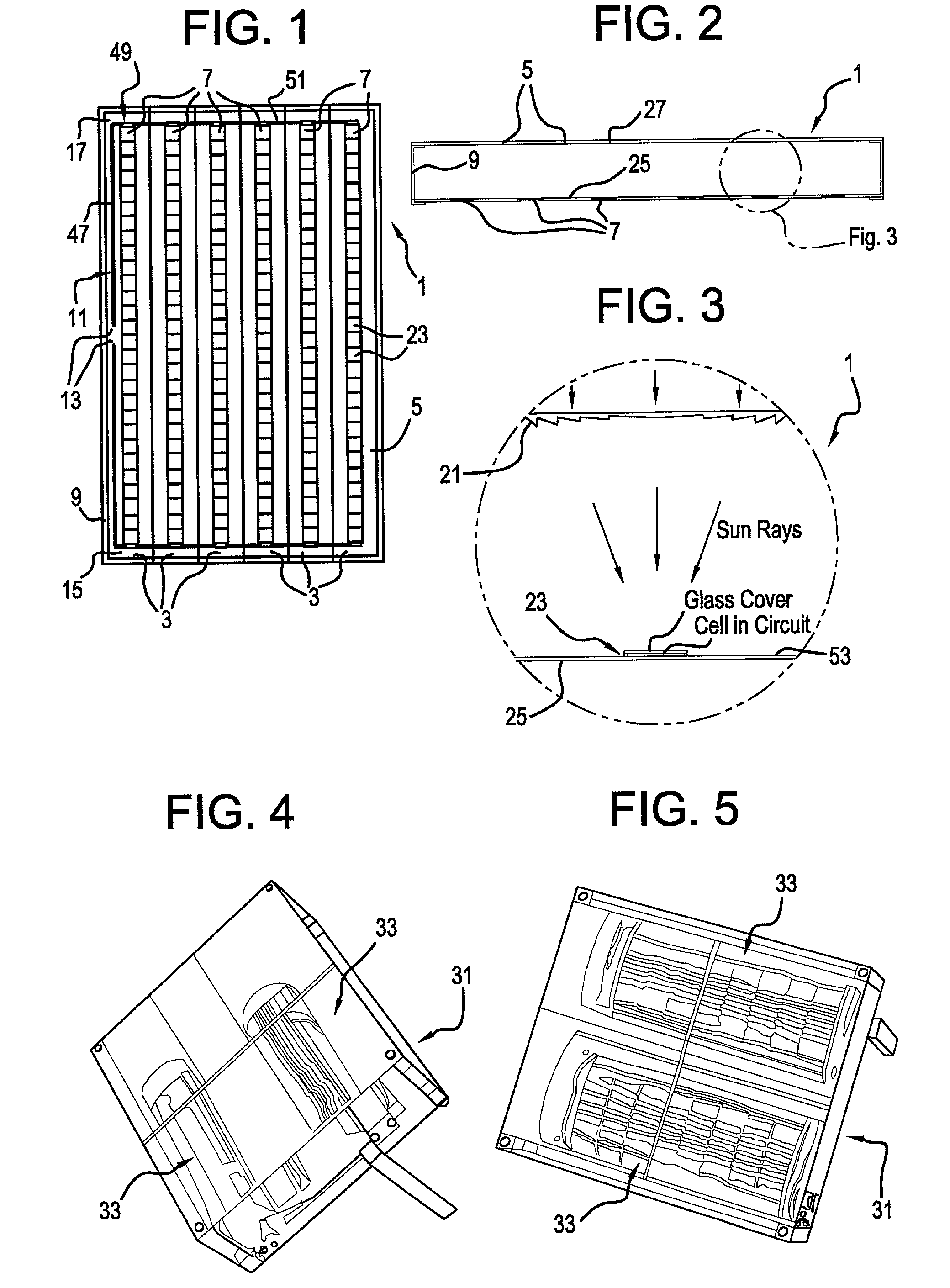

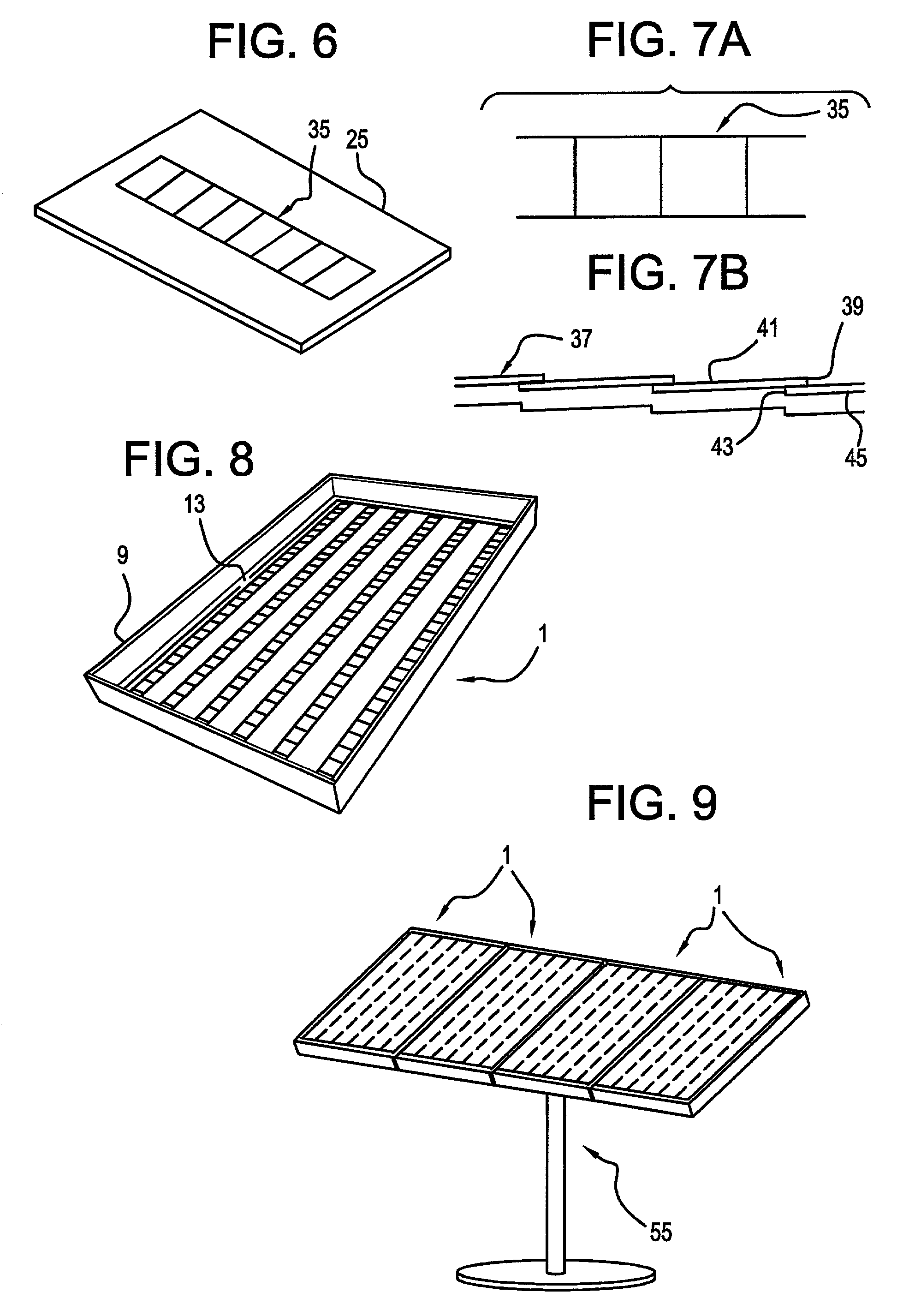

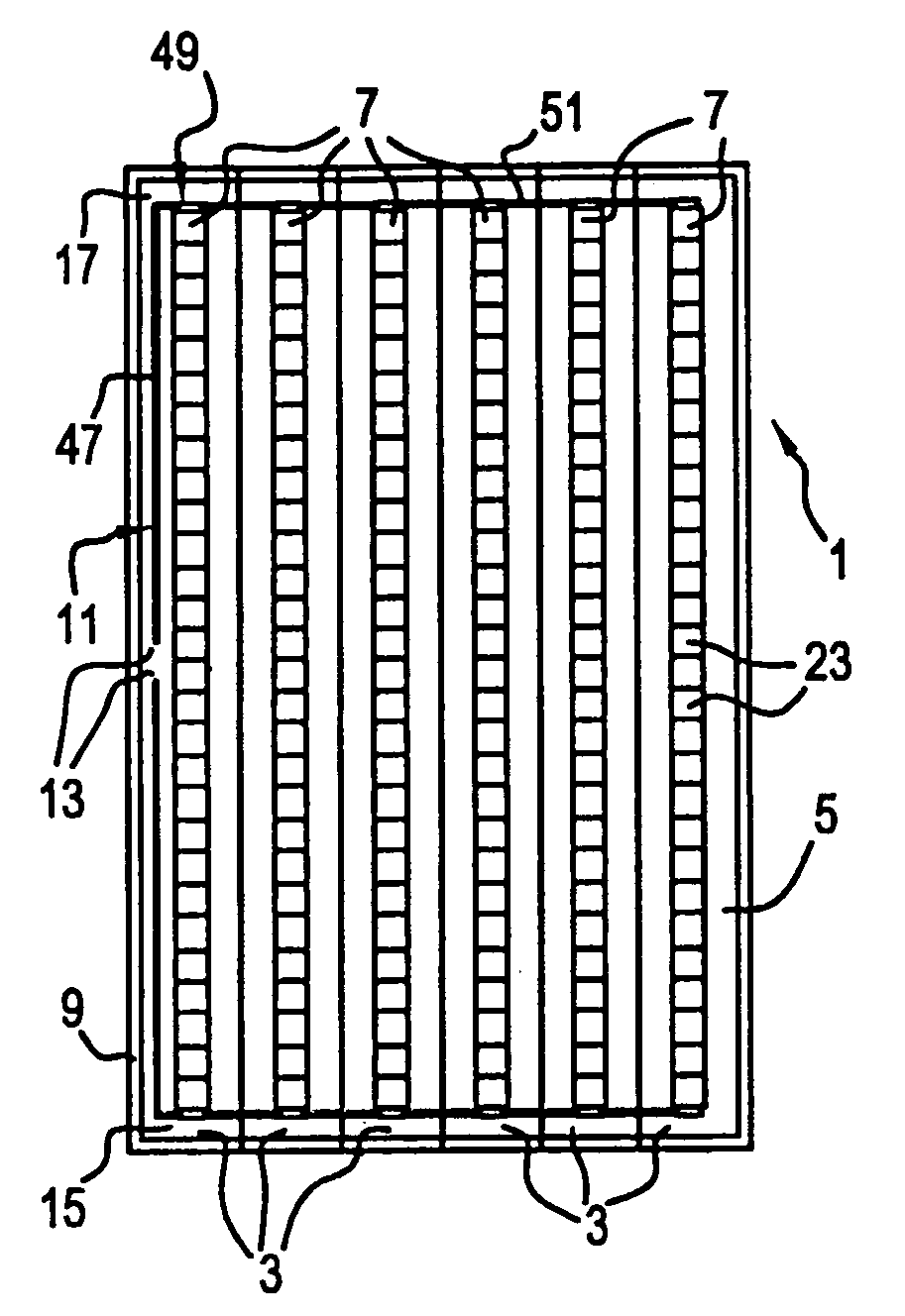

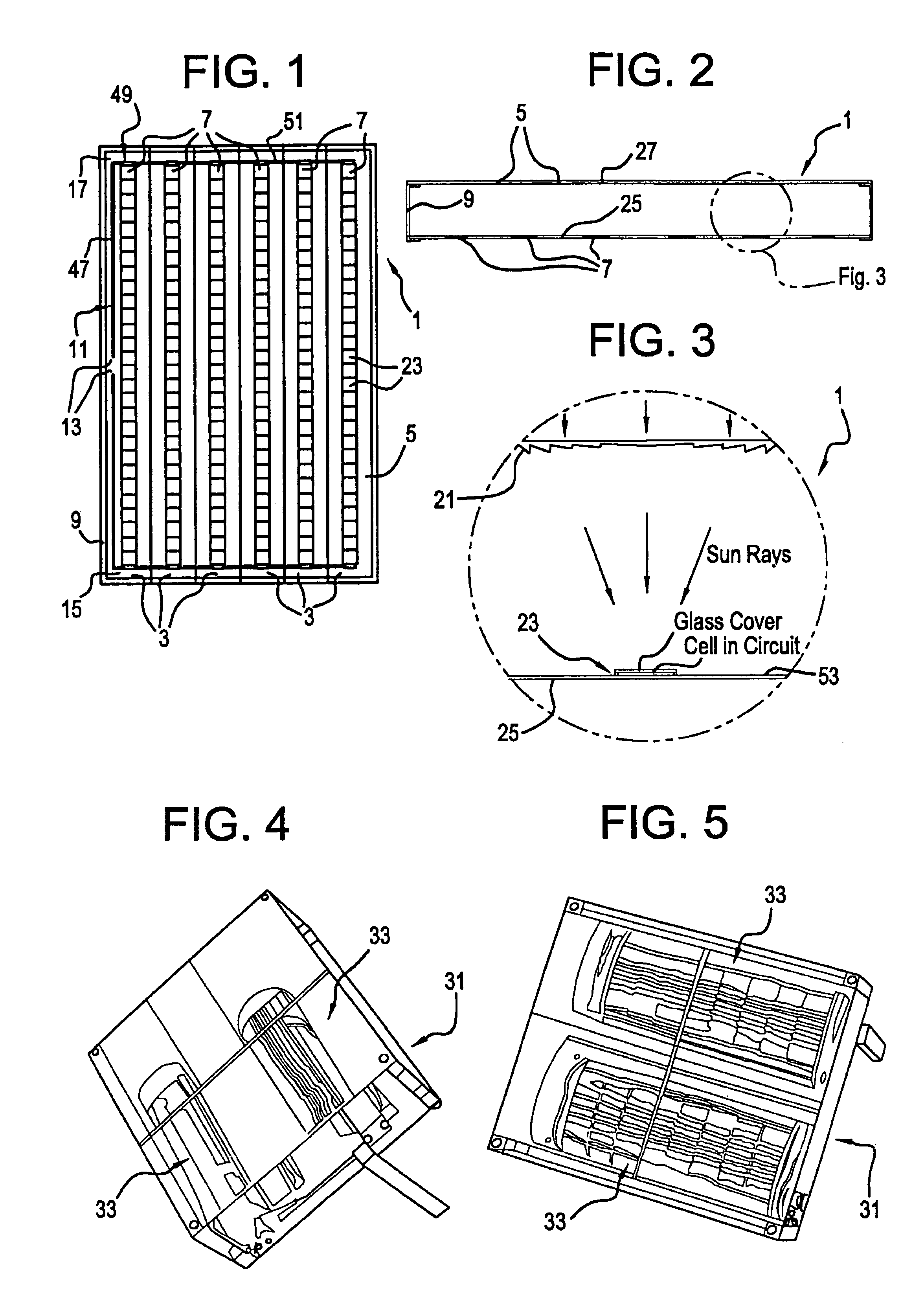

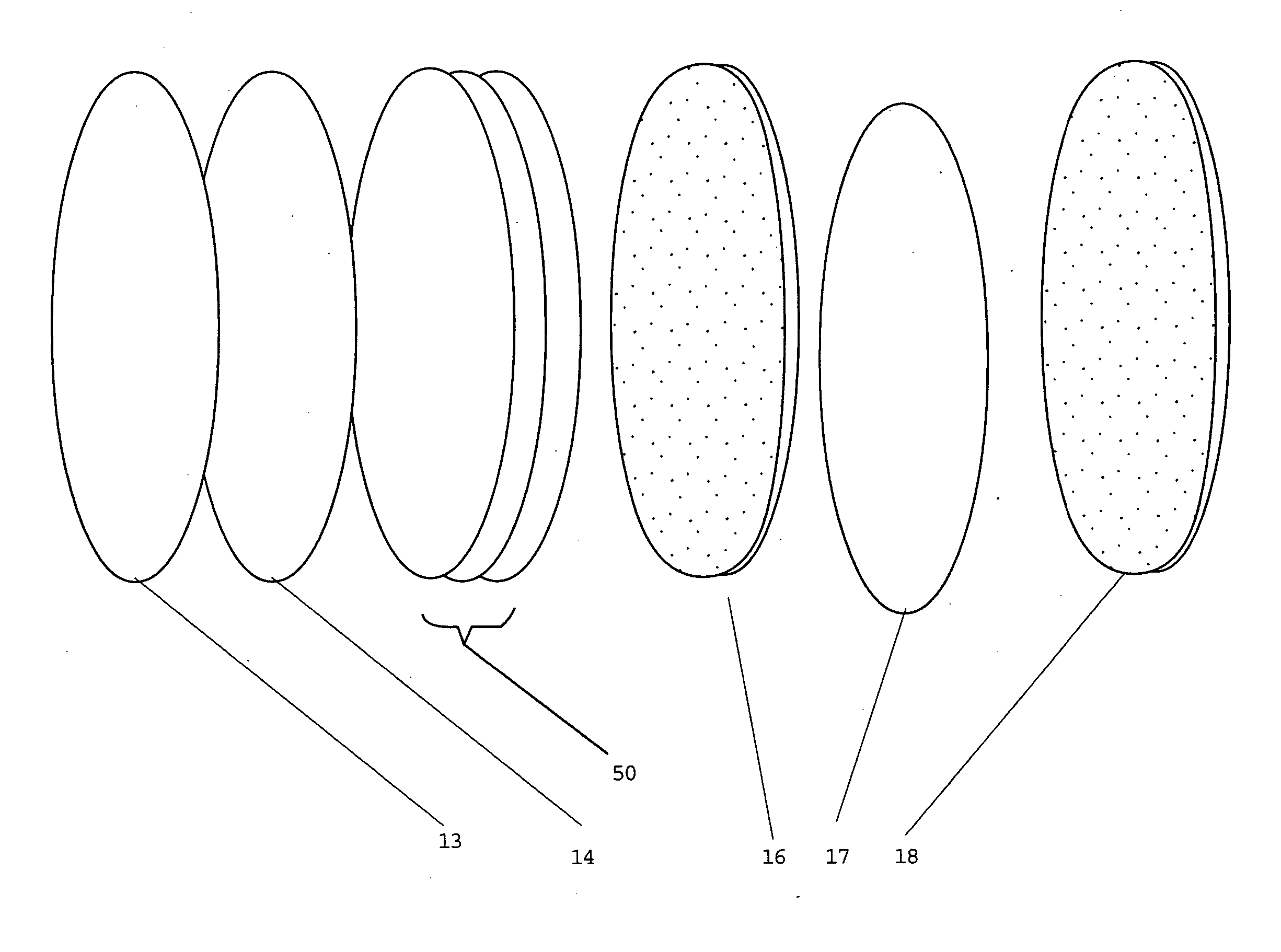

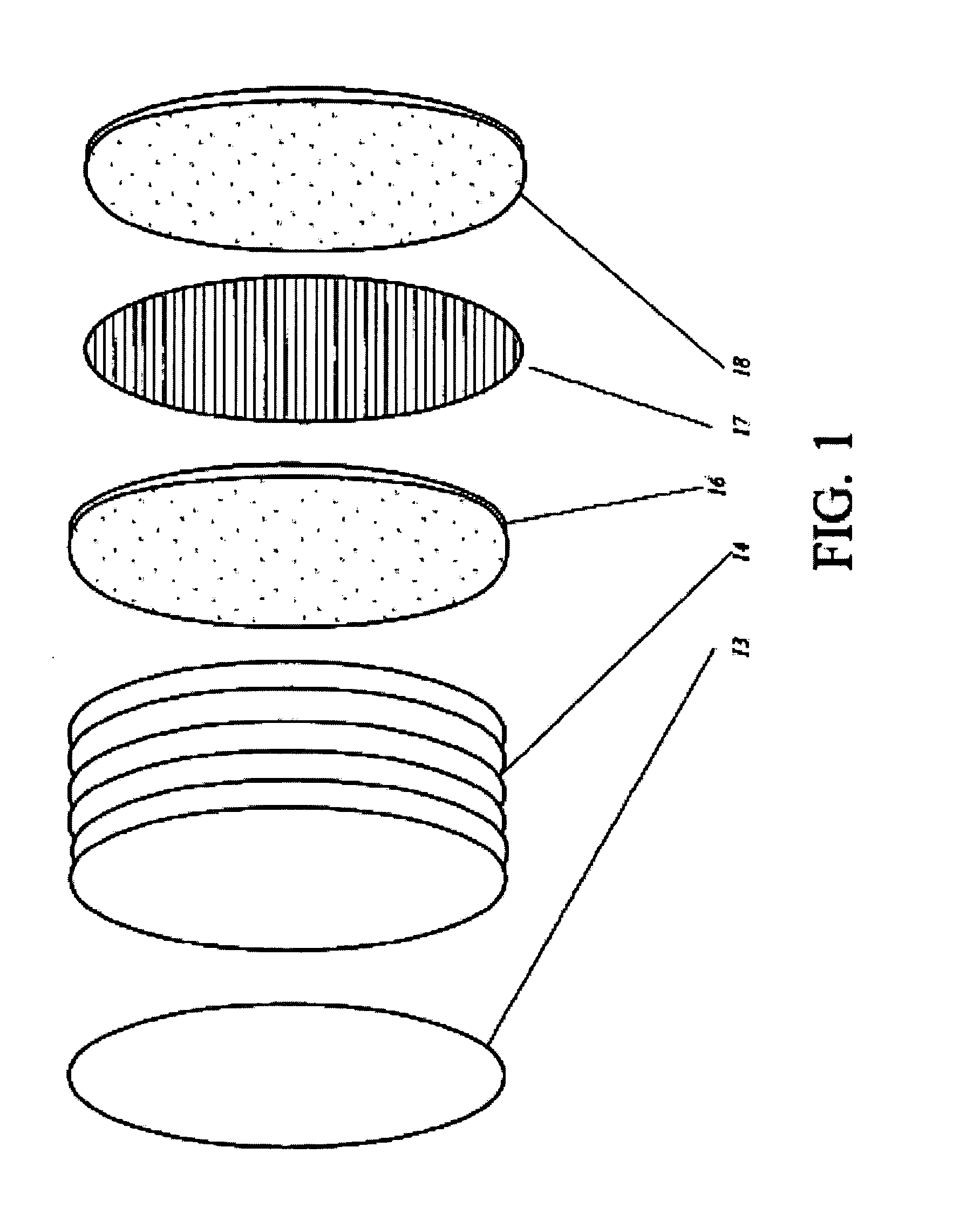

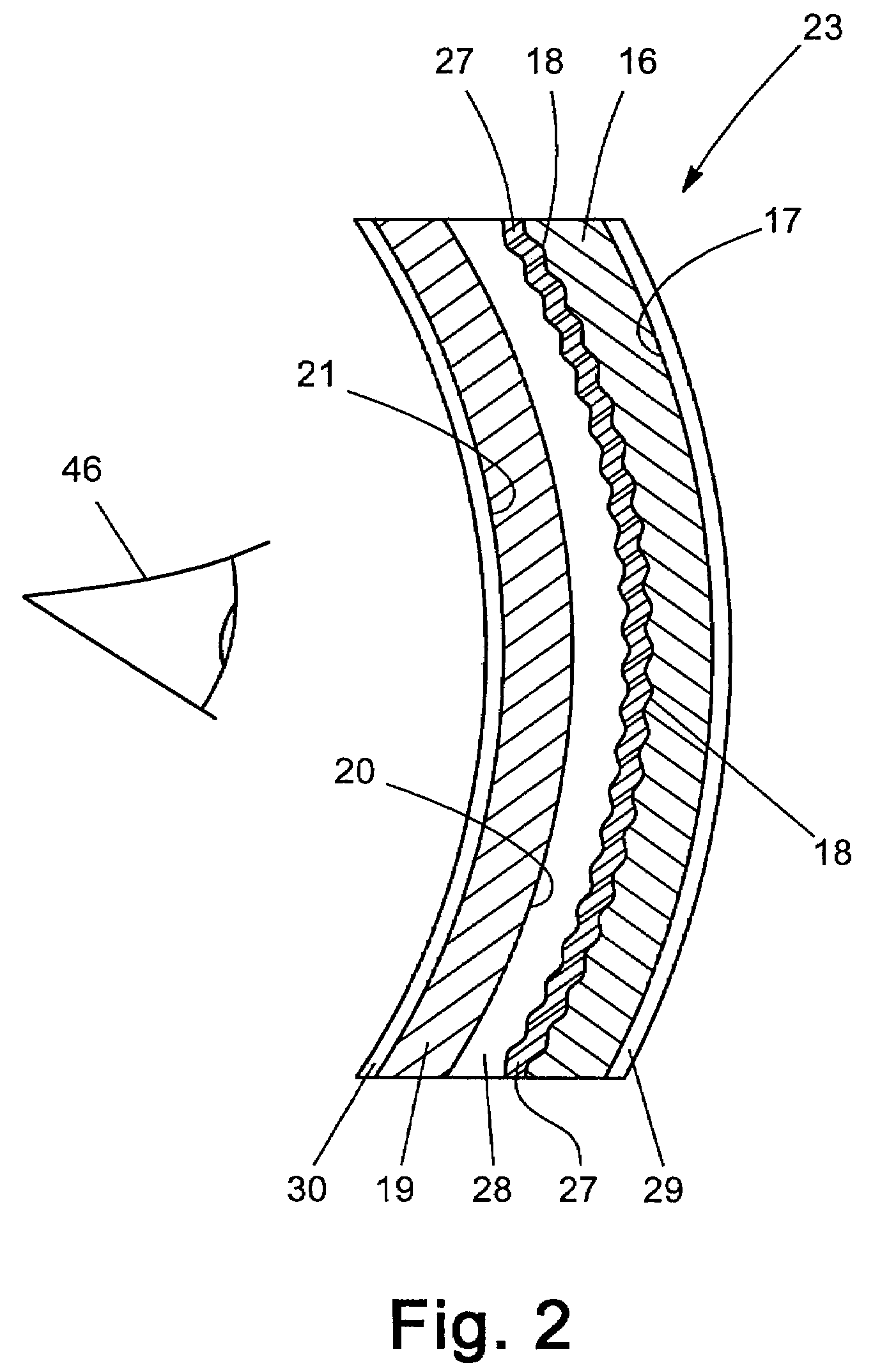

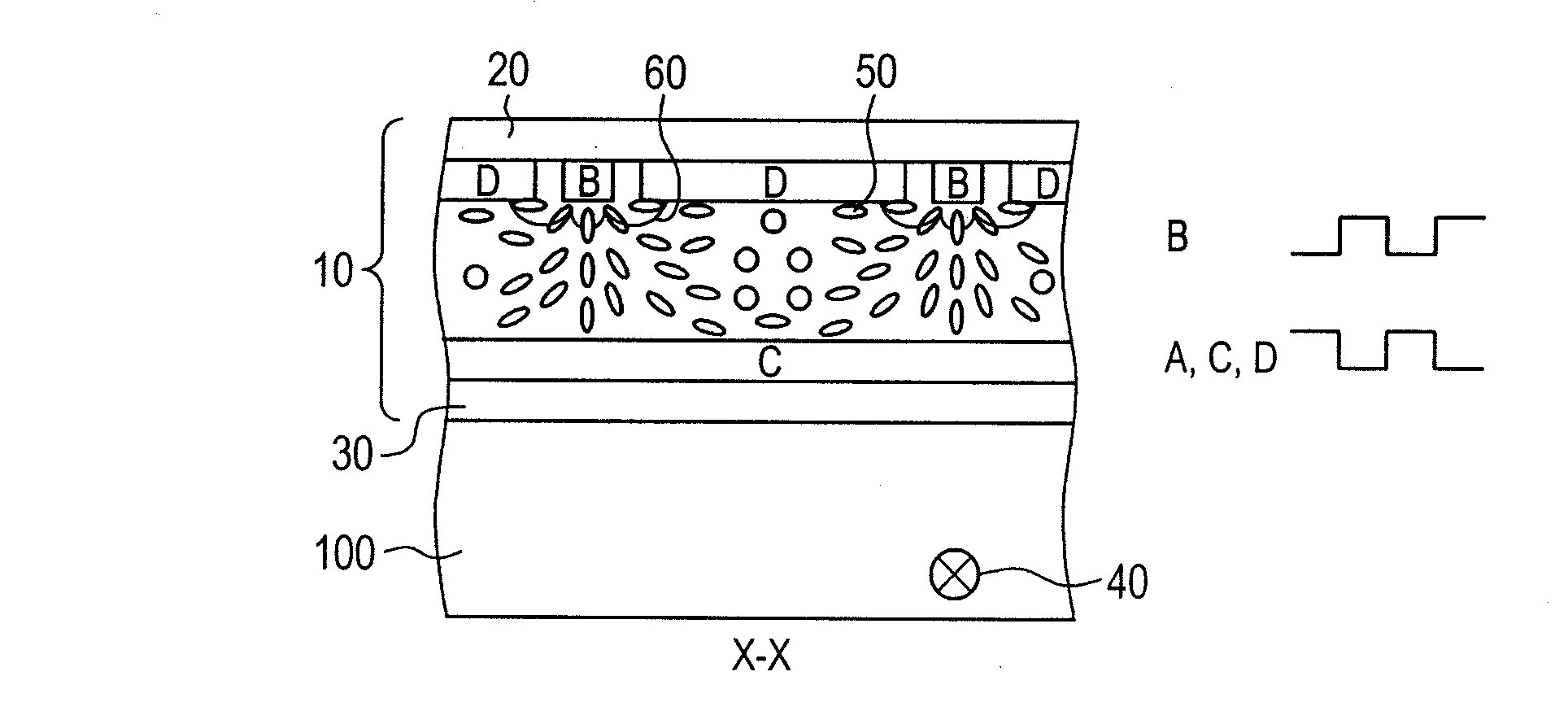

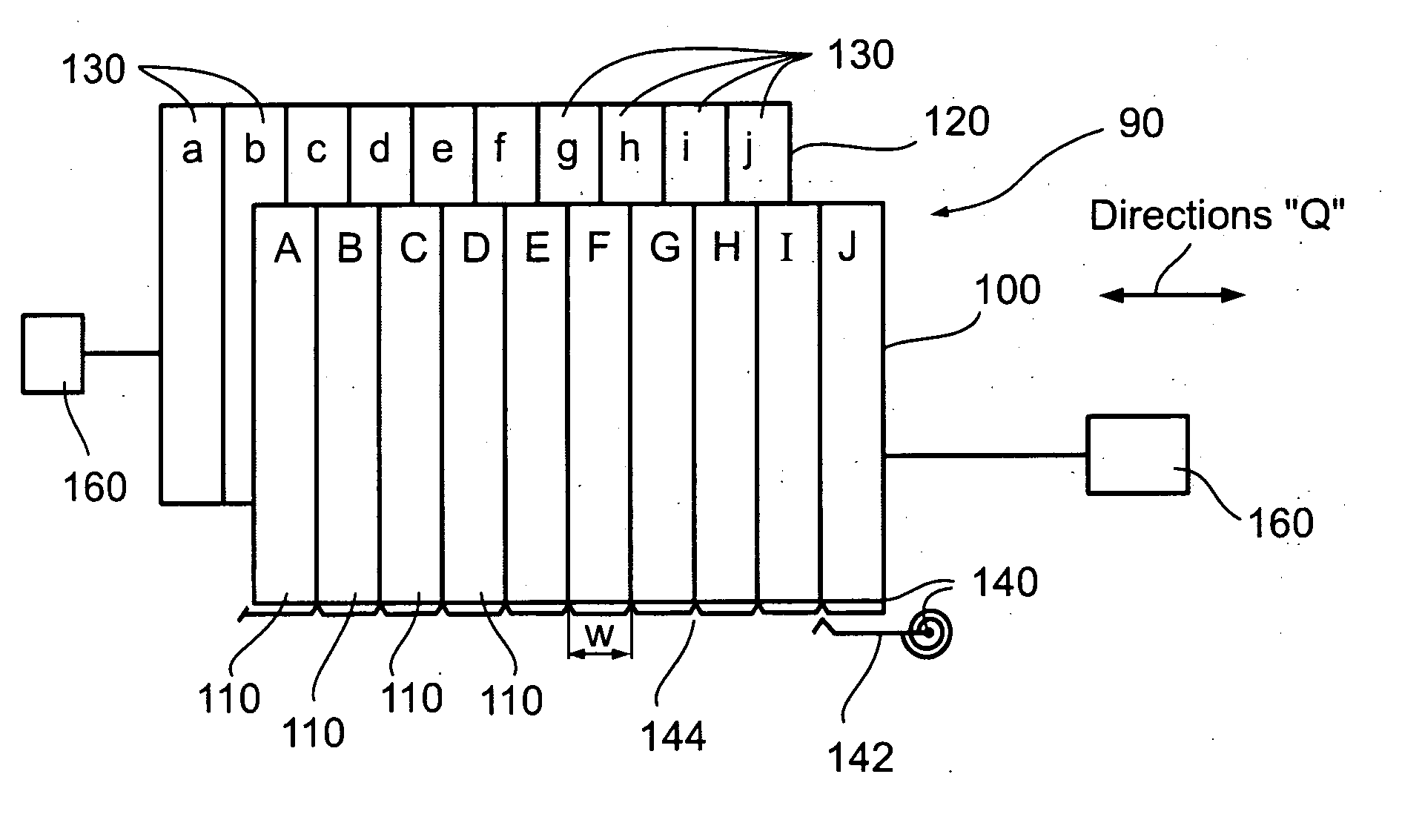

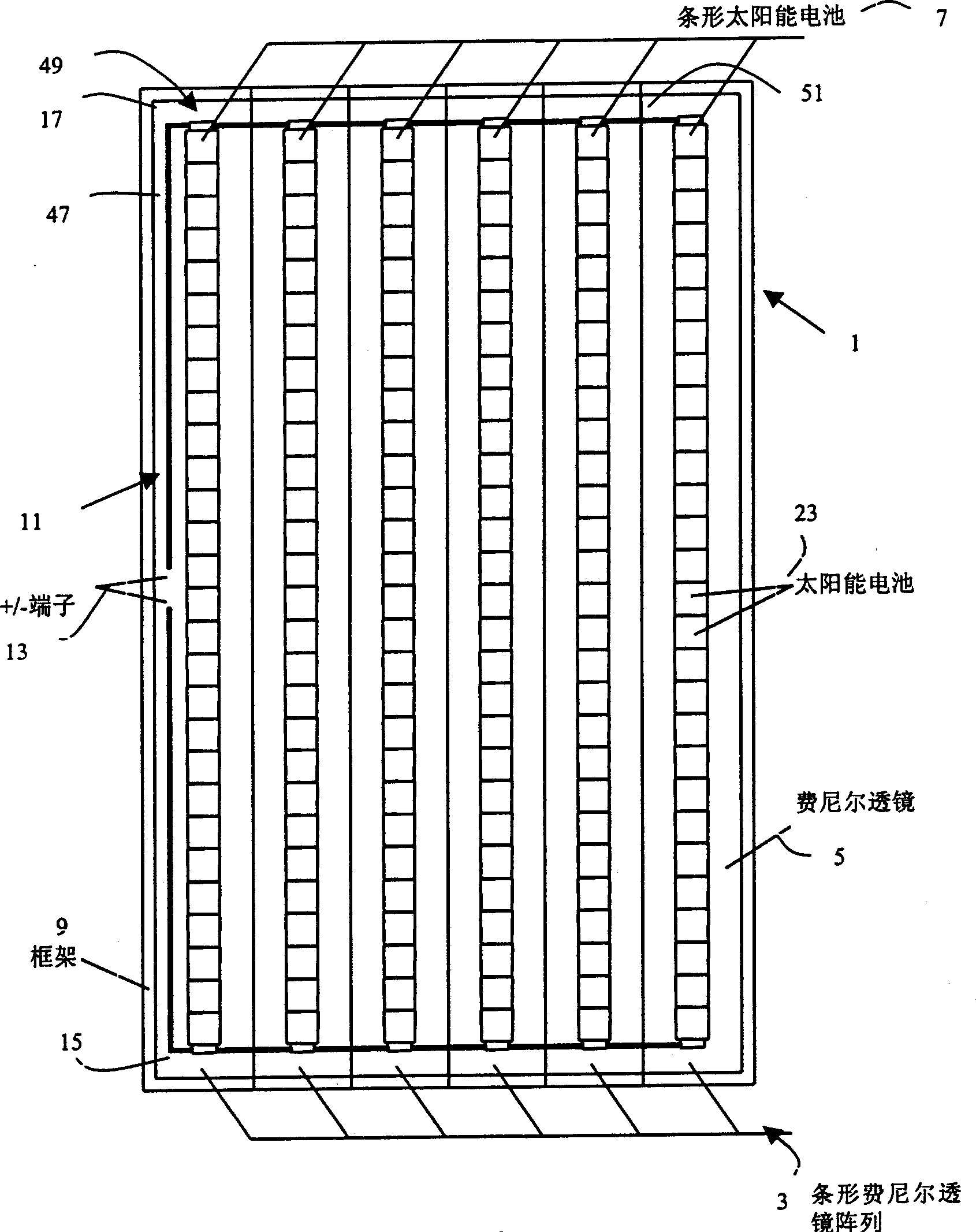

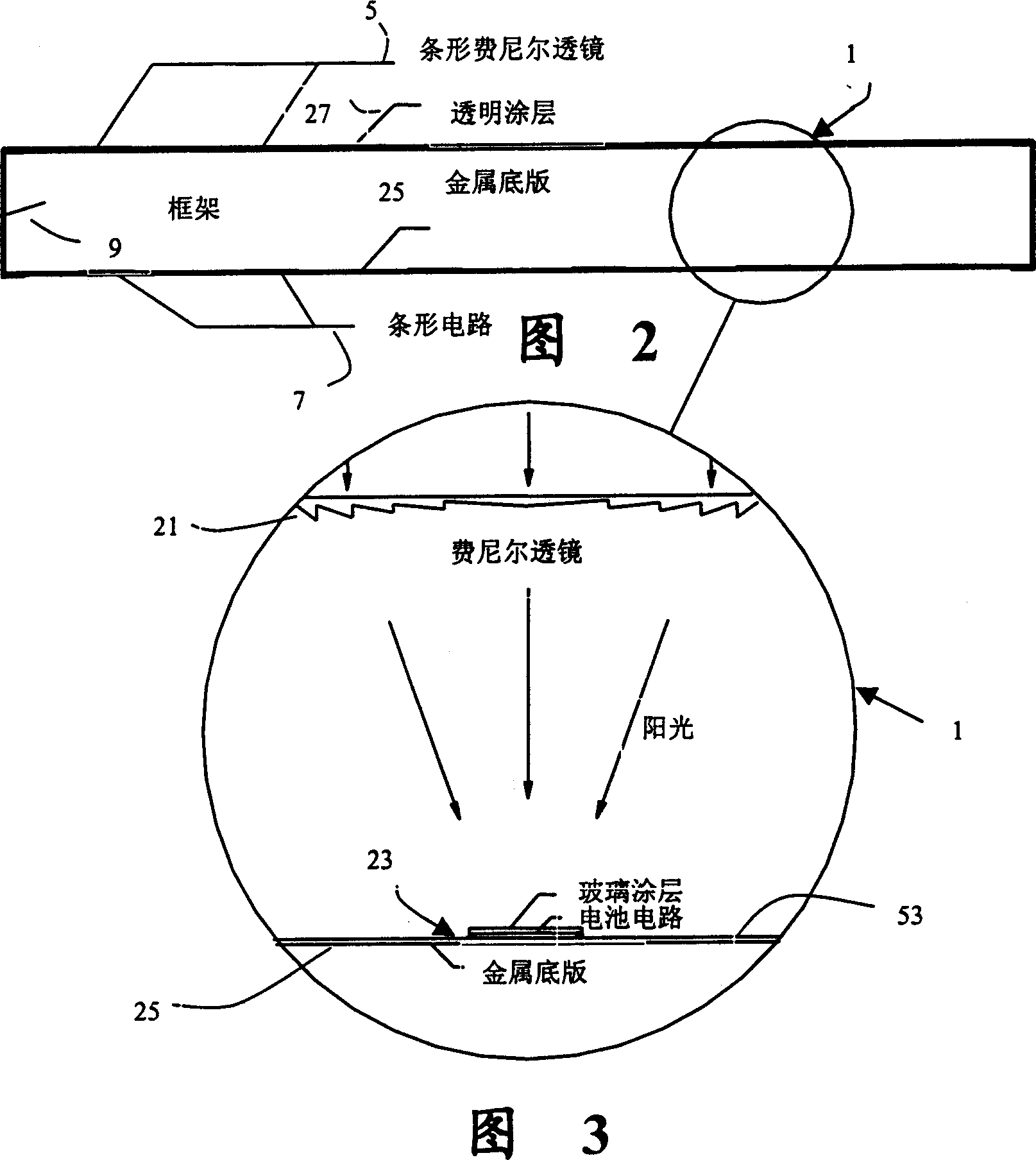

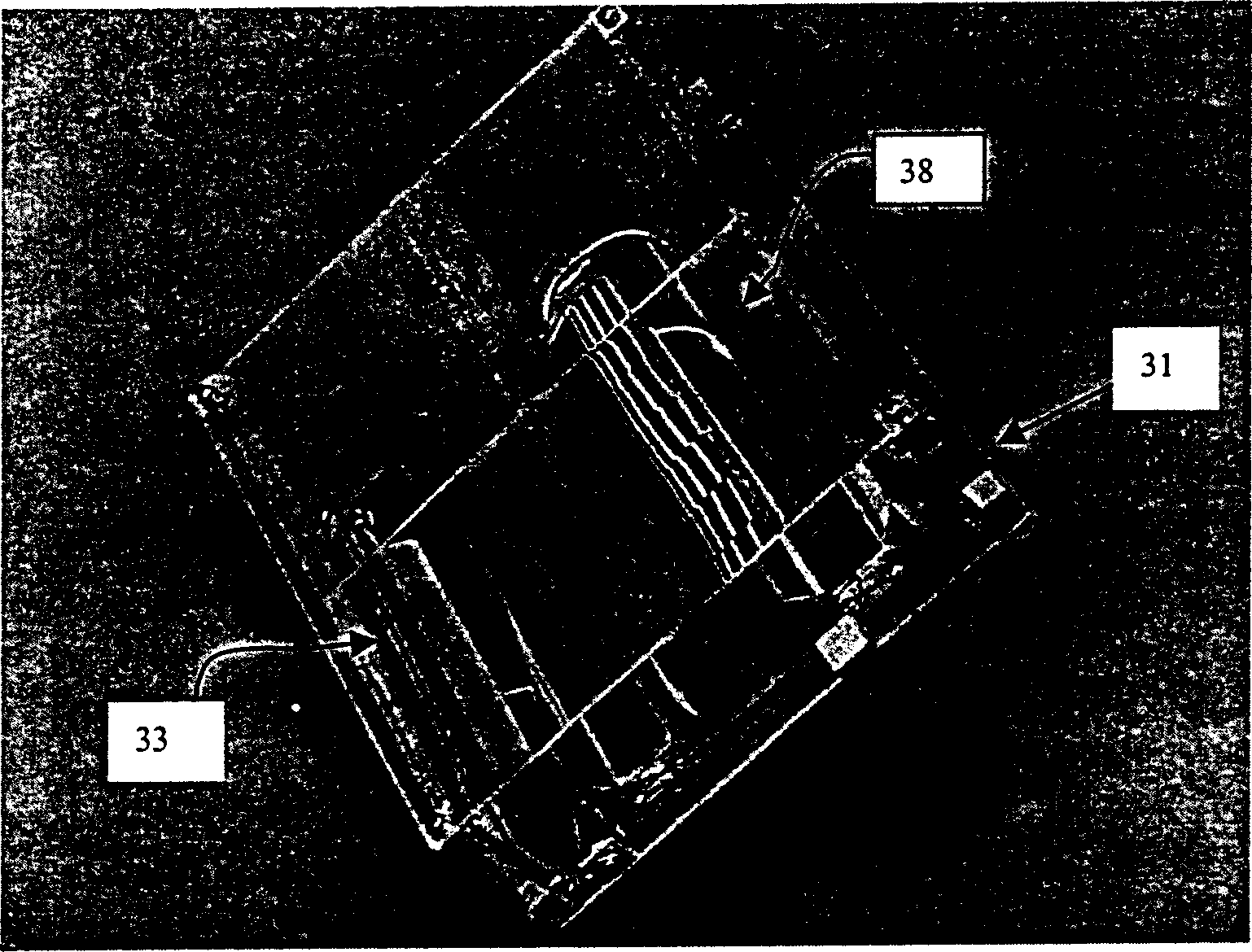

Planar solar concentrator power module

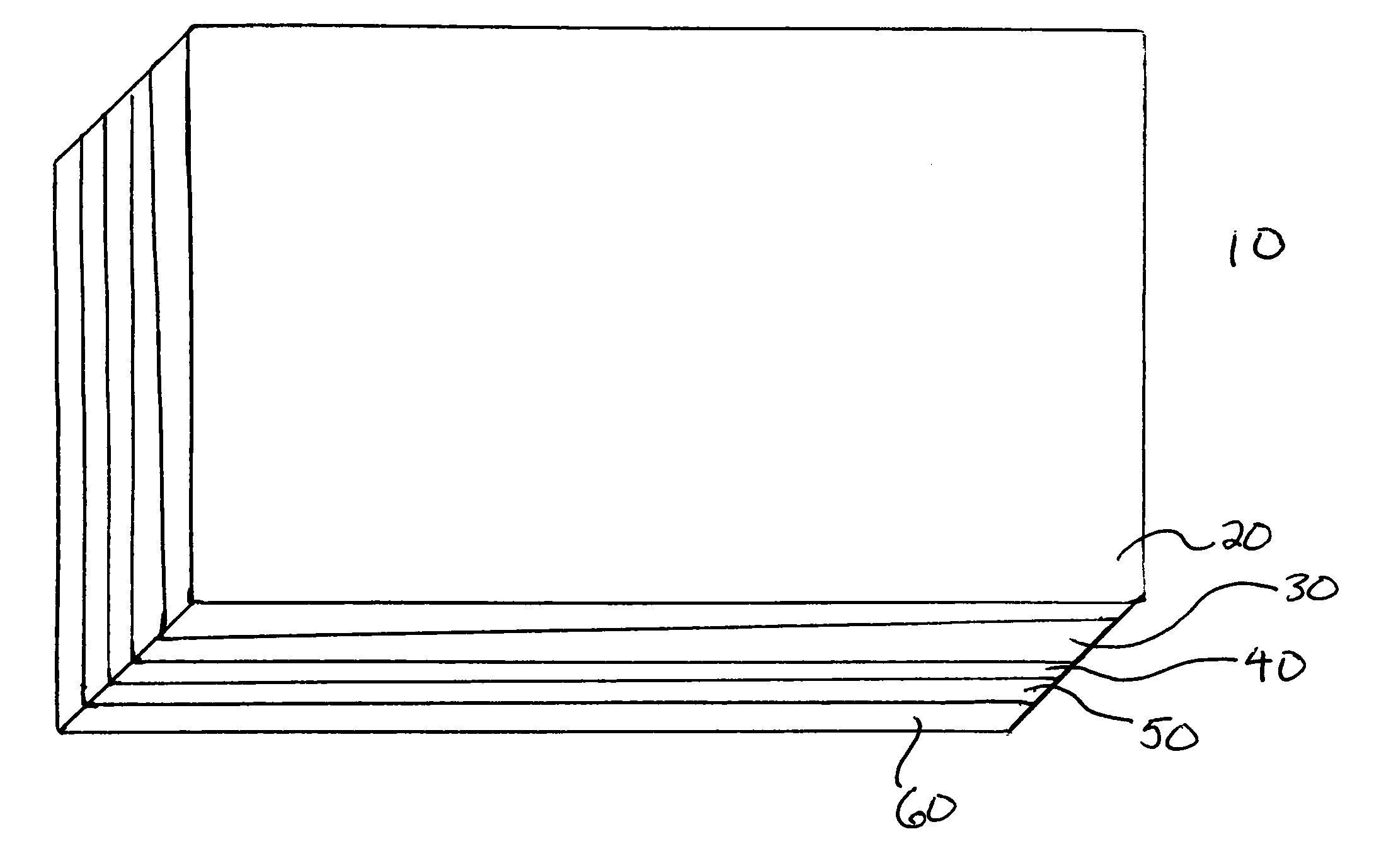

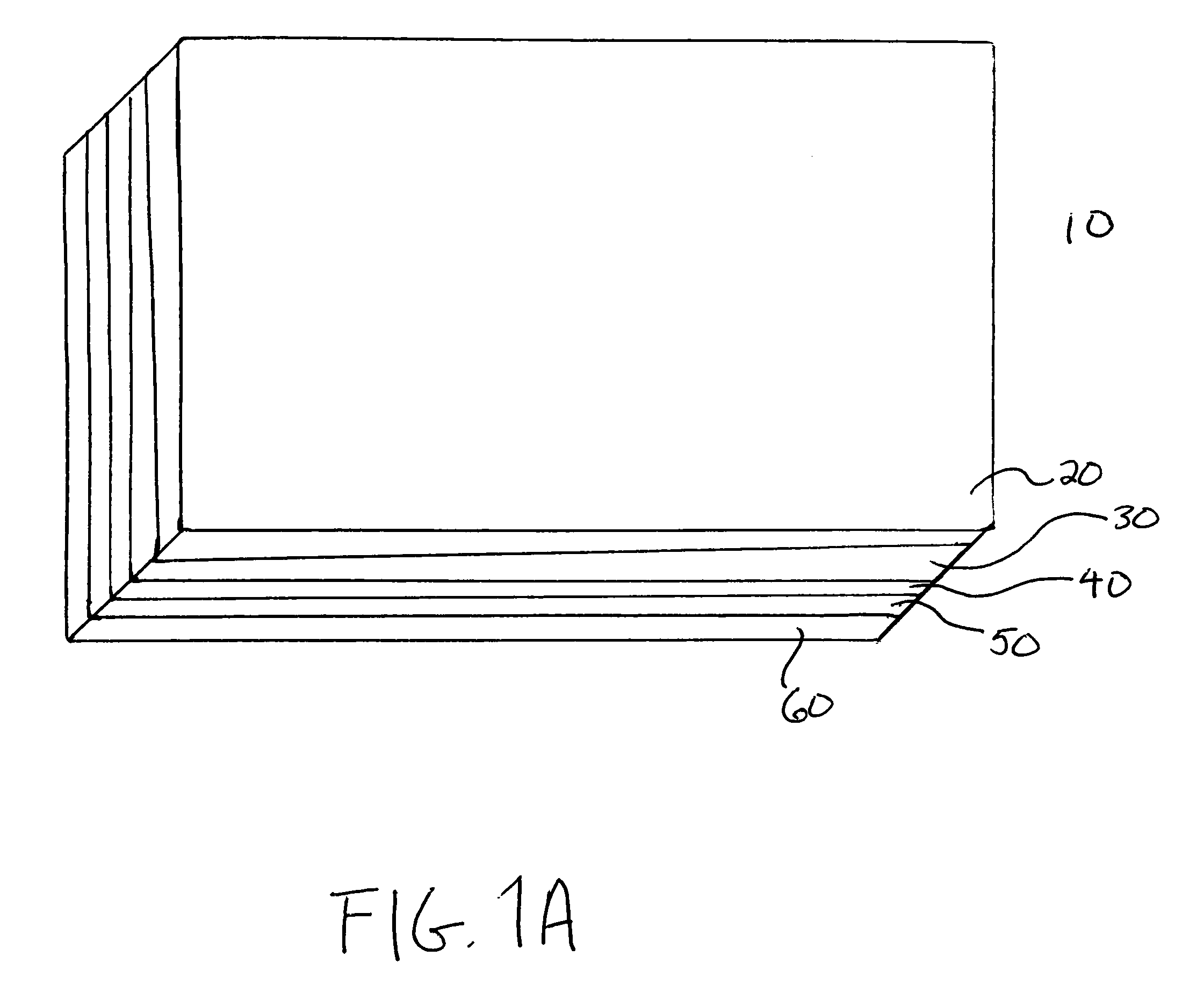

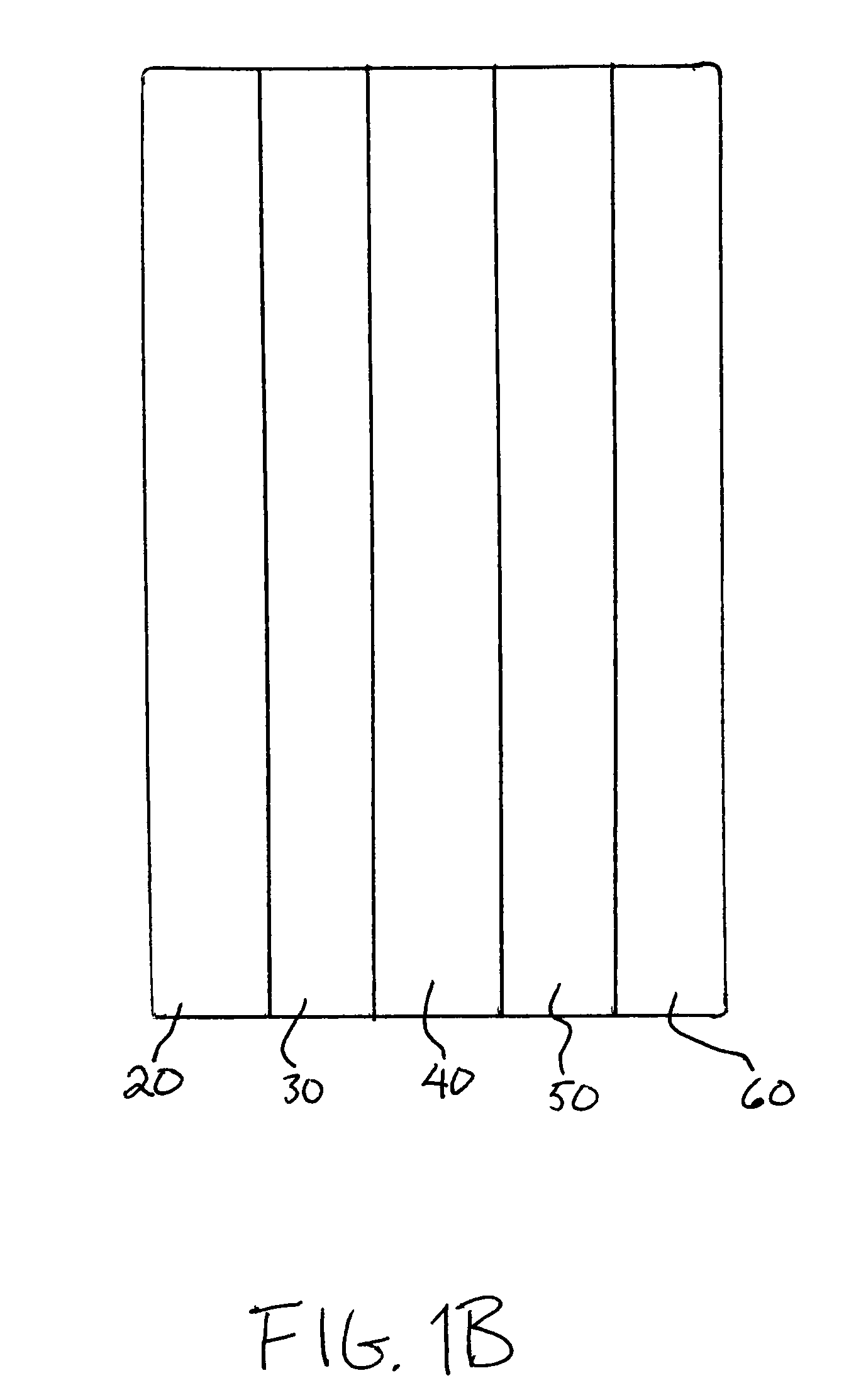

InactiveUS7388146B2Low costEasy customer acceptanceSolar heating energySolar heat devicesElectrical batterySolar power

A planar concentrator solar power module has a planar base, an aligned array of linear photovoltaic cell circuits on the base and an array of linear Fresnel lenses or linear mirrors for directing focused solar radiation on the aligned array of linear photovoltaic cell circuits. The cell circuits are mounted on a back panel which may be a metal back plate. The cell circuit area is less than a total area of the module. Each linear lens or linear mirror has a length greater than a length of the adjacent cell circuit. The cell circuit may have cells mounted in shingle fashion to form a shingled-cell circuit. In an alternative module, linear extrusions on the circuit element have faces for mounting the linear mirrors for deflecting sun rays impinging on each mirror onto the shingled-cells. The linear extrusions are side-wall and inner extrusions with triangular cross-sections. The circuit backplate is encapsulated by lamination for weather protection. The planar module is generally rectangular with alternating rows of linear cell circuits and linear lenses or linear mirrors.

Owner:JX CRYSTALS

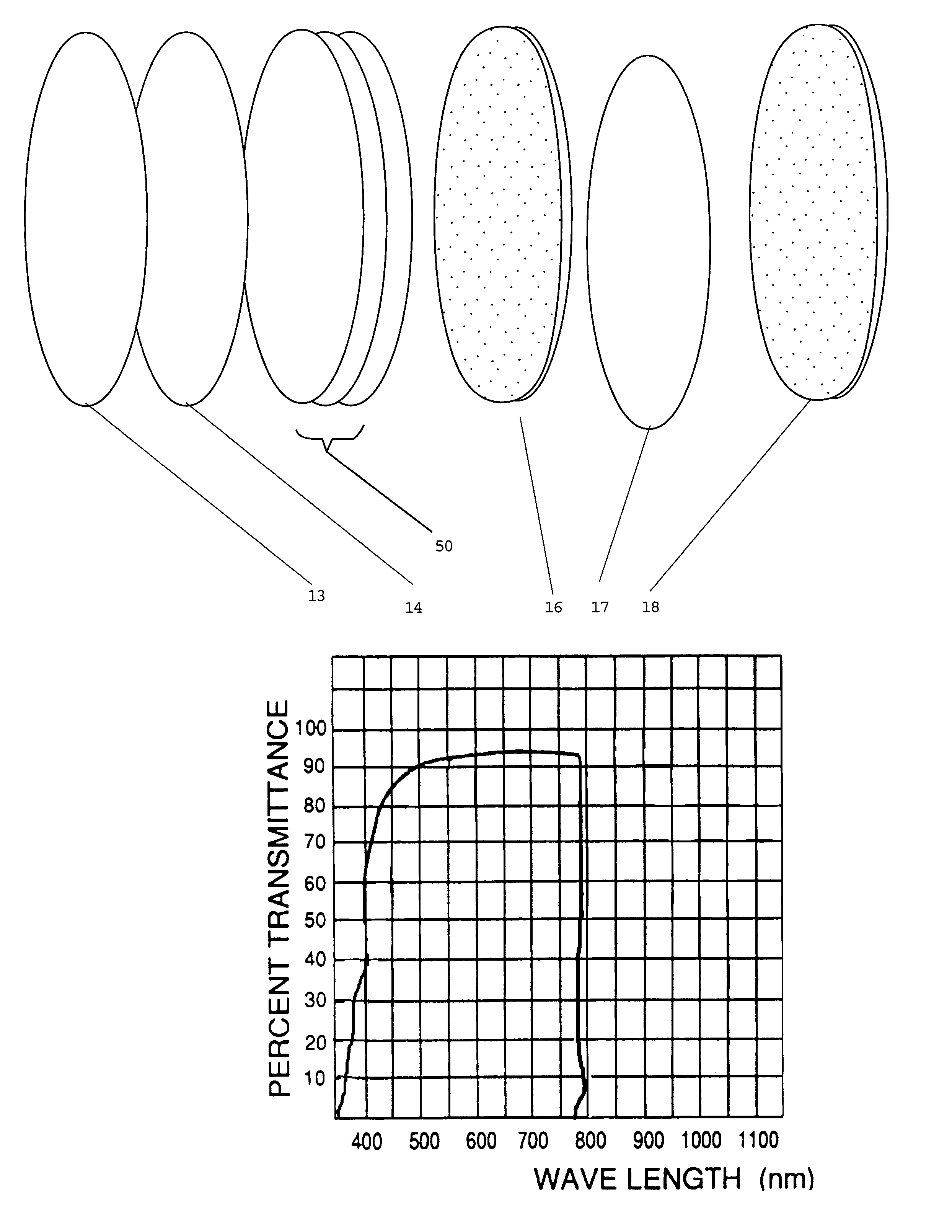

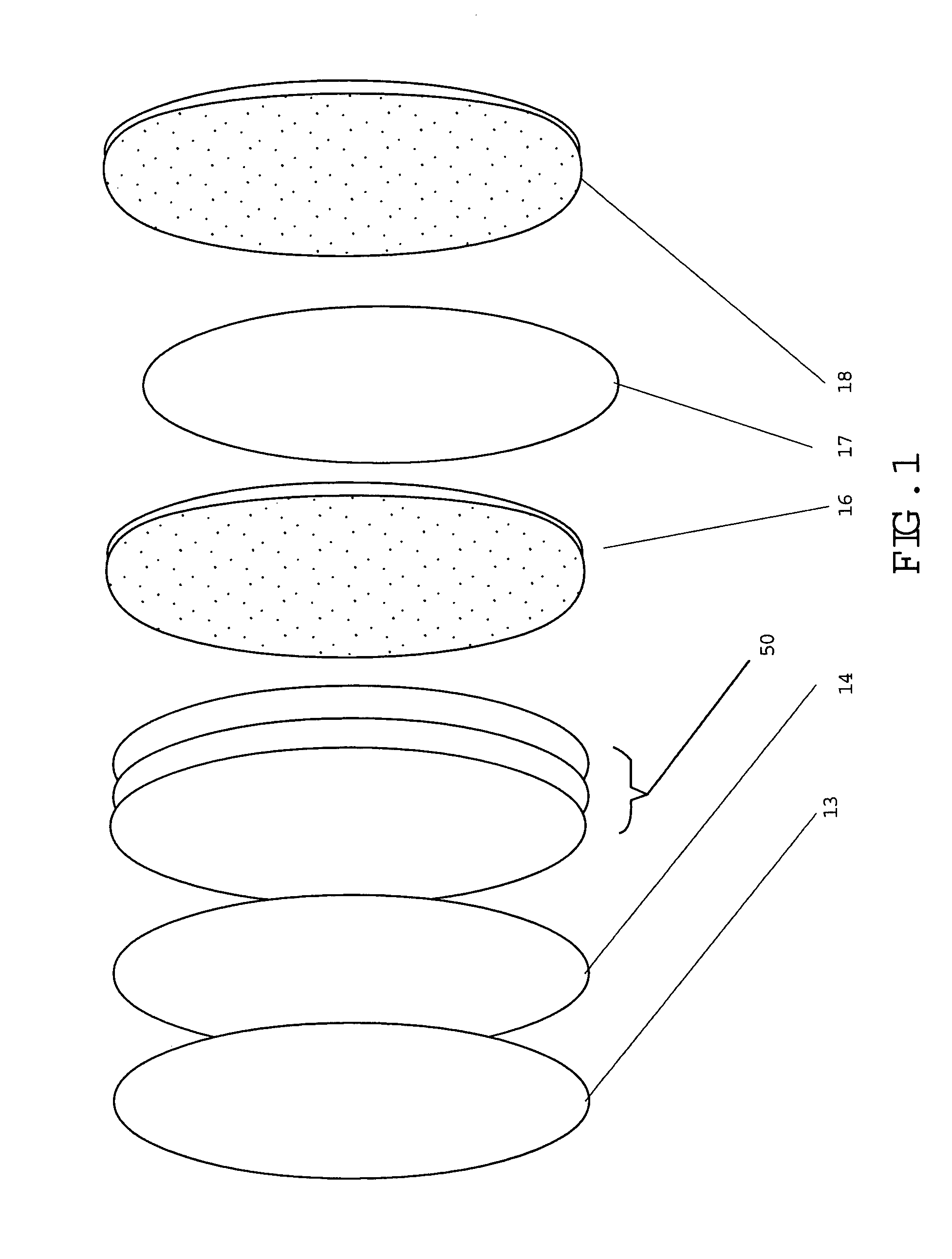

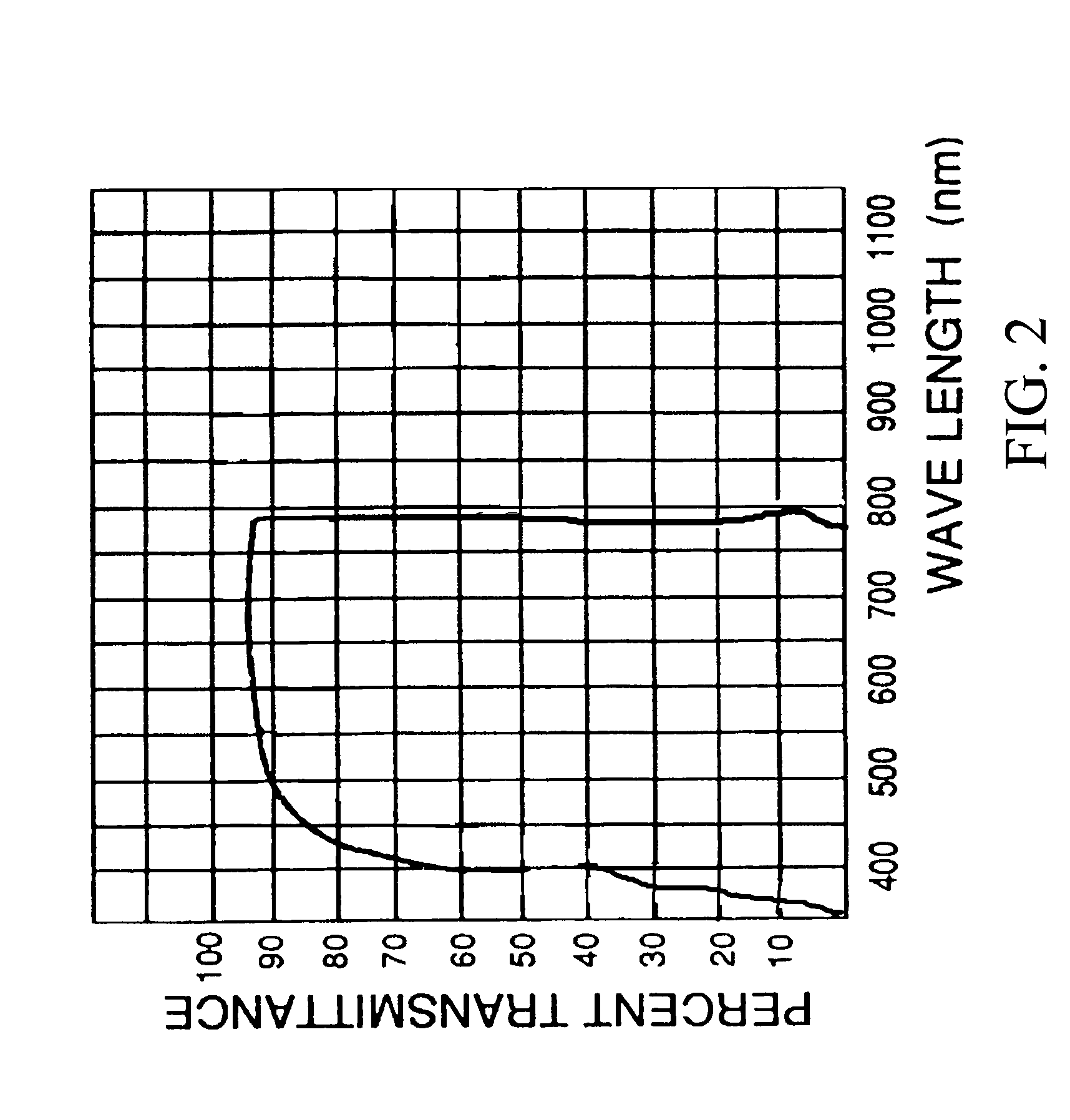

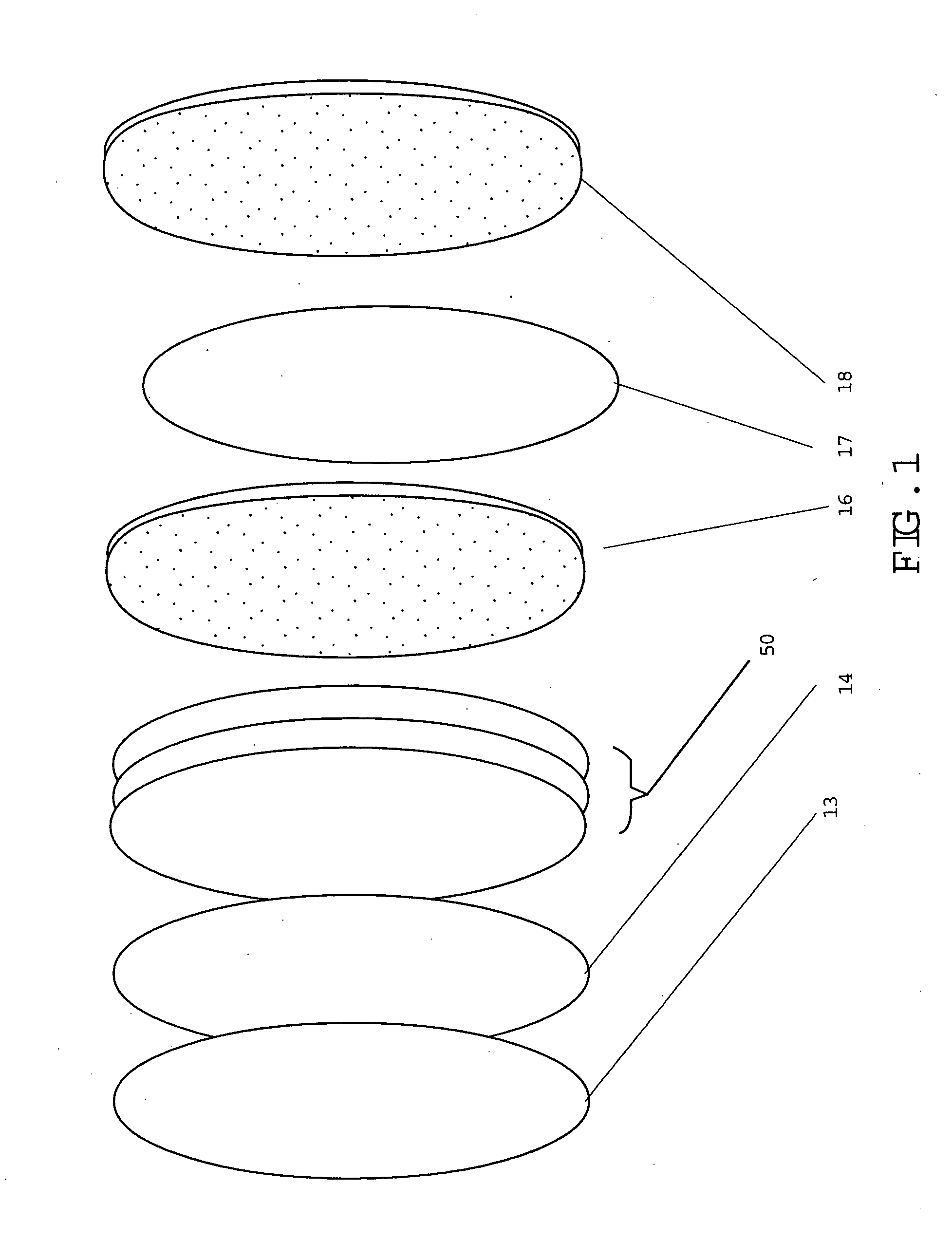

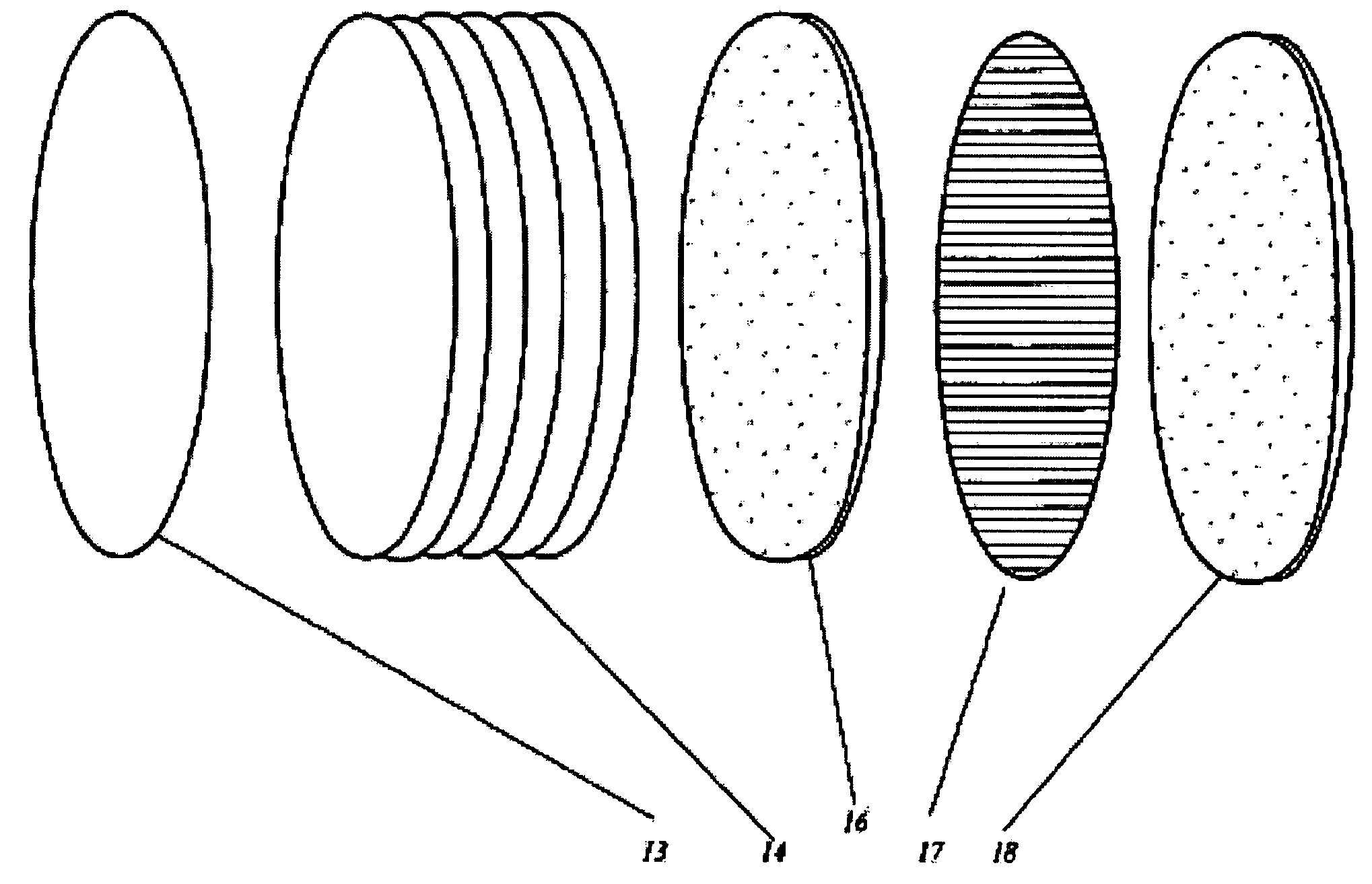

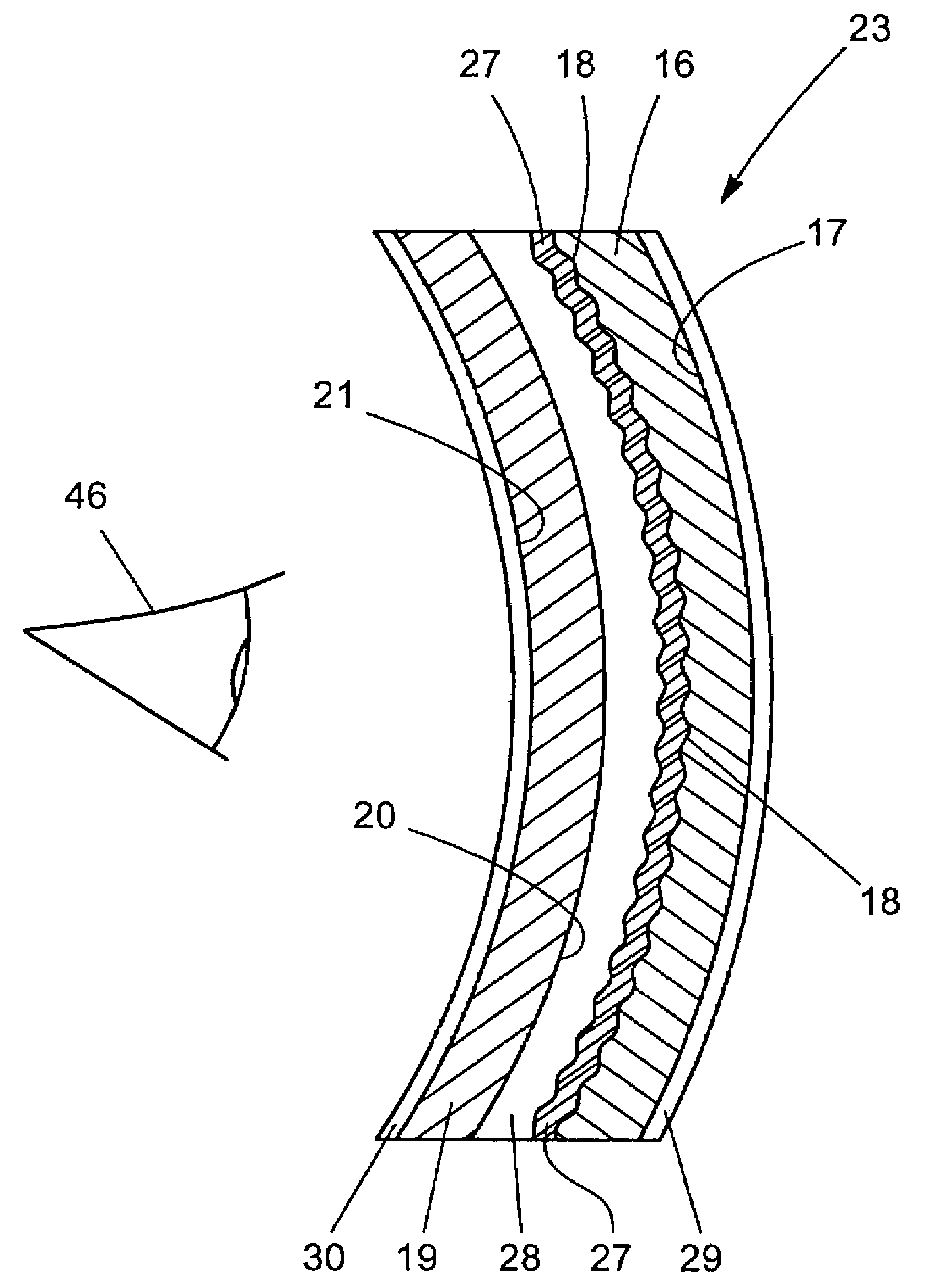

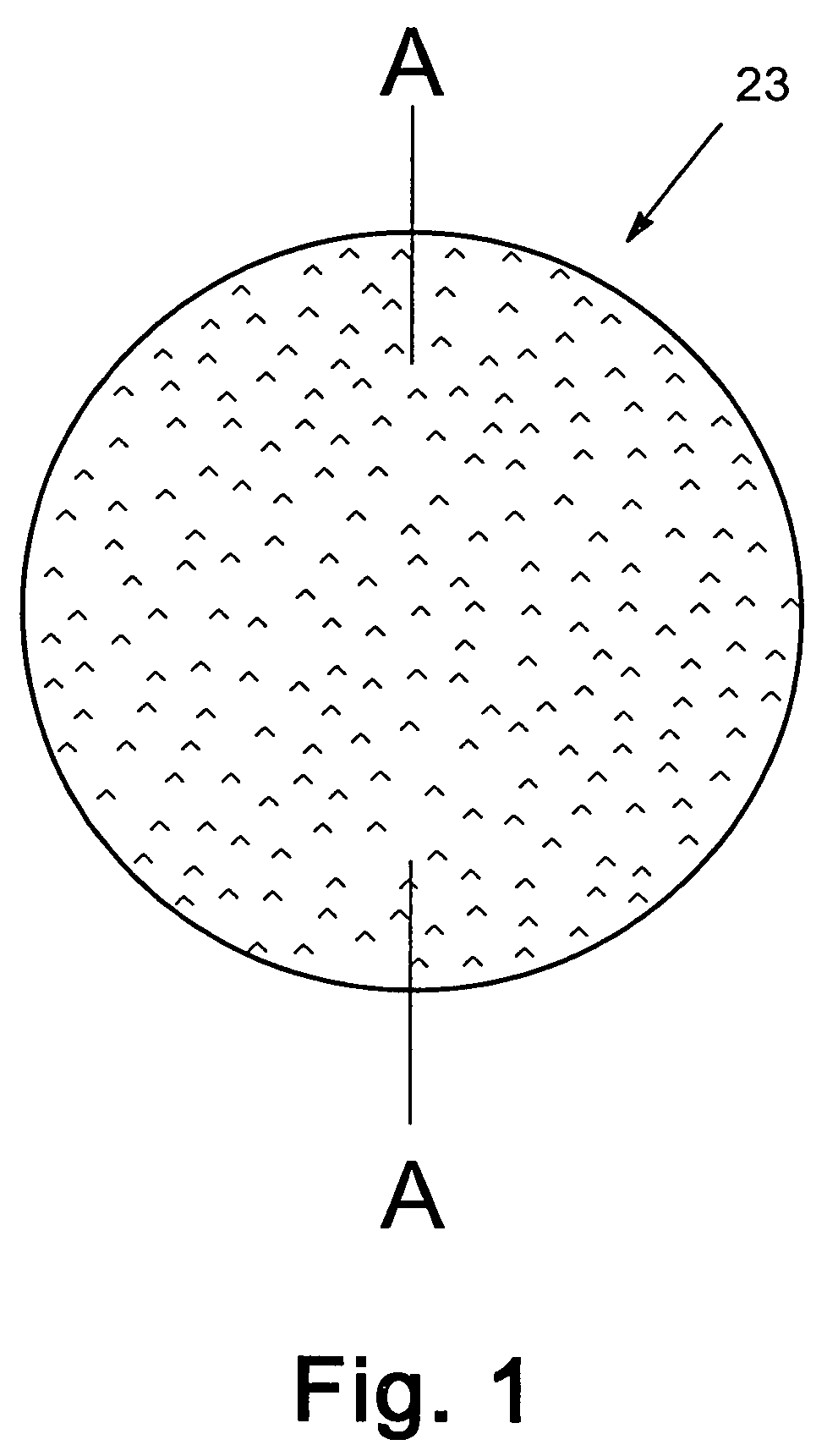

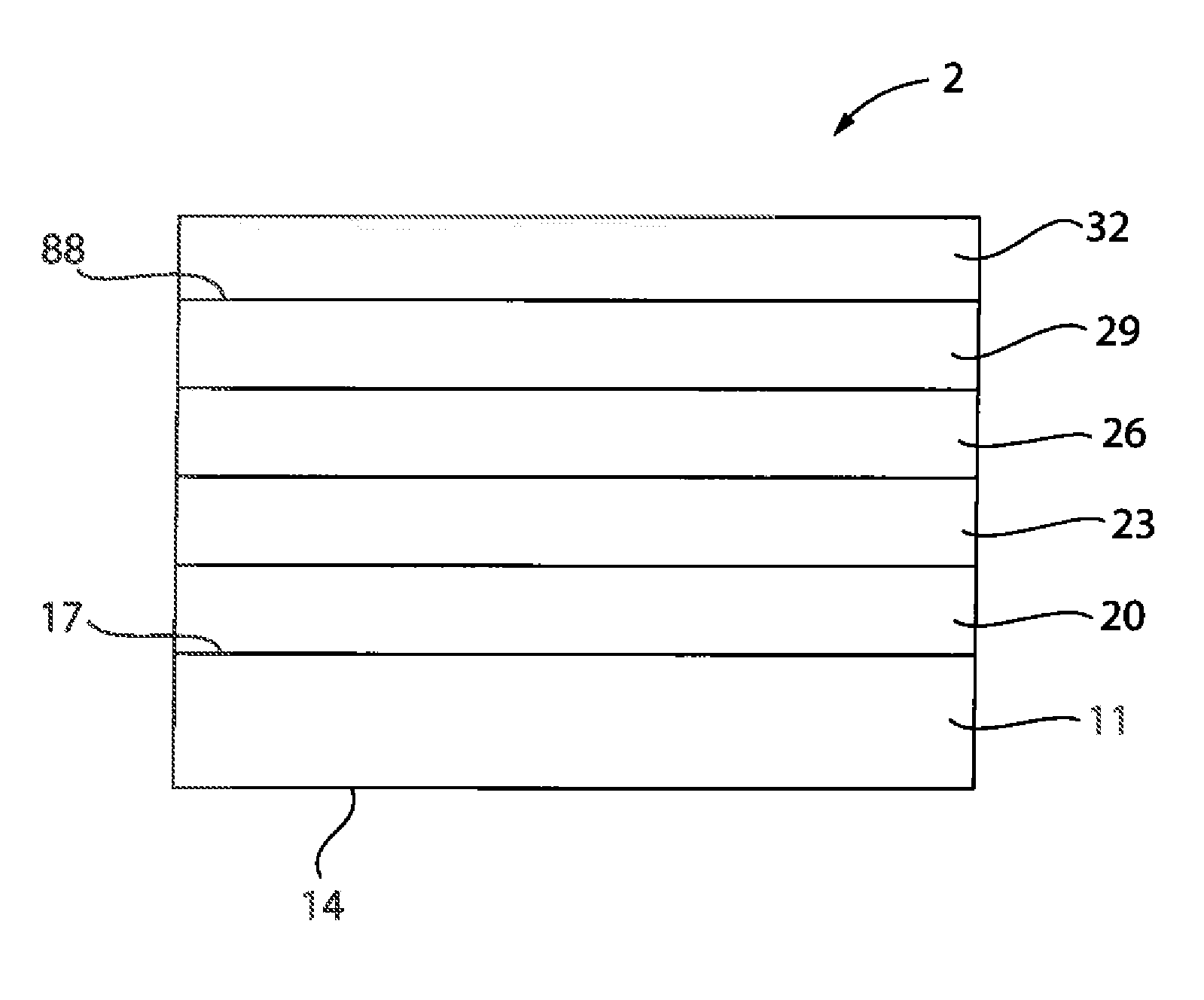

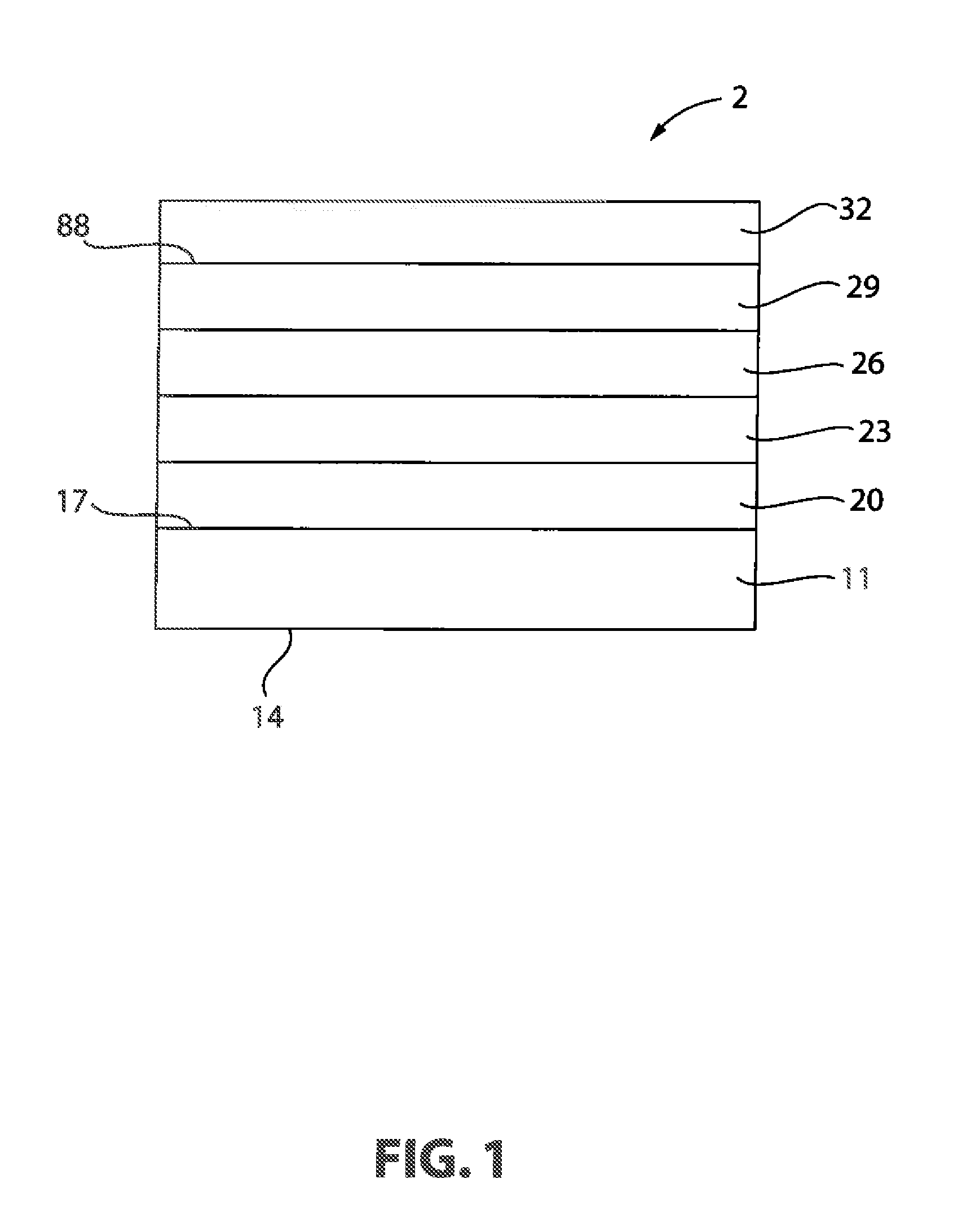

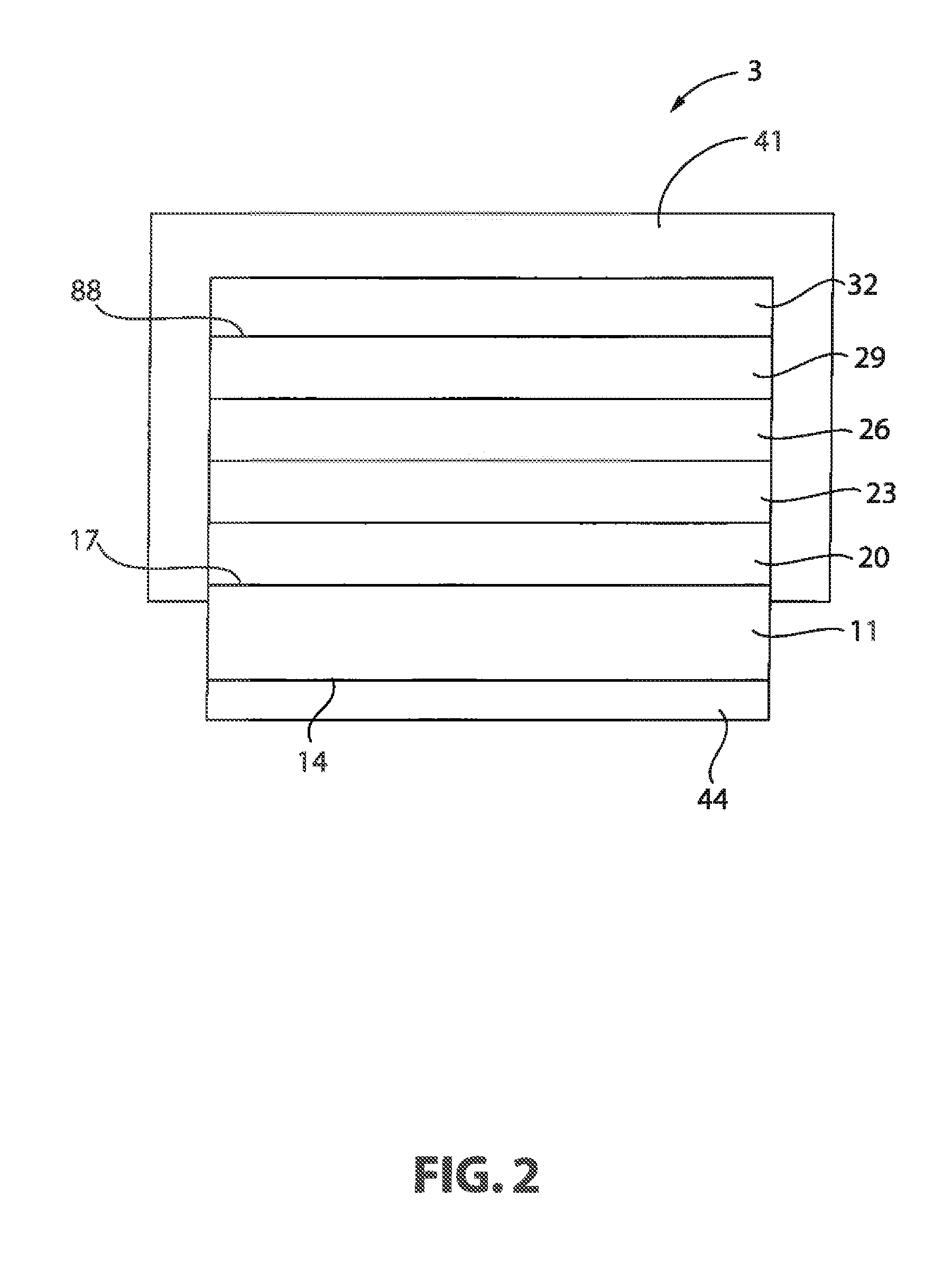

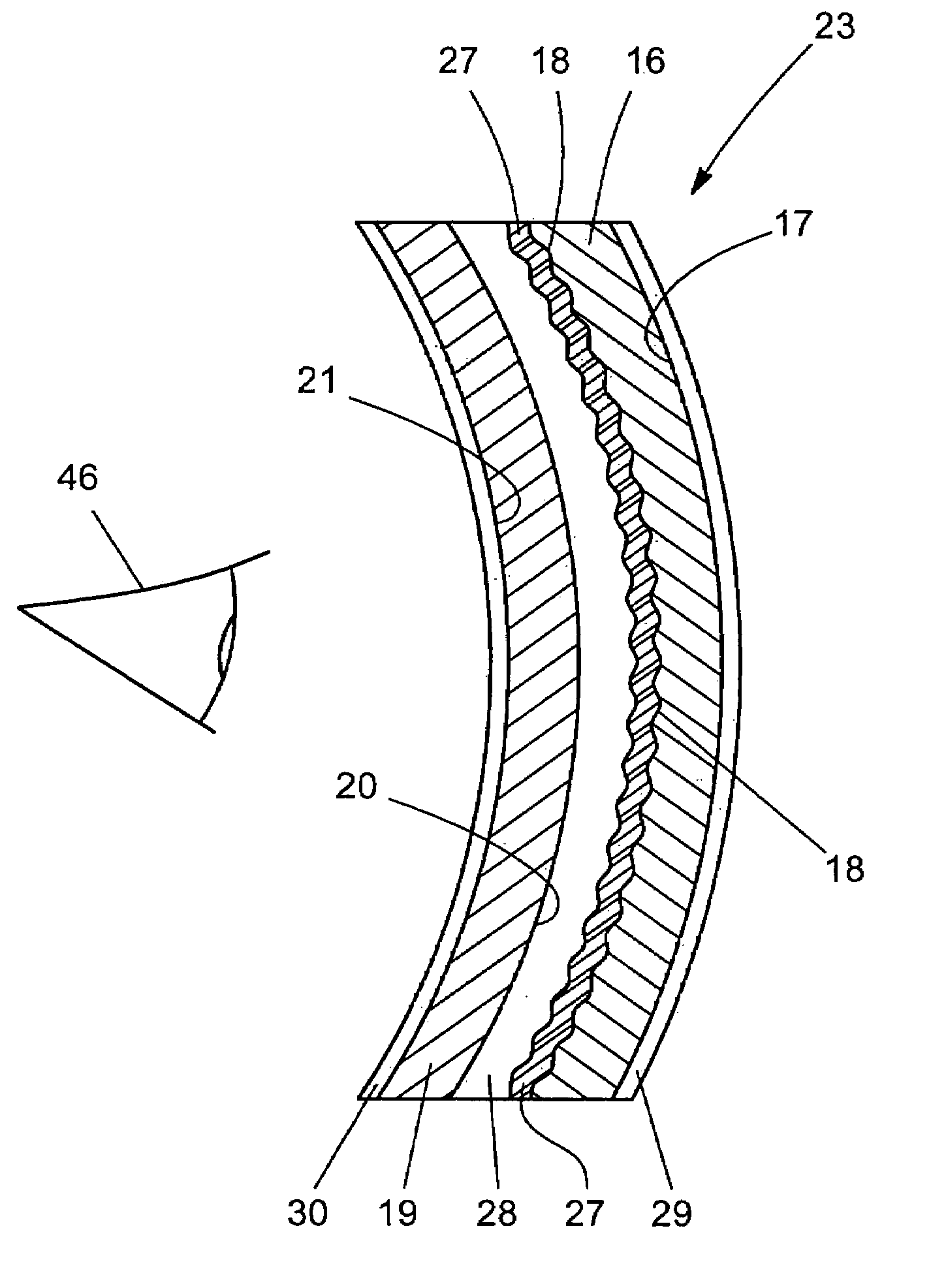

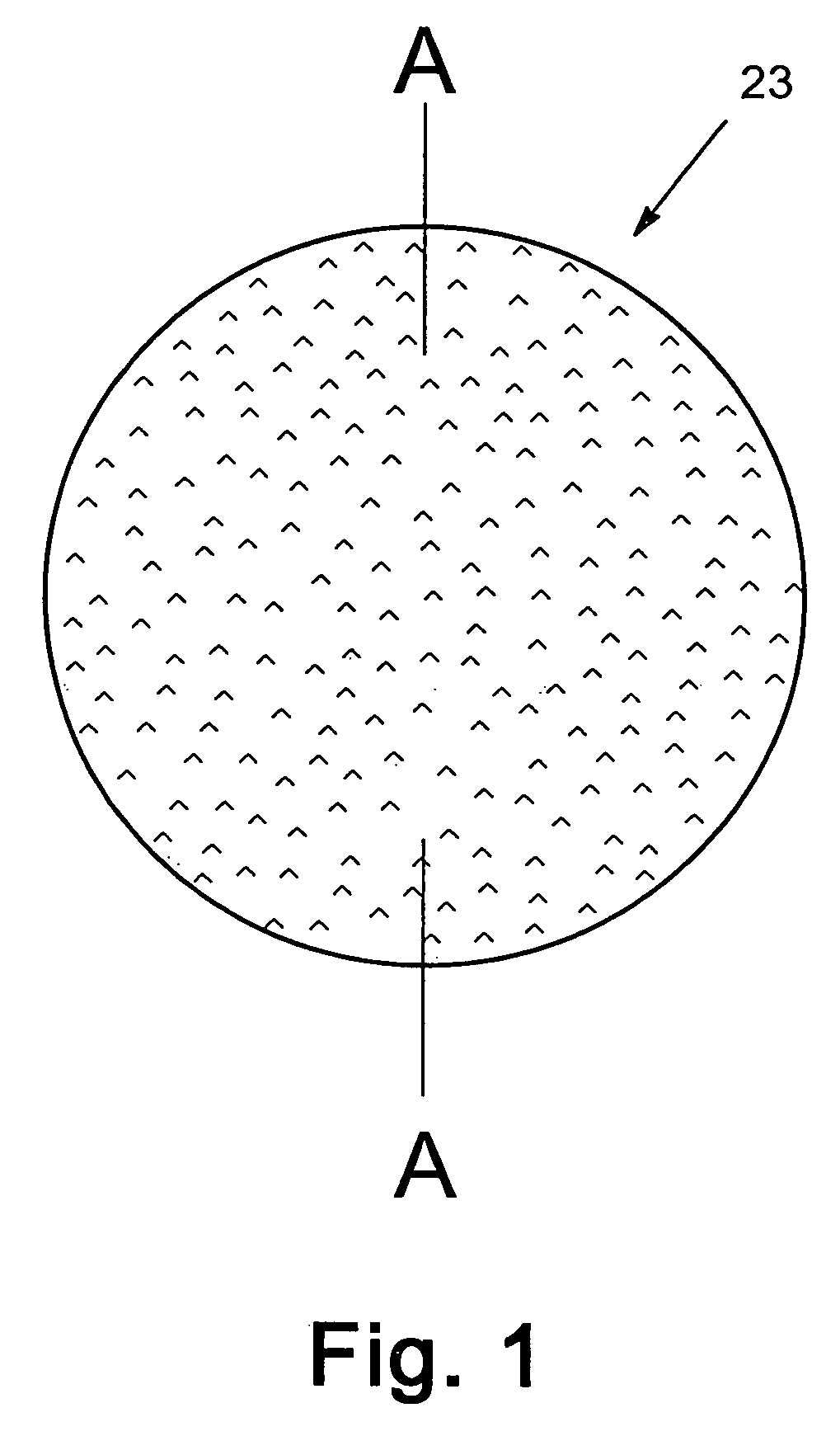

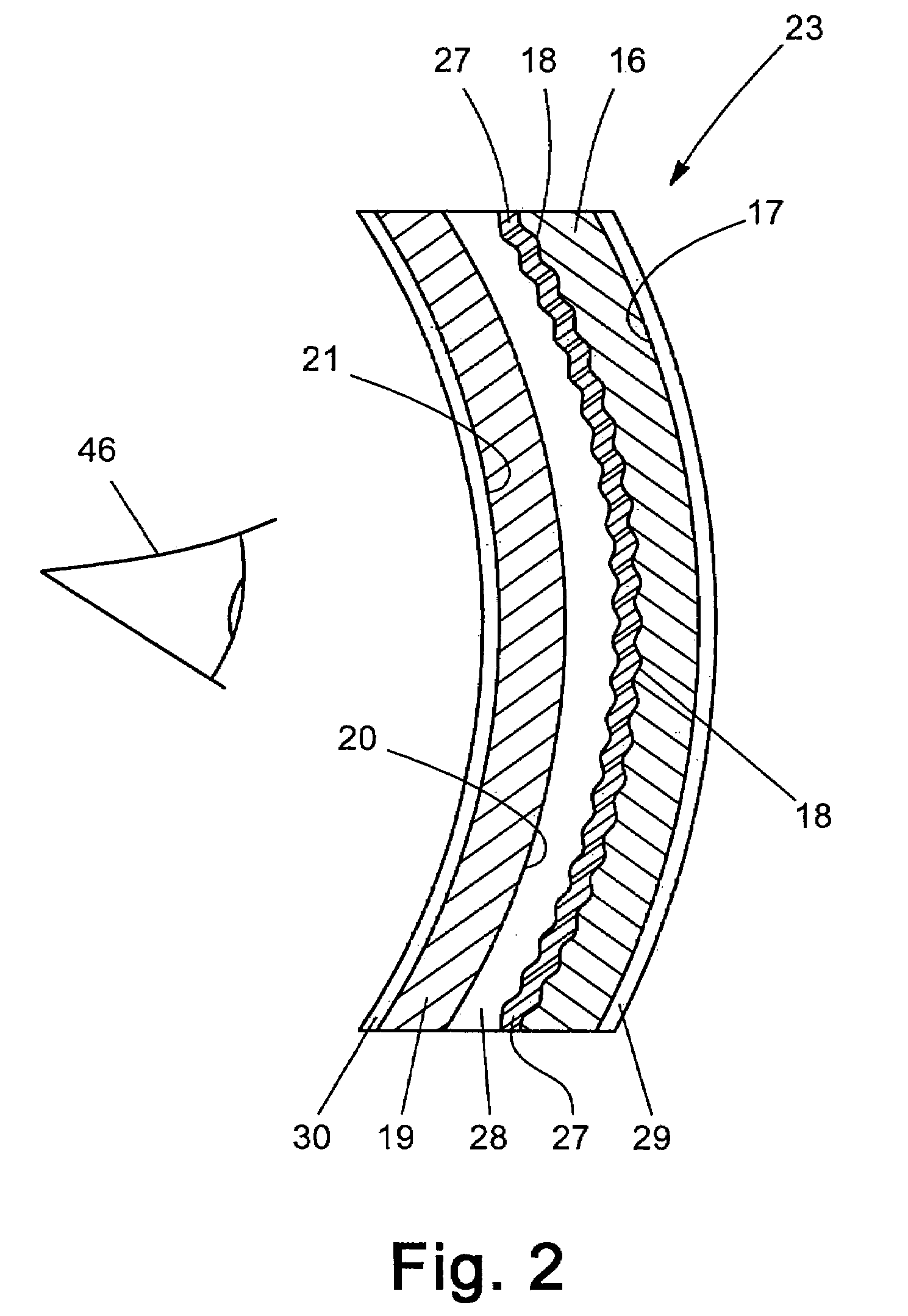

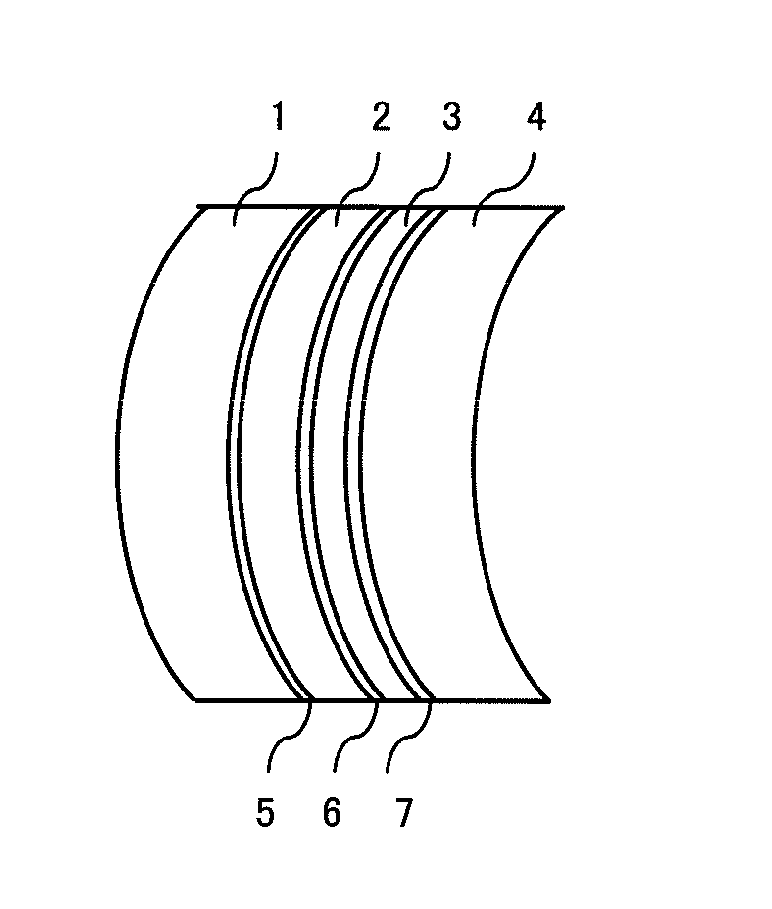

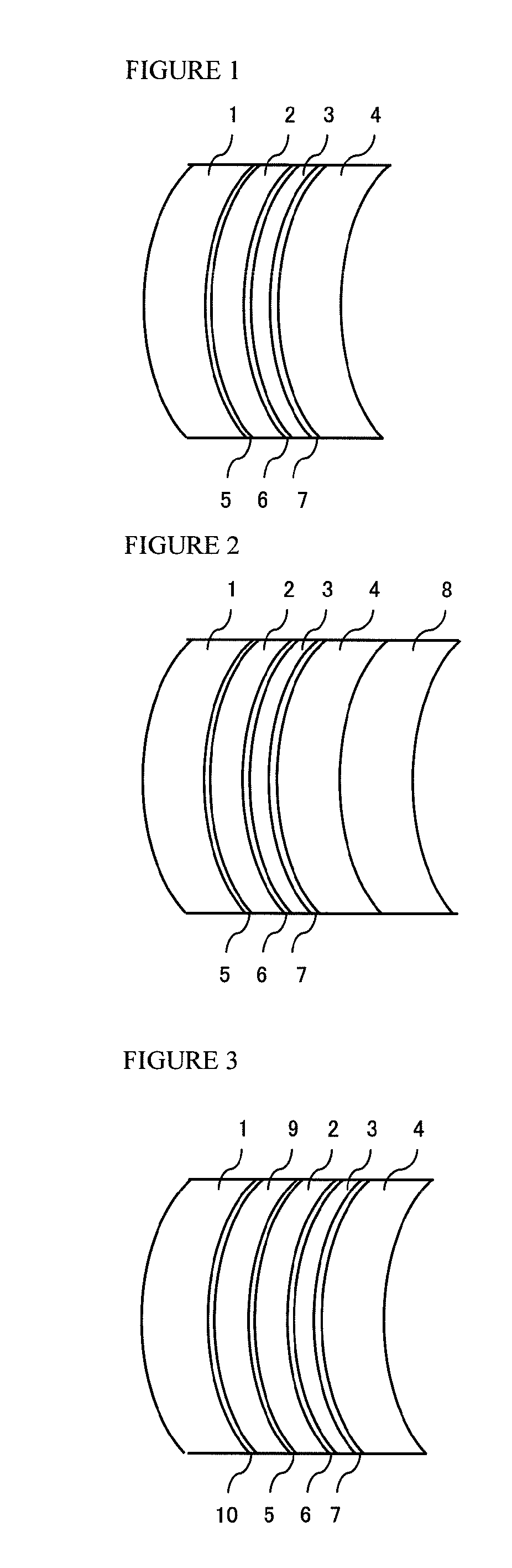

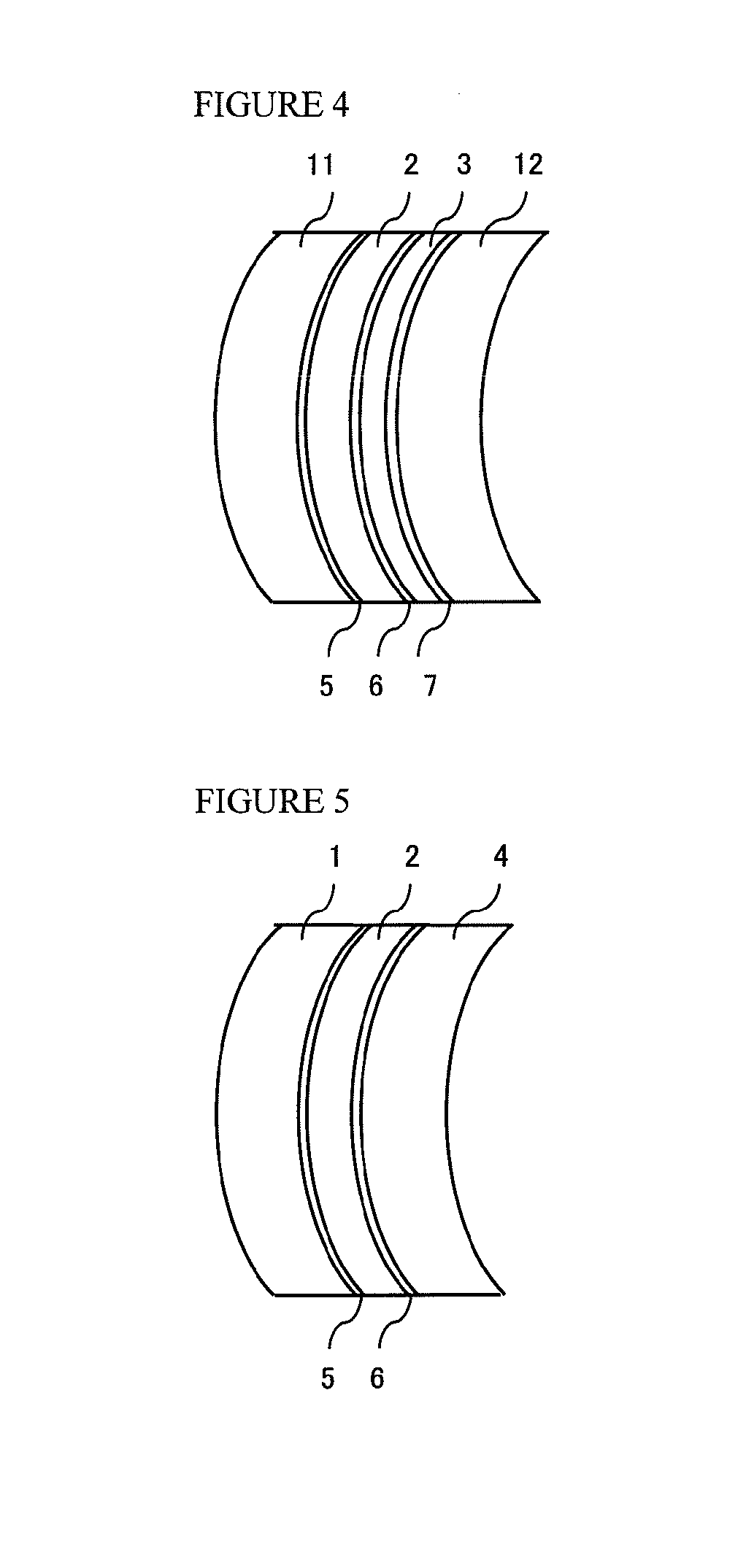

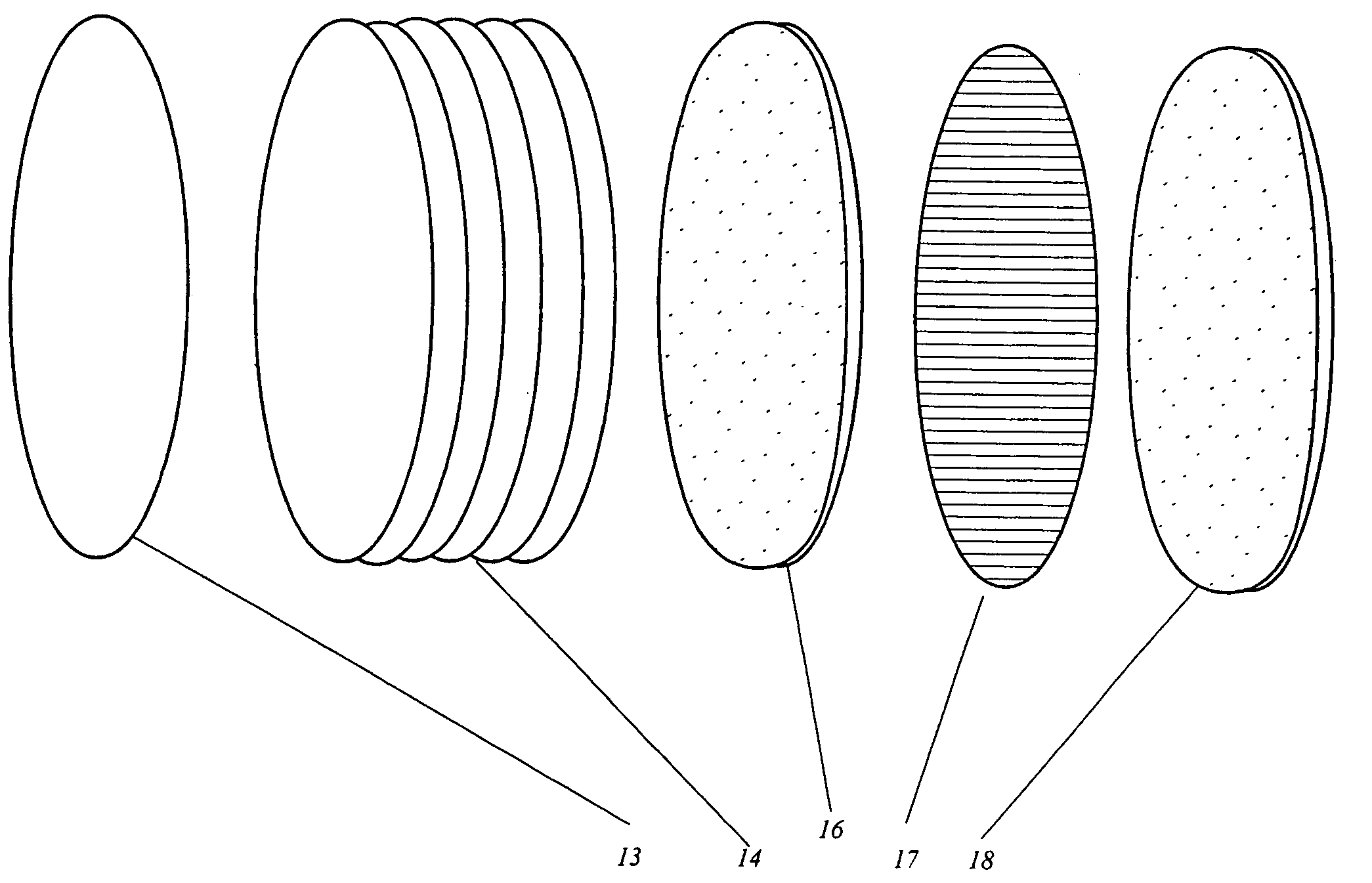

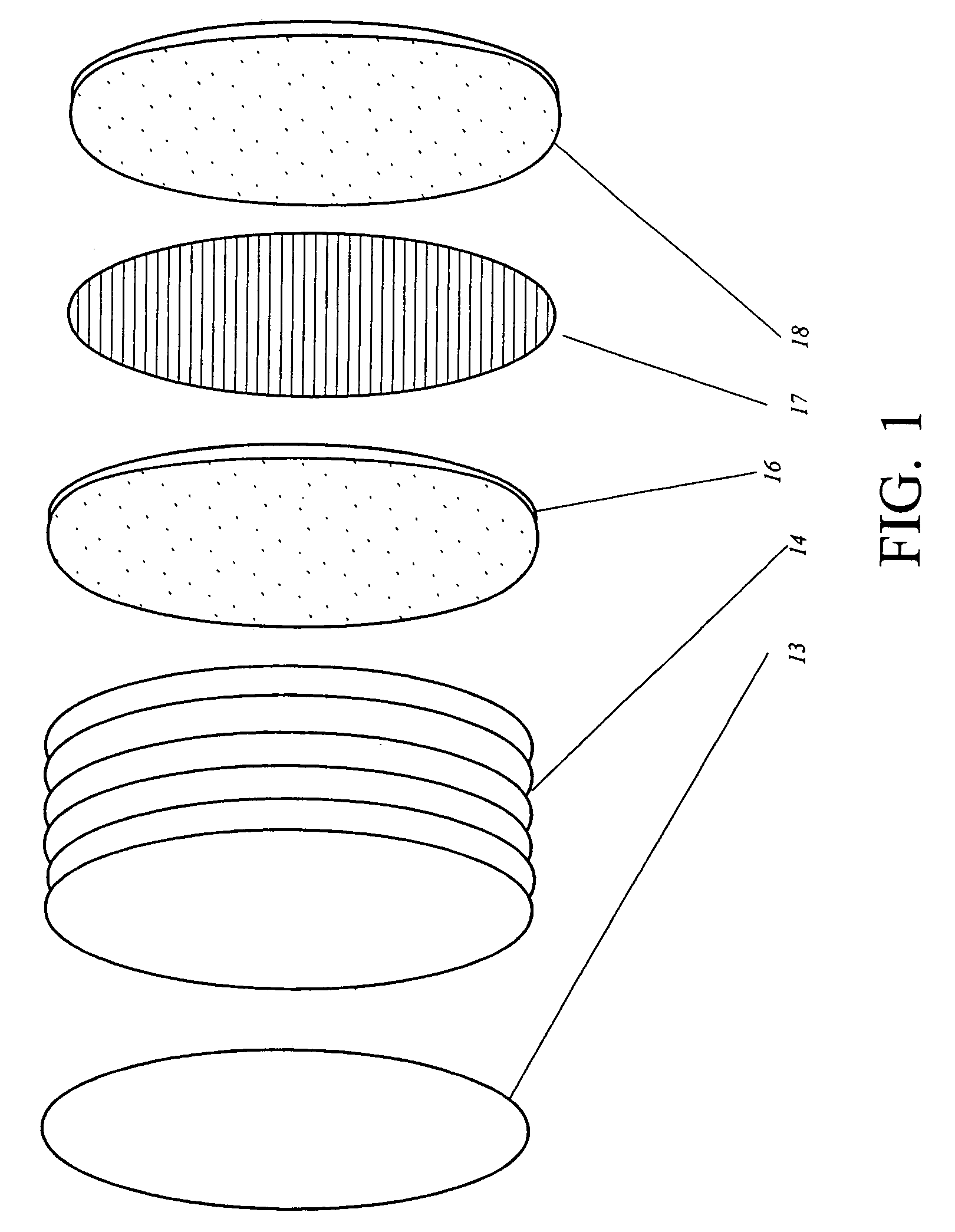

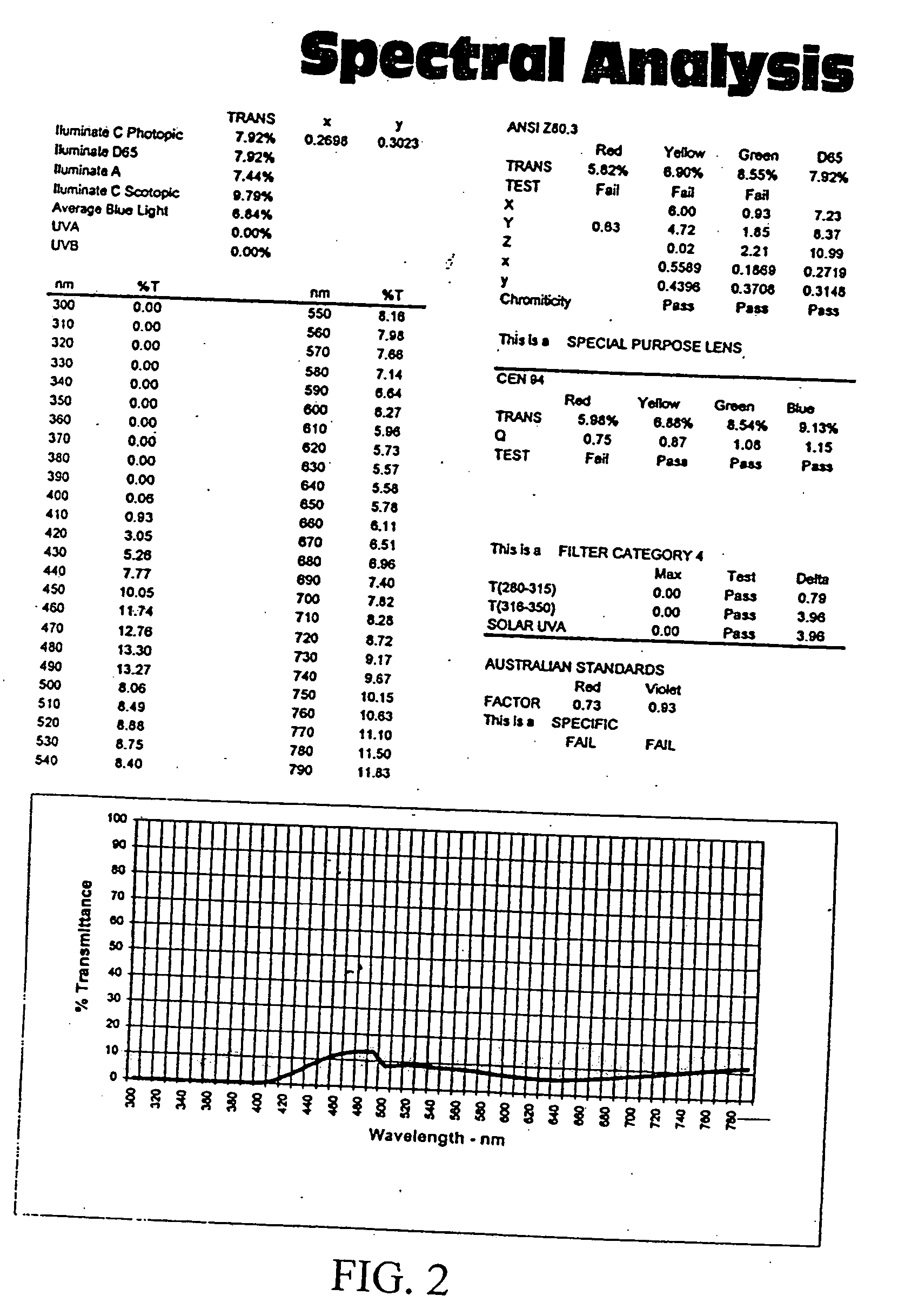

Rugate lens for glasses

InactiveUS7066596B2Maximizing degreeClear visionSpectales/gogglesOptical partsUses eyeglassesCLARITY

An improved multi-layer performance lens for protective eyewear such as sunglasses which includes a pass band Rugate filter. The lens design is a sandwich configuration including a polarizing layer between two ophthalmic lens layers in a sandwich configuration, and a Rugate filter applied to one side thereof to yield an exceptional light transmission profile under all light conditions, thereby maximizing protection as well as clarity of vision. In addition, an optional dielectric layer and / or hydrophobic overcoat may be applied. The foregoing layers are arranged to provide a balanced light transmission profile optimum for preventing macular degeneration, cataracts and other ocular injuries.

Owner:HIGH PERFORMANCE OPTICS

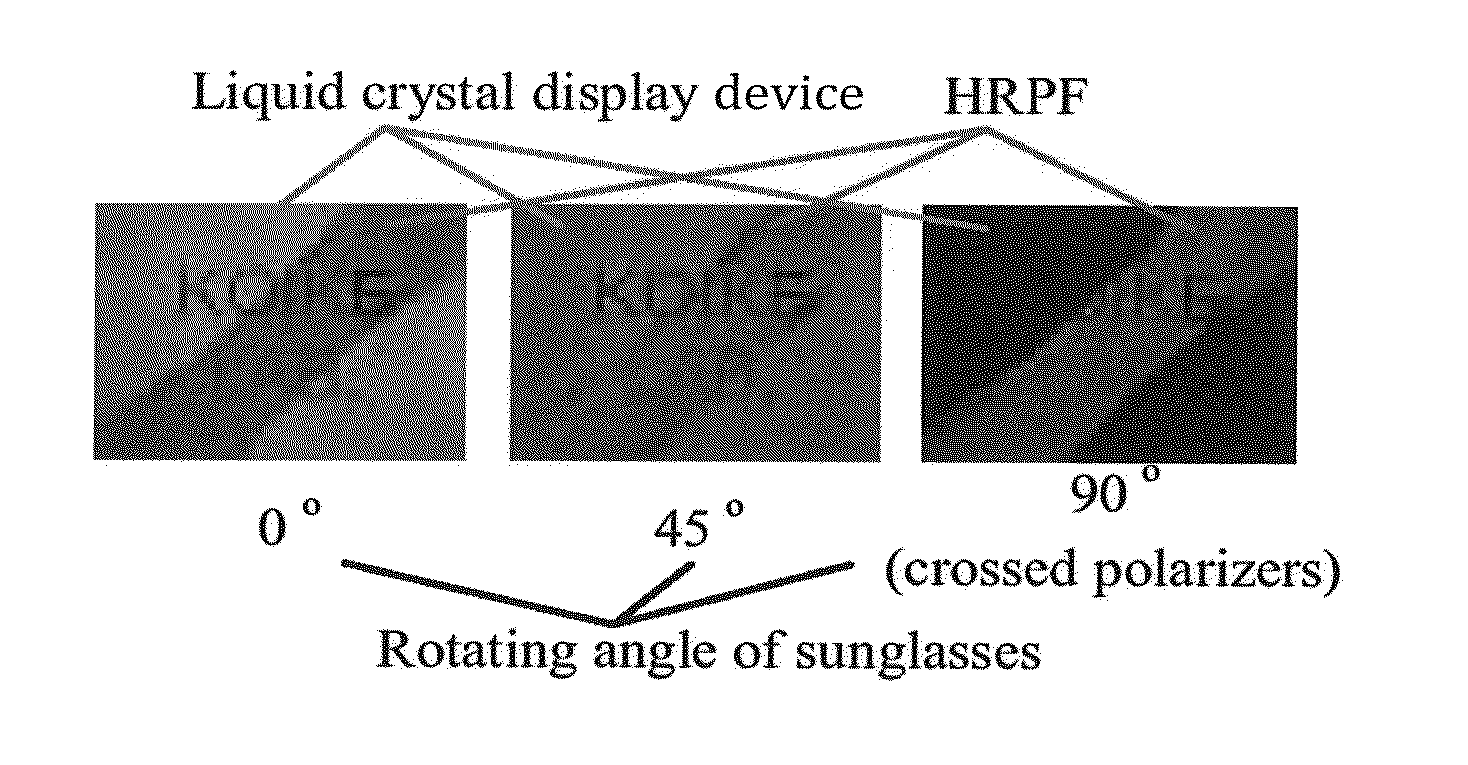

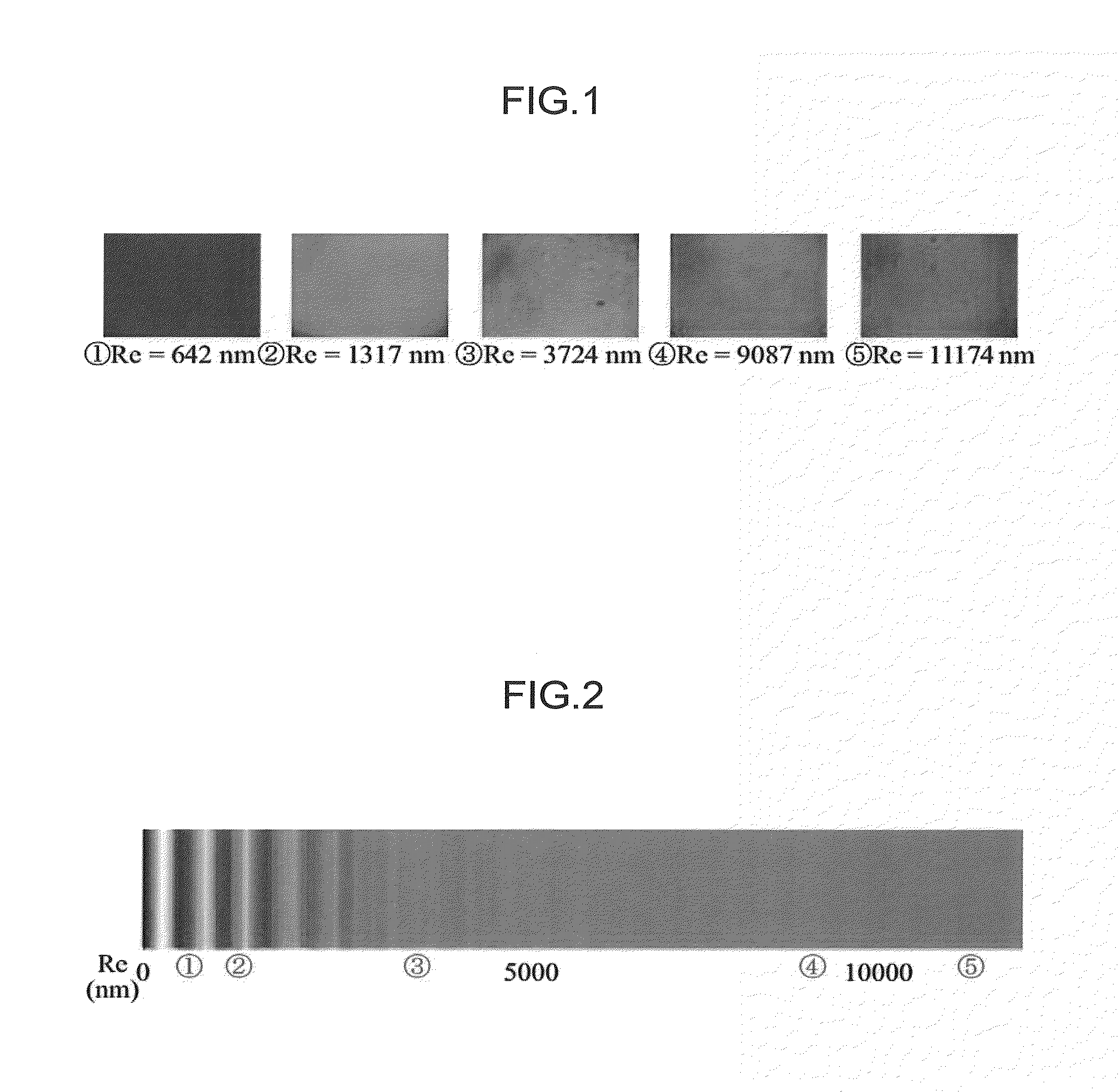

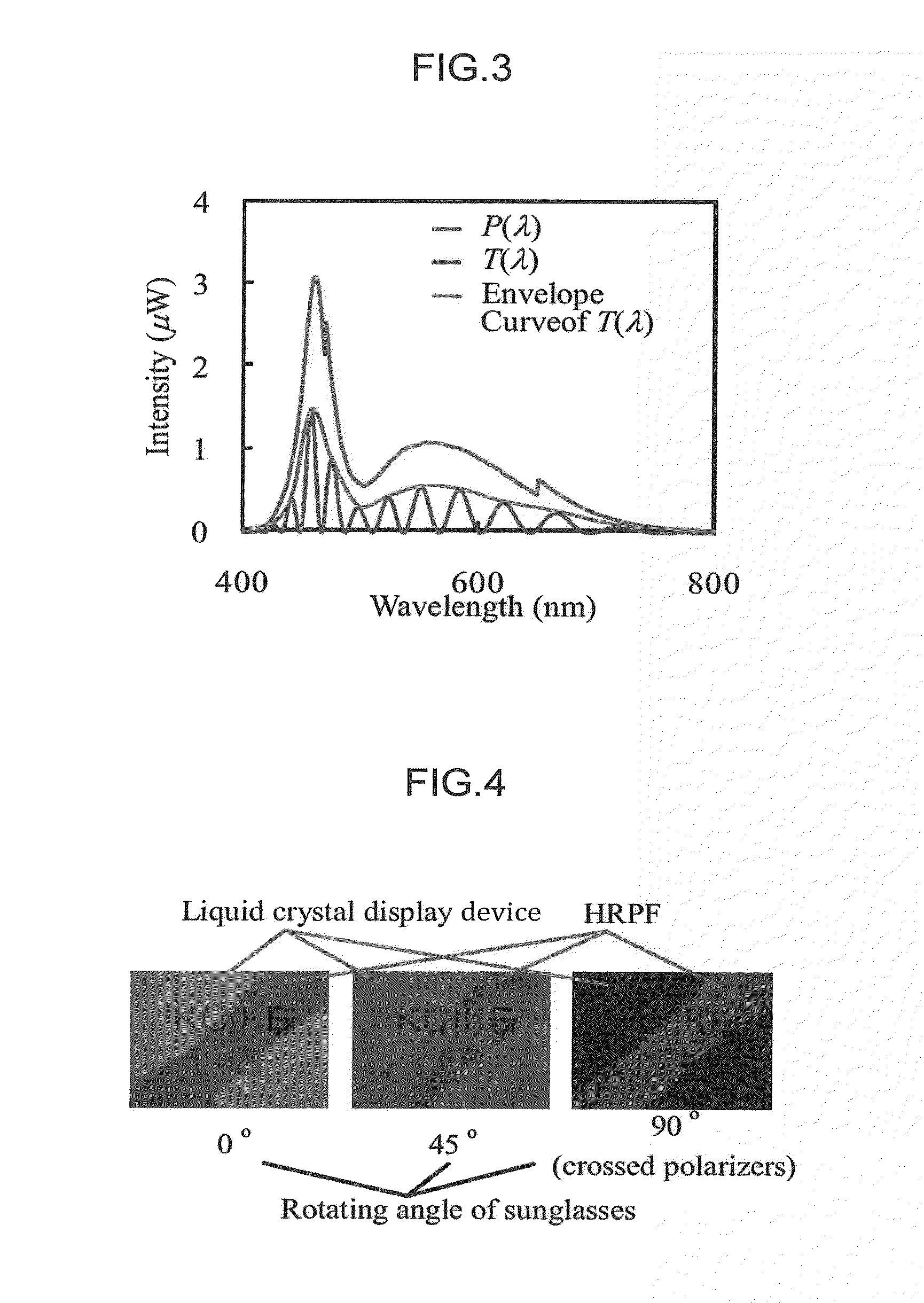

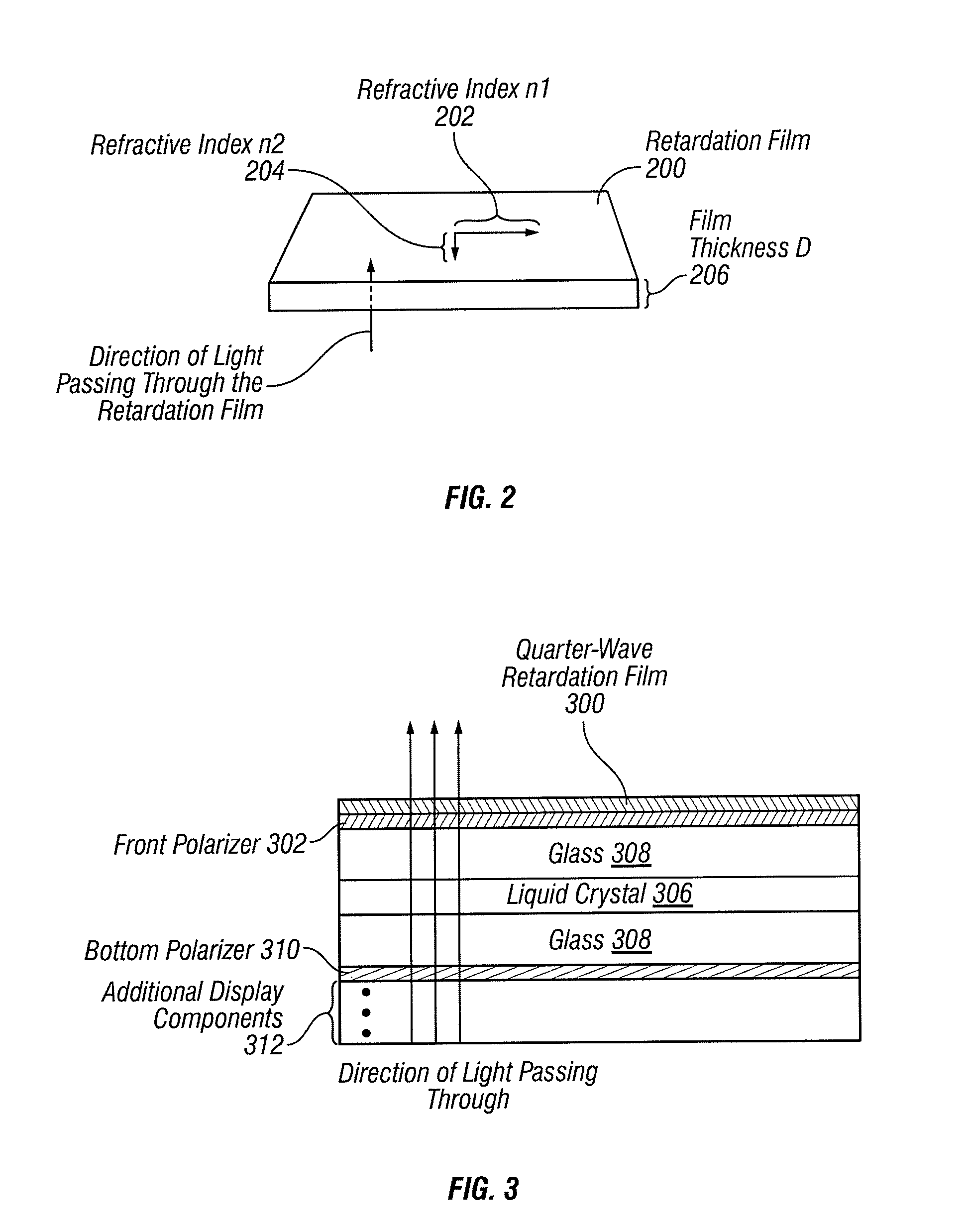

Method for improving visibility of liquid crystal display device, and liquid crystal display device using same

The present invention provides a liquid crystal display method capable of when a screen thereof is observed through a polarizer such as sunglasses, ensuring an excellent visibility regardless of the angle of observation. In a liquid crystal display device at least having a backlight light source, a liquid crystal cell, and a polarizer disposed on a viewing side of the liquid crystal cell, a white light-emitting diode is used as the backlight light source; and a polymer film having a retardation of from 3,000 nm to 30,000 nm is used so as to be disposed on the viewing side of the polarizer so that an angle between an absorption axis of the polarizer and a slow axis of the polymer film becomes about 45 degrees.

Owner:TOYOBO CO LTD +1

Planar solar concentrator power module

InactiveUS7872192B1Low costEasy customer acceptanceSolar heating energySolar heat devicesFresnel lensSolar power

A planar concentrator solar power module has a planar base, an aligned array of linear photovoltaic cell circuits on the base and an array of linear Fresnel lenses or linear mirrors for directing focused solar radiation on the aligned array of linear photovoltaic cell circuits. The cell circuits are mounted on a back panel which may be a metal back plate. The cell circuit area is less than a total area of the module. Each linear lens or linear mirror has a length greater than a length of the adjacent cell circuit. The cell circuit may have cells mounted in shingle fashion to form a shingled-cell circuit. In an alternative module, linear extrusions on the circuit element have faces for mounting the linear mirrors for deflecting sun rays impinging on each mirror onto the shingled-cells. The linear extrusions are side-wall and inner extrusions with triangular cross-sections. The circuit backplate is encapsulated by lamination for weather protection. The planar module is generally rectangular with alternating rows of linear cell circuits and linear lenses or linear mirrors.

Owner:JX CRYSTALS

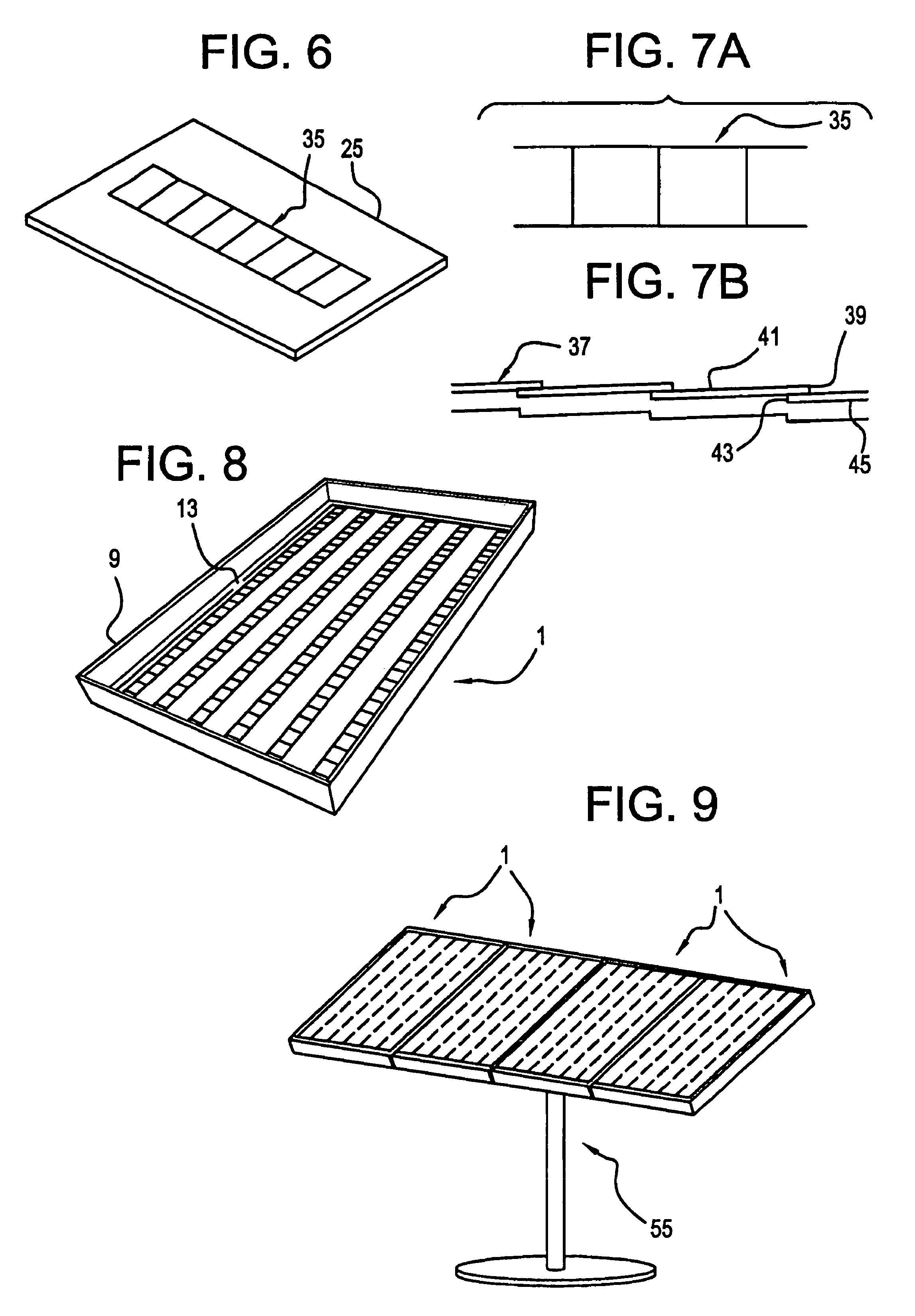

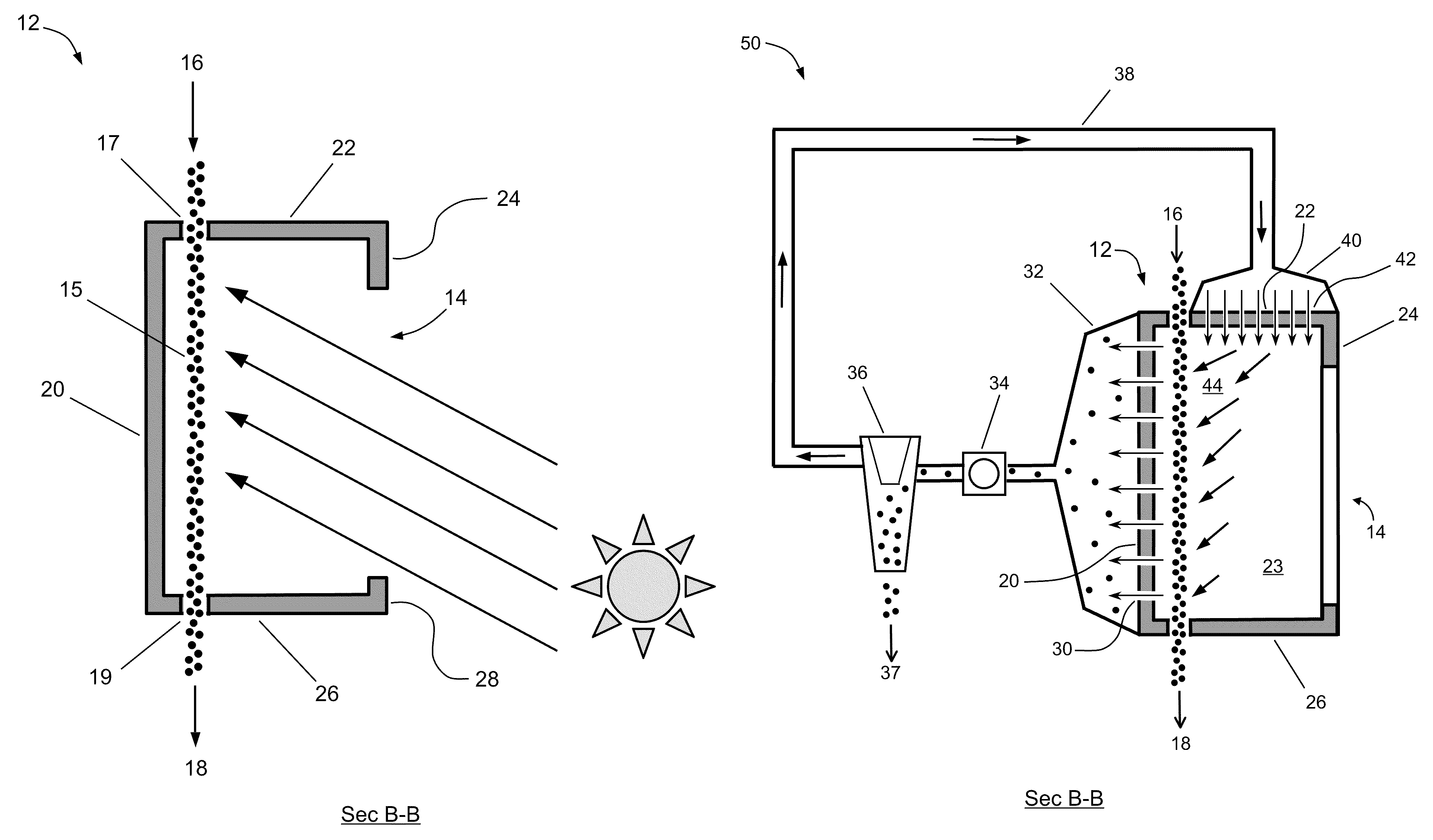

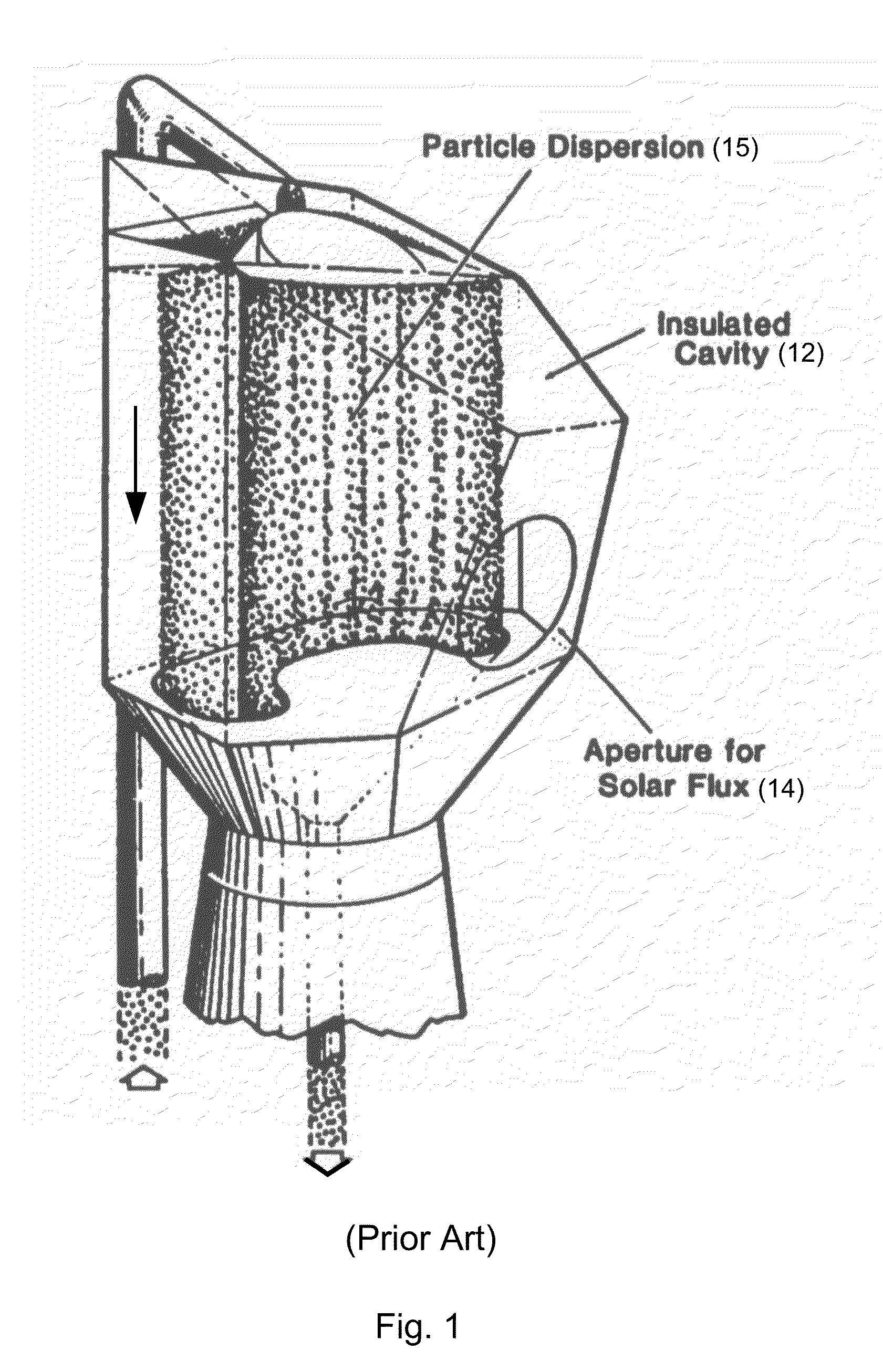

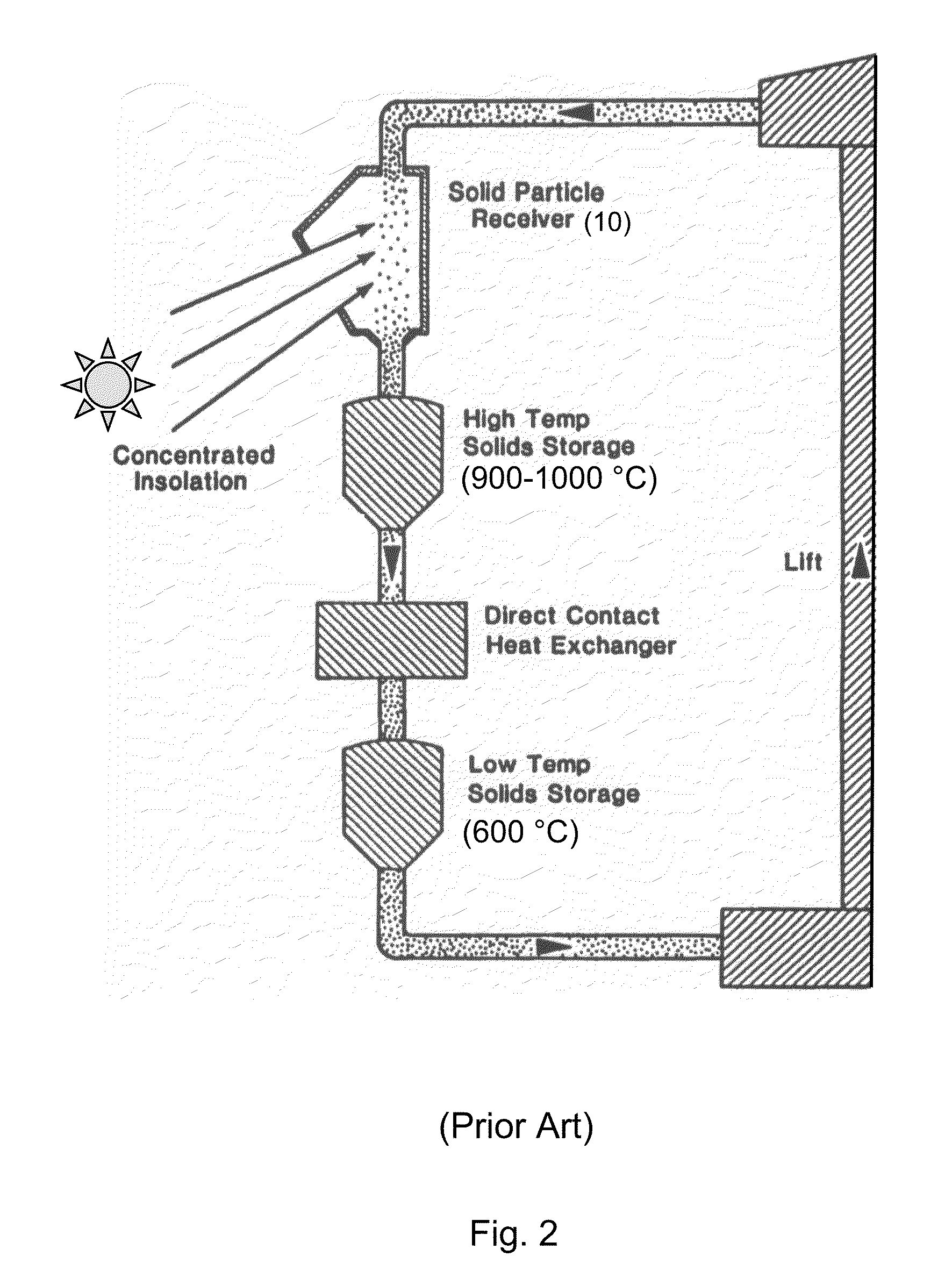

Suction-recirculation device for stabilizing particle flows within a solar powered solid particle receiver

ActiveUS8109265B1Reduce heat lossImprove efficiencySolar heating energySolar heat devicesCycloneSolar power tower

A suction-recirculation device for stabilizing the flow of a curtain of blackened heat absorption particles falling inside of a solar receiver with an open aperture. The curtain of particles absorbs the concentrated heat from a solar mirror array reflected up to the receiver on a solar power tower. External winds entering the receiver at an oblique angle can destabilize the particle curtain and eject particles. A fan and ductwork is located behind the back wall of the receiver and sucks air out through an array of small holes in the back wall. Any entrained particles are separated out by a conventional cyclone device. Then, the air is recirculated back to the top of the receiver by injecting the recycled air through an array of small holes in the receiver's ceiling and upper aperture front wall. Since internal air is recirculated, heat losses are minimized and high receiver efficiency is maintained. Suction-recirculation velocities in the range of 1-5 m / s are sufficient to stabilize the particle curtain against external wind speeds in excess of 10 m / s.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

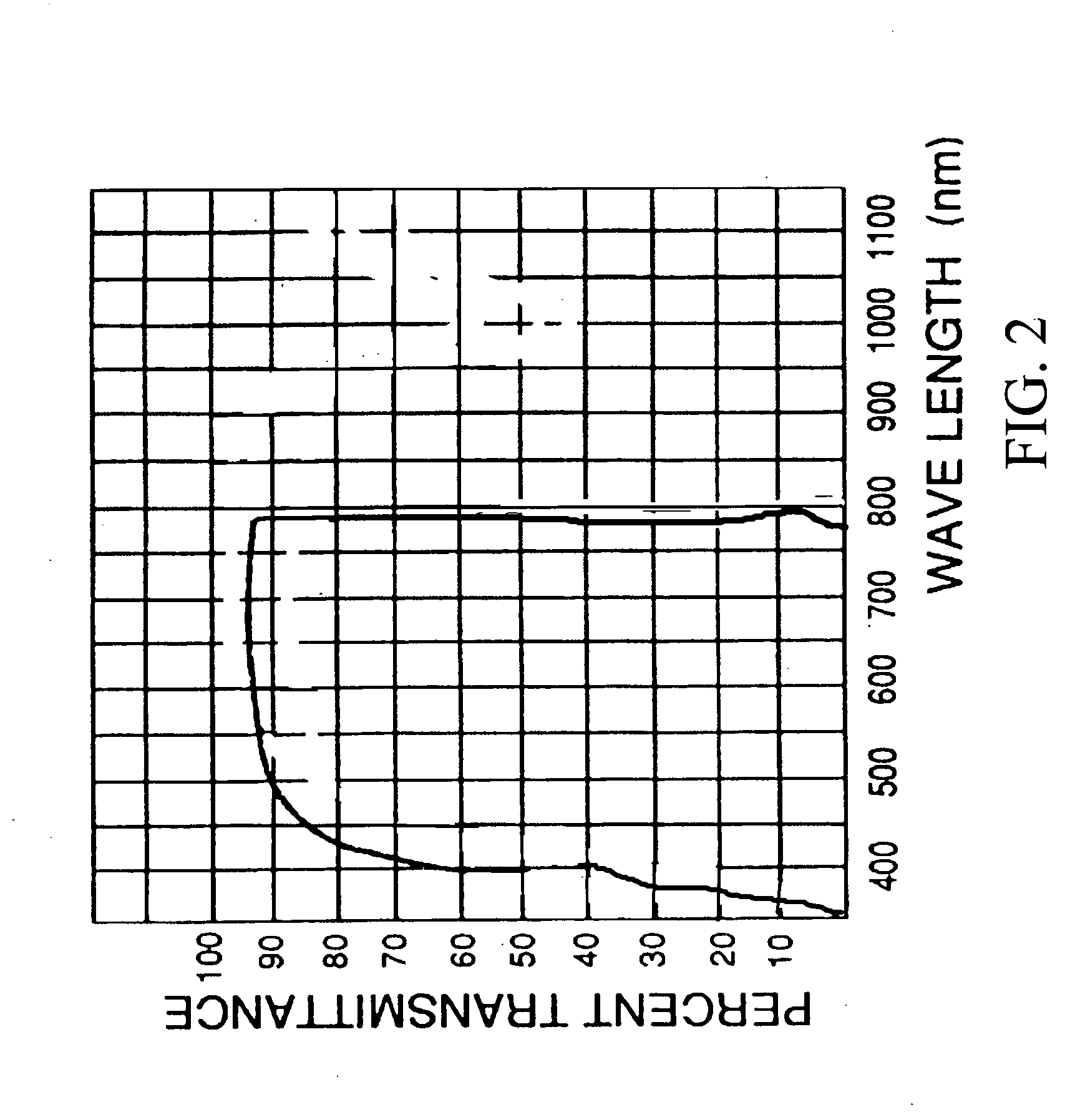

Rugate lens for glasses

InactiveUS20050018131A1Maximize degree of protectionMaximize of clarity of visionSpectales/gogglesOptical partsCLARITYSolar mirror

An improved multi-layer performance lens for protective eyewear such as sunglasses which includes a pass band Rugate filter. The lens design is a sandwich configuration including a polarizing layer between two ophthalmic lens layers in a sandwich configuration, and a Rugate filter applied to one side thereof to yield an exceptional light transmission profile under all light conditions, thereby maximizing protection as well as clarity of vision. In addition, an optional dielectric layer and / or hydrophobic overcoat may be applied. The foregoing layers are arranged to provide a balanced light transmission profile optimum for preventing macular degeneration, cataracts and other ocular injuries.

Owner:HIGH PERFORMANCE OPTICS

Lenses having dispersed metal nanoparticles for optical filtering including sunglasses

InactiveUS20070298242A1Evenly dispersedSpectales/gogglesSynthetic resin layered productsMethylmethacrylatesPoly(methyl methacrylate)

Lenses appropriate for use as sunglasses and other optical filtering devices include one or more composite layers including metal nanoparticles dispensed in a polymer matrix. The entire lens can be a single layer of the composite or the composite can be a coating on one or both faces of the lens. Gold nanoparticles can be dispersed in a poly(methylmethacrylate) or polycarbonate polymer at 0.01 to 1 weight percent.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

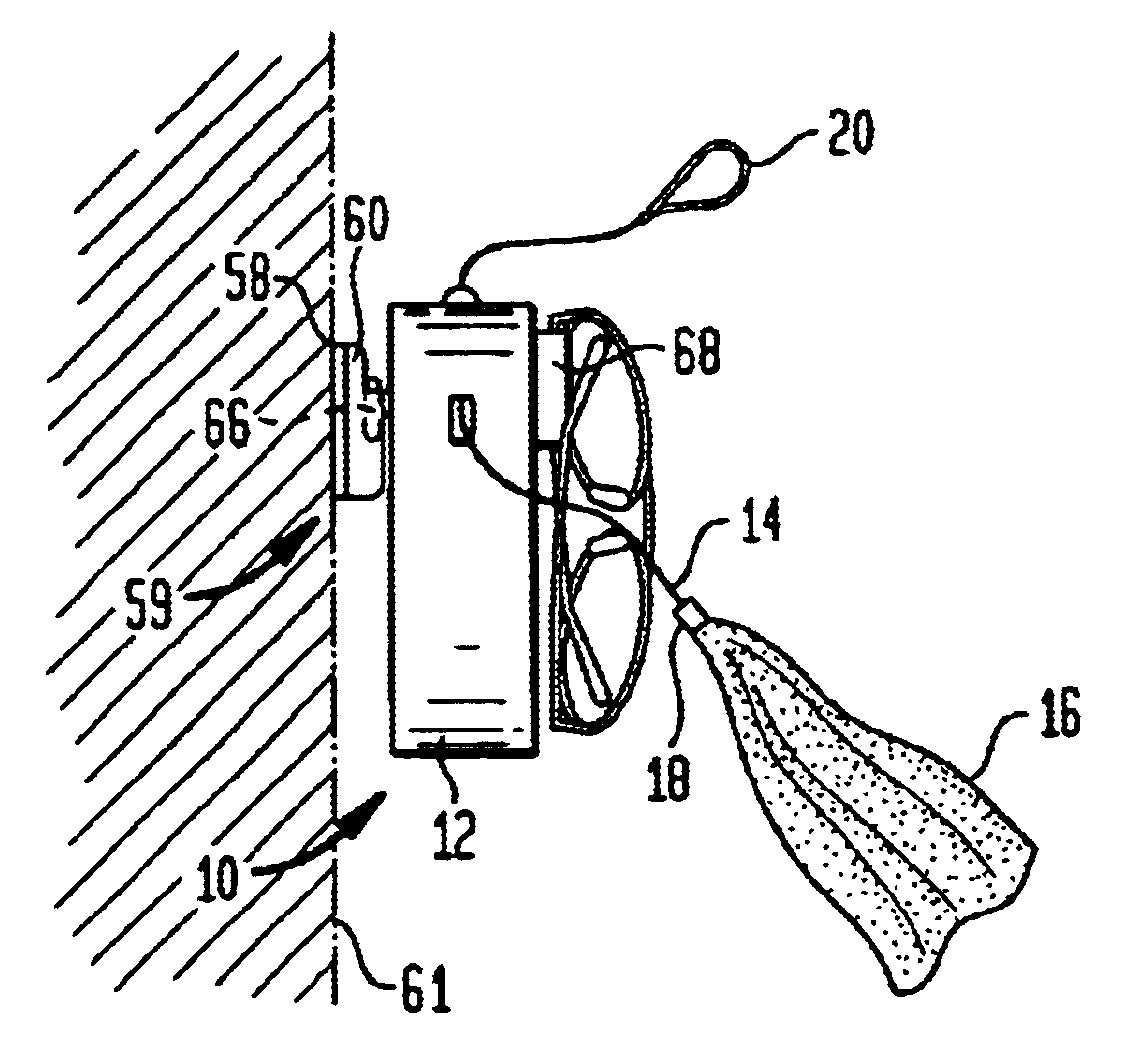

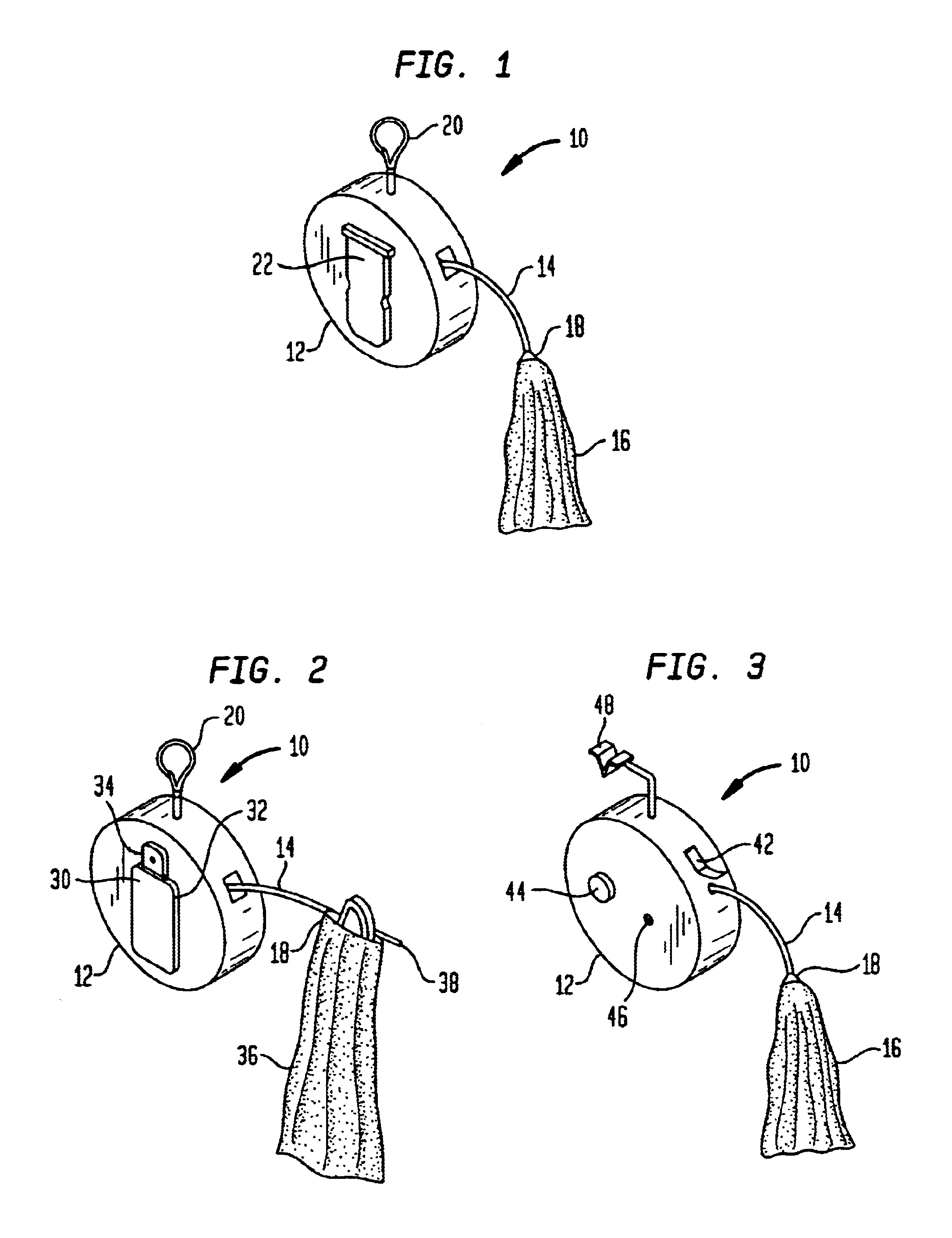

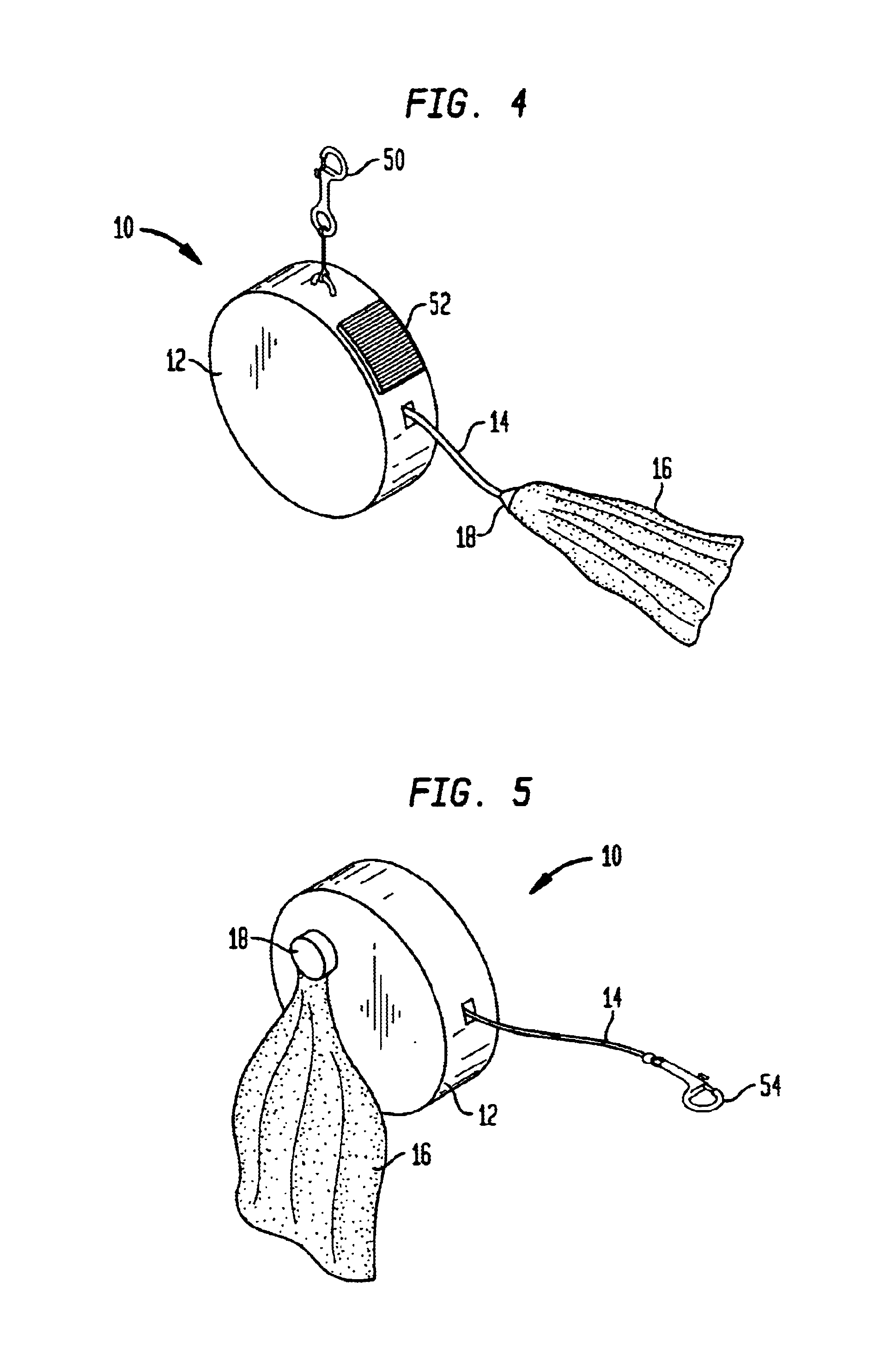

Eyewear cleaning device

An eyewear cleaning device and method provides convenient cleaning of various types of eyewear, such as glasses and sunglasses. The eyewear cleaning device comprises a housing with a retractable cord, at the end of which is attached a soft, nonabrasive cloth for cleaning eyewear lenses. A cleaning fluid dispenser may be included with or attached to the housing. The device can be attached to clothing or other items in proximity to the user of the device, such as a dashboard, sports bag or backpack.

Owner:OBERMAN CHARLES D

Ion beam process for deposition of highly abrasion-resistant coatings

InactiveUSRE37294E1High hardnessReduce coefficient of frictionLayered productsVacuum evaporation coatingEye lensVacuum chamber

An ion beam deposition method is provided for manufacturing a coated substrate with improved abrasion resistance, and improved lifetime. According to the method, the substrate is first chemically cleaned to remove contaminants. In the second step, the substrate is inserted into a vacuum chamber, and the air in said chamber is evacuated. In the third step, the substrate surface is bombarded with energetic ions to assist in the removal of residual hydrocarbons and surface oxides, and to activate the surface. <DEL-S DATE="20010724" ID="DEL-S-00001">Alter<DEL-E ID="DEL-S-00001"> <INS-S DATE="20010724" ID="INS-S-00001">After <INS-E ID="INS-S-00001">the substrate surface has been sputter-etched, a protective, abrasion-resistant coating is deposited by ion beam deposition. The ion beam-deposited coating may contain one or more layers. Once the chosen thickness of the coating has been achieved, the deposition process on the substrates is terminated, the vacuum chamber pressure is increased to atmospheric pressure, and the coated substrate products having improved abrasion-resistance are removed from the vacuum chamber. The coated products of this invention have utility as plastic sunglass lenses, ophthalmic lenses, bar codes scanner windows, and industrial wear parts that must be protected from scratches and abrasion.

Owner:MORGAN ADVANCED CERAMICS

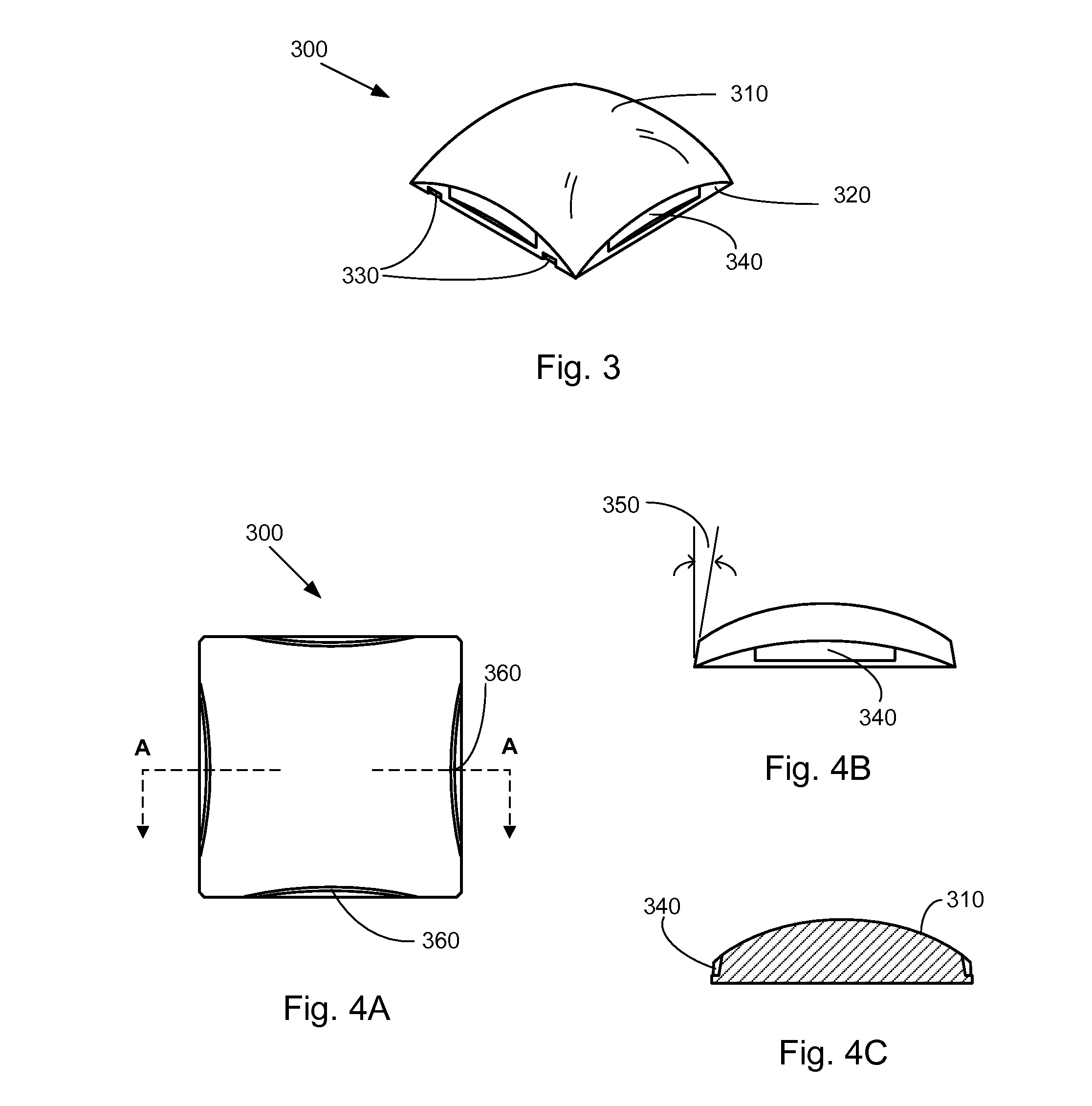

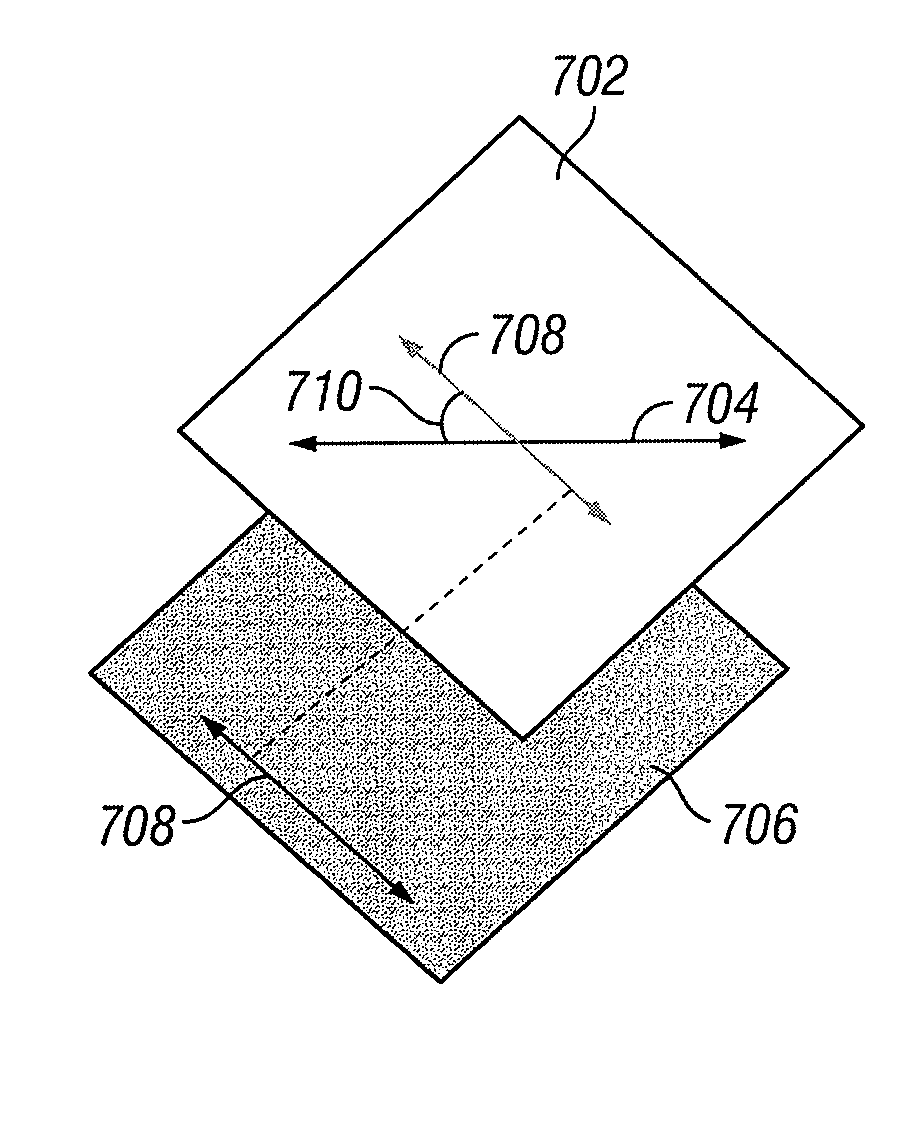

Solar concentrator with square mirrors

InactiveUS20090114213A1Efficient throughput of lightMinimal shadingSolar heating energySolar heat devicesEngineeringSolar concentrator

The present invention is a solar concentrator system incorporating a square primary mirror, a square secondary mirror, and an optical receiver. The square secondary mirror provides highly efficient throughput of light in combination with the square primary mirror, with minimal shading. Manufacturing features may be incorporated into the square secondary mirror to assist in simplifying fabrication issues and assembly steps related to its non-circular shape. An optional heat shield around the optical receiver may be included, further enhancing performance of the solar concentrator system.

Owner:SOLFOCUS

Optical article

InactiveUS20110043902A1High surface hardnessHigh transparencySpectales/gogglesMirrorsElectromagnetic electron waveX-ray

The present invention relates to an optical article which has high surface hardness and absorbs an electromagnetic wave such as a visible light, ultraviolet radiation, infrared radiation, X-rays, β-rays and γ-rays, in particular, a functional optical article represented by a prescription lens, sunglasses, a goggle lens, a shield and an optical filter. The present invention provides an optical article comprising a laminated substance in which a plastic sheet, a resin layer and a backup resin are laminated in this order, wherein the resin layer containing an electromagnetic wave absorbing agent.

Owner:SWANS

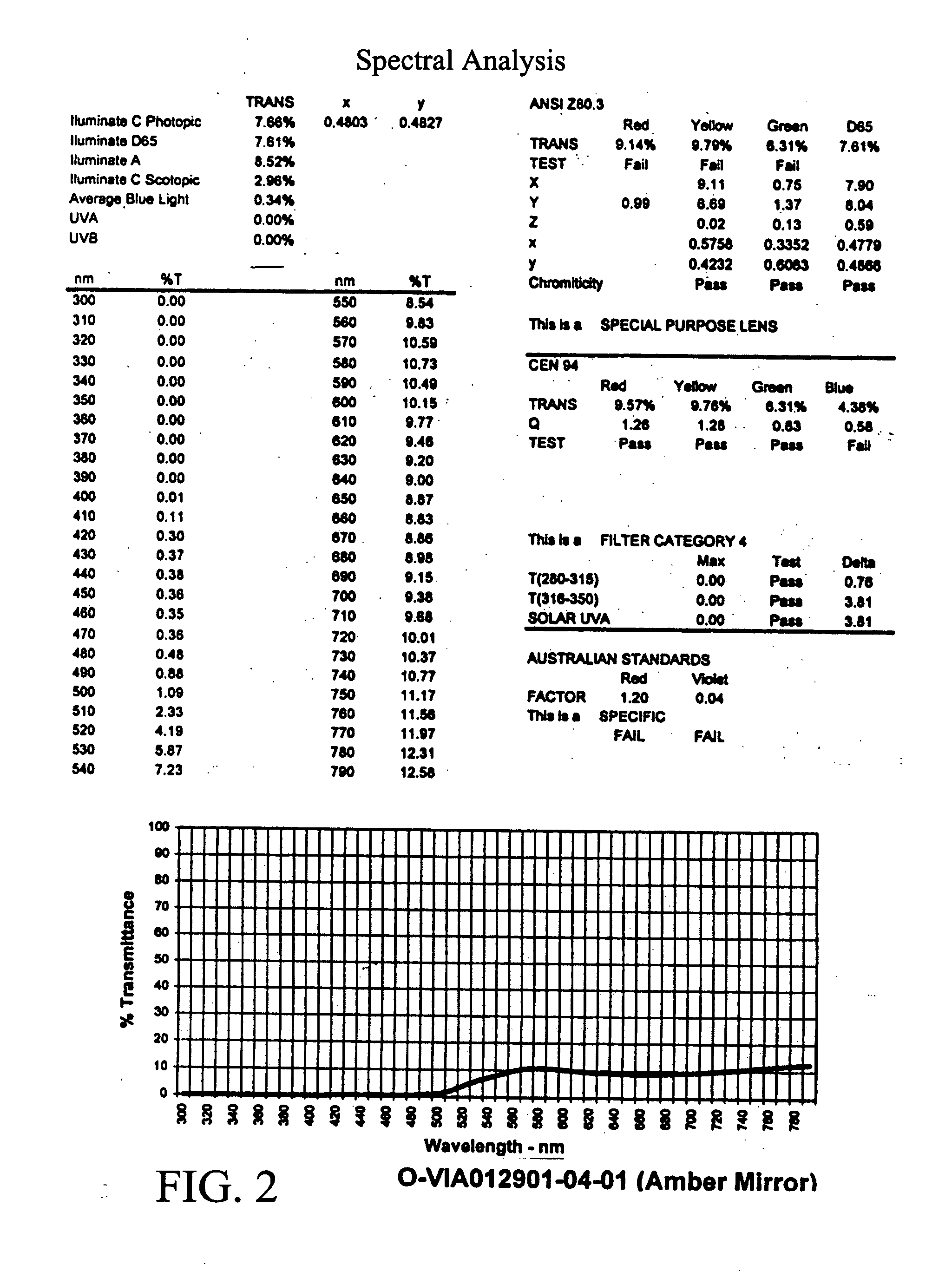

Waterman's sunglass lens

InactiveUS20050099589A1Reduce light transmittanceDecrease transmission valueSpectales/gogglesOptical partsPolycarbonateDielectric mirror

An improved ten-layer performance polarized lens for sunglasses. The lens design maximizes visual acuity while minimizing blue-light transmission using a multi-layer dielectric mirror to reduces glare and overall light transmission, two layers of high-contrast blue-blocking amber CR-39 plastic or polycarbonate, sandwiching a polarizing layer. An outer hydrophobic overcoat is also provided to protect against haze, delamination, and smudging, The foregoing layers are arranged to provide a balanced light transmission profile optimum for use on the water in which 100% of UV-A & B light is absorbed to at least 400 nm. The resulting dielectric-mirrored sunglass lens reduces both overall light transmission and ocular photochemical damage.

Owner:HIGH PERFORMANCE OPTICS

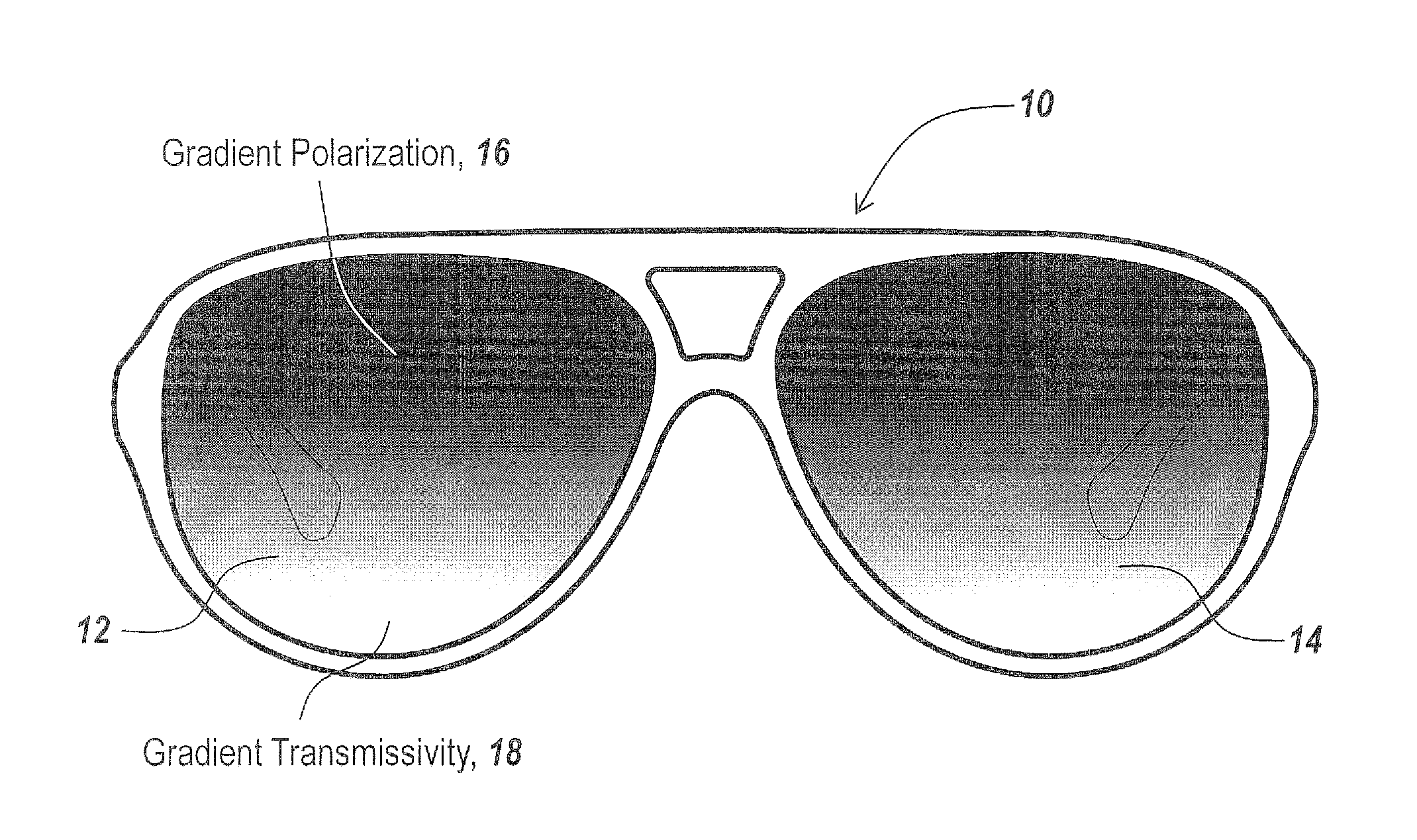

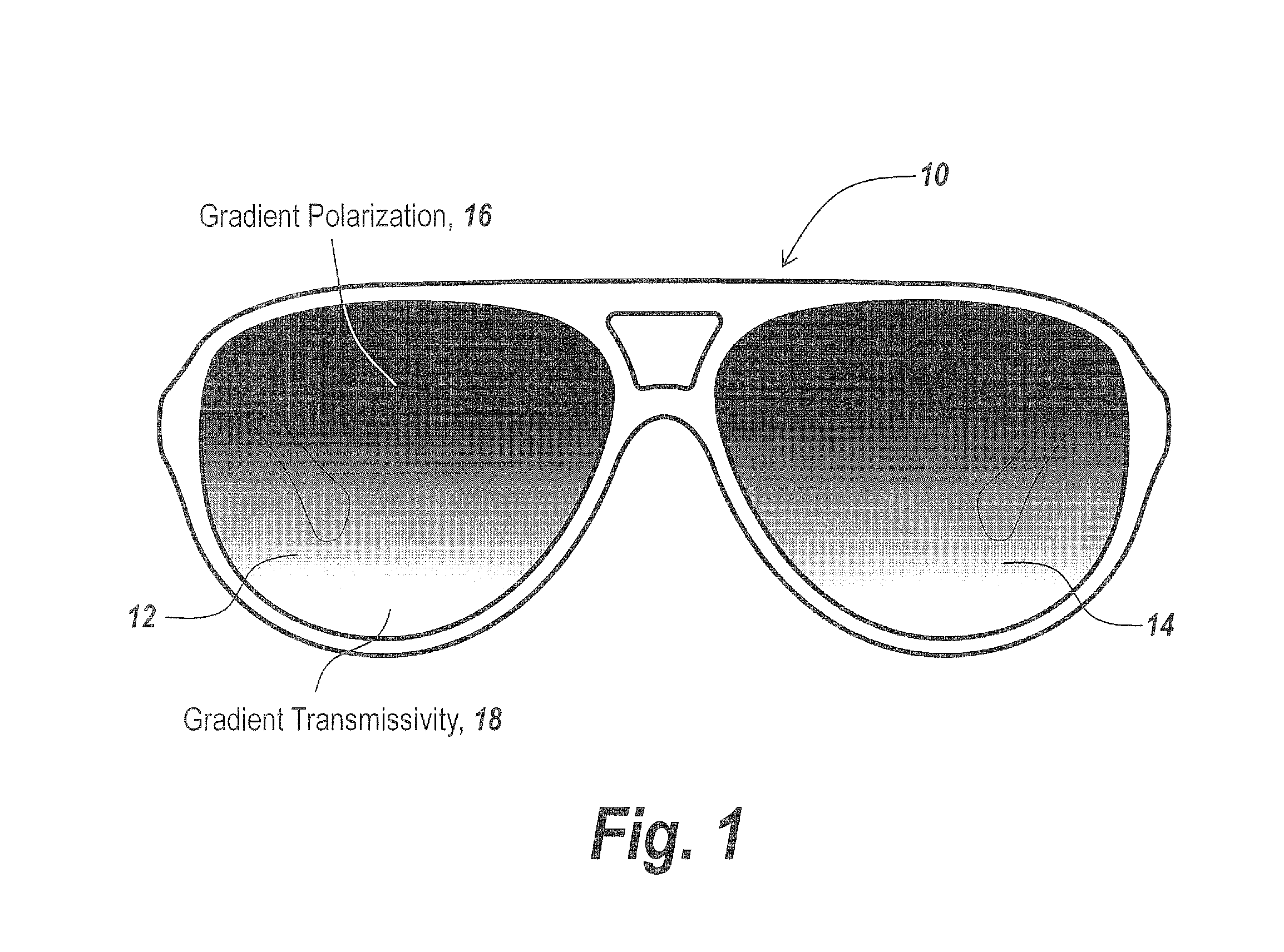

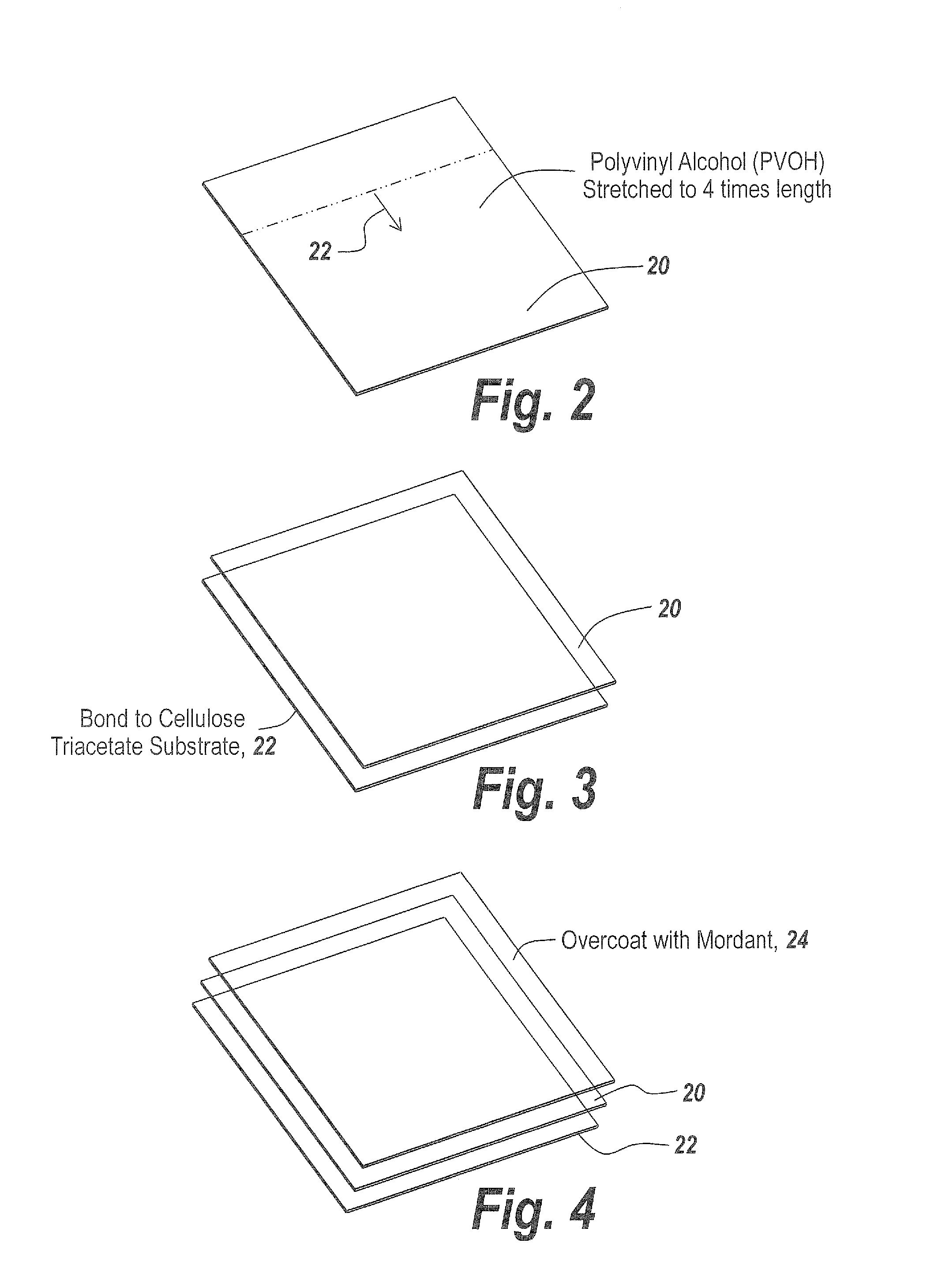

Method and apparatus for forming sunglass lenses with a predetermined gradient

InactiveUS20150253465A1Accurate locationCharacteristic is differentLamination ancillary operationsLaminationEngineeringSolar mirror

A method for forming sunglass lenses with a predetermined optical gradient, namely a polarized gradient, transmissivity gradient or color gradient in which an ink jet printer is used to print a gradient pattern on an oriented sheet, with the ink jet printer being provided with a dye, in one embodiment a dichroic dye and in another embodiment an iodine dye. The printed oriented sheet is incorporated into a lens to provide the lens with the associated gradient.

Owner:DISTRIBUTED POLARIZATION

Reflective Polarized Lenses With High Transmission

InactiveUS20090122261A1Increase brightnessImprove efficiencyOther chemical processesMixing methodsNight visionPolarizer

The present invention relates to unique reflective polarized lenses that are anti-dazzling and reduce glare. In particular, it relates to polarized lenses utilizing a reflective polarizer, a high-transmission absorptive polarizer and photochromic treatment in a unique combination that can be injection molded to make thermoplastic ophthalmic lenses. The resulting lenses have high luminous transmission, high polarization efficiency for use in sunglasses and has potential applications for night vision

Owner:HOYA OPTICAL LABS OF AMERICA INC +1

Safety sun glasses with high intensity light protection

A pair of safety sunglass, particularly for use when arc welding, includes auto darkening lenses having suitable characteristics for providing high intensity light protection during welding procedures. The sunglasses have a tight fitting frame conforming to an individual's face curvature. When an arc is struck, or another high intensity light source is present, the lenses instantly and automatically darken to protect the individual's eyes from damage. Each lens includes a plurality of layers for prohibiting the high intensity direct light rays from passing therethrough. A feature and benefit of such eyewear is that welding operations may be performed in confined spaces where a conventional welding face shield can not fit. When the welding is completed, the eyeglasses would quickly return to their sun tinted state allowing them to be used as a conventional pair of sunglasses.

Owner:PEREZ JOSE R

Uniform diffuse omni-directional reflecting lens

ActiveUS7443608B2Improve reflective effectReduce the amount requiredOptical partsOptical elementsAnti-reflective coatingDiffuse reflection

Owner:DILLON STEPHEN M

Reflective article having a sacrificial cathodic layer

The present invention relates to reflective articles, such as solar mirrors, that include a sacrificial cathodic layer. The reflective article, more particularly includes a substrate, such as glass, having a multi-layered coating thereon that includes a lead-free sacrificial cathodic layer. The sacrificial cathodic layer includes at least one transition metal, such as a particulate transition metal, which can be in the form of flakes (e.g., zinc flakes). The sacrificial cathodic layer can include an inorganic matrix formed from one or more organo-titanates. Alternatively, the sacrificial cathodic layer can include an organic polymer matrix (e.g., a crosslinked organic polymer matrix formed from an organic polymer and an aminoplast crosslinking agent). The reflective article also includes an outer organic polymer coating, that can be electrodeposited over the sacrificial cathodic layer.

Owner:VITRO FLAT GLASS LLC

Uniform diffuse omni-directional reflecting lens

ActiveUS20080030675A1Improve reflective effectReduce the amount requiredOptical partsOptical elementsAnti-reflective coatingDiffuse reflection

A transparent multi-layer lens construction to be worn as a sunglass lens, or a fashion lens, that reflects light in a diffuse manner. The multi-layer lens construction is, in part, a combination of surface form and surface texture combined with a reflective medium and an anti-reflective coating. The present invention offers vast improvements over previously disclosed lens constructions in that it provides for both improved reflectivity and improved optical quality.

Owner:DILLON STEPHEN M

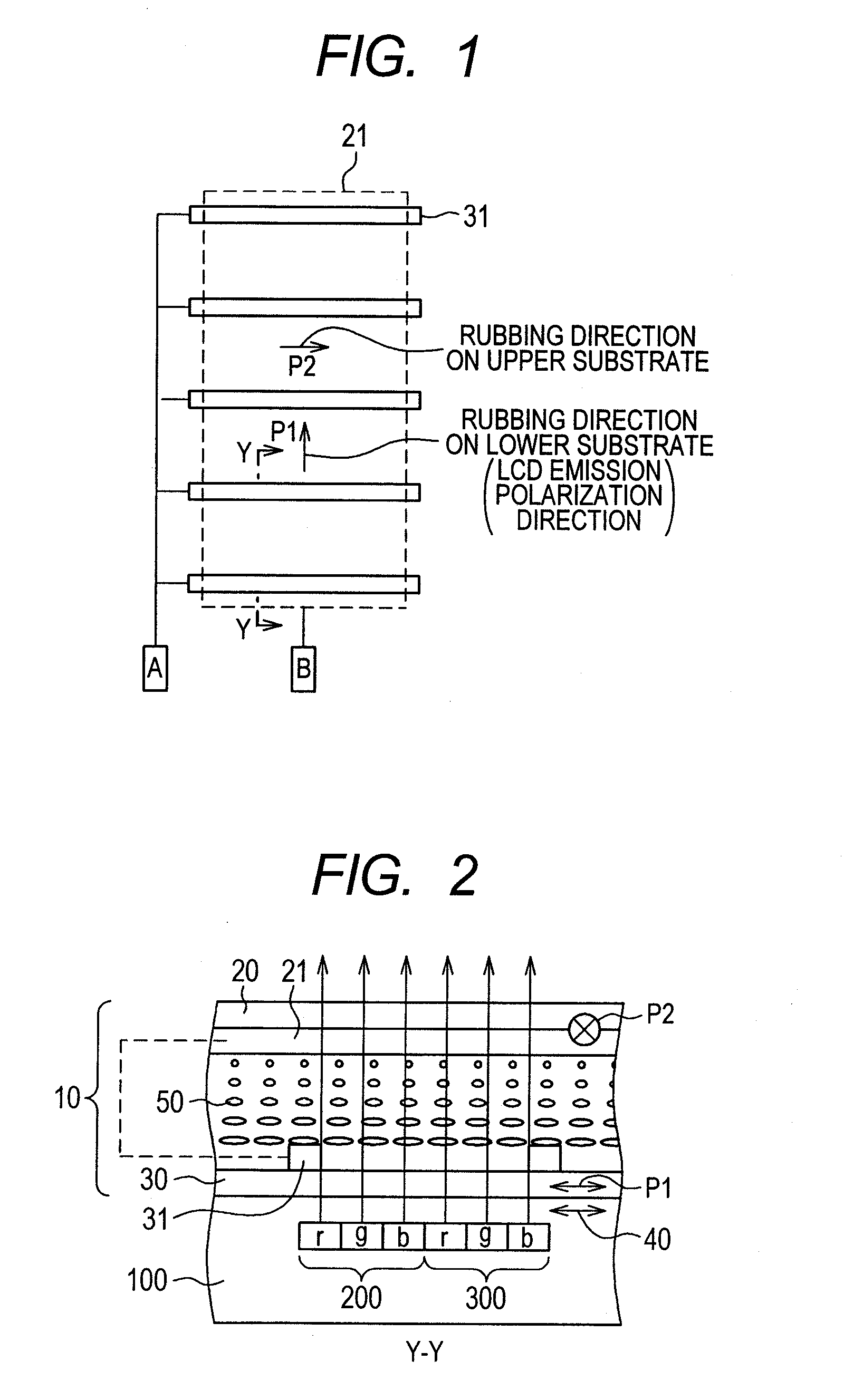

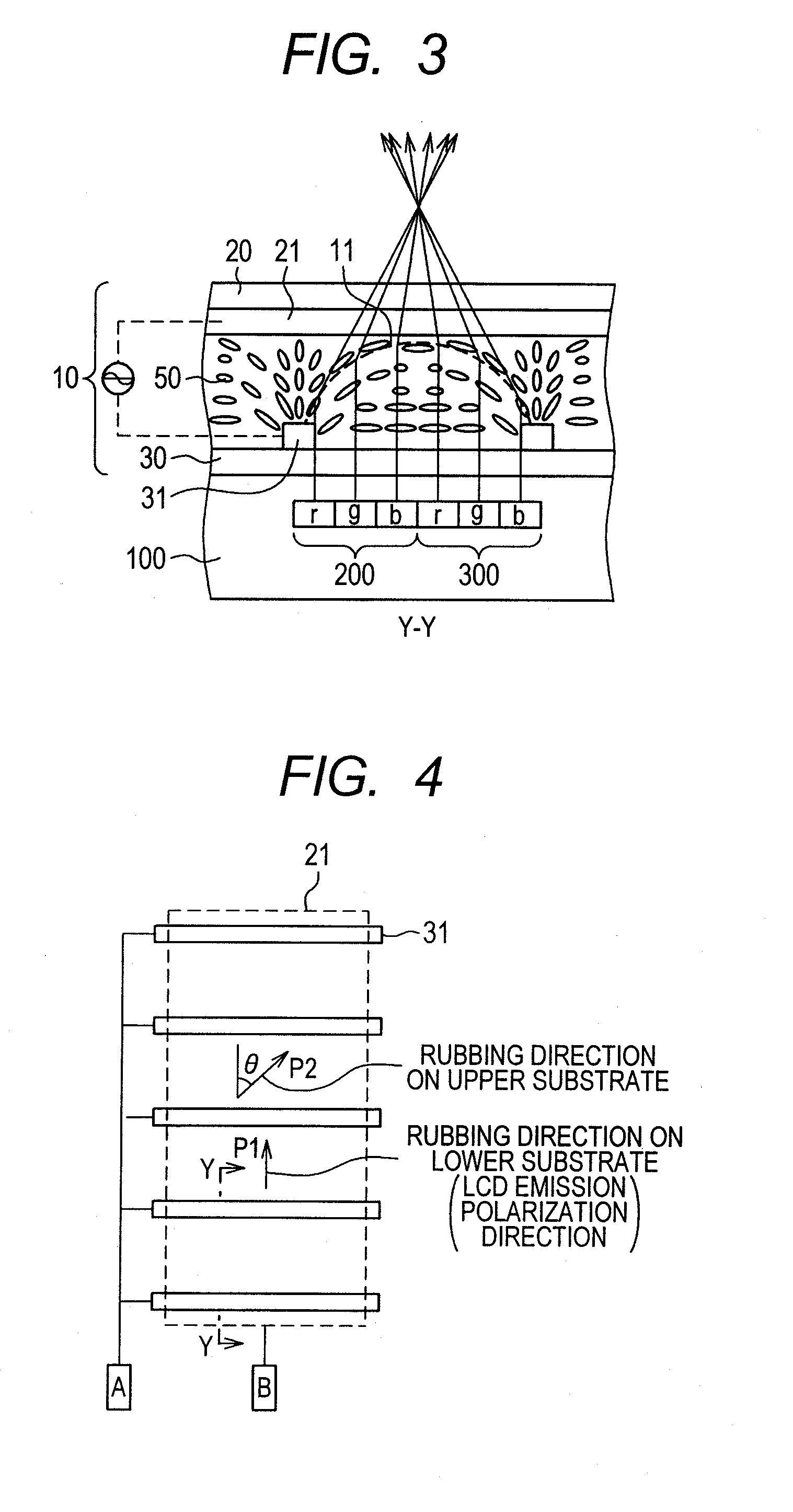

Liquid crystal display device

ActiveUS20120257127A1Clear visualizationSteroscopic systemsNon-linear opticsLiquid-crystal displaySolar mirror

In a liquid crystal display device, a first substrate adjacent to a liquid crystal display panel is subjected to rubbing in a first direction that is the same as a polarization axis direction of light emitted from the liquid crystal display panel, and a second substrate that interposes a liquid crystal layer with the first substrate is subjected to rubbing in a second direction at a right angle with the first direction. The second direction is made the same as the polarization axis direction of polarized sunglasses to allow visual recognition of the image using the polarized sunglasses. Electrode patterns formed by alternately providing narrow and wide electrodes are arranged on the upper and lower substrates in a direction at a right angle with each other so that the rubbing directions on the upper and lower substrates form a right angle to ensure stable 3D display.

Owner:JAPAN DISPLAY INC

Apparatus for cleaning view screens and lenses and method for the use thereof

A lens and / or a view screen of an electronic device having at least one case can be cleaned by wiping the view screen with a cleaning component wherein the cleaning component is configured to selectively couple to the at least one case or some other substrate using a magnetic attractive force. The cleaning devices may have secondary applications such as securing fly fishing lures, activating or deactivating a device having a magnetic switch, or preventing sunglasses from sinking. They may also be manufactured without a cleaning component for use with the secondary applications.

Owner:GUI GLOBAL PROD

Polarized mirrored glasses lens

ActiveUS20140232983A1Prevents appearance of reflectionHigh light transmittanceOptical partsOptical elementsSolar mirrorField of view

Provided is a spherical or aspherical polarized mirrored glasses lens that substantially prevents the appearance of reflections caused by reflection from the mirrored surface, has a high transmittance, and with the use of a colored absorption-polarization film layer, allows arbitrary selection of the color of the field of view of the sunglasses user and the color of the lens as seen by others. A polarized mirrored glasses lens is fabricated, said lens being characterized by having, in order from the light-incidence side, at least a reflection-polarization film layer and an absorption-polarization film layer, and further characterized in that: the transmission axes of said layers are aligned; and the light-incidence side is a convex spherical or aspherical surface.

Owner:MITSUBISHI GAS CHEM CO INC +1

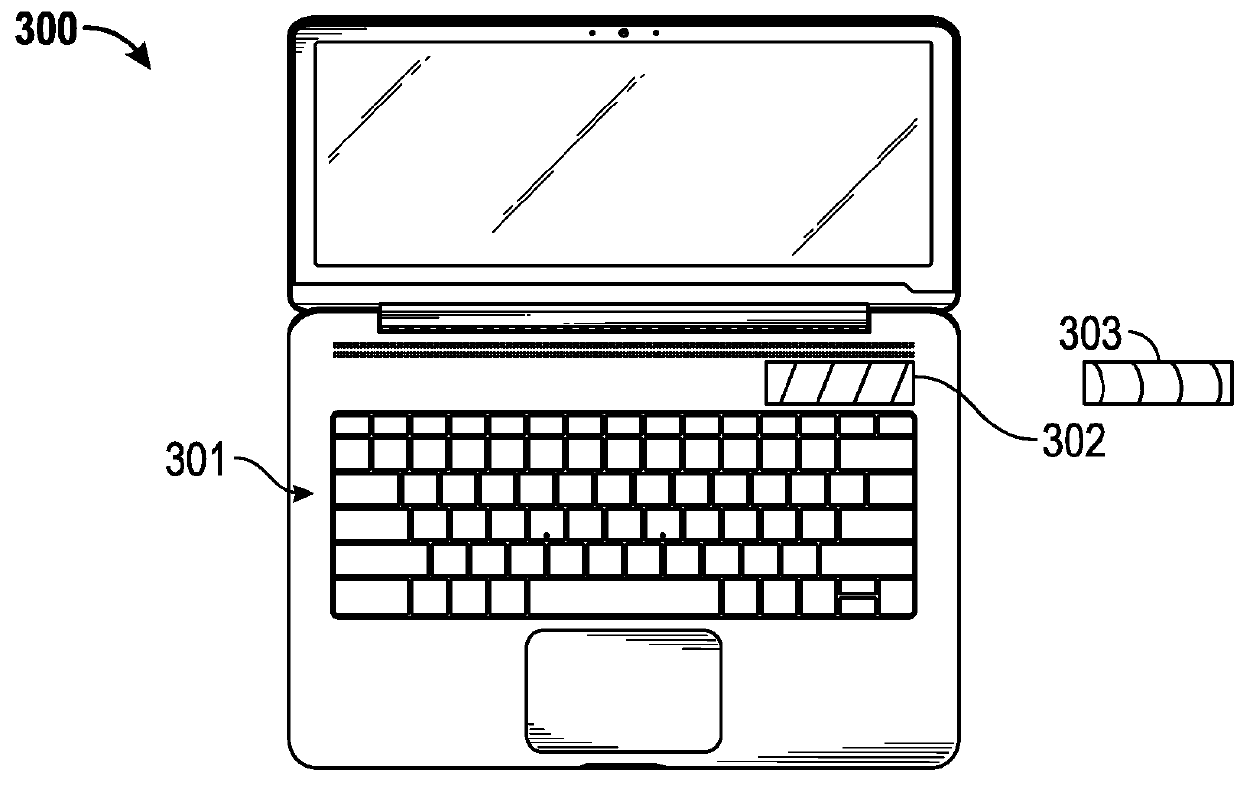

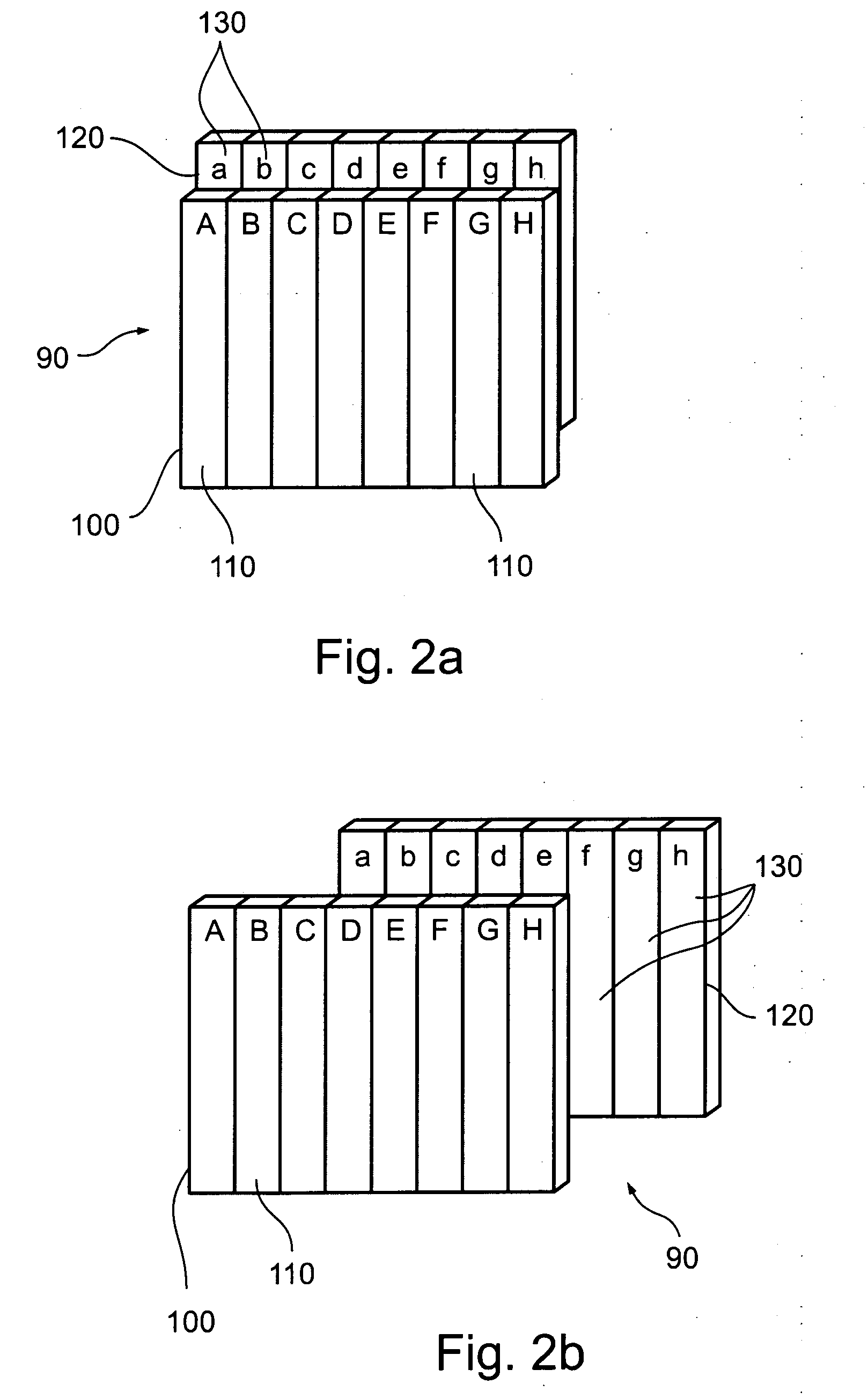

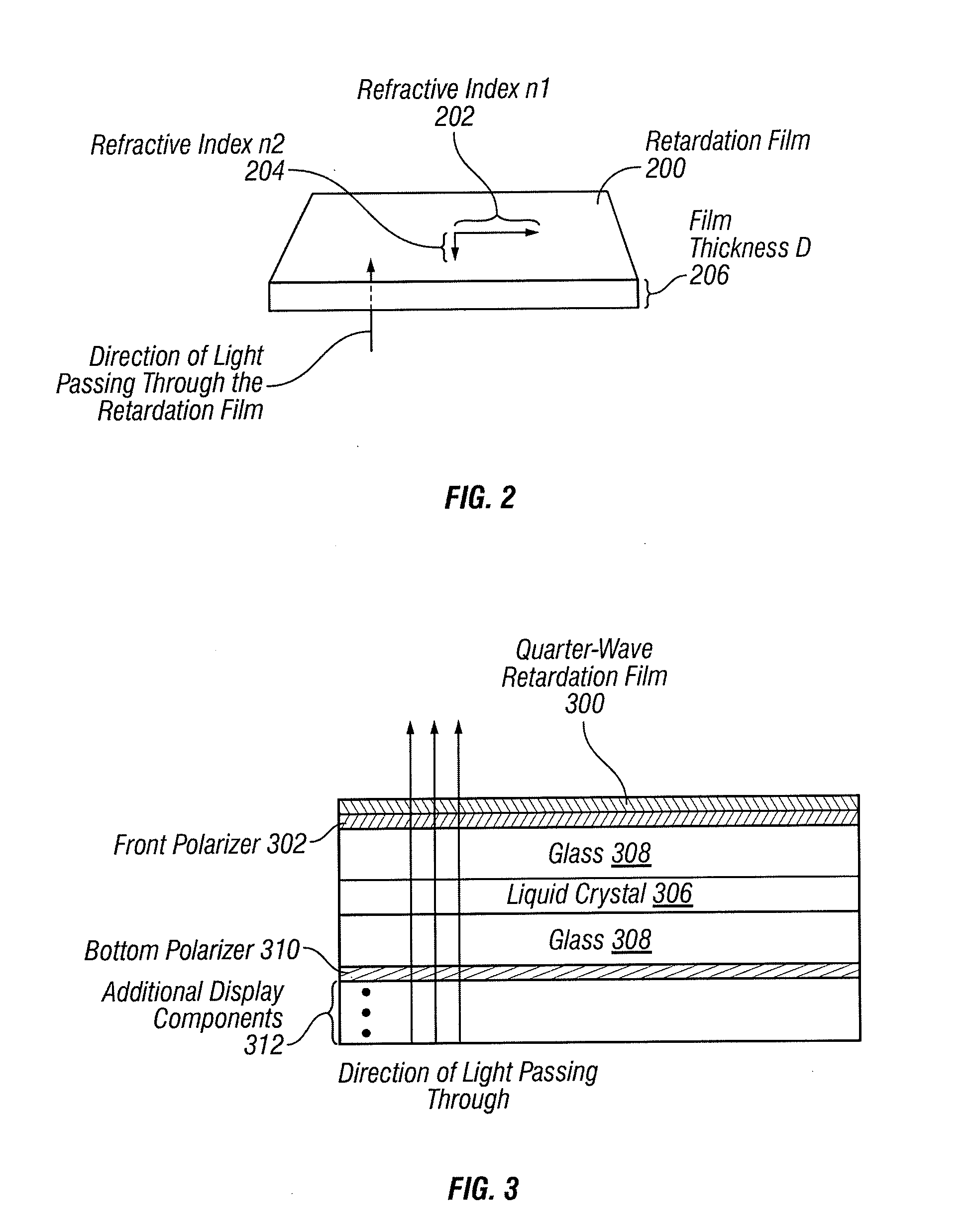

Dual purpose touch sensor panel and optical retarder

InactiveUS9158143B2Improve visibilityIncreasing the thicknessSolid-state devicesSemiconductor/solid-state device manufacturingVisibilityOptical property

Owner:APPLE INC

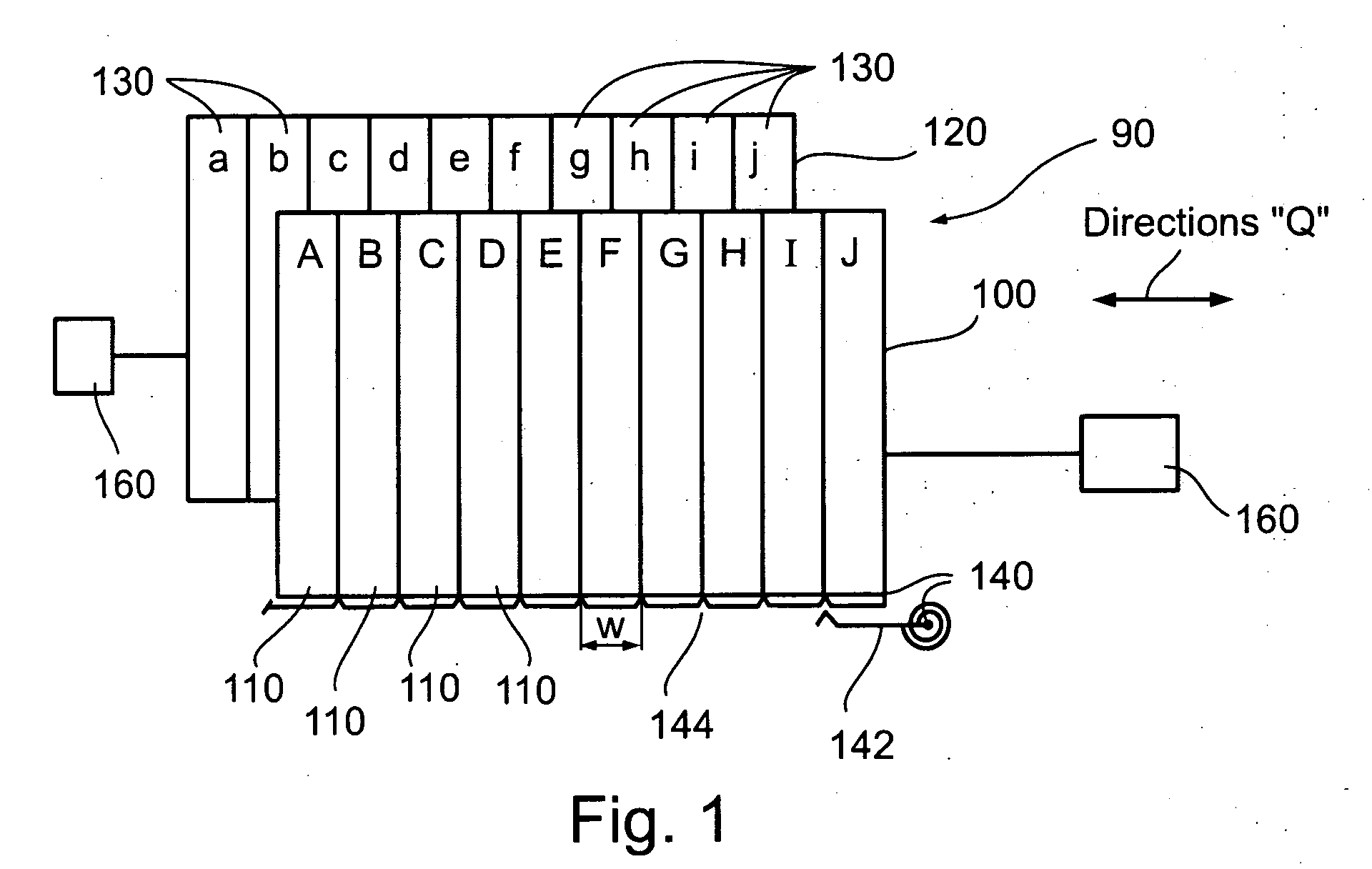

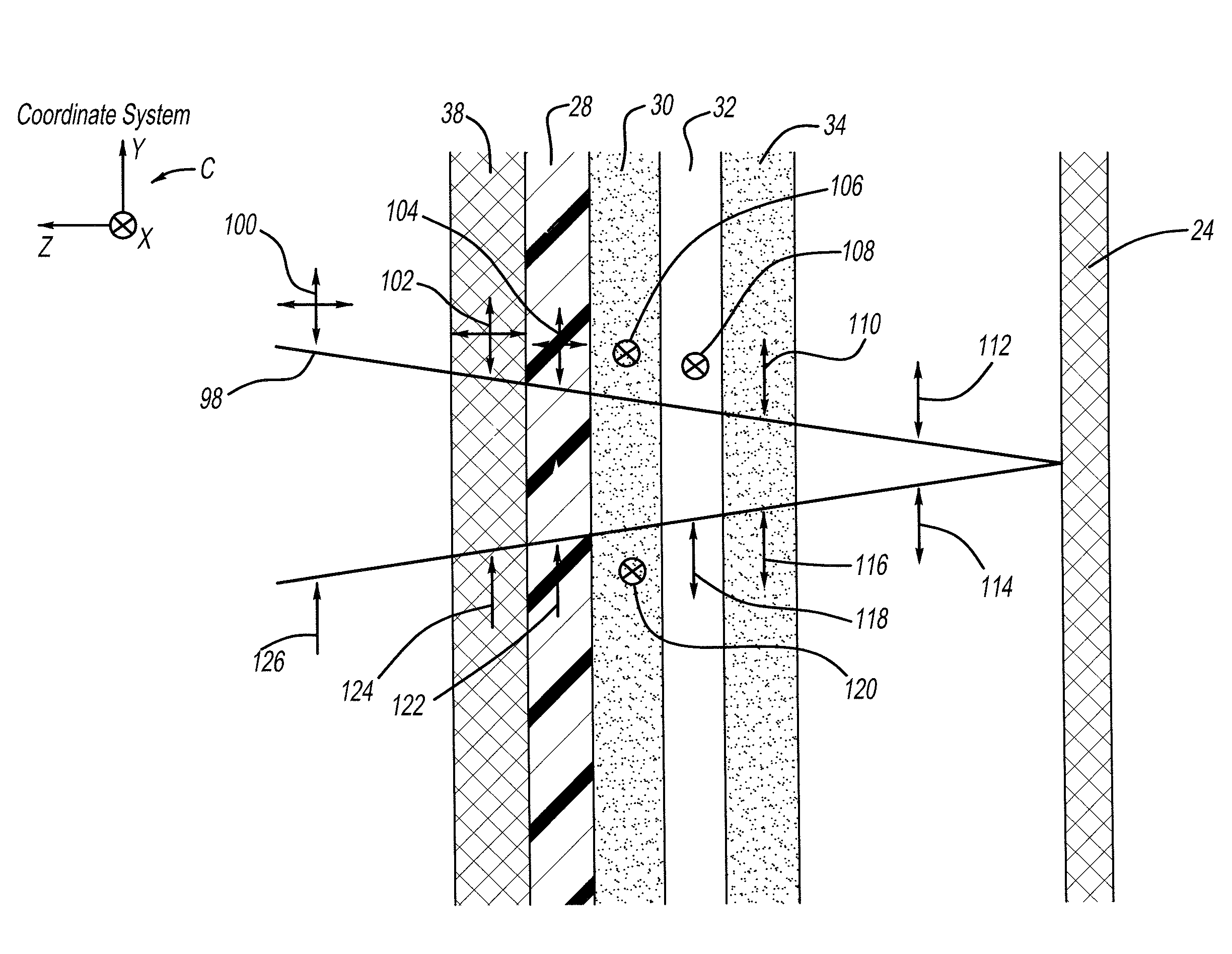

Controllable transparence device controlled by linearly translated polarizers and method of making same

InactiveUS20060193046A1Limited controlSimpler and easy to maintainAntiglare equipmentLight protection screensDimmerPolarizer

A controlled transparency device is presented. The device is operable to control a ratio of light transmitted by the device to light blocked by the device. Control is achieved by linear translation of a first polarizing layer with respect to a second polarizing layer. In a preferred embodiment, each of the first and second polarizing layers comprises a plurality of polarizing areas of standard width, wherein polarization orientation of each area on layer differs from the polarization orientation of an adjacent area by a standard angular difference. The device is usefully embodied as a window, a space divider for open-space offices, a curtain wall, a sun visor for a vehicle, a visor for welding, adjustable sunglasses, and a controllable dimmer for a mirror such as the rear-view mirror of a vehicle.

Owner:YELLIN AZGAD

Dual purpose touch sensor panel and optical retarder

ActiveUS20130063684A1Reduce glareReduce the impactSolid-state devicesPolarising elementsVisibilityOptical property

When a user operates a touch sensor panel having an LCD device outdoors or in a bright environment, light reflecting off the device can create glare. In order to reduce glare, a user can view the device through polarized filters such as polarized sunglasses.Doing so can reduce the visibility of the image displayed on the LCD. A quarter-wave retardation film can be added to the touch sensor panel's LCD device to mitigate these effects by producing circularly polarized light. However, adding a separate quarter-wave retardation film can increase the thickness and cost of manufacturing the touch sensor panel. Embodiments of the present disclosure are directed to a touch sensor panel constructed from a base film having quarter-wave retardation properties that can produce circularly polarized light. Because the base film has the desired optical properties, a separate quarter-wave retardation film may not be needed.

Owner:APPLE INC

Plane solar energy spotlight power supply module

InactiveCN1461059ALow costLow light concentrationSolar heating energySolar heat devicesElectrical batteryComputer module

A planar concentrator solar power module has a planar base, an aligned array of linear photovoltaic cell circuits on the base and an array of linear Fresnel lenses or linear mirrors for directing focused solar radiation on the aligned array of linear photovoltaic cell circuits. The cell circuits are mounted on a metal back plate. The cell circuit area is less than a total area of the module. Each linear lens or linear mirror has a length greater than a length of the adjacent cell circuit. The cell circuit may have cells mounted in shingle fashion to form a shingled-cell circuit. In an alternative module, linear extrusions on the circuit element have faces for mounting the linear mirrors for deflecting sun rays impinging on each mirror onto the shingled-cells. The linear extrusions are side-wall and inner extrusions with triangular cross-sections. The circuit backplate is encapsulated by lamination for weather protection. The planar module is generally rectangular with alternating rows of linear cell circuits and linear lenses or linear mirrors.

Owner:JX CRYSTALS

Waterman's sunglass lens

InactiveUS20050007548A1Reduce light transmittanceDecrease transmission valueSpectales/gogglesOptical partsCR-39Polycarbonate

An improved ten-layer performance polarized lens for sunglasses. The lens design maximizes the benefit to watermen, giving them a combination of outer hydrophobic overcoat to protect the lens from seawater and smudging, multi-layer dielectric mirror which further reduces glare and overall light transmission, two layers of high-contrast blue-blocking amber or color-discriminating grey ophthalmic CR-39™ plastic or polycarbonate, sandwiching a polarizing layer. The foregoing layers are arranged to provide a balanced light transmission profile optimum for use on the water in which 100% of UV-A & B light is absorbed to at least 400 nm. An alternative embodiment is described in which a Rugate filter is incorporated in place of or in addition to the multi-layer dielectric mirror. The resulting watermens' dielectric-mirrored sunglass lens reduces both overall light transmission and ocular photochemical damage, and is available in either high-contrast blue-light blocking amber or grey coloration.

Owner:HIGH PERFORMANCE OPTICS

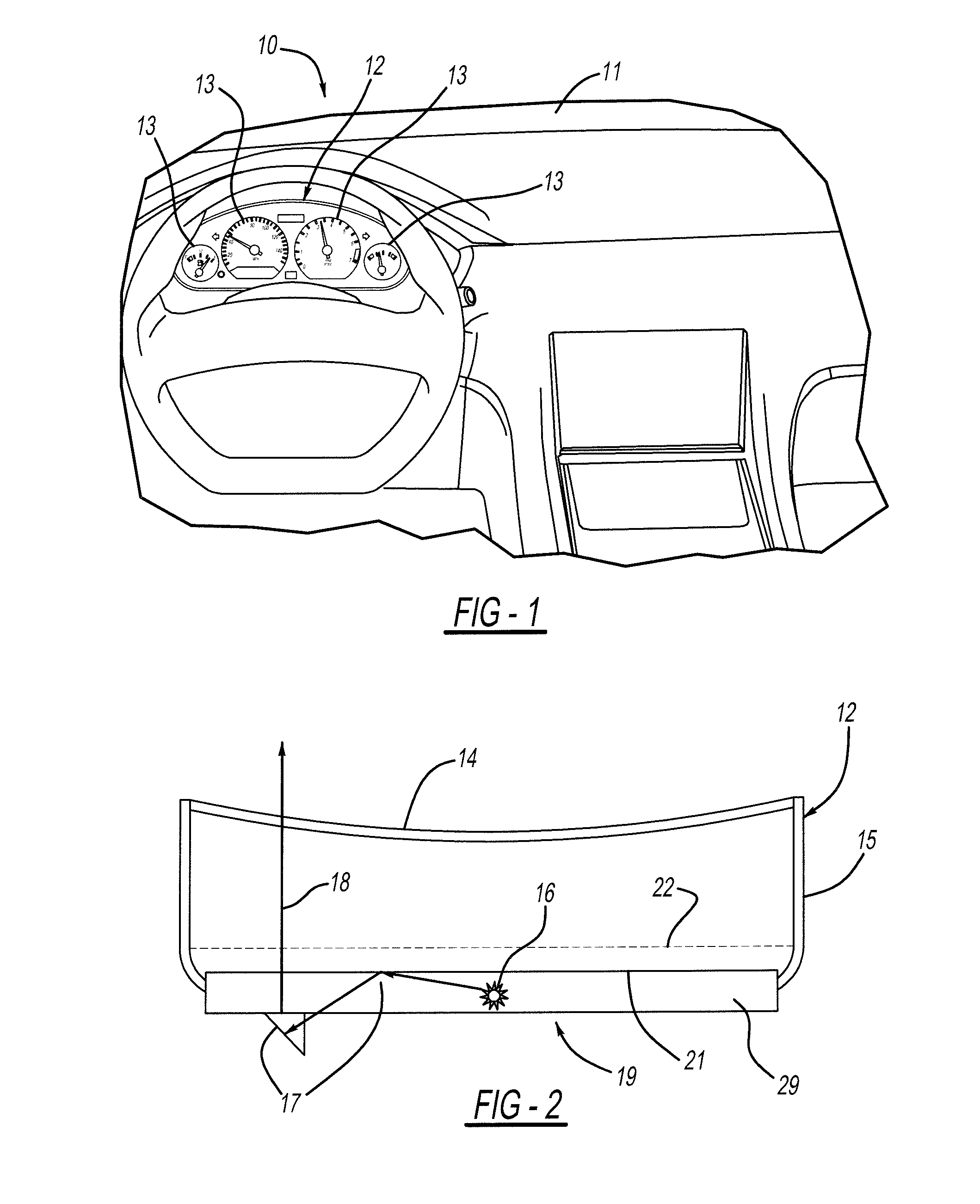

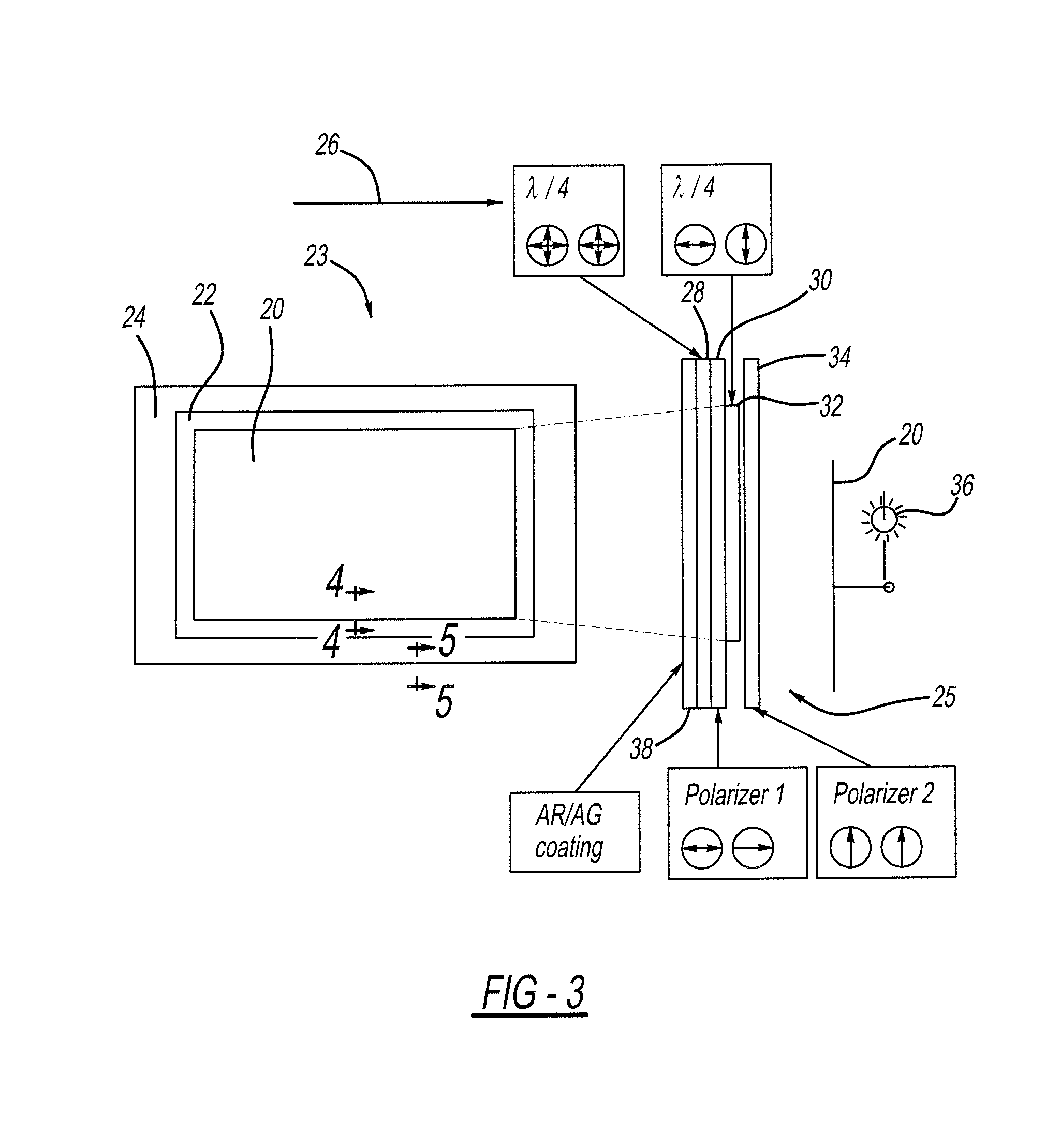

Dead-front lens for interior vehicle display

InactiveUS20160091645A1Reduce intensityAvoid darkeningPolarising elementsUses eyeglassesOptoelectronics

A vehicle instrument cluster lens assembly for a vehicle instruments panel includes a first layer comprised of a quarter-wave plate (λ / 4). A second layer which is a polarizer, a third layer of another quarter-wave plate (λ / 4); the first and a fourth layer being a polarizer light to a new orientation. The quarter-wave plates change the orientation of the light angle that it can be seen with a polarized eye glass lens. The vehicle lens assembly functions in a dual manner depending on the light source direction and orientation of the light to prevent light emitted from the instrument as well as making the display light visible to viewers wearing polarized sunglasses.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Blue-ray-proof lens and resin raw material thereof

InactiveCN106674852ARealize coating modificationGood dispersionOptical filtersOptical partsHigh energySilanes

The invention relates to the field of a lens and specifically relates to a blue-ray-proof lens and a resin raw material thereof. A substrate polymer and a blue-ray-proof additive are contained in the lens; a nanometer rare earth oxide subjected to surface modification treatment is served as the blue-ray-proof additive; 3-methacryloxy trimethoxy silane and polymethyl methacrylate are contained in a modifying material used for the surface modification treatment. According to the invention, the nanometer rare earth oxide subjected to surface-cladding treatment is added into the substrate polymer, so that the lens has a better converting absorbing function for the 400-470nm high-energy blue ray; the high transparency and low haze of the lens can be guaranteed; the lens can meet the manufacturing requirements of the myopic lens, presbyopic glasses and sun glasses; the lens has wide adaptability.

Owner:HEFEI WIYE OPTICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com