Concentration emulsified diesel fuel and preparation method thereof

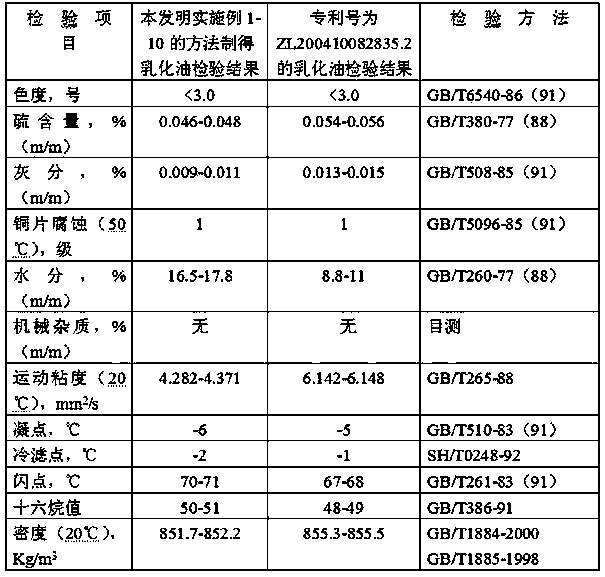

A technology for emulsified diesel oil and diesel oil, which is applied in the field of concentrated emulsified diesel oil and its preparation, can solve the problems such as the shelf life and fluidity need to be further provided, the shelf life of emulsified diesel oil is short, and the development is restricted, so as to achieve low kinematic viscosity, reduced emission, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Concentrated emulsified diesel oil is prepared from the following raw materials in stated parts by weight:

[0019] 30 parts of diesel oil, 21 parts of oleic acid, 8 parts of methanol, 4 parts of sodium nitrate, 32 parts of water, 8 parts of monoethanolamine, 0.55 parts of isooctyl nitrate or amyl nitrate, 0.55 parts of ethylene glycol.

[0020] Its preparation method comprises the following steps:

[0021] Get one of diesel oil, oleic acid, methanol, sodium nitrate, monoethanolamine, isooctyl nitrate or amyl nitrate, and ethylene glycol that meet the above parts by weight and add them to the stirring container and stir for 15 minutes, then mix the Add the weight of water and continue to stir until the stirring is uniform and transparent.

[0022] Monoethanolamine in this embodiment can be replaced by diethanolamine or triethanolamine.

Embodiment 2

[0024] Concentrated emulsified diesel oil is prepared from the following raw materials in stated parts by weight:

[0025] 20 parts of diesel oil, 22 parts of oleic acid, 12 parts of methanol, 6 parts of sodium nitrate, 36 parts of water, 14 parts of diethanolamine, 0.8 parts of isooctyl nitrate or amyl nitrate, 0.8 parts of ethylene glycol.

[0026] Its preparation method comprises the following steps:

[0027] Get one of diesel oil, oleic acid, methanol, sodium nitrate, diethanolamine, isooctyl nitrate or amyl nitrate, and ethylene glycol that meet the above-mentioned parts by weight and add them to the stirring container for 20 minutes. Add the weight of water and continue to stir until the stirring is uniform and transparent.

[0028] Diethanolamine in this embodiment can be replaced by monoethanolamine or triethanolamine.

Embodiment 3

[0030] Concentrated emulsified diesel oil is prepared from the following raw materials in stated parts by weight:

[0031] 40 parts of diesel oil, 16 parts of oleic acid, 5 parts of methanol, 2 parts of sodium nitrate, 26 parts of water, 5 parts of diethanolamine, 0.3 parts of isooctyl nitrate or amyl nitrate, 0.3 parts of ethylene glycol.

[0032] Its preparation method comprises the following steps:

[0033] Take one of diesel oil, oleic acid, methanol, sodium nitrate, diethanolamine, isooctyl nitrate or amyl nitrate, and ethylene glycol that meet the above-mentioned parts by weight and add them to the stirring container and stir for 30 minutes. Add the weight of water and continue to stir until the stirring is uniform and transparent.

[0034] Diethanolamine in this embodiment can be replaced by monoethanolamine or triethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com