Preparation method of water-based light-reflective coating used on solar mirror surface

A technology of reflective coatings and solar energy, which is applied in the direction of reflection/signal coatings, polyester coatings, coatings, etc., can solve the problems of decreased adhesion, decreased reflectivity, and low salt spray resistance, and achieves excellent salt spray resistance. The effect of increasing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

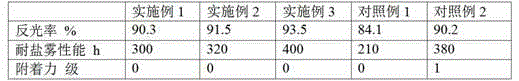

Examples

Embodiment 1

[0025] The preparation method of the water-based reflective paint used on the solar mirror, the steps are as follows:

[0026] Step 1: Add 20g of n-butyl titanate and 10g of tetraethyl orthosilicate into 400g of water, then add 80g of ethanol and 10g of silver nitrate, stir evenly, raise the temperature to 40°C, add 40g of hydrochloric acid aqueous solution dropwise, and add 40g of hydrochloric acid aqueous solution The concentration is 5wt%. After the dropwise addition is completed, cool down to room temperature and age. The aging time is 48h to obtain the aged sol;

[0027] Step 2, sol, water-based alkyd resin 20g, glycerin 10g, sorbitol 5g, ethanol 30g, amyl nitrate 5g, pentaerythritol 5g, sodium borate 2g, thickener dipolyurea 2g, methylcellulose 5g, ten Take 5g of octaalkyldimethylbenzyl ammonium chloride, stir evenly, and the stirring speed is 600 rpm.

[0028]

Embodiment 2

[0030] The preparation method of the water-based reflective paint used on the solar mirror, the steps are as follows:

[0031] Step 1: Add 30g of n-butyl titanate and 20g of tetraethyl orthosilicate into 600g of water, then add 100g of ethanol and 30g of silver nitrate, stir evenly, raise the temperature to 60°C, add 70g of hydrochloric acid aqueous solution dropwise, and add 70g of hydrochloric acid aqueous solution The concentration is 15wt%. After the dropwise addition is completed, cool down to room temperature and age for 72 hours to obtain the aged sol;

[0032] Step 2, sol, water-based alkyd resin 30g, glycerin 20g, sorbitol 10g, ethanol 40g, amyl nitrate 10g, pentaerythritol 10g, sodium borate 4g, thickener dipolyurea 4g, methylcellulose 10g, ten 10g of octaalkyl dimethyl benzyl ammonium chloride, stir evenly, and the stirring speed is 800 rpm.

[0033]

Embodiment 3

[0035] The preparation method of the water-based reflective paint used on the solar mirror, the steps are as follows:

[0036] Step 1: Add 25g of n-butyl titanate and 15g of tetraethyl orthosilicate into 500g of water, then add 90g of ethanol and 20g of silver nitrate, stir evenly, raise the temperature to 50°C, add 60g of hydrochloric acid aqueous solution dropwise, and add 60g of hydrochloric acid aqueous solution The concentration is 10wt%. After the dropwise addition is completed, cool down to room temperature and age for 60 hours to obtain the aged sol;

[0037] Step 2, sol, water-based alkyd resin 25g, glycerin 15g, sorbitol 7g, ethanol 35g, amyl nitrate 7g, pentaerythritol 7g, sodium borate 3g, thickener dipolyurea 3g, methylcellulose 7g, ten Take 8g of octaalkyldimethylbenzyl ammonium chloride, stir evenly, and the stirring speed is 700 rpm.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com