Purified diesel and its preparation process

A preparation process, diesel technology, applied in the petroleum industry, water treatment and refining, liquid carbon-containing fuels, etc., can solve problems such as unsatisfactory, insufficient stability, lack of versatility, and inability to completely change the appearance, and meet the safety market demand. The effect of potential, strong competitiveness and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

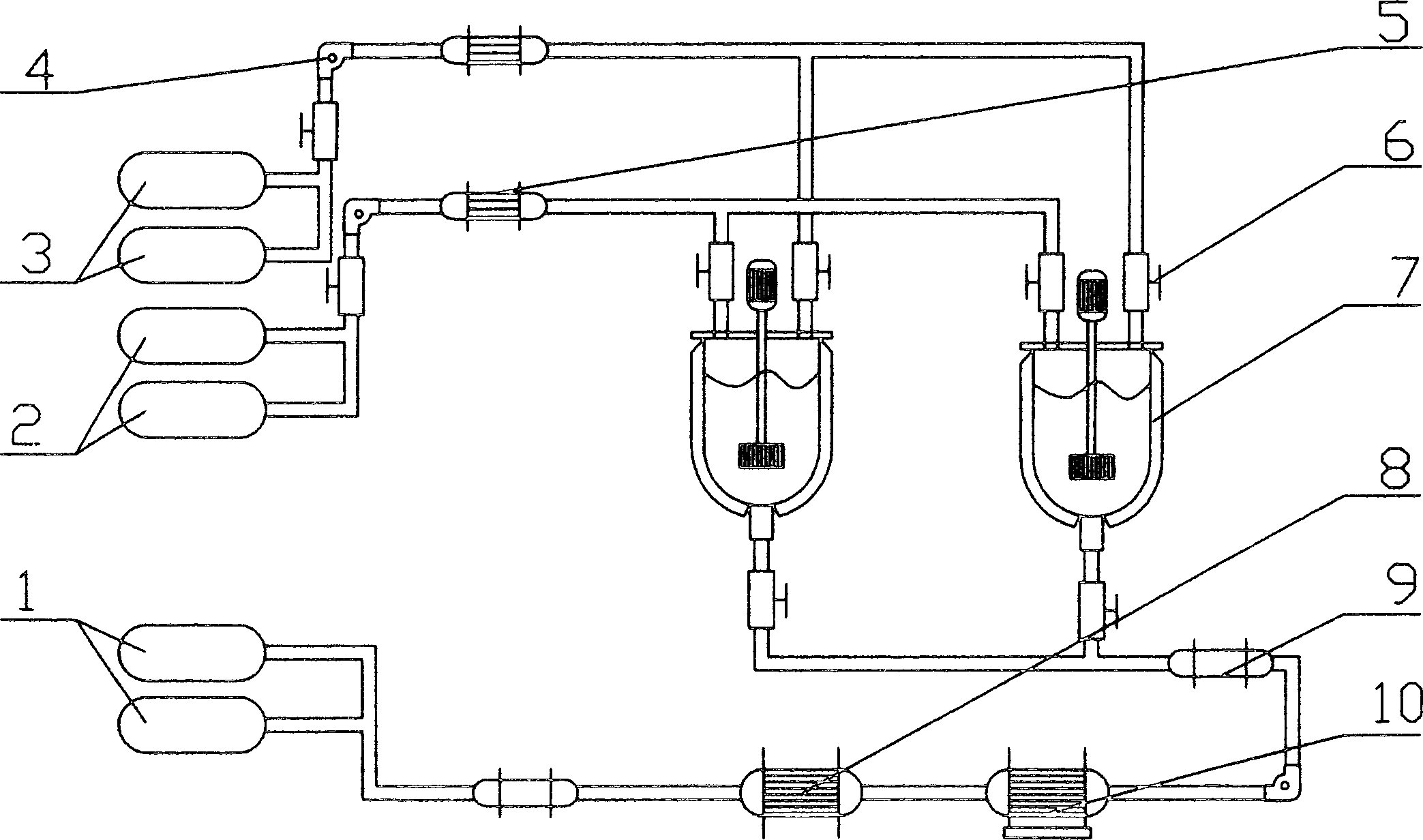

Image

Examples

Embodiment 1

[0036] Embodiment 1: be made up of the raw material of following parts by weight: 60 parts of No. zero diesel oils, 20 parts of water, 20 parts of composite additives;

[0037] The composite additive is composed of the following components by weight: 5 parts of amyl nitrate, 0.3 parts of olefin, 5 parts of demulsifier, 0.3 part of tetraethyl lead, 15 parts of extreme pressure saponified oil, 5 parts of Italian red oil, heavy diesel oil 45 parts, 15 parts of engine oil, 15 parts of white mineral oil, 6 parts of naphthenes, 0.3 parts of methyl naphthalene, 0.3 parts of aromatic hydrocarbons, 0.6 parts of acetone, 0.7 parts of methyl (base) ethyl (base methyl) ketone, 0.3 parts of methylamine, 0.5 parts of methyl isopropyl ketone, 5 parts of acetyl chloride, 5 parts of industrial alcohol, 5 parts of carbon amine, 0.9 parts of urea, and 0.3 parts of baking powder.

[0038]The preparation process is as follows: the preparation of the purified diesel oil is carried out in raw materi...

Embodiment 2

[0064] Embodiment 2: be made up of the raw material of following parts by weight: 60 parts of No. zero diesel oils, 20 parts of water, 20 parts of composite additives;

[0065] The composite additive is composed of the following components in parts by weight: 5 parts of amyl nitrate, 0.3 parts of olefin, 5 parts of demulsifier, 0.3 part of tetraethyl lead, 15 parts of extreme pressure saponified oil, and 5 parts of Italian red oil.

[0066] The preparation process is the same as in Example 1, and its effect can also meet the requirements of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com