Methyl diesel

A technology of methyl diesel and diesel, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem that the storage temperature cannot reach below -10°C, achieve simple blending process, save oil resources, and reduce production costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

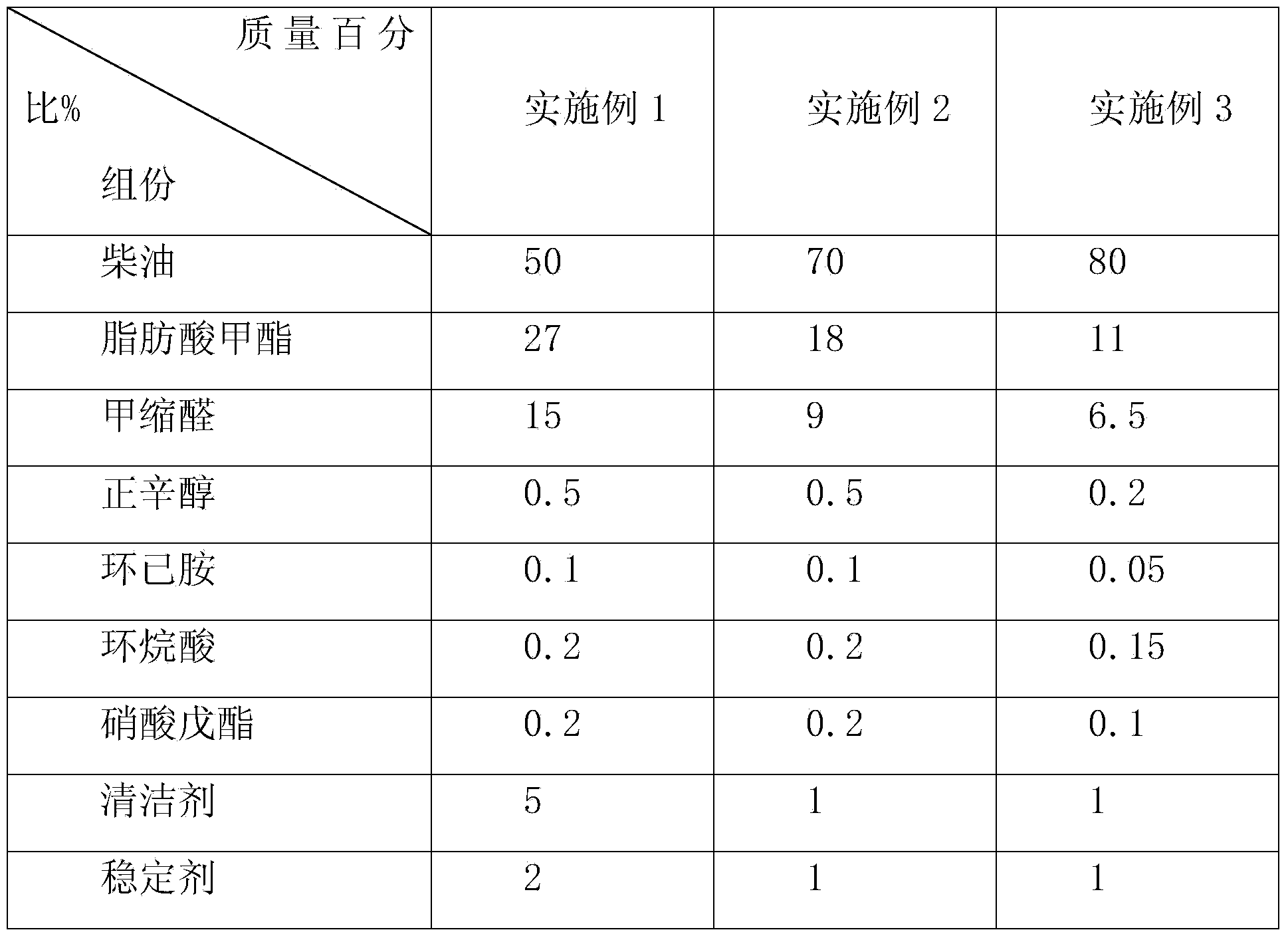

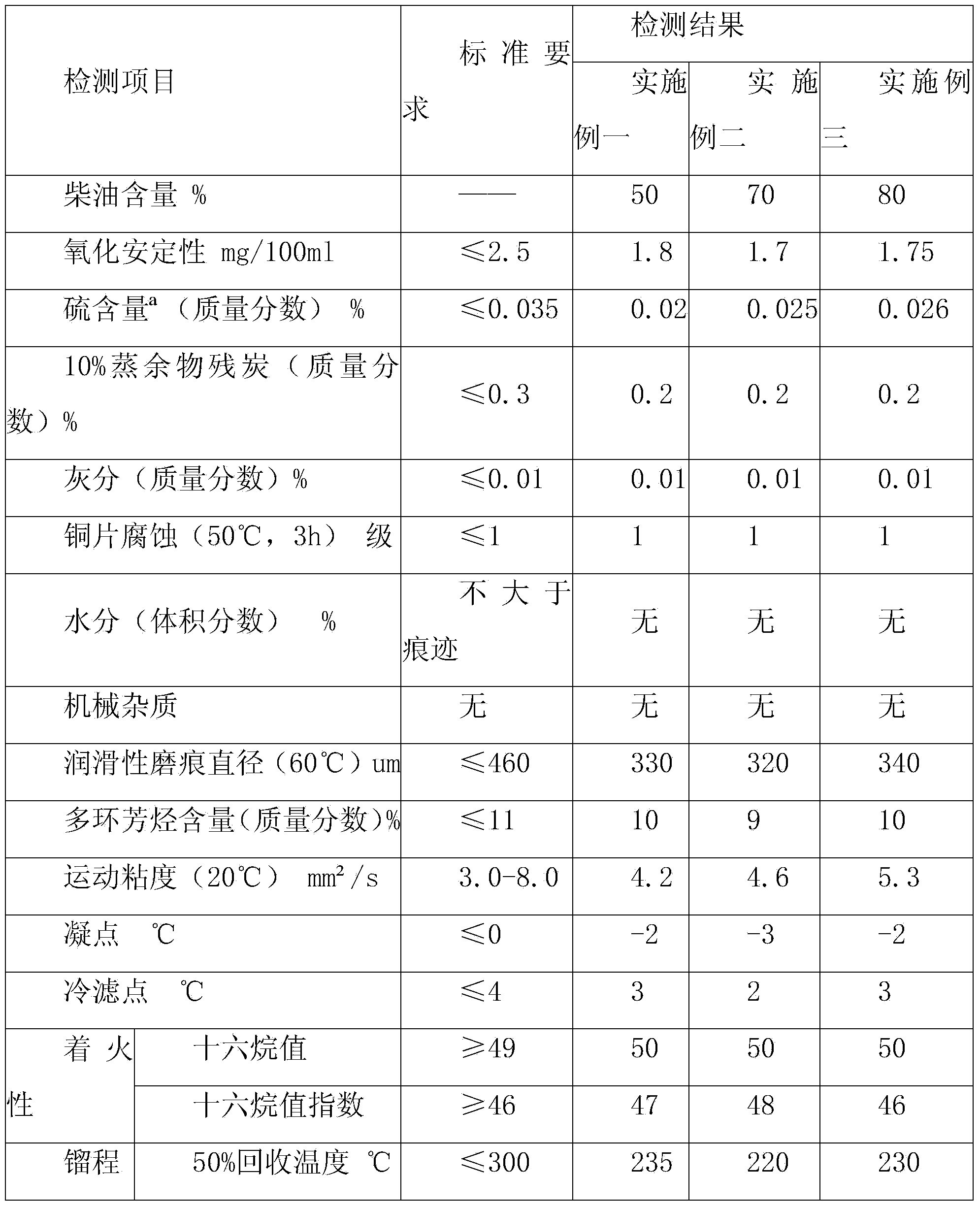

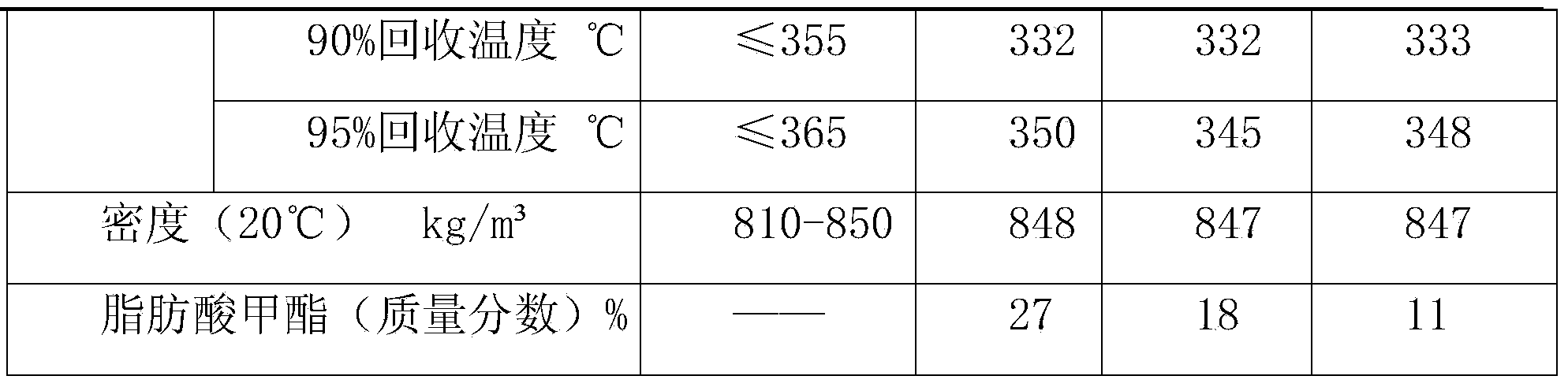

[0015] A methyl diesel oil, comprising the following components in mass percentage: diesel oil 50-80%, fatty acid methyl ester 11-27%, methylal 6-15%, n-octanol 0.2-0.6%, cyclohexylamine 0.05-0.2% %, naphthenic acid 0.1-0.3%, amyl nitrate 0.1-0.2%, detergent 0.8-5%, stabilizer 1-2%. Its diesel oil can choose national standard diesel oil and so on.

[0016] Further clarification with the following example:

[0017] The component situation of table 1 different embodiment methyl diesel oil

[0018]

[0019] The above components are circulated and stirred at normal temperature and pressure to obtain the methyl diesel oil described in the present invention. There are various ways of circulating and stirring, which will not be repeated here.

[0020] Wherein, the cleaning agent can be composed of dimethyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com