Process for making bio-diesel oil by using municipal sludge

A biodiesel, municipal sludge technology, applied in the petroleum industry, biofuels, sludge treatment and other directions, to achieve the effect of reducing investment in plant construction, reducing product costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

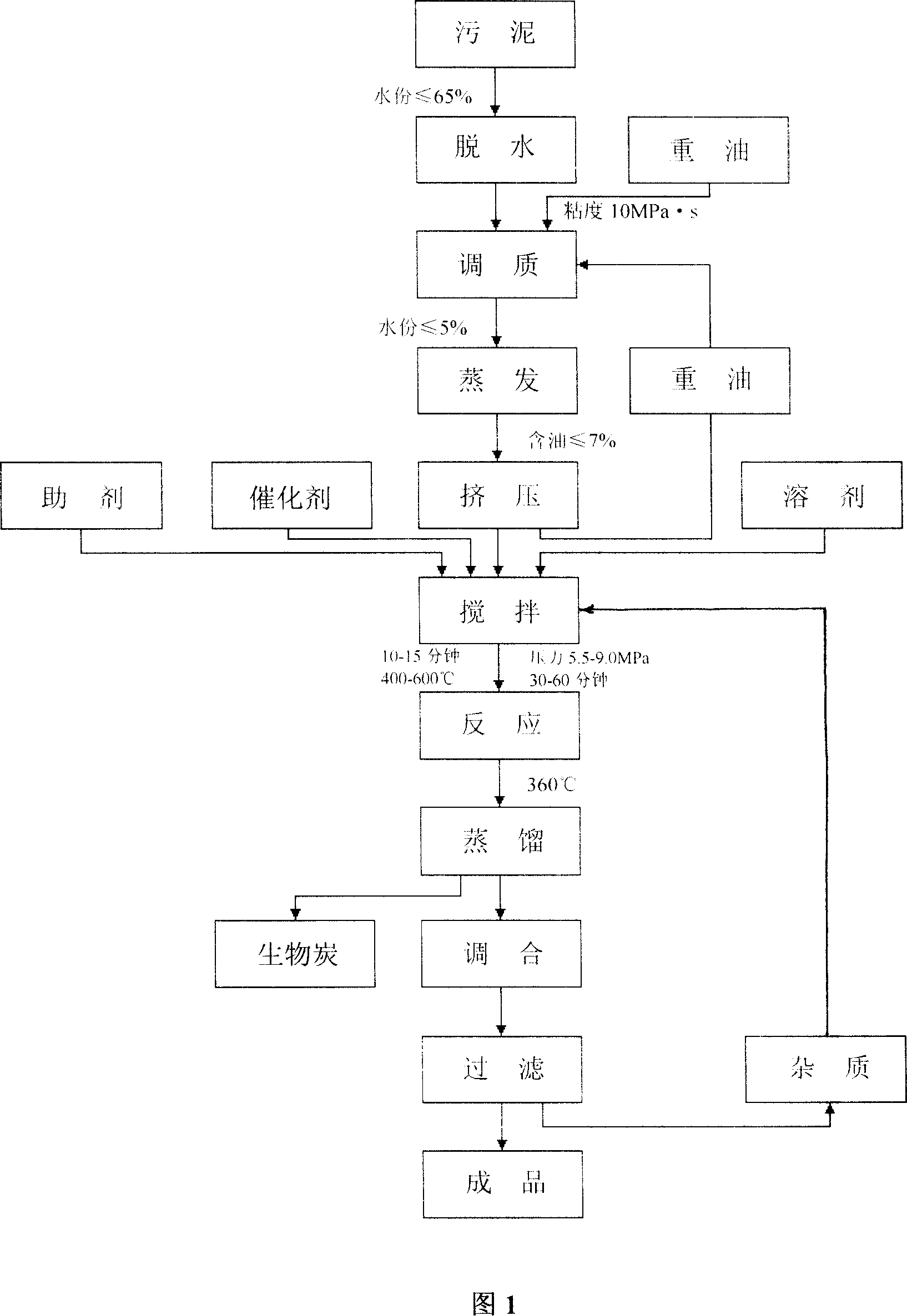

[0022] Biodiesel is produced from municipal sludge. The process of the present invention is composed of mechanical dehydration, tempering, evaporation, extrusion, stirring, reaction, distillation, blending, and filtration. The composition formula and its content (% by weight): sludge 70.5-56.5, solvent 20.0-40.0, additives 8.5-2.5, catalyst 1.0; the raw material is urban trench bottom sludge, or domestic sewage sedimentation sludge; solvents are rapeseed oil, kitchen waste oil, soybean oil, peanut oil, castor oil, corn oil, a Or mixed oil can be used; the auxiliary agent is methanol or cetyl alcohol; the catalyst is aluminum trichloride.

[0023] The process method is to pretreat the sludge at the bottom of urban road ditches, firstly through mechanical dehydration, so that the water content of the sludge is ≤ 65%, and then transfer to the sludge conditioning process, and add heavy oil with a viscosity of 10MPa·s, weight It is 6 times that of sludge, fully stirred evenly, and...

Embodiment 2

[0029] Biodiesel is produced from sludge. Raw material formula provided by the present invention and content (weight %) ratio thereof:

[0030] Sludge 63.5, solvent soybean oil (or kitchen waste oil) 30.0, additive cetyl alcohol 5.5, catalyst 1.0.

[0031] Weighing various raw materials:

[0032] 635kg of sludge, 300kg of soybean oil (or kitchen waste oil), 55kg of cetyl alcohol, and 10kg of catalyst; according to the amount of sludge, heavy oil with a viscosity of 10MPa s is added in the conditioning process, 5080kg, which is 8 times that of sludge; various raw materials Enter the stirring process, after fully stirring for 15 minutes, transfer to the reaction process, heat to 450 ° C, the reaction pressure is 6.8 MPa, and the reaction time is 50 minutes; enter the blending process, according to the test results of the gas oil, when the blending agent amyl nitrate When 2kg is added, the proportion of the blending agent is 0.2%, and qualified biodiesel can also be produced; t...

Embodiment 3

[0034] According to formula of the present invention and content (weight %) ratio thereof:

[0035] Sludge 56.5, solvent 40.0, additive 2.5, catalyst 1.0.

[0036] Weigh various raw materials, sludge is 565kg, solvent is peanut oil or castor oil 400kg, auxiliary agent is methanol 2.5kg, catalyst aluminum trichloride is 10kg; sludge is roadside ditch sludge. Sludge weight, add 7 times heavy oil 3920kg; Put the pretreated sludge and various raw materials into the mixer and stir for 14 minutes, then transfer to the reaction process, the reaction temperature is 500 ° C, the pressure is 6.5 MPa, and the time is 45 minutes; The detection and analysis result of the test, add blending agent pentyl nitrate 25kg altogether, account for 2.5% of gas oil; Other process conditions are all with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com