Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Less investment in building a factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

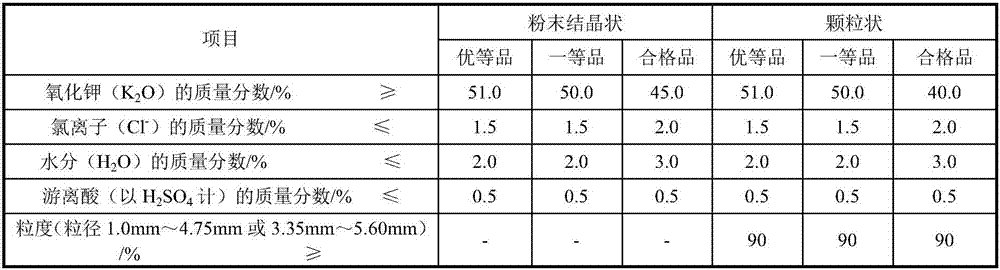

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

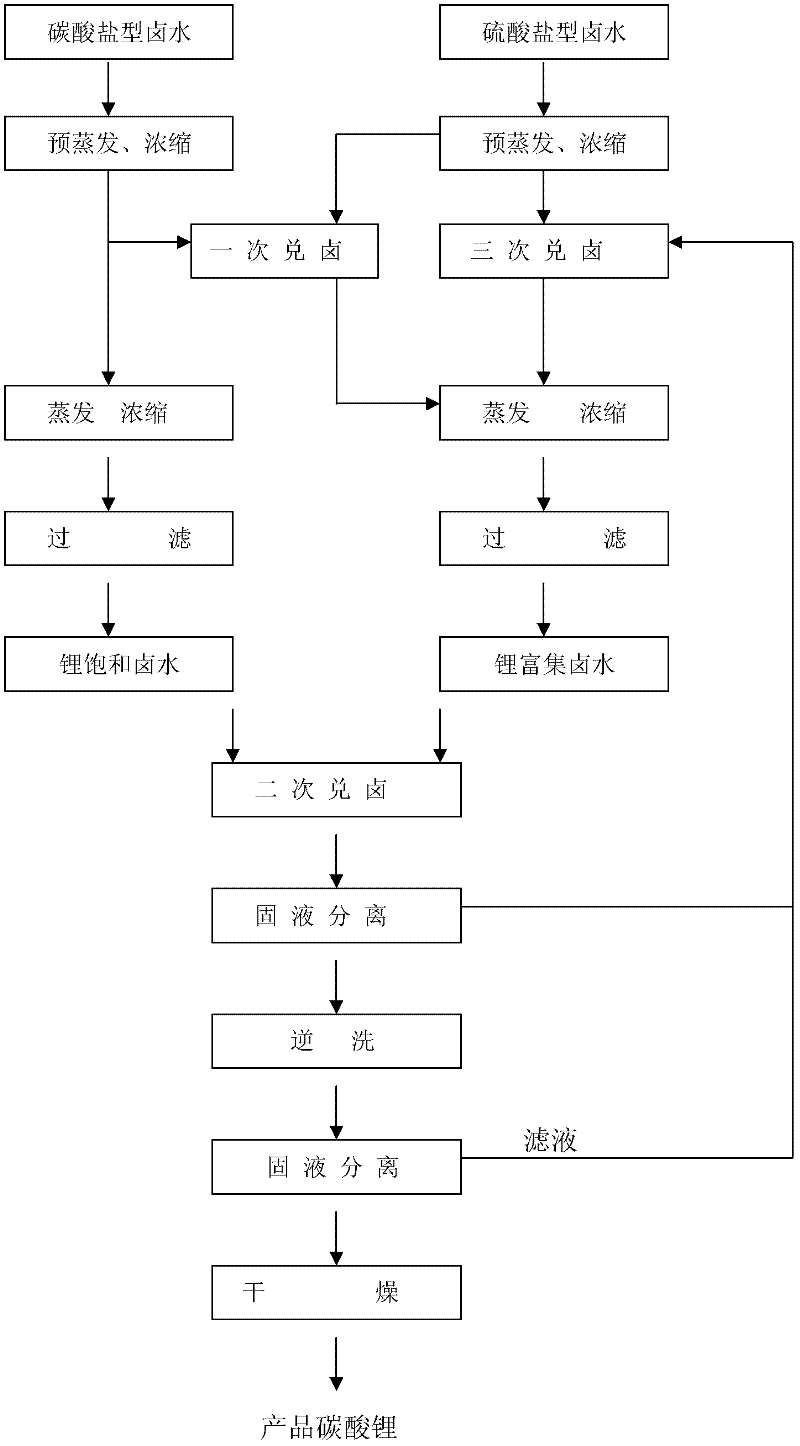

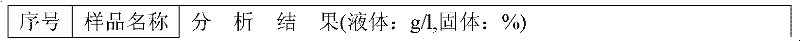

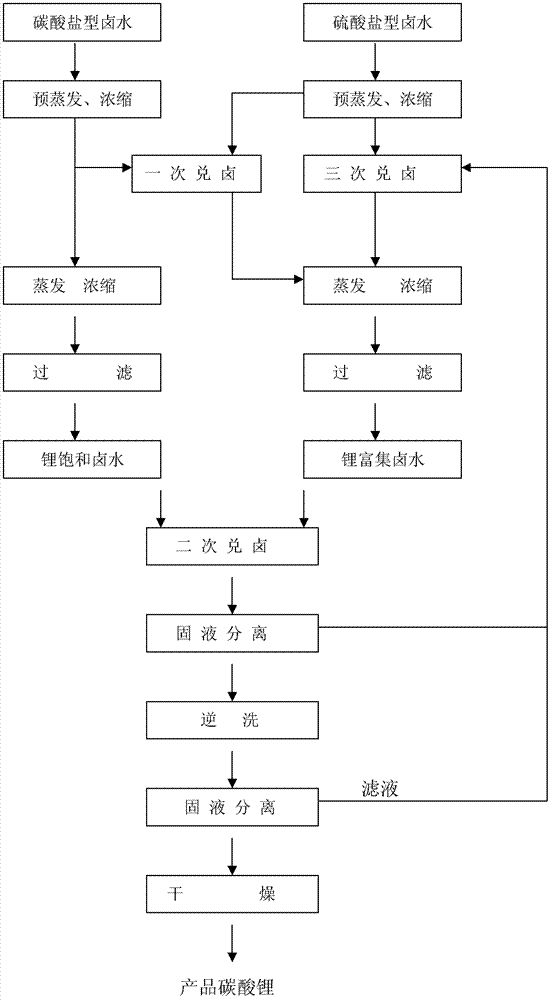

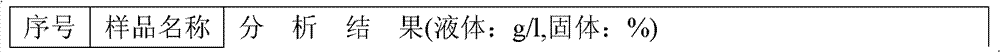

Producing method for preparing lithium carbonate by taking carbonate type brine and sulphate type brine as raw material and by repeatedly mixing brine

ActiveCN102491378AReduce investmentSimple processMagnesium carbonatesLithium carbonates/bicarbonatesElectricityLithium carbonate

The invention discloses a producing method for preparing lithium carbonate by taking carbonate type brine and sulphate type brine as raw material and by repeatedly mixing brine. Firstly carbonate type brine and sulphate type brine are mixed for performing the first brine mixing, so as to ensure that CO3<2-> ion and Mg<2+> ion in the mixed brine are completely reacted to produce basic magnesium carbonate, brine is evaporated and concentrated, and solid and liquid are separated, so that basic magnesium carbonate precipitate is removed, and lithium enrichment brine is obtained; and then the lithium enrichment brine and carbonate type brine, the lithium ion concentration of which is evaporated and concentrated to be saturated or nearly saturated, are mixed for performing second brine mixing, so that Li+ ion in the mixed brine produces lithium carbonate, solid and liquid are separated, lithium carbonate precipitate is removed, and the lithium carbonate precipitate is washed with hot water and dried, so that lithium carbonate products are obtained. Besides electricity, the method basically does not require foreign material, the investment is less, the technology is simple, the method can be applied to the mass production of lithium carbonate, the acquisition rate is high, the product quality meets the national standard, and the method is particularly suitable for the development of lithium resources of saline lake in Tibet.

Owner:陈兆华

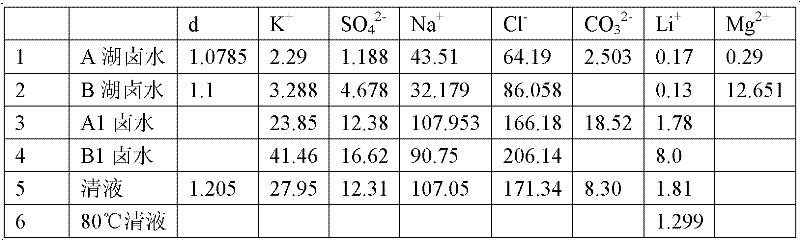

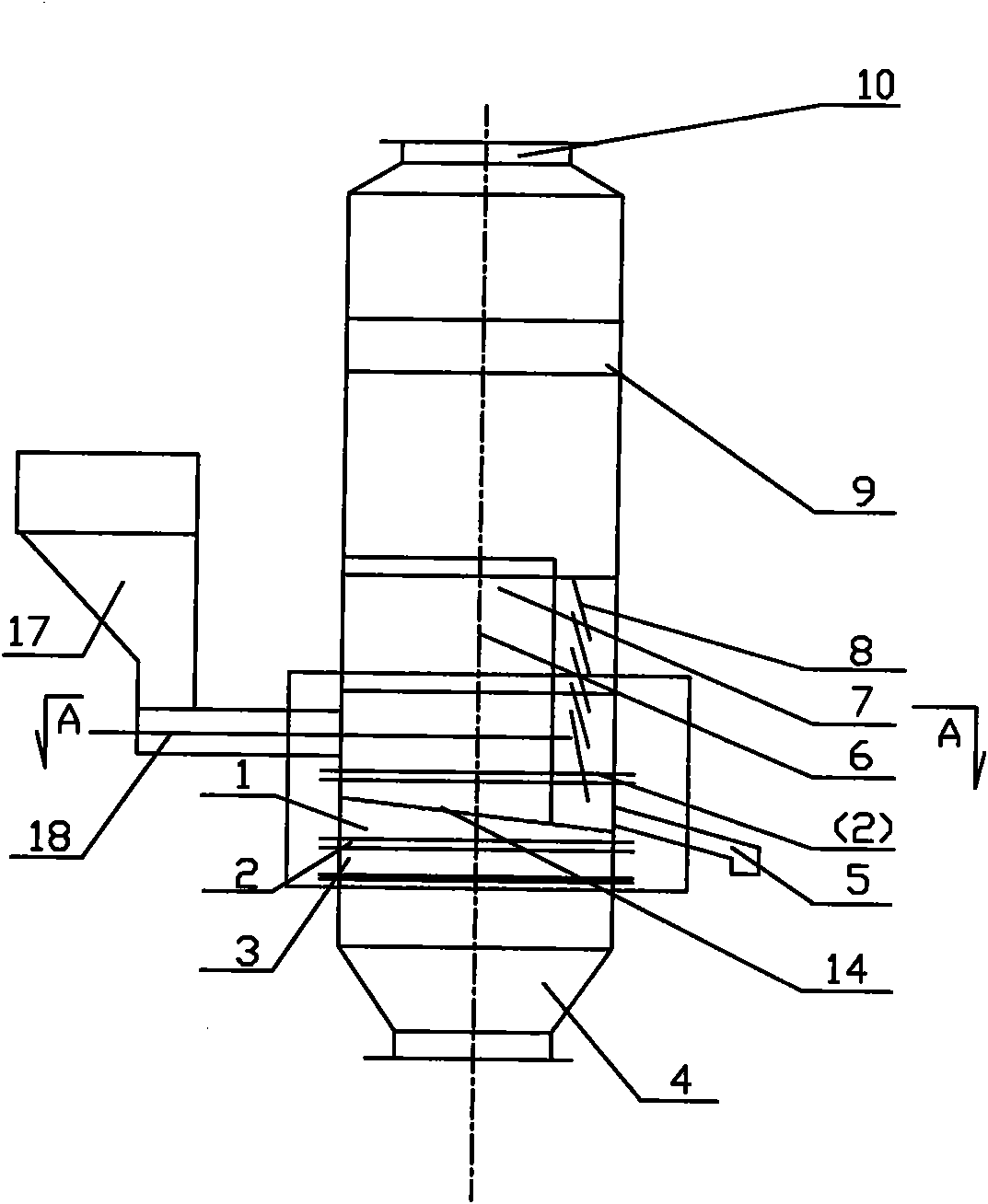

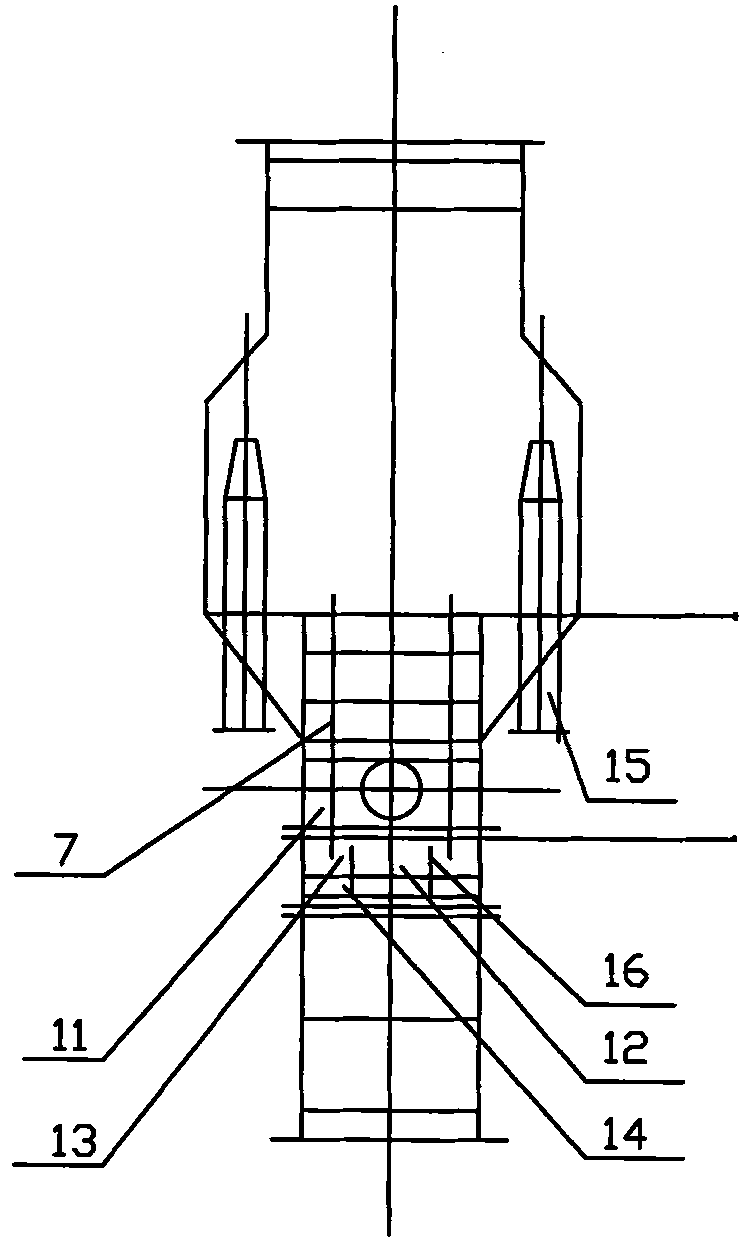

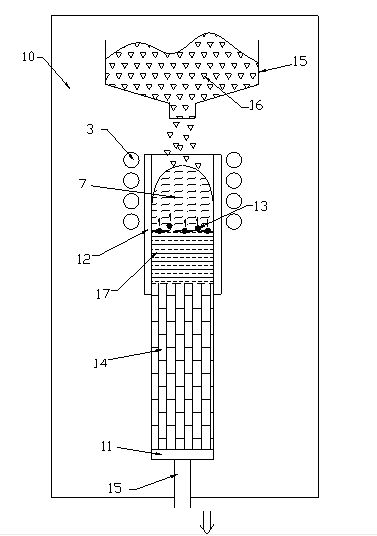

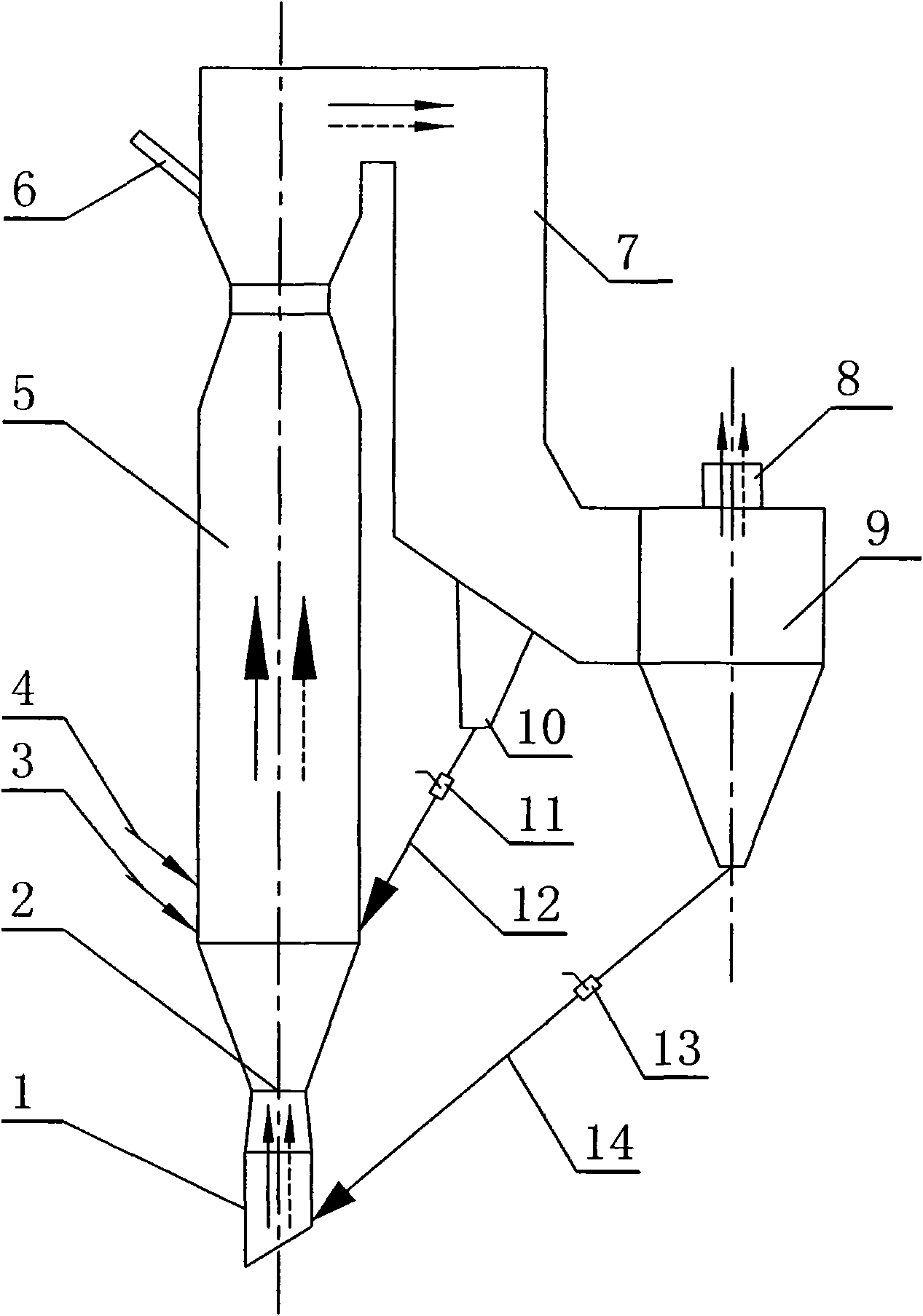

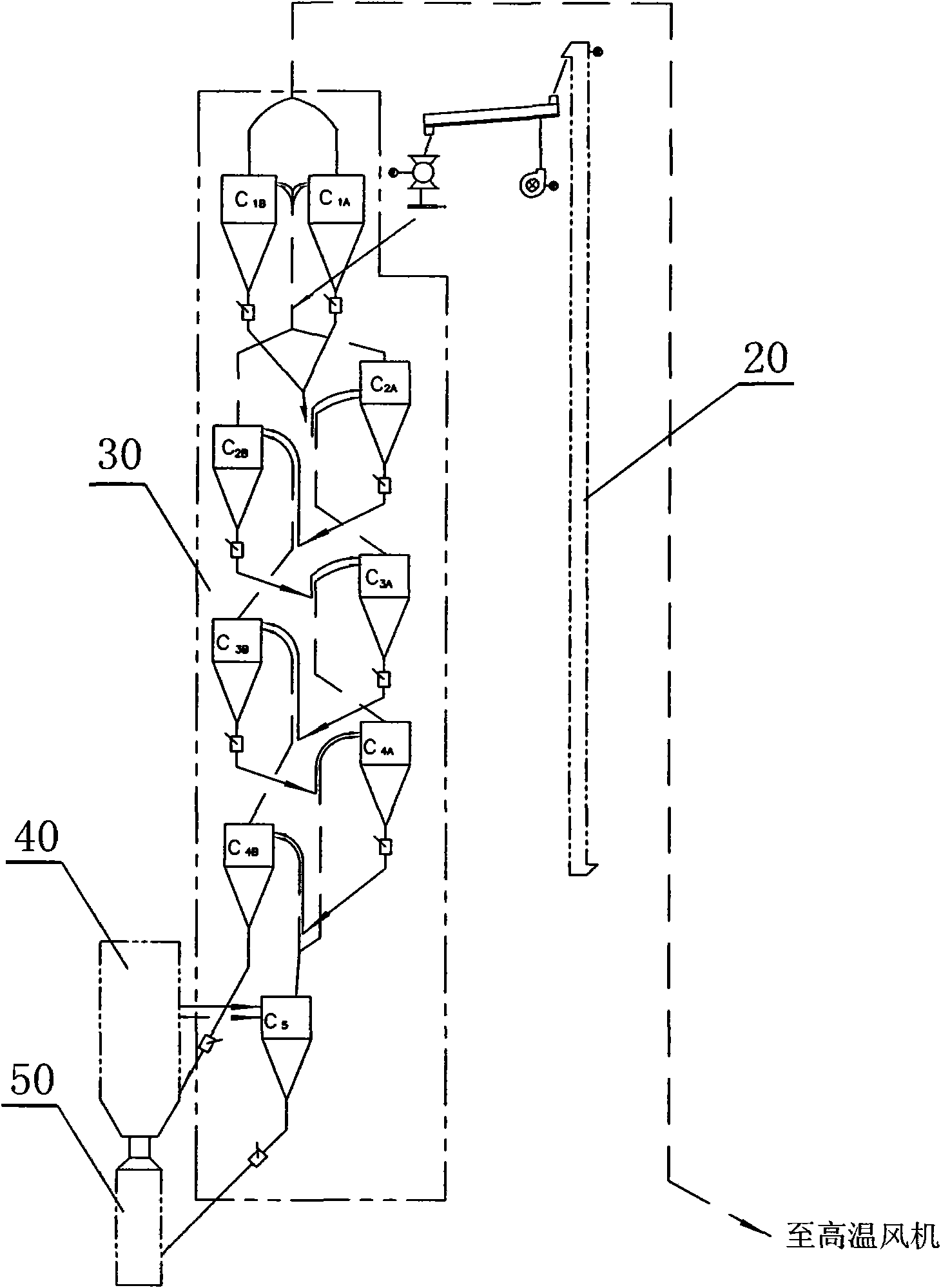

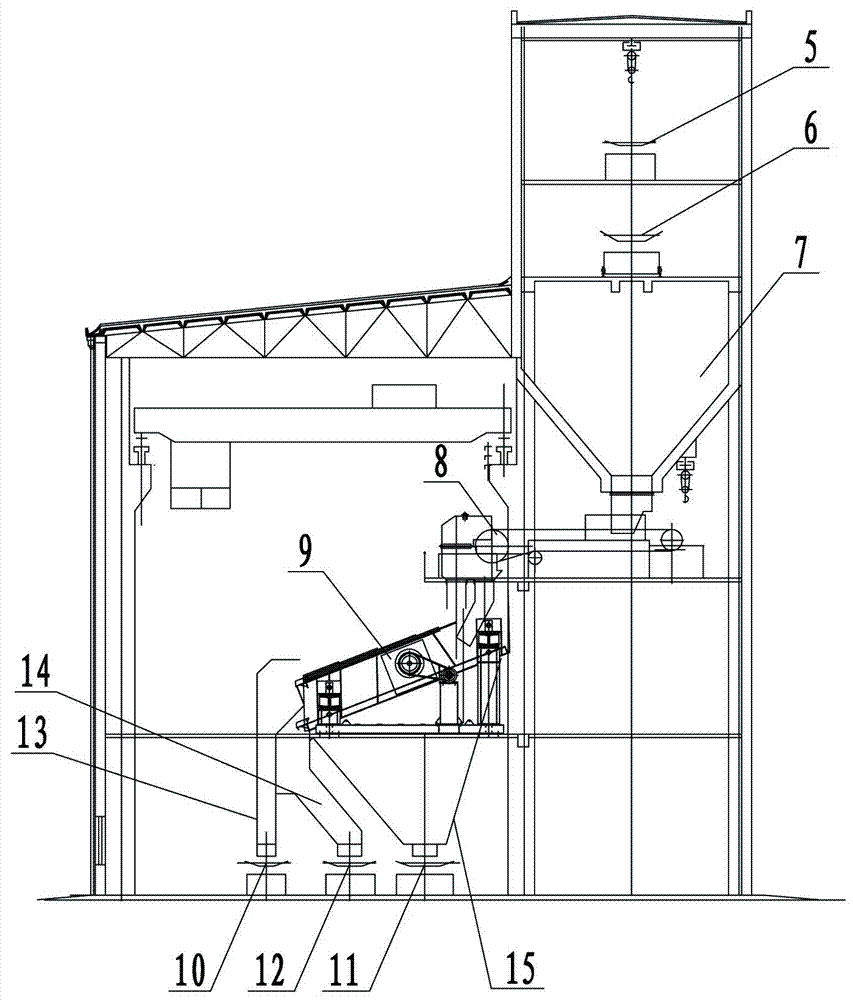

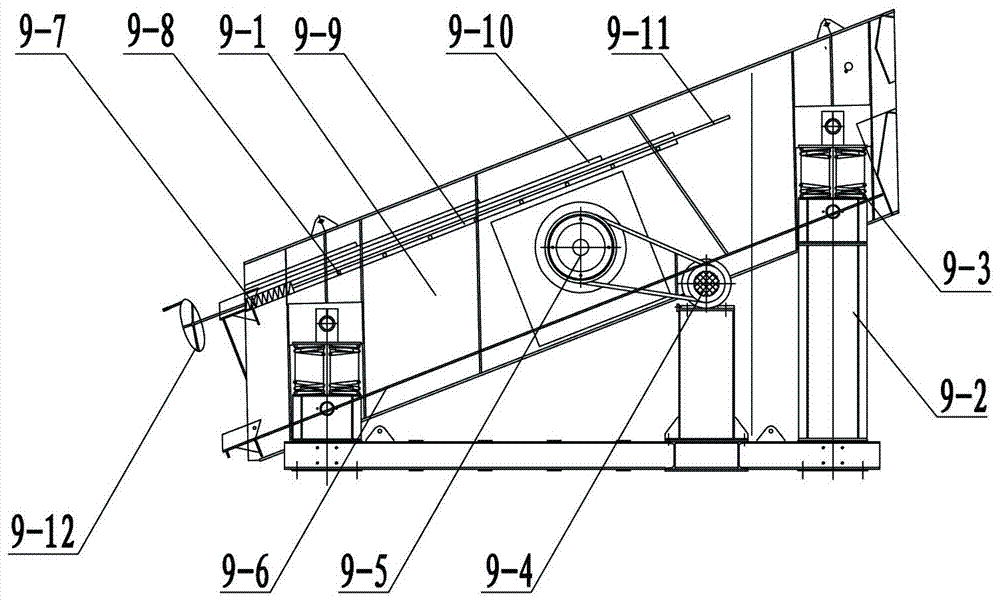

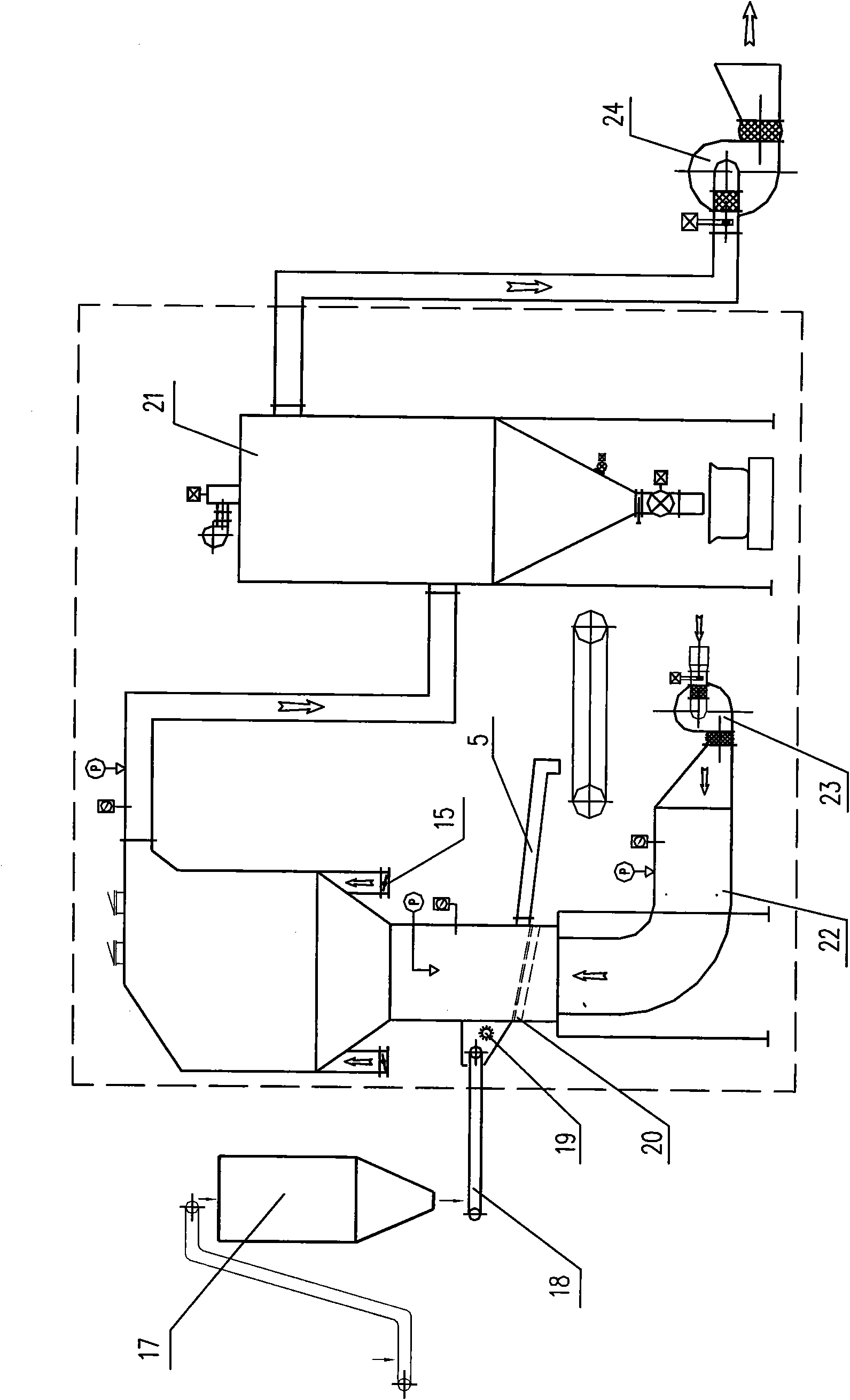

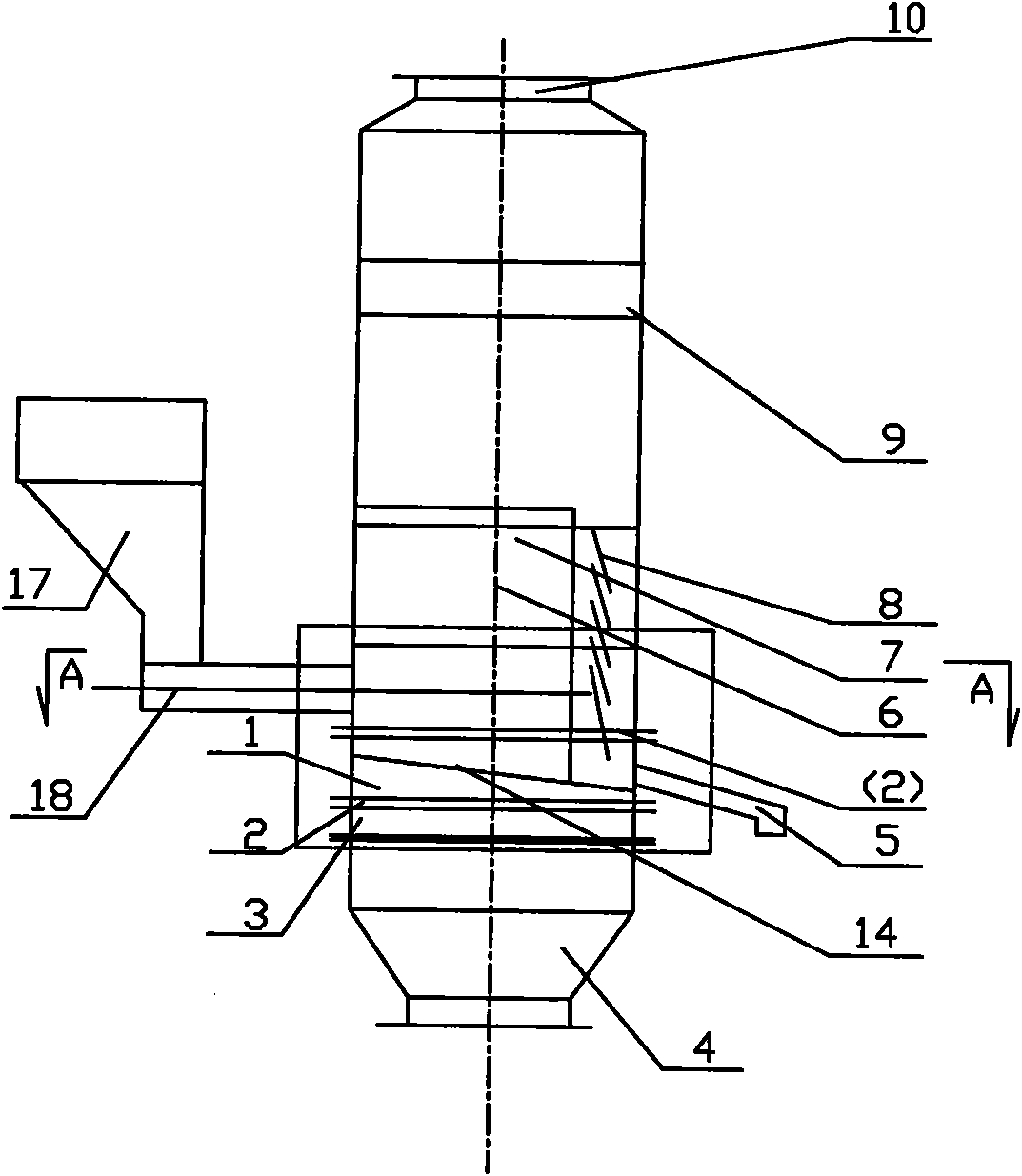

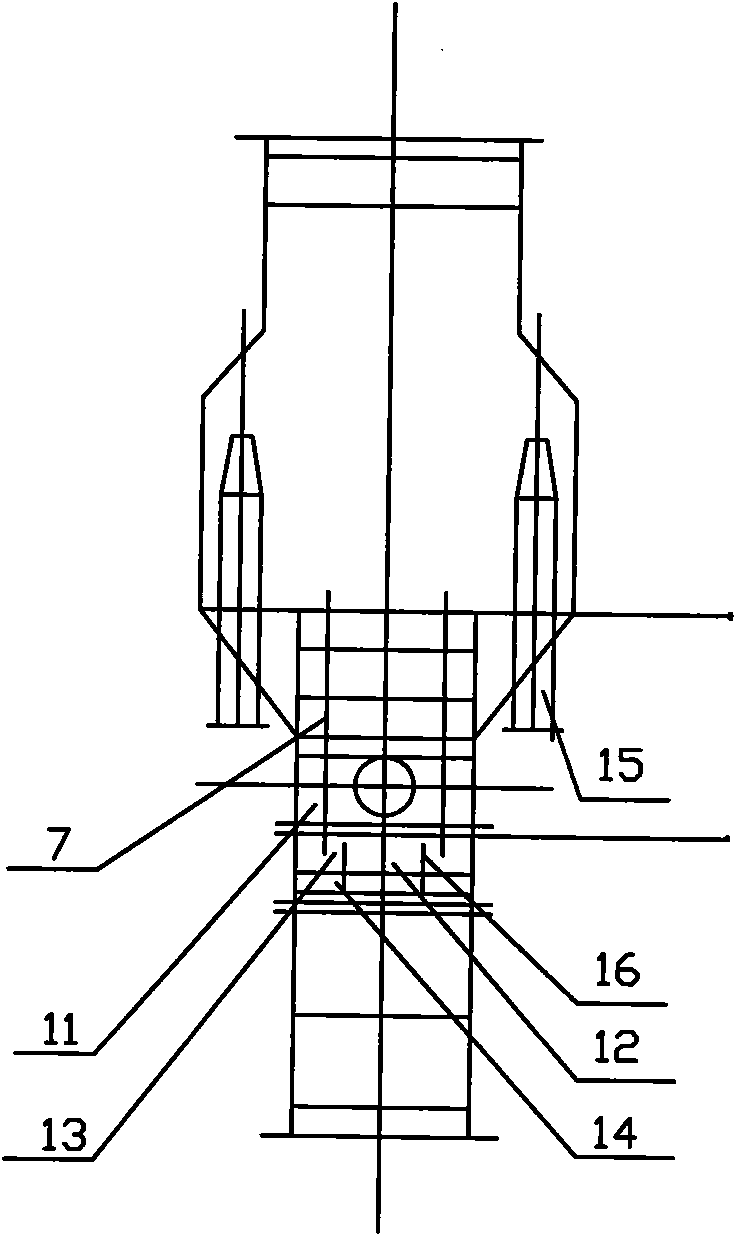

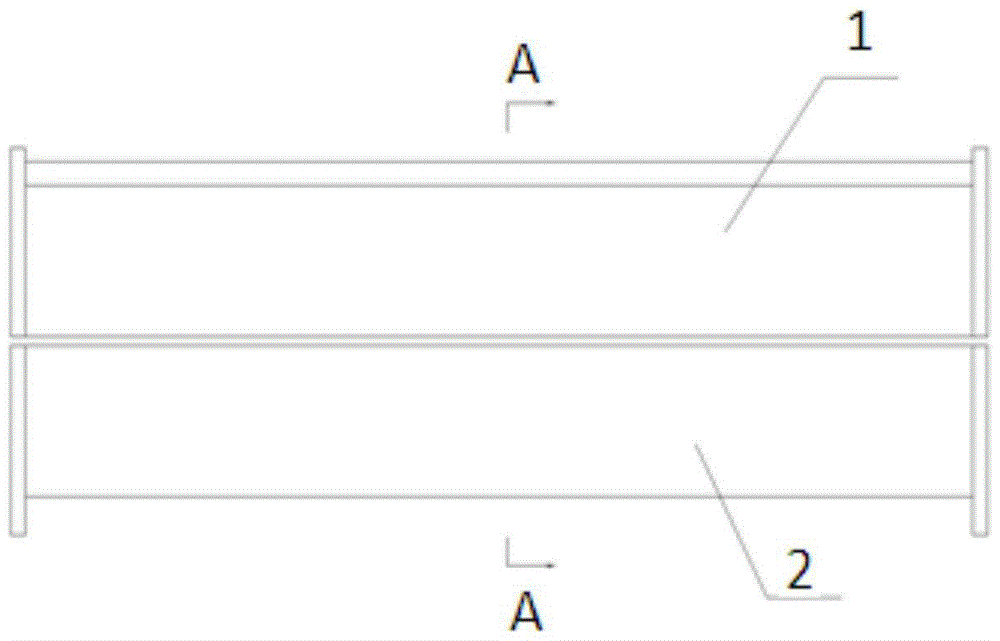

Airflow classifying and airflow drying process for coking coal

ActiveCN102019275ASave energyReduce pollutionDrying solid materials with heatGas current separationWastewaterProcess engineering

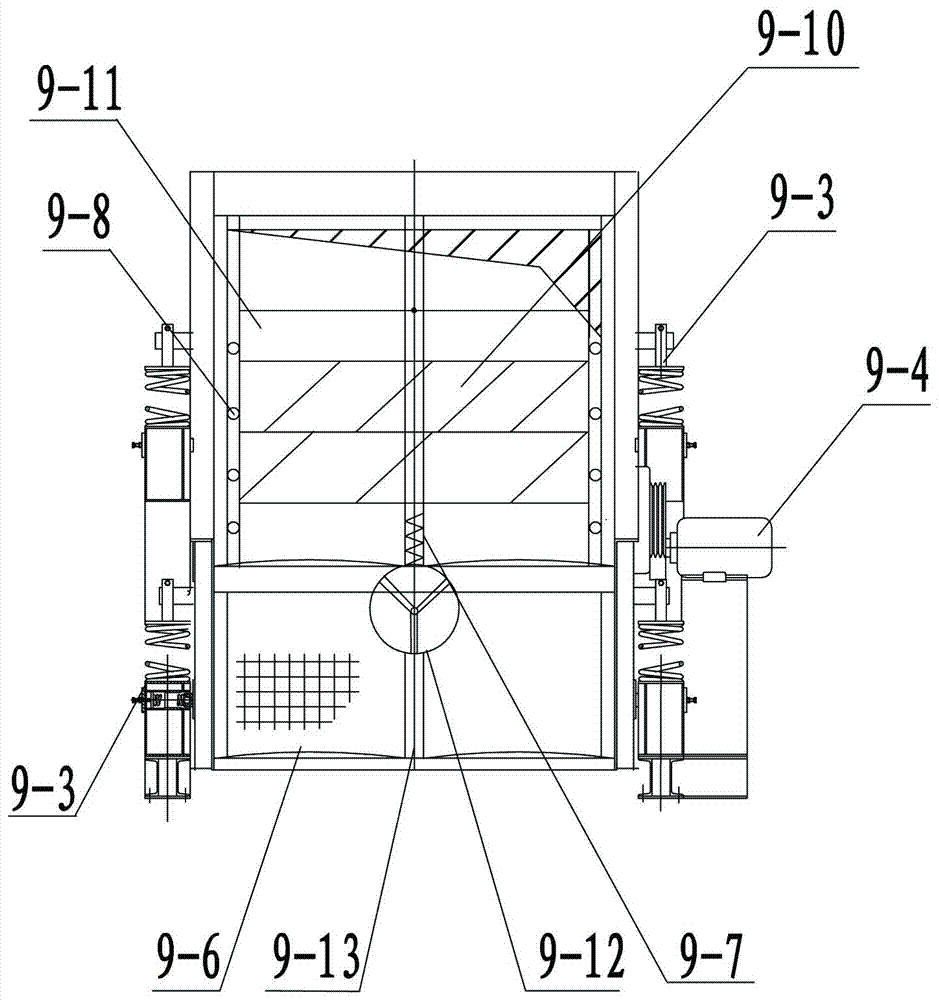

The invention relates to an airflow classifying and airflow drying process for coking coal. In the process, coke oven flue waste gas is taken as a drying medium, the fluidization technology is adopted for drying the coal, and simultaneously the coal is classified into several classes according to particle sizes by an airflow separation principle. A device consists of a vibrating fluidized bed main body and a classifying collection device, wherein the vibrating fluidized bed main body comprises a primary air supply device, a vibrating main box body with an air distributing plate, a sedimentation classifying section and a drying section with a secondary air inlet; and the classifying collection device completes the final collection of small-particle materials through a group of dust collection devices or several groups of duct collection devices with different structures according to different requirements of the process on the classification of the particle sizes. The airflow classifying and airflow drying process has the advantages that: energy is saved, the wastewater generated in the coking process is reduced, the environmental pollution is lightened and the production capacity of the coke oven can be improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

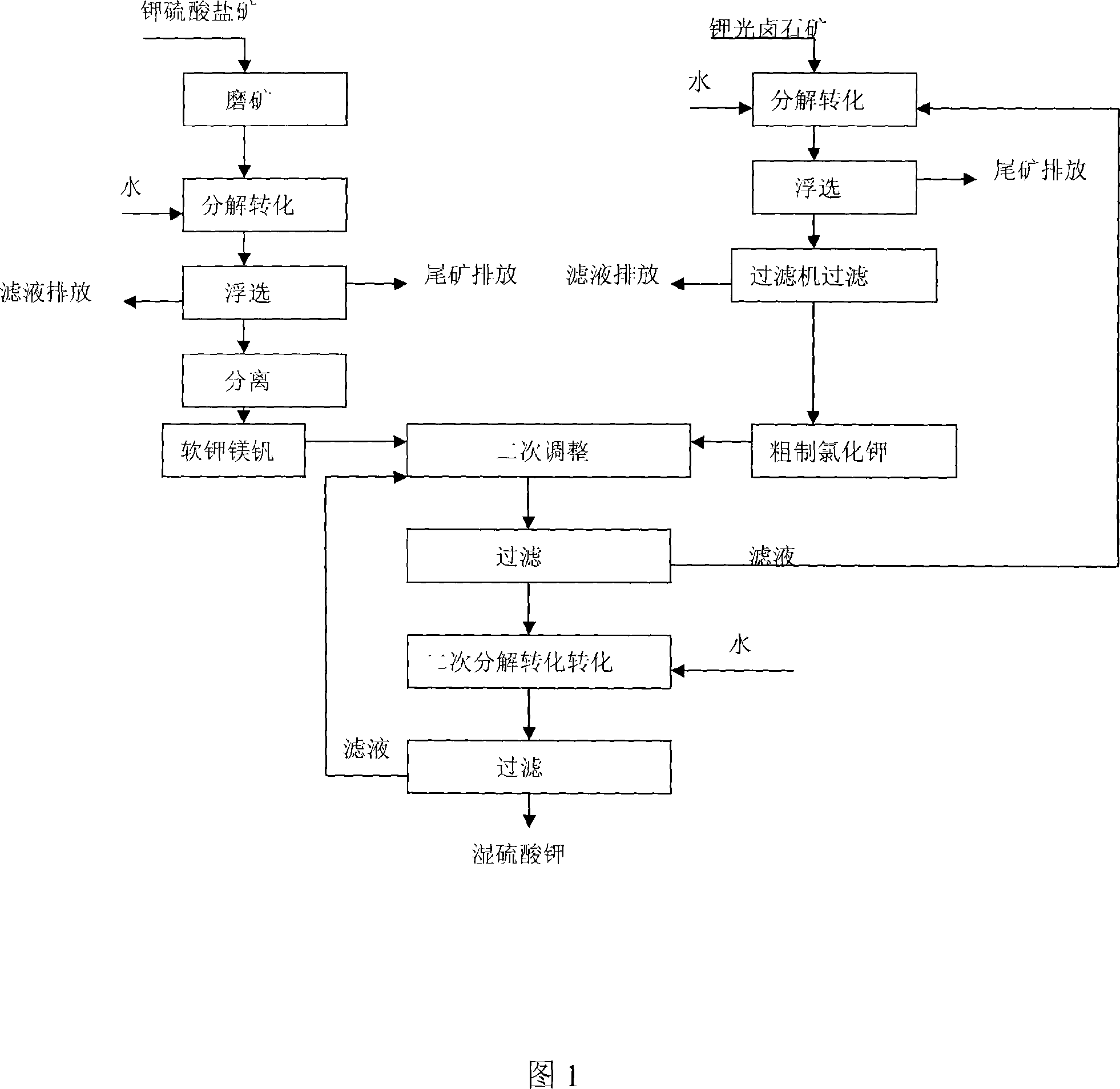

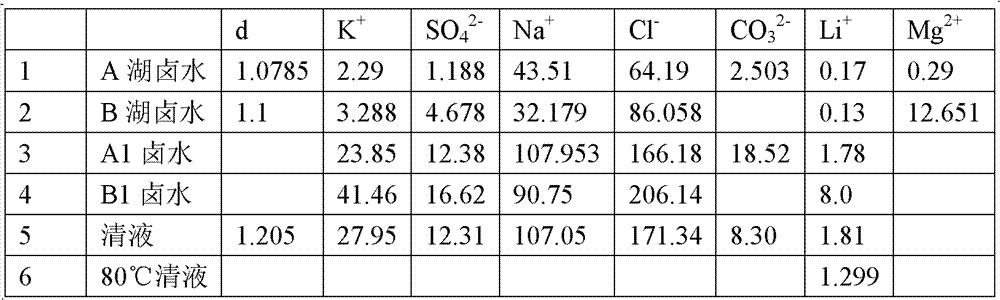

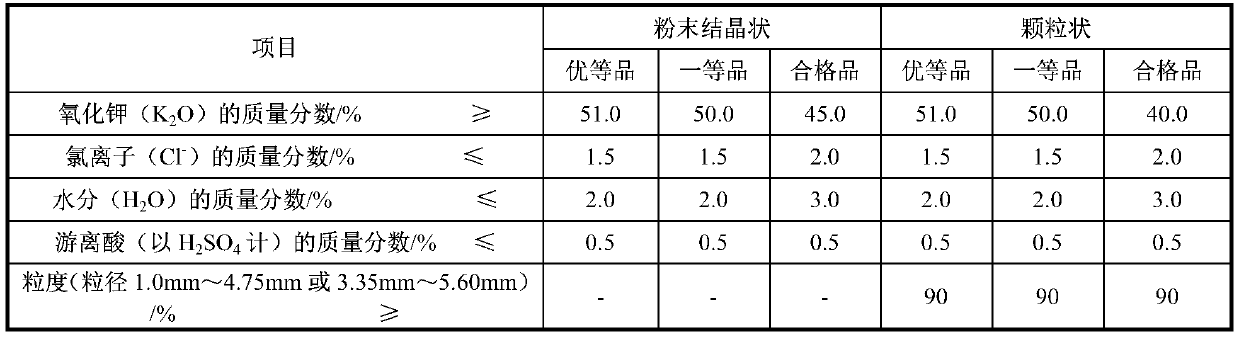

Process of preparing potassium sulfate with potassium containing bittern of magnesium sulfate subtype

The present invention provides process of preparing potassium sulfate with potassium containing subtype magnesium sulfate bittern. The process includes naturally evaporating potassium containing subtype magnesium sulfate bittern from salt lake to crystallize and separate out potassium containing sulfate and sulfate radical containing carnallite successively; grinding the potassium containing sulfate, decomposing to convert and floating to obtain picromerite; decomposing sulfate radical containing carnallite to convert and floating to obtain coarse potassium chloride; mixing picromerite, coarse potassium chloride and potassium sulfate mother liquid to obtain slurry, washing, filtering, decomposing to convert and filtering separation to obtain potassium sulfate. The present invention has low production cost, high yield and high product quality.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Technology for making lime-sand brick cured by steam

InactiveCN1381655ASimple production methodLow priceCeramic shaping apparatusBuilding componentsBrickSlag

A technology for producing the steam-cured lime-sand bricks uses the volcanic ash material or granular slags of blast furnace (8-15 wt. portions), calcium lime (6-10) and sand (75-85) as raw materials, and includes such steps as ball grinding the volcanic ash material or granular slags and calcium lime, mixing with sand and water, and steam curing at 80-100 deg.c and with relative humidity greater than 95% for 8-24 hr. Its advantages are low cost, saving energy and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Method for recovering NdFeB waste material by cold crucible induction smelting technology

ActiveCN102492848AAchieve purificationReduce consumptionIncreasing energy efficiencyCruciblePre treatment

A method for recovering an NdFeB waste material by a cold crucible induction smelting technology. The method comprises steps of: 1. a pre-treatment operation; 2. a crude purification operation; 3. a fine purification operation; and 4. a mixing remelting operation. The method for recovering an NdFeB waste material by a cold crucible induction smelting technology of the invention has simple process, no pollution, low cost and small investment.

Owner:SHENZHEN SUMMIT LEVITATION METALLURGICAL SCI & TECHN

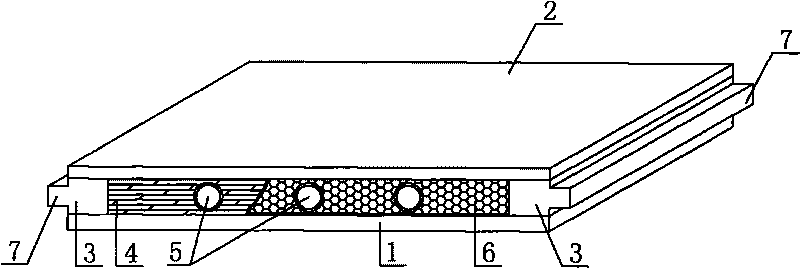

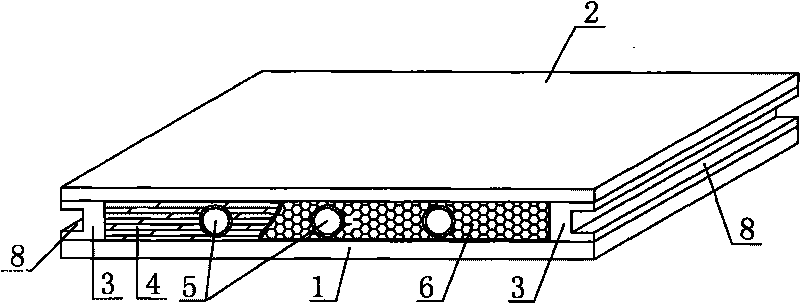

Heat accumulation and heat slow-release composite floor module

InactiveCN101713563ANo pollution in the processEvenly heatedCentral heating with accumulated heatLighting and heating apparatusSurface layerModular design

The invention discloses a heat accumulation and heat slow-release composite floor module, which comprises a heat insulation soleplate and a bamboo-based floor surface layer. Battens are arranged between the heat insulation soleplate and the bamboo-based floor surface layer and on the two sides of the module respectively and are provided with connecting structures for connecting with the adjacent modules; the two ends of the module are provided with an end plate positioned between the heat insulation soleplate and the bamboo-based floor surface layer respectively; a through circular bamboo tube is arranged between the heat insulation soleplate and the bamboo-based floor surface layer, and the two ends of the circular bamboo tube are arranged in corresponding circular holes of the two end plates respectively; and a phase-change heat accumulation material is also filled between the heat insulation soleplate and the bamboo-based floor surface layer. The heat accumulation and heat slow-release composite floor module can make use of hot air converted from solar energy and uniformly supply heat to a room, belongs to clear, environmentally-friendly, energy-saving and carbon-free technology, has the characteristics of little thermal loss, high thermal efficiency, convenient standardization, storage, transportation, mounting and use due to a modular design, simple production process and low factory building cost, and also can make full use of bamboo resources.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

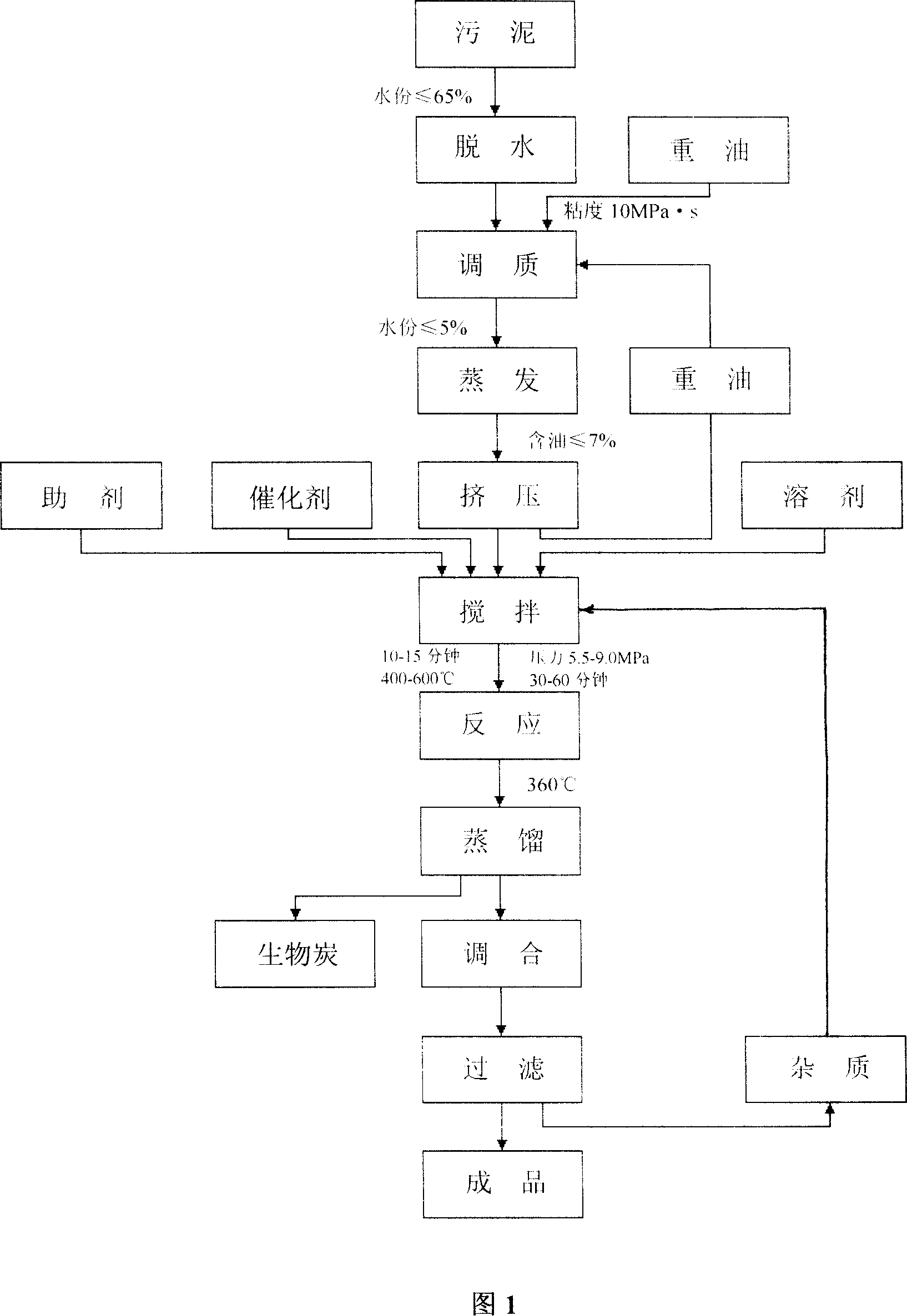

Process for making bio-diesel oil by using municipal sludge

The invention discloses a new technique of biological diesel through urban sludge in the energy domain, which comprises the following steps: allocating the component formula with 70.5-56.5% sludge, 20.0-40.0% solvent, 0.5-2.5% adjuvant and 1.0% catalyst; adopting urban sludge or living effluent mud as sludge; selecting the solvent form rape oil, soyabean oil, waste kitchen oil and arachis oil; setting carbinol as adjuvant and aluminium chloride as catalyst; stirring these materials completely for 10-15min; reacting under 400-600 Deg C at 5.5-9.0Mpa for 30-60min; heating to 360 Deg C to obtain the distillate oil (gas oil); transmitting to blending procedure; adding 0.2-1.0% amyl nitrate to generate the diesel.

Owner:任春山

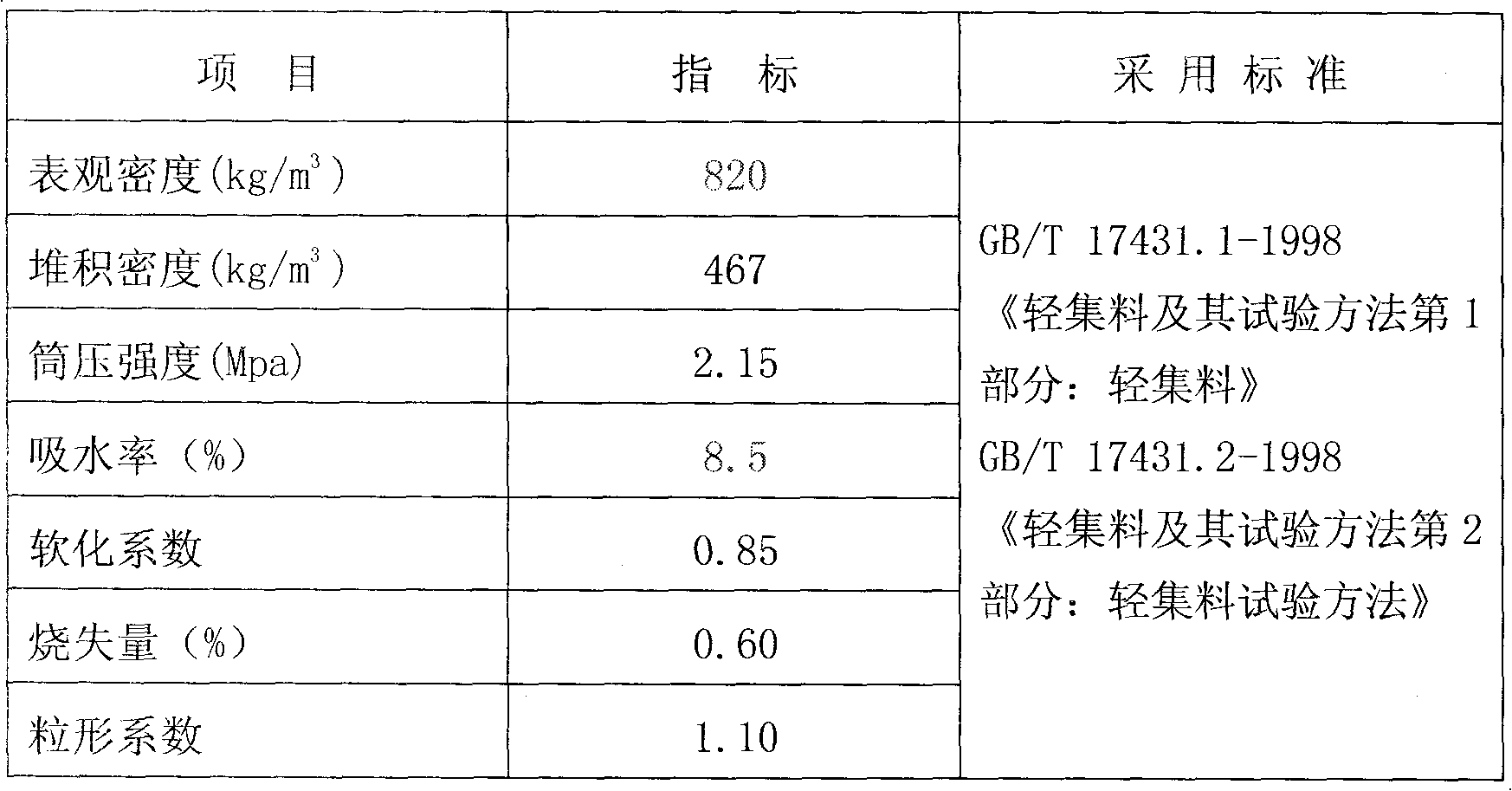

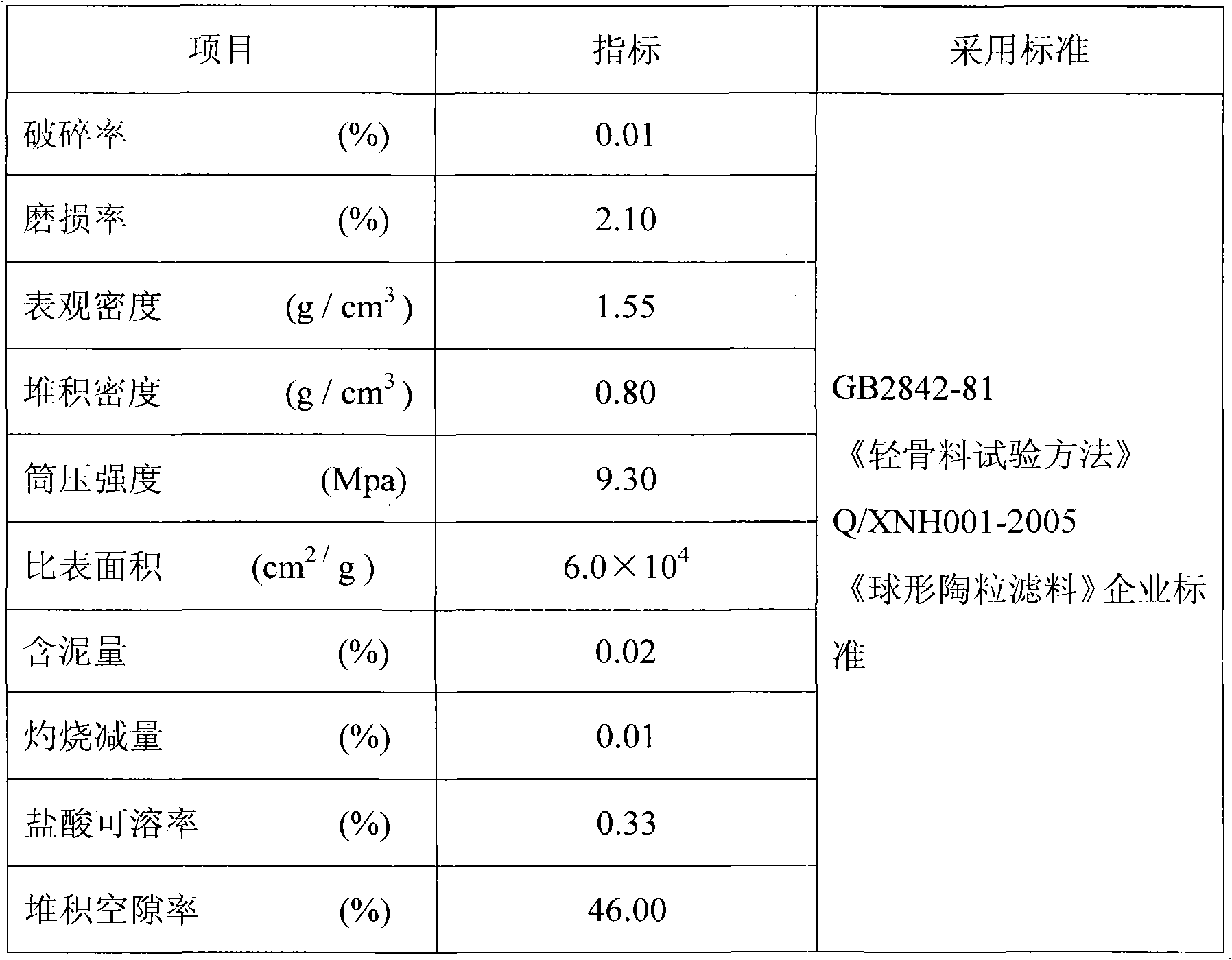

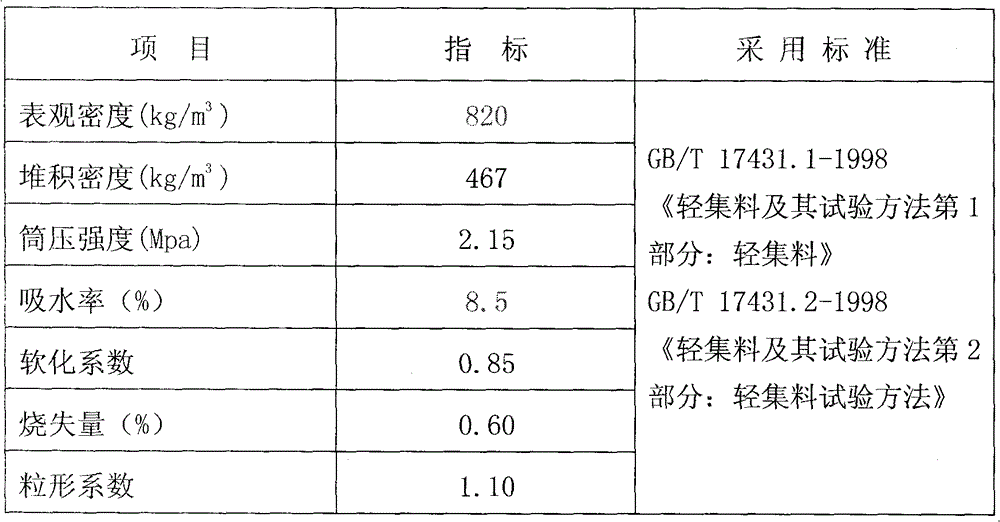

Method for preparing light building material ceramic particle by utilizing slate sawn mud

InactiveCN101851110ASimple production processReduce manufacturing costSolid waste disposalCeramicwareSodium silicateBuilding material

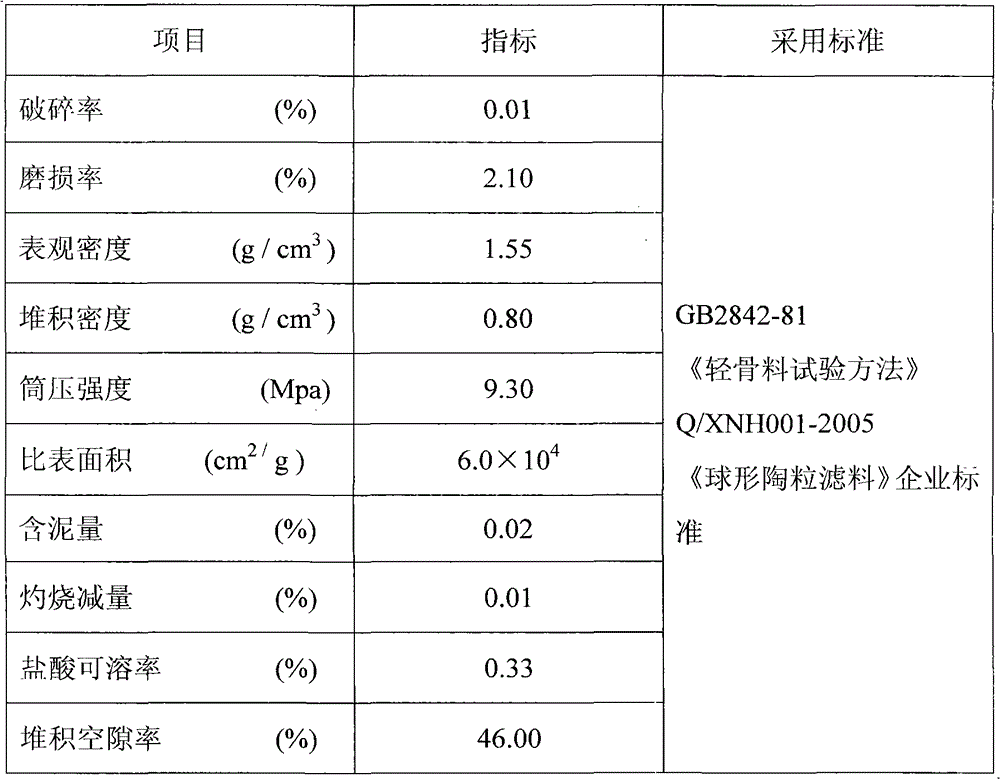

The invention relates to a method for preparing light building material ceramic particle by utilizing slate sawn mud. The product formula includes: 60-100% of slate sawn mud (containing 30% of moisture) and 0-40% of slate dry powder; and 1-2% of sodium silicate binder is additionally doped. The manufacturing processing step includes that the slate sawn mud is filtered until moisture is less than 30%, the slate sawn mud and powder material obtained by sieving crushed slate are pre-stirred into bulk particles in a dual spindle stirring machine, so as to form cue ball, when the moisture contained in the slate sawn mud is less than 15%, the slate sawn mud also can be independently stirred and broken into particles in the stirring machine, then the cue ball is fed into a ball forming mill to be sprayed with mist water, and a small amount of binder is added, so that the particle forms a spherical particle with the diameter Phi of 5-30mm by rolling, then the material ball is fed into a rotary kiln to be calcined, the calcining temperature is 1100-1200 DEG C, and calcining time is 25-40min, and the fiery material ball taken out from the kiln is cooled by adopting a monocular cooling machine. The method has simple production technology and low cost, and the prepared slate sawn mud ceramic particle has high tube pressure strength and wide application.

Owner:NANCHANG UNIV

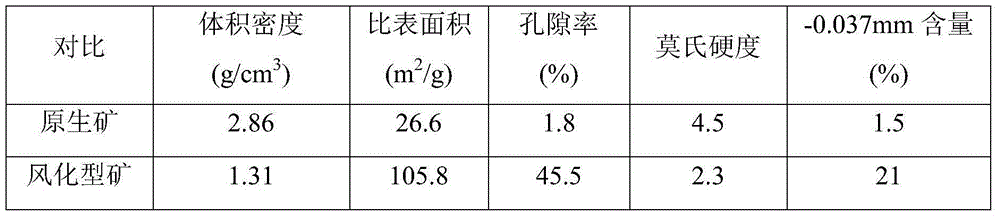

Weathering type stone coal vanadium ore beneficiation method

InactiveCN104941791ALess investment in building a factoryReduce processingWet separationPorosityResource utilization

The invention discloses a weathering type stone coal vanadium ore beneficiation method; a raw ore bulk density is 1-2g / cm cubic, a specific surface area is 80-110 m2 / g, a porosity factor is 45-50%, a Mohs hardness is 2-3, and the raw ore has more than 20% of 0.037mm fraction size. The grinding ore method comprises the following steps: screening the raw ore so as to obtain oversize products and undersize products, crushing the oversize products into granularity 15mm so as to be combined with the undersize products, and the screening particle fraction is 15mm; b, the combined ore material and grinding agent are added in a grinding machine, so granularity 0.074mm ore material can take 55-70wt% of the grinding ore after grinding; c, grading the grinded ore material so as to obtain coarse grain products and fine grain products, wherein the coarse grain products serve as tailings for direct discarding, and the fine grain products serve as vanadium concentrate. The weathering type stone coal vanadium ore beneficiation method improves resource utilization rate, and reduces beneficiation cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

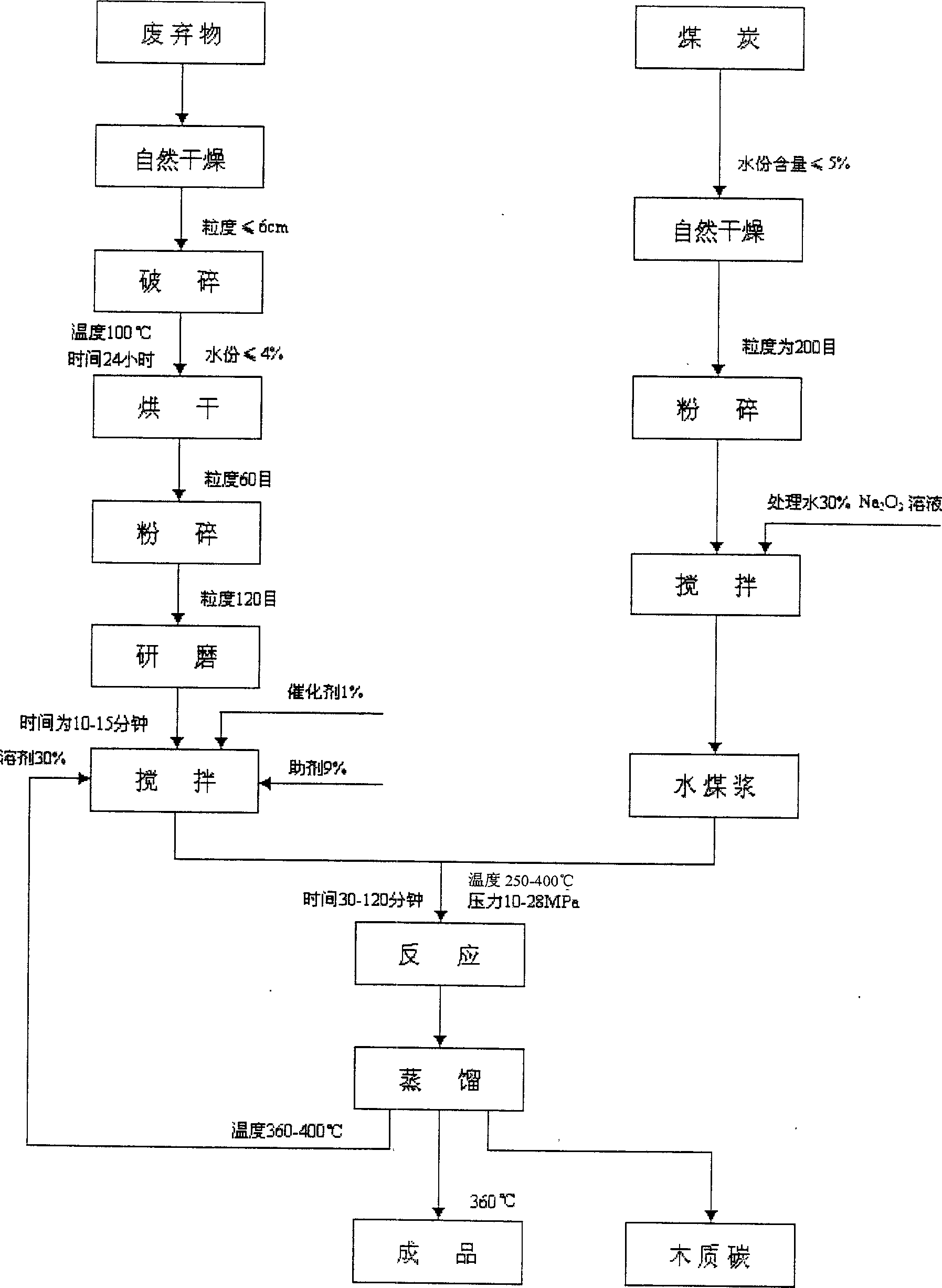

Process for producing diesel oil from wastes in agricultural and forest industries

InactiveCN1818024AEase the tense situationRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionForest industryBiodiesel

Production of biological diesel oil from agricultural and forest refuse is carried out by: drying, crushing, agitating, reacting and distilling. The biological diesel oil consists of agricultural and forest refuse 35-55wt%, solvent 30wt%, auxiliaries 9wt%, catalyst 1wt% and additive 5-25wt%. The raw materials include one or multiple kinds of agricultural and forest refuse, tree braches and leaves, straws and cottonseed shell etc; solvent is refined anthracene oil, auxiliaries is methanol, catalyst is aluminum chloride and additive is water coal slurry. It has good effect.

Owner:任春山

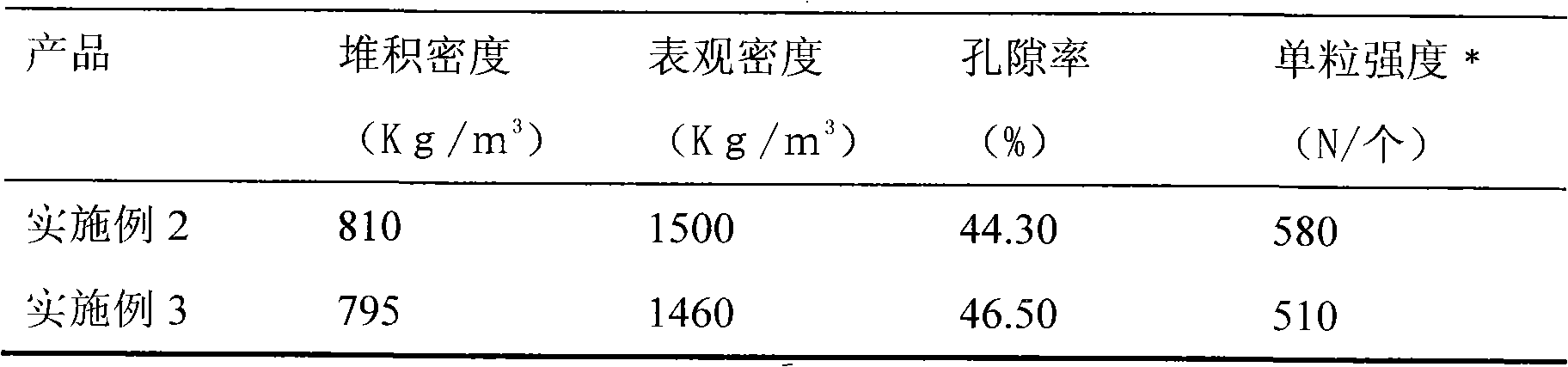

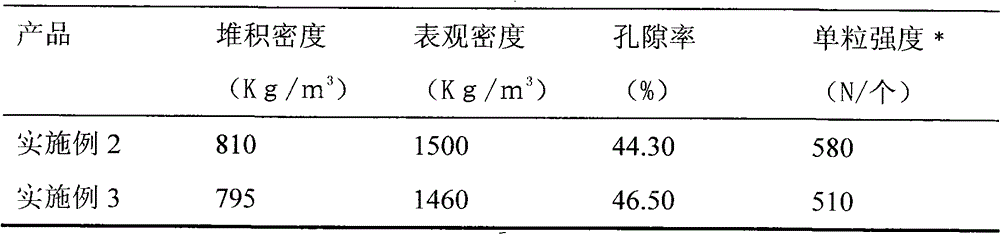

Method for preparing porous ceramsite filter material from slate saw mud

InactiveCN102068855AConducive to gas expansionSelf-inflatingFiltration separationDry basisFilter material

The invention discloses a method for preparing a porous ceramsite filter material from slate saw mud. According to a formula, a product prepared by the method comprises the following raw materials in percentage by mass: 60 to 80 percent of slate saw mud (a dry basis), 15 to 30 percent of dry slate powder and 5 to 10 percent of kieselguhr, wherein the raw materials are mixed and stirred into spherical particles, then calcined and cooled to obtain the product. The method has the advantages of simple process and low production cost, and has great significance to resource cycling and environmental protection.

Owner:NANCHANG UNIV

Producing method for preparing lithium carbonate by taking carbonate type brine and sulphate type brine as raw material and by repeatedly mixing brine

ActiveCN102491378BReduce investmentSimple processMagnesium carbonatesLithium carbonates/bicarbonatesLithium carbonateSulfate

Provided is a method for the production of lithium carbonate by applying multi-bittern-adding method, and using carbonate type bittern and sulfate type bittern( or magnesium-containing bittern) as raw material, which comprises applying the first bittern-adding step by mixing carbonate type bittern with sulfate type bittern, CO32- and Mg2+ ions in the bittern reacting with each other completely to produce basic magnesium carbonate, evaporating and concentrating the bittern, applying solid-liquid separation to remove the precipitation of basic magnesium carbonate, and to obtain lithium-enriched bittern; applying the second bittern-adding step by mixing the lithium-enriched bittern with carbonate type bittern which is evaporated and concentrated to a lithium ion saturation concentration or a concentration close to the lithium ion saturation concentration, so as to produce lithium carbonate by Li+ ion contained in the mixed bittern, applying solid-liquid separation to remove the precipitation of lithium carbonate, washing the obtained precipitation of lithium carbonate with hot water, drying, and then to obtain lithium carbonate product. The method is simple, the raw material can be easily obtained, and the yield is high.

Owner:陈兆华

Method for producing potassium sulfate from magnesium sulfate-metachloride potassium-containing brine

ActiveCN107265482ASolve the difficulty of filteringReduce carryoverSulfate/bisulfate preparationDecompositionBrackish water

A method for producing potassium sulfate from magnesium sulfate-metachloride potassium-containing brine comprises the following steps: 1, injecting the magnesium sulfate-metachloride potassium-containing brine into a sodium chloride saltern, and naturally spreading sodium chloride saltern to precipitate primary carnallite ore and secondary carnallite ore; 2, mixing and decomposing the primary carnallite, water or brackish water and a conversion mother liquor, and carrying out conversion, floatation and separation to obtain picromerite concentrate and the conversion mother liquor; 3, mixing the secondary carnallite ore, water or brackish water and the above obtained potassium mixed secondary conversion mother liquor, and carrying out decomposition, separation and washing to obtain crude potassium chloride; and 4, mixing and converting the crude potassium chloride, the picromerite and the water or brackish water. The method has the advantages of no external addition of sulfate ions, no introduction of a floatation agent in the production process of the crude potassium chloride, removal of ore milling and floatation processes, convenience in operation, easiness in control, high raw material utilization rate, no pollution, and reduction of the factory building investment by 10-20%.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Cold wine and preparation method thereof

InactiveCN104962442ADoes not affect preferencesAvoid damage to human healthDigestive systemAlcoholic beverage preparationFruit wineFlavor

The invention discloses a cold wine and a preparation method thereof. The cold wine is a new type of wine, and is prepared from a base wine for Chinese medicine theory and moderate cold traditional Chinese medicines. The cold wine can keep the color, aroma and texture of the base wine, can be made into a Luzhou-flavor cold white wine, a Fen-flavor cold white wine, a Maotai-flavor cold white wine, a rice-flavor cold white wine, various cold yellow wines, cold red wines, cold beer, cold fruit wines and the like, does not influence the fondness of people for various flavors and types of alcoholic beverages, can be used as an elegant gift and used for commercial affairs, entertainment, banquets and the like, and avoids injuring human health due to the hot nature of drugs.

Owner:邢贯森

Composite agglomeration technology of iron powdered ore

Iron ore powder composite agglomeration process. In the present invention, the fine-grained iron concentrate is separately separated and prepared into pellets, and then mixed with coarse-grained iron-containing ore powder and other raw materials, spread on a traditional sintering machine for roasting, and is made of acidic pellets embedded in high-alkalinity sintering Composite ironmaking charge composed of ore. With the present invention, the existing iron-containing raw materials can be fully and rationally utilized; the shortcomings of poor air permeability and difficult sintering of the material layer in the sintering process of the fine-grained concentrate are overcome; Disadvantages of segregation; significantly reduce sintering energy consumption and save investment in plant construction.

Owner:CENT SOUTH UNIV

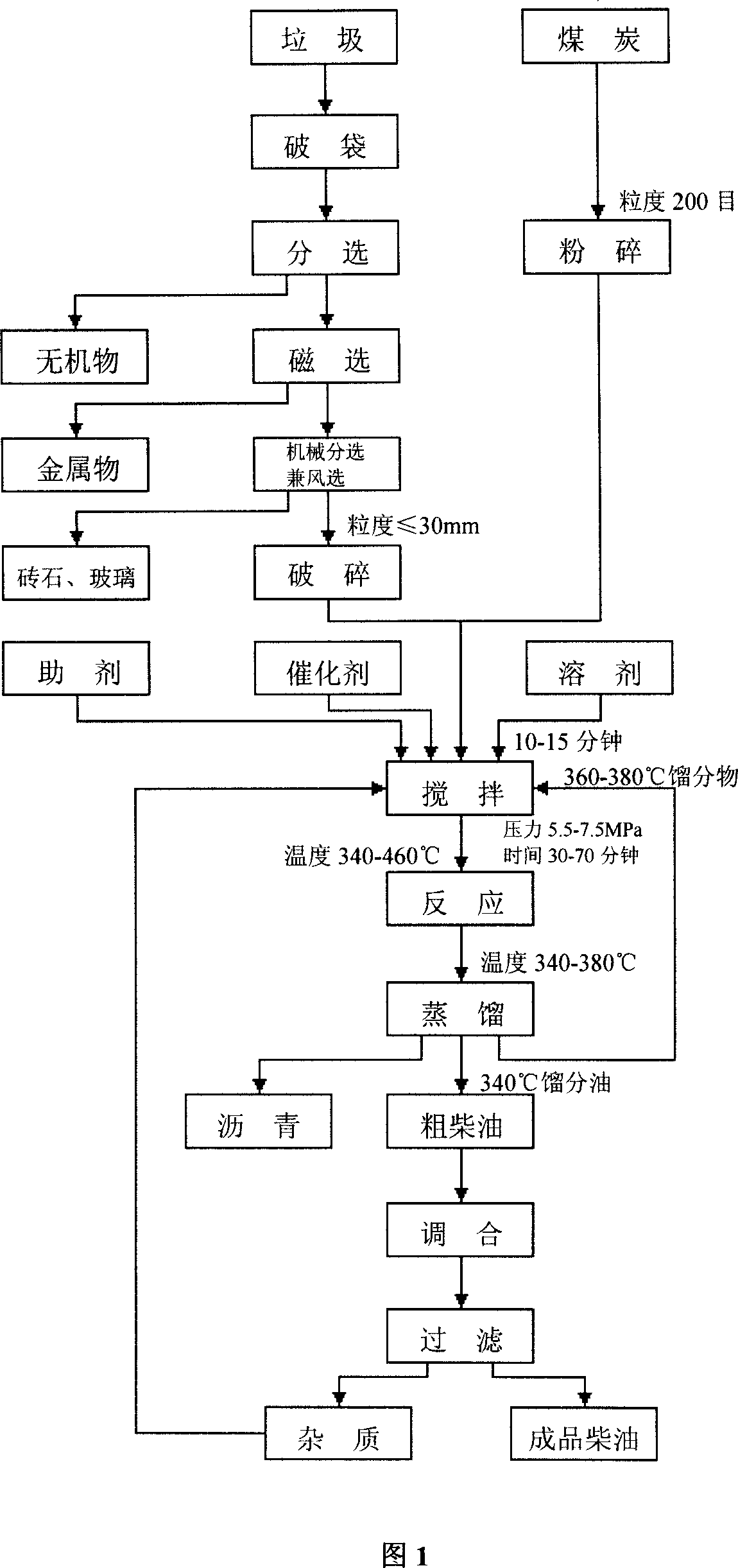

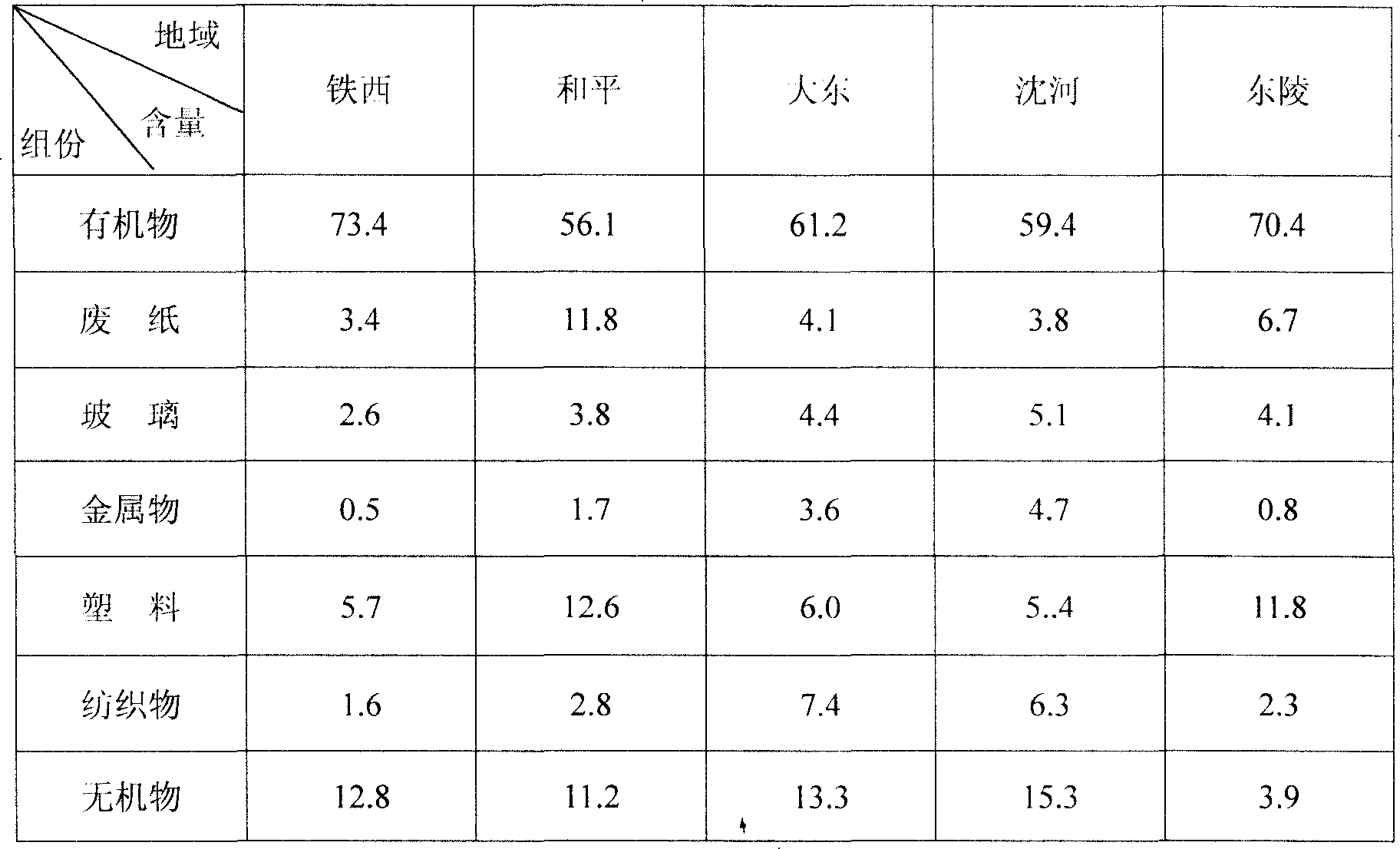

Process of preparing diesel oil substitute with domestic garbage and coal

InactiveCN1986736AConvenient sourceAlleviate shortagesLiquid hydrocarbon mixture productionPre treatmentSolvent

The present invention relates to energy source technology, and is especially process of preparing diesel oil substitute with domestic garbage and coal. The present invention features that the material consists of domestic garbage 25-45 wt%, coal 15-35 wt%, solvent 30 wt%, assistant 5 wt% and catalyst 5 wt%. The coal is lignite, subbituminous coal, oil shale or turf; the solvent is anthracene oil in the initial operation stage and the 340-380 deg.c distillate oil after the equipment is in continuous operation; the assistant is methanol and the catalyst is industrial hydrochloric acid. Pre-treated garbage and coal as well as other materials are first mixed through stirring for 10-15 min, then reacted at 340-460 deg.c and 5.5-7.5 MPa for 30-70 min and finally distilled to obtain the 340 deg.c below distillate oil as the coarse diesel oil. The coarse diesel oil is blended with amyl nitrate to obtain the diesel oil substitute.

Owner:任春山

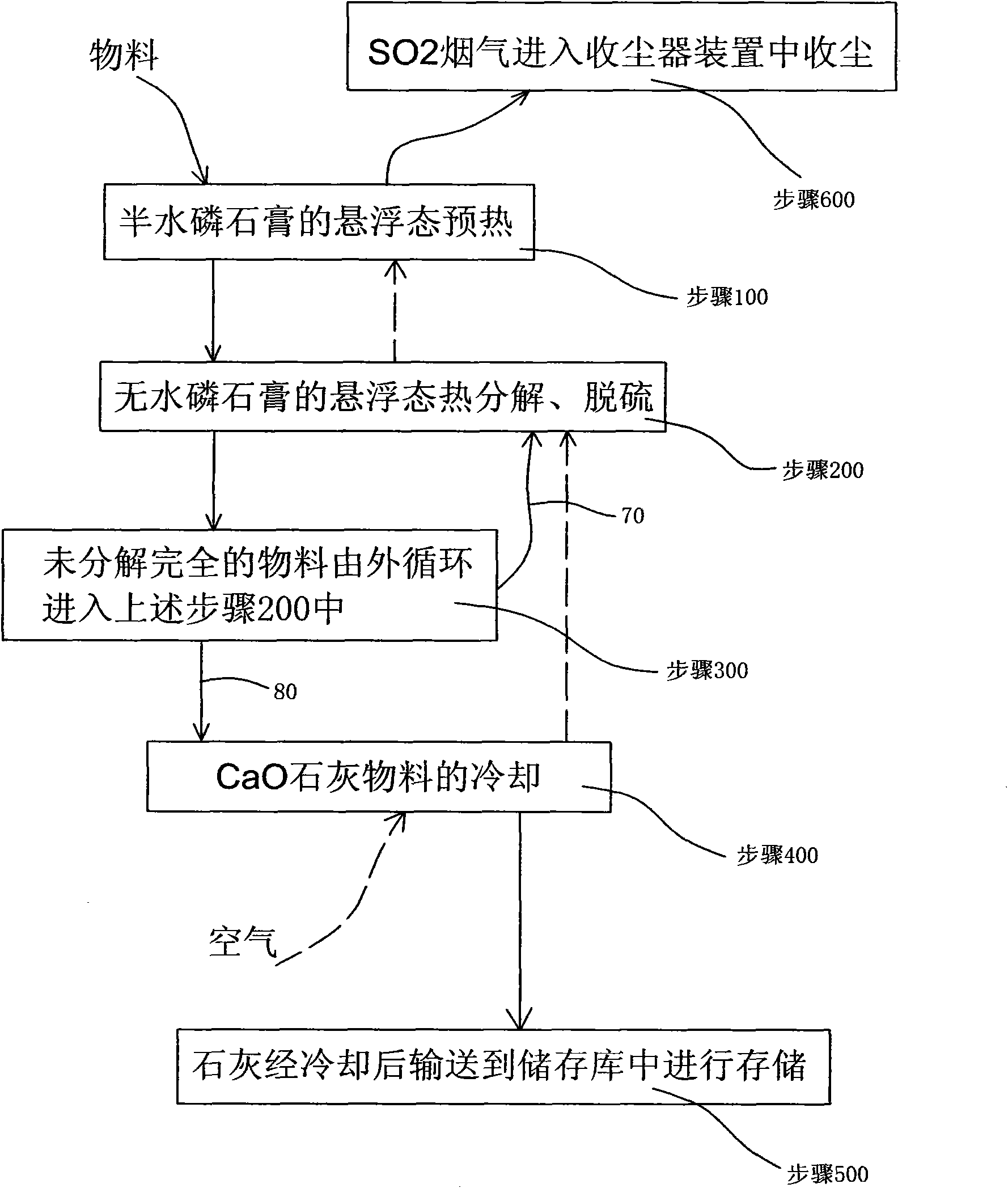

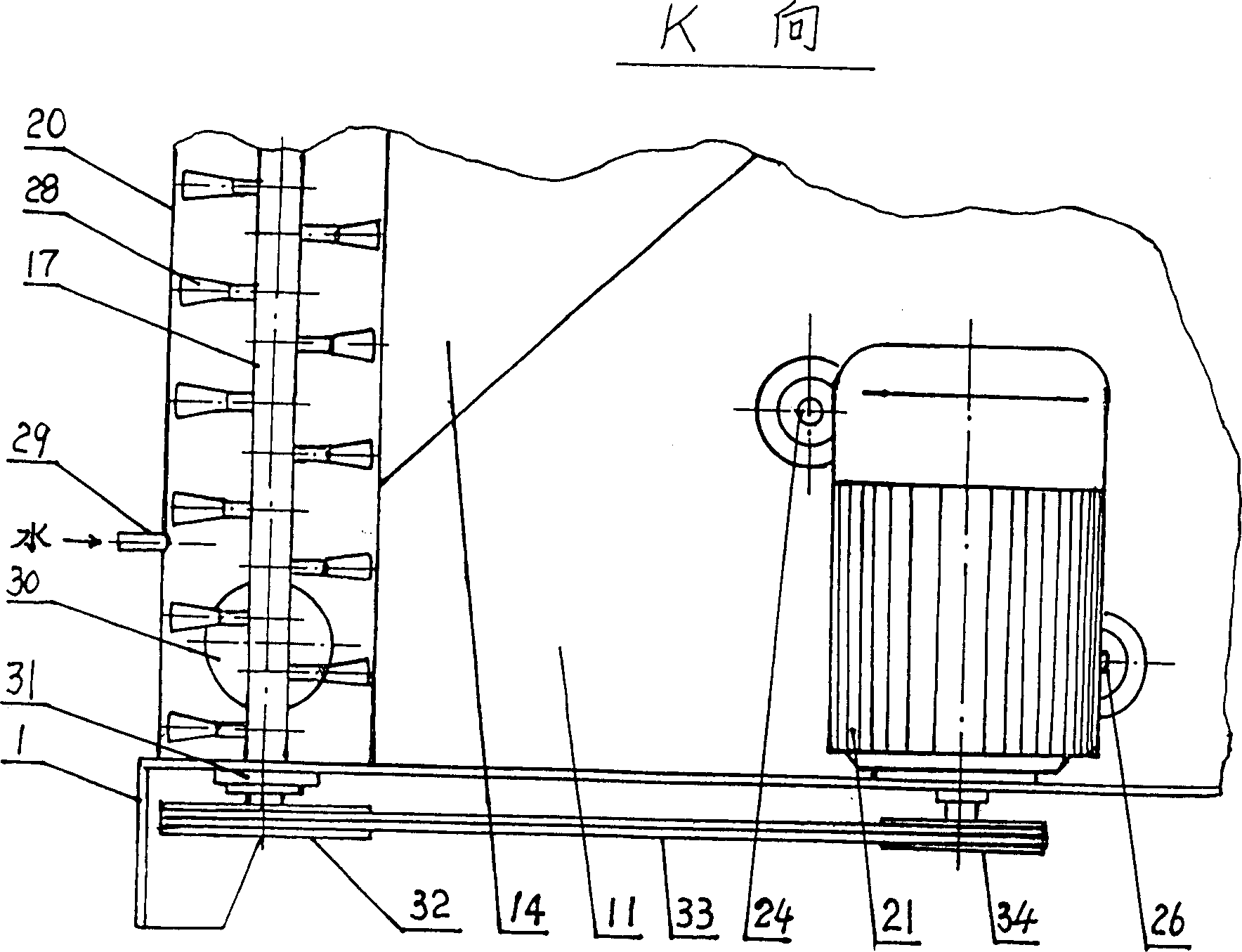

Method for decomposing semi-hydrated phosphogypsum

ActiveCN101955166BImprove gas-solid transfer conditionsImprove thermal efficiencySolid waste disposalSulfur compoundsPhosphogypsumGypsum

The invention relates to a method for decomposing semi-hydrated phosphogypsum, which comprises the following steps of: A. suspended state preheating of the semi-hydrated phosphogypsum: adding a semi-hydrated phosphogypsum material into a suspended state preheating system, carrying out heat exchange with high-temperature smoke in a suspended state, and after dehydrating the semi-dydrated phosphogypsum, forming anhydrous phosphogypsum; B: suspended state thermal decomposition and desulfuration of the anhydrous phosphogypsum: leading the anhydrous phosphogypsum to enter a suspended state thermaldecomposition system connected with an outlet of the suspended state preheating system, simultaneously adding a reducing agent with the weight ratio of (0.01-0.4):1 to the semi-hydrated phosphogypsuminto the suspended state thermal decomposition system and finishing the high-temperature decomposing and desulfurizing process of phosphogypsum; and C. cooling of materials. The method for decomposing the semi-hydrated phosphogypsum can overcome the defects of low decomposing rate and low desulfurizing rate of CaSO4, and the like in the traditional production method and solves the problem of increasing shortage of natural lime and limestone resources while effectively utilizing a sulphur element in the phosphogypsum at high quality.

Owner:WENGFU (GRP) CO LTD +1

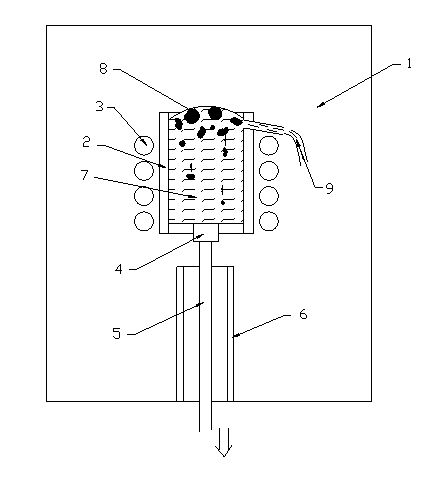

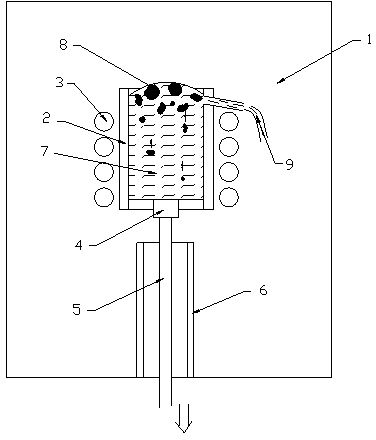

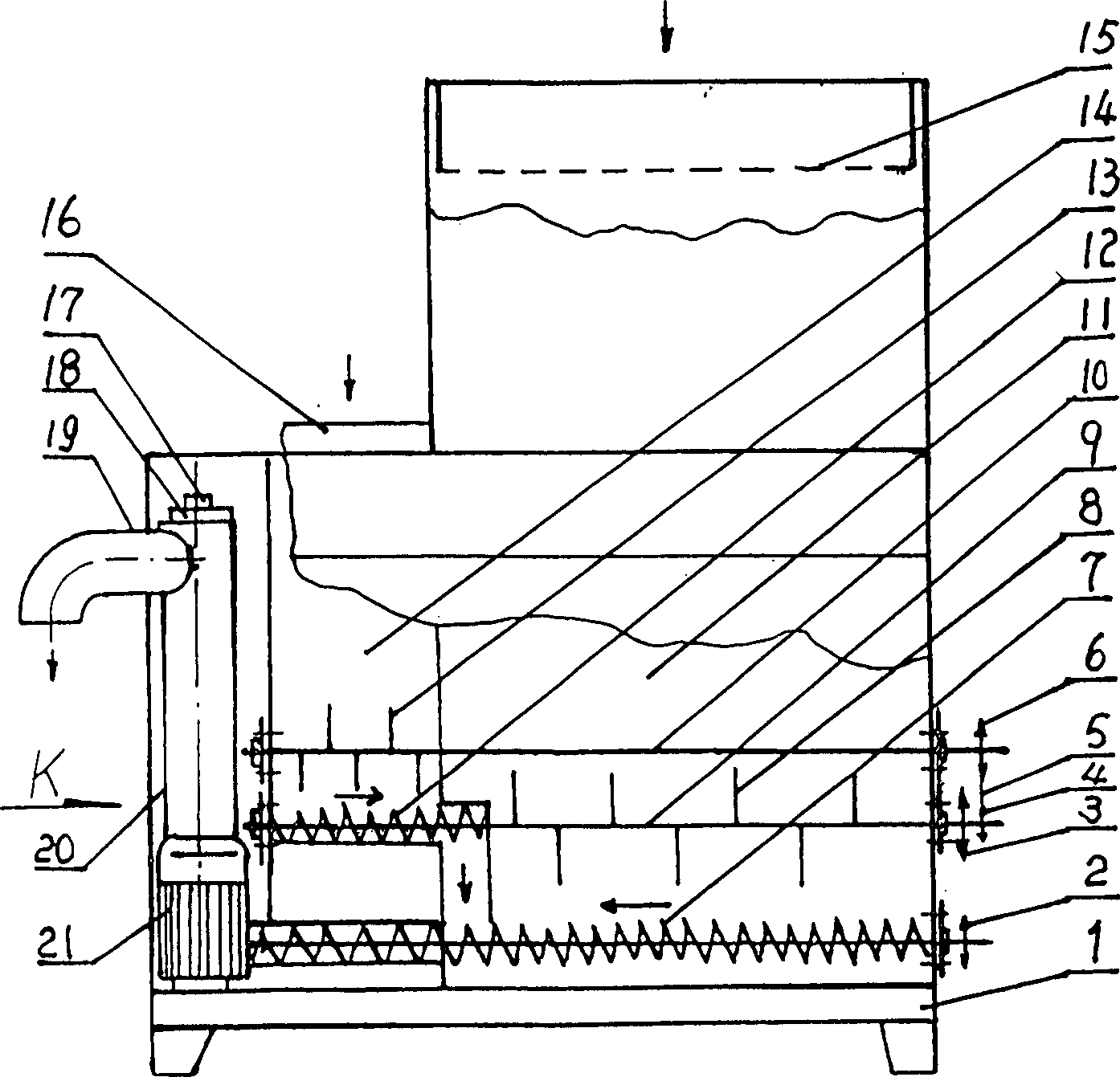

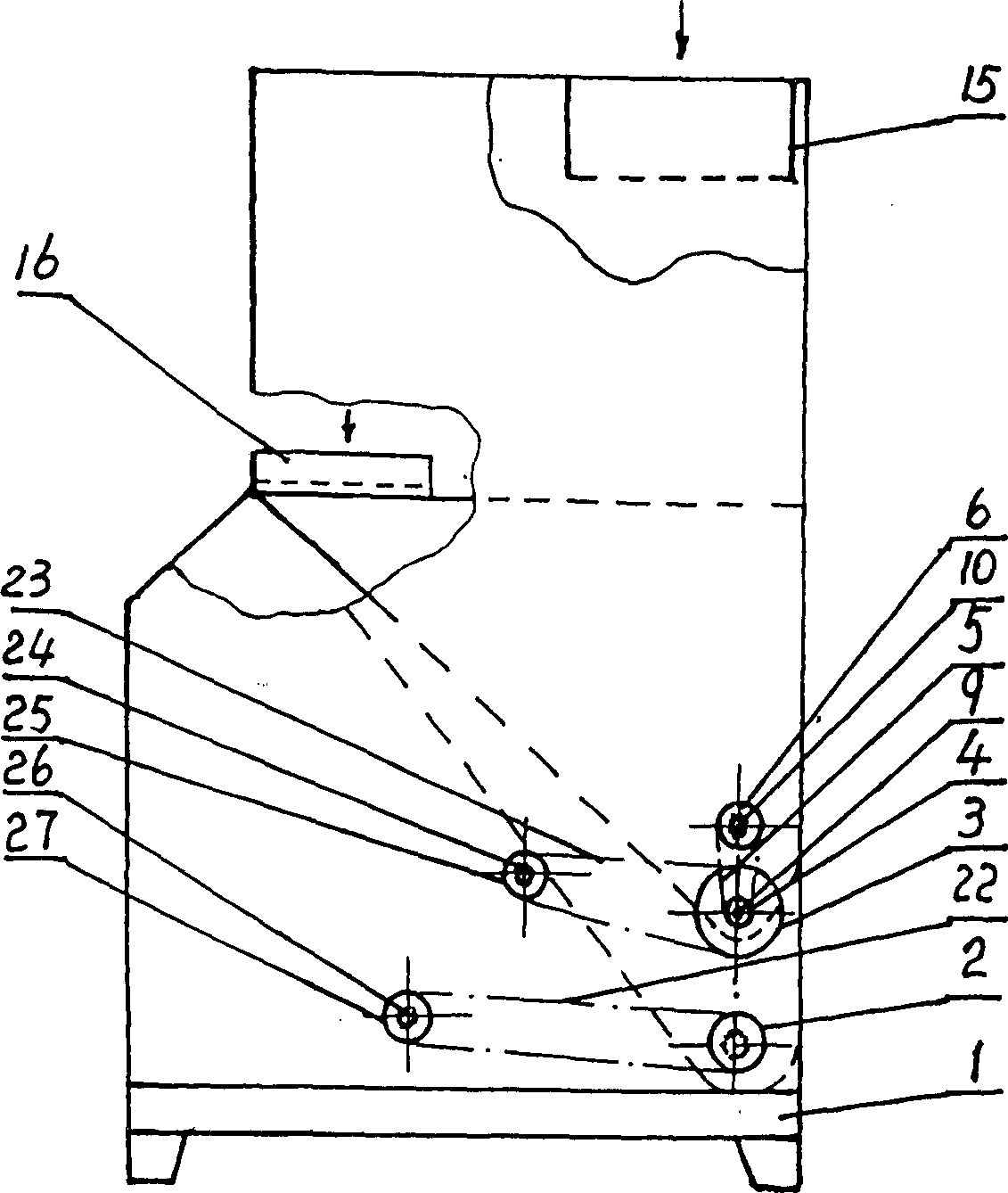

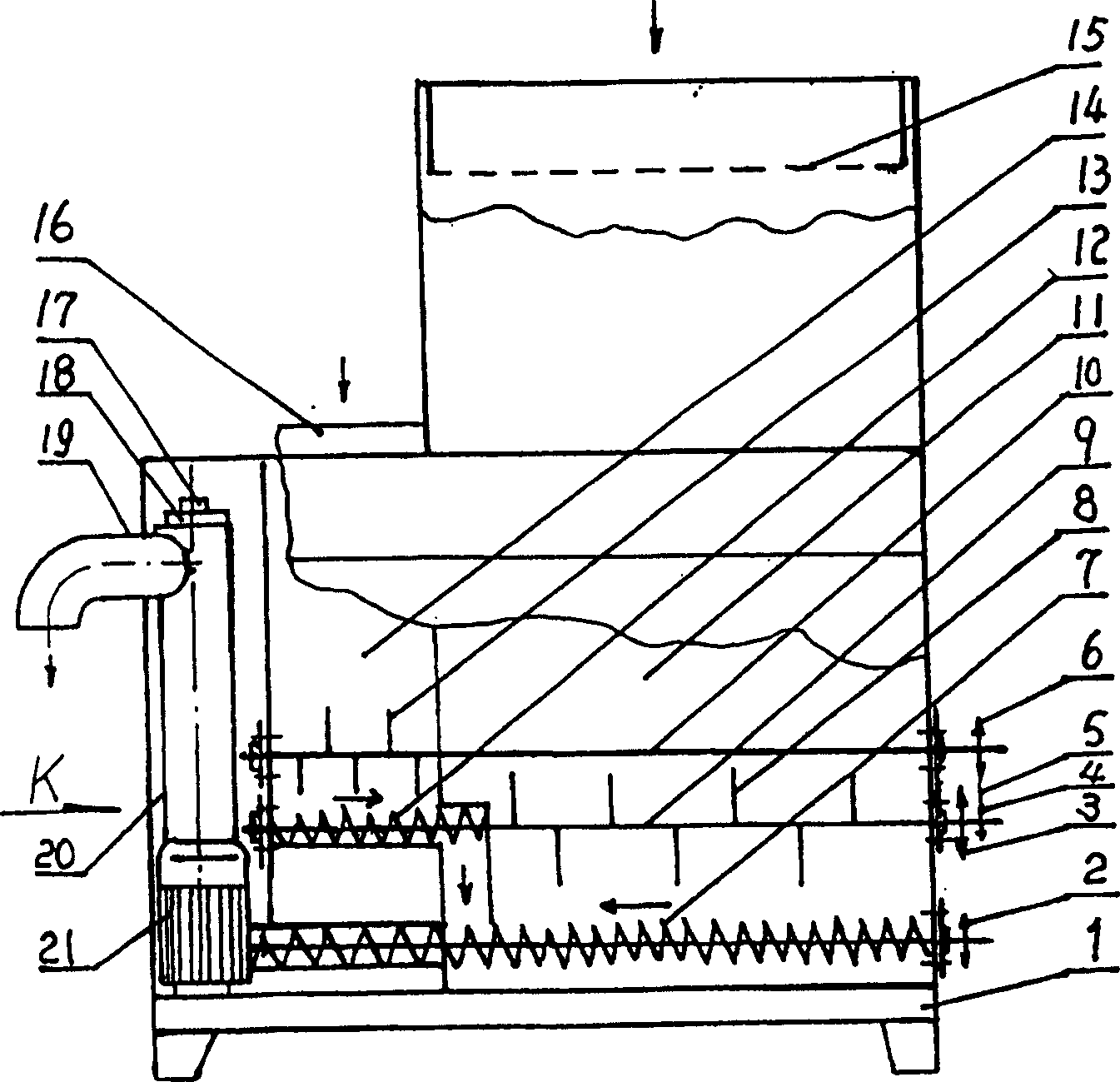

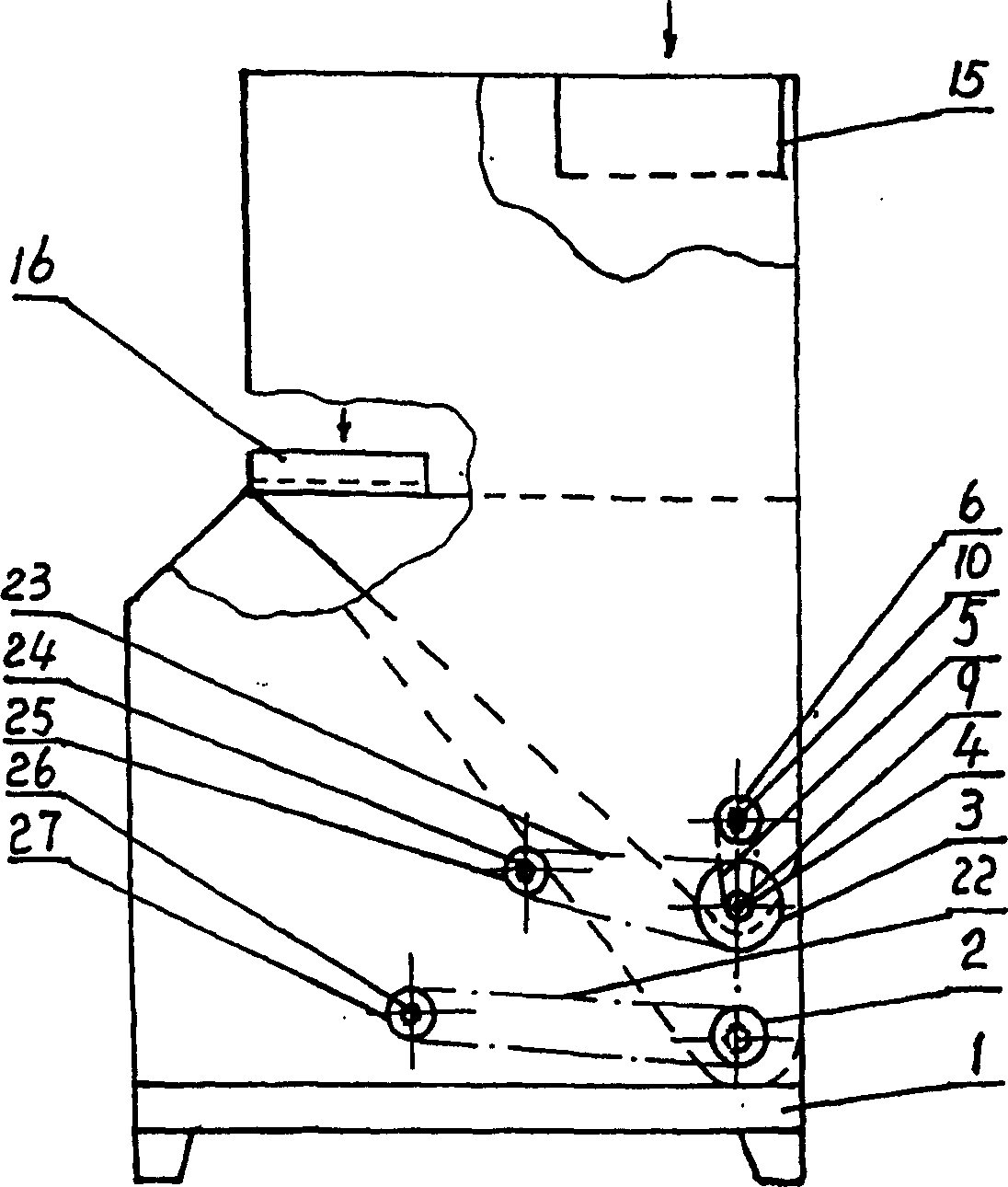

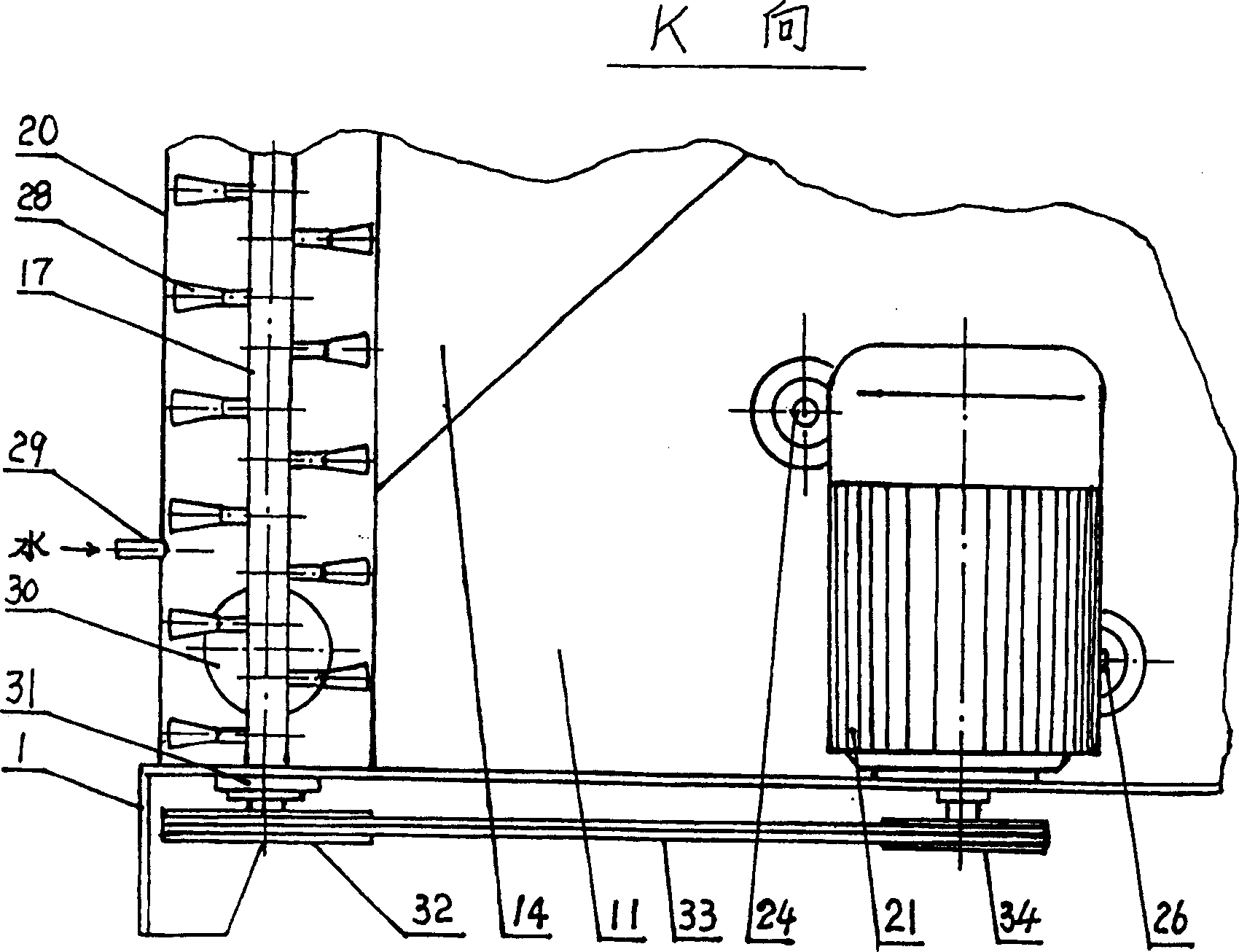

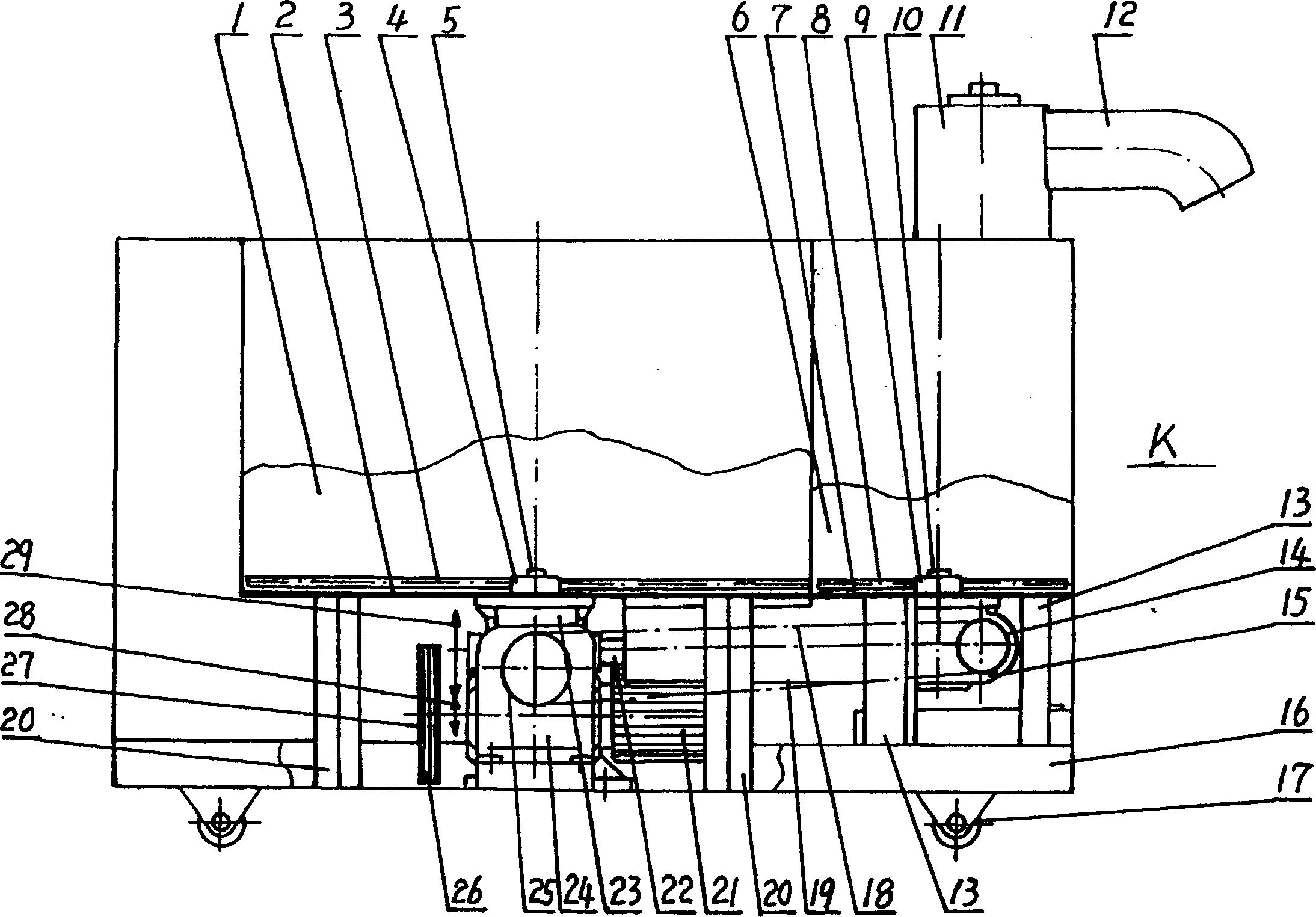

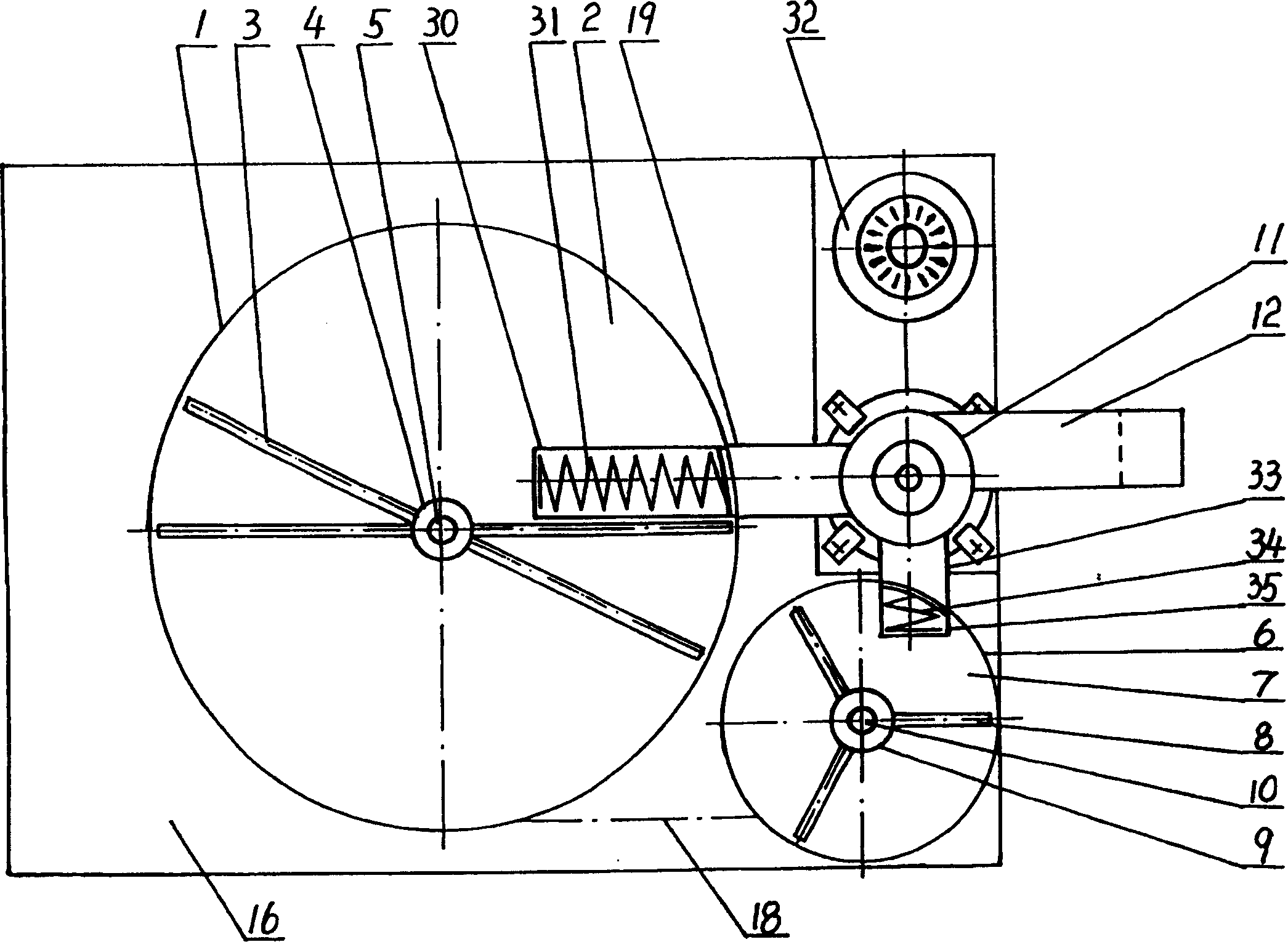

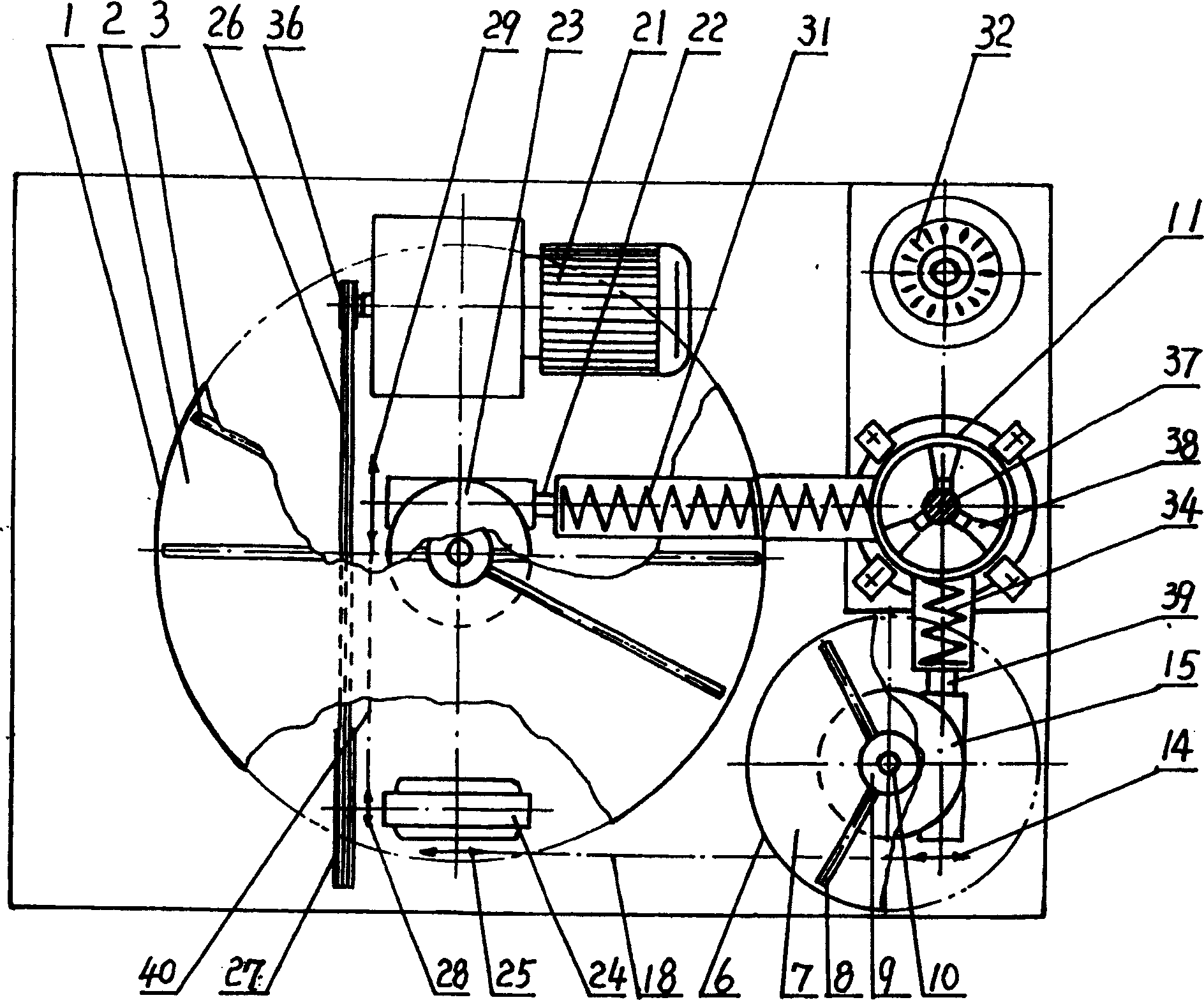

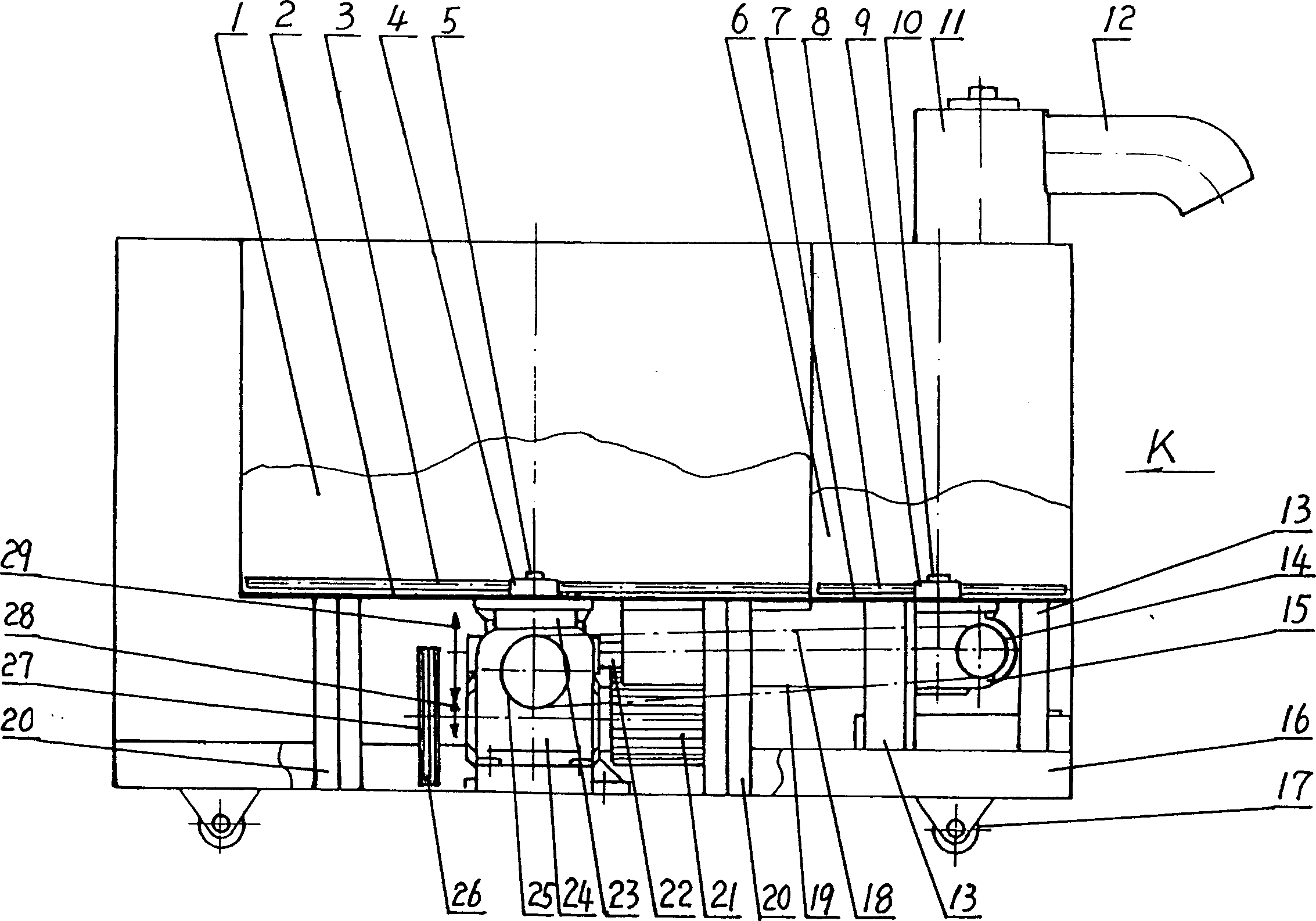

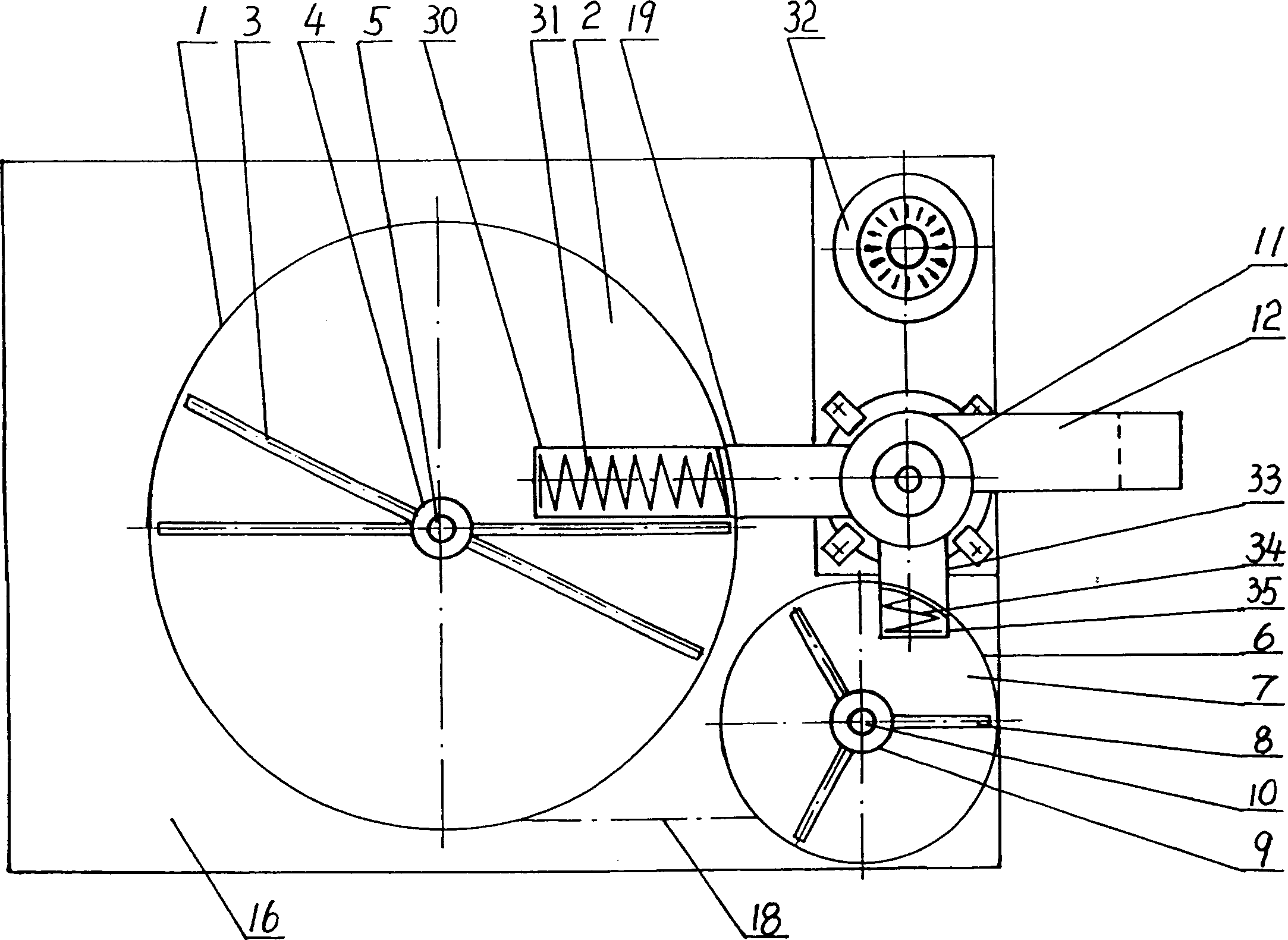

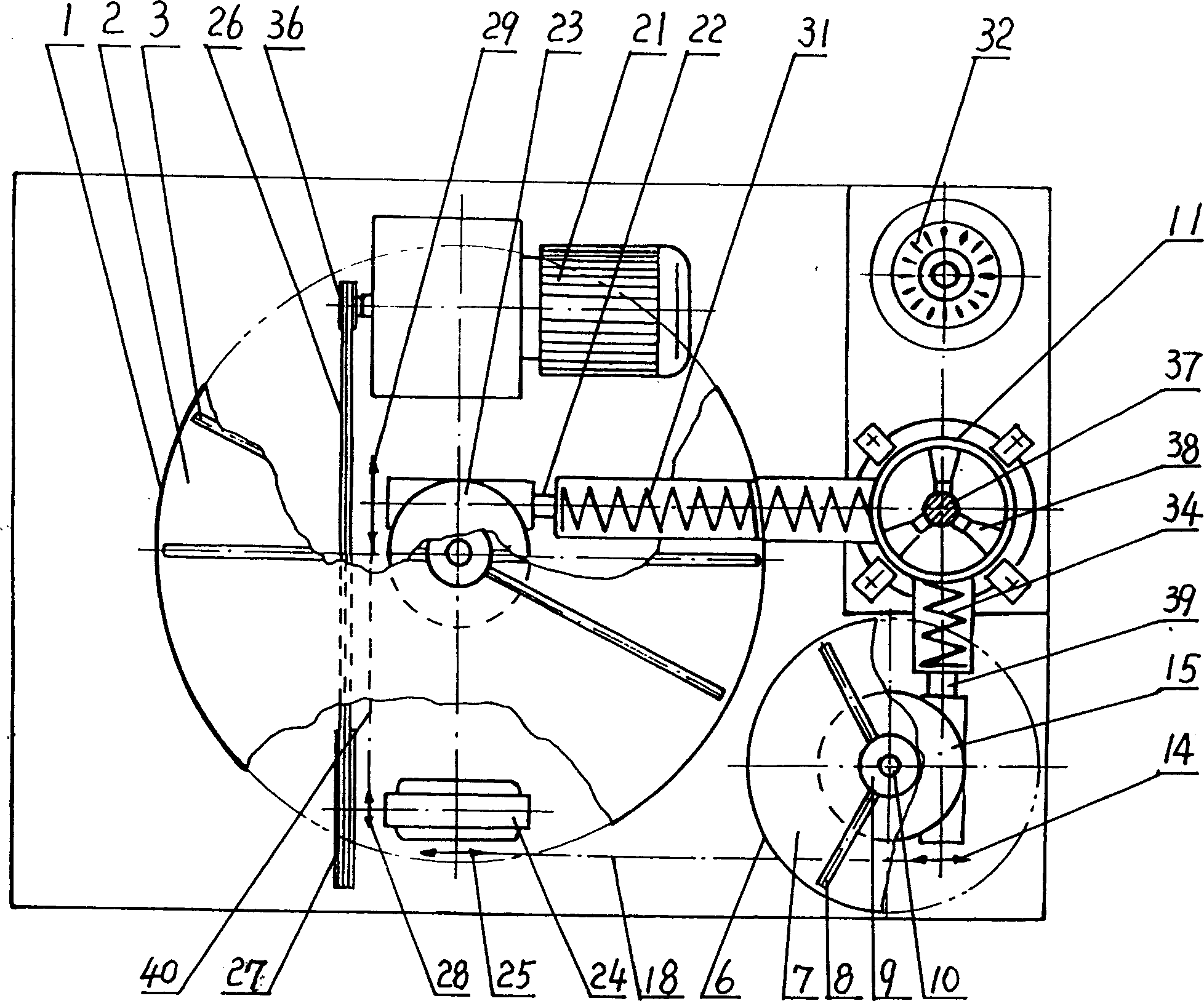

Continuous automatic dough kneading machine

InactiveCN1484962AImprove work performanceRealize flat layoutMixing/kneading with vertically-mounted toolsProviding materialManufacturing line

It relates to an automatic continuous doughmaker. The doughmaker which is used for processing flour dough. It comprises: upright dough mixer, main material box, auxiliary material box, the upright dough mixer, electromotor and feeding member, the gearing system and speed control eletromotor installing on the base, helical conveyers on bottoms of main material box and auxiliary material box, the feed inlet at the lower part of the upright dough mixer linked with main material feed conveyer, the feed outlet of the auxiliary material box communicating with the main material box, the water inlet in the lower part of the upright dough mixer, the feed outlet of dough mixer in the upper part, the main shaft of upright dough mixer driven by driving electromotor, helical feed conveyers of main material and auxiliary material driven by the speed control eletromotor, providing material for the next process in the noodle production line.

Owner:张念江

Technological method for preparing biodiesel by using agricultural and forestal waste

InactiveCN106367096AEase the tense situationRaw materials are easy to getBiofuelsLiquid carbonaceous fuelsForest industryBiodiesel

The invention provides a technological method for preparing biodiesel by using agricultural and forestal waste, and relates to the field of energy. The invention provides a new method for producing the biodiesel aiming at the defects that the biodiesel research is complicated in technology, high in cost, expensive in manufacturing cost, and the like. The method comprises multiple processes, i.e., natural drying, crushing, stirring, reacting and distilling; the biodiesel is characterized by being prepared according to the following component formula by weight percent: 55-35% of agricultural and forestal waste, 30% of a solvent, 9% of an auxiliary agent, 1% of a catalyst and 5-25% of an additive; the agricultural and forestal waste as well as tree branches and leaves are taken as raw materials; the agricultural and forestal waste comprises one or more of rice straw, cotton seed hull and the like; refined anthracene oil is taken as the solvent, methyl alcohol is taken as the auxiliary agent, aluminum chloride is taken as the catalyst, and coal water slurry is taken as the additive; the biodiesel is prepared by stirring the needed materials, carrying out a reaction, and distilling. After being tried in an agricultural vehicle on the road, the biodiesel is proved to have a good effect, thus being quite popular with users.

Owner:威海印九红果蔬种植专业合作社

Continuous automatic dough kneading machine

InactiveCN1185939CImprove work performanceRealize flat layoutMixing/kneading with vertically-mounted toolsProviding materialManufacturing line

It relates to an automatic continuous doughmaker. The doughmaker which is used for processing flour dough. It comprises: upright dough mixer, main material box, auxiliary material box, the upright dough mixer, electromotor and feeding member, the gearing system and speed control eletromotor installing on the base, helical conveyers on bottoms of main material box and auxiliary material box, the feed inlet at the lower part of the upright dough mixer linked with main material feed conveyer, the feed outlet of the auxiliary material box communicating with the main material box, the water inlet in the lower part of the upright dough mixer, the feed outlet of dough mixer in the upper part, the main shaft of upright dough mixer driven by driving electromotor, helical feed conveyers of main material and auxiliary material driven by the speed control eletromotor, providing material for the next process in the noodle production line.

Owner:张念江

Automatic dough kneading machine

InactiveCN1180696CImprove work performanceLower installation heightMixing/kneading with vertically-mounted toolsHelical lineMotor drive

The invention relates to an automatic dough mixer, which is a mixing machine with vertical installation parts for dough preparation in the noodle production line, vertical dough mixer, main material box, vertical dough mixer drive motor and feeding material The speed-regulating motor driven by the transmission system of the mechanism is installed on the machine base. The outlet of the main material box on the bottom plate of the main material box is connected with the shell of the main material screw conveyor. The outlet of the main material screw conveyor is connected with the vertical and The main material inlet of the noodle machine is connected. The main shaft of the vertical noodle kneading machine is equipped with a vertical noodle kneading machine material spiral lifting device and a vertical noodle kneading machine material stirring and elevating paddle arranged in a spiral line. The vertical noodle kneading machine The lower part of the vertical kneading machine is equipped with the main material inlet and water inlet, and the vertical kneading machine is equipped with a vertical kneading machine outlet on the upper part of the vertical kneading machine. The kneaded dough enters from the bottom of the noodle kneading machine, and the kneaded dough is discharged from the top of the vertical noodle kneading machine, and is fed to the next step of the cooking machine in the noodle production line, which can realize the planar layout of the host part of the noodle production line, the installation height of the machine is low, and the investment in building the factory is small. , easy to operate, which is conducive to improving the working efficiency of the noodle production line.

Owner:张念江

Magnetic ore dry separation and screening concentrated sorting system

The invention relates to a magnetic ore dry separation and screening concentrated sorting system which comprises a medium crushing ore storage bin feeding movable sealing-tape machine I, a medium crushing ore storage bin, a medium crushing machine feeding belt conveyor II and a medium crushing machine. The magnetic ore dry separation and screening concentrated sorting system is characterized in that a medium crushing ore discharge sealing-tape machine is arranged at the lower portion of the medium crushing machine, the medium crushing ore discharge sealing-tape machine is connected with the ore feeding end of a movable sealing-tape machine III with an unloading trolley, a dry separation and screening unified preselection ore storage bin is arranged below the movable sealing-tape machine III with the unloading trolley, ore fine dry separation machines are correspondingly arranged below the dry separation and screening unified preselection ore storage bin, and a dry separation classification vibrating screen is correspondingly arranged below each ore fine dry separation machine. The magnetic ore dry separation and screening concentrated sorting system has the beneficial effects that system arrangement is compact, waste ore can be removed to the maximum degree before ore grinding, the feeding grade is improved, energy saving and cost reducing of an ore treatment plant are achieved, and the ore separation cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Technology for making lime-sand brick cured by steam

InactiveCN1172065CReduce dosageSimple production methodCeramic shaping apparatusBuilding componentsBrickSlag

A technology for producing the steam-cured lime-sand bricks uses the volcanic ash material or granular slags of blast furnace (8-15 wt. portions), calcium lime (6-10) and sand (75-85) as raw materials, and includes such steps as ball grinding the volcanic ash material or granular slags and calcium lime, mixing with sand and water, and steam curing at 80-100 deg.c and with relative humidity greater than 95% for 8-24 hr. Its advantages are low cost, saving energy and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing porous ceramsite filter material from slate saw mud

InactiveCN102068855BConducive to gas expansionSelf-inflatingFiltration separationPhysical chemistryExpanded clay aggregate

The invention discloses a method for preparing a porous ceramsite filter material from slate saw mud. According to a formula, a product prepared by the method comprises the following raw materials in percentage by mass: 60 to 80 percent of slate saw mud (a dry basis), 15 to 30 percent of dry slate powder and 5 to 10 percent of kieselguhr, wherein the raw materials are mixed and stirred into spherical particles, then calcined and cooled to obtain the product. The method has the advantages of simple process and low production cost, and has great significance to resource cycling and environmental protection.

Owner:NANCHANG UNIV

Method for preparing light building material ceramic particle by utilizing slate sawn mud

InactiveCN101851110BConducive to gas expansionSelf-inflatingSolid waste disposalCeramicwareMining engineeringExpanded clay aggregate

The invention relates to a method for preparing light building material ceramic particle by utilizing slate sawn mud. The product formula includes: 60-100% of slate sawn mud (containing 30% of moisture) and 0-40% of slate dry powder; and 1-2% of sodium silicate binder is additionally doped. The manufacturing processing step includes that the slate sawn mud is filtered until moisture is less than 30%, the slate sawn mud and powder material obtained by sieving crushed slate are pre-stirred into bulk particles in a dual spindle stirring machine, so as to form cue ball, when the moisture contained in the slate sawn mud is less than 15%, the slate sawn mud also can be independently stirred and broken into particles in the stirring machine, then the cue ball is fed into a ball forming mill to be sprayed with mist water, and a small amount of binder is added, so that the particle forms a spherical particle with the diameter Phi of 5-30mm by rolling, then the material ball is fed into a rotary kiln to be calcined, the calcining temperature is 1100-1200 DEG C, and calcining time is 25-40min, and the fiery material ball taken out from the kiln is cooled by adopting a monocular cooling machine. The method has simple production technology and low cost, and the prepared slate sawn mud ceramic particle has high tube pressure strength and wide application.

Owner:NANCHANG UNIV

Airflow classifying and airflow drying process for coking coal

ActiveCN102019275BSave energyReduce pollutionGas current separationDrying solid materials with heatWastewaterCoke oven

The invention relates to an airflow classifying and airflow drying process for coking coal. In the process, coke oven flue waste gas is taken as a drying medium, the fluidization technology is adopted for drying the coal, and simultaneously the coal is classified into several classes according to particle sizes by an airflow separation principle. A device consists of a vibrating fluidized bed main body and a classifying collection device, wherein the vibrating fluidized bed main body comprises a primary air supply device, a vibrating main box body with an air distributing plate, a sedimentation classifying section and a drying section with a secondary air inlet; and the classifying collection device completes the final collection of small-particle materials through a group of dust collection devices or several groups of duct collection devices with different structures according to different requirements of the process on the classification of the particle sizes. The airflow classifying and airflow drying process has the advantages that: energy is saved, the wastewater generated in the coking process is reduced, the environmental pollution is lightened and the production capacity of the coke oven can be improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

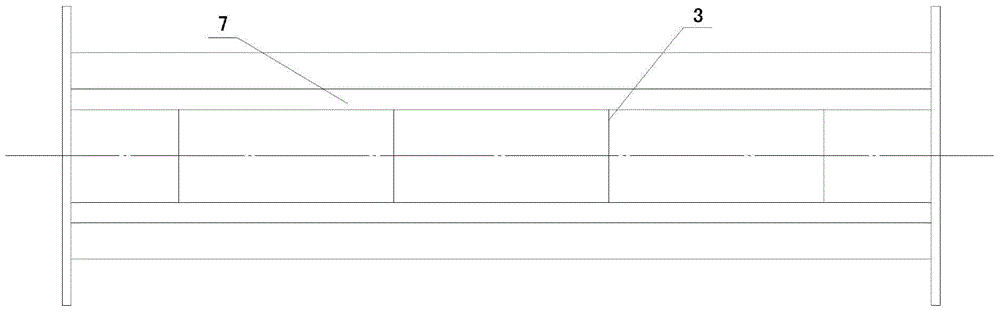

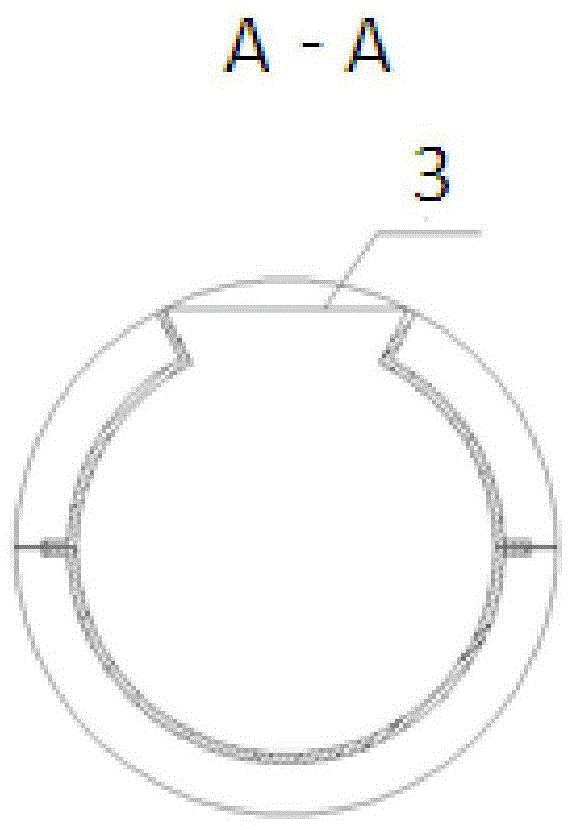

A centrifugal-free manufacturing method for prestressed concrete pipe piles

ActiveCN104760134BPut an end to quality accidents with insufficient wall thicknessImprove noise pollutionShaping reinforcementsCentrifugationPre stress

The invention discloses a centrifuging-free manufacturing method of a prestressed concrete pipe pile. Compared with the currently used centrifugal forming method, the manufacturing method has the advantages that one operation of inflating an air die is added and brings great affect on the manufacturing of the whole prestressed concrete pipe pile, the investment on plant construction is reduced, and the serious noise pollution of a centrifuging machine is also solved. The manufacturing method is free of residual slurry, so that the problem of pollution of slurry can be completely solved; the quality accident caused by insufficient concrete wall thickness can be avoided, thus the yield of the product is increased, and the production cost can be effectively reduced.

Owner:JIANGSU LONGGUAN NEW MATERIAL TECH

Automatic dough kneading machine

InactiveCN1500393AMeet the process requirementsMeet the demands of changing productivityMixing/kneading with vertically-mounted toolsHelical lineVertical mixing

The automatic flour mixing machine for mixing flour and water to make dough in noodle producing line consists of vertical mixing mechanism, main material bin, driving motor and feeding mechanism driving system mounted on a chassis. The main material bin, spiral feeder and the vertical mixing mechanism are connected together; and on the main shaft of the vertical mixing mechanism, there are spiral material raising and conveying unit and spiral material stirring and raising blades. The vertical mixing mechanism is provided with material inlet in the lower part and dough discharging port in the upper part to provide dough to the next step in noodle production. Using the automatic flour mixing machine can realize the planar arrangement of the noodle producing line and raise the efficiency of the noodle producing line.

Owner:张念江

A method for producing potassium sulfate from magnesium sulfate-metachloride type potassium-containing brine

ActiveCN107265482BSolve the difficulty of filteringReduce carryoverSulfate/bisulfate preparationEnvironmental engineeringCarnallite

A method for producing potassium sulfate from magnesium sulfate-metachloride potassium-containing brine comprises the following steps: 1, injecting the magnesium sulfate-metachloride potassium-containing brine into a sodium chloride saltern, and naturally spreading sodium chloride saltern to precipitate primary carnallite ore and secondary carnallite ore; 2, mixing and decomposing the primary carnallite, water or brackish water and a conversion mother liquor, and carrying out conversion, floatation and separation to obtain picromerite concentrate and the conversion mother liquor; 3, mixing the secondary carnallite ore, water or brackish water and the above obtained potassium mixed secondary conversion mother liquor, and carrying out decomposition, separation and washing to obtain crude potassium chloride; and 4, mixing and converting the crude potassium chloride, the picromerite and the water or brackish water. The method has the advantages of no external addition of sulfate ions, no introduction of a floatation agent in the production process of the crude potassium chloride, removal of ore milling and floatation processes, convenience in operation, easiness in control, high raw material utilization rate, no pollution, and reduction of the factory building investment by 10-20%.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com