Magnetic ore dry separation and screening concentrated sorting system

A sorting system and ore-drying technology, applied in the direction of filter screen, solid separation, grille, etc., can solve problems such as difficult management, high construction cost, complex structure, etc., to reduce electrical equipment, reduce plant height, and simplify layout way effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

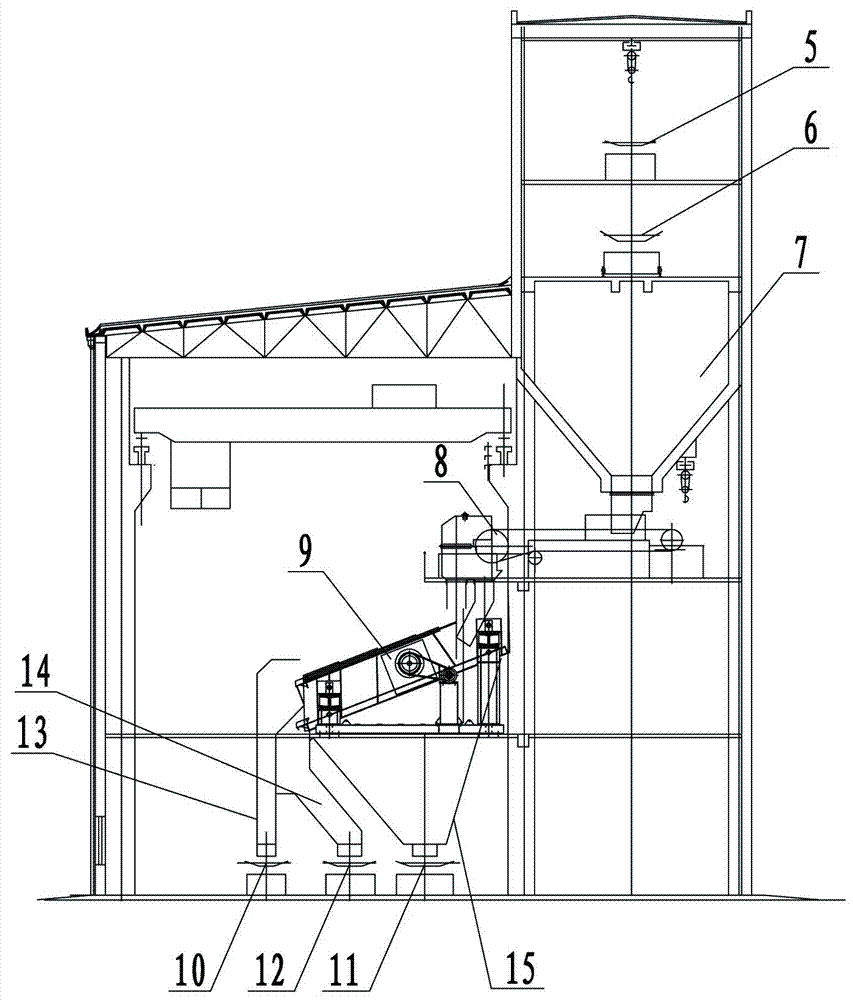

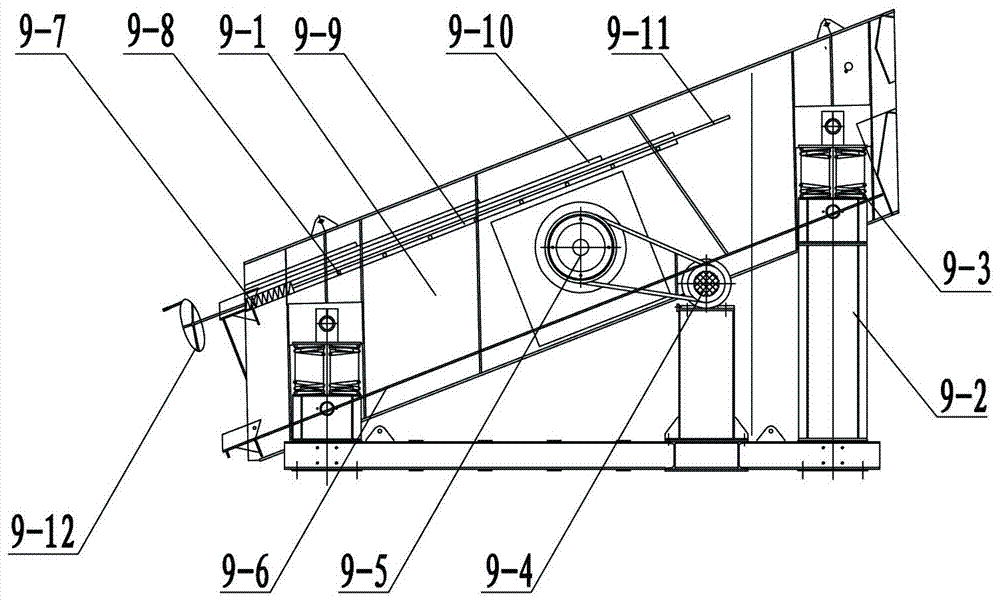

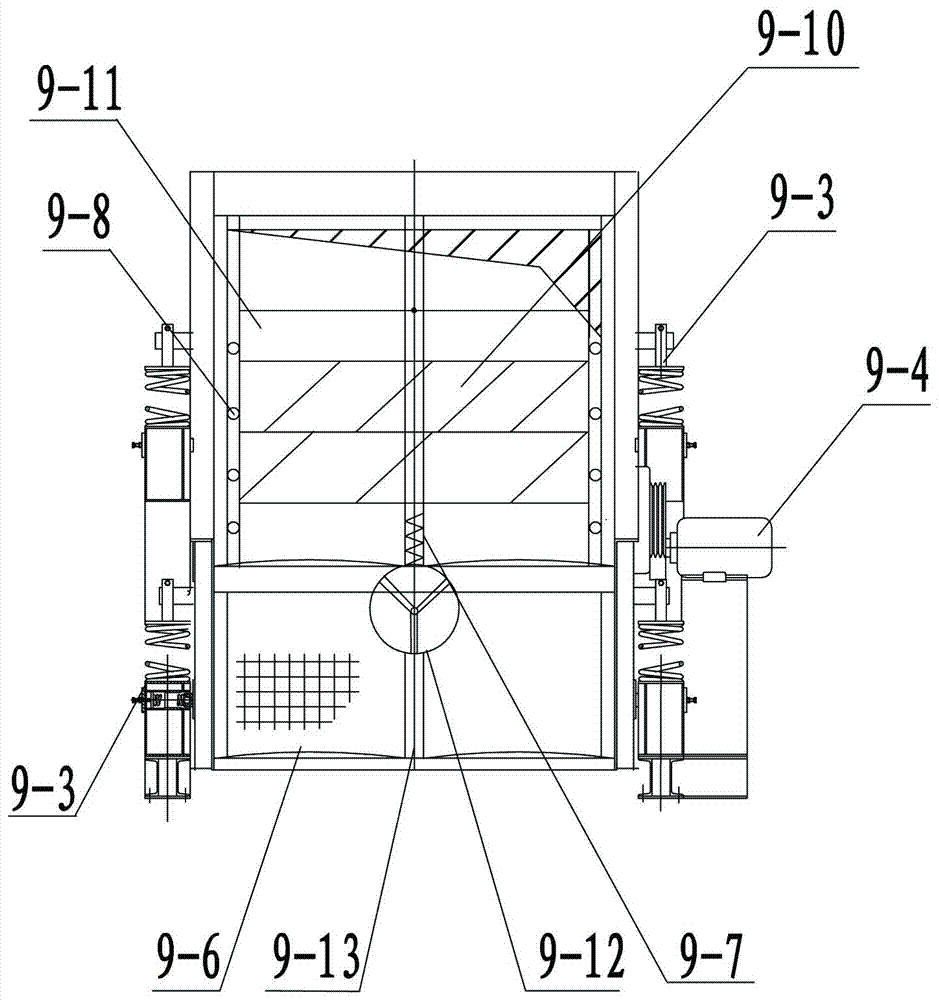

[0024] Such as figure 1 and figure 2 As shown, a magnetic ore dry separation screening centralized separation system of the present invention includes a group of medium crushing ore feeding mobile belt conveyors I1 with unloading trolleys, which are installed in the medium crushing ore feeding with unloading trolleys. A group of medium crushing ore bins 2 under the ore moving belt conveyor Ⅰ1, set under a group of medium crushing ore bins 2, a group of medium crusher feeding belt conveyor Ⅱ3, set at the lower part of a group of medium crusher feeding belt conveyor Ⅱ3 A group of middle crushers 4, characterized in that a middle crushing ore discharge belt conveyor 5 is provided at the bottom of the middle crusher 4, and the middle crushing and discharge belt conveyor 5 is connected with a dry belt discharge trolley The ore feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com