Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Reduce sintering energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

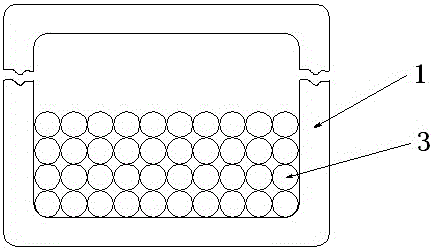

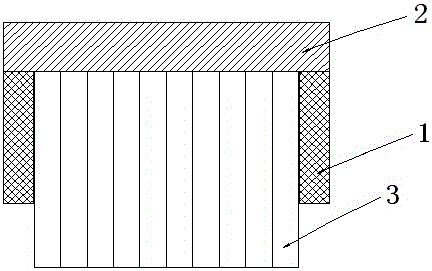

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

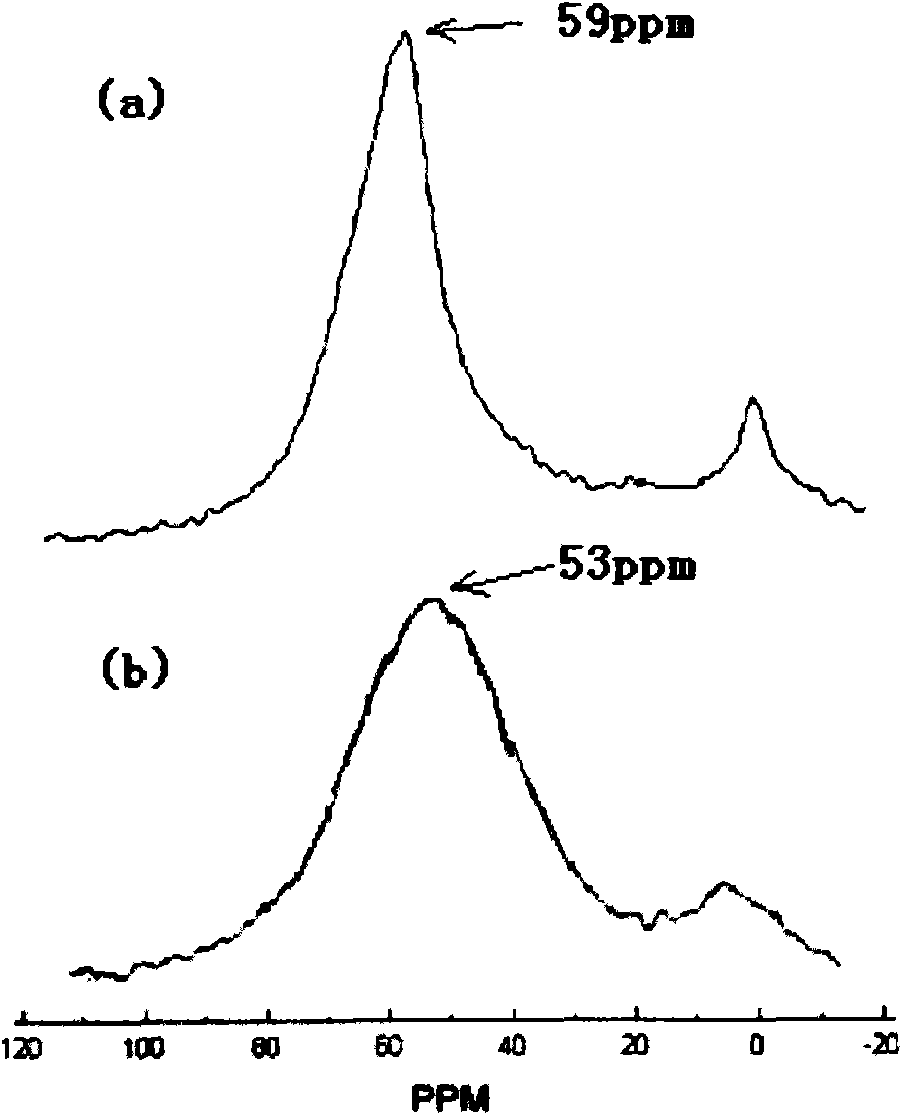

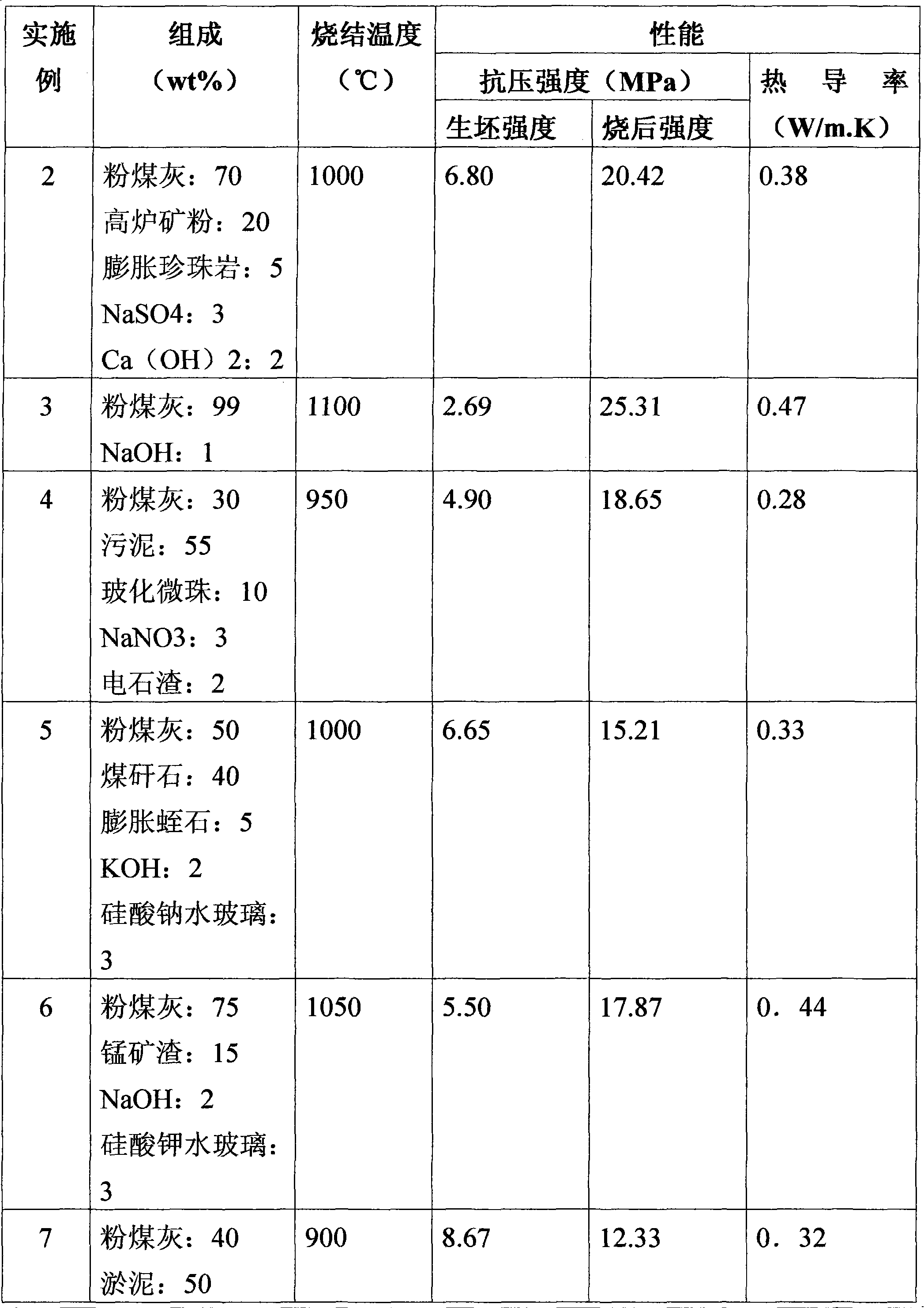

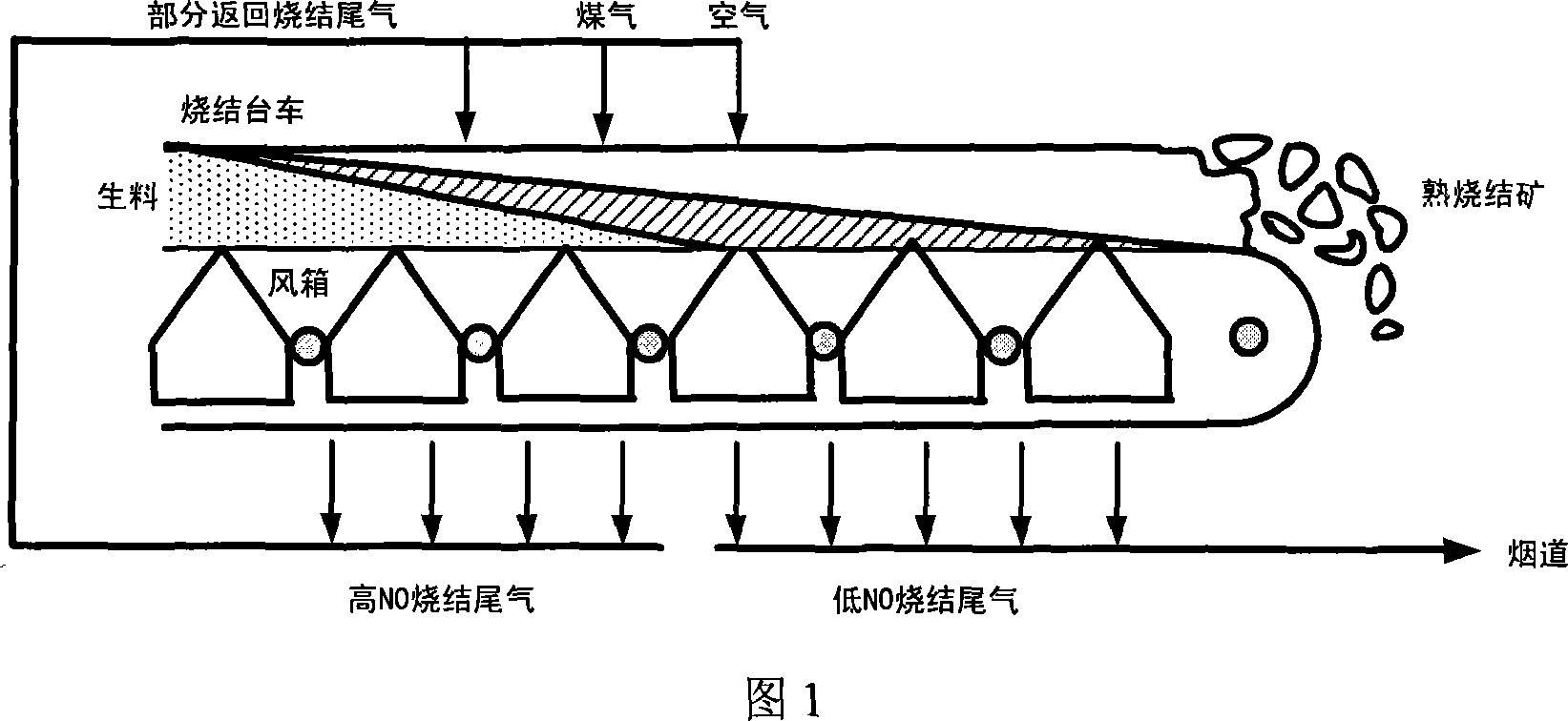

Fly ash thermal-insulation sintered material and production technique thereof

InactiveCN101905961AImprove thermal insulationImprove thermal insulation performanceThermal insulationRoom temperature

The invention discloses a fly ash thermal-insulation sintered material and a production technique thereof, and belongs to the fields of construction materials and production techniques. Aiming at the problem that the fly ash thermal-insulation material can not easily obtain high green strength and can not be easily sintered, the invention provides the fly ash thermal-insulation sintered material. The fly ash thermal-insulation sintered material comprises the following raw materials in percentage by weight: 30-99% of fly ash, 1-40% of curing excitant, 0-40% of light-weight aggregate and 0-69% of other solid raw materials. The production technique of the fly ash thermal-insulation sintered material comprises the following steps: evenly stirring fly ash, curing excitant, light-weight aggregate and other solid raw materials; evenly mixing the mixture with water to obtain the green compact; molding the green compact; after molding, drying the green compact in an oven, or naturally drying at room temperature; and sintering the dried green compact at 800-1100 DEG C. The fly ash thermal-insulation sintered material has the advantages of high green strength, high sintering strength and favorable thermal insulation property. The production technique is suitable for mass production.

Owner:翁履谦

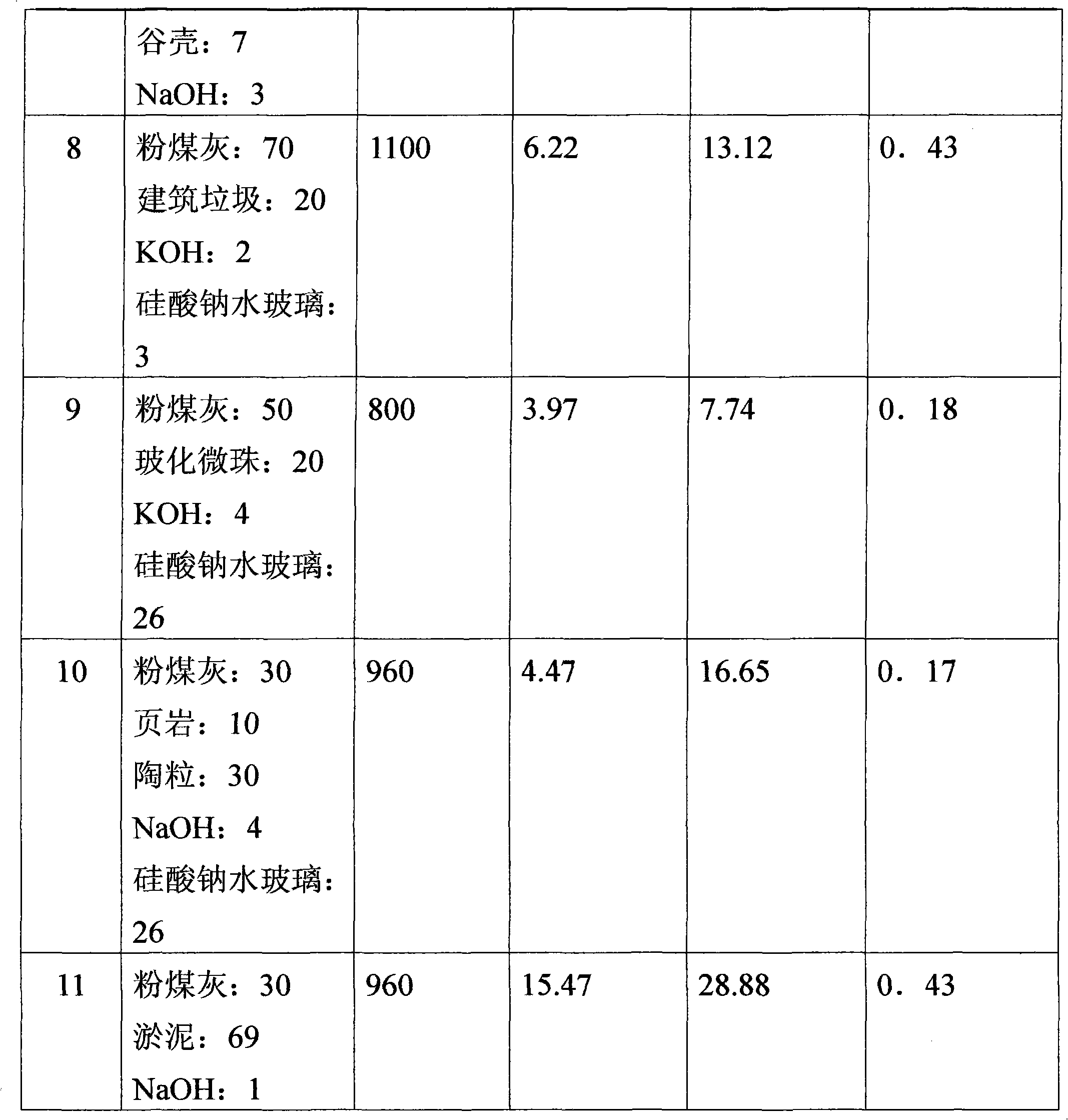

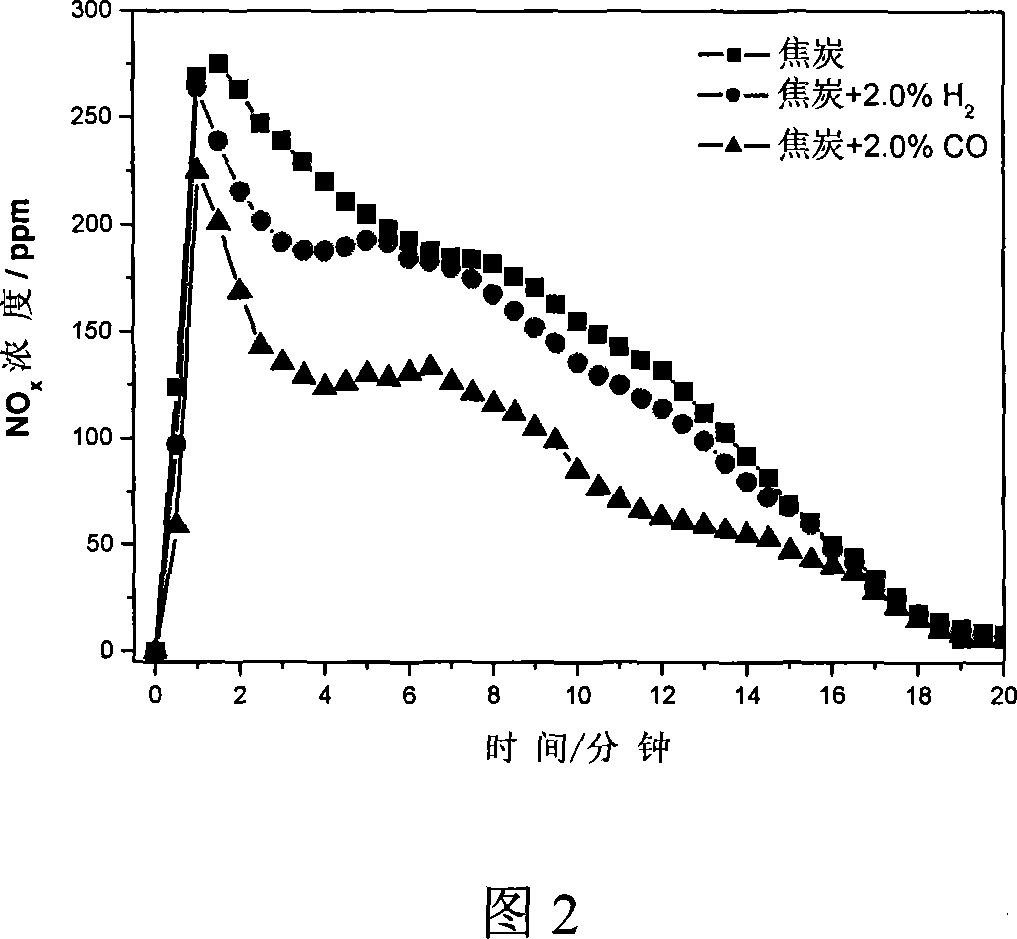

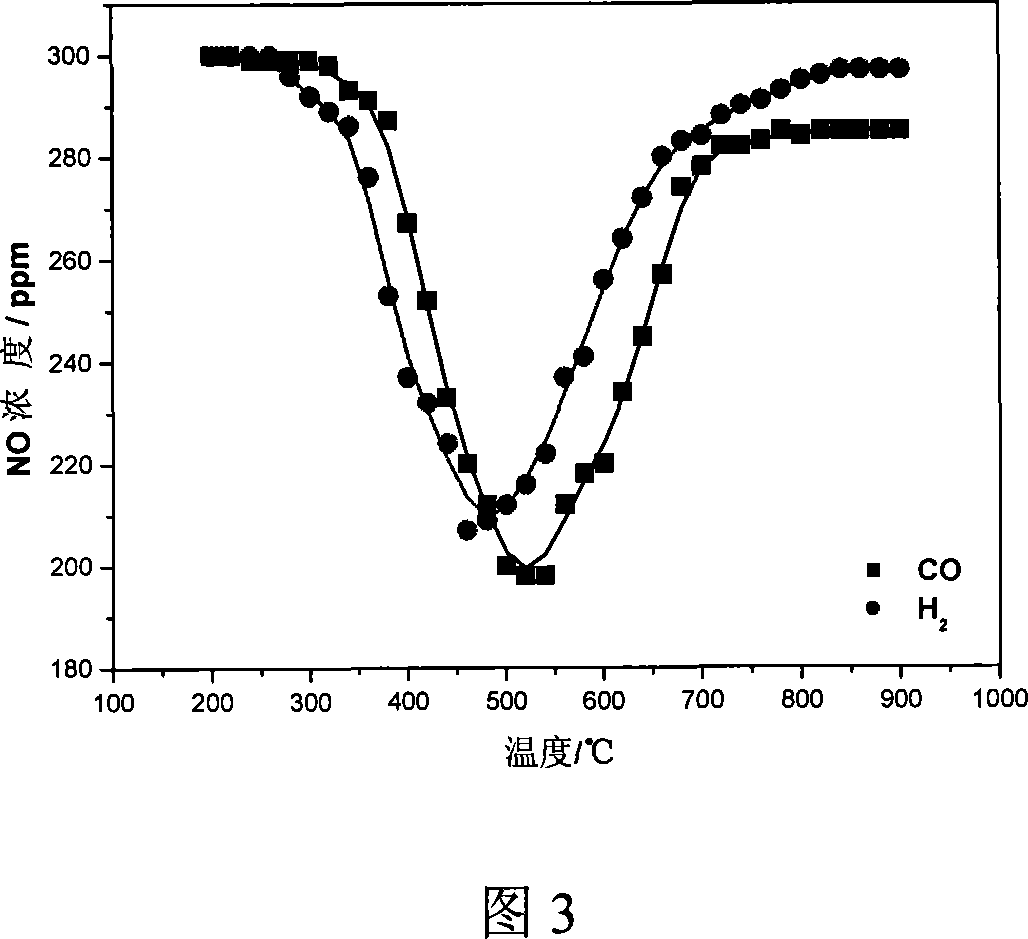

Method of eliminating NOx in metallurgy sintering process

InactiveCN101033503AReduce concentrationEmission reductionDispersed particle separationExhaust gasNOx

The invention relates to a method for removing NOx during a sintering process. In the invention, it adds coke powder or semi-coke powder as fuel in the ingredients, and it connects to gas during sintering process, meanwhile, it returns 10%~50% of the sintered exhaust to the sintering process, and it uses the reducing gas (H2, CH4, and CO)of gas, precursor (NHi and HCN) of NOx and coke to reduce the NOx of the sintered exhaust and NOx of the combustion of coke to N2, thereby it reduces the density of NOx in the exhaust gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

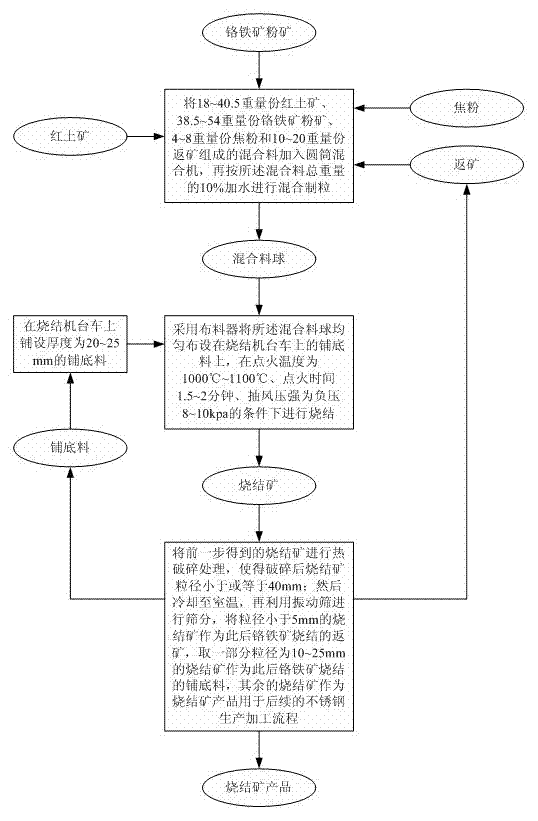

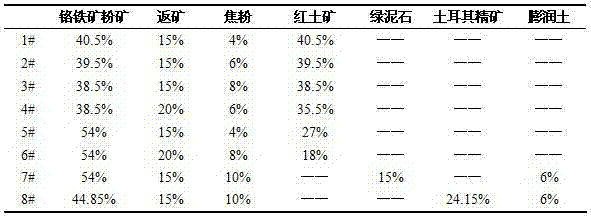

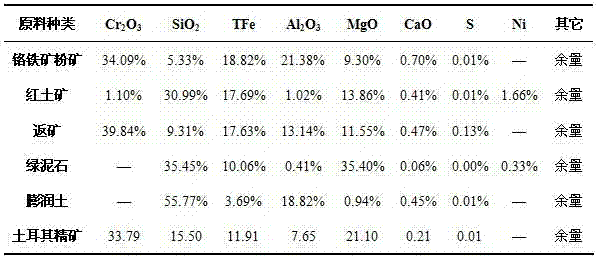

Chromium-iron mineral powder sintering method for stainless steel production

The invention provides a chromium-iron mineral powder sintering method for stainless steel production. According to the chromium-iron mineral powder sintering method, pelletization and sintering are carried out after laterite is added to chromium-iron mineral powder; as the laterite and water have good wetting property, the laterite serving as nucleation particles and the chromium-iron mineral powder adhere to each other and grow, and then are pelletized and clustered in a pelletization process, thus solving the problem that the chromium-iron mineral powder is difficult in pelletizaiton; simultaneously, the sintering temperature of chromite can be reduced due to the addition of the laterite, the amount of a liquid phase is increased, the energy consumption is reduced, the rate of finished product and the strength of a sinter are increased, and the problems of difficulty in sintering of the chromium-iron mineral powder, high content of mixed carbon and high energy consumption in the prior art are solved; as compositions of the laterite are similar to that of a smelting slag system, follow-up smelting and slagging working procedures for stainless steel production are not added, the price is relatively low, and the total cost of the stainless steel production can be effectively reduced; and the chromium-iron mineral powder sintering method has the advantages of increasing the economic benefits of enterprises and relieving the energy saving and emission reduction pressure of the enterprises.

Owner:CHONGQING UNIV

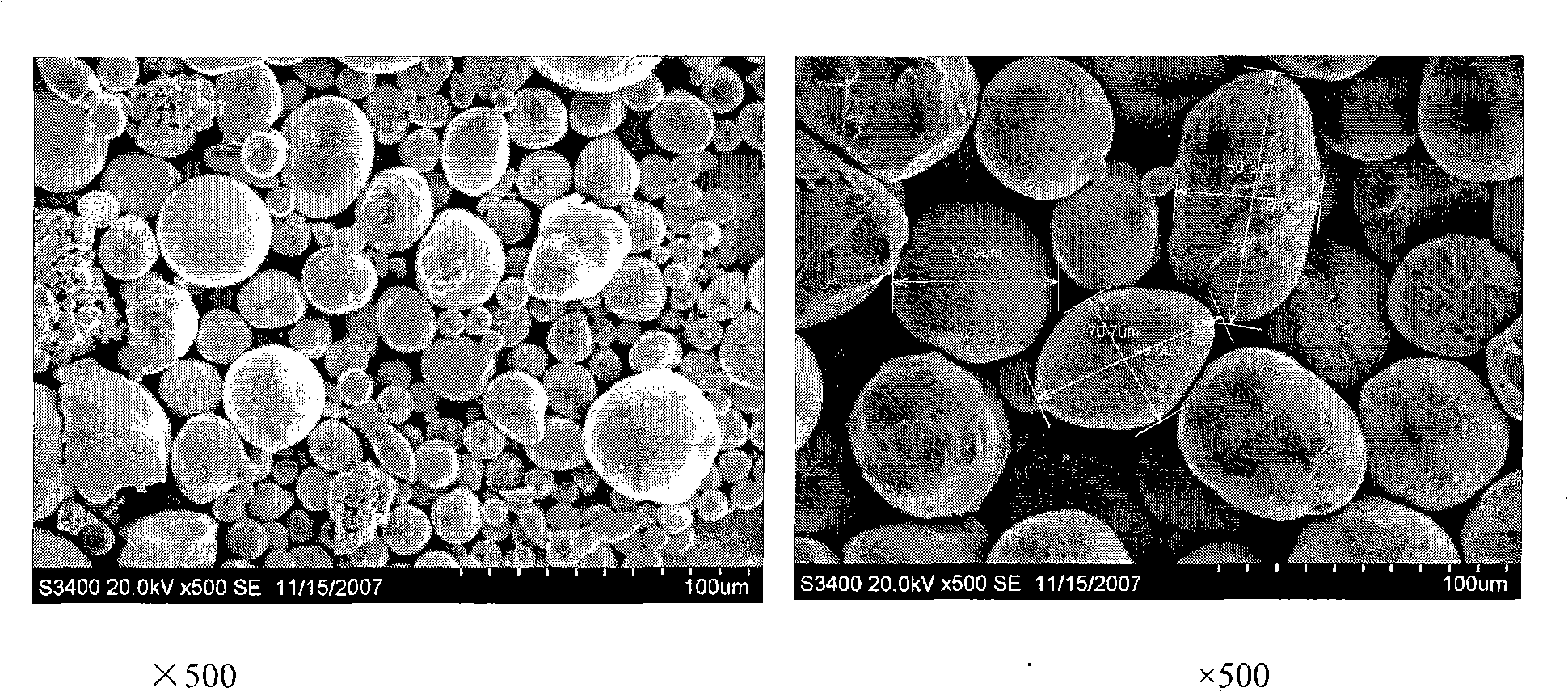

Method for preparing special type molybdenum powder

A method for preparing a special molybdenum powder relates to a method for preparing the molybdenum powder specially used for the industries of thermal spraying and machining as well as pressing fine apparatuses. The powder is characterized in that the preparing process includes the steps as follows: (1) sintering normal molybdenum powder for increasing the granularity; (2) grading the molybdenum powder, the granularity of which is increased; carrying out spheroidisation on the molybdenum powder with approximate granularity by a plasma device, then cooling and collecting the molybdenum powder; (3) reducing the molybdenum powder after being spheroidized, screening, grading and then obtaining the special molybdenum powder. The molybdenum powder prepared by the method of the invention has the advantages of good fluidity, simple technique, high finished product rate and relates to a technique for preparing the special molybdenum powder used in the fields of thermal spraying and pressing fine apparatuses.

Owner:JINDUICHENG MOLYBDENUM CO LTD

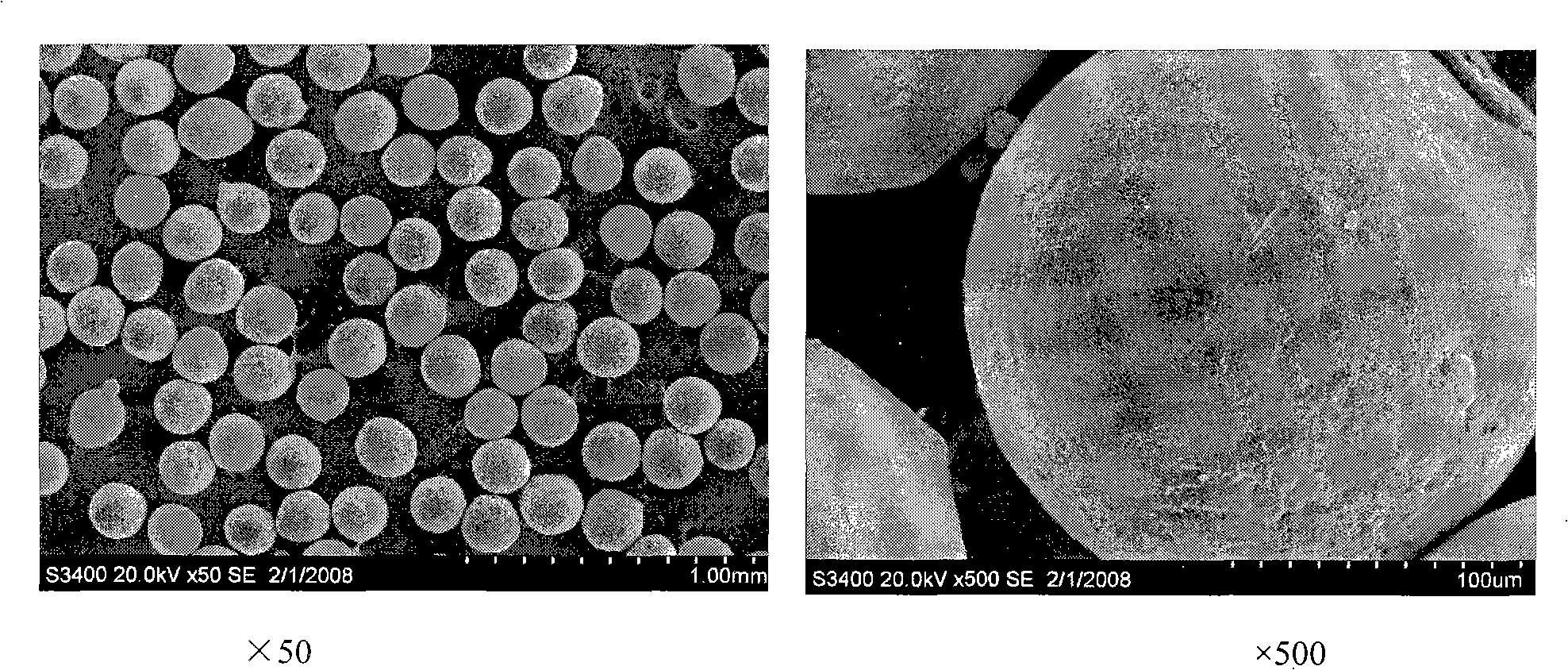

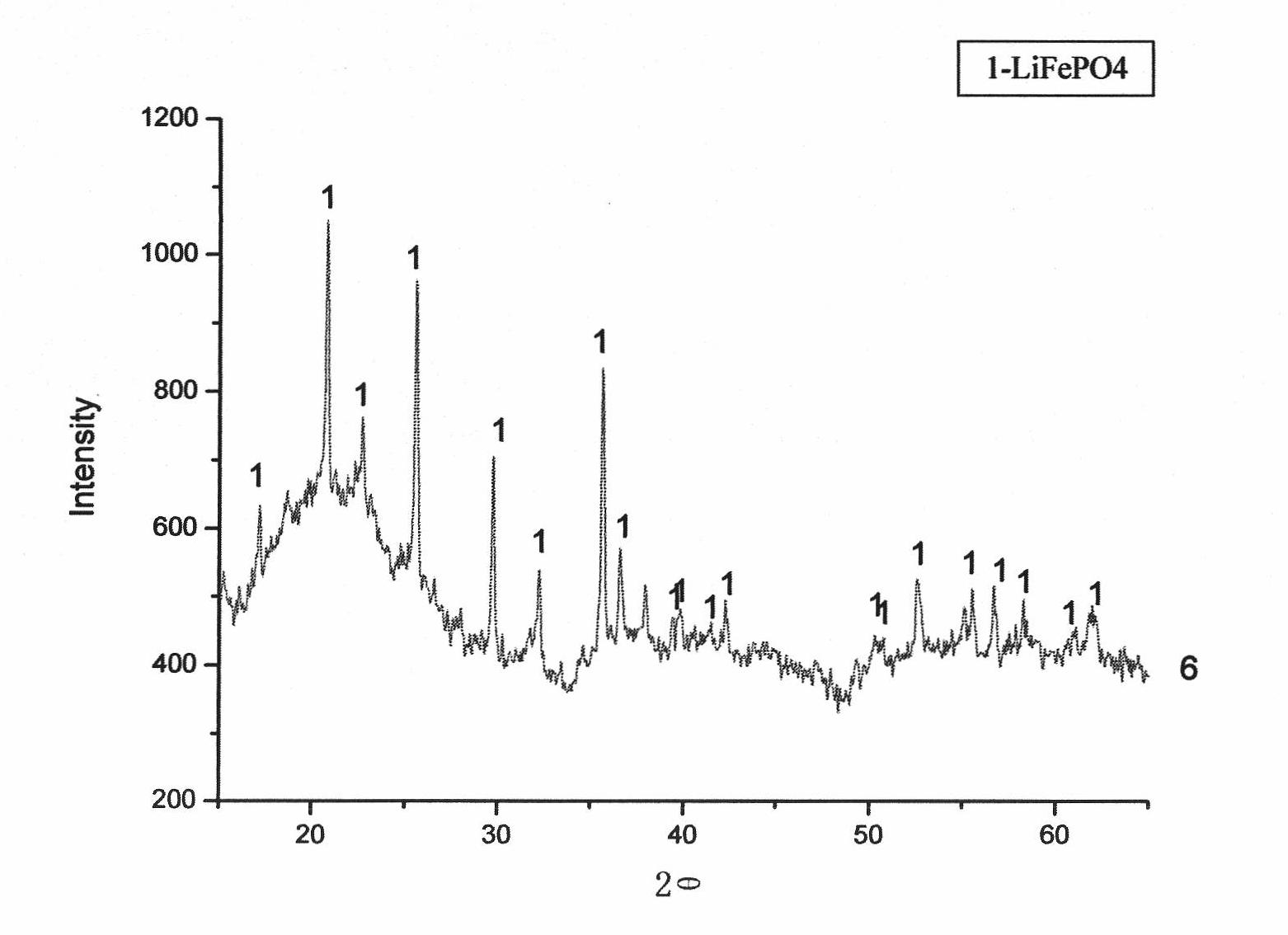

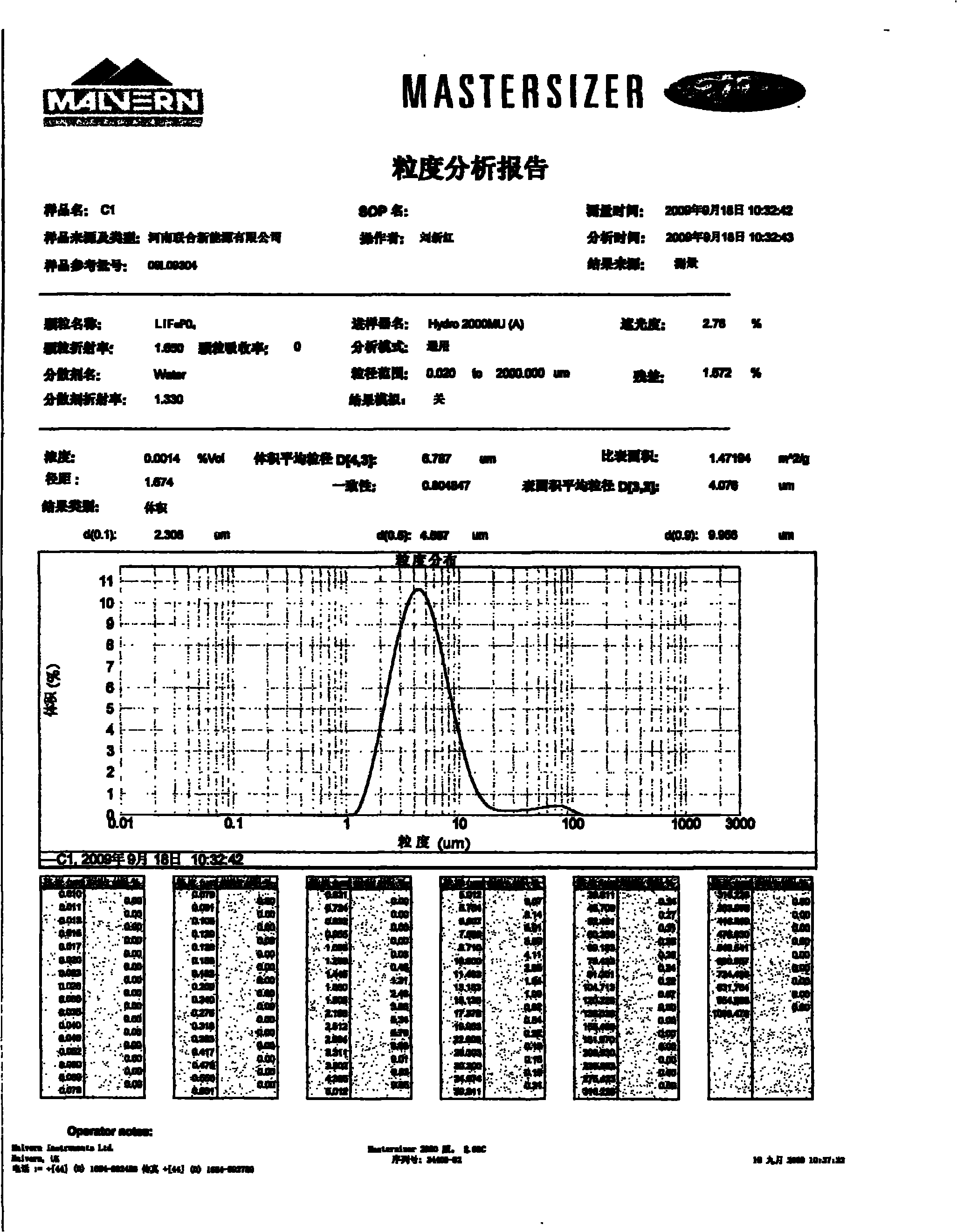

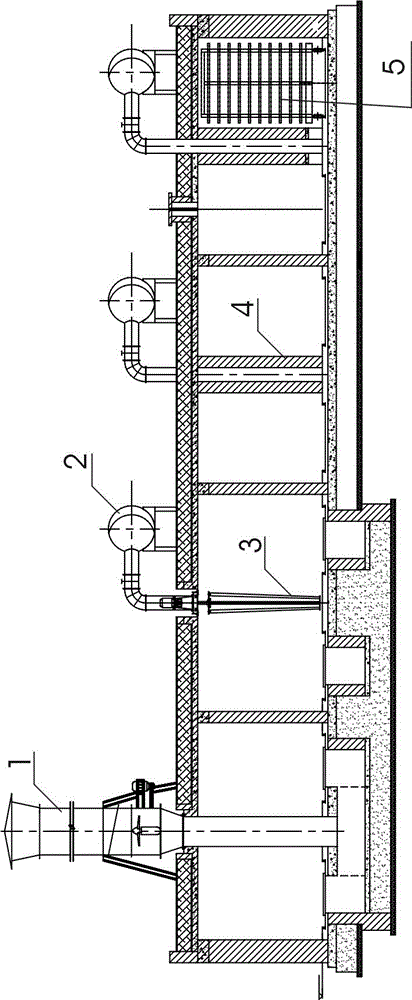

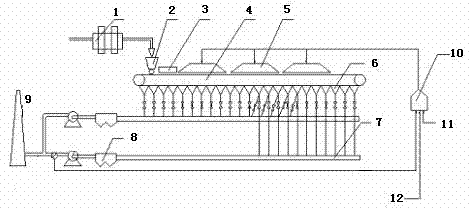

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

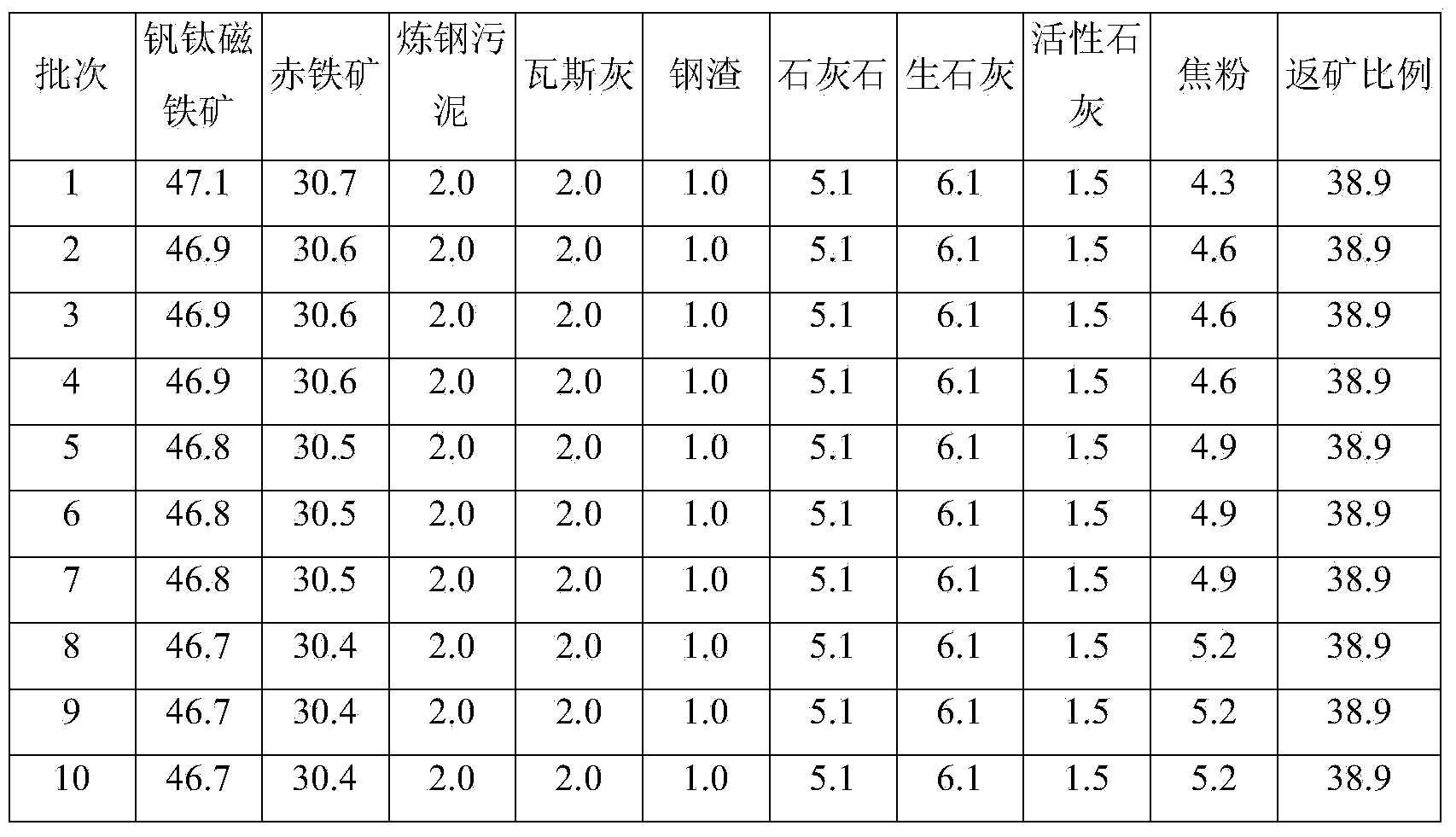

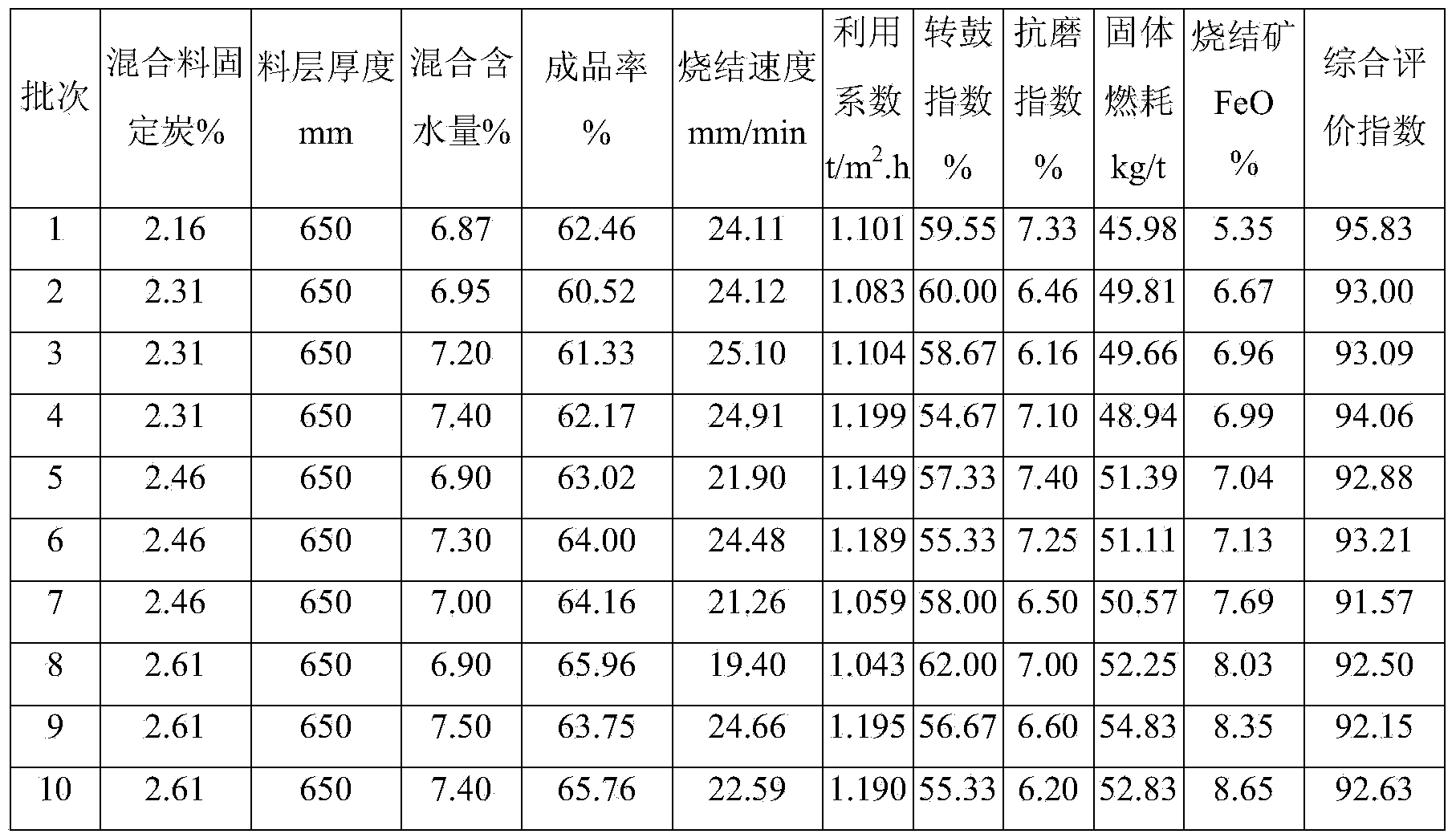

Sintering distribution process optimized control method based on multi-objective genetic algorithm

The invention discloses a sintering distribution process optimized control method based on a multi-objective genetic algorithm, which is characterized by comprising the following steps: 1, building an optimization model of segregation distribution, namely establishing a sample collection by using a large-flue negative pressure, the rotation speed of a nine-roller distributor, the feed level of a feed tank and the depth of a feed bed and establishing a segregation distribution comprehensive satisfaction function; and 2, with a goal of optimizing segregation distribution comprehensive satisfaction, constructing the optimization model on the basis of the principle of the multi-objective genetic algorithm so as to optimize the set values of the depth of the feed bed and the rotation speed of the nine-roller distributor. In the invention, the set values of the depth of the feed bed and the degree of segregation are optimized according to the actual conditions of sintering distribution, so that the setting of the depth of the feed bed and the degree of segregation always adapts to the change of working conditions, and the advantage of deep-feed bed sintering is fully played.

Owner:CENT SOUTH UNIV

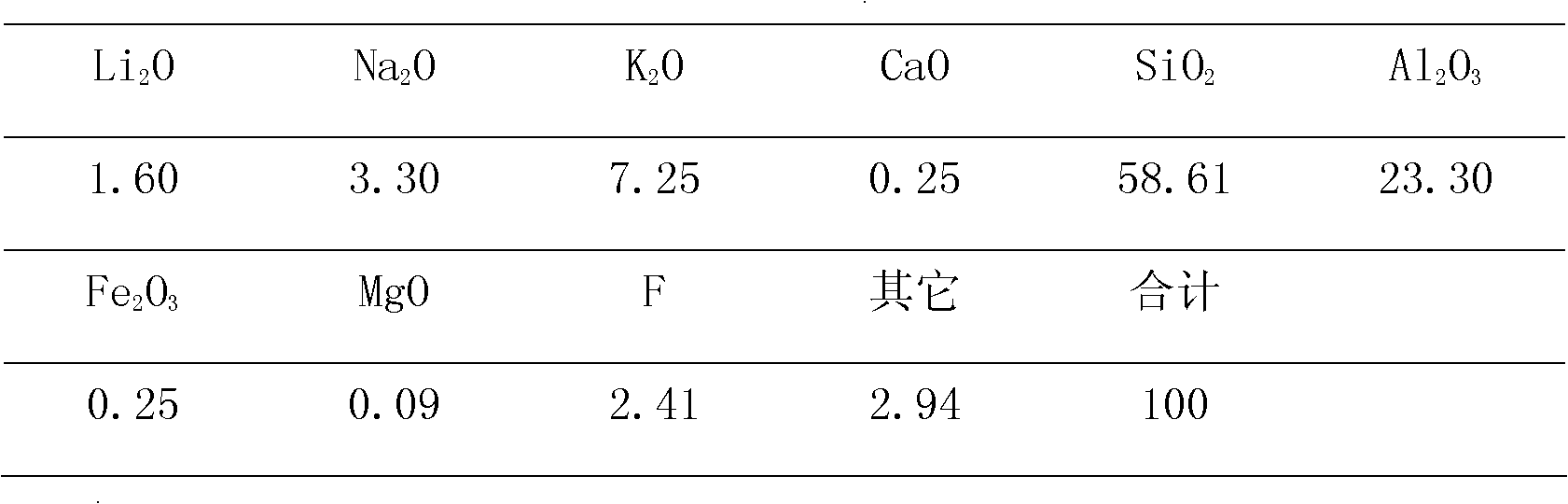

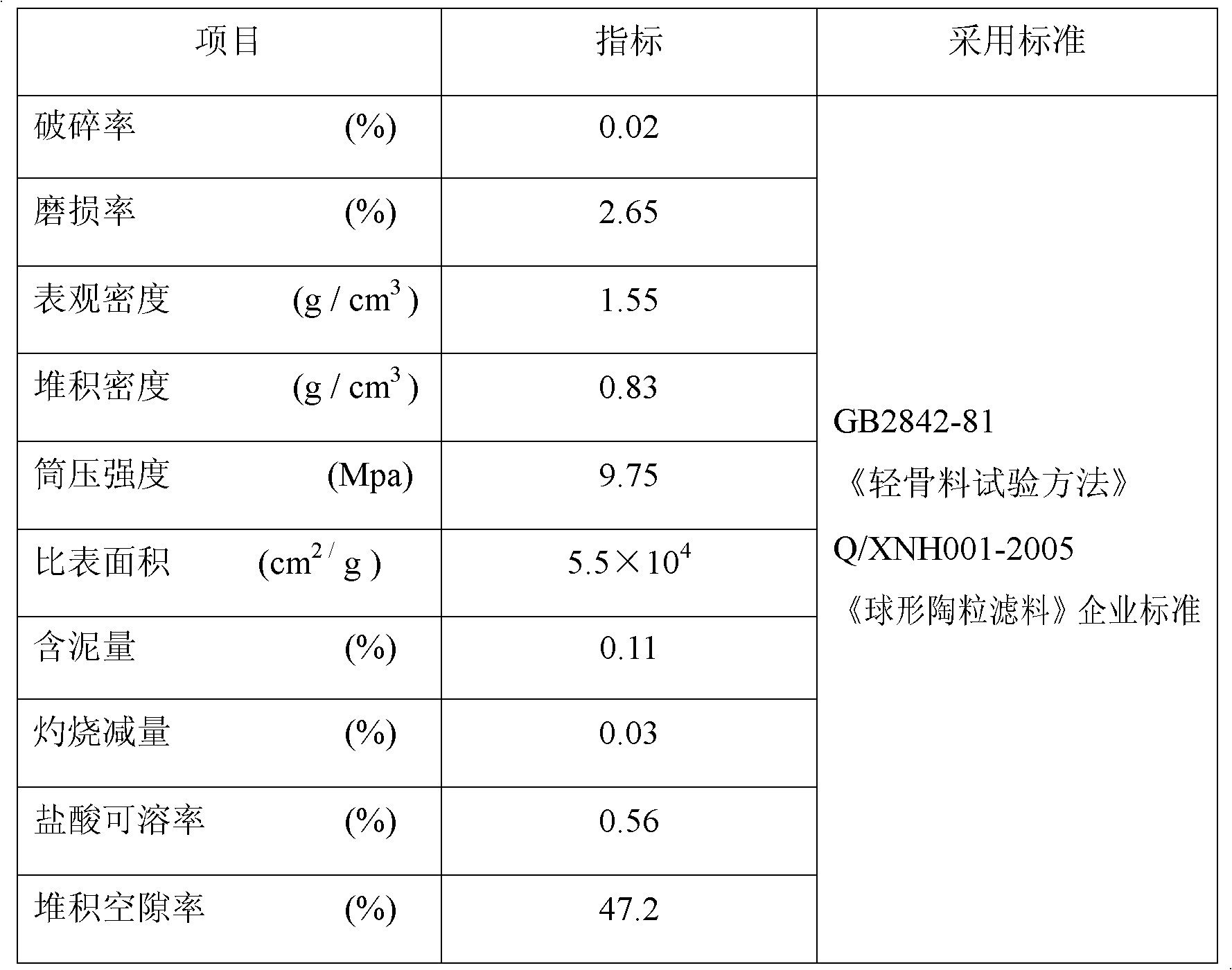

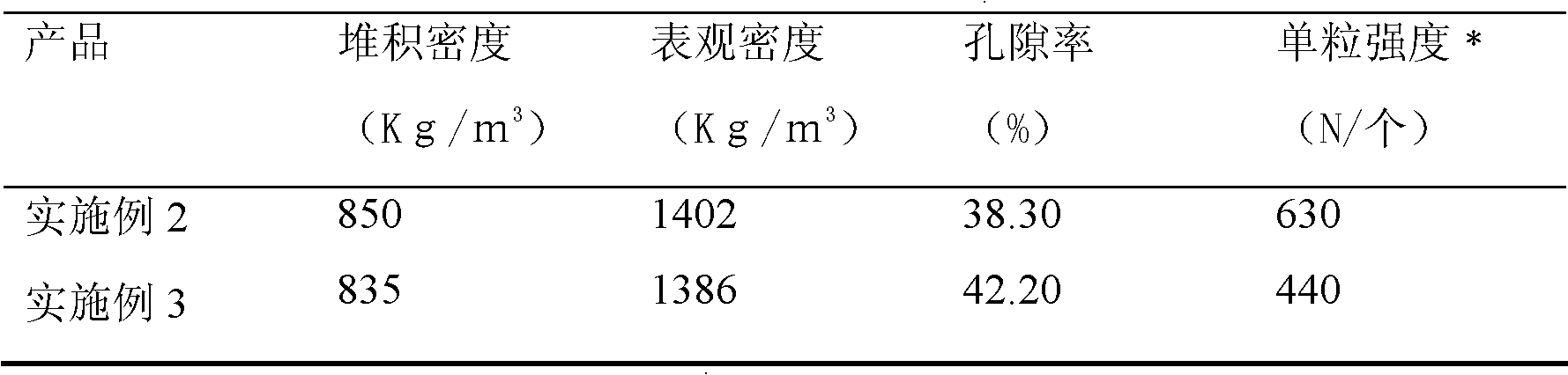

Method for preparing porous ceramsite filter material by using lepidolite extracted lithium slag

InactiveCN102125786AReduce drying energy consumptionReduce grinding energy consumptionFiltration separationPore distributionSlag

The invention discloses a method for preparing a porous ceramsite filter material by using lepidolite extracted lithium slag. The lithium slag extracted by a lepidolite sodium chloride pressure digestion method is used as a main raw material. The method comprises the following steps of: adding partial ground clay powder serving as a plasticizer, adulterating a little amount of pore forming agent (one or two of carbon powder, bran powder, calcium carbonate powder and waste glass powder), balling, sintering and sintering. The filter material has the characteristics of low stacking density, high porosity, uniform pore distribution, high cylinder pressure strength and long service life. The method can simplify the production process and reduce the production cost, is favorable for pollution-free production of a lepidolite mineral lithium extracting process, and has significance for resource recycle and environmental friendliness.

Owner:NANCHANG UNIV

Detecting method for iron ore sintering machine air leakage rate

ActiveCN109490001ACompact structureEasy to useFurnace componentsStructural/machines measurementIron ore sinteringEnergy consumption

The invention discloses a detecting method for the iron ore sintering machine air leakage rate. The detection method comprises the following steps that detection devices are made firstly, and a row ofthe detection devices are arranged on a sinter bed; when sintering is conducted, wind speeds measured by all the detection devices are recorded, the material surface of the sinter bed is subjected tomesh generation, all wind speeds recorded by the detection devices from beginning to end sequentially serve as the wind speeds of all grid points on longitudinal boundary lines where the detection devices are located, and the effective air amount QY passing through the bed within unit time is calculated; the total flue gas amount QZ in a flue within unit time is calculated; the amount QE of vapour generated within the unit time is calculated; the QY, the QZ and the QE are converted into the amount under the standard state, the sintering system air leakage QLstandard within unit time is calculated, and the sintering system air leakage rate K within unit time is calculated. Accordingly, by means of an optimized sintering effective air amount measurement and calculation method, the calculation accuracy of the sintering air leakage rate is improved, maneuverability is high, rapidness and convenience are achieved, and then the theoretical basis is provided for lowering energy consumption and increasing the yield for sintering production.

Owner:MAANSHAN IRON & STEEL CO LTD

Iron ore low-carbon sintering method

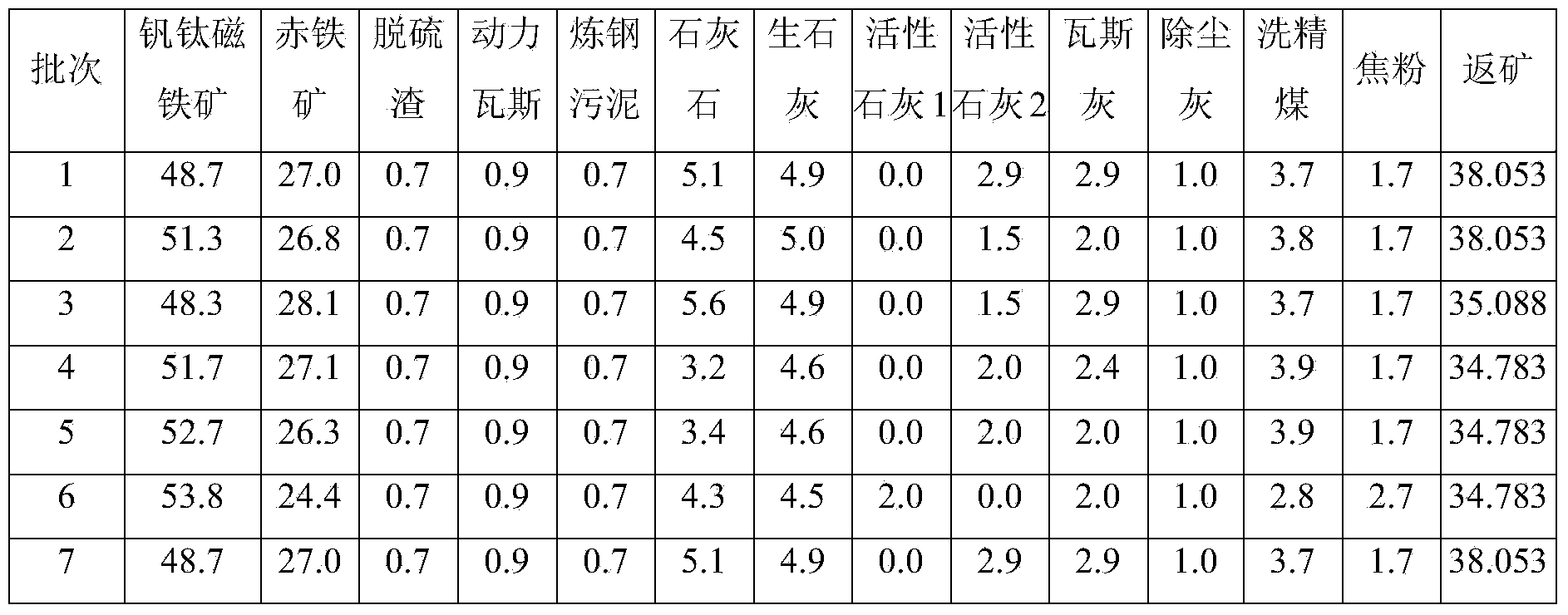

ActiveCN104313308AIncrease incomeReduce the amount of carbonProcess efficiency improvementIronstoneMagnetite

The invention belongs to the field of steel smelting, and particularly relates to an iron ore low-carbon sintering method which is low in sintering energy consumption. According to the technical scheme, the iron ore low-carbon sintering method includes the steps that iron ore, fuel and a fluxing agent are distributed and mixed to form a mixture for sintering, wherein magnetite in the iron ore is not smaller than 50% by mass, non-magnetite m1 is greater than 0 but smaller than or equal to 40%, metallurgy waste m2 is greater than or equal to 0 but smaller than or equal to 10%, the non-magnetite is at least one of hematite, limonite and siderite, and the metallurgy waste is iron waste mainly composed of Fe and FeO. According to the method, raw material constitutes of the mixture and technical parameters are adjusted, so that non-carbon heat input is increased, carbon content is reduced, and sintering energy consumption is reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

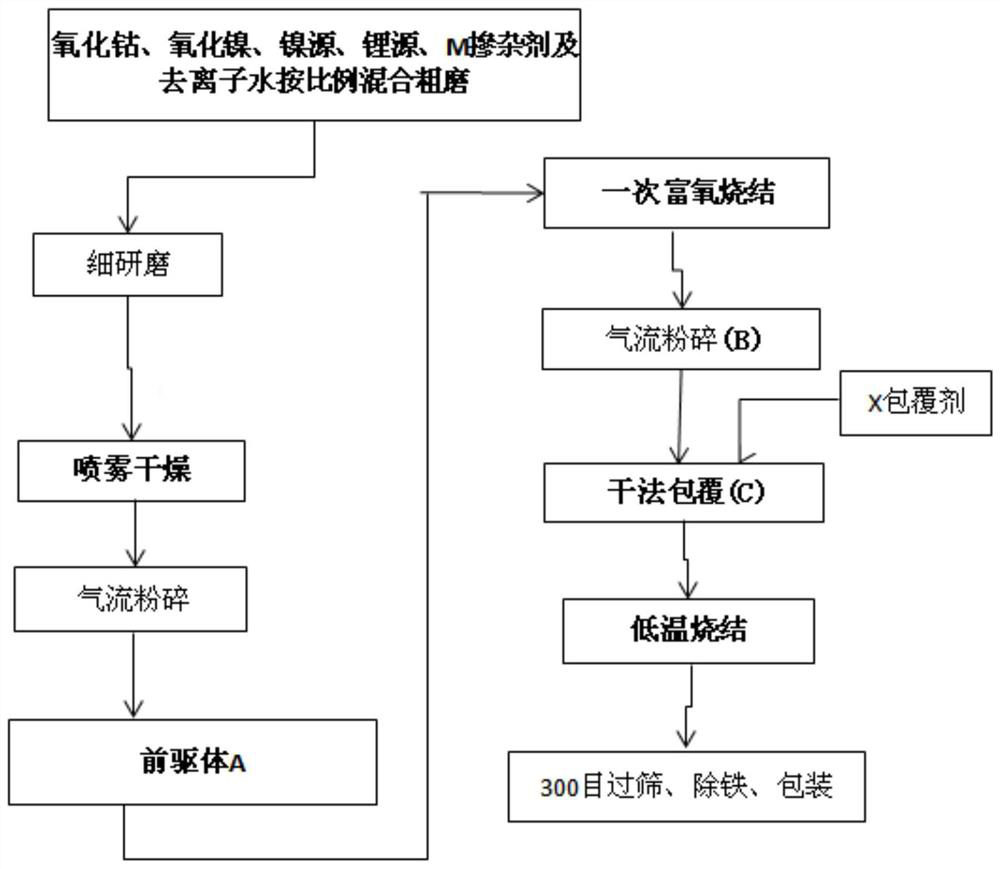

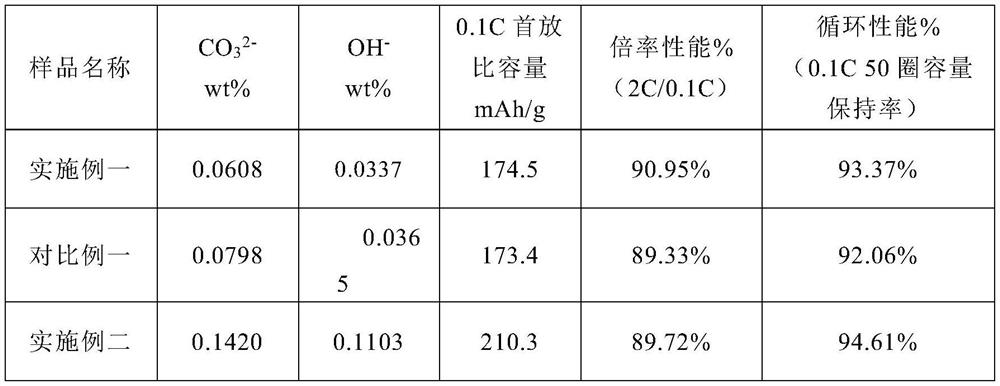

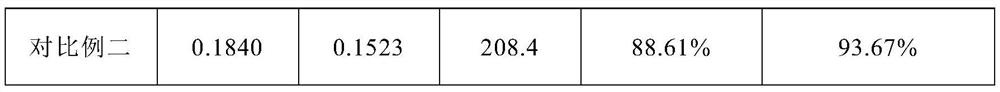

Low-cost low-cobalt single crystal ternary positive electrode material and preparation method thereof

InactiveCN112342605AAvoiding Emissions Disposal IssuesResidual alkali controlPolycrystalline material growthFrom solid stateAir atmosphereSingle crystal

The invention discloses a low-cost low-cobalt single crystal ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: adding a nickelsource, cobalt oxide, manganese oxide, a lithium source and an M doping agent in a certain stoichiometric ratio into a grinding machine, carrying out wet grinding until the particle size of insolublesubstances is less than or equal to 0.5 mu m, and carrying out spray drying to obtain an energy-saving, low-cost and low-cobalt lithium-containing ternary precursor A; carrying out high-temperature oxygen-enriched sintering and crushing treatment on the A to obtain a high-dispersion single-crystal ternary material matrix B; and coating X with B by a dry method, carrying out solid-phase sinteringin a low-temperature air atmosphere, and carrying out crushing treatment to obtain the low-cost low-cobalt single-crystal positive electrode material. The manufacturing process is environmentally friendly, pollutant emission in the precursor preparation and product sintering process is avoided, the operation process is simple and controllable, and the cost is low. Meanwhile, double doping and surface coating are achieved, the structure of the material is stabilized, the migration speed of lithium ions on the surface of the product is increased, and residual alkali on the surface of the productis reduced. The material is high in capacity and good in cycling and high-temperature safety.

Owner:陕西彩虹新材料有限公司

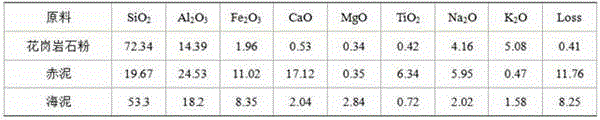

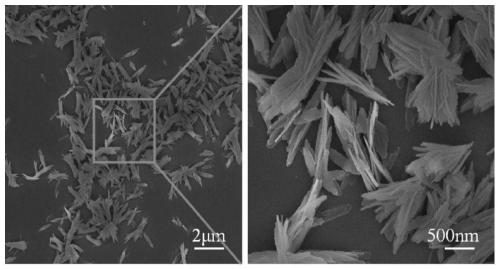

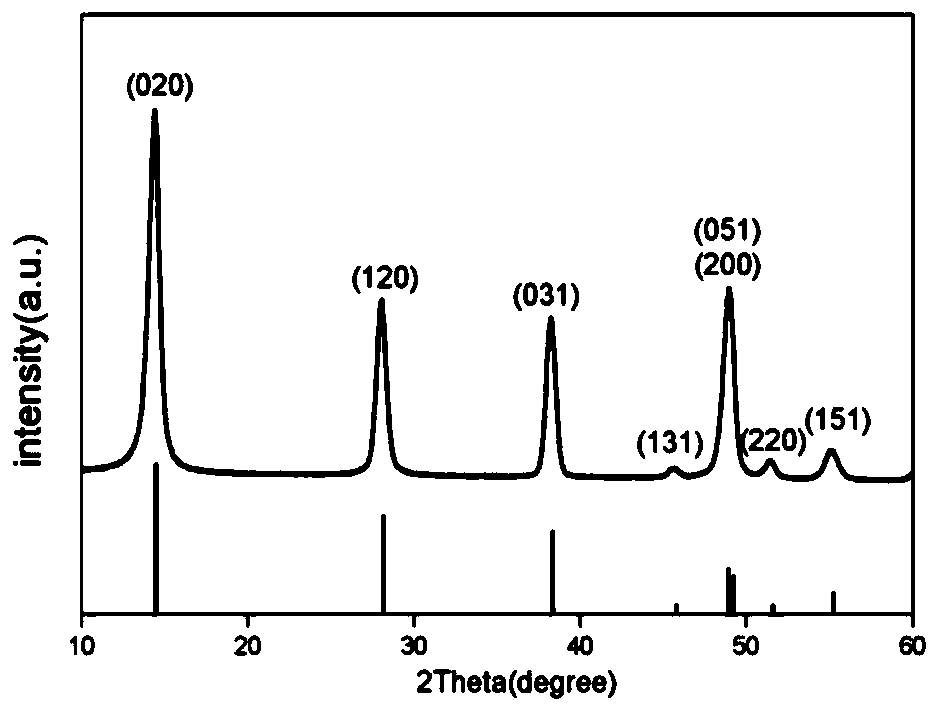

Microwave sintering method for granite rock flour ceramsite

The invention discloses a microwave sintering method for granite rock flour ceramsite. The granite rock flour ceramsite is prepared from the following raw materials in mass percent: 60% to 80% of granite rock flour, 10% to 30% of red mud, 0% to 29% of sea mud, 0% to 20% of high-carbon coal cinder and 0.15% to 0.3% of microwave sensing agent. Bulk density of the prepared high-performance ceramsite is 430 to 1200kg / m<3>, apparent density is 850 to 1700kg / m<3>, water absorption is 5% to 19%, and cylinder compressive strength is 3.5MPa to 9.5MPa. According to the granite rock flour ceramsite disclosed by the invention, waste granite rock flour generated by stone processing plants, sea mud generated by sea dredging and metro construction, industrial solid waste red mud drained by aluminum manufacturers and the like are utilized as the raw materials, and waste utilization rate can be 95% or more; the microwave sintering method has high sintering efficiency, can save sintering energy consumption by 20% to 30% and has better social and economical benefits.

Owner:FUJIAN JIANGXIA UNIV

Method for producing aluminum hydroxide by roasting bauxite at low temperature

InactiveCN109279633AReduce trafficReduce sintering energy consumptionAluminium silicatesProcess efficiency improvementAluminium hydroxideRed mud

The invention belongs to the technical field of aluminum industries, and specifically discloses a method for producing aluminum hydroxide by roasting bauxite at a low temperature. The method includesmixing crushed bauxite with a caustic solution to obtain raw slurry; roasting the raw slurry with 160-890 DEG C to obtain clinkers; performing dissolution reaction on the clinkers to obtain digestionliquor, and performing solid-liquid separating on the digestion liquor, wherein a solid phase is a pug whose iron content is larger than or equal to 40%, the pug can be sold as an iron concentrate rawmaterial after washing, a liquid phase is crude liquid, and a desilication solid phase is a sodium aluminosilicate product after the desiliconization of the crude liquid; and adding aluminum hydroxide seeds into the liquid phase to perform decomposition reaction, and performing solid-liquid separating on decomposition liquid, wherein the obtain liquid phase is seeded precipitation spent liquor, and the solid phase is an aluminum hydroxide product. The method enhances decomposition rate and cyclic efficiency, and reduces energy consumption; and compared with traditional sintering methods, theroasting temperature can be obviously reduced, the method does not generate red mud, more than 70% of silicon dioxide in the bauxite is made into the sodium aluminosilicate products, and the standardof the quality of the prepared aluminum hydroxide is better than that of the aluminum hydroxide produced by the traditional sintering methods and Bayer process.

Owner:陈湘清

Method for preparing light porous ceramsite from municipal sewage sludge

InactiveCN107188601ASimple systemGood technical and economic effectCeramic materials productionCeramicwareAir atmosphereResource utilization

The invention provides a method for preparing light porous ceramsite from municipal sewage sludge. The method comprises the following steps that 1, the light porous ceramsite is prepared from, by weight, 70-80% of municipal sludge, 15-25% of coal gangue powder, 1-5% of carborundum powder and 2-10% of calcium phosphate; 2, all the components are mixed to be uniform, then, a pressing molding method is adopted for molding, the molding pressure is 5-15 Mpa, the mixture is dried in the air atmosphere under the temperature of 100-120 DEG C for 40 min after being molded, and placed into a sintering furnace, the temperature is slowly increased to 120-600 DEG C for 80 min, and then, the temperature continues to be increased at the speed of 5-10 DEG C / min to about 1,060 DEG C to obtain the light porous ceramsite can be obtained. According to the finished ceramiste, the water absorptivity is not larger than 10%, the stacking density range is not larger than 500 kg / m<3>, and the cylinder compressive strength is not smaller than 0.4 MPa. The technical index can reach the standard of GBT 17431.1-2010 'lightweight aggregate and a testing method thereof'. The method is suitable for ceramsite for buildings. Waste can be turned into wealth, environment pollution is improved, and therefore the suitable high-valued outlet is provided for sludge disposal and resource utilization, and remarkable economic benefits and social benefits are achieved.

Owner:新岛世纪(北京)新型材料技术有限公司 +5

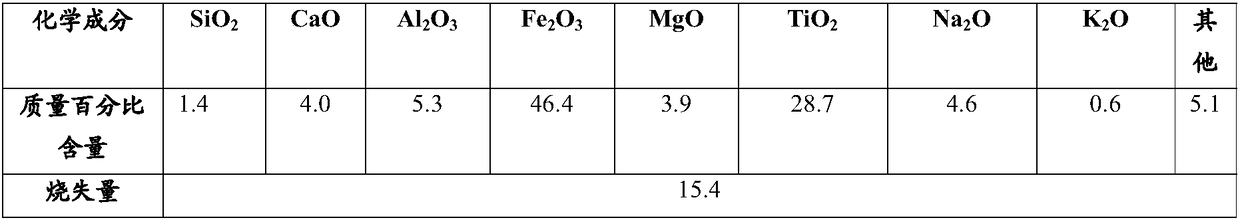

Lithium titanium aluminum phosphate solid electrolyte material and preparation method thereof

ActiveCN111233458AStop lossImprove surface activitySolid electrolytesSecondary cellsPhysical chemistryALUMINUM PHOSPHATE

The invention provides a lithium titanium aluminum phosphate solid electrolyte material and a preparation method thereof. The preparation method specifically comprises the steps that 1, soluble aluminum salt and a precipitator are mixed and dissolved in water according to the molar ratio of 1: (1.5-2), and a mixed solution is obtained; the mixed solution is placed into a reaction kettle for heating, and a product is subjected to filtering, washing and drying to obtain an AlOOH precursor; (2) the AlOOH precursor obtained in the step (1) is mixed with lithium salt, titanium salt and phosphorus salt; Li, Al, Ti and P are mixed according to a molar ratio of (1+x): x: (2-x): 3, an ethanol medium is added, ball milling is performed, and presintering and secondary molding sintering are carried out in a dry air atmosphere to obtain the lithium titanium aluminum phosphate solid electrolyte material. The method is simple in process, low in synthesis temperature and easy to implement industrially, and the prepared lithium titanium aluminum phosphate solid electrolyte material is high in purity, good in density and high in lithium ion conductivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

PTC thermal sensitive ceramic heating element

ActiveCN101252813AReduce sintering energy consumptionReduce manufacturing costCeramicsPositive temperature coefficient thermistorsAdditive ingredientHeat sensitive

The invention discloses a heating element of PTC thermosensitive ceramics. The main ingredient of the heating element comprises the following components and the material proportioning by weight: 37.56 to 42.65 percent of BaCO2, 26.16 to 31.23 percent of Pb3O4, 26.74 to 28.23 percent of TiO2, and 2.16 to 3.13 percent of CaCO3. The heating element has the advantages that firstly, the curie temperature of the receipt of the heating element, and the range for being suitable for the service voltage are both wider, and the conformity and the stability of the finished product are obviously improved; secondly, the electrical property of the heating element is better, the heating element is uneasy to be punctured and spark, and the thermal efficiency and the service life of the element are both greatly prolonged; thirdly, the physical property of the heating element is obviously improved, the cold-hot resistant catastrophic property is greatly enhanced, and the anti-aging property is improved; fourthly, the manufacturing process of the heating element is simple, the energy consumption for sintering is obviously saved, and the manufacturing cost is greatly reduced; fifthly, after the PTC heating element manufactured through the invention is assembled into a heating device, the production cost is obviously reduced, and the conformity, the operation reliability and the security of the product are all greatly improved.

Owner:WUXI GUOWEI CERAMIC ELECTRICAL APPLIANCES CO LTD

High efficiency and energy saving fly ash sintered brick making method

ActiveCN104129972AEasy to transformLow drying efficiencySolid waste managementBrickResource utilization

The invention provides a high efficiency and energy saving fly ash sintered brick making method. The optimization of granularity graduation of shale powder and the introduction of a single layer drying process capable of realizing large-scale continuous production solve the problems of low strength and easy deformation of green bricks in the drying process of ultrahigh-content fly ash sintered bricks, and multi-time mixing, forced mixing, heat insulation time prolongation processes further improve the product stability, so the large-scale industrial production of ultrahigh-content fly ash sintered bricks is successfully realized, the sintered bricks obtained in the invention has high yield, excellent strength and reduced weight, and energy consumed by sintering is effectively reduced. The selection of a kiln top and a hanging structure made of a sintered refractory material improves the acid corrosion resistance of a kiln body, can effectively adapt to the production of high--sulfur high-carbon fly ash sintered bricks, solves the problem of difficult utilization of fly ash from a circulating fluidized bed power plant, and improves the resource utilization rate.

Owner:西安瑞泰机械设备制造有限公司

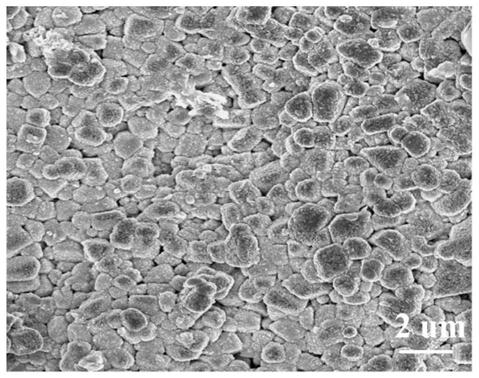

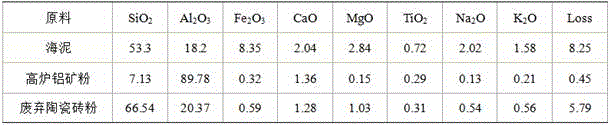

Microwave sintering method of sea mud ceramsite

InactiveCN106747559AImprove sintering efficiencyReduce sintering energy consumptionCeramic materials productionCeramicwareBrickSludge

The invention discloses a microwave sintering method of sea mud ceramsite. The sea mud ceramsite is prepared from raw materials in percentage by mass as follows: 60%-100% of sea mud, 0%-30% of waste ceramic tile powder and 0%-20% of blast-furnace aluminium ore powder. In terms of the prepared high-performance ceramsite, bulk density is 400-1,100 kg / m<3>, apparent density is 800-1,600 kg / m<3>, water absorption is 5%-18% and cylinder compressive strength is 3.0 MPa-10.0 MPa. The raw materials comprise marine sludge produced through marine dredging and metro construction, waste ceramic pulverized powder of a ceramic tile factory and the blast-furnace aluminium ore powder produced in an aluminium factory, utilization rate of waste reaches 95% or higher, and good social benefit is obtained; the microwave sintering method is high in sintering efficiency, can reduce sintering energy consumption by about 25% and has better economic benefit.

Owner:FUJIAN JIANGXIA UNIV

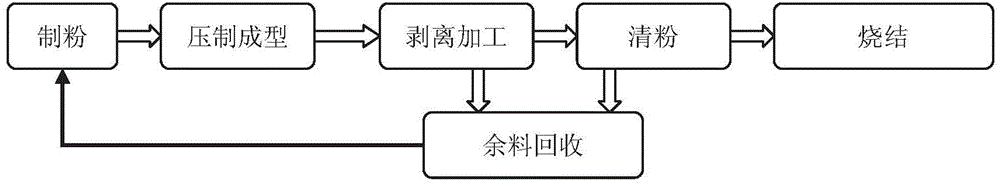

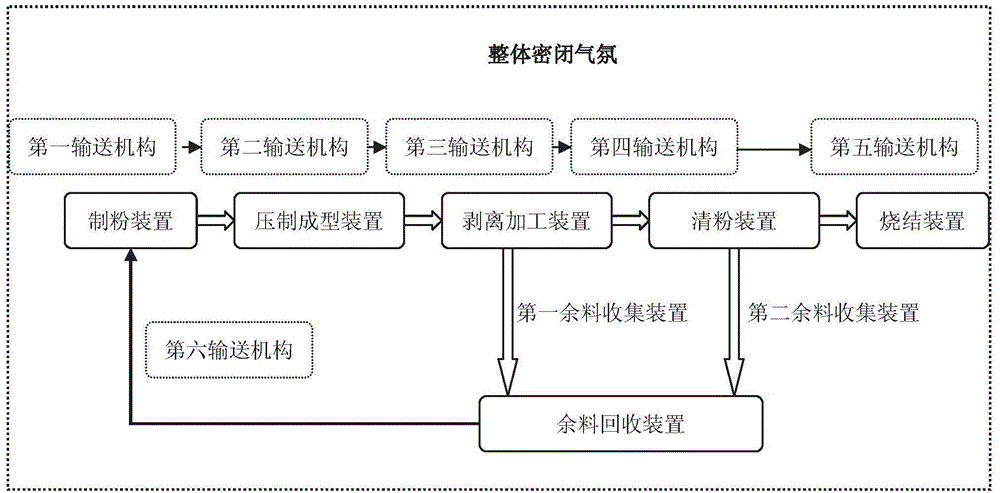

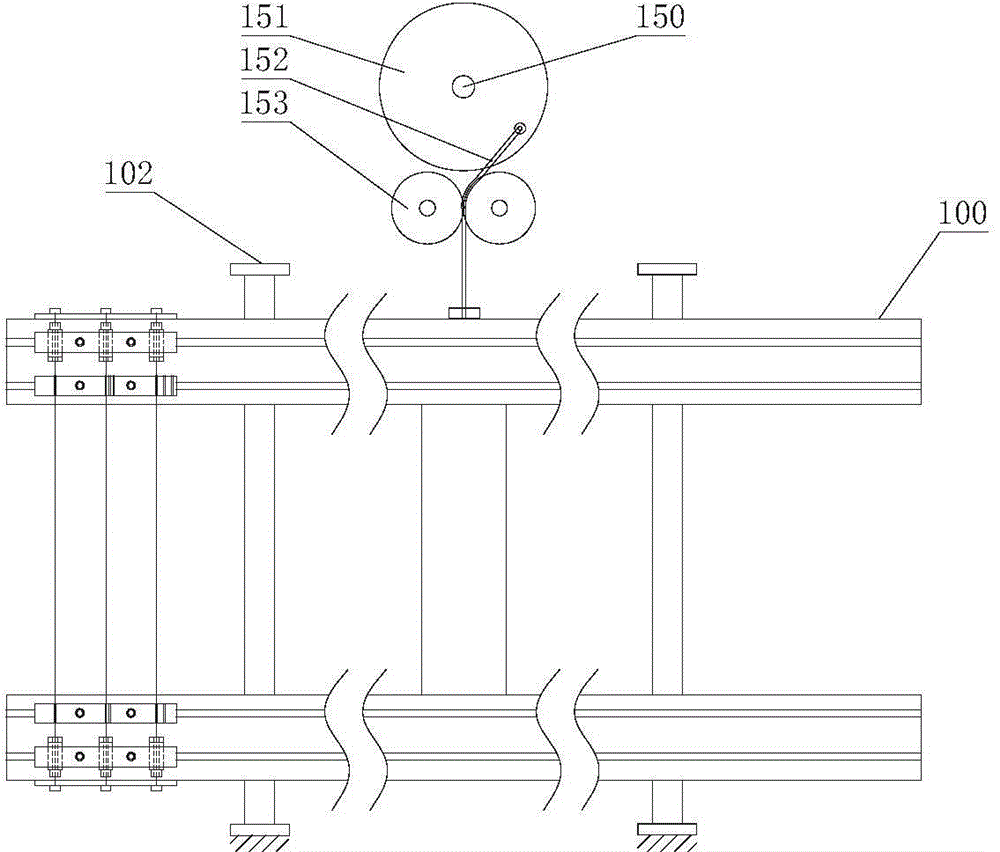

A rare earth permanent magnetic material preparing method

ActiveCN104907558AReduce lossEliminate finishing processMagnetic materialsRare earthSintered magnets

The invention relates to a rare earth permanent magnetic material preparing method comprising the steps of preparing a press blank of powder of sintered magnets, using row wires to machine the press blank and then performing sintering. All the steps are performed in a wholly sealed atmosphere. The row wire machining means line machining for the press blank formed by pressing; after the press blank is clamped and located, a driving mechanism drives the row wires to move back and forth linearly; the press blank is machined according to a preset path along with the rotation of a locating clamp and finally forms a block body or a sheet body with a preset shape and size, an arched body or other specially-shaped bodies; the final forming size contains the sintering shrinkage allowance. The rare earth permanent magnetic material preparing method has the advantages of short preparation technological process, high machining efficiency, low magnetic powder loss, and high rare earth utilization rate. The machining is near net machining, so that a finish machining procedure performed after sintering is saved.

Owner:浙江三环康盈磁业有限公司

PERC crystalline silicon solar main grid positive silver paste for silk-screen printing and preparation method thereof

InactiveCN108074656ASolve EL dimmingSolve the blackening phenomenonFinal product manufactureNon-conductive material with dispersed conductive materialSilver pasteScreen printing

The invention relates to the technical field of electronic materials, in particular to PERC crystalline silicon solar main grid positive silver paste for silk-screen printing. The paste comprises, bymass, 60-80% of spherical silver powder, 5-40% of sheet-shaped silver powder, 5-20% of nanometer silver powder, 1-10% of glass powder, 20-50% of organic carrier and 0.2-3% of sintering accelerant. Byutilization of main grid positive silver paste, sintering temperature is low, energy consumption in sintering is reduced, sintering can be performed at the temperature of 730 DEG C-820 DEG C, and after the main grid positive silver paste is sintered, the main problems of EL darkening and blacking are solved.

Owner:北京市合众创能光电技术有限公司

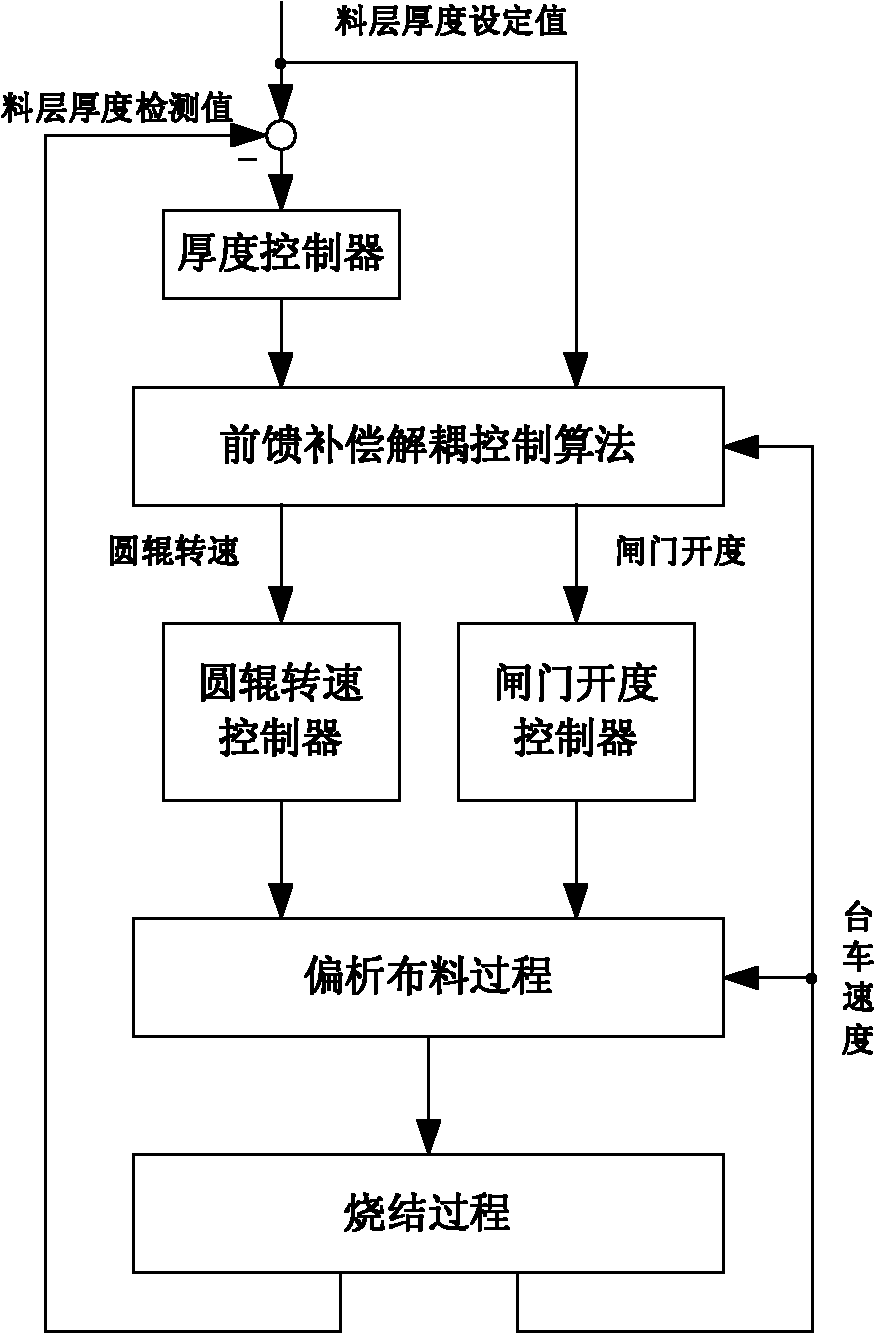

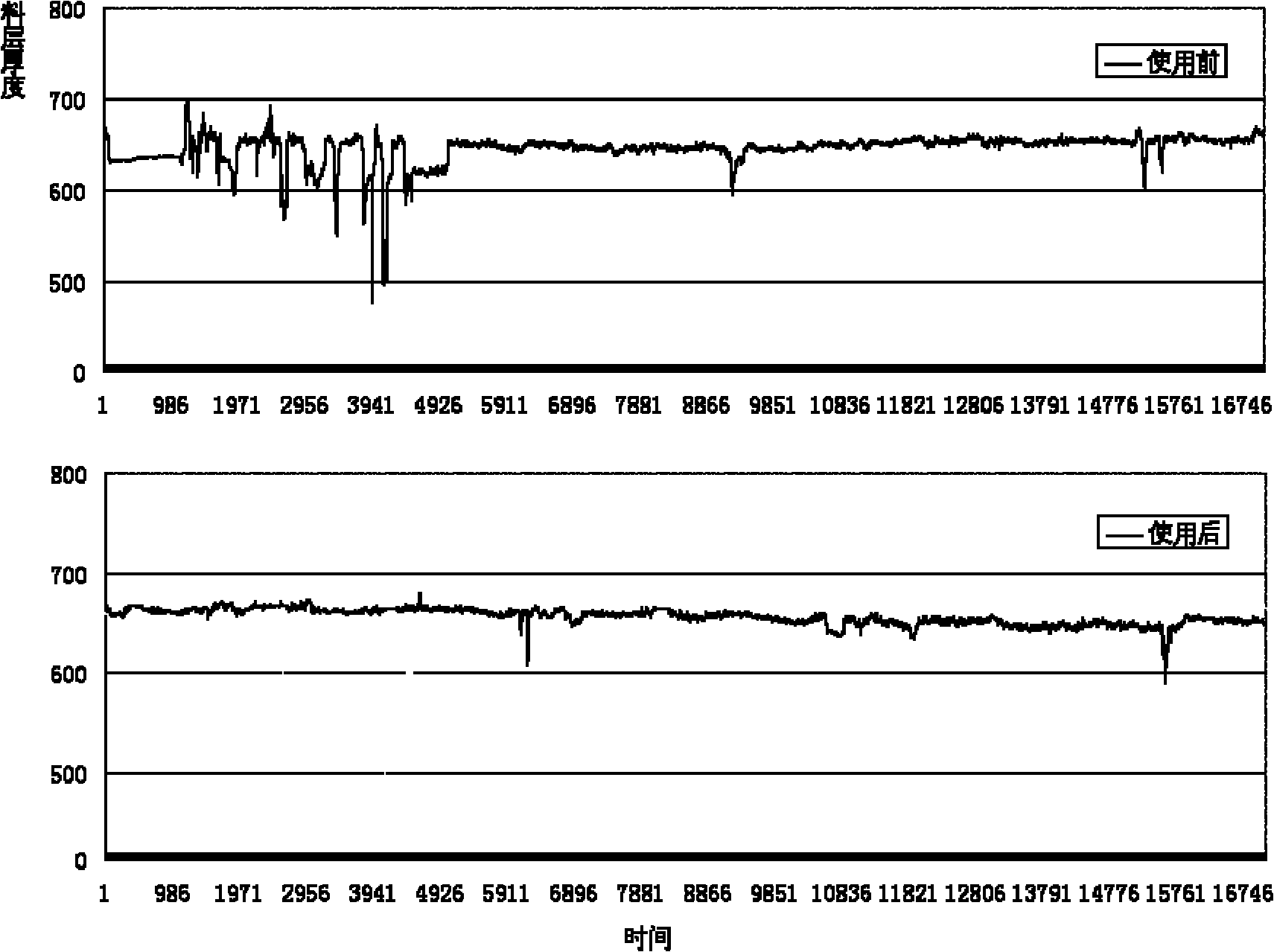

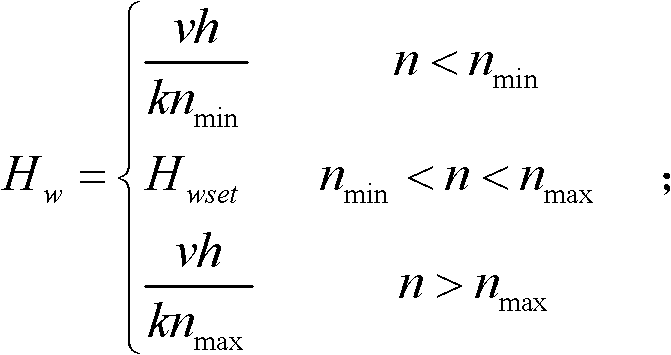

Sintering segregation distribution controlling method for stabilizing material layer thickness

ActiveCN102072658ASolve the problem of unstable thicknessGuaranteed stabilityFurnace typesStabilization controlLayer thickness

The invention discloses a sintering segregation distribution controlling method for stabilizing material layer thickness. In the method, a material layer thickness feed-forward cascade intelligent control system with a two-layer hierarchical structure is provided for stabilizing the material layer thickness, wherein a feed-forward compensation decoupling control algorithm is adopted in the upper layer structure to decouple the material layer thickness, the rotation speed of a round roller feeder and the opening of a discharging gate and eliminate the coupling relation of the material layer thickness, the rotation speed of the round roller feeder and the opening of the discharging gate; in the lower layer structure, a discharging gate opening controller and a round roller rotation speed controller are arranged aiming at the two operation parameters, namely the decoupled rotation speed of the round roller feeder and the decoupled opening of the discharging gate, so that stabilization control over the material layer thickness is realized; and in order to eliminate deviation between an actual value and a set value of the material layer thickness, a thickness difference controller is arranged to correct the material layer thickness feed-forward cascade intelligent control system. By the control technique, the stable and smooth sintering of a thick material layer can be effectively guaranteed, the sintering energy consumption is reduced, and the quality and the yield of sintered ore are improved.

Owner:CENT SOUTH UNIV

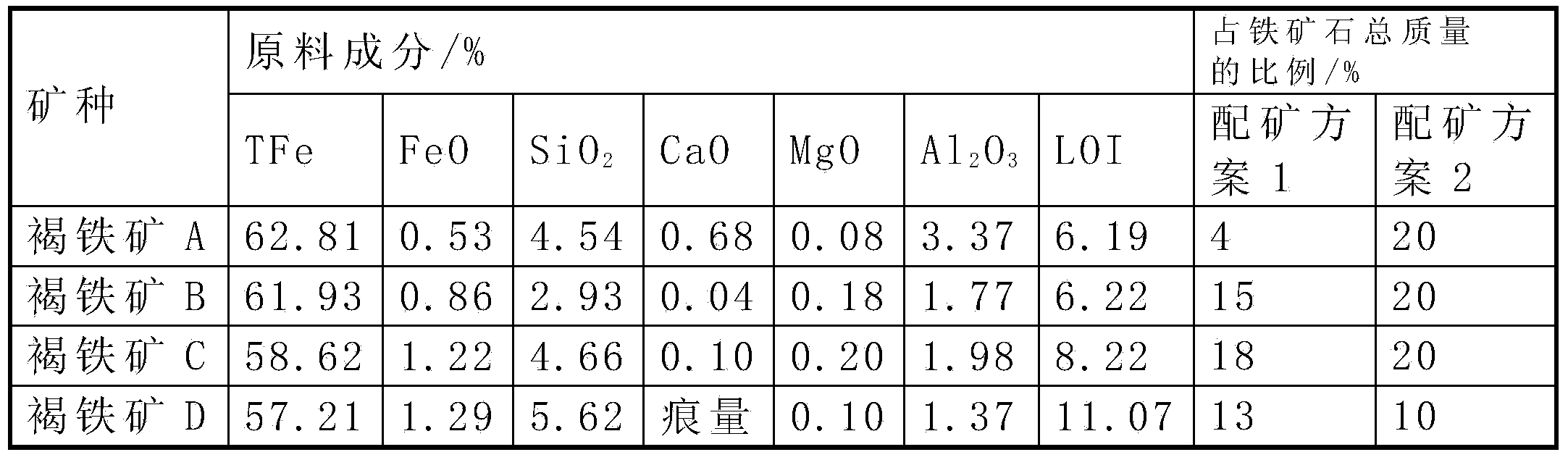

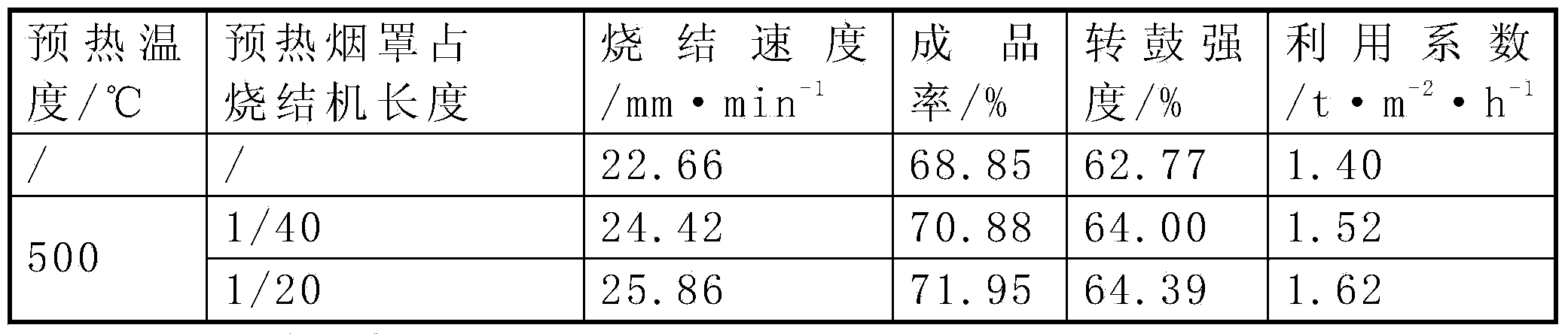

Method for enhancing sintering of high-proportion limonite by utilization of waste heat of exhaust gas

ActiveCN103484661AImprove the quality index of sintering outputRaise the sintering temperatureEvaporationSmoke hood

The invention discloses a method for enhancing the sintering of high-proportion limonite by the utilization of waste heat of exhaust gas. According to the high-proportion limonite, limonite accounts for 50-70% of the total mass of iron ore, the content of crystal water in the limonite is 5-15%, after distribution of a mixture and before sintering ignition, a sealed smoke hood is additionally arranged, high temperature exhaust gas from a sintering ring cooler or high temperature exhaust gas at the tail portion of a sintering machine is guided in to be used for heating the mixture, crystal water and free water in the mixture at the surface layer of a bed of material are removed, thermal decomposition of the crystal water of the material on the surface layer in the sintering process and thermal emission of evaporation of water are reduced, the sintering temperature of the surface layer of the bed of material is increased, accordingly, the sintering yield and quality index of the high-proportion limonite are improved, and energy consumption for sintering is reduced.

Owner:CENT SOUTH UNIV

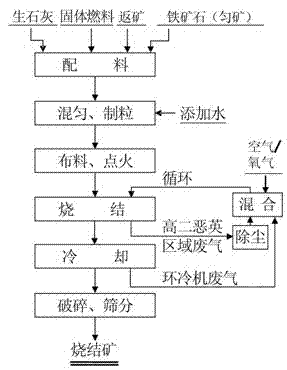

Low-energy-consumption method for reducing emission of dioxin in sintering waste gas

ActiveCN102901365AEmission reductionIncrease CaO contentEnergy industryWaste heat treatmentTemperature controlFlue gas

The invention discloses a low-energy-consumption method for reducing emission of dioxin in sintering waste gas. The low-energy-consumption method includes firstly, dividing air boxes from the machine head to the machine tail of a sintering machine into a low-dioxin containing area and a high-dioxin containing area; secondly, mixing dedusted hot waste gas at the temperature of 100-400 DEG C of the high-dioxin containing area of the sintering machine with hot waste gas at the temperature of 100-400 DEG C of a ring cooler, then adding air or oxygen in a certain quantity, keeping the oxygen content in the mixed gas higher than 14%, controlling the temperature within 100-250 DEG C, and conveying gas used for sintering to the surface of a material layer of the sintering machine; and thirdly, discharging low-temperature waste gas subjected to dedusting and desulfurizing in the low-dioxin containing area into the air from a chimney, wherein the high-dioxin containing area includes the 4th to the 10th air boxes from the machine tail to the machine head of the sintering machine, the low-dioxin containing area includes the rest air boxes and the length of the high-dioxin containing area is smaller than or equal to that of the low-dioxin containing area. By the low-energy-consumption method for reducing emission of the dioxin in the sintering waste gas, emission of the dioxin of the sintering process can be evidently reduced and waste heat in flue gas can be recovered.

Owner:BAOSHAN IRON & STEEL CO LTD +1

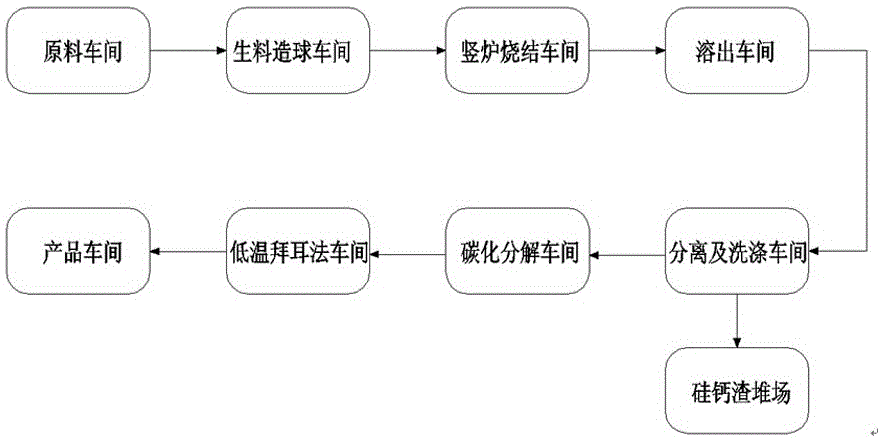

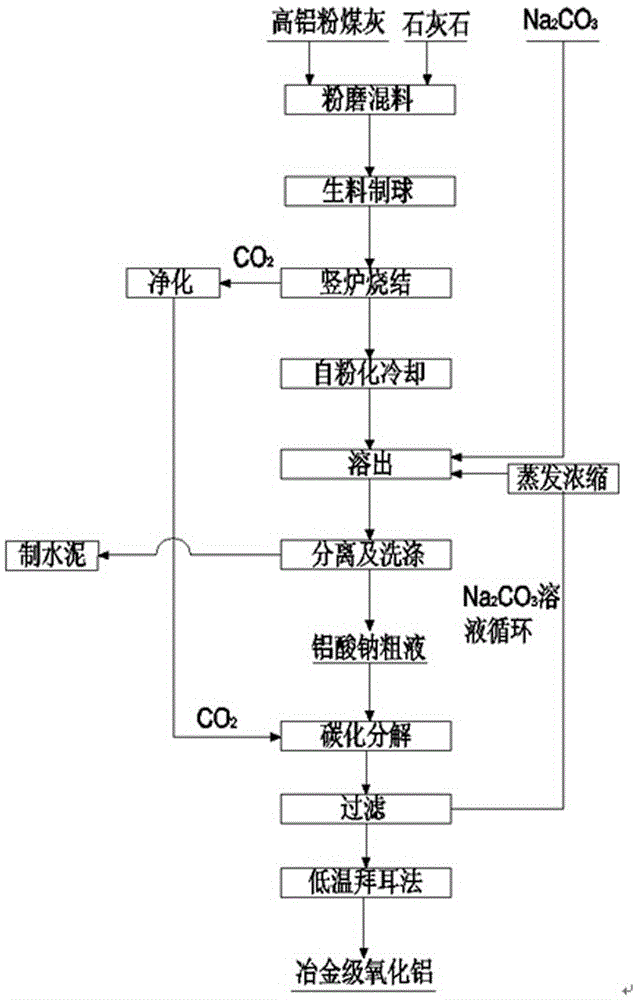

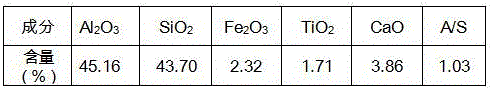

Method for extracting aluminum oxide from coal ash on basis of lime sinter process

InactiveCN105753024AHigh temperatureLarge outputAlkaline-earth metal silicatesAluminium oxides/hydroxidesShaft furnaceCalcination

The invention discloses a method for extracting aluminum oxide from coal ash on basis of a lime sinter process.The method includes steps: (1) grinding and mixing; (2) raw material balling; (3) shaft furnace calcining; (4) autogenous pulverizing and cooling; (5) dissolving out; (6) separating and washing; (7) carbonizing and decomposing; (8) filtering; (9) treating according to a low-temperature Bayer process, so that metallurgical aluminum oxide is obtained.The method has the advantages that by shaft furnace calcinations, energy consumption is greatly reduced, and production cost is evidently reduced; by the method, sintering under high-temperature large-scale operating conditions can be realized easily, product sintering quality is guaranteed, and the method is suitable for large-scale industrial production.

Owner:JIUQUAN IRON & STEEL GRP

Method for comprehensively utilizing low-grade aluminum resource

ActiveCN110436492AHigh dissolution rateGood dissolution effectAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium/strontium/barium oxides/hydroxidesSlagDecomposition

The invention relates to the technical field of alumina production, and specifically discloses a method for comprehensively utilizing a low-grade aluminum resource. The method comprises the followingsteps: mixing the low-grade aluminum resource with lime and calcium ferrite, performing roasting dissolution to obtain a dissolution crude slag and a dissolution liquid, and performing impurity removal, carbonation decomposition and calcination on the dissolution liquid to obtain alumina; and performing smelting and refining on the dissolution crude slag and a carbonaceous reducing agent to obtaina ferrosilicon alloy. The provided method for improving a dissolution rate of alumina in the low-grade aluminum resource uses the low-grade aluminum resource as a raw material, a phase composition ofa clinker is changed by adding calcium ferrite, a lime compounding amount, sintering energy consumption and a slag discharge amount are reduced, a dissolution rate of alumina is 92% or more, and theferrosilicon alloy is also prepared while alumina is prepared.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ceramic shaft rod sintering process

InactiveCN106083072AImprove sintering capacityReduce sintering energy consumptionEnergy consumptionAluminium oxide

The invention discloses a ceramic shaft rod sintering process. The process employs a corundum sagger and a bottom bearing plate. The ceramic shaft rod sintering process provided by the invention solves the bending phenomenon of long shaft rod products prepared from alumina and zirconia ceramics during sintering, changes from existing flat sintering to vertical standing sintering, field certification proves that the process can achieve good effect, the product straightness qualification rate is increased from original about 80% to 98%, also the process greatly improves the sintering capacity, and reduces the sintering energy consumption of single product, thereby lowering the production cost of enterprises.

Owner:CHANGSHU CITY YINYANG CERAMIC CO LTD

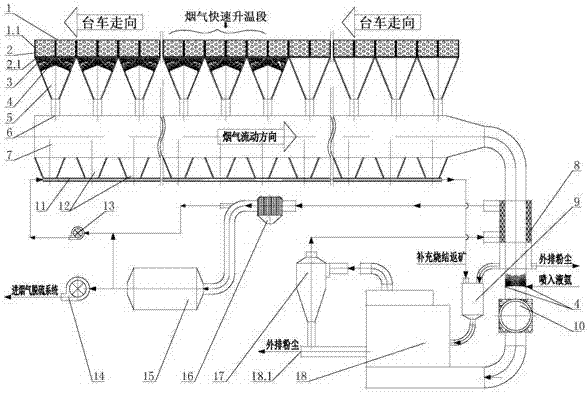

Sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke

ActiveCN107198962AReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationFluidized bedFlue gas

The invention relates to a sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke, which solves the problems of large investment, high running cost and lower denitrifying efficiency in the existing denitrifying system. The sintering smoke self-catalyzing denitrifying system adopts the technical scheme that the sintering smoke self-catalyzing denitrifying system comprises a sintering machine, wherein air bellows are arranged under a trolley of the sintering machine; an exit of the bottom part of each air bellow is communicated with a main flue; the sintering machine is sequentially provided with an ignition section, a machine head section, a flue gas quick heating section and a machine tail section along the moving direction of the trolley; the main flue is sequentially connected with a denitrifying reactor of a fluidized bed through a denitrifying flue gas heat exchanger shell or tube, and a flue gas heater; liquid ammonia spray nozzles are respectively arranged in the air bellows under the machine tail section to the flue gas quick heating section area, and in the flue gas exit pipeline of the flue gas heater. The sintering smoke self-catalyzing denitrifying system has the advantages that the system is simple, the additional purchase of the catalyst is avoided, the effective denitrifying and sintering process is realized, the recycling rate of residual heat is high, the energy-saving and consumption-reducing effects are realized, the land occupation area is small, and the equipment investment and running cost are low.

Owner:武汉钢铁有限公司 +2

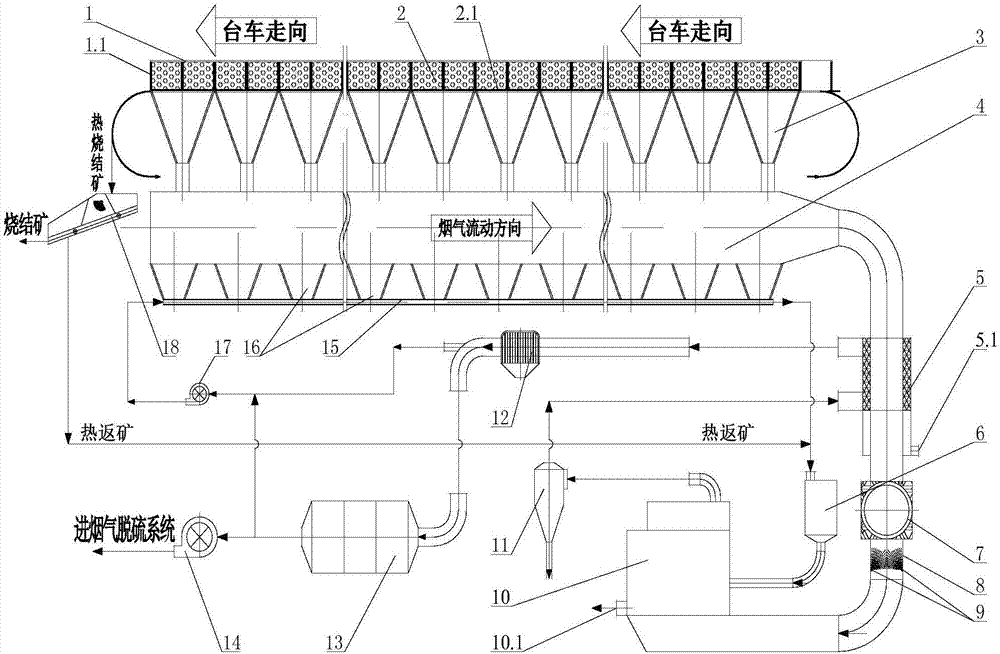

Sintering flue gas denitrification process based on sintering hot returning ore catalysis

ActiveCN107261840AReduce dustImprove denitrification efficiencyGas treatmentDispersed particle separationParticulatesFlue gas

The invention relates to a sintering flue gas denitrification process based on sintering hot returning ore catalysis and aims at solving the problems of long denitrification process route, large equipment investment and high operating cost in an existing denitrification process. According to the technical scheme, the sintering flue gas denitrification process comprises that sintering flue gas passes through a sintering bed, a backing material, a grate at the bottom of a sintering machine trolley and an air bellow below the trolley under the action of draft of a high pressure fan to enter a main flue; sintering ore leaves the sintering machine trolley and then is broken by a single roller at the tail of a sintering machine and screened by a heated oscillating screen, an oversize product is hot sintering ore, screen underflow is hot returning ore, and the hot returning ore is fed into a fluidized-bed denitrification reactor through a particulate matter stock bin and is used as a catalyst for reduction and denitrification of the sintering flue gas. The sintering flue gas denitrification process provided by the invention has the advantages that technological process is simple, a denitrification catalyst is not out-purchased, waste heat recovery is high, controllability is good, floor area is small and equipment investment and operating cost are low.

Owner:WUHAN WUTUO TECH

Ti-Mn-Si intermetallic compound porous material and preparation method thereof

ActiveCN108517442AReduce sintering energy consumptionGood pore structure stability and microstructural uniformityVacuum furnaceWarming rate

The invention relates to a Ti-Mn-Si intermetallic compound porous material and a preparation method thereof. The Ti-Mn-Si intermetallic compound porous material is prepared from raw materials in partsby weight: 20-60 parts of Ti, 15-55 parts of Mn and 25-65 parts of Si. The preparation method comprises the steps that the raw materials are weighed and mixed, and mixed powder is obtained; a stearicacid alcoholic solution is added while the materials are turned over, then the mixture is dried in a vacuum drying box, and sieved by adopting a 60-mesh sieve, and a screen underflow is taken and used; pressing is conducted by adopting cold-pressing forming equipment, and a cold-pressing green body is obtained; the cold-pressing green body is subjected to degreasing in a hydrogen or inert gas furnace, the degreasing temperature is 400-500 DEG C, the heat preservation time is 120-240 minutes, the warming rate is controlled to be 1-5 DEG C / min, and a degreased green body is obtained; the degreased green body is placed in a vacuum furnace to be subjected to two-stage reaction sintering; and after sintering is ended, the cooling speed is controlled to be 10-20 DEG C / min, the product is cooledto be at the room temperature, and the Ti-Mn-Si intermetallic compound porous material is obtained. The prepared Ti-Mn-Si intermetallic compound porous material is stable in quality, has the good repeatability, and is suitable for being used in the fields of filtration and electrode materials and the like.

Owner:CENT SOUTH UNIV

Tungsten smelting waste residue ceramsite without added components and preparation method thereof

The invention discloses a short-flow and low-cost preparation method of tungsten smelting waste residue ceramsite without any added component and relates to the technical field of resource utilizationand harmless treatment of smelting slag. Raw materials for preparing the ceramsite are completely composed of tungsten smelting waste residues and no other component needs to be added; the preparation method of the ceramsite comprises the following steps: after naturally drying the tungsten smelting waste residues produced by tungsten smelting for a certain time, directly conveying the tungsten smelting waste residues into a paired roller granulation machine for granulating and molding; finally, drying is performed and then calcining is performed to obtain a ceramsite finished product. The ceramsite provided by the invention is light in weight and high in strength and can be used as a building material; the preparation method provided by the invention is used for carrying out the resourceutilization on the tungsten smelting waste residues, has the simplest preparation flow and has good economic benefits and social benefits.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com