Microwave sintering method for granite rock flour ceramsite

A technology of granite powder and microwave sintering, applied in the field of materials, can solve the problems that have never been seen before, and achieve the effects of good economic benefits, saving energy consumption for sintering, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

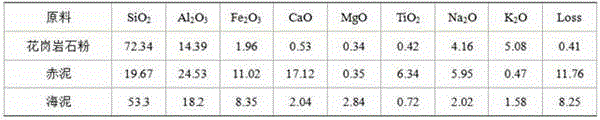

Embodiment 1

[0028] 1) The impurity in the granite stone powder is removed by water washing and sedimentation to obtain a granite stone powder sediment with a particle size less than 0.08mm;

[0029] 2) Dehydrating, drying and drying the granite stone powder sediment and red mud respectively;

[0030] 3) Add 75 parts by weight of granite stone powder and 25 parts by weight of red mud to the mixing bin, add water and stir for 12 minutes, so that the water content is controlled at 11wt%;

[0031] 4) Extrude the mixed material obtained in 3) into raw meal balls with a particle size of 10-15 mm by extruding a ball machine;

[0032] 5) Put the raw material balls into a microwave oven with a frequency of 2.45GHZ, continuously heat up to 300°C at a heating rate of 10°C / min, and dry for 20 minutes; then continuously heat up to 1050°C at a heating rate of 20°C / min , roasted for 5 minutes; then immediately lower the temperature to 750 ° C, and finally let it cool to obtain spherical ceramsite with ...

Embodiment 2

[0035] 1) The impurity in the granite stone powder is removed by water washing precipitation method to reach the granite stone powder sediment whose particle size is less than 0.08mm;

[0036]2) Dehydrating, drying and drying the granite stone powder sediment, red mud and sea mud respectively;

[0037] 3) Stir 10 parts by weight of sea mud and 0.2 parts by weight of microwave induction agent in a dry mixing mixer for 3 minutes to make it evenly stirred;

[0038] 4) Add 64.8 parts by weight of granite stone powder treated in 2), 25 parts by weight of red mud and the material obtained in 3) into the mixing bin, add water and stir for 12 minutes, so that the water content is controlled at 11wt%;

[0039] 5) Extrude the mixed material obtained in 4) into raw meal balls with a particle size of 10-15mm with a ball extrusion machine;

[0040] 6) Put the raw material balls into a microwave oven with a frequency of 2.45GHZ, continuously heat up to 400°C at a heating rate of 12°C / min, ...

Embodiment 3

[0043] 1) The impurity in the granite stone powder is removed by water washing precipitation method to reach the granite stone powder sediment whose particle size is less than 0.08mm;

[0044] 2) Dehydrating, drying and drying the granite stone powder sediment, red mud and sea mud respectively;

[0045] 3) Grinding the high-carbon cinder in a ball mill to obtain a dry powder with a particle size less than 0.06mm;

[0046] 4) Stir 0.2 parts by weight of microwave sensing agent and 9.8 parts by weight of high-carbon cinder treated in 3) in a dry blender for 3 minutes to make them evenly stirred;

[0047] 5) Add 60 parts by weight of granite stone powder, 15 parts by weight of red mud and 15 parts by weight of sea mud treated in 2) and the dry powder obtained in 4) into the mixing bin, add water and stir for 15 minutes, so that the water content is controlled at 16wt %;

[0048] 6) Extrude the mixed material obtained in 5) into raw meal balls with a particle size of 10-15mm wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com