Method for forming bismuth telluride based thermoelectric material through 3D printing

A thermoelectric material and 3D printing technology, applied in the field of 3D printing and forming bismuth telluride-based thermoelectric materials, to achieve the effects of simple process, high cooling rate, and refined grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

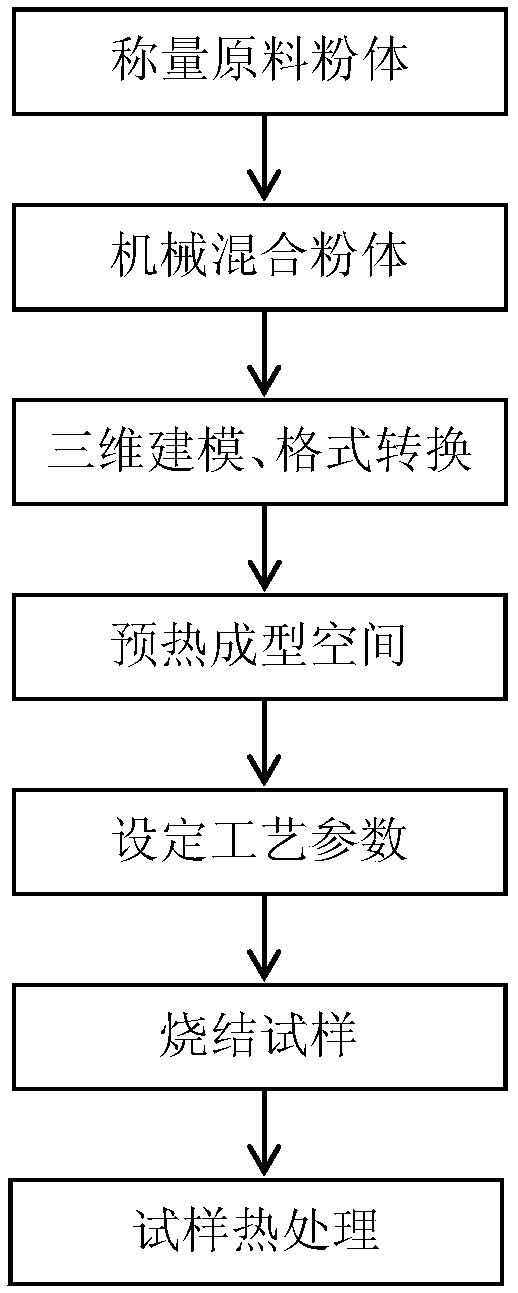

Method used

Image

Examples

Embodiment , Embodiment 1

[0033] Provide micron-scale N-type bismuth telluride-based thermoelectric material powder, the composition formula of the bismuth telluride-based thermoelectric material powder is Bi 2 Te 2.85 Se 0.15 . Using the mechanical powder mixing method, a certain amount of N-type Bi 2 Te 2.85 Se 0.15 The thermoelectric material powder and the binder epoxy resin (EP) are put into the ball mill according to the volume ratio of 1:1 (the mass fraction of the epoxy resin is 12.5%), and then put into the mixing ball, so that the mixing ball and the powder to be mixed The volume ratio is controlled at about 1:3, and then mixed in a ball mill for about 2 hours to obtain Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing hybrid powder.

[0034] Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing mixed powder is put into HK P320SLS selective laser sintering molding machine for sintering and molding under the protection of argon, and the laser source is continuous CO 2 The laser has a rated po...

Embodiment 2

[0037] Provide micron-scale N-type bismuth telluride-based thermoelectric material powder, the composition formula of the bismuth telluride-based thermoelectric material powder is Bi 2 Te 2.85 Se 0.15 . Using the mechanical powder mixing method, a certain amount of N-type Bi 2 Te 2.85 Se 0.15 The thermoelectric material powder and the binder epoxy resin (EP) are put into the ball mill according to the volume ratio of 1:1 (the mass fraction of the epoxy resin is 12.5%), and then put into the mixing ball, so that the mixing ball and the powder to be mixed The volume ratio is controlled at about 1:3, and then mixed in a ball mill for about 2 hours to obtain Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing hybrid powder.

[0038] Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing mixed powder is put into HK P320SLS selective laser sintering molding machine for sintering and molding under the protection of argon, and the laser source is continuous CO 2 The laser has a rated po...

Embodiment 3

[0041] Provide micron-scale N-type bismuth telluride-based thermoelectric material powder, the composition formula of the bismuth telluride-based thermoelectric material powder is Bi 2 Te 2.85 Se 0.15 . Using the mechanical powder mixing method, a certain amount of N-type Bi 2 Te 2.85 Se 0.15 The thermoelectric material powder and the binder epoxy resin (EP) are put into the ball mill according to the volume ratio of 1:1 (the mass fraction of the epoxy resin is 12.5%), and then put into the mixing ball, so that the mixing ball and the powder to be mixed The volume ratio is controlled at about 1:3, and then mixed in a ball mill for about 2 hours to obtain Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing hybrid powder.

[0042] Bi 2 Te 2.85 Se 0.15 / Epoxy resin 3D printing mixed powder is put into HK P320SLS selective laser sintering molding machine for sintering and molding under the protection of argon, and the laser source is continuous CO 2 The laser has a rated po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com