Method for preparing porous ceramsite filter material by using lepidolite extracted lithium slag

A technology for extracting lithium slag and porous pottery, which is applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of poor film-hanging performance of plastic fillers, large water flow resistance, and easy aging, and achieves simplified production processes and high production efficiency. The effect of low cost and saving grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The product formula (in terms of mass percentage) is: 70% of press-impregnated lithium slag (moisture ≤ 30%), 27% of clay powder, 1% of carbon powder, and 2% of calcium carbonate powder.

[0021] Preparation Process:

[0022] (1) Make a cue ball of ф1-2mm in a blender by pressing lithium slag and clay powder;

[0023] (2) Roll the cue ball into a spherical particle of ф3-10mm in the granulator;

[0024] (3) Feed the pellets into the pre-calcination section of the rotary kiln and pre-fire at 200-500°C for 10-20 minutes, then enter the firing zone and calcinate at 1050-1180°C for 10-30 minutes;

[0025] (4) After leaving the kiln, the red-hot ball enters the single-cylinder cooler to cool and then the product is obtained.

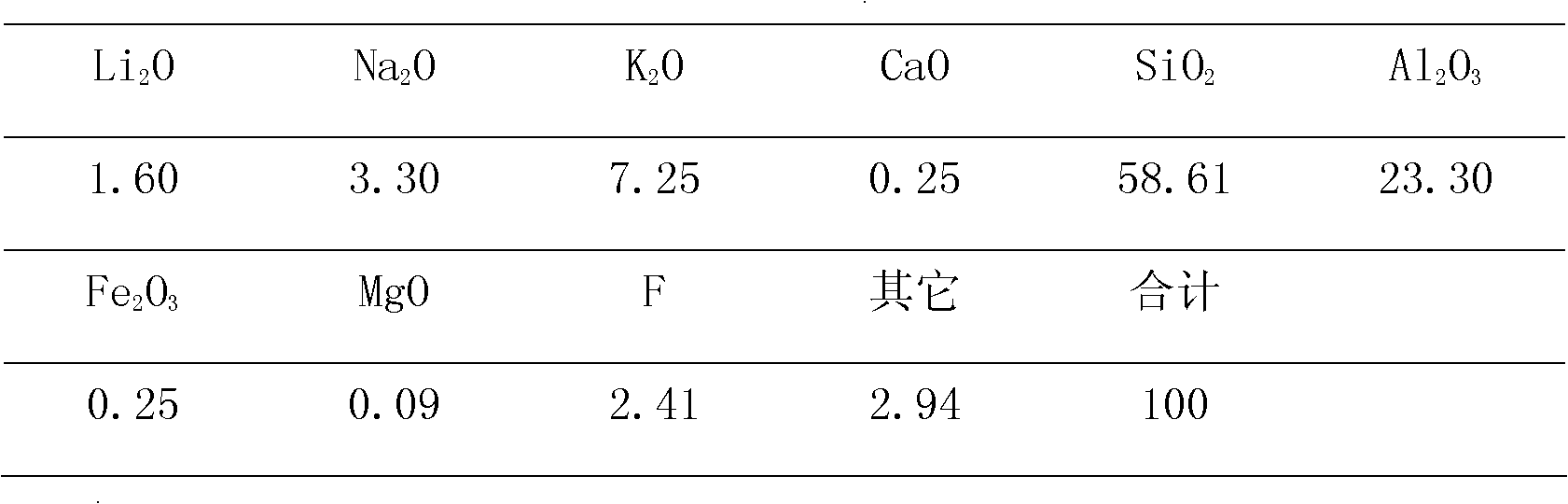

[0026] The performance index of the product is shown in Table 2.

[0027] Table 2 Technical performance indicators of pressure immersion lithium slag ceramsite filter material

[0028]

Embodiment 2

[0030] The ratio of raw materials is as follows: 65% of press-impregnated lithium slag (30% of water content), 27% of clay powder, 1% of carbon powder, and 2% of waste glass powder. Technological process is the same with embodiment 1.

Embodiment 3

[0032] The ratio of raw materials is as follows: 60% of pressing lithium slag (30% of water content), 37% of clay, 2% of bran powder, and 1% of calcium carbonate powder. Technological process is the same with embodiment 1.

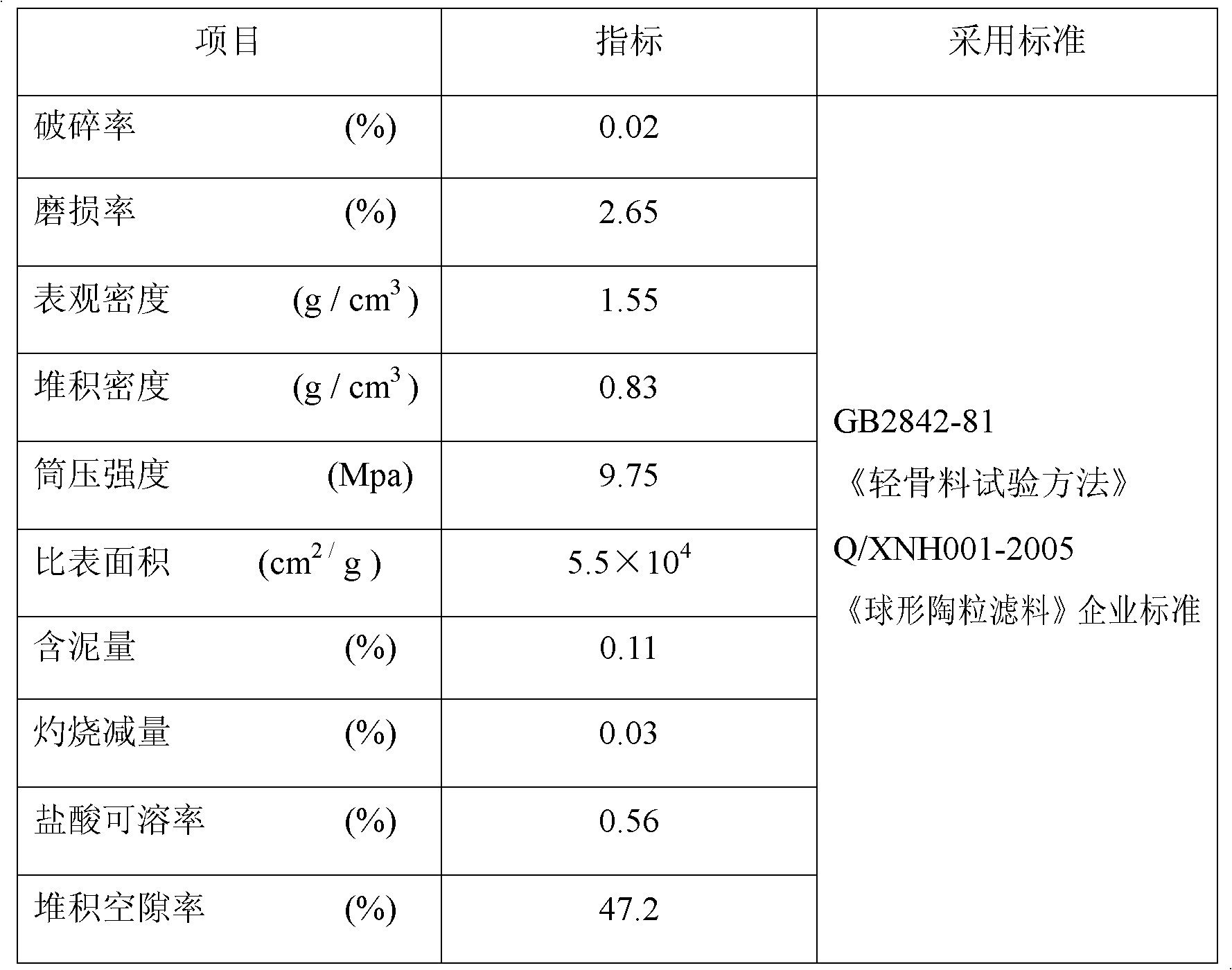

[0033] Some performance technical indicators of the products of Examples 2 to 3 are shown in Table 3.

[0034] Table 3 Some performance indicators of different example products

[0035]

[0036] *Take 10 ф8mm±1mm material balls to measure the compressive strength on the electronic universal testing machine, and take the average value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com