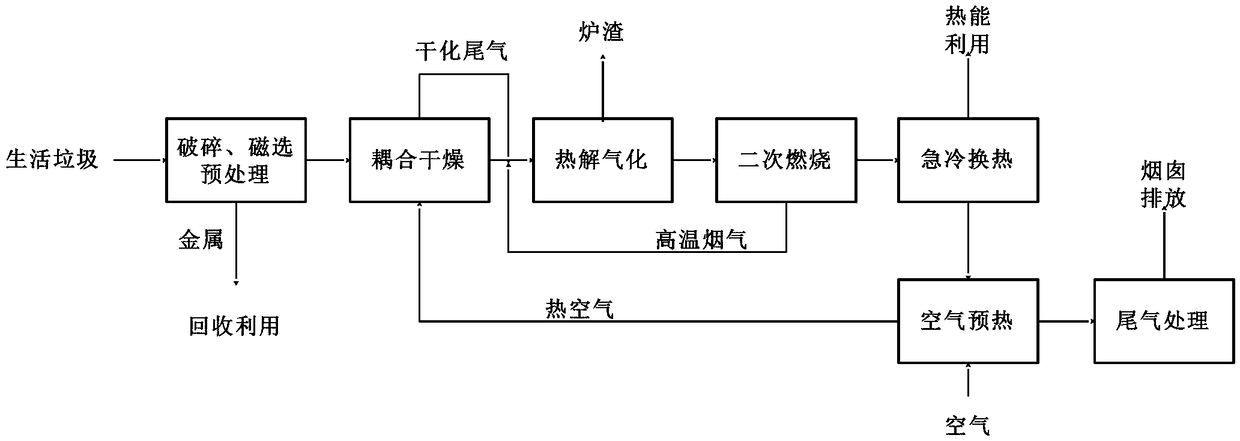

Treatment process and system for coupling, drying and pyrolyzing household garbage

A technology of domestic waste and treatment process, which is applied in the field of domestic waste coupled drying pyrolysis treatment process and treatment system to achieve the effects of improving domestic waste pyrolysis efficiency, low operating cost and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

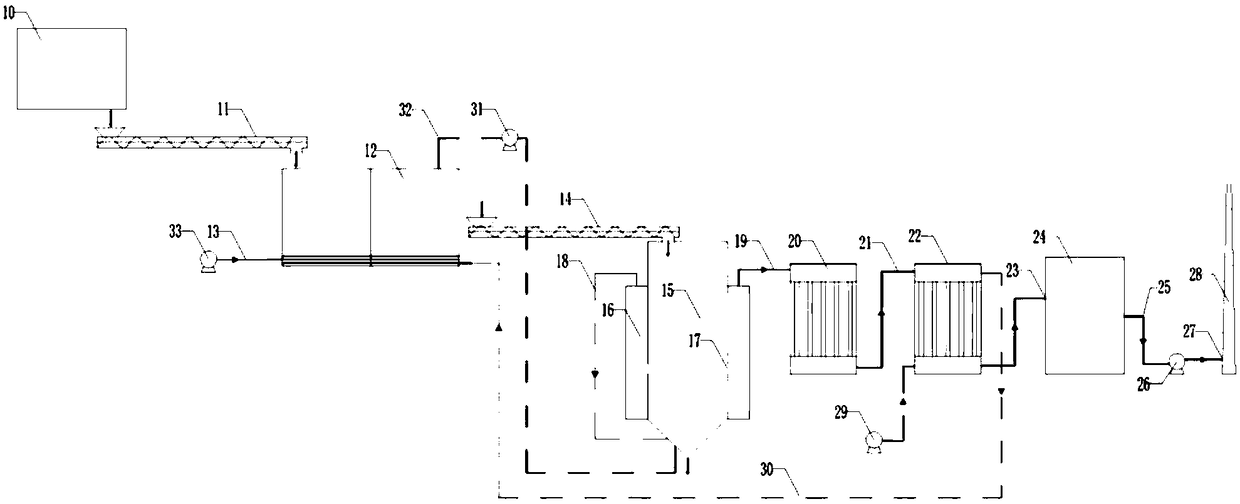

[0053] The domestic waste is crushed to a particle size of 20mm by a shearing double-shaft crusher. The magnetic separator selects metal materials for recycling. The crushed waste is sent to the waste feeding pool; the crushed domestic waste is dried by biological hot air coupling, and the The drying time is 5 days, the biological drying temperature is 75°C, the hot air drying time is 0.5 days, the drying temperature is 110°C, the moisture content of domestic waste after coupling drying is less than 20%; the oxygen content of the air entering the coupling drying is 21 %, 3% of the oxygen is consumed through coupling drying, which is used for biological drying reaction, and the oxygen content of coupling drying tail gas is 18% as the primary air for domestic waste pyrolysis; after drying, the waste is evenly sent to the domestic waste pyrolysis gasifier for further processing Pyrolysis and gasification, the gasification temperature is 600°C, pyrolysis produces combustible gas an...

example 2

[0055] The domestic waste is crushed to a particle size of 35mm by a shearing double-shaft crusher, and the metal materials are selected by the magnetic separator for recycling. The crushed waste is sent to the waste feeding pool; The drying time is 6 days, the biological drying temperature is 68°C, the hot air drying time is 0.75 days, the drying temperature is 100°C, the moisture content of domestic waste after coupling drying is less than 20%; the oxygen content in the coupled drying air is 21 %, 4.5% of the oxygen is consumed by coupling drying, which is used for biological drying reaction, and the oxygen content of coupling drying tail gas is 16.5% as the primary air for domestic waste pyrolysis; after drying, the waste is evenly sent to the domestic waste pyrolysis gasifier for further processing Pyrolysis and gasification, the gasification temperature is 700°C, pyrolysis produces combustible gas and ash; the combustible gas generated by pyrolysis enters the secondary com...

example 3

[0057] The domestic waste is crushed to a particle size of 50mm by a shearing double-shaft crusher, and the metal materials are selected by the magnetic separator for recycling. The crushed waste is sent to the waste feeding pool; The drying time is 7 days, the drying temperature is 61°C, the hot air drying time is 1 day, the drying temperature is 90°C, the moisture content of domestic waste after coupling drying is less than 20%; the oxygen content of the air entering the coupling drying is 21% After coupled drying, 6% of the oxygen is consumed, which is used for biological drying reaction, and the oxygen content of coupling drying tail gas is 15% as the primary air for domestic waste pyrolysis; after drying, the waste is evenly sent to the domestic waste pyrolysis gasifier for thermal Decomposition and gasification, the gasification temperature is 800°C, pyrolysis produces combustible gas and ash; the combustible gas generated by pyrolysis enters the secondary combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com