Smashing device and smashing and squeezing integrated device with same

A crushing device and equipment technology, applied in the direction of presses, feed, grain processing, etc., can solve the problems of burning motors, mold, and affecting processing efficiency, etc., to prevent crop fibers from winding cutters, improve the degree of fineness and water content, and improve cutting The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, further illustrate the present invention.

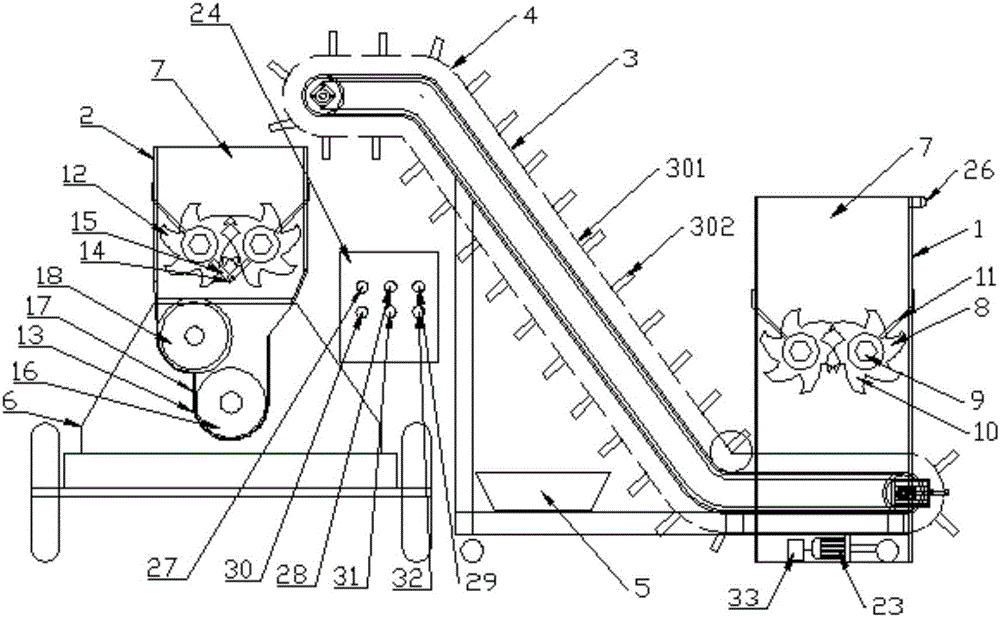

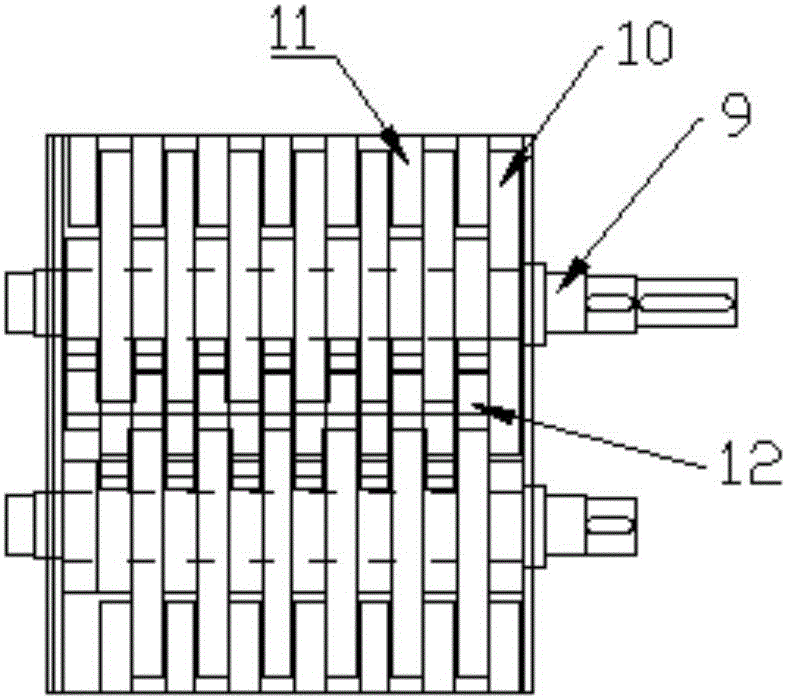

[0033] Such as Figure 1-4 As shown, a pulverizing and pressing integrated equipment includes a primary pulverizer 1 and a secondary pulverizing dehydrator 2. The primary pulverizer 1 is connected to the secondary pulverizing and dehydrating machine 2 through a partition conveyor belt 3. The partition type The conveyor belt 3 is driven by a conveyor motor 23 , and the conveyor motor 23 is connected with a frequency converter 33 for controlling the speed of the conveyor motor 23 . The partition conveyor belt 3 is provided with transverse partitions 302 at intervals on the conveyor belt 301 . A mesh 4 is provided on the partition conveyor belt 3, and a water collection tank 5 is provided below the partition conveyor belt 3 to collect water discharged from the mesh 4 during material transfer. The clapboard conveyor belt 3 can realize the function of automatically conveying material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com