Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

841results about How to "Prevent throwing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

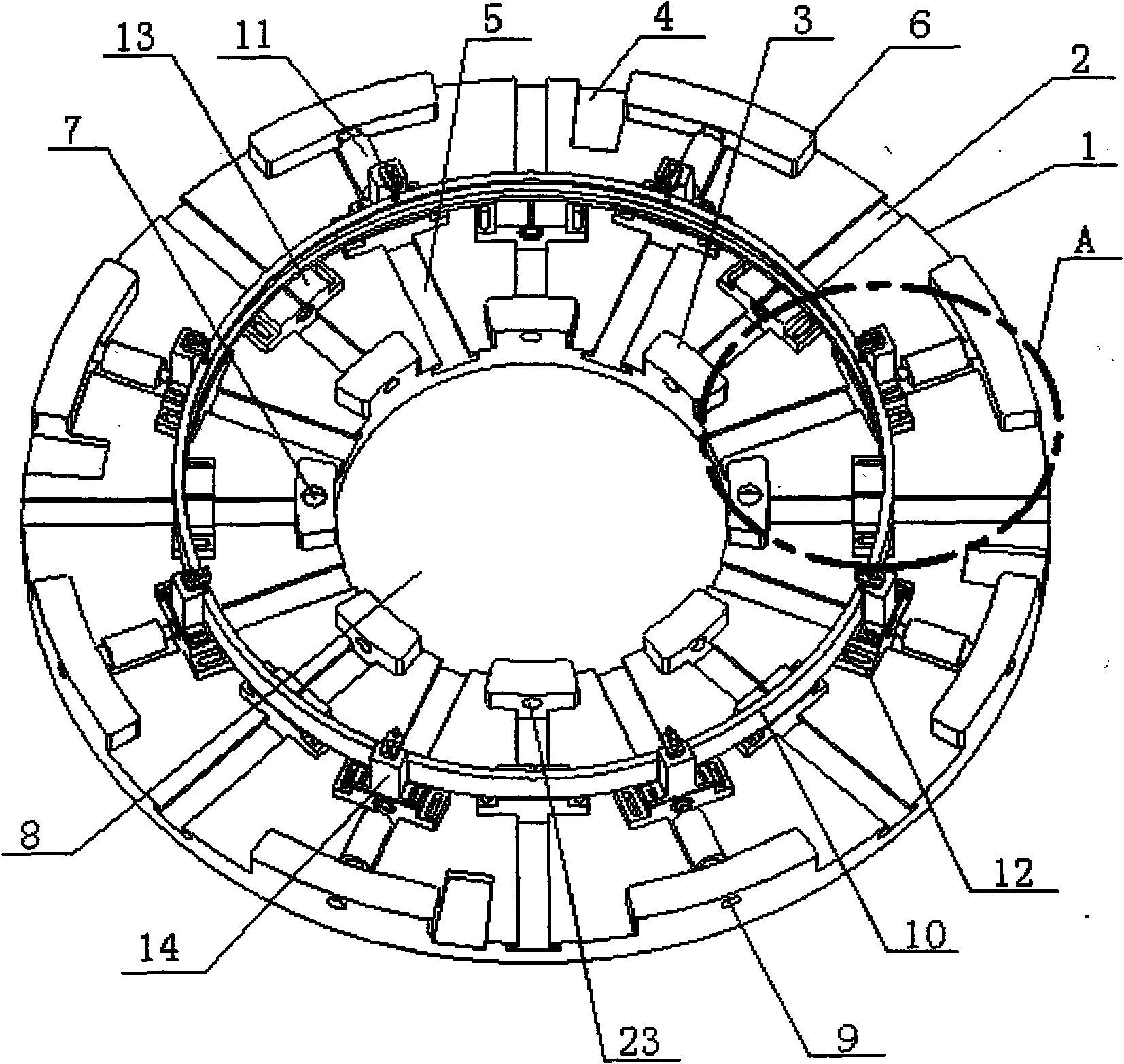

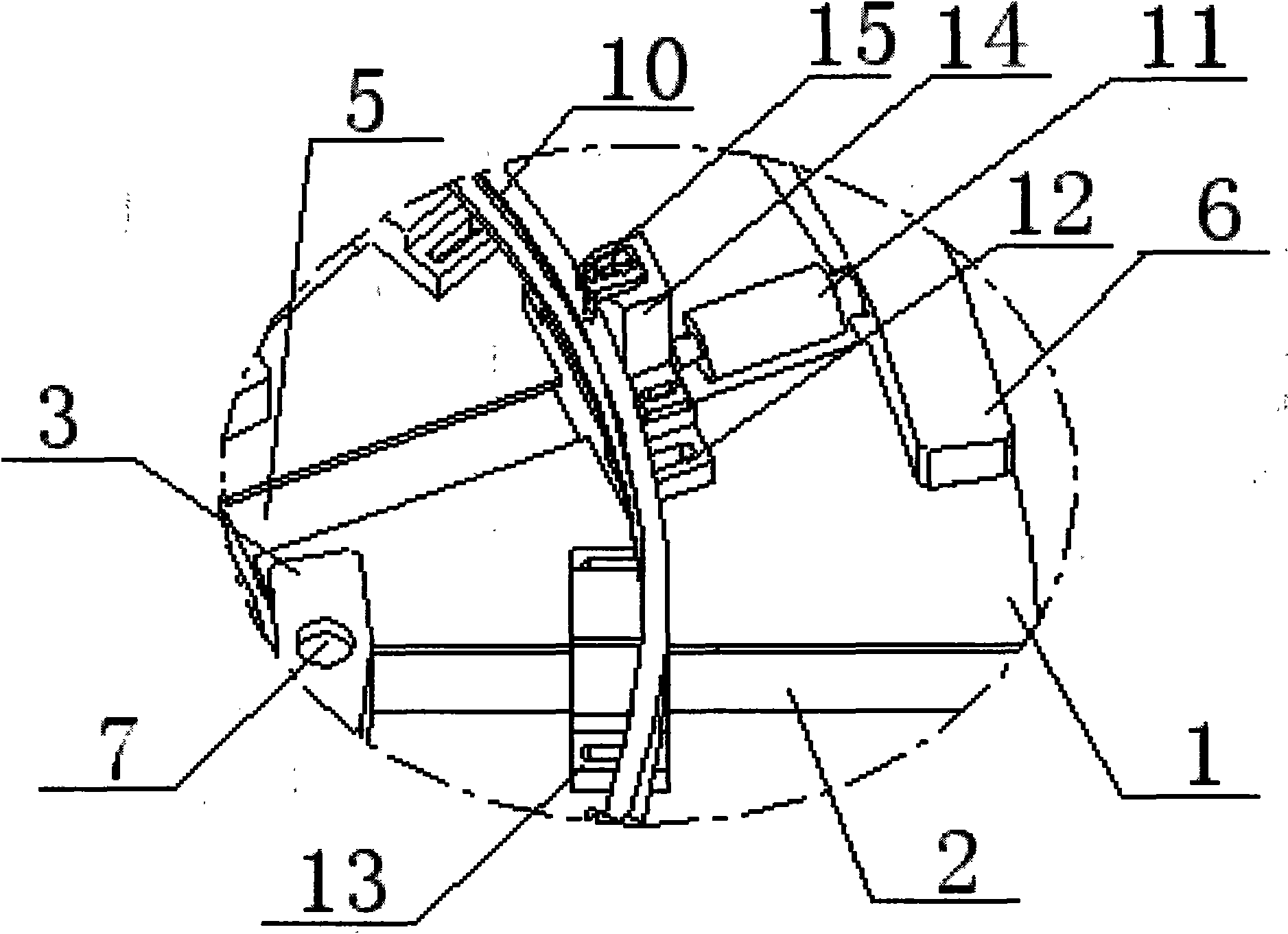

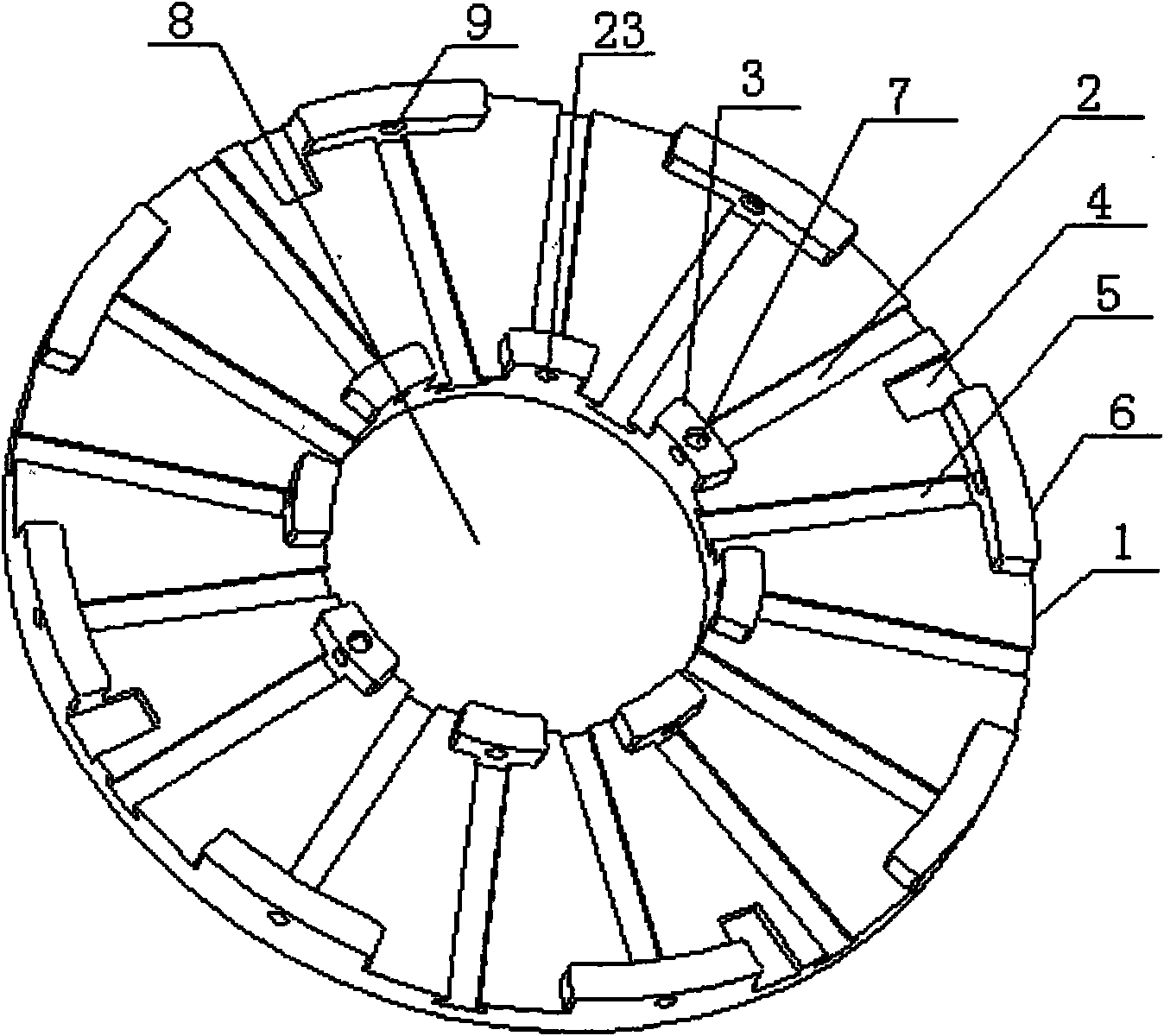

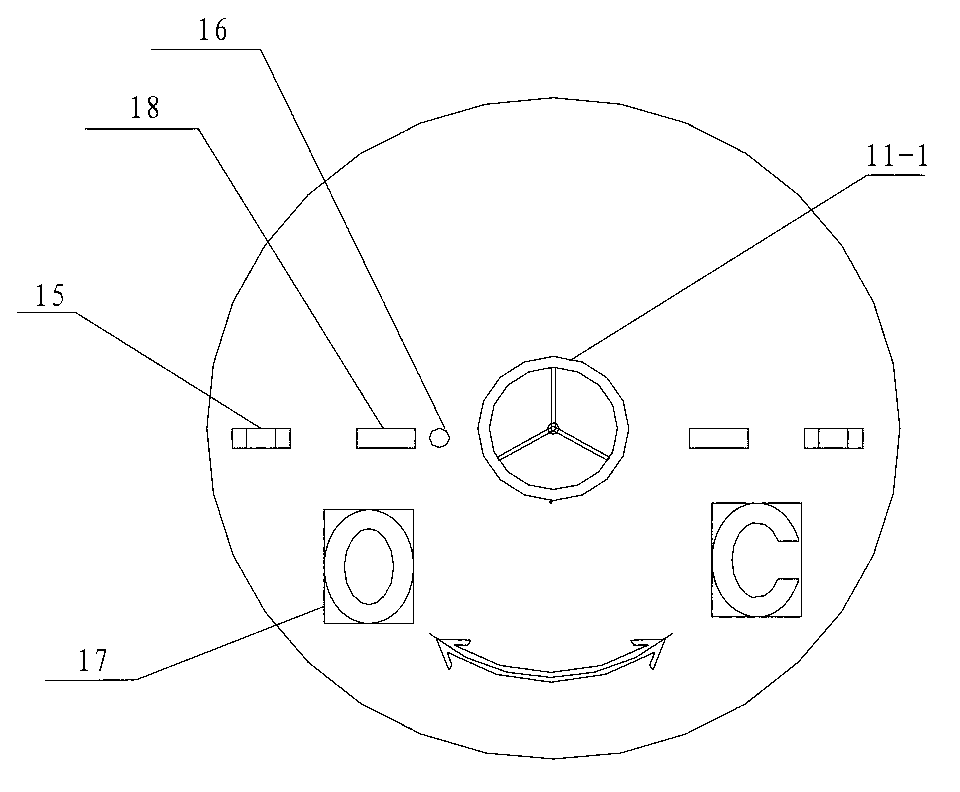

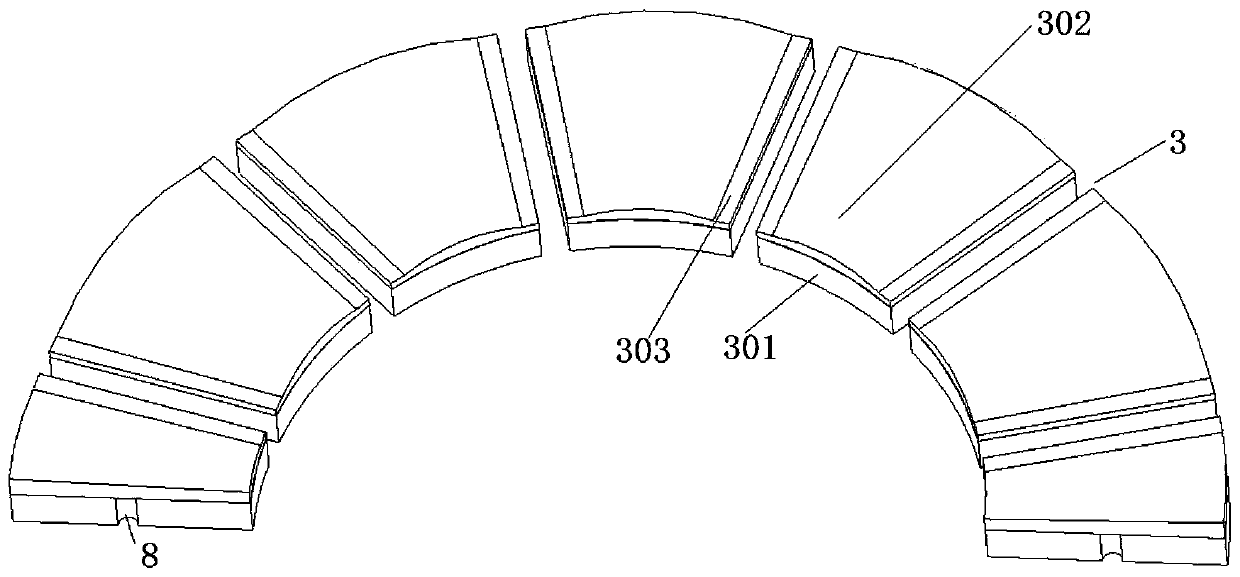

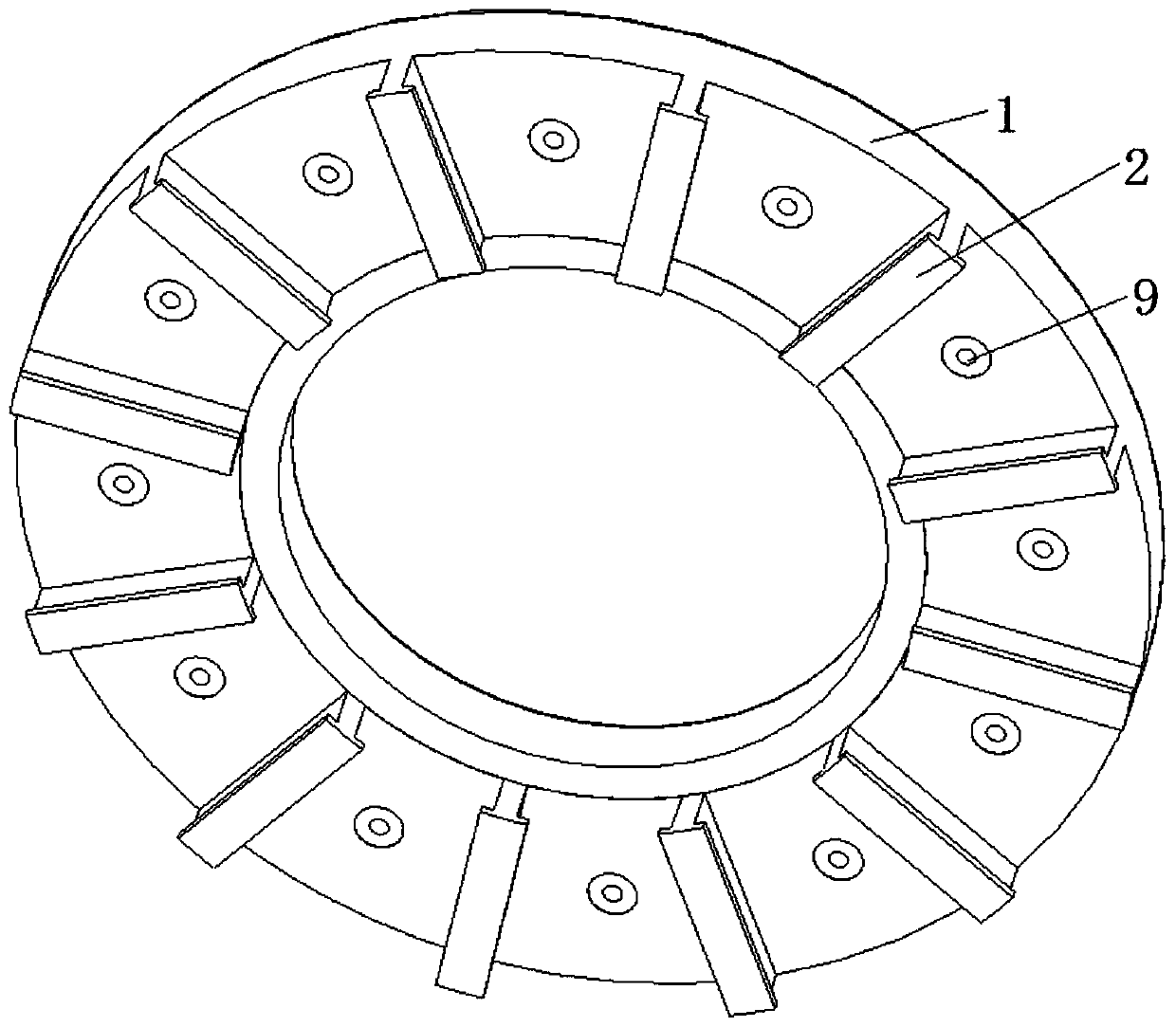

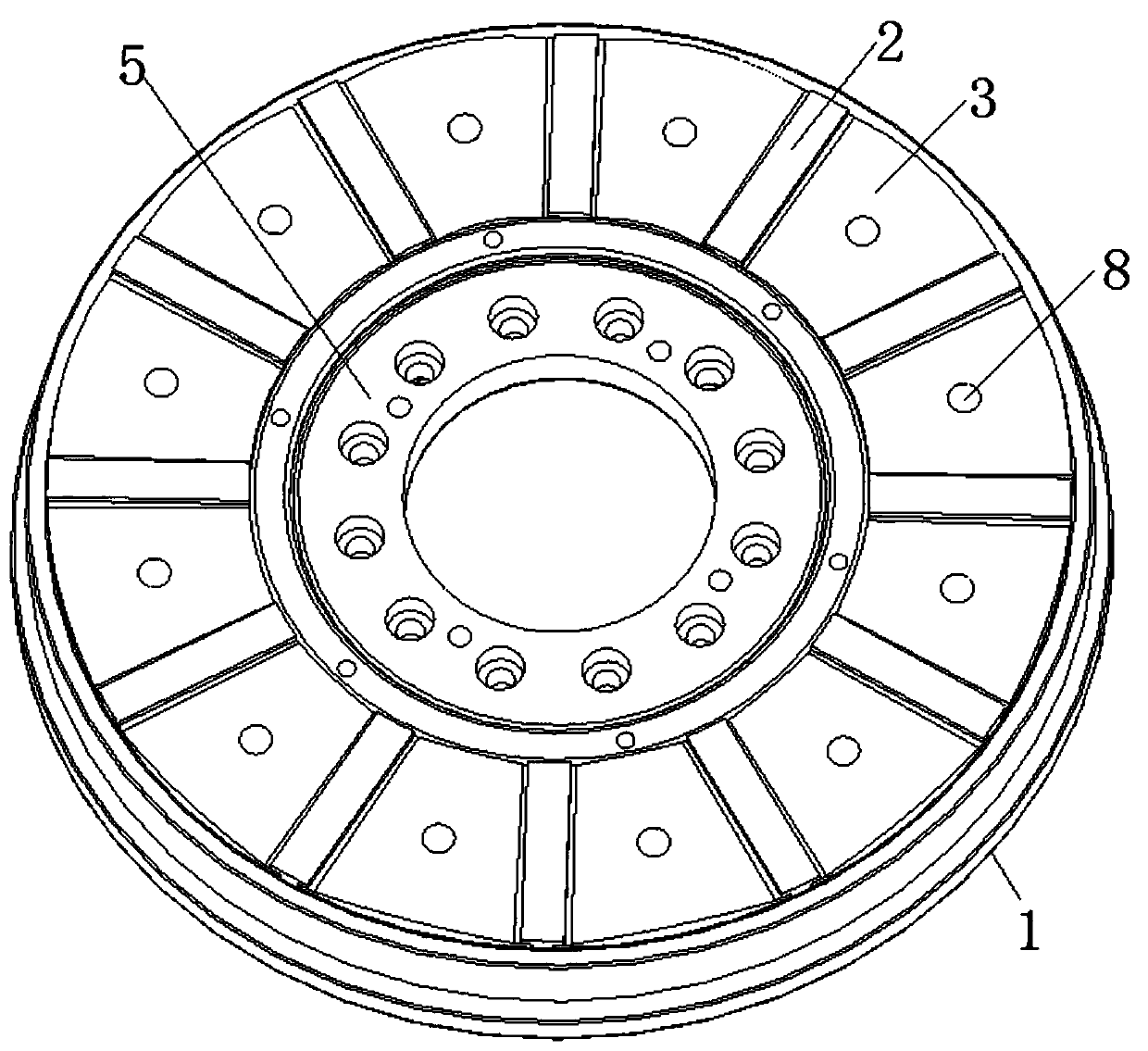

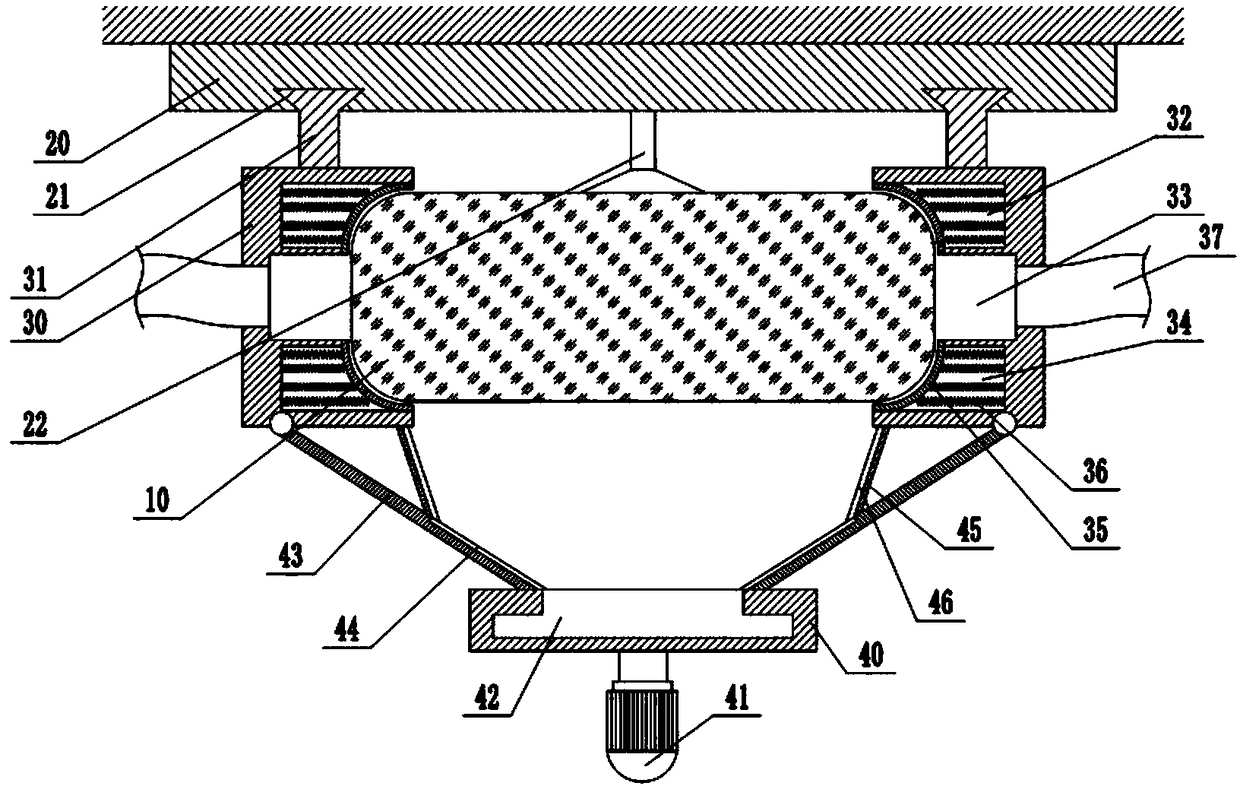

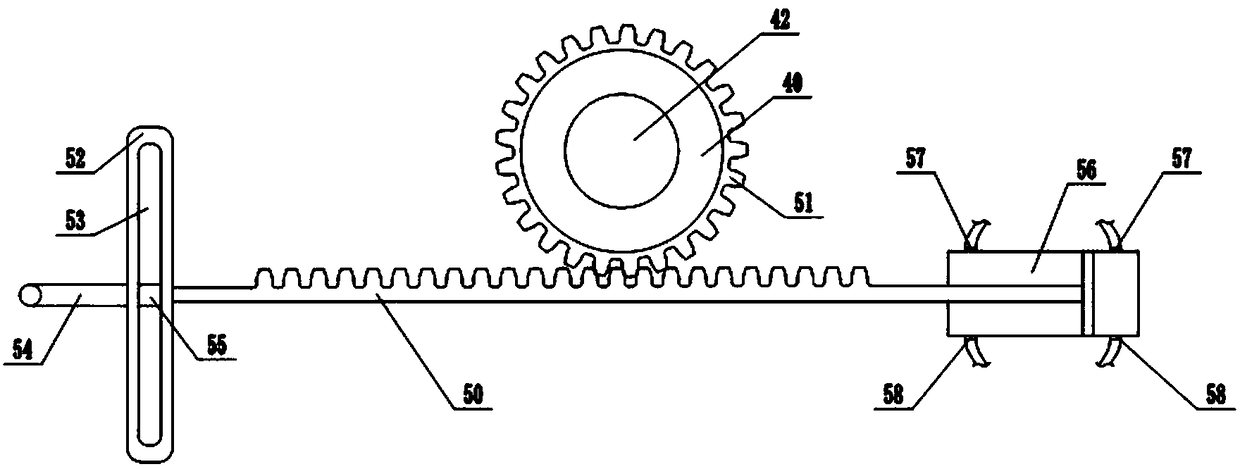

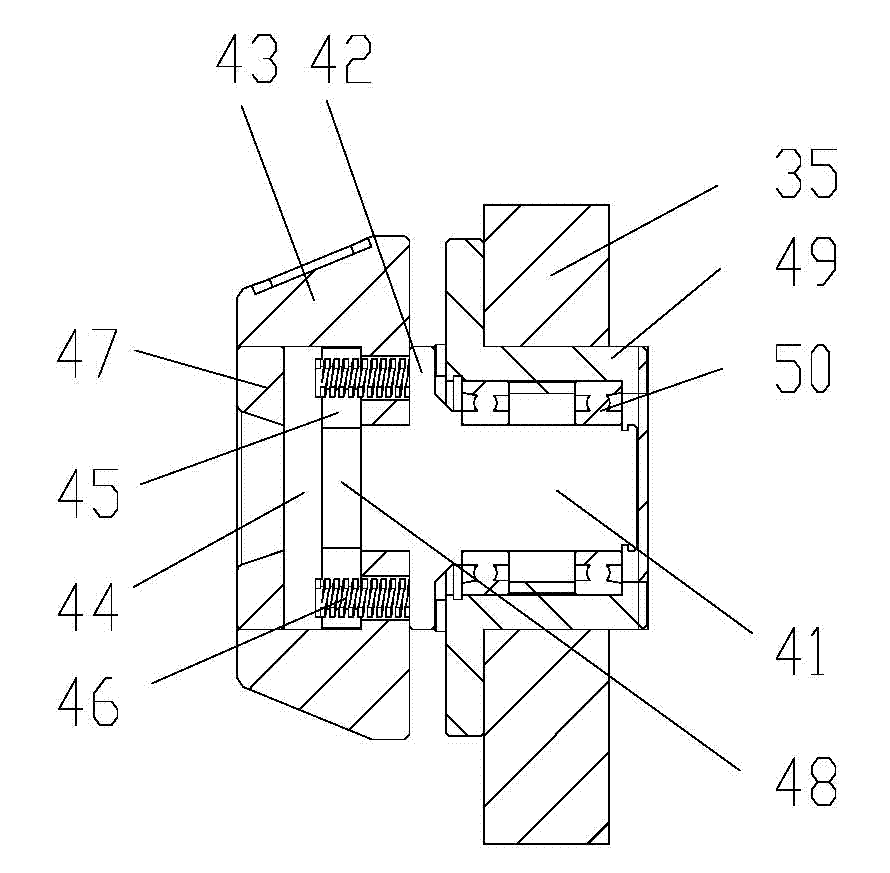

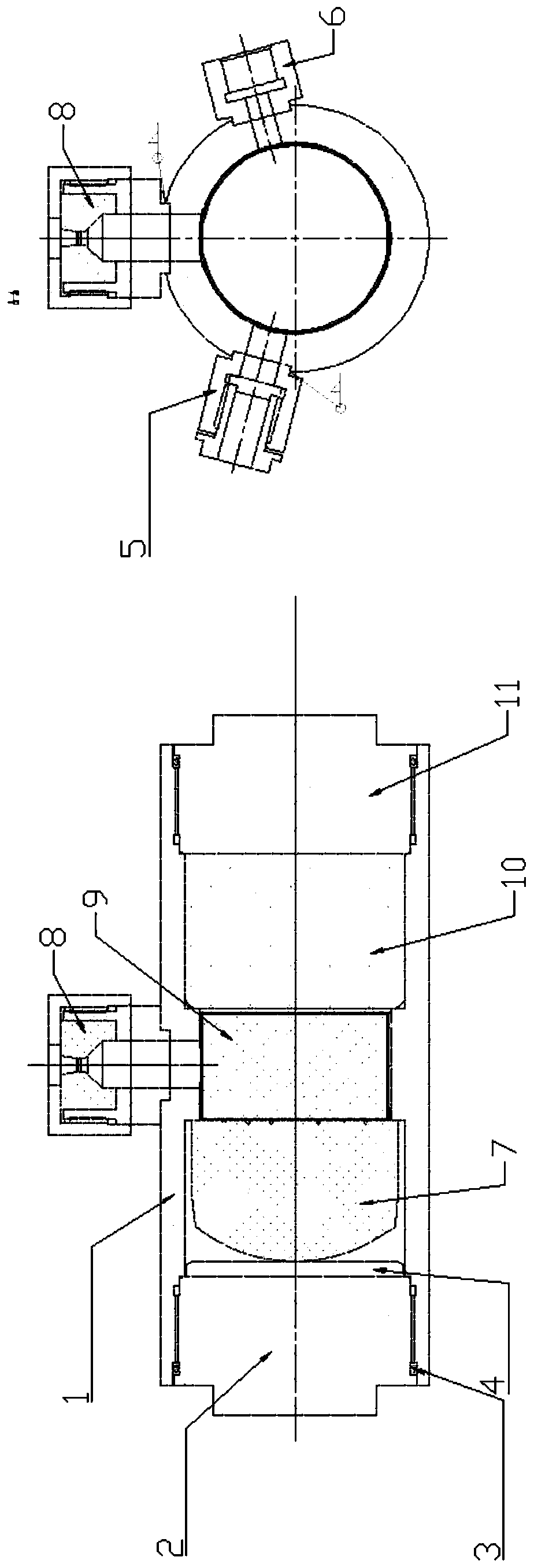

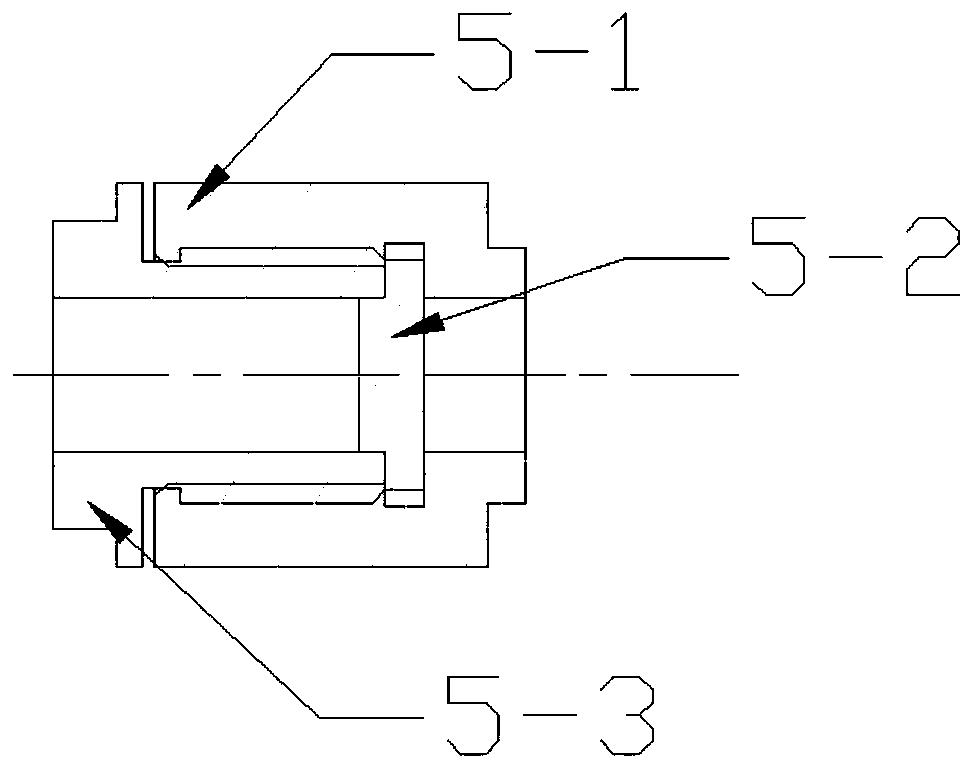

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

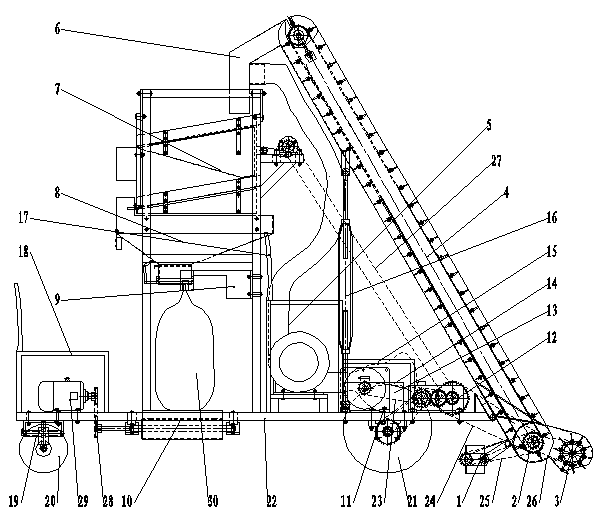

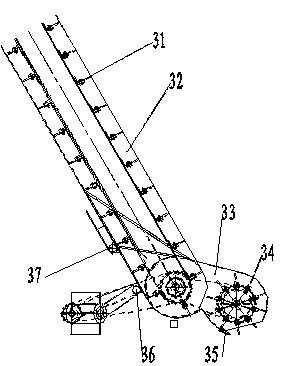

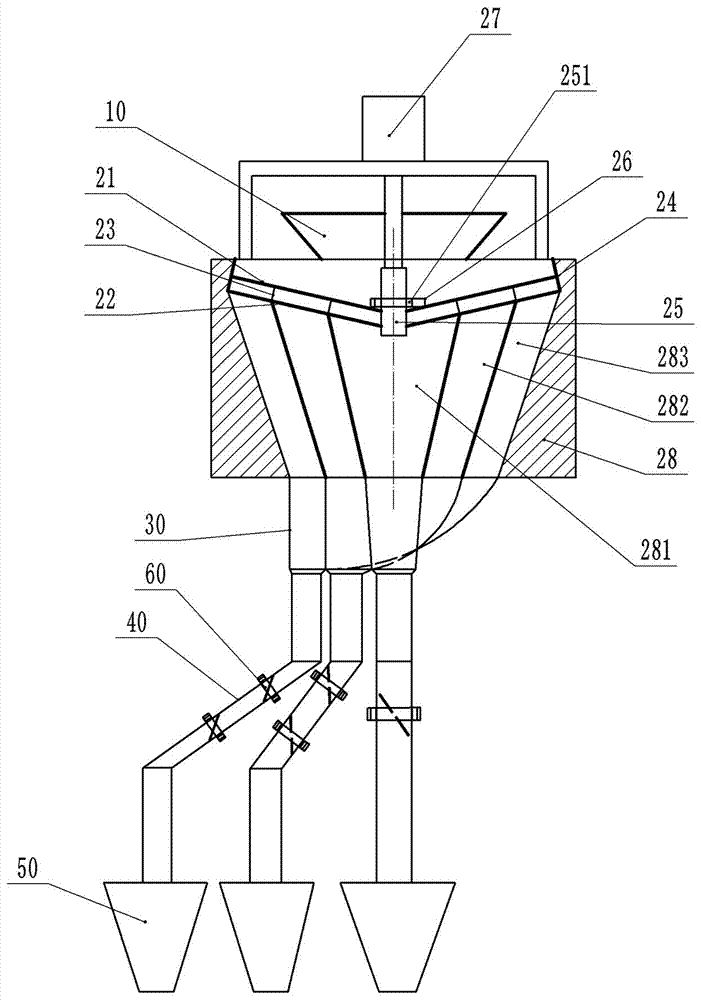

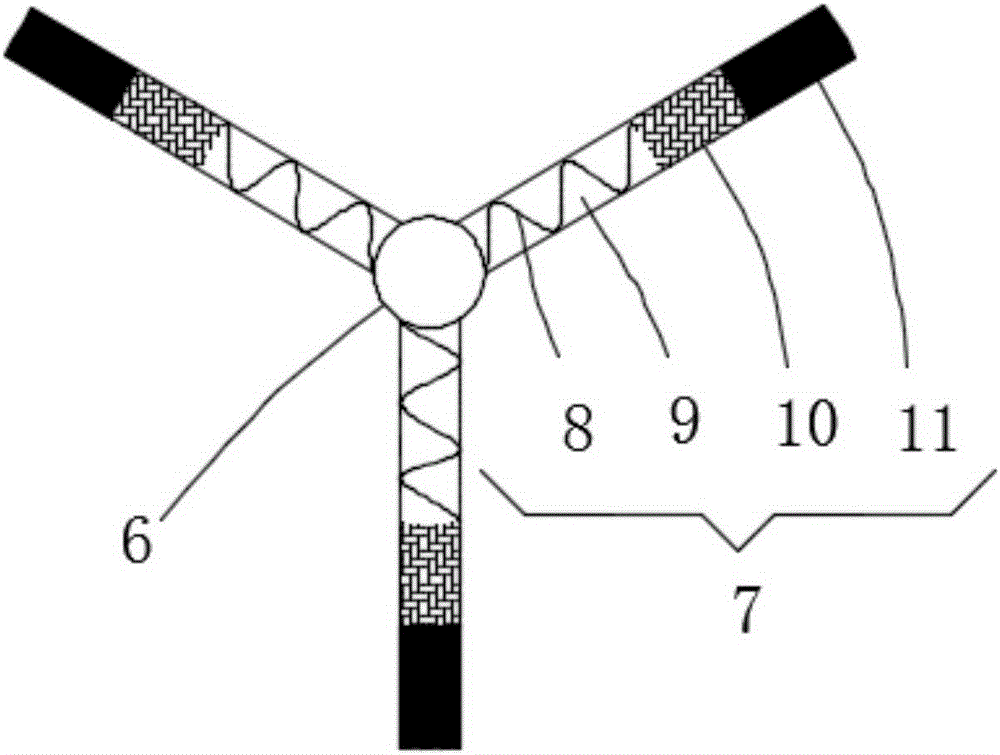

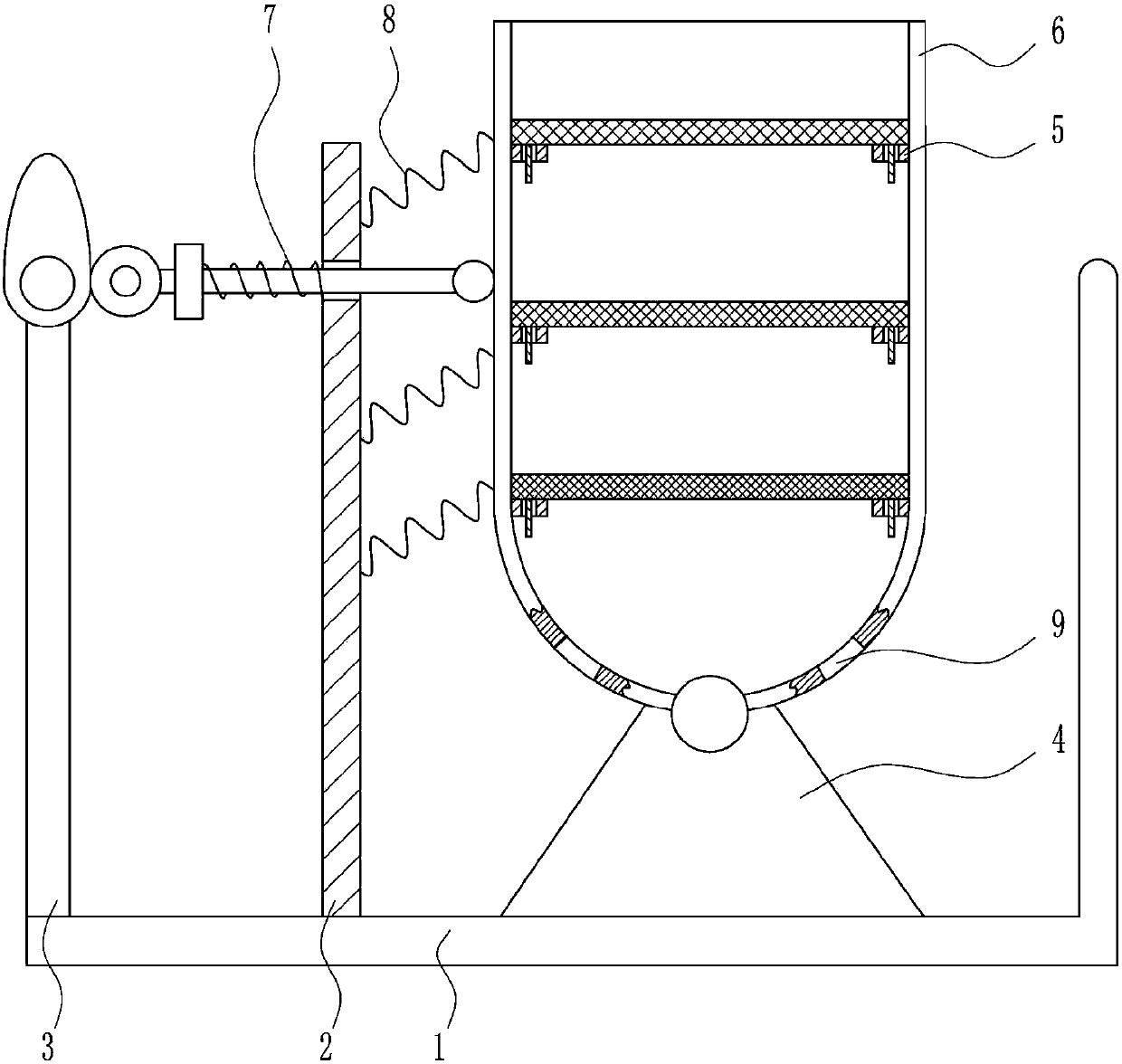

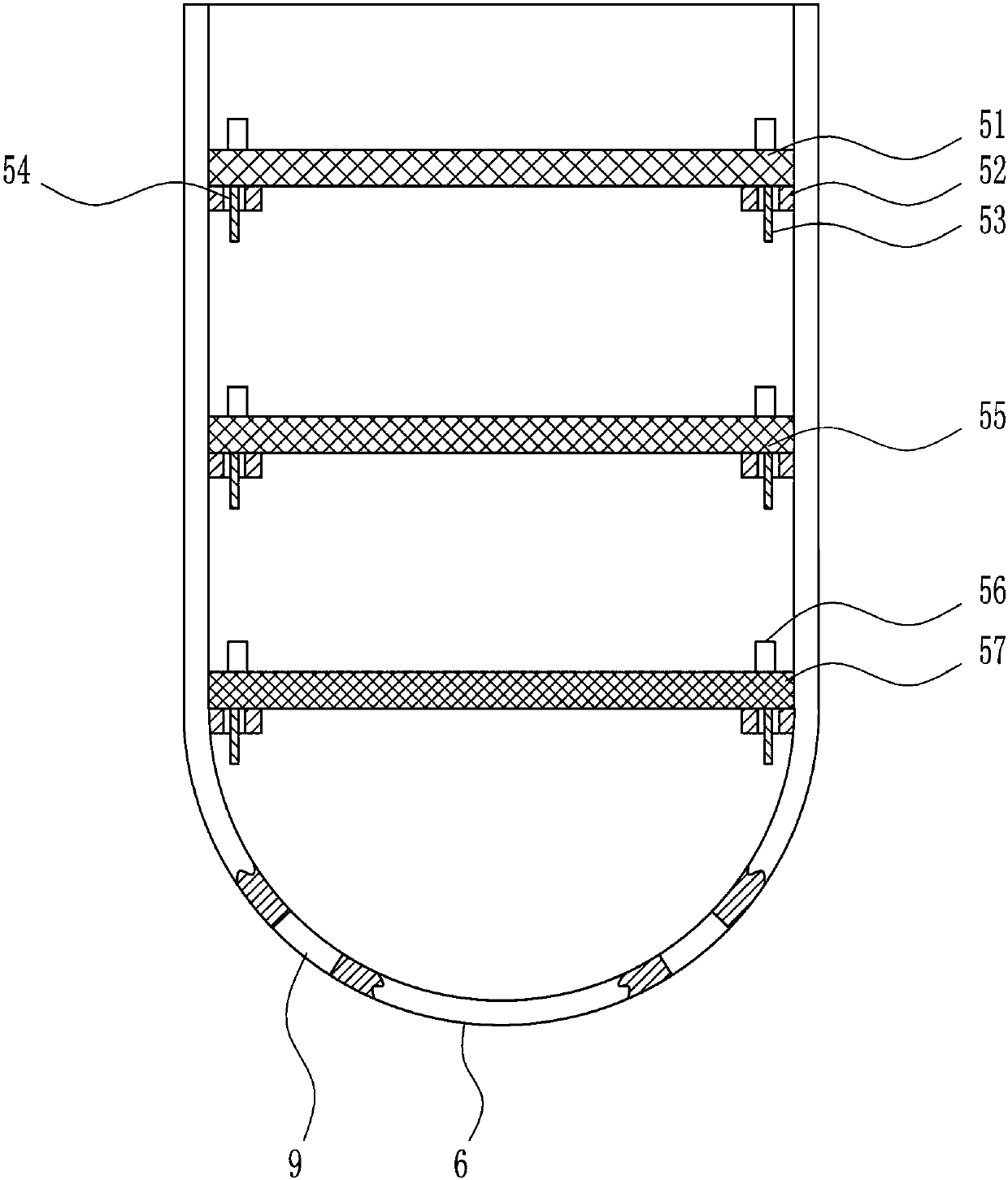

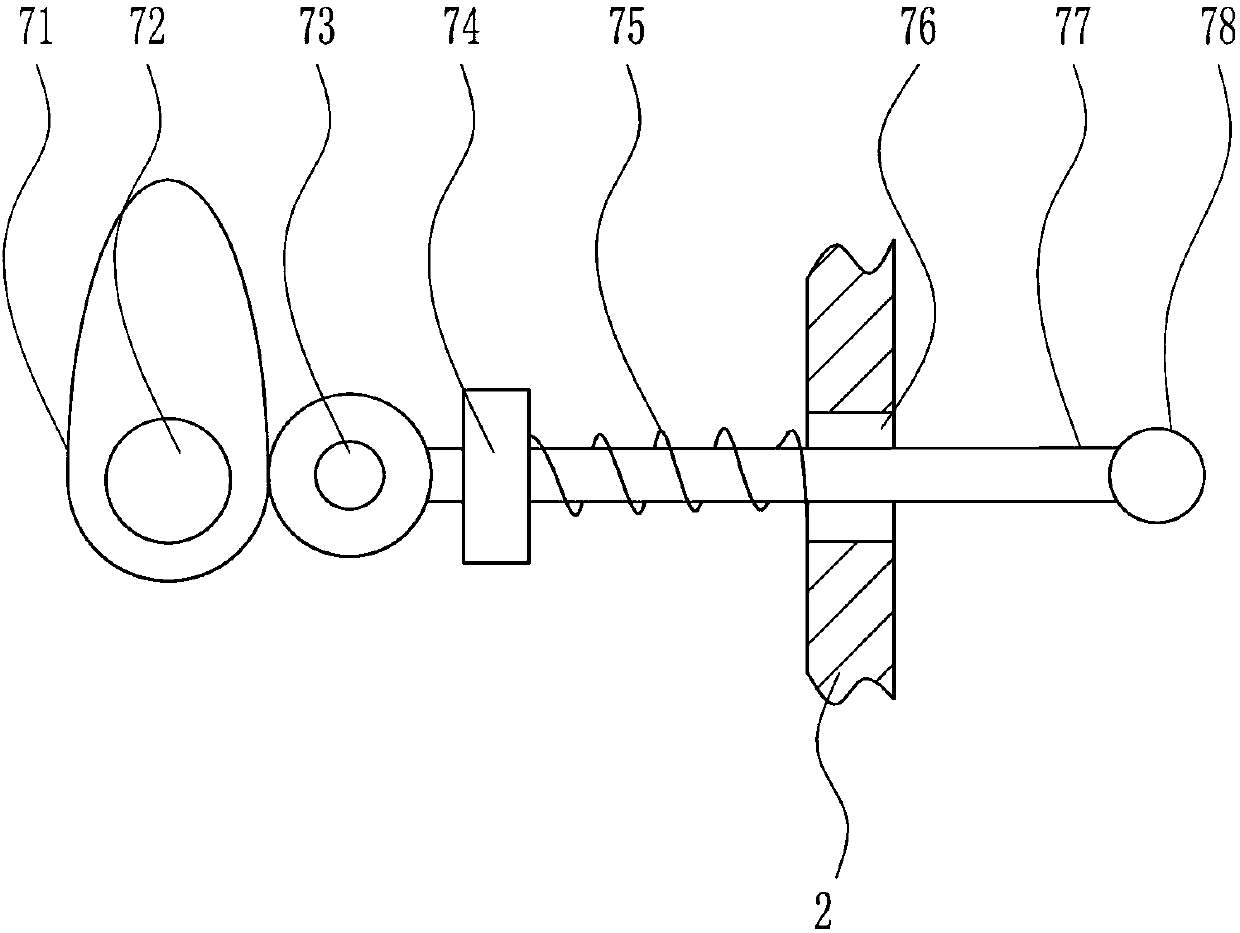

Sack packer for automatically collecting grain

InactiveCN102745348APrevent throwingAchieve one-offSolid separationSolid materialTransmission systemEngineering

The invention discloses a sack packer for automatically collecting grain. The sack packer comprises a leaked grain cleaning device, an auger, a grain poking device, a lift conveyer, a wind impurity removing device, a grain feeding mechanism, a vibrating screen and a magnetic impurity removing device, a barn, a quantitative packing and conveying system, an automatic bag sealing system, and a power and transmission system, wherein all devices are fixed on the frame, and cooperate to finish automatic the collecting, automatic cleaning, quantitative packing, and automatic bag sealing functions of the grain; the grain poking device (the leaked grain cleaning device is started when a field is not smooth) collects the grain paved on a seasoning yard into the auger when working; the auger conveys the grain to the lift conveyor; the lift conveyor lifts the grain to a grain feeding mechanism; the wind impurity removing device absorbs light impurity mixed in the grain in the process that the grain falls off, and plays a certain airing role; the vibrating screen and the magnetic impurity removing device remove and collect different sizes and properties of impurities, and the grain is quantitatively packed and automatically sealed after entering into the barn.

Owner:SHANDONG UNIV OF TECH

Control method for oil return of DC inverter compressor

ActiveCN101968248APrevent throwingAvoid exclusionCompressorSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses a control method for oil return of a DC inverter compressor, which comprises the following steps of: (1) initially supplying power to start the machine, and setting the opening of an electronic expansion valve according to the number of the started indoor units; (2) adopting different upconvert methods according to the target frequency of the compressor; (3) if an air conditioning unit starts for 10 minutes, starting oil return circulation; and (4) after oil return, if the machine is in a heating mode, judging whether the temperature of an outdoor coil is less than or equal to -12DEG C, if so, beginning defrosting circulation, and starting a conventional automatic adjustment mode after defrosting, otherwise, starting the conventional automatic adjustment mode, and if the machine is not in the heating mode, directly starting the conventional automatic adjustment mode; and (5) when a stop command is received, adopting different stop modes according to different operating frequencies of the compressor. Compared with the conventional methods, the method has the characteristic of effectively solving the problem of oil starvation in the starting process, normally running process and stopping process of the compressor.

Owner:NINGBO AUX ELECTRIC

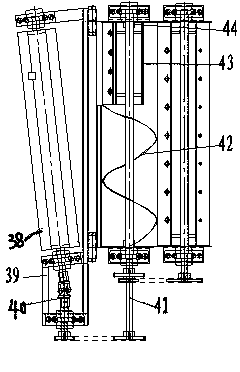

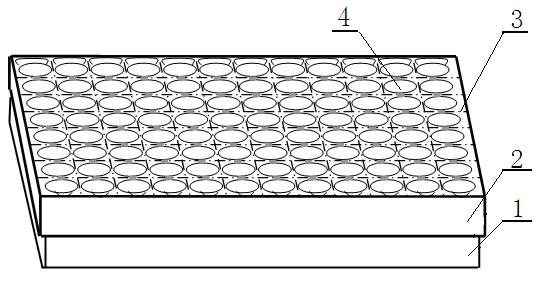

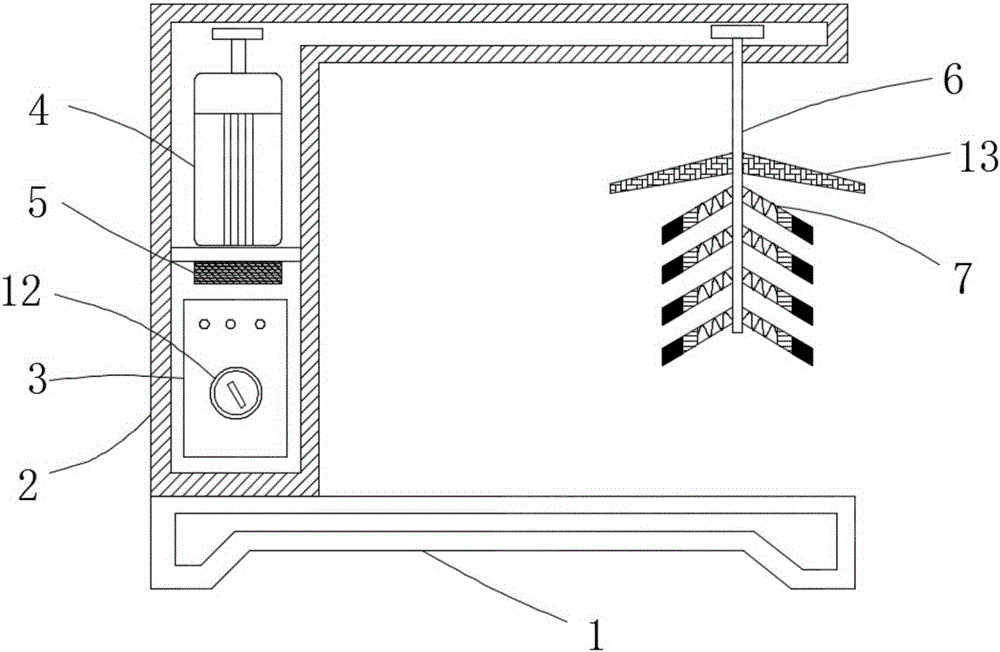

Kit for extracting nucleic acid by magnetic bead-microtiter plate method and method for extracting nucleic acid by same

The invention relates to a kit for extracting nucleic acid by a magnetic bead-microtiter plate method and a method for extracting nucleic acid by the same. The kit comprises a kit body and a reagent, wherein, the kit body consists of a detachable microtiter plate (2) similar to an Elisa plate as well as a magnetic plate (1), and the reagent comprises magnetic beads, lysis-binding solution, washing solution A, washing solution B and eluent; the detachable microtiter plate (2) consists of micropores (4) and a pore frame (3), the micropores (4) are made from polystyrene, polyethylene or polypropylene, the bottom of each micropore is in a 'U' or 'V' shape, and the micropores (4) are classified into two forms, namely single pores and multi-connected pores; and the magnetic plate (1) is matched with the bottom of the detachable microtiter plate (2) in shape and size. The kit can be used for extracting a large quantity of the nucleic acid from a sample at one time, and has the advantages of low cost and high operating efficiency, and is simple in operation.

Owner:南宁海关技术中心

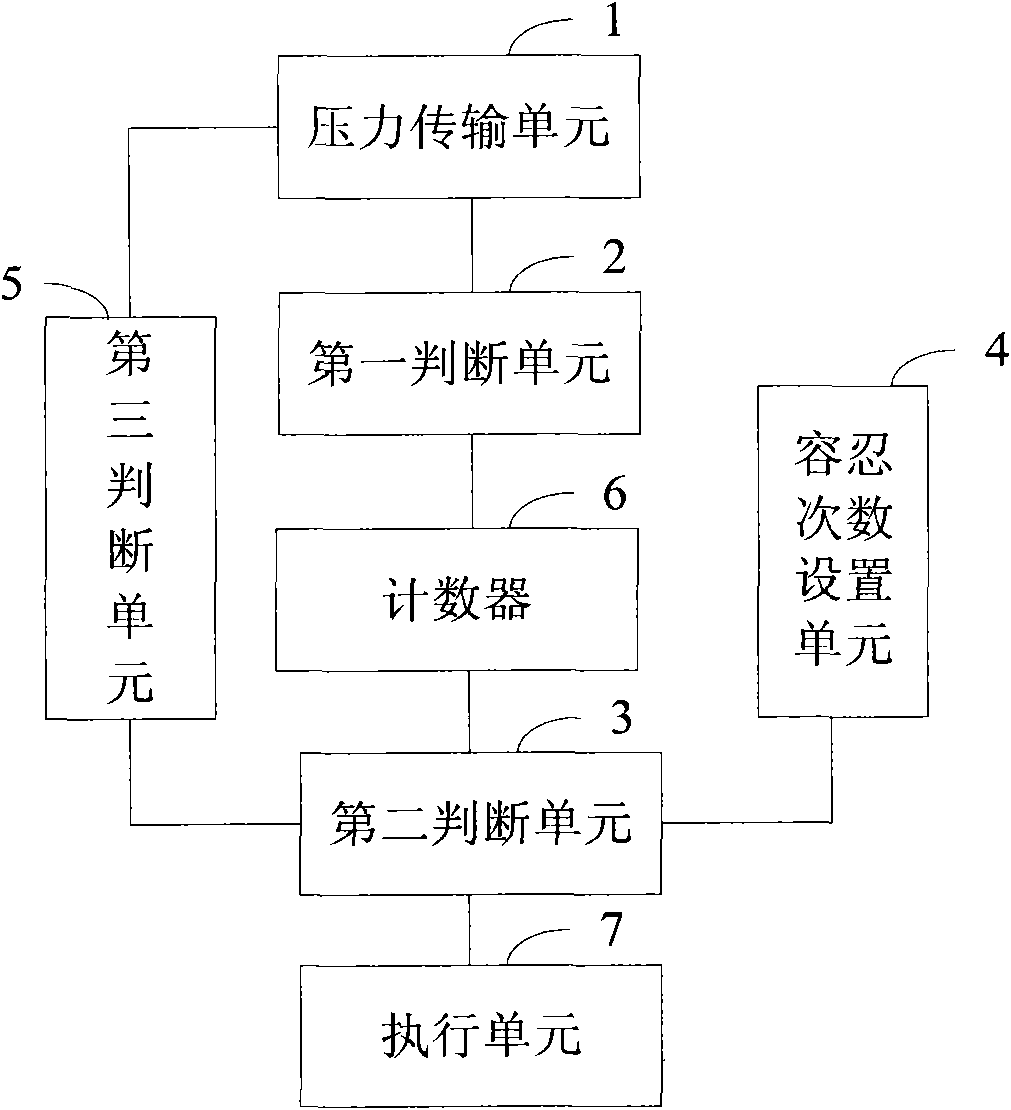

Method and device for processing monitoring alarm and plasma processing device

ActiveCN102566475AImprove anti-interference abilityPrevent throwingProgramme controlComputer controlAnti jammingNormal values

The invention provides a method and a device for processing monitoring alarm and a plasma processing device. The method for processing the monitoring alarm comprises obtaining toleration times according to monitoring cycles and toleration time which corresponds to a certain continuous time section in the technological process; obtaining monitoring values of monitored parameters according to the monitoring cycles; judging whether the monitoring values obtained each time are within a preset normal value range, if the monitoring values obtained each time are within the preset normal value range, adding one to abnormal times, and if the monitoring values obtained each time are not within the preset normal value range, zero clearing the abnormal times; and judging whether the abnormal times accumulated within the certain continuous time section in the technological process are larger than or equal to the toleration times, if the abnormal times accumulated within the certain continuous time section in the technological process are larger than or equal to the toleration times, executing safety actions, and giving out alarming signals. The method for processing the monitoring alarm only executes the safety actions and gives out the alarming signals when the abnormal times of an air pressure value in an input pipeline of a quality flow controller continuously reach the toleration times. Therefore, the method for processing the monitoring alarm is strong in anti-jamming performance.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Automatic lathe for processing spanner

InactiveCN101797691APrecise positioningInaccurate positioningOther manufacturing equipments/toolsGas cylinderElectric machinery

The invention relates to a lathe, in particular to an automatic lathe for processing a spanner. The lathe is characterized in that a positioning ring is installed on a principal shaft; a positioning groove is arranged on the lateral side of the positioning ring; a positioning block is pushed by a gas cylinder to be clamped in the clamping groove, at the same time, an inductive switch is induced to send out an induction signal to enable a spindle motor to stop running, and thereby the principal shaft can be positioned and stops running. The automatic lathe can position accurately, the positioning block is clamped in the positioning groove to enable the principal shaft to be firmly fixed, and the principal shaft can not be positioned inaccurately due to rotational inertia; and the automatic lathe is simple in design and low in cost.

Owner:ZHEJIANG YIYANG TOOL MFG

Vehicle-mounted road fence cleaning device for municipal use

InactiveCN109183689AAvoid repositioningImprove scrubbing efficiencyRoad cleaningWater storage tankSprocket

The invention discloses a vehicle-mounted road fence cleaning device for municipal use. A water storage tank is arranged on a sprinkler vehicle body and a storage tank is arranged on one side of the water storage tank. A lifting device is arranged in the contain box, and the lifting device comprises a lifting frame, a lifting cylinder, a sprocket wheel III, a chain and a sliding block; a cleaningdevice is arranged on one side of the lifting device, and the cleaning device comprises a fixed brush roller, an adjusting brush roller, a transmission box and a transmission device, wherein the transmission box is provided with a transmission device; a high-pressure water pipe is arranged on one side of the fixed brush roller; the other side of the guard rail is provided with an adjusting brush roller symmetrical to the fixed brush roller, and the structure and size of the adjusting brush roller are consistent with those of the fixed brush roller. The upper part of the transmission box of theadjusting brush roller is provided with an obstacle overtaking device. When the invention meets obstacles such as traffic indication signs, the adjusting brush roller is folded up by using a flippingdevice and a retracting device, and the adjusting brush roller is reset by using the flipping device and the retracting device after the flipping device and the retracting device pass over the obstacles, thereby avoiding the repositioning of the cleaning device and improving the scrubbing efficiency.

Owner:房思群

Organic fertilizer screening plant

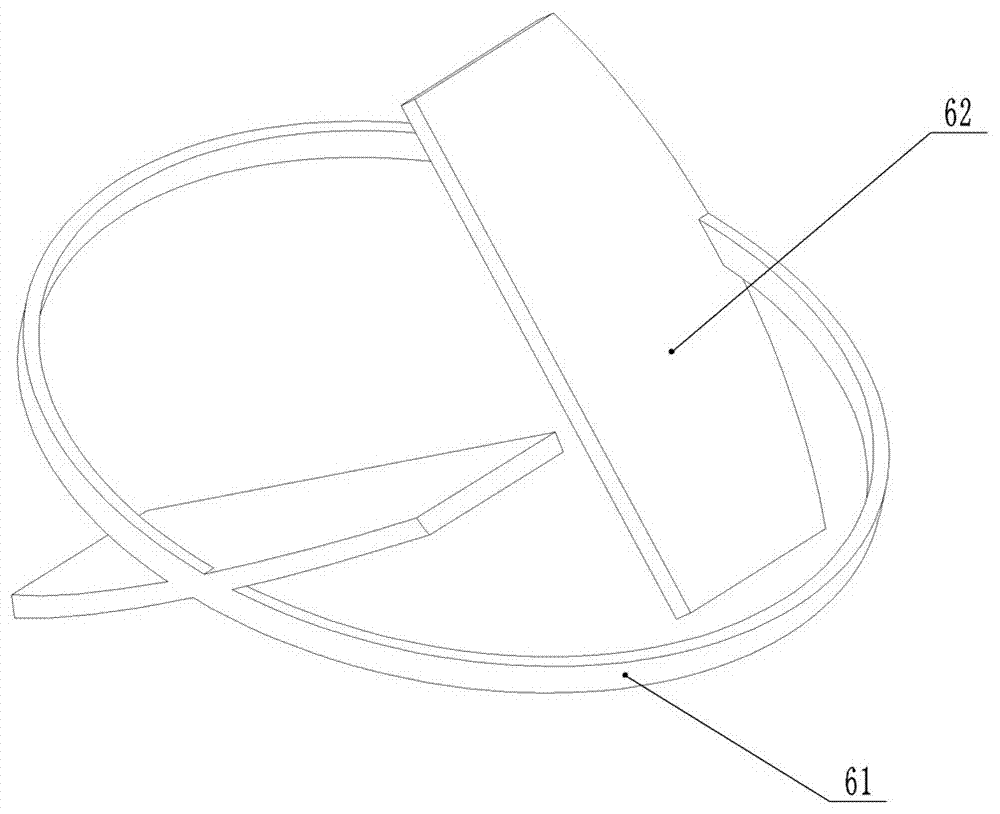

The invention discloses an organic fertilizer screening plant which comprises a feeding hopper, a separating mechanism, a receiving hopper, a feeding pipe, a discharging hopper and a conveying mechanism which are sequentially connected. The separating mechanism comprises a separating screen, a motor and a collecting chamber, the separating screen is in a bucket shape, a center shaft is connected to the middle portion of the separating screen, the motor and the center shaft are coaxially connected, and a cam is rotationally connected to the center shaft; the separating screen comprises an upper screen plate and a lower screen plate which are fixedly connected, screen holes in the upper screen plate are gradually decreased from the center to the edge; small screen holes, middle screen holes and large screen holes are sequentially formed in the lower screen plate from the center to the edge, and a small cavity, a middle cavity and a large cavity are arranged in the collecting chamber; and the conveying mechanism comprises an annular groove, a ring rotationally connected with the annular groove and blades arranged in an inclined manner in the axial direction of the feeding pipe, and the blades are fixed to the ring. Compared with the prior art, the organic fertilizer screening plant can rapidly screen organic fertilizer according to the organic fertilizer particle size, and meanwhile, the screened organic fertilizer can be prevented from generating blockage in the feeding pipe.

Owner:习水县和平有机肥业有限公司

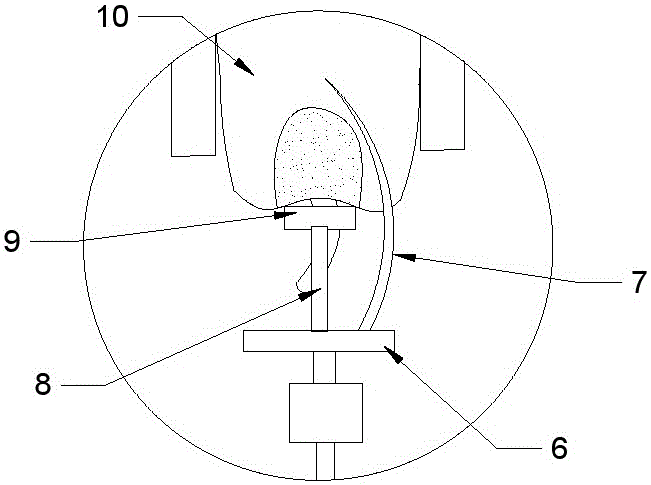

Cartoon game character model display device

ActiveCN106852607AImprove vividnessPrevent throwingShow shelvesShow hangersDisplay deviceSoftware engineering

The invention relates to a display device, in particular to a cartoon game character model display device. Against to-be-solved technical problems, the invention provides a cartoon game character model display device capable of protecting displayed objects and attracting tourists. In order to solve the technical problems, the cartoon game character model display device comprises a mounting plate, a round sliding rail, a roller, a connecting rod and a rotating mechanism and the like. The top of the mounting plate is provided with the round sliding rail, the roller is arranged in the round sliding rail, the center of the top of the mounting plate is connected with the rotating mechanism, the top of the rotating mechanism is provided with a first rotating rod, the top of the first rotating rod is connected with a placing platform, and the connecting rod is connected between the roller and the placing platform. The cartoon game character model display device is designed, the placing platform is driven by the arranged rotating mechanism to rotate, so the tourists sees the displayed objects with half an eye, the vitality of the displayed objects is enhanced, and the tourists' sight is attracted.

Owner:江苏绿途环保科技有限公司

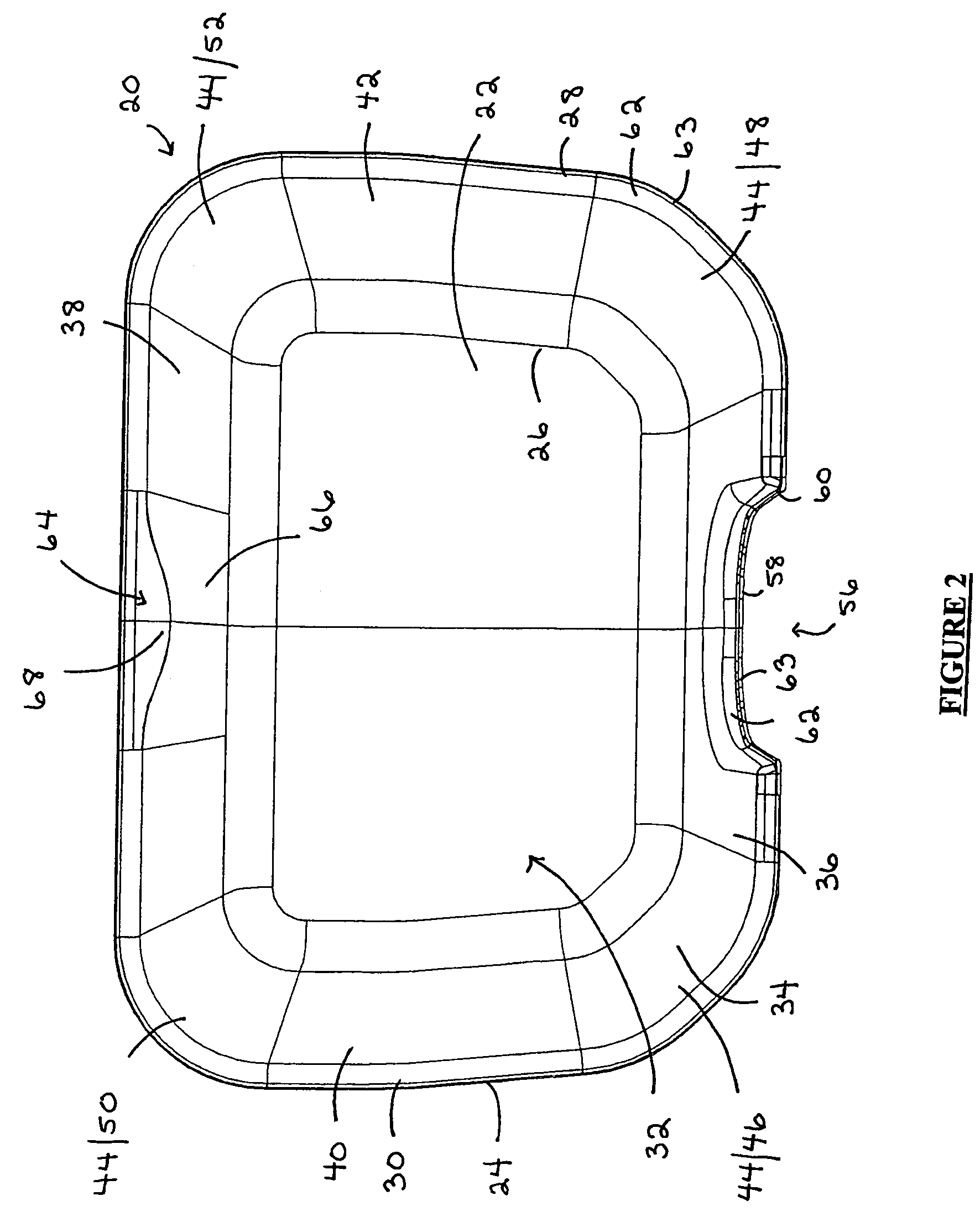

Animal litter box

ActiveUS7150242B2High strengthImprove rigidityAnimal housingOther apparatusEngineeringIndividual animal

Owner:SCHUSTER HAROLD +1

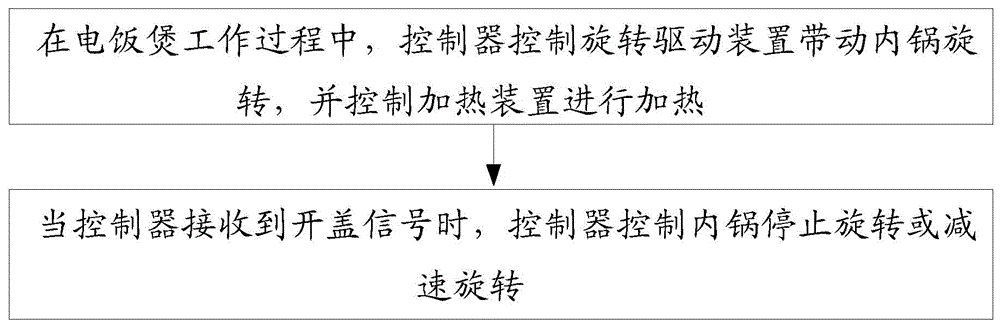

Control method of electric rice cooker

The invention provides a control method of an electric rice cooker. The electric rice cooker comprises a cooker cover, an inner pot, a rotating driving device, a heating device, a cover opening induction device and a controller; the rotating driving device drives the inner pot to rotate, the heating device heats the inner pot, the cover opening induction device is used for detecting whether the cooker cover is in an opened or closed state, and the controller is connected with the cover opening induction device, the heating device and the rotating driving device. When the cover opening induction device detects that the cooker cover is in the opened state, the controller controls the inner pot to stop working or rotate in a speed reducing mode. According to the control method of the electric rice cooker, in the rice cooking process, if a user opens the cooker cover carelessly, the cover opening induction device can detect that the cooker cover is in the opened state in time, the rotating speed of the inner pot is controlled to be decreased through the controller, and the situation that the user is scalded due to the fact that the inner pot rotates at a high speed, and rice water is thrown out of the inner pot is avoided.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

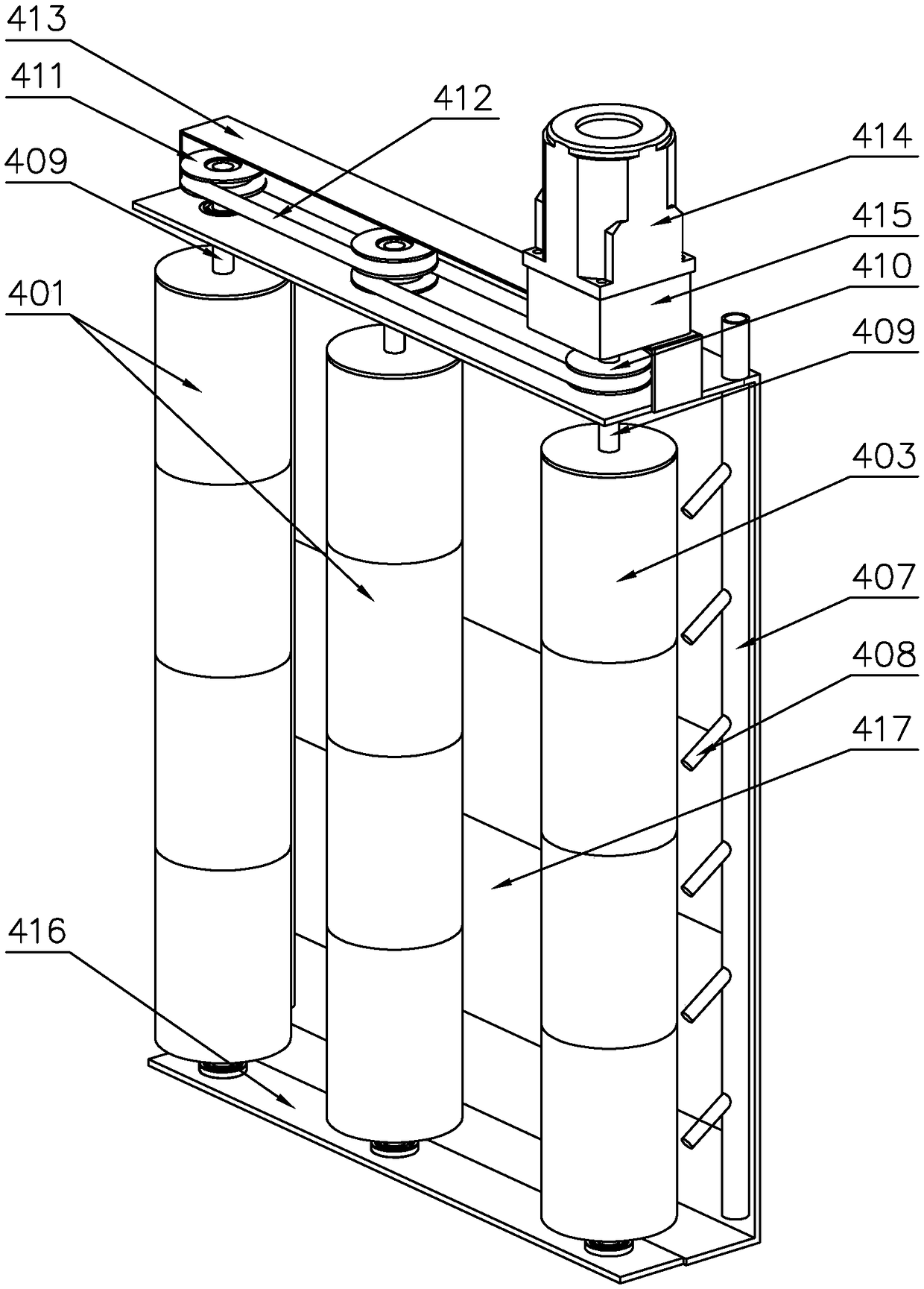

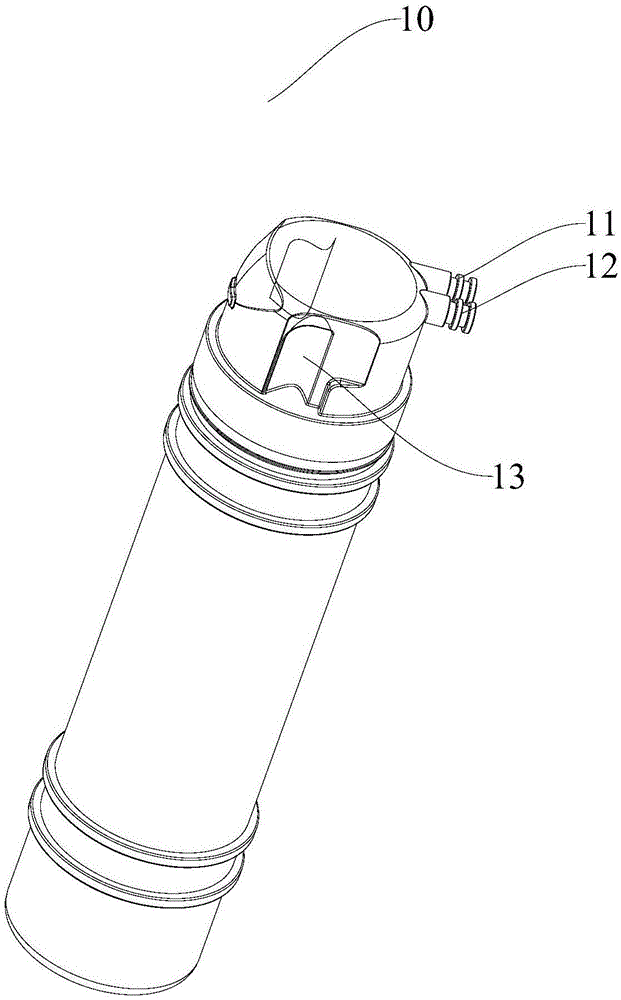

Water purifier

ActiveCN106345168AEasy to fixSimple structureMembrane filtersFiltration separationWorking pressureWaste management

The invention discloses a water purifier. The water purifier comprises a shell, a filter core assembly, a water path board and a filter core fixing structure, wherein the filter core assembly is arranged on the shell and comprises a filter core; a water inlet and a water outlet are formed in the filter core, and the water inlet and the water outlet are respectively formed in the side parts of the filter core; a water path is limited in the water path board, and a direct inserting type filter core interface connected with the water inlet and the water outlet is formed in the water path board; the filter core fixing structure is detachably connected to the water path board or the shell and is connected with the filter core so as to fix the position of the filter core relative to the water path board. According to the water purifier disclosed by the embodiment of the invention, by inserting the filter core in the water path board and fixing the position of the filter core relative to the water path board through the filter core fixing structure, the filter core can be effectively locked, the degree of freedom of the filter core relative to the water path board is limited, and the filter core is further prevented from being thrown away from the water path board due to larger working pressure of the water inlet and the water outlet or the action of an external force, the filter core or the water path board is prevented from being destroyed, the connection reliability is ensured, and the cost is reduced.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

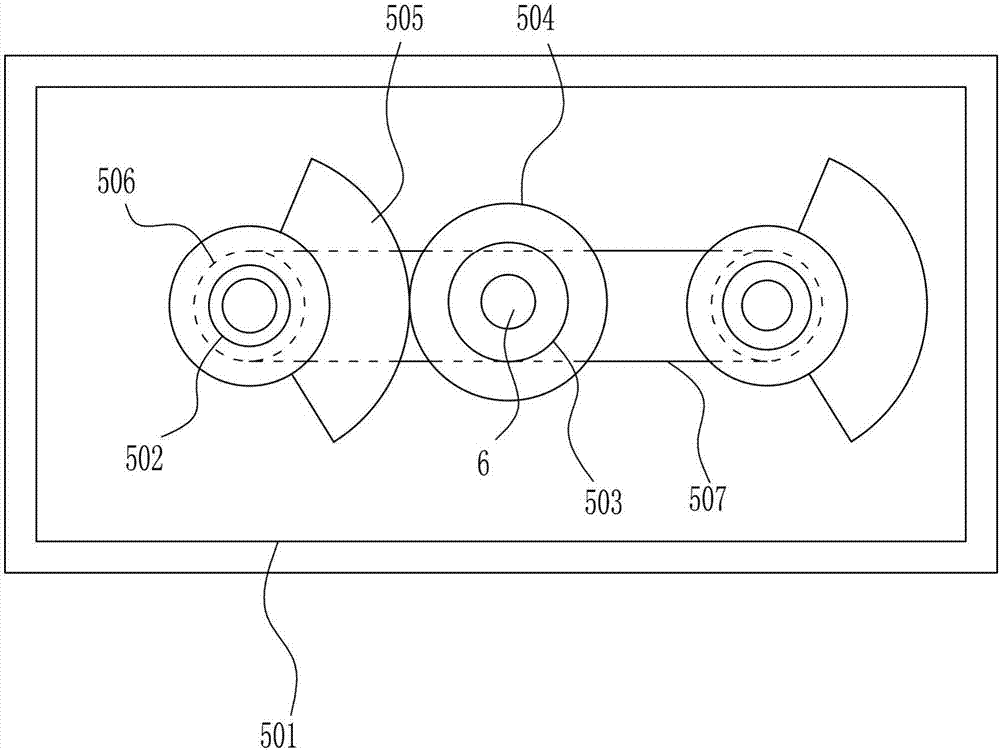

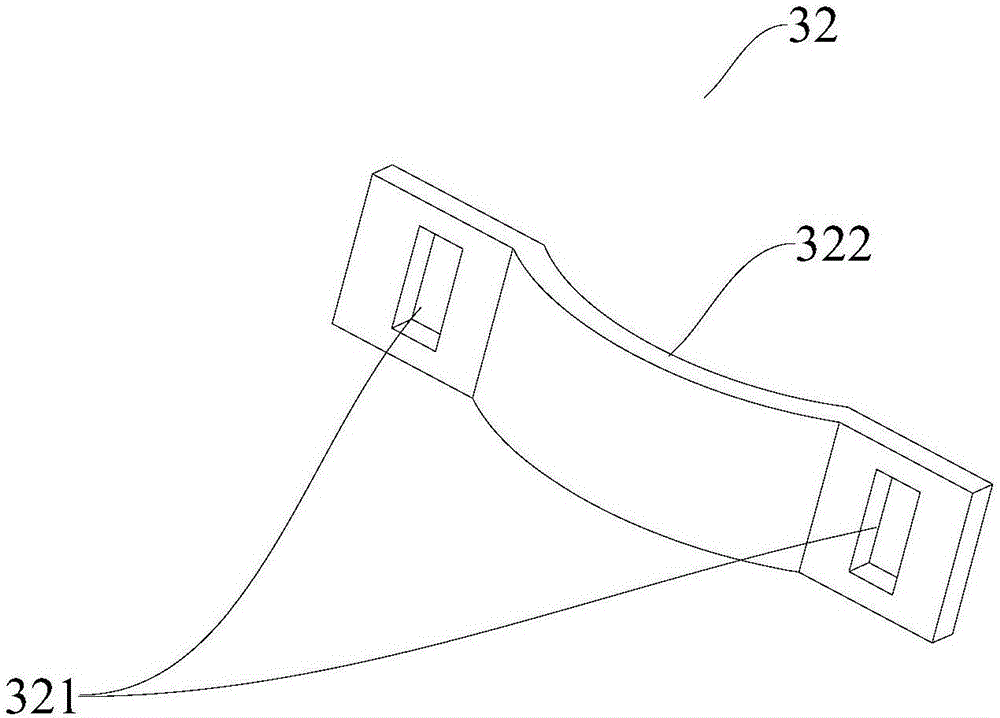

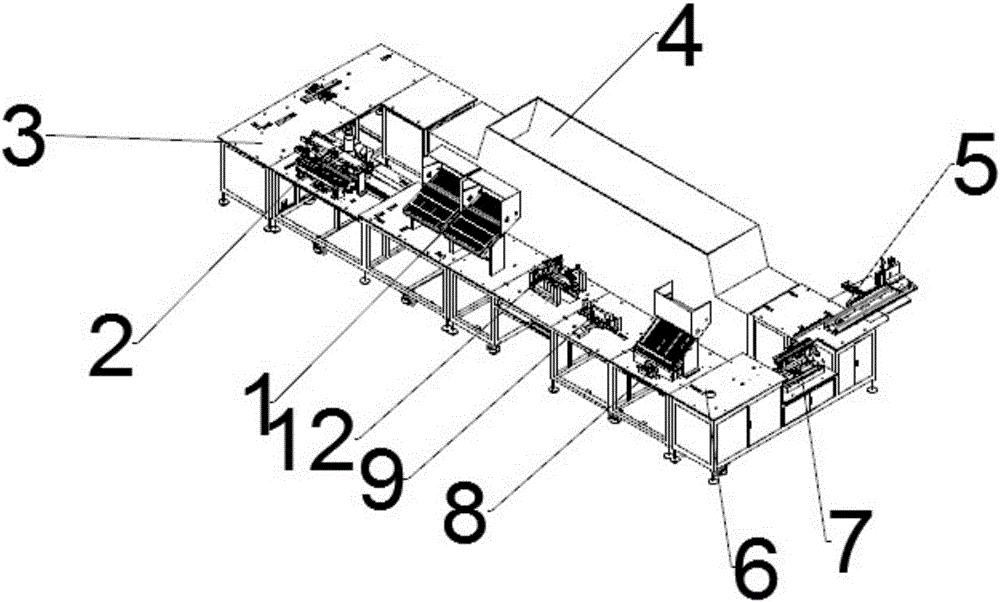

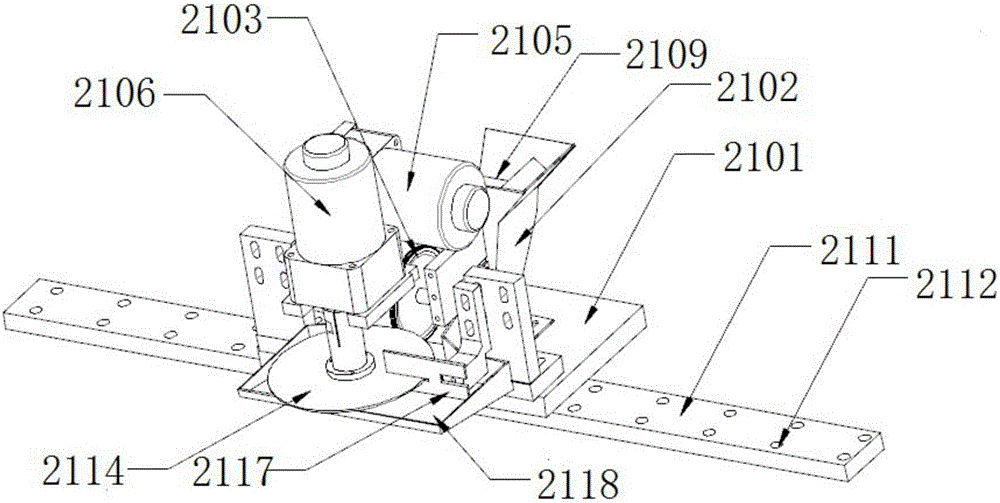

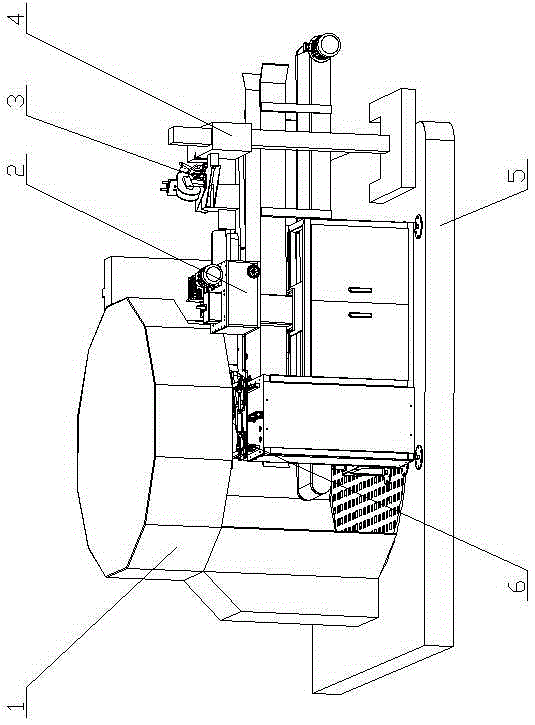

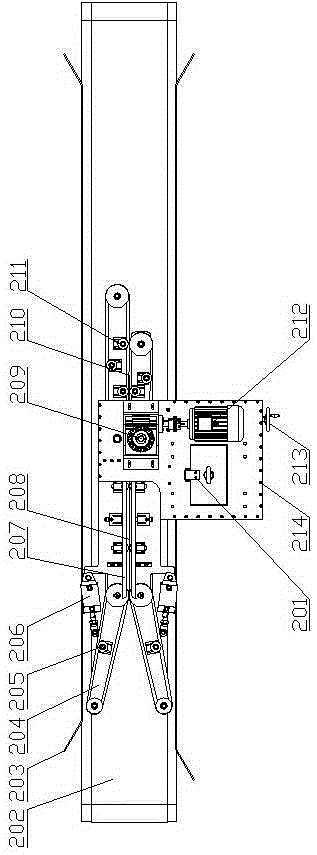

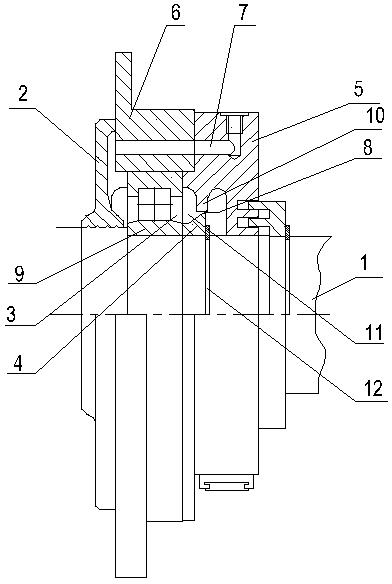

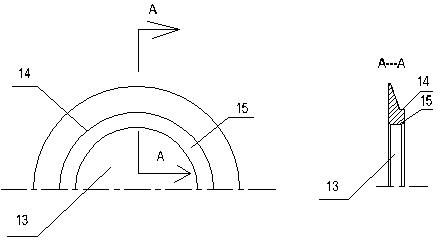

Single-wing intravenous needle assembling machine

The invention belongs to the field of production of medical apparatus, and particularly relates to a single-wing intravenous needle assembling machine. The single-wing intravenous needle assembling machine comprises a wing charging device (1) for positioning a wing into a carrier (13); starting with the wing charging device (1), a needle charging assembly (2) is connected to a conveyor belt at the back of the wing charging device (1); a right-angle conveying assembly (3) is connected to a conveyor belt at the back of the needle charging device (2); an oven (4) is connected to a conveyor belt at the back of the right-angle conveying assembly (3); a return needle detecting assembly (5) is connected to a conveyor belt at the back of the oven (4); a first air testing device (7) is connected to a conveyor belt at the back of the return needle detecting assembly (5); a carrier reversing device (6) is arranged at the back of the first air testing device (7). With the adoption of the single-wing intravenous needle assembling machine, a single-wing intravenous needle is hardly attached with bacteria during being assembled, so that the safety is high; in addition, the single-wing intravenous needle assembling machine is high in automation degree, so that the assembling efficiency can be greatly improved, and mass production can be achieved; the whole design of the single-wing intravenous needle assembling machine is reasonable, and the structure is simple.

Owner:梁启明

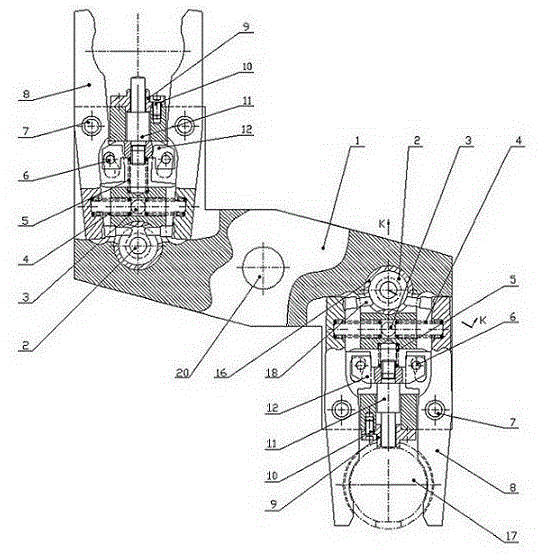

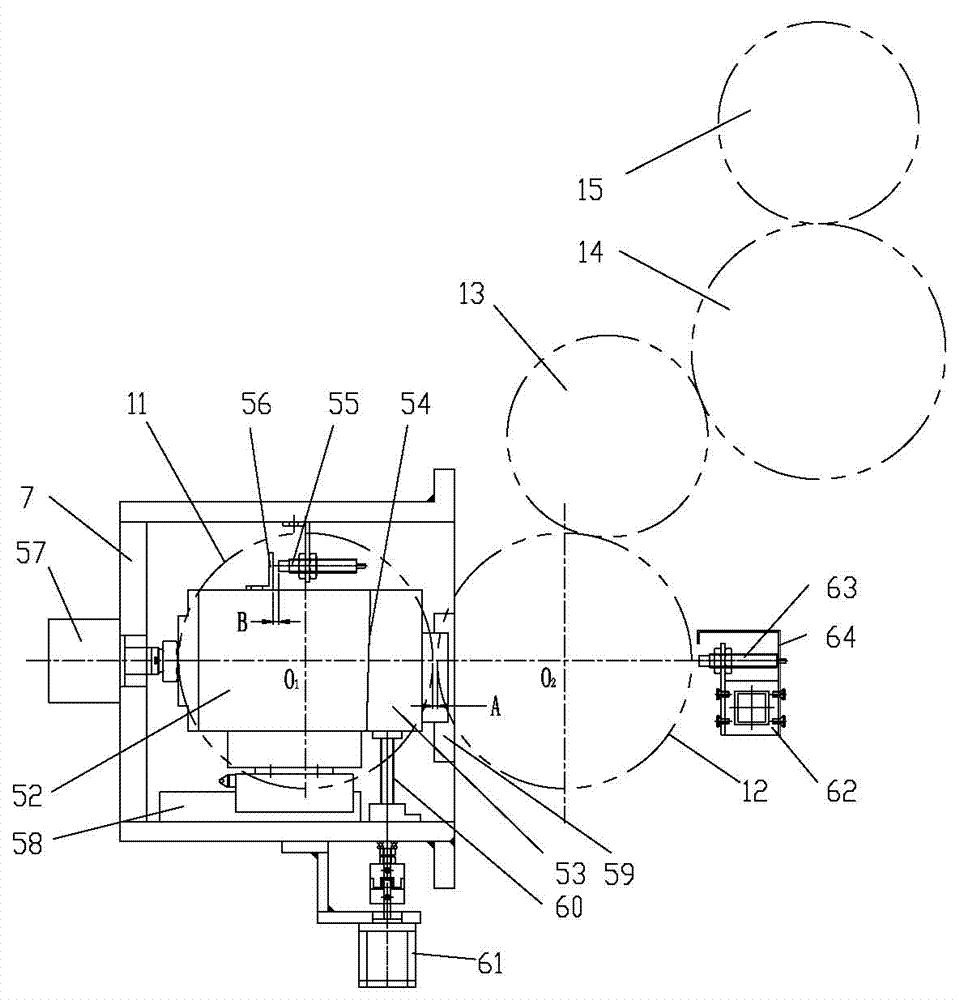

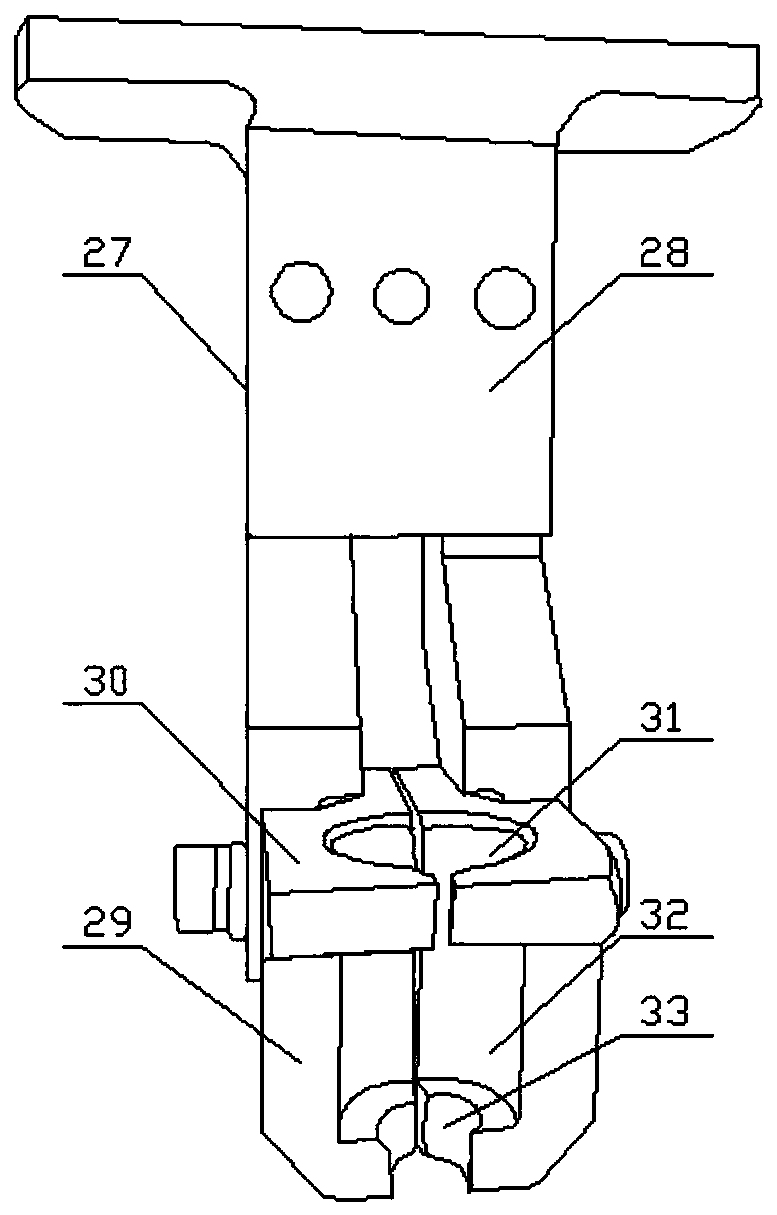

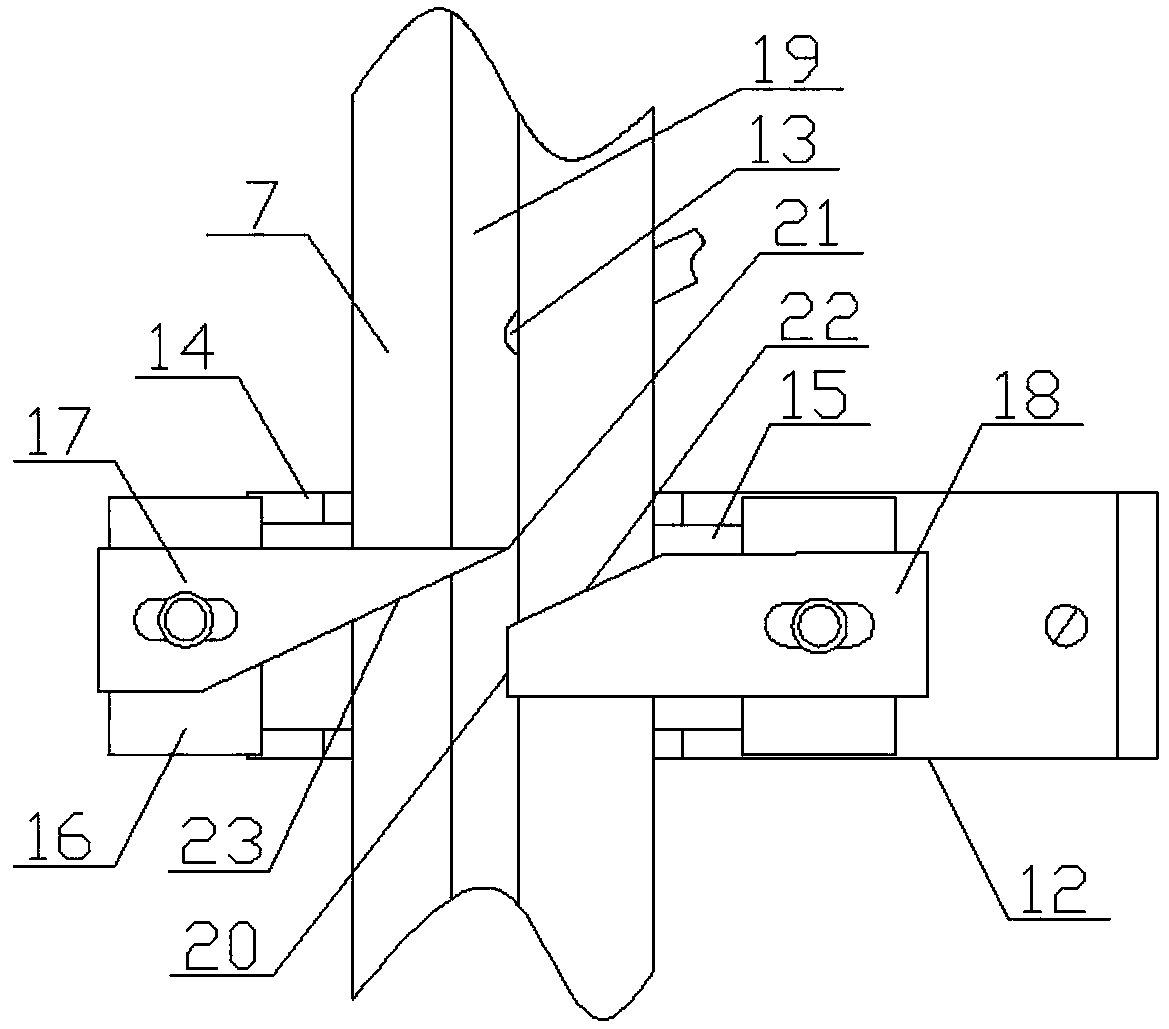

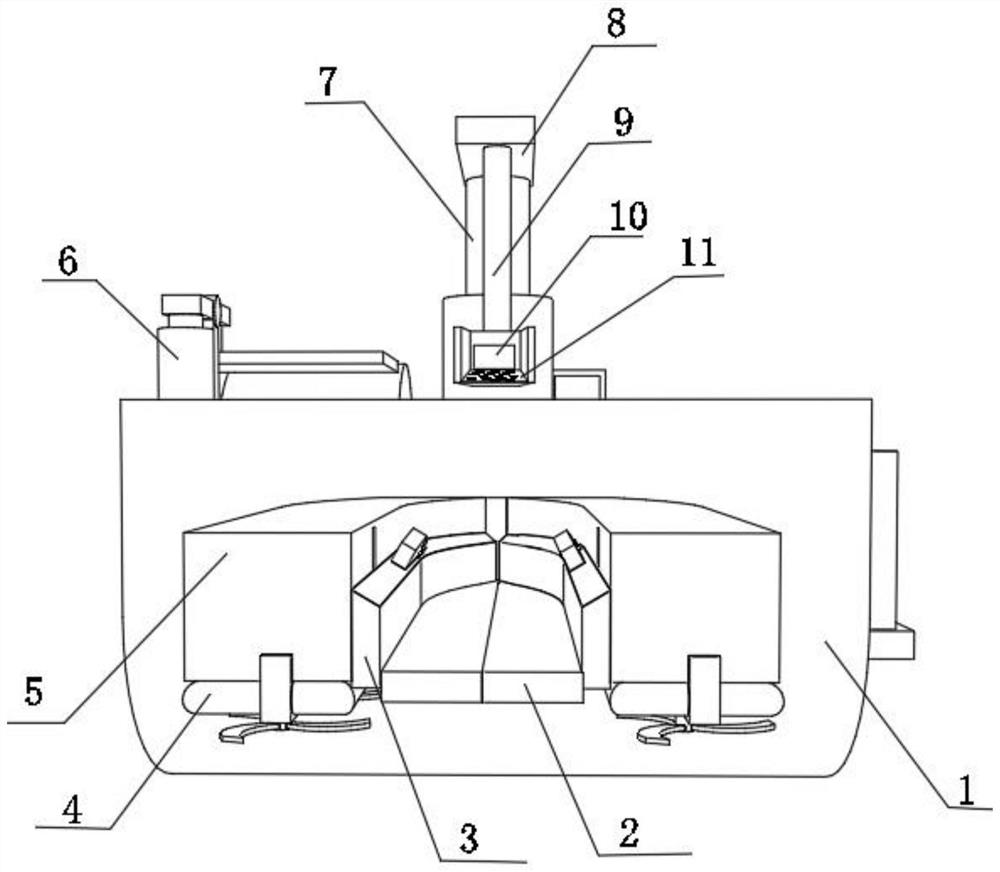

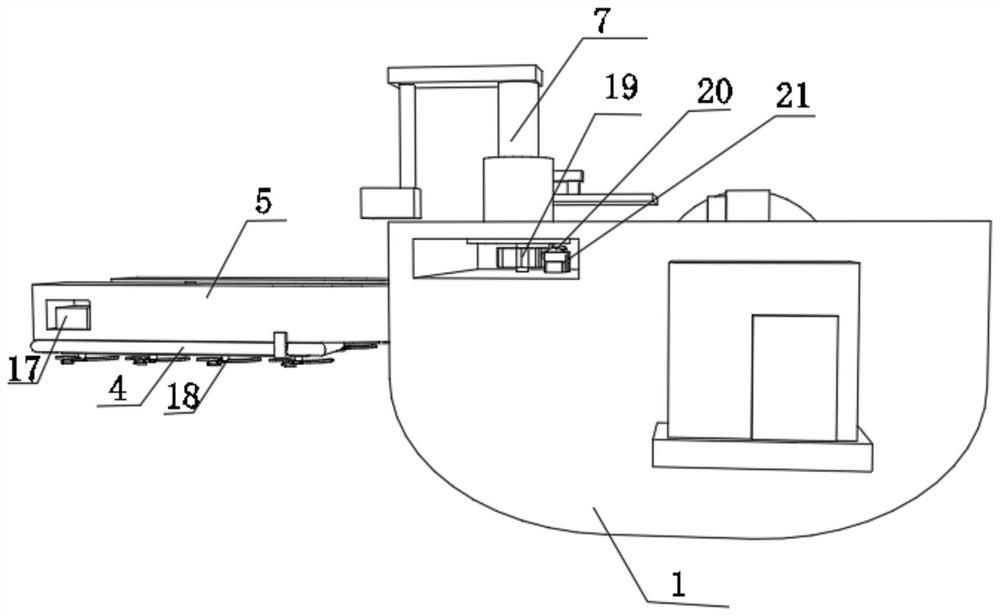

Interlocking type tool changing mechanical arm device

InactiveCN104690586APrevent throwingReduce tool change timePositioning apparatusMetal-working holdersRobot handClassical mechanics

The invention relates to an interlocking type tool changing mechanical arm device which comprises a mechanical arm body, a claw, an ejector rod mechanism, a spring clamping mechanism and a locking mechanism. The ejector rod mechanism is composed of an ejector rod (11), a U-shaped fork (12) and a spring (5). A slide pin (12) slides in a kidney-shaped hole (19) of the claw (8) so as to push the claw (8) to be opened and closed. The spring clamping mechanism and the locking mechanism are arranged at the tail portion of the claw (8). According to the driven type tool clamping mechanism arm, the ejector rod (11) is triggered by a tool to push the claw (8) to be opened or closed, automatic interlocking is achieved through the locking mechanism when the tool is clamped, the claw is effectively prevented from getting loose, and the tool is prevented from falling and being thrown away; a main shaft and a tool magazine directly push the tool into the mechanical arm, the tool changing time is saved, and work efficiency is high.

Owner:JIANGSU HENGLI MACHINE TOOL

Ventilator device for pirate prevention security cabin of ship

InactiveCN103010446AEasy to operateProtect personal safetyAuxillariesVessel ventillation/heating/coolingEngineering

The invention provides a ventilator device for a pirate prevention security cabin of a ship, which comprises an air duct, a hood and a connecting rod. The hood is of a hollow structure and is arranged at the upper part of the air duct; a weather proof cover is arranged in the hood and the weather proof cover covers the upper end port of the air duct; the connecting rod is arranged in the air duct; one end of the connecting rod extends out of the hood after being screwed with the weather proof cover, and is provided with an outer handwheel; and the other end of the connecting rod passes through the bottom or the lateral part of the air duct and is provided with an inner handwheel, wherein the lower end part of the connecting rod is also provided with a locking device and the bottom of the hood is provided with an air inlet and a protection grid. According to the invention, a ventilator can be opened or closed inside and outside the cabin; and under the condition of pirate attack, the air duct can be locked in the security cabin so as to fulfill the aim of protecting boatmen and properties.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

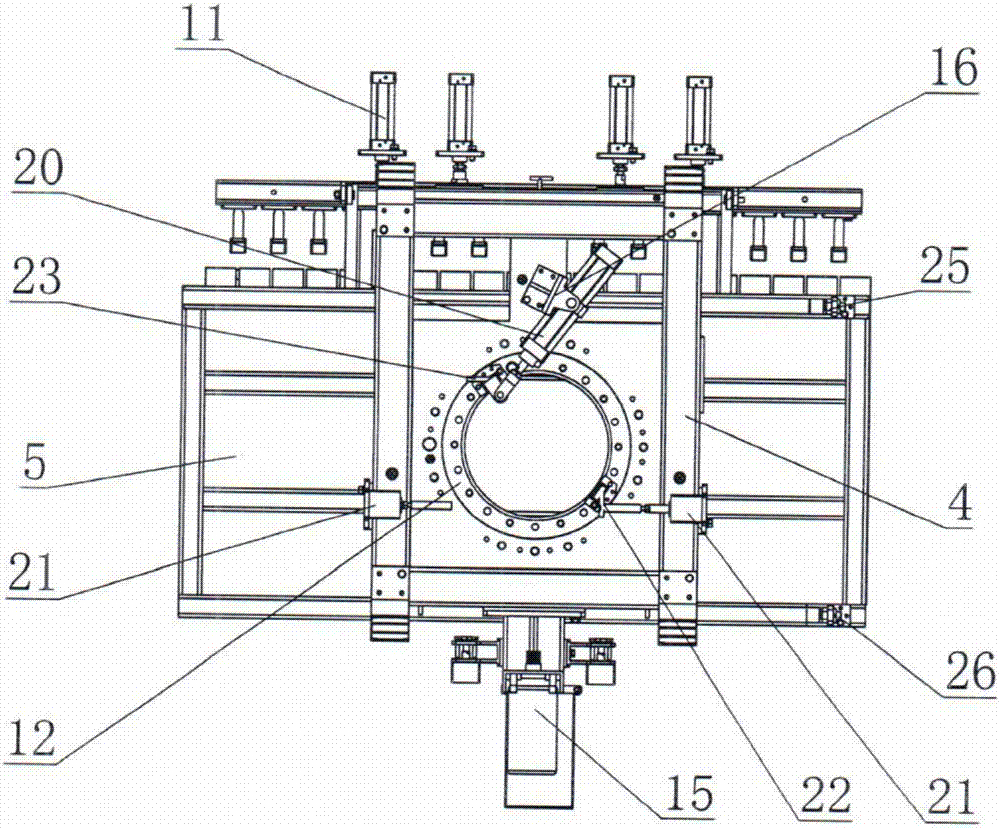

Multifunctional automatic stone cutting machine

ActiveCN107186892AImprove cutting accuracyGood qualityWorking accessoriesStone-like material working toolsAutomatic controlProduct processing

The invention discloses a multifunctional automatic stone cutting machine which comprises a rack, two groups of spindle systems, a working table part and an automatic control system. The two groups of spindle systems are arranged in parallel at the upper part of the rack front and back; and the working table part is arranged below the two groups of spindle systems and comprises a working table as well as a working table longitudinal moving mechanism, a working table transverse moving mechanism and a working table rotary mechanism sequentially arranged from bottom to top. The multifunctional automatic stone cutting machine can automatically cut a large-specification entire stone into a plurality of square and oblong small-specification formed stone, can realize one-time longitudinal cutting and twice transverse cutting, realizes automatic control in the entire cutting process, is high in moving speed, steady in moving, accurate in positioning and firm in locking, greatly improves the working efficiency, greatly reduces the product processing cost, and is high in cutting precision and quality, low in labor intensity, and convenient and safe to use.

Owner:LAIZHOU FULIN MACHINERY

Automatic packaging machine for bulk materials

The invention belongs to the technical field of packaging equipment and particularly discloses an automatic packaging machine for bulk materials. The automatic packaging machine comprises a base and is characterized in that a multi-position discharge structure, a mechanical arm structure, a conveying system, an automatic label conveying machine, a sack sewing machine and a control system are sequentially arranged on the base. The automatic packaging machine is simple in structure, good in packaging effect and low in cost.

Owner:河南济开电器有限公司

Disc type motor rotor with pole shoe composite magnetic pole structure

PendingCN111355323AGood magnetic conductivityEasy to processMagnetic circuit rotating partsMagnetic polesElectric machinery

The invention discloses a disc type motor rotor with a pole shoe composite magnetic pole structure, and relates to the field of motors. The disc type motor rotor comprises a rotor supporting disc, a hole is formed in the center of the rotor supporting disc, and a groove is formed in the surface of one side of the rotor supporting disc and used for installing a rotor core and composite magnetic poles; the rotor iron core is of an annular structure, is arranged at the bottom of the groove and is tightly attached to the rotor supporting disc, T-shaped baffles distributed in the radial direction are arranged on a surface of a side, away from the rotor supporting disc, of the rotor iron core, and the T-shaped baffles divide the rotor iron core into a plurality of fan-shaped spaces at equal intervals along the circumference; the composite magnetic poles are arranged in the fan-shaped spaces on the rotor iron core; the composite magnetic poles comprise permanent magnets and pole shoes, and the pole shoes made of composite soft magnetic materials are installed on the surface of the permanent magnet. The radians of the pole shoes on the surface of the permanent magnet can be adjusted, sinewave air gap flux density is generated, the output torque of a motor is smooth, the pole shoes can protect the permanent magnets against field loss under the action of a demagnetization field, the field weakening capacity of the motor is improved, and the motor is easy to machine and suitable for batch production.

Owner:仪坤动力科技(上海)有限公司

Cleaning device for nursing

The invention relates to a cleaning device for nursing. The device comprises a shell base, a driving rolling wheel, a continuous rotation shaft, an intermittent rotation shaft, a pair of single-direction rollers, bristles, baffles and a handheld handle; the shell base comprises a middle core body, a garbage chamber and a side insertion hole; the driving rolling wheel comprises a rolling wheel rotation shaft, a rolling wheel body, annular insertion grooves and jacking compression springs; the continuous rotation shaft comprises a left shaft body, a left conical wheel, a notch disc, a crank shifting fork, a driving threaded rod and a friction ring; the intermittent rotation shaft comprises a right shaft body, a right conical wheel and a groove wheel; the pair of single-direction rollers comprises cylinder walls and ratchet rotation shafts; the bristles are densely arranged on the outer wall of the cylinder wall of the single-direction roller at the left side; the baffles are evenly distributed on the outer wall of the cylinder wall of the single-direction roller at the right side in the circumference direction; the handheld handle is hinged to the upper end face of the shell base.

Owner:QINGDAO CITY CHENGYANG DISTRICT PEOPLES HOSPITAL

Vehicle glass edge grinding device

InactiveCN108296921ARealize recyclingReduce labor intensityEdge grinding machinesGrinding work supportsEngineeringUltimate tensile strength

The invention relates to the technical field of vehicle glass production equipment, and in particular, discloses a vehicle glass edge grinding device. The vehicle glass edge grinding device comprisesa positioning plate; polishing boxes connected below the positioning plate, and are positioned around square glass; a sucker is arranged on the lower surface of the positioning plate; openings are formed in the sides, near the square glass, of the polishing boxes; first accommodating cavities, second accommodating cavities and third accommodating cavities are arranged in the polishing boxes; flexible polishing pieces are arranged in the openings of the first accommodating cavities and the third accommodating cavities; the polishing pieces are connected with the inner walls of the polishing boxes through pressure springs; a turntable is arranged below the positioning plate, is connected with a driving device, and is provided with a collecting tank; the lower end surfaces of all the polishing boxes are connected with connecting rods; the connecting rods are connected to the upper end surface of the turntable, and are provided with guide grooves; and collecting plates are aslant arrangedon the connecting rods. The vehicle glass edge grinding device has no need to stop to take down glass and to mount again, so that the polishing efficiency is improved, operation steps are reduced, andthe labor intensity of operators is relieved.

Owner:宁波高新区新柯保汽车科技有限公司

Dry-type compound machine

ActiveCN104325772AEasy to adjustAchieve outputLiquid surface applicatorsLamination ancillary operationsHigh concentrationDiluent

The invention discloses a dry-type compound machine. The dry-type compound machine comprises a drying tunnel, a coating device, a compound device, a first unreeling mechanism corresponding to the coating device, and a second unreeling mechanism and a reeling device both corresponding to the compound device, wherein the coating device and the compound device are arranged under the two ends of the drying tunnel, respectively; the coating device is a five-roller coating device which comprises roller frames located on the two sides, and a five-roller coating mechanism, a guide roller I for guiding a first base material unreeled by the first unreeling mechanism to the five-roller coating mechanism and a guide roller II for guiding the first base material coated with glue by use of the five-roller coating mechanism to the drying tunnel are arranged between the two roller frames. The coating glue of the five-roller coating device can be high-concentration glue, and therefore, the problem of environmental pollution caused by glue leakage due to excessive diluent can be avoided; in addition, the coating amount of the coating glue on the first base material can be adjusted conveniently by adjusting the rotating speed of the five-roller coating mechanism, and the adjustment of the coating amount is simpler and more accurate.

Owner:CHONGQING SINSTAR PACKAGING MACHINERY

Feeding conveying device of ring bobbin and control method thereof

ActiveCN109230373AReduce labor intensityImprove the efficiency of residual yarn cleaningConveyorsConveyor partsYarnEngineering

The invention discloses a feeding conveying device of ring bobbin. The device comprises a bracket and a conveying belt arranged on the bracket, a plurality of storage cases are uniformly arranged on the periphery surface of the conveying belt, and the ring bobbin is arranged in one of the storage cases and is of a circular truncated cone structure; a hopper is arranged on the portion, located above the conveying belt, of the bracket, a first air cylinder is arranged on one side of the conveying belt, and the output end of the first air cylinder is aligned with the ring bobbin; a second air cylinder is arranged on the other side of the conveying belt, a revolving turntable is arranged between the second air cylinder and the conveying belt, and a groove is formed in the top of the revolvingturntable in the diameter direction of the revolving turntable; two opening ends of the groove are respectively aligned with the output end of the second air cylinder and the ring bobbin, and a revolving air cylinder is arranged at the bottom of the revolving turntable; a metal ring sleeves the large diameter end of the ring bobbin, and metal sensors are arranged on the portions, located on the two sides of each storage case, of the bracket. The design of the device not only reduces the labor intensity of residual yarn cleaning but also improves the efficiency of cleaning residual yarns away.

Owner:HUBEI TIANMEN TEXTILE MACHINERY

Test engine and test method for combustion of double-base system propellant in different overload directions

ActiveCN110596301AImprove safety and reliabilityChange overload directionChemical analysis using combustionRocket engine plantsInternal ballisticsThroat

The invention discloses a test engine and a test method for combustion of a double-base system propellant in different overload directions, which successfully eliminate the influence of the overload directions on combustion of the propellant. The test engine comprises a combustion chamber shell body, wherein the combustion chamber shell body is provided with a blasting device, and a large-small dual-circular-step-shaped blasting sealing plug is installed on the blasting device and screwed up by means of a blasting cover; a spray pipe is arranged in the middle of the combustion chamber shell body, and high-strength graphite is installed in a spray pipe base and screwed up by means of a gland so as to prevent the graphite from being sprayed out of a graphite spray throat in a test; and the combustion chamber shell body takes the center of the spray pipe as a symmetry axis, an end surface combustion propellant charge and a fake grain are placed on the two sides, and the purpose of changing the overload directions is achieved through exchanging the positions of the propellant charge and the fake grain. In order to prevent the spray pipe from being blocked and the ignition powder from being thrown out due to combustion of the charge under overload, the celluloid box without residues after combustion is used for fixing the ignition powder, thereby guaranteeing safety and reliabilityof the engine test under overload. The test engine and the test method is suitable for measuring and evaluating propellant charge combustion properties and internal ballistic trajectory performance indifferent overload directions.

Owner:XIAN MODERN CHEM RES INST

Rapid cup washing device

The invention discloses a rapid cup washing device comprising a base and a rotating shaft. A machine box is fixedly connected with the upper end face of the left side of the base. A control panel is arranged on the outer surface of the bottom of the left side of the machine box. A motor is installed in the middle of the machine box. A controller is installed on the lower side of the motor. A rotating shaft is connected with the upper right side of the machine box in a penetrating manner. The top of the rotating shaft is connected with a rotating shaft of the motor through a belt. A splash-proof outer cover is fixedly connected with the middle portion of the rotating shaft and is in an umbrella-shaped structure. A brush head is fixedly connected with the lower portion of the rotating shaft. The brush head comprises a spring. One end of the spring is fixedly connected with the rotating shaft. A rubber shell is wrapped around the outer side of the spring. The other end of the spring is fixedly connected with the brush handle. The outer side of the brush handle is fixedly connected with brush bristles. To sum up, the rapid cup washing device is simple in structure, easy to use, capable of cleaning up cups thoroughly and suitable for application and popularization.

Owner:CHONGQING QIANSHUN SCI & TECH CO LTD

Deslagging type tea leaf grading screening device

The invention relates to a screening device, in particular to a deslagging type tea leaf grading screening device. The deslagging type tea leaf grading screening device comprises a support, a guide plate, support rods, a support, a grading mechanism, a screening tank, a screening mechanism and first elastic parts, wherein the supporting rods and the like are sequentially arranged at the top of thesupport from left to right; the screening mechanism is arranged at the tops of the support rods; the top of the support is rotationally connected with the screening tank; the first elastic parts areconnected between the left wall of the screening tank and the right wall of the guide plate; slag outlets are formed in the left side and the right side of the front side of the bottom of the screening tank in a symmetry mode; and the grading mechanism is arranged inside the screening tank. The deslagging type tea leaf grading screening device realizes the effects that impurities are removed in time, and safety and environmental protection are achieved.

Owner:江西云台山有机茶实业有限公司

Riveting press with automatic feeding function

The invention relates to an riveting press with an automatic feeding function. The riveting press comprises a machine body, a vibrating disc, a feeding rail controller, a feeding rail, a lower die, anupper die capable of moving up and down along the machine body and an auxiliary clamping mechanism used for clamping the upper die; the auxiliary clamping mechanism, the vibrating disc and the feeding rail controller are installed at the machine body, the upper die is in sliding connection with the machine body, and the lower die is fixedly installed on a workbench of the machine body and is located right below the upper die; the discharging port of the vibrating disc communicates with the feeding end of the feeding rail, a driving mechanism connected with the feeding rail is arranged in thefeeding rail controller, and the feeding rail controller is electrically connected with the driving mechanism; and the driving mechanism drives the feeding rail to be close to or far away from the machine body, the auxiliary clamping mechanism is in contact with the discharging end of the feeding rail, and a duckbilled head for limiting the moving direction of a part is arranged at the dischargingend of the feeding rail. According to the riveting press, the feeding speed is high, the fault rate is low, the practicability is high, the fault removal is simple, and the maintenance is easy.

Owner:史广材

Floating waste removing device for channel improvement

ActiveCN111827232AEasy to collectFacilitate the declineWater cleaningMagnetic separationGear wheelElectric machinery

The invention discloses a floating waste removing device for channel improvement, and relates to the technical field of channel improvement. In order to solve the problem that floating objects hookedby water plants cannot be removed, the floating waste removing device specifically comprises a boat body, the inner wall of the boat body is provided with two flow guide plates, the two flow guide plates are distributed in a scissors fork manner, the outer wall of one side of one flow guide plate is provided with an electric telescopic column, and the extension end of the electric telescopic column is connected with the outer wall of one side the other flow guide plate through a bolt. According to the floating waste removing device, the two flow guide plates are separated and closed through rotating shafts; in the separated state, second motors are started to drive cutting knives to rotate at a high speed through second gears so as to cut off water plants and the like under floating objects, so that the floating objects are separated from the growing water plants; and in the running process of the boat body, the floating objects are surrounded by the two open flow guide plates to moveonto fishing filter plates. A certain removing effect on the water plants and the like is also achieved when the floating wastes are fished, and the floating objects can be conveniently collected.

Owner:金银河

Method for vegetable filling

ActiveCN106723236APrevent throwingSufficient powerFood coatingFood treatmentMechanical engineeringEngineering

The invention relates to a method for vegetable filling. A conveyer conveyed in an intermittent manner is prepared; a plurality of clamping devices in a scissor structure are prepared; a conveyer belt passes through through holes of two clamping parts, so that the clamping parts can achieve 360-degree rotation around the axis of the conveyer belt; two baffle plates are arranged at the output end of the conveyer and are located at two sides of the conveyer belt; a spiral guide plate is arranged at one end, close to an input end, of each baffle plate; the spiral guide plates are arranged around the conveyer belt as the center; a cutting mechanism is arranged at the lower part of the input end of the conveyer belt; the cutting mechanism comprises a turnplate; an arc-shaped cutting knife is arranged on the turnplate and a locating part is arranged at the center of the turnplate; and a sensor for detecting vegetables is arranged on the cutting mechanism. Through implementation of the method, the problem of low efficiency in an existing vegetable filling technology is solved.

Owner:重庆刘二嘎农业科技有限公司

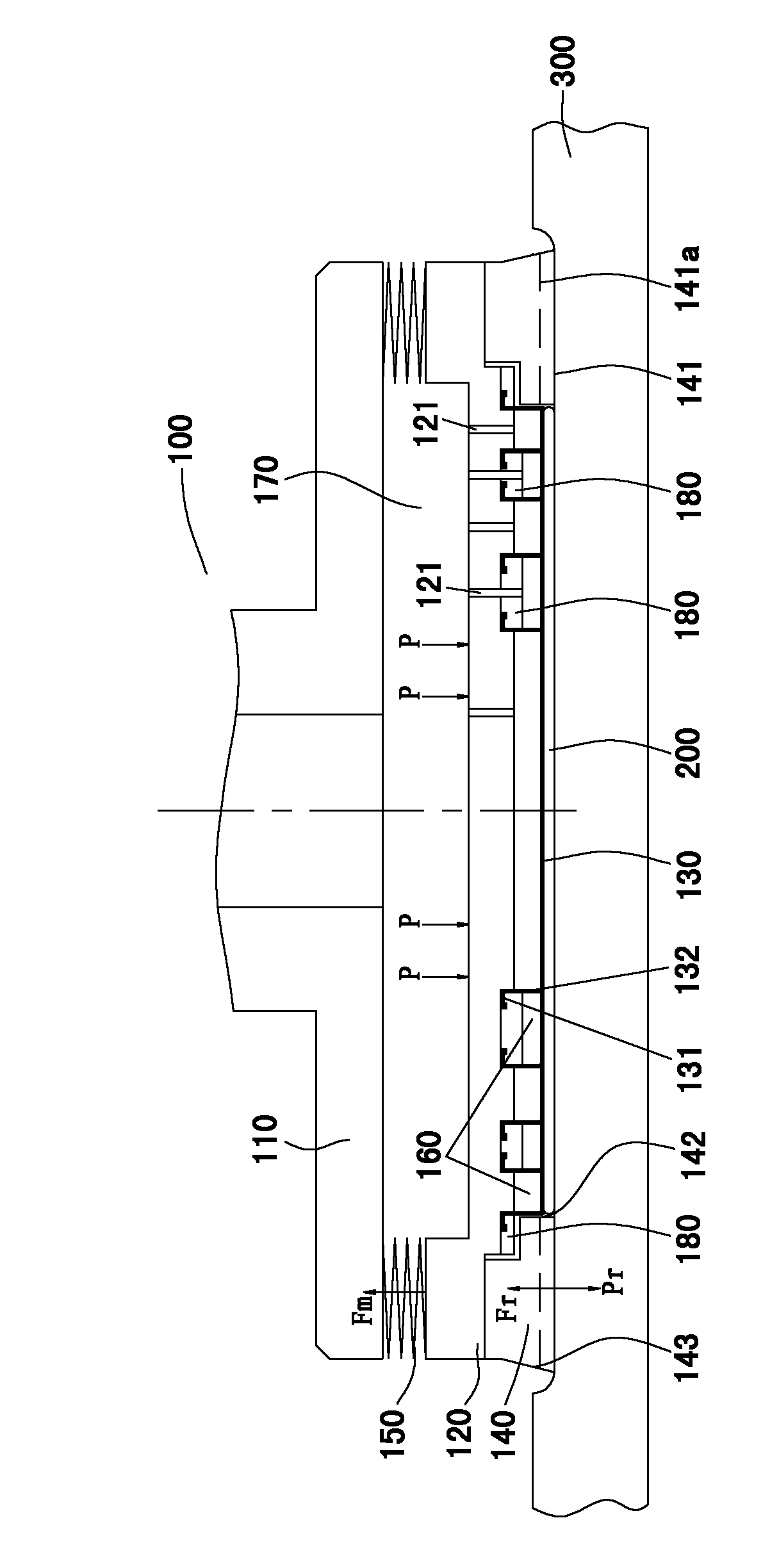

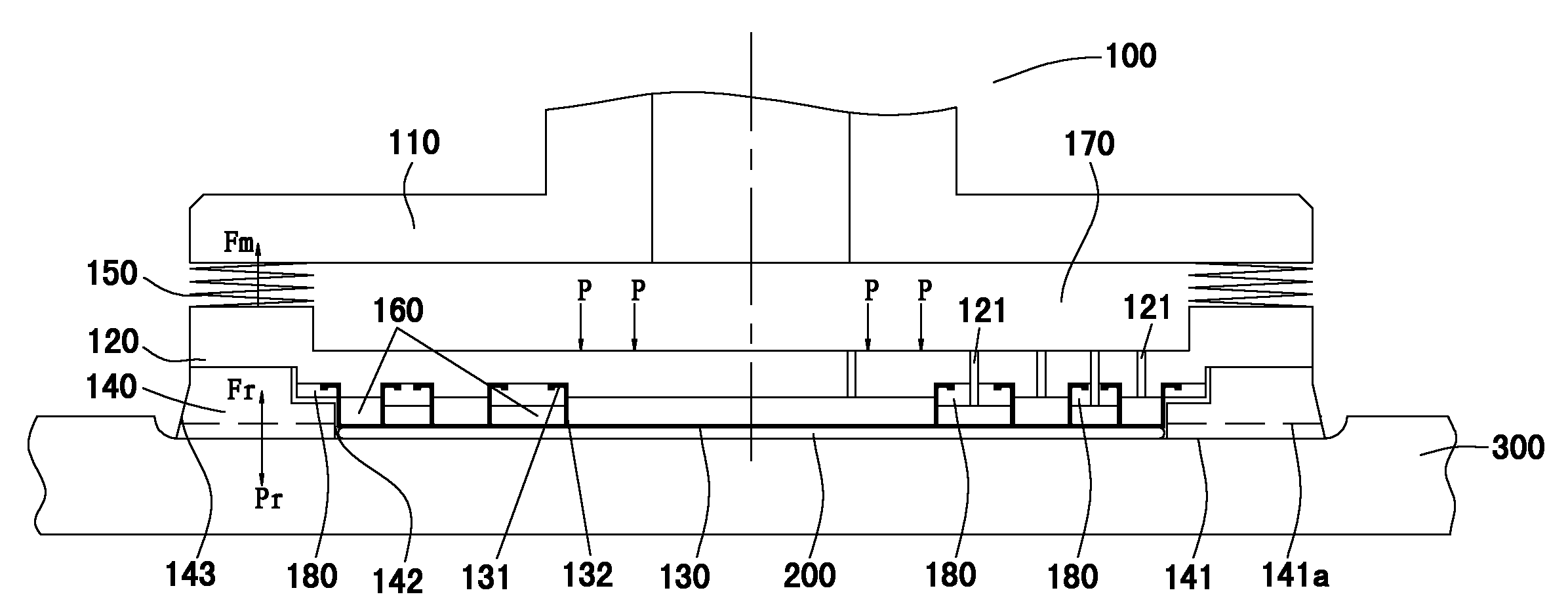

Polishing head

The invention discloses a polishing head comprising a cover plate, a main diaphragm, a substrate, a flexible membrane and a retaining ring, wherein the main diaphragm is annular, has elasticity and is fixed on the lower surface of the cover plate; the substrate is fixed on the lower surface of the main diaphragm; the flexible membrane is fixed on the lower surface of the substrate, and the flexible membrane and the substrate limit a lower cavity communicated with the outside; the retaining ring is fixed on the lower surface of the substrate; and the area of the radial cross section of the retaining ring is gradually decreased from bottom to top. According to the polishing head of the embodiment disclosed by the invention, a wafer can be prevented from throwing in the chemical mechanical polishing process, and even and consistent effect can be obtained. In addition, the abrasion of the retaining ring can not lower polishing effect, and thus the retaining ring has longer service life soas to lower polishing cost.

Owner:HWATSING TECH

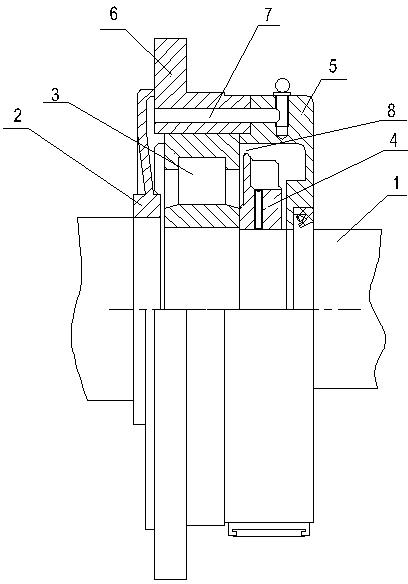

Lubricating device of motor bearing

InactiveCN102647040AThe overall thickness is thinEasy to processSupports/enclosures/casingsEngineeringMechanical engineering

The invention relates to a motor matching device. In order to solve the technical problems that oil throwers of lubricating devices of existing motor bearings cannot prevent lubricating grease from being thrown off and waste oil grease can not discharged, lubricating devices of conventional motor bearings are improved and the innovations are that the oil thrower is a round tray with an inner hole, the thickness of the oil thrower is tapered in a radial direction outwards from a contacting contour circle of an inner sleeve of a bearing to the oil thrower, the oil thrower and a non contacting face of the bearing are in a same plane, the oil thrower and the bearing are assembled in a combining mode, a V-shaped hollow cavity is formed between the oil thrower and the bearing, the height of the oil thrower is lower than the diameter of the inner sleeve of the bearing, an annular boss is assembled on the inner wall of an outer cover of the bearing, a spigot is arranged on the inner wall of the outer cover of the bearing, and a narrow gap serving as an oil overflowing channel is formed between the outer edges of the boss and the oil thrower. The lubricating device is easy to process, convenient to install, and guarantees not only residual amount of the lubricating grease in a bearing chamber but also cleanness of the lubricating grease and discharge of the waste oil grease.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com