Annular thin-wall article clamping device and using method thereof

A technology of clamping device and thin-walled parts, which is applied in the direction of positioning device, clamping, tool holder accessories, etc., can solve the problems that affect the production efficiency of enterprises, spend a lot of time on alignment, and affect the positioning accuracy of workpieces, so as to ensure accurate Sexuality, time-saving, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

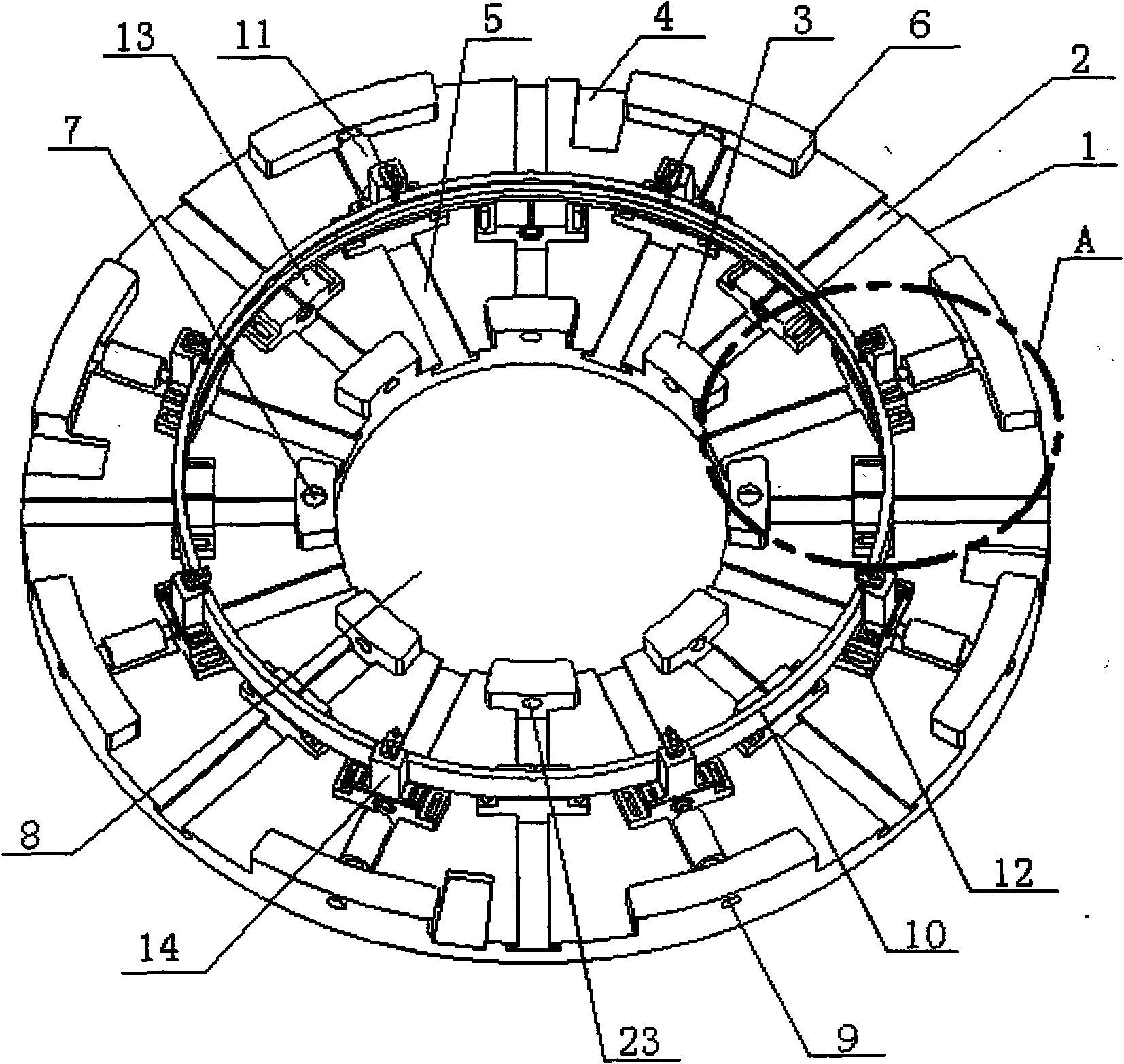

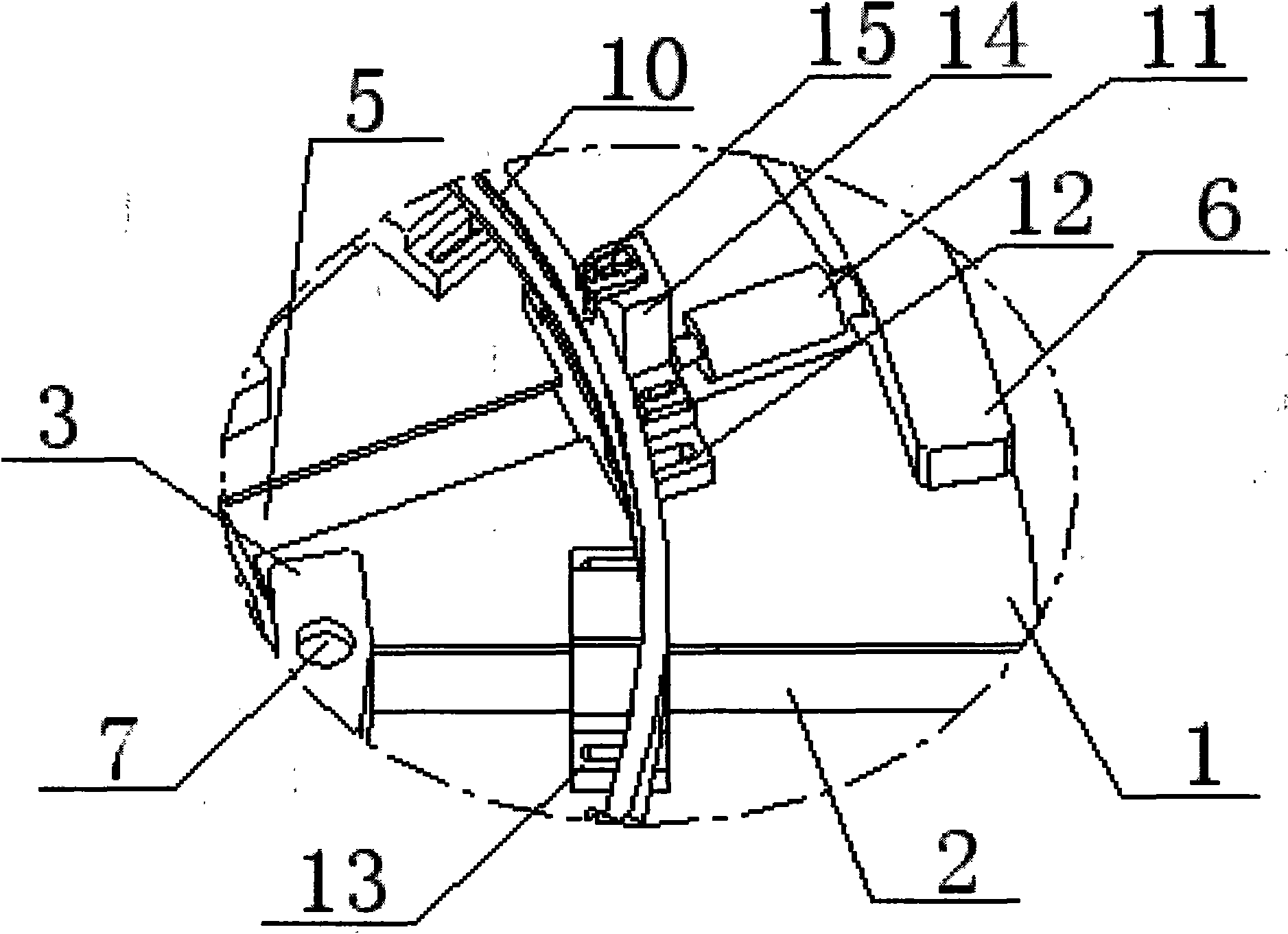

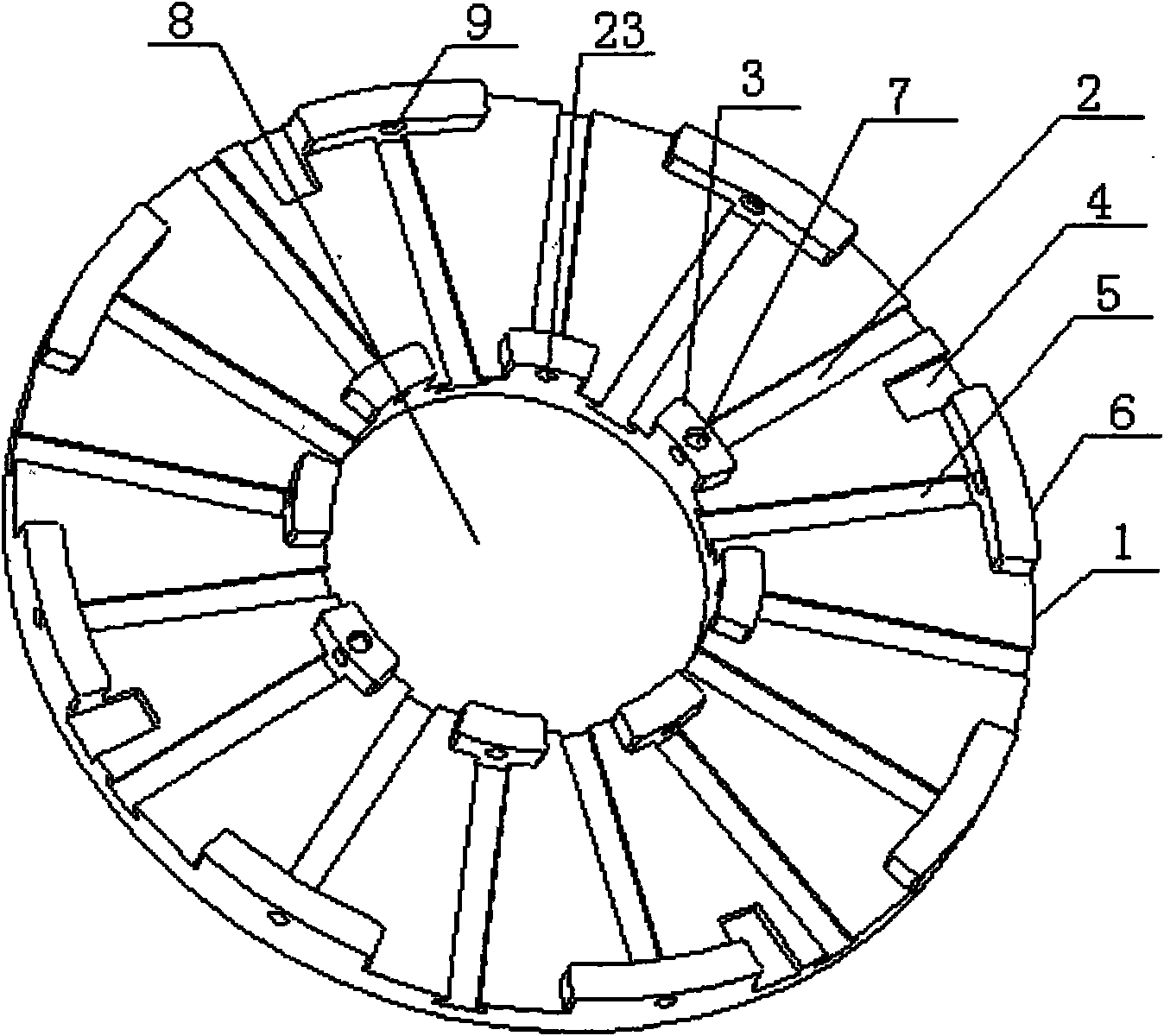

[0049] see Figure 1 to Figure 4 , the present invention includes an annular chassis 1, the diameter of the chassis 1 is at least 2800mm, such as 3600mm, 4200mm, 5500mm or 62000mm, etc., and the inner circle 8 of the chassis 1 has a maximum diameter of 1000mm, such as 900mm, 750mm, 600mm or 500mm, etc. . Its clamping coverage is large, and it can be suitable for clamping workpieces of various sizes and specifications. Four pressing grooves 4 are arranged on the outer circumference of the chassis 1 .

[0050] A radial adjustment mechanism for positioning the workpiece 10 is provided on the annular chassis 1. The radial adjustment mechanism is composed of a push rod and a slider. The radial adjustment mechanism is divided into two groups: the inner radial adjustment mechanism and the outer radial adjustment mechanism, namely the inner radial adjustment mechanism The slider 13 and the ejector rod form an inner radial adjustment mechanism, and the outer slider 12 and the ejector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com