Crusher for drying debris

A crusher and fragment technology, which is applied in the fields of recycling technology, mechanical material recycling, plastic recycling, etc., can solve the problems of unfine crushed finished products, long time-consuming, barrel deposition, etc., so as to avoid debris from sinking to the bottom and increase the number of cuts The effect of chance, structure compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

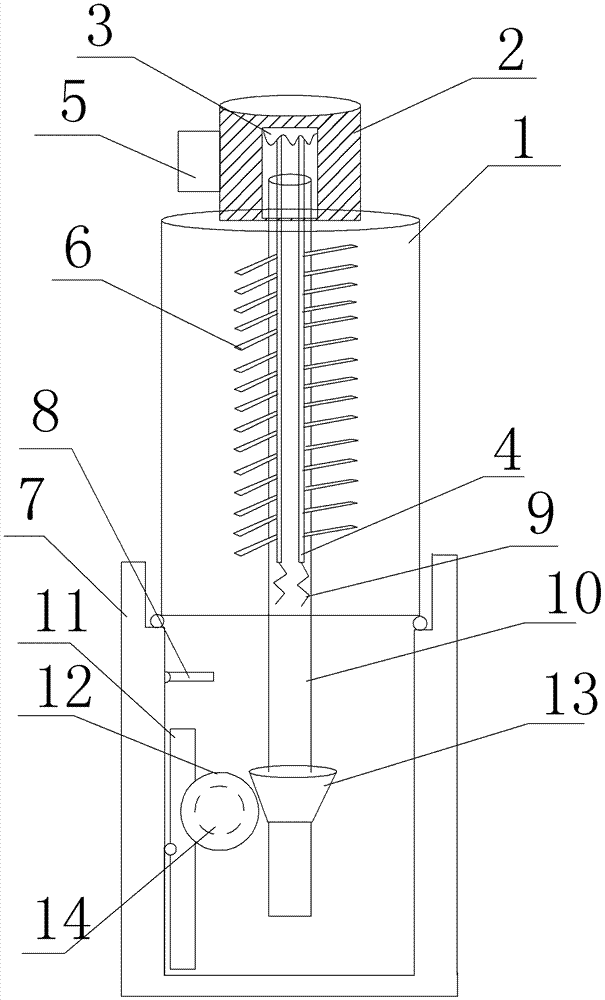

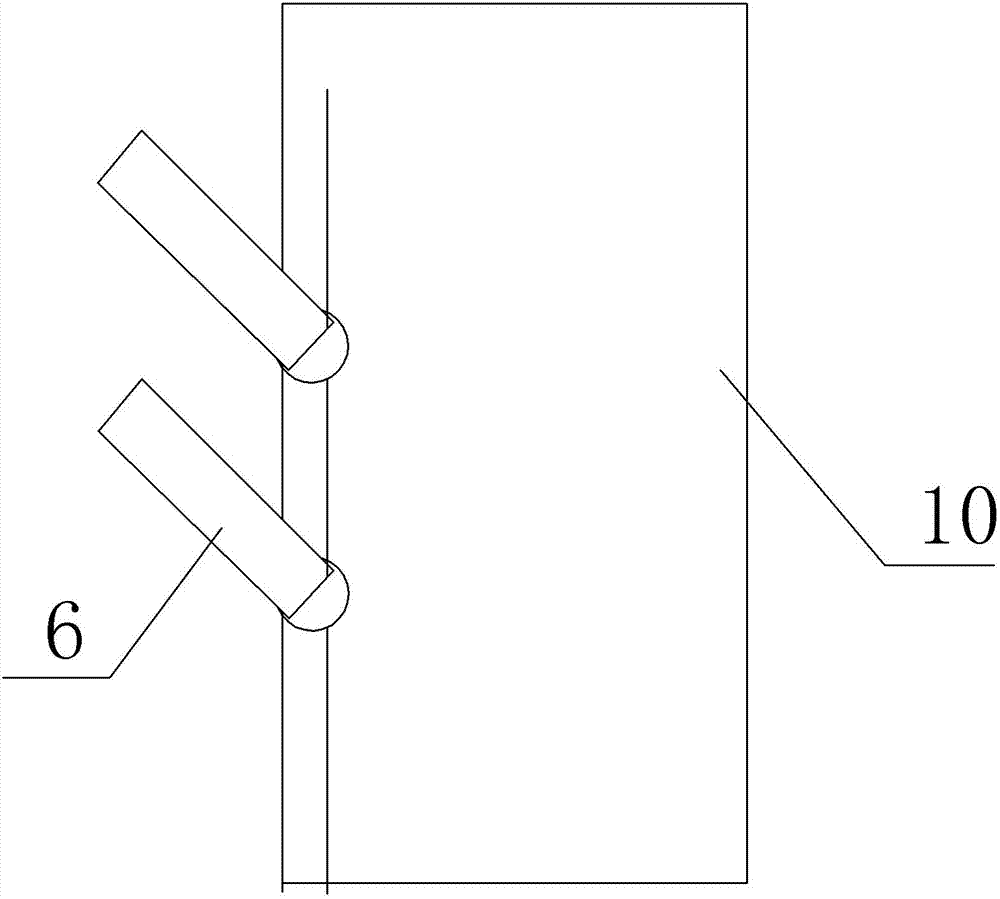

[0016] Embodiment: The working principle and the composition of the machine of the present invention will be further described below. The present invention is mainly composed of a barrel 1 and a base. The barrel 1 is cylindrical (1m in height and 0.6m in radius) and is made of hard and light material. The height of the base is 1-1.7m, and its cross-sectional area is larger than the cross-sectional area of the barrel 1. There is a circular groove on the upper end of the base, and a sliding mechanism is laid around the circular groove. The barrel 1 is embedded in the circular groove and forms a rotation with the base. connect. The top of the barrel 1 is located at the center of the circle at 0.9m, and a center feed inlet with a radius of 0.05m is provided. At the center of the barrel 1, there is a cylindrical bump 2 with a height of 0.15m and a radius of 0.1m. 2. A motor 5 that provides power for the rotating shaft 10 is provided on the side. A cylindrical inner cavity with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com