Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Increase the amount of liquid phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

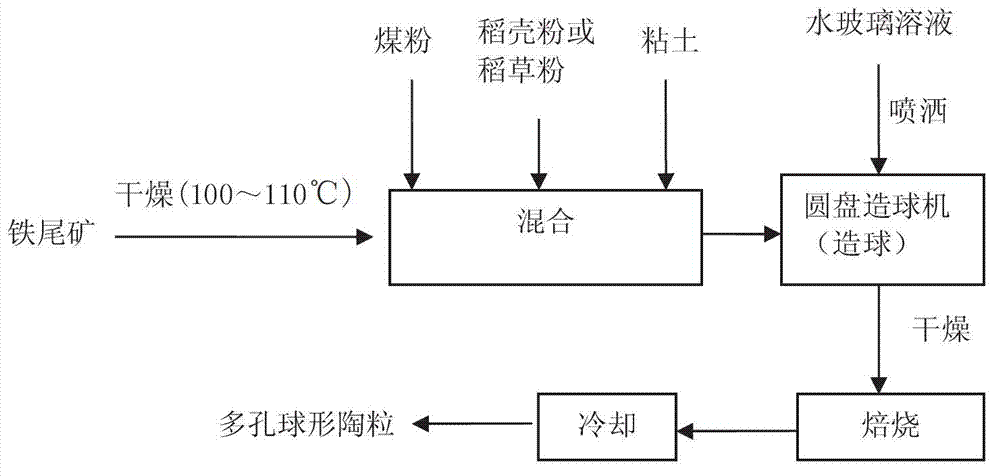

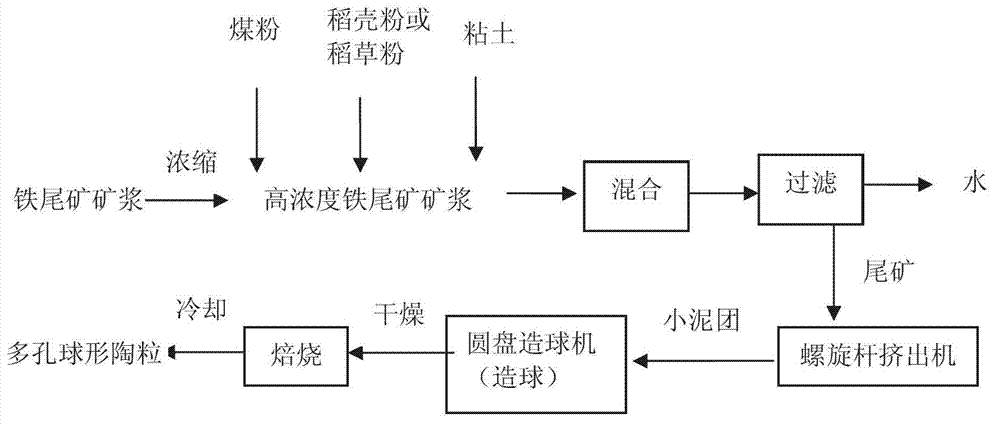

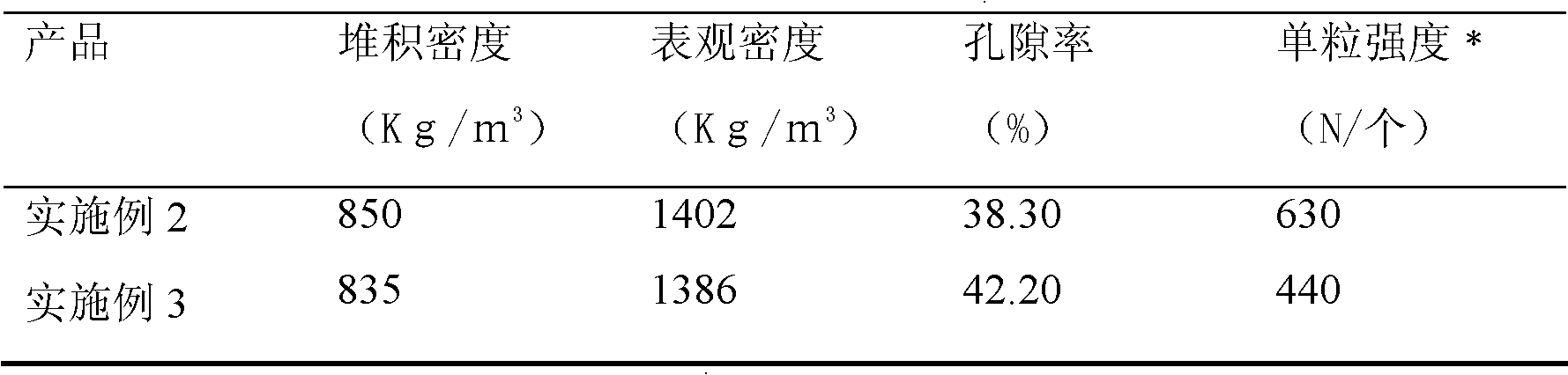

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

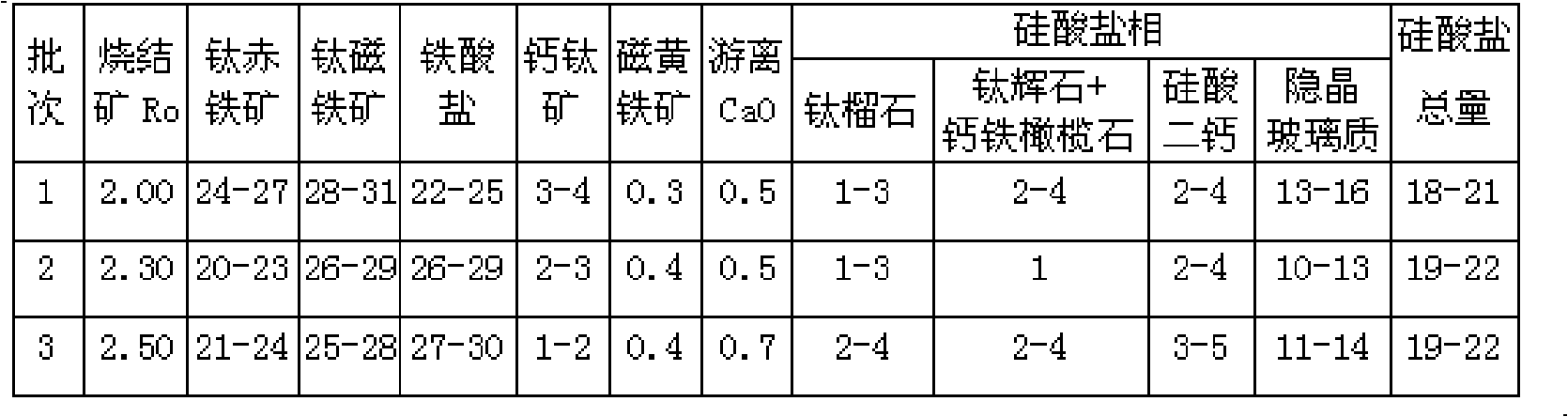

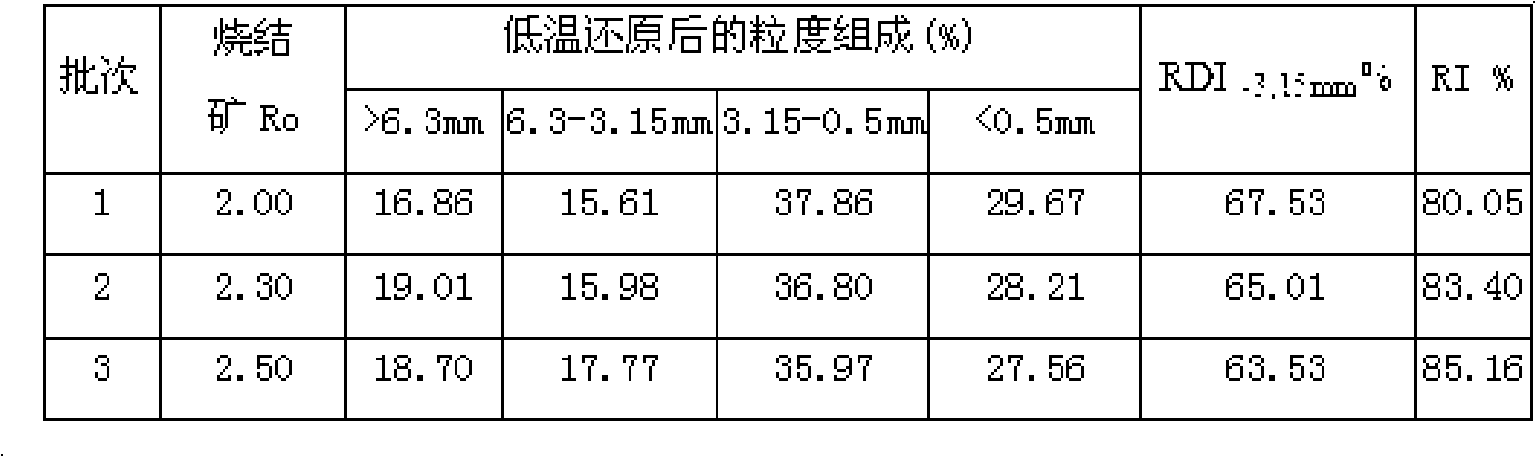

High titan type high alkalinity sinter and method for preparing same

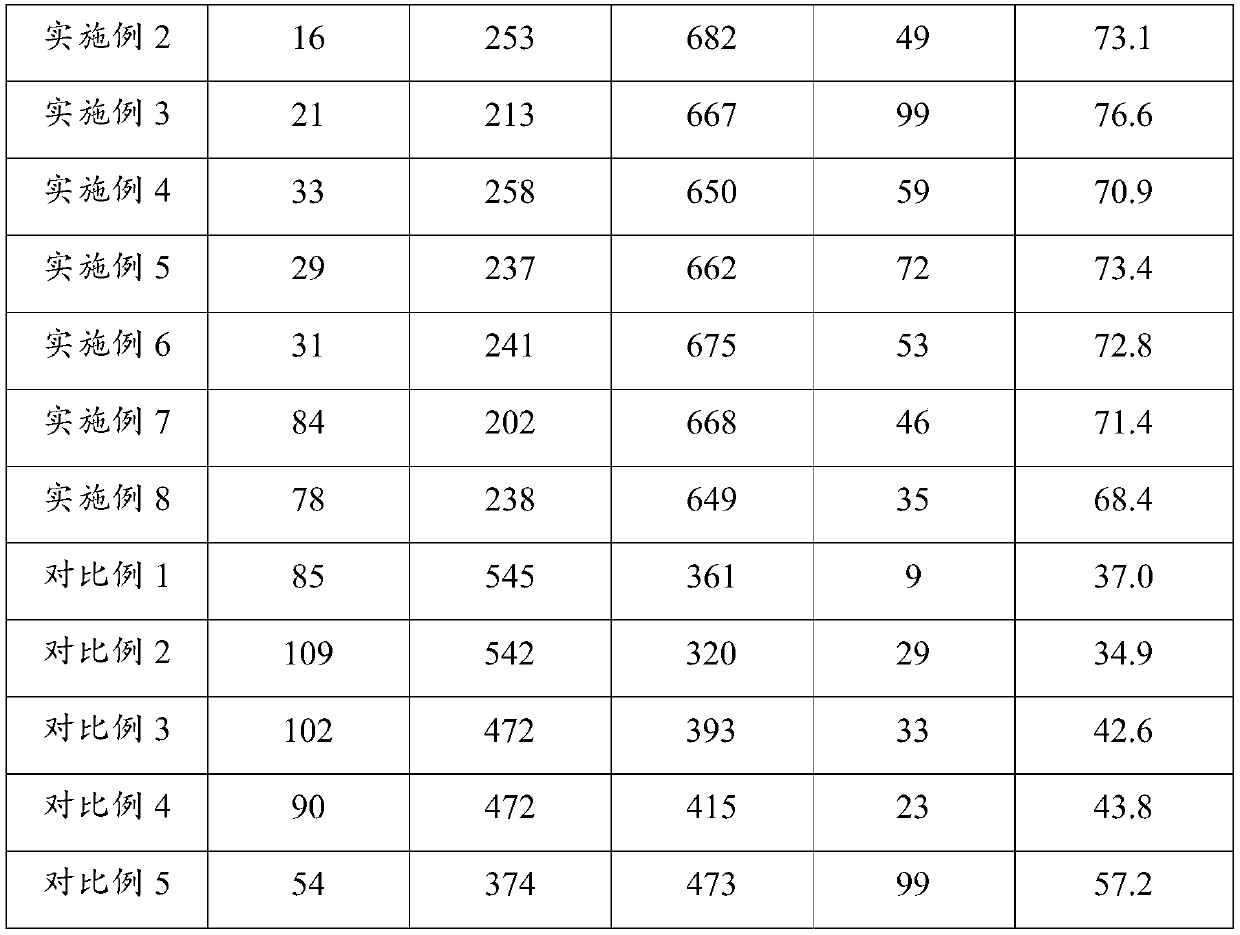

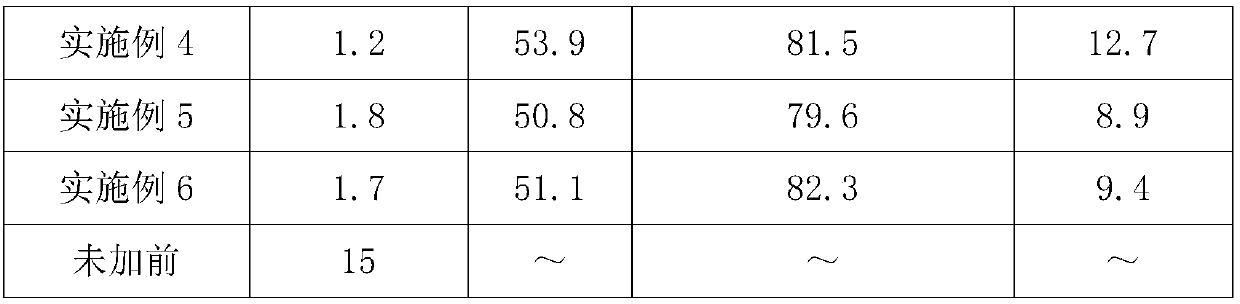

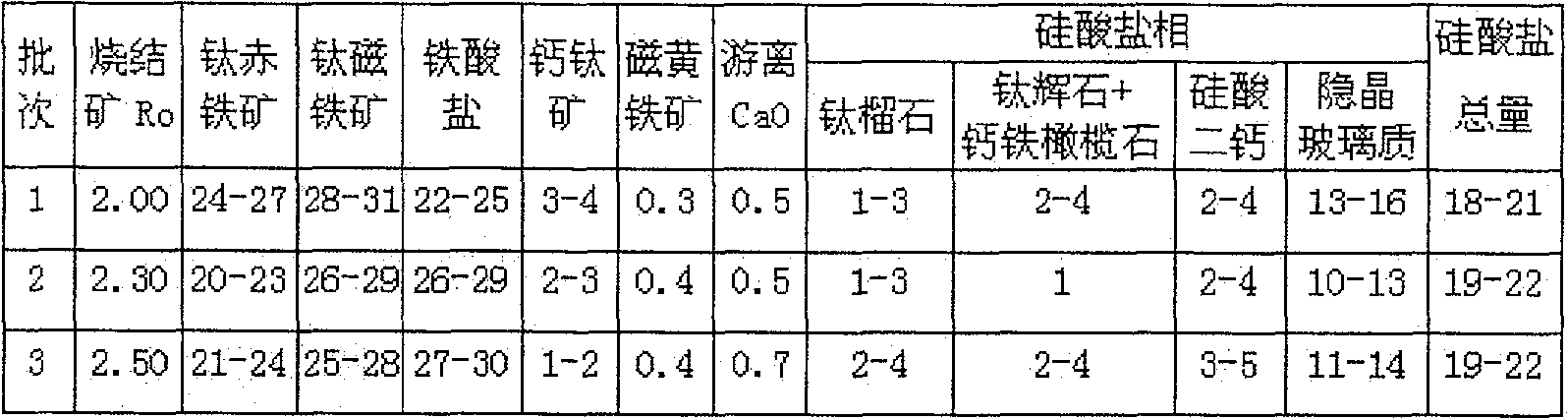

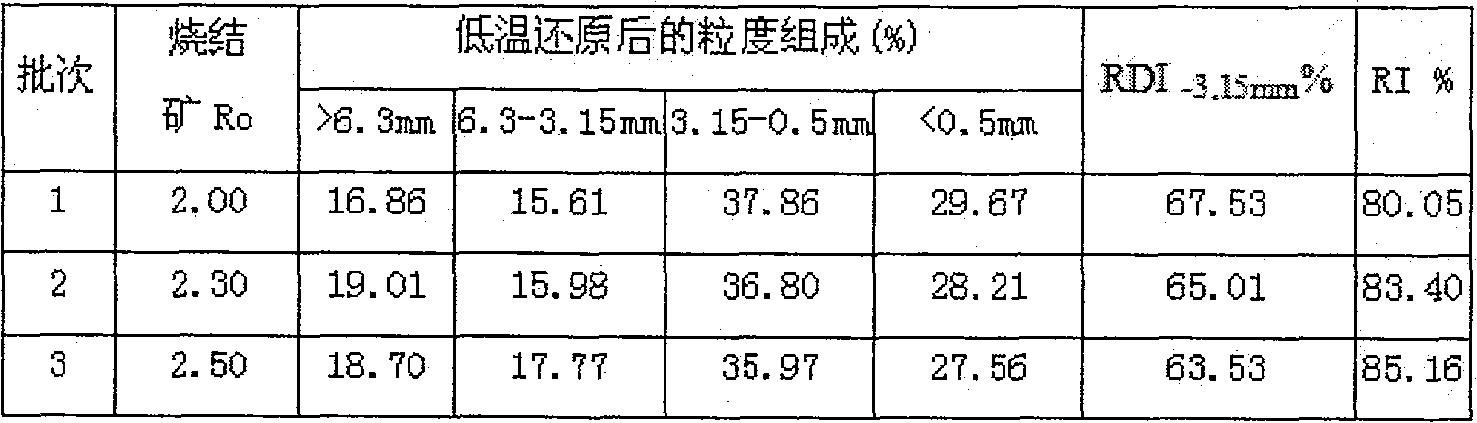

The invention belongs to the field of metallurgy and mainly relates to a manufacture method for preparing a high titanium high pH value sintering ore by a v-ti magnetite concentrate ore. The technical problem needed to be solved is to provide a preparation method which takes the high titanium v-ti magnetite concentrate ore specially owned by Panzhihua as the material to prepare the high titanium high pH value sintering ore. The method is mainly characterized by taking the high titanium v-ti magnetite concentrate ore as the material with a sintering temperature of 1300 to 1400 DEG C. The technique of the invention applied to prepare the sintering ore is simply controlled; the high pH value sintering ore obtained by sintering is smelted; the technical economic indexes like the operating factors of a blast furnace, a coke ratio, a coal ratio, etc, and the like, are all improved. The method of the invention essentially improves the minimal components of a v-ti sintering ore, improves the intensity of the sintering ore and improves the metallurgy performance by improving the pH value of the v-ti sintering ore to 2.0 to 3.2, controlling a proper carbon addition amount and increasing the amount of a liquid phase.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

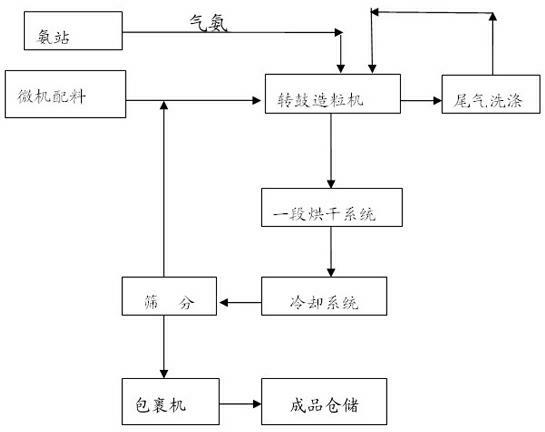

Production method of readily available and controlled release composite fertilizer containing three nitrogen elements

The invention discloses a production method of a readily available and controlled release composite fertilizer containing three nitrogen elements. The production method is as follows: raw materials containing nitric nitrogen, ammonium nitrogen and amido nitrogen are added in materials; in order to prevent that urea reacts with nitro phosphate fertilizer to generate too much urea nitrate and the production can not performed, ammonia gas is introduced in the granulation process according to different proportions to ammonify nitro phosphate fertilizer, reduce the generation of urea nitrate and increase the neutralization degree of monoammonium phosphate; and powdery fundamental fertilizers containing nitrogen, phosphorous and potassium are added to granulate, and then the composite fertilizer can be obtained through drying, cooling, screening and coating. In the production method of the invention, a lot of heat generated in the thermolysis of the nitro phosphate fertilizer and the neutralization heat of the reaction of ammonia gas and monoammonium phosphate are fully utilized to heat materials and increase the granulation temperature; and the viscosity of urea nitrate is utilized, the solubility of ammonium phosphate salt is increased, the quantity of the liquid phase for granulation can be satisfied, higher granulation rate can be realized without using other adhesive, the cost is reduced, the water content of the granulation material is significantly reduced, the drying energy consumption can be reduced and a large amount of energy consumption can be saved.

Owner:天津芦阳肥业股份有限公司

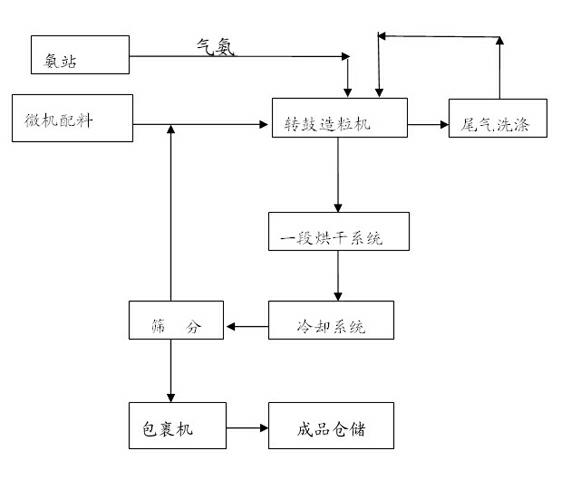

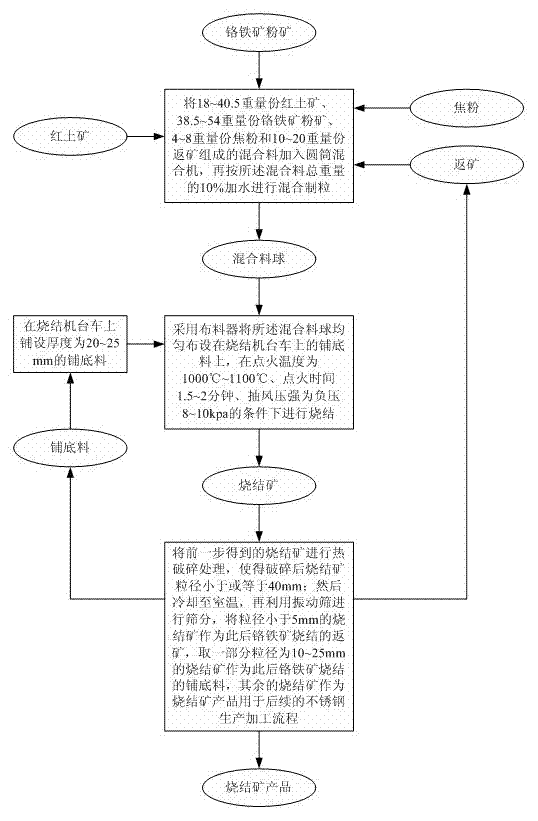

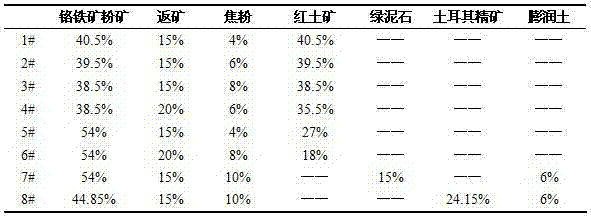

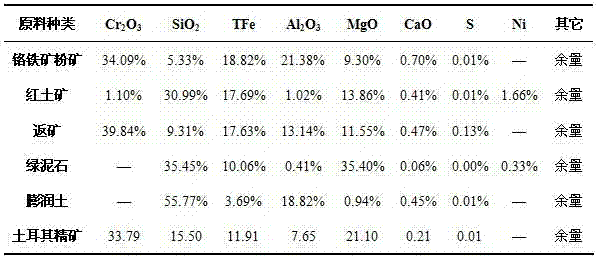

Chromium-iron mineral powder sintering method for stainless steel production

The invention provides a chromium-iron mineral powder sintering method for stainless steel production. According to the chromium-iron mineral powder sintering method, pelletization and sintering are carried out after laterite is added to chromium-iron mineral powder; as the laterite and water have good wetting property, the laterite serving as nucleation particles and the chromium-iron mineral powder adhere to each other and grow, and then are pelletized and clustered in a pelletization process, thus solving the problem that the chromium-iron mineral powder is difficult in pelletizaiton; simultaneously, the sintering temperature of chromite can be reduced due to the addition of the laterite, the amount of a liquid phase is increased, the energy consumption is reduced, the rate of finished product and the strength of a sinter are increased, and the problems of difficulty in sintering of the chromium-iron mineral powder, high content of mixed carbon and high energy consumption in the prior art are solved; as compositions of the laterite are similar to that of a smelting slag system, follow-up smelting and slagging working procedures for stainless steel production are not added, the price is relatively low, and the total cost of the stainless steel production can be effectively reduced; and the chromium-iron mineral powder sintering method has the advantages of increasing the economic benefits of enterprises and relieving the energy saving and emission reduction pressure of the enterprises.

Owner:CHONGQING UNIV

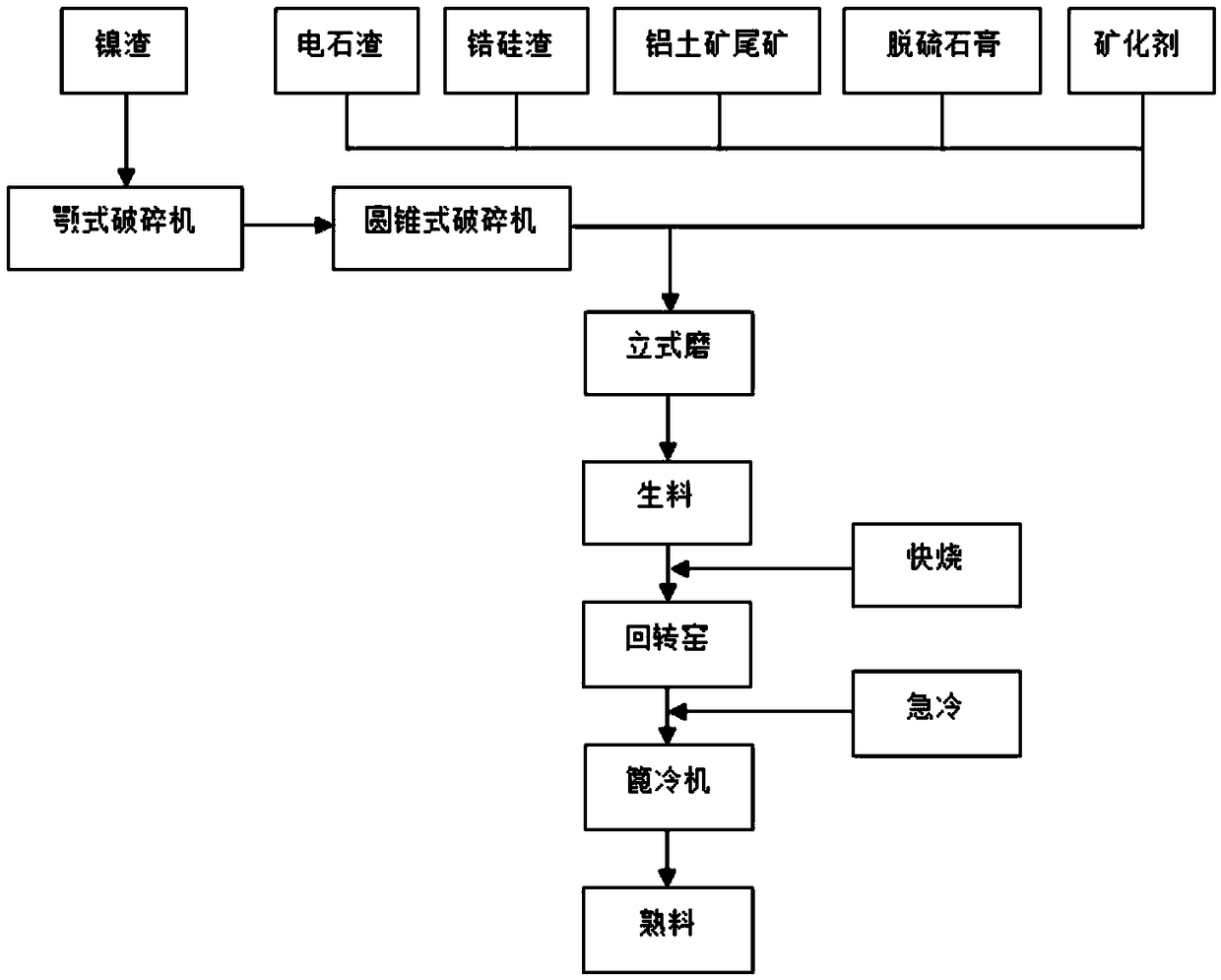

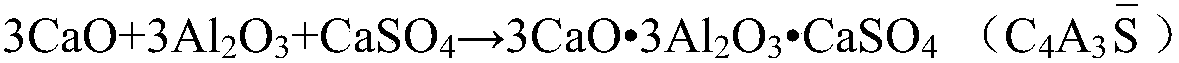

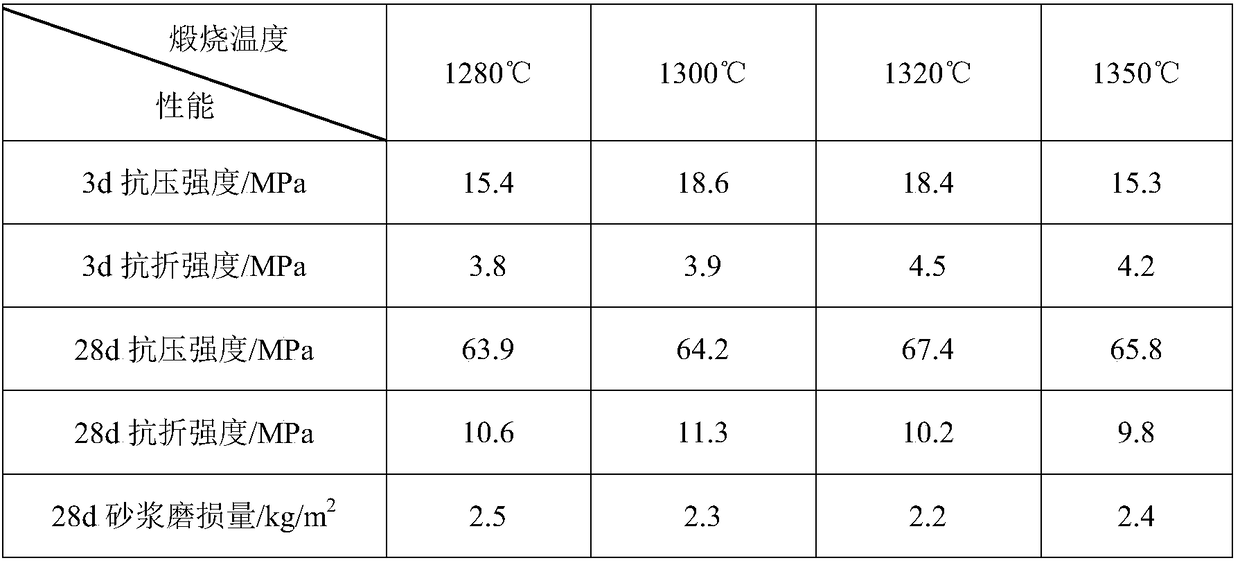

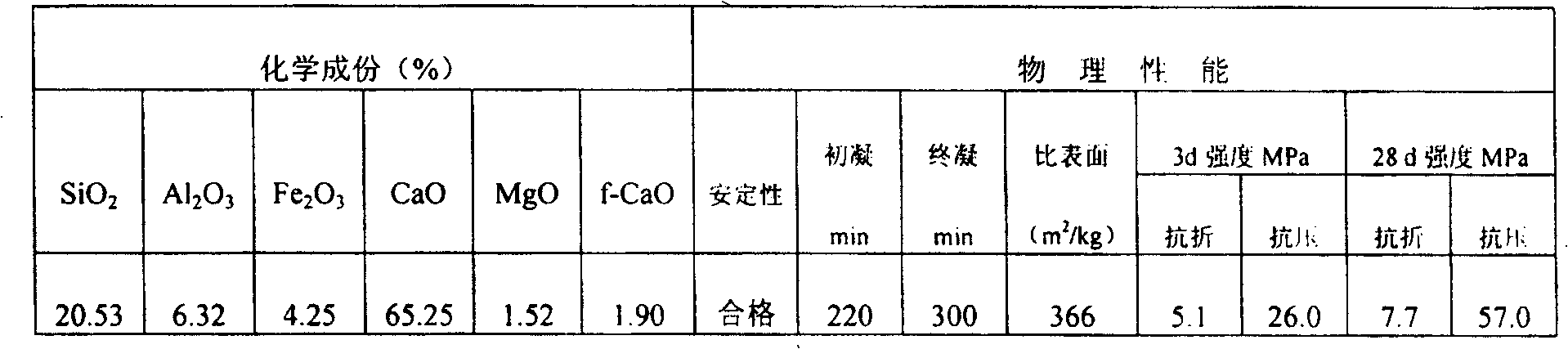

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

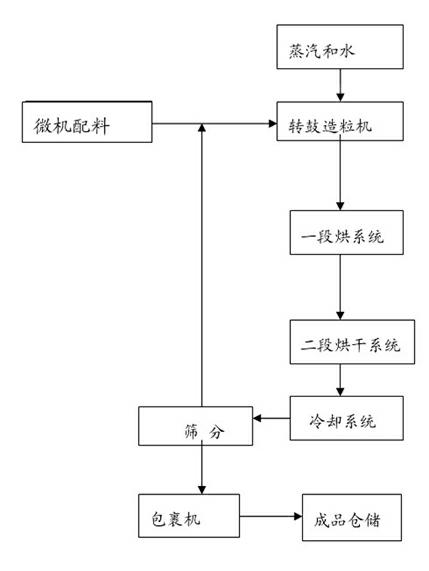

Production process of high tower melt-granulated compound fertilizer

InactiveCN101993277ALower melting temperatureReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumSlurry

The invention relates to a production process of a high tower melt-granulated compound fertilizer. Potassium chloride is added in the process of melting urea, and the temperatures of urine and slurry are reduced according to a characteristic that the melting temperature is reduced after the urea is mixed with the potassium chloride serving as a cosolvent. The liquid solid ratio of the slurry can be regulated so as to reduce the melting temperature of the urea, the melting capacity of urea melting equipment is improved, and the foundation for improving the yield is laid.

Owner:河南财鑫实业化工有限责任公司

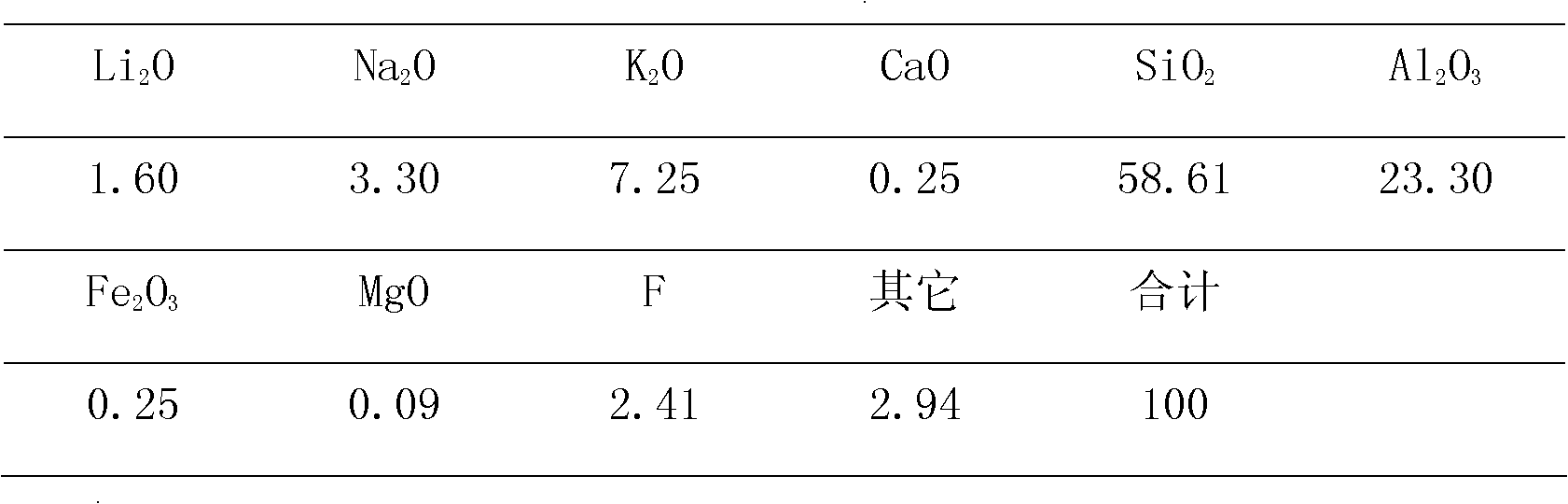

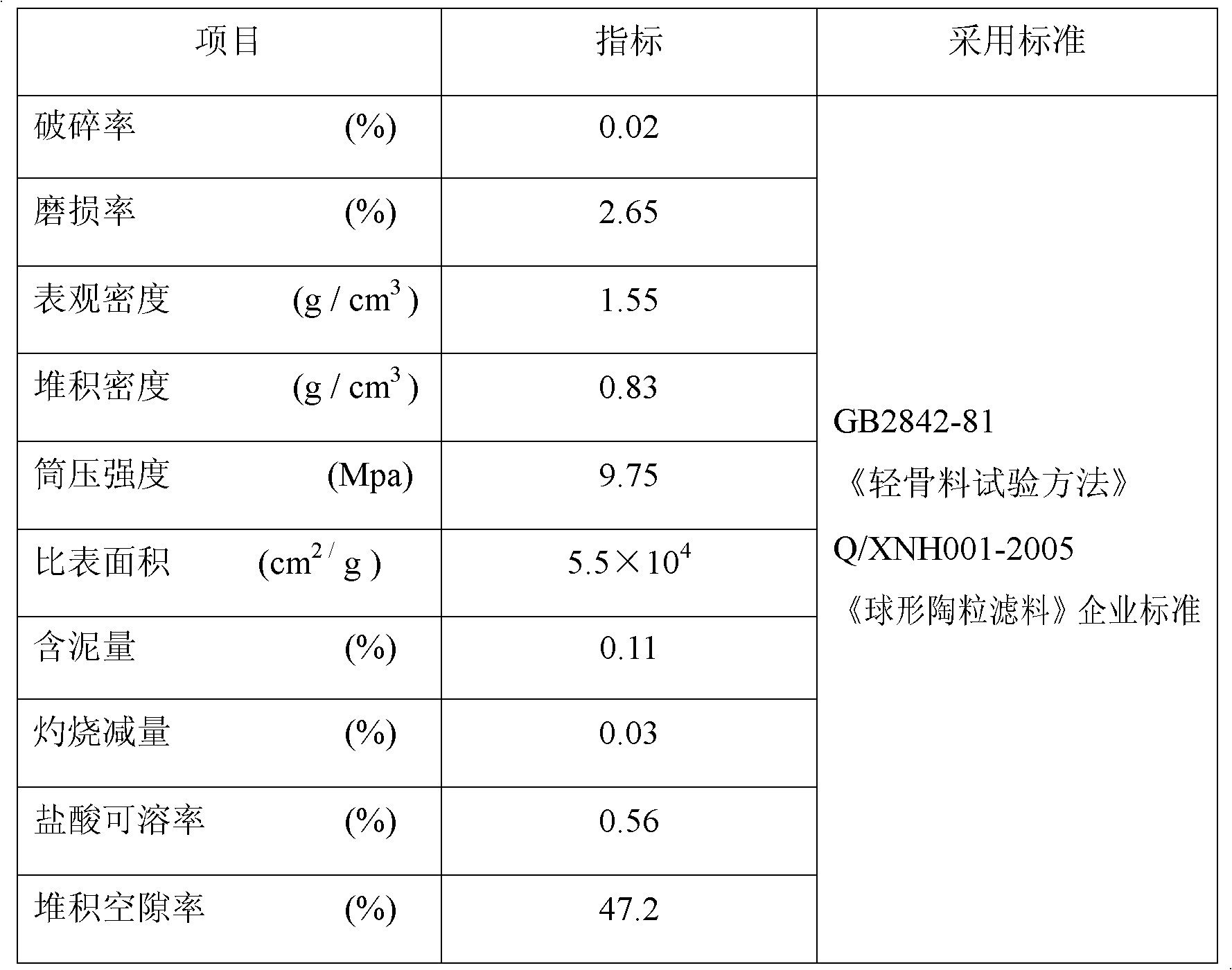

Method for preparing porous ceramsite filter material by using lepidolite extracted lithium slag

InactiveCN102125786AReduce drying energy consumptionReduce grinding energy consumptionFiltration separationPore distributionSlag

The invention discloses a method for preparing a porous ceramsite filter material by using lepidolite extracted lithium slag. The lithium slag extracted by a lepidolite sodium chloride pressure digestion method is used as a main raw material. The method comprises the following steps of: adding partial ground clay powder serving as a plasticizer, adulterating a little amount of pore forming agent (one or two of carbon powder, bran powder, calcium carbonate powder and waste glass powder), balling, sintering and sintering. The filter material has the characteristics of low stacking density, high porosity, uniform pore distribution, high cylinder pressure strength and long service life. The method can simplify the production process and reduce the production cost, is favorable for pollution-free production of a lepidolite mineral lithium extracting process, and has significance for resource recycle and environmental friendliness.

Owner:NANCHANG UNIV

Manufacturing process of high-temperature resistant nixing pottery

ActiveCN106242526AGood thermal shock resistanceHigh mechanical strengthClaywaresUltimate tensile strengthMaterials science

The invention discloses a manufacturing process of a high-temperature resistant nixing pottery. The manufacturing process comprises the steps of preparing a preform body, moulding, finishing, drying and calcining the preform body, and is characterized in that the preform body comprises the following materials in parts by weight: 5-6 parts of white mud, 4-5 parts of purple mud, 1.5-2 parts of TiO2, and 1.5-2 parts of MgO. A high-temperature resistant nixing pottery vessel prepared from the high-temperature resistant nixing pottery has the advantages of excellent spalling resistance and better mechanical strength, can be directly used on various heat sources, does not crack after being used for a long period of time, and meets the requirements of the fine ceramic cookware standard QB / T2580-2002.

Owner:广西古窑坭兴陶文化有限公司

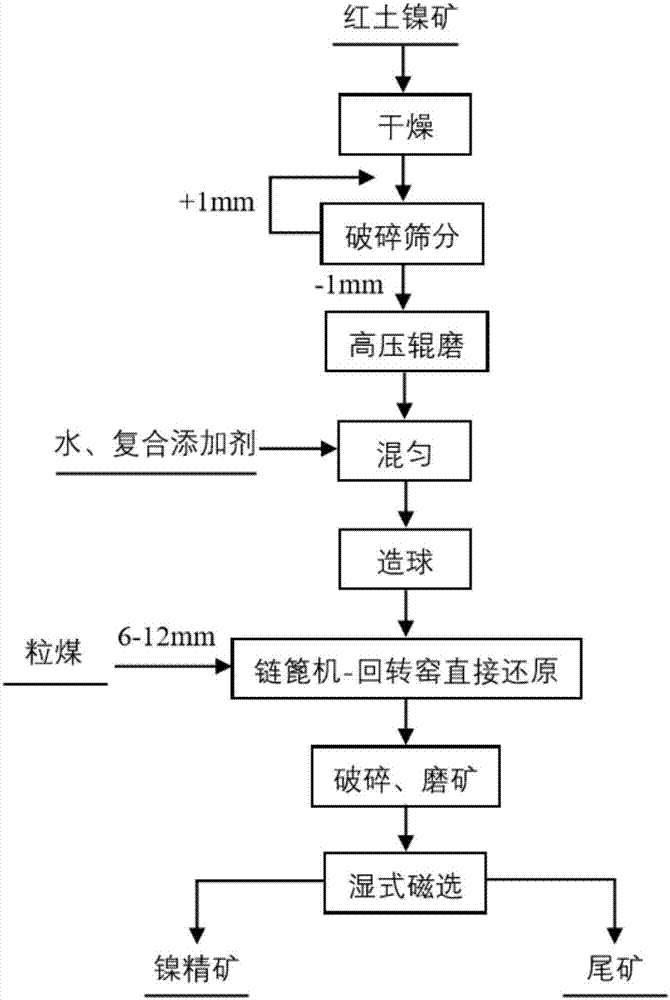

Composite additive for strengthening middle-high magnesium-type laterite-nickel ore direct reduction and application of composite additive

The invention provides a composite additive for strengthening high magnesium-type laterite-nickel ore direct reduction and an application of the composite additive. The composite additive comprises, by weight, 25-35% of desulphurization gypsum, 20-30% of sodium carbonate, 10-15% of sodium humate, 10-15% of polyacrylamide, 5-10% of coal powder, 5-10% of calcium oxide and 1-5% of iron powder. According to the composite additive for strengthening high magnesium-type laterite-nickel ore direct reduction, high-nickel concentrate can be prepared from high magnesium-type middle-low grade laterite-nickel ore and can be applied to direct reduction of high magnesium-type laterite-nickel ore. The application method of the composite additive comprises the steps that laterite-nickel ore and the composite additive are mixed, and a fresh pellet is obtained through pelletizing; the fresh pellet is dried, so that the fresh pellet is solidified to be a dried pellet, wherein the strength of the dried pellet exceeds 300 N; the dried pellet is placed into a rotary kiln, reduction coal is added into the rotary kiln to conduct segmented reduction, and a reduced product is obtained; and after water quenching and splat cooling are conducted on the reduced product, crushing ball-milling and wet magnetic separation are conducted, and high nickel iron ore concentrate is obtained.

Owner:CENT SOUTH UNIV

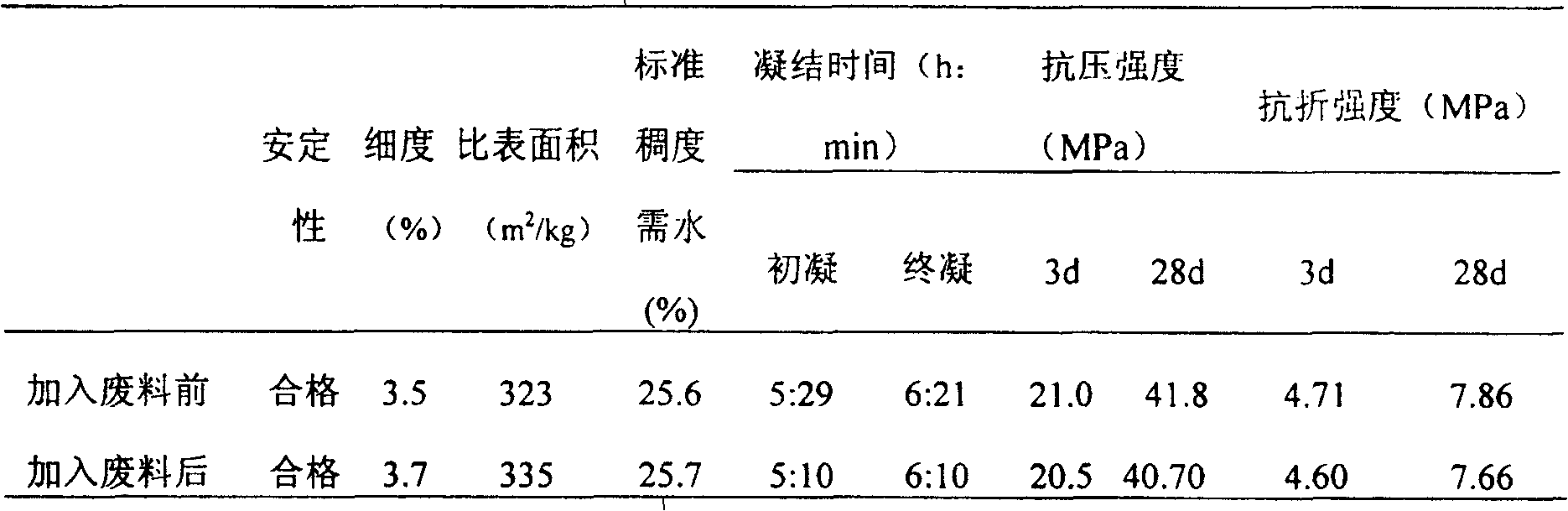

Process of preparing portland cement with waste ceramic tile polishing material

InactiveCN100412020CNo harmful effects on product qualityIncrease productionCement productionPortland cementSlag

The present invention discloses process of preparing Portland cement with waste ceramic tile polishing material. Portland cement clinker in 77-84 wt%, setting retarder gypsum in 3-6 wt% and mixed material in 10-20 wt% are mixed and ball milled in a ball mill to form Portland cement of specific surface area 350 sq m / kg, where the mixed material comprising waste ceramic tile polishing material of 3-6 wt%, mineral slag of 4-8 wt% and flyash of 3-6 wt%. Using waste ceramic tile polishing material as partial material for Portland cement can dispose waste, save resource and raise production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

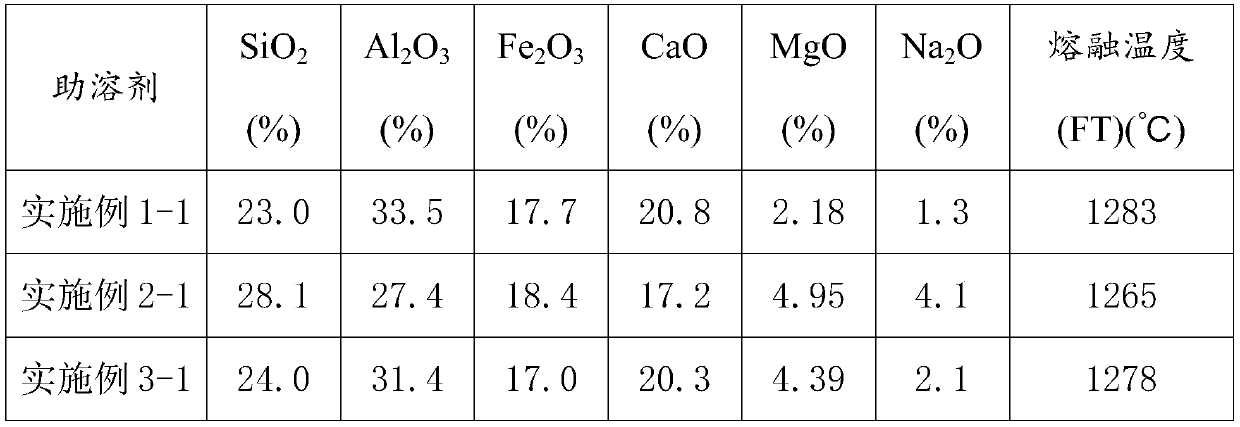

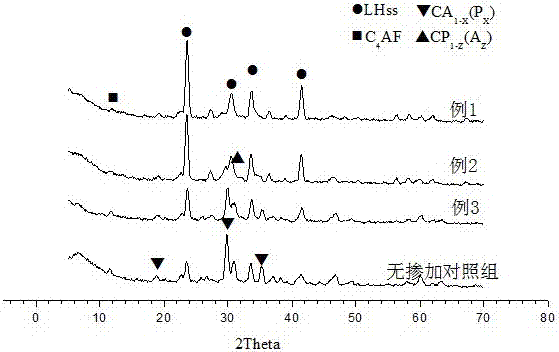

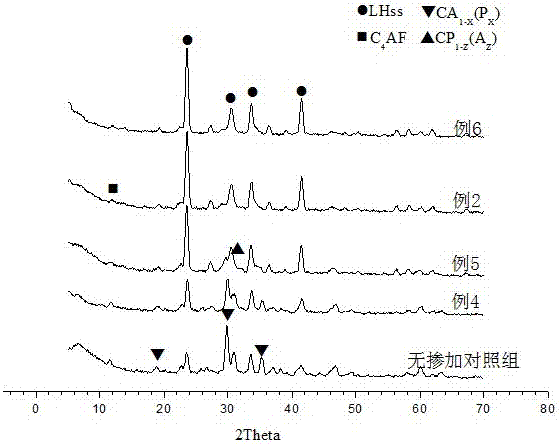

Fluxing agent for reducing melting point of coal ash

InactiveCN111534355AImprove high temperature fluidityImprove mass transfer effectSolid fuelsFuel additivesSlagCoal

The invention discloses a fluxing agent for reducing the melting point of coal ash. The fluxing agent is composed of the following components in percentage by weight: 20-90% of organic matter, 0-70% of CaO, 1-40% of MgO, 0-50% of Fe2O3, 0-30% of Na2O and 0-30% of K2O. The fluxing agent effectively increases the amount of a liquid phase generated by ash fusing, and improves the high-temperature fluidity of ash slag; the softening point is low, and the formation of an eutectic system can be promoted; the ash melting point can be reduced, and meanwhile, organic hazardous wastes are used for producing H2 / CO and the like to save feed coal; organic matters are used as a binder and a water repellent agent, so that the addition amount of the ash melting point reducing additive can be greatly higher than that of other ash melting point reducing additives, and the yield of effective gas is not influenced; the phenomenon that the addition amount of limestone is increased and the melting point ofcoal ash is increased is avoided. The fluxing agent solves the problems of high coal ash melting point, high treatment cost and the like of difficult-to-gasify coal (such as Huainan coal) with high ash melting point.

Owner:绍兴凤登环保有限公司

Production method of sintered ores

The invention provides a production method of sintered ores. The production method comprises the following steps: taking the following raw materials: 70-85% of iron ore powder, 5-10% of steel slag, 5-15% of boron-containing iron ore powder, 3-6% of coke powder or pulverized coal and 1-5% of SiC powder; adjusting the alkalinity of sintered ores as ingredients to be 1.8-2.2 by adding limestone and quick lime; feeding a mixture formed by mixing iron ore powder, steel slag, boron-containing iron ore powder and coke powder or pulverized coal uniformly into a drum mixer, adding the SiC powder after pellets are formed, enabling the SiC powder to uniformly wrap the surfaces of the mixture pellets, and finally distributing the materials, thus completing production of the sintered ores. The production method has the beneficial effects that environments with higher alkalinity than the finished sintered ores can be formed inside the sintered ores, and the indexes such as reduction degradation and the like of the sintered ores can be improved, so that the low-temperature reduction degradation index RDI+3.15 is 83.73% and the low-temperature reduction degradation index RDI-0.15 is 4.16%; meanwhile, the metallurgical performance and cold and hot strength of the sintered ores can be substantially improved, the drum strength of the sintered ores is 83.13%, and the fuel consumption of the sintered ores can be reduced.

Owner:ANGANG STEEL CO LTD

Composite mineralizer for barium calcium phosphoaluminate cement

The invention relates to a mineralizer for cement production, and in particular, relates to a composite mineralizer for barium calcium phosphoaluminate cement. The composite mineralizer for the barium calcium phosphoaluminate cement comprises the main chemical components by the mass percentage: 20-54% of Fe2O3, 13.5-33.3% of SO3, 13.5-20.8% of MgO, 5-10.4% of CaF2, and 13.5-16.5% of Na2O or K2O, wherein the mixing mass percentage of the composite mineralizer in a barium calcium phosphoaluminate cement raw material is 1.25-10%. According to the composite mineralizer, SO3 comes from a variety of industrial waste gypsums, MgO comes from high-magnesium limestone, Fe2O3 comes from steel slag, and Na2O or K2O comes from cement main raw material impurities. According to the composite mineralizer for the barium calcium phosphoaluminate cement, cement clinker formation is promoted by introducing the compound mineralizer, the calcination temperature is reduced by 150-200 DEG C, the formation of a main mineral phase barium calcium phosphoaluminate is significantly promoted, a conventional rotary kiln production line can be applied to production of the barium calcium phosphoaluminate cement, the large-scale production is facilitated, and energy saving and consumption reduction of the production process are achieved.

Owner:UNIV OF JINAN

Treatment method for construction residue soil in construction waste

InactiveCN109956686AIncrease the amount of liquid phaseImprove early strengthCement productionChemical compositionCalcination

The invention relates to a treatment method for construction residue soil in construction waste. The method comprises the following steps: performing material separation on the construction waste to obtain the construction residue soil, detecting a chemical component content of the obtained construction residue soil, performing preparation to obtain a cement raw material including limestone, the construction residue soil, an iron raw material and sandstone, enabling a saturation ratio of the cement raw material to be 0.8-1.0, a silicon ratio to be 1.9-2.5 and an aluminum ratio to be 1.3-1.9, and producing cement clinker. The treatment method for the construction residue soil in the construction waste provided by the invention can continuously and effectively utilize the construction residue soil in the construction waste and is almost not limited by generation time and regions of the construction waste of each batch, and after high-temperature calcination is performed to form the cement clinker, harmful substances mixed in the construction residue soil are solidified in the cement clinker and do not cause harm to the environment and humans, and cement products produced by the method are qualified.

Owner:广西华润红水河水泥有限公司 +1

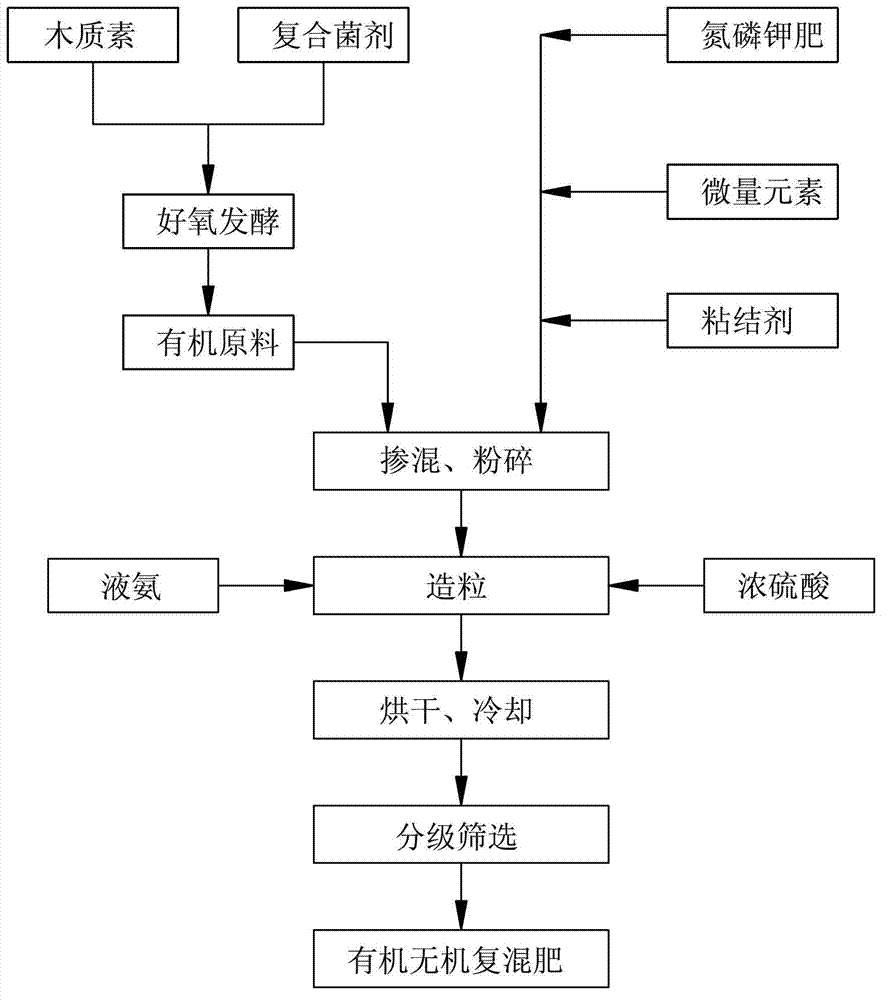

Lignin-containing organic-inorganic compound fertilizer prepared by ammonia-acid method as well as ammonia-acid production method

InactiveCN102924175AGood water stabilityImprove effectivenessFertiliser formsFertilizer mixturesChemistryLiquid ammonia

The invention disclose a lignin-containing organic-inorganic compound fertilizer prepared by an ammonia-acid method as well as the ammonia-acid production method. According to the invention, the organic-inorganic compound fertilizer is prepared by using the following components in parts by weight through an ammonia-acid process: 20-30 parts of lignin, 50-60 parts of nitrogen-phosphorus-potassium fertilizer, 0.2-0.5 parts of compound inoculant, 3-5 part of concentrated sulfuric acid, 2.5-3.5 parts of liquid ammonia and 5-15 parts of binding agent; and the raw materials also include 2-4 parts of chelated trace element fertilizer. The organic-inorganic compound fertilizer prepared by the ammonia-acid method uses the lignin as the source of organic material, has a large amount of organic active materials and a large amount of nitrogen, phosphorus and potassium elements, and can satisfy the growth needs of the farm corps completely.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

Fabrication process of low expansion Nixing pottery

ActiveCN106348728ALower eutectic temperatureLower sintering temperatureClaywaresUltimate tensile strengthThermal shock

The invention discloses a fabrication process of low expansion Nixing pottery. The process comprises the steps of blank preparation, blank forming, blank trimming, blank stoving and blank firing. The process of low expansion Nixing pottery is characterized in that the blank prepared from, by weight, 5-6 parts of east mud, 4-5 parts of west mud, 0.5-1 part of NiO, 1.5-2 parts of TiO2 and 1.5-2 parts of MgO. The Nixing dishes prepared through the fabrication process of low expansion Nixing pottery have the advantages of excellent thermal shock resistance, good mechanical strength and capable of being used in various heat sources directly without cracking even after being used for a long period. The Nixing pottery dishes prepared through the process of low expansion Nixing pottery can meet the requirements of QB / T2580-2002 <Fine ceramic cookware>.

Owner:钦州六艺龙窑坭兴陶有限公司

Fireproof paint

InactiveCN109517474AGood compatibilityTightly boundFireproof paintsLime coatingsPentaerythritolCellulose acetate

The invention relates to the technical field of paint and in particular relates to fireproof paint. The fireproof paint comprises the following raw materials in parts by weight: 35-50 parts of diphenylether-formaldehyde resins, 16-27 parts of modified expanded graphite, 12-17 parts of perlite powder, 7-12 parts of yttria powder, 5-9 parts of aluminum dihydrogen tripolyphosphate, 2-6 parts of cellulose acetate, 8-15 parts of ortho-xylene, 5-12 parts of a film-forming agent, 3-9 parts of pentaerythritol, 0.3-1.5 parts of a coupling agent, 1.5-4.5 parts of an antifoaming agent, 0.2-0.6 part of awetting agent, 1.5-2.5 parts of a stabilizer and 0.2-0.7 part of microgel. The fireproof paint disclosed by the invention has excellent fire resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

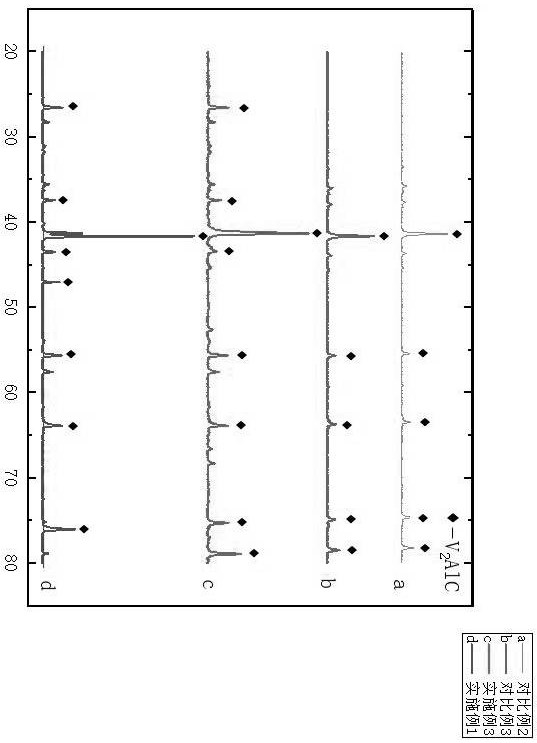

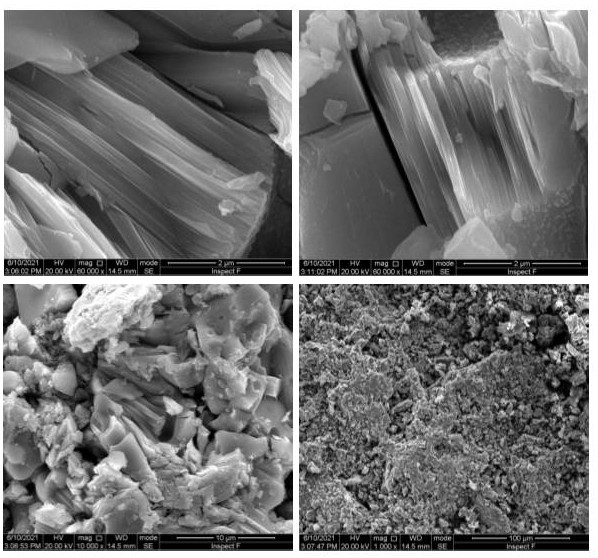

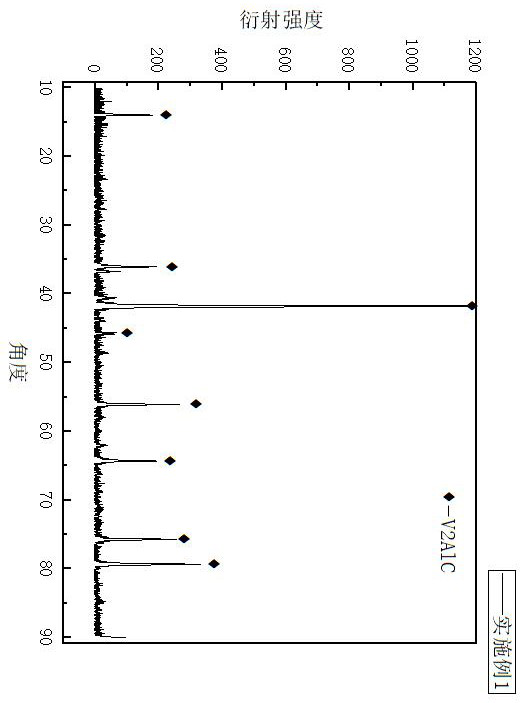

V2AlC block material synthesized by microwave sintering as well as preparation method and application of V2AlC block material

The invention relates to a V2AlC block material synthesized by microwave sintering and a preparation method thereof. The method comprises the following steps: weighing vanadium powder, aluminum powder and graphite powder according to a molar ratio of V:Al:C of 2:(1.1-1.4):1; a sintering aid LaF3 or CeF3 is added; adding the powder into absolute ethyl alcohol, grinding for 30 minutes by using a quartz mortar, and carrying out vacuum drying for 5 hours at the temperature of 50 DEG C to obtain a mixed raw material; placing the mixed raw materials in a steel grinding tool to be pressed for 60 s under the pressure of 240 MPa, and forming a cylindrical blank; and putting the pressed blank into a microwave sintering device, heating the material to 1250 DEG C in an argon atmosphere, preserving heat for 5 minutes, and cooling the material to obtain the V2AlC block material.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

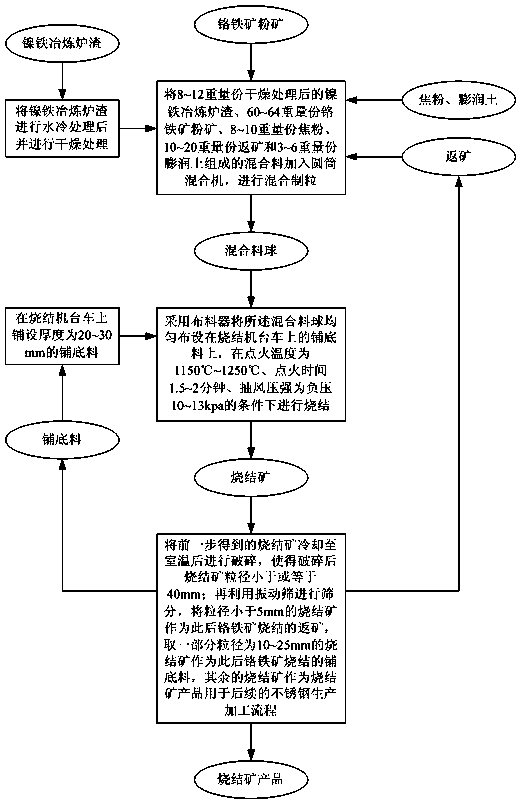

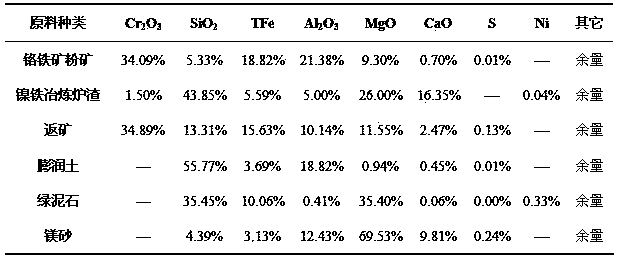

Method for sintering chromite powder recycled based on ferronickel smelting furnace slag

InactiveCN103060548BRealize comprehensive utilizationLow costProcess efficiency improvementCokeNichrome

The invention provides a method for sintering chromite powder recycled based on ferronickel smelting furnace slag. According to the method, the chromite powder is added with the ferronickel smelting furnace slag and then is granulated and sintered, so that the sintering temperature of the chromite can be reduced, the liquid phase amount is increased, the carbon proportion can be decreased, the yield and the strength of the sintered ore are improved, the difficult chromite powder sintering problem is solved, the energy consumption for the production is reduced simultaneously, an expensive solvent is unnecessary, and the obtained sintered product is a nickel-chromium-iron alloy which can be directly applied to the stainless steel production and does not increase a subsequent smelting slag discharge process of the stainless steel production. Compared with the chromite sintering process in the prior art, the method has the advantages that the coke proportion is low, the sintering temperature is low, the quality of the sintered ore is high, the ferronickel smelting furnace slag is effectively recycled and the production cost is low, the waste utilization in the nickel alloy production process is realized, the total cost of the stainless steel production is reduced, the economic benefit of enterprises is increased, and the energy conservation and emission reduction pressure of the enterprises is relieved.

Owner:CHONGQING UNIV

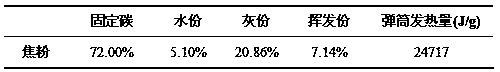

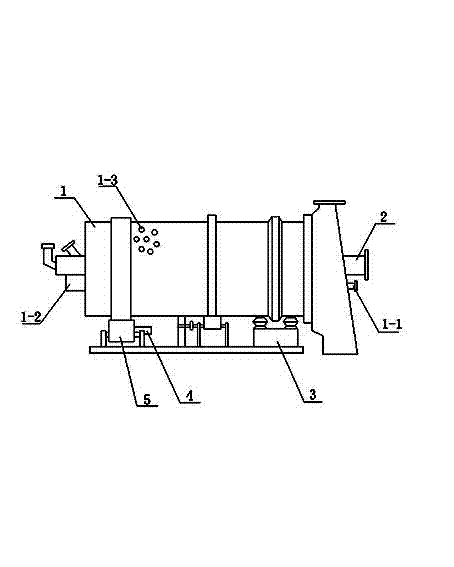

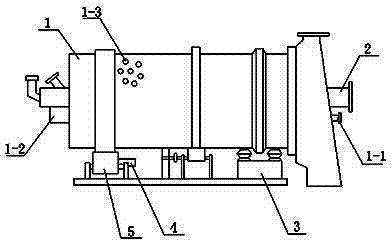

Drum ammoniation granulating machine

InactiveCN102531807AIncrease temperatureIncrease production capacityFertiliser formsFertilizer mixturesSolubilitySprayer

The invention provides a drum ammoniation granulating machine which comprises a drum granulating machine which mainly comprises a barrel (1), a catch wheel group (3), a driving device (4) and a riding wheel group (5) and also comprises a tubular beam (2), a group of flexible rubber plates (6), a slurry sprayer (7) and an ammonia distributer (8). The drum ammoniation granulating machine has the advantages that the drum granulating machine is capable of realizing a heat granulating process, improving material temperature, increasing the salt solubility of a granulating system material, obtaining high liquid phase quantity under the condition of low water content and meeting the liquid phase quantity required by the granulation of the material, thereby greatly reducing the evaporated water quantity required by a drying process, improving the production capacity of drying equipment, reducing the re-granulation degree of the material in a drying machine, lowering large-particle and particle-adhering phenomena and being beneficial to normal operation of the drying process.

Owner:HUBEI NEWYANGFENG FERTILIZER STOCK

Method for producing foam microcrystal glass by utilizing composite industrial residue and product

The invention discloses a method for producing a foam microcrystal glass by utilizing a composite industrial residue, and is characterized by comprising the following steps of: crushing different industrial residues, after mixing proportionally, grinding to raw material powder, heating, melting, quenching and drying the raw material powder, grinding to clinker powder, adding a nucleation agent, a foaming agent, a foam stabilizer, a fluxing agent and an enhancer to form a foam microcrystal batch, after pressing the batch, preheating, foaming, stabilizing the foam and annealing, sintering to obtain the foam microcrystal glass. According to the invention, burnability of the batch is remarkably improved, the burning temperature is reduced, the production cost of the foam microcrystal glass is reduced, and the method has the characteristics of abundant raw material sources, low cost, simple process, environmental friendliness, and the like. The product foam microcrystal glass has the characteristics of excellent performance quality, low volume weight, high intensity, fire protection, water tightness, corrosion resistance, no ageing, no radioactivity and the like, and is an environmental-friendly new material.

Owner:苏州新苏化工机械有限公司

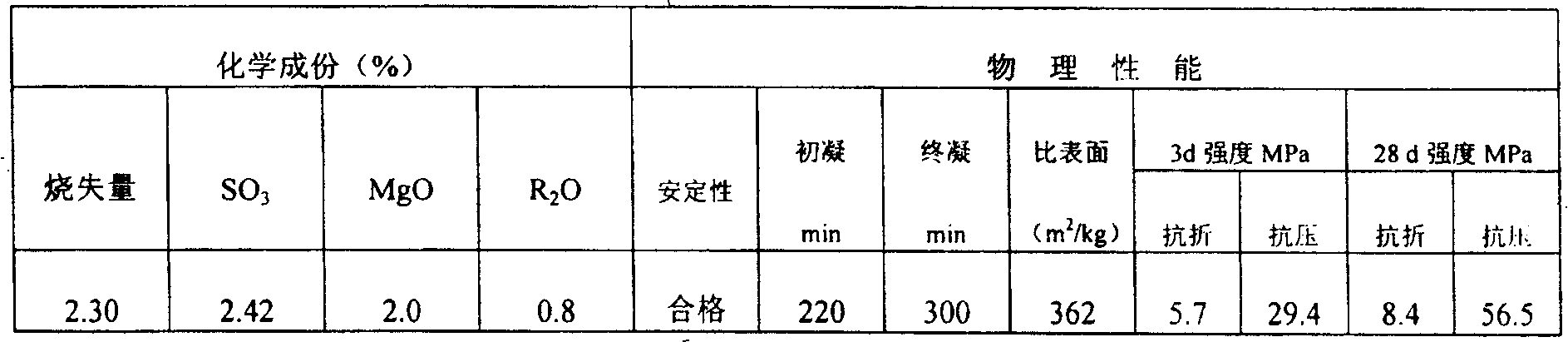

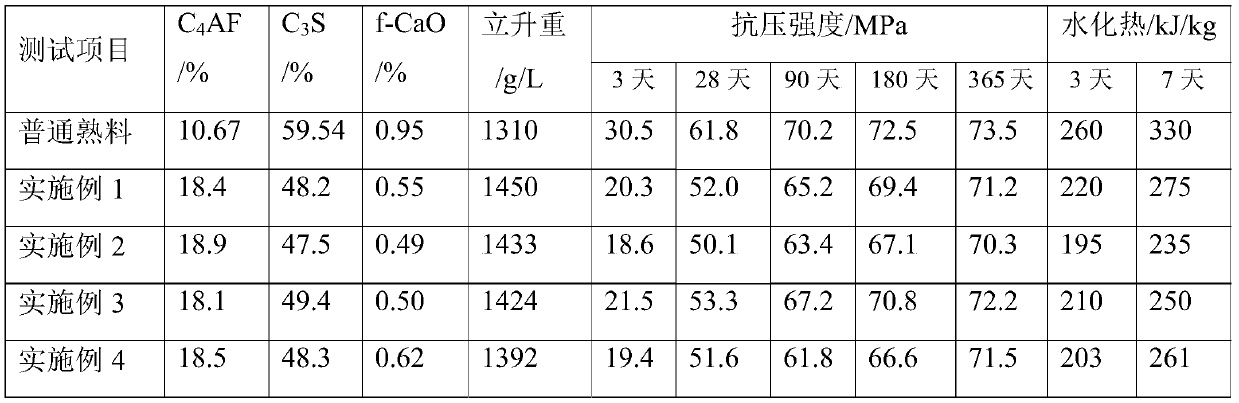

Method for producing high-iron low-calcium clinker

PendingCN110563356ALow saturation ratioHigh in ironCement productionNonferrous metalUltimate tensile strength

The invention discloses a method for producing high-iron low-calcium clinker and belongs to the technical field of building materials. The method comprises the following steps: by taking 78-83% of limestone, 12-16% of sandstone, 3-6% of nonferrous metal ash and 0.3-0.8% of a composite additive consisting of CaF2, CuO, P2O5 and Zn as raw materials, performing powdering, preparing cakes, crushing the cakes, further performing calcining so as to obtain clinker, and finally cooling and crushing the clinker, so as to obtain the high-iron low-calcium clinker. The method is low in raw material cost,and the prepared high-iron low-calcium clinker is high in strength, low in hydration heat and applicable to engineering or parts with special requirements.

Owner:GUANGXI YUFENG CEMENT

Production process of high tower melt-granulated compound fertilizer

InactiveCN101993277BLower melting temperatureReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumChloride

The invention relates to a production process of a high tower melt-granulated compound fertilizer. Potassium chloride is added in the process of melting urea, and the temperatures of urine and slurry are reduced according to a characteristic that the melting temperature is reduced after the urea is mixed with the potassium chloride serving as a cosolvent. The liquid solid ratio of the slurry can be regulated so as to reduce the melting temperature of the urea, the melting capacity of urea melting equipment is improved, and the foundation for improving the yield is laid.

Owner:河南财鑫实业化工有限责任公司

Manufacturing Technology of Low Expansion Nixing Pottery

ActiveCN106348728BLower eutectic temperatureLower sintering temperatureClaywaresUltimate tensile strengthThermal shock

The invention discloses a fabrication process of low expansion Nixing pottery. The process comprises the steps of blank preparation, blank forming, blank trimming, blank stoving and blank firing. The process of low expansion Nixing pottery is characterized in that the blank prepared from, by weight, 5-6 parts of east mud, 4-5 parts of west mud, 0.5-1 part of NiO, 1.5-2 parts of TiO2 and 1.5-2 parts of MgO. The Nixing dishes prepared through the fabrication process of low expansion Nixing pottery have the advantages of excellent thermal shock resistance, good mechanical strength and capable of being used in various heat sources directly without cracking even after being used for a long period. The Nixing pottery dishes prepared through the process of low expansion Nixing pottery can meet the requirements of QB / T2580-2002 <Fine ceramic cookware>.

Owner:广西千叶科技有限公司

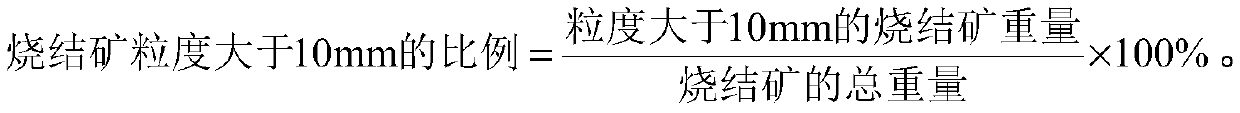

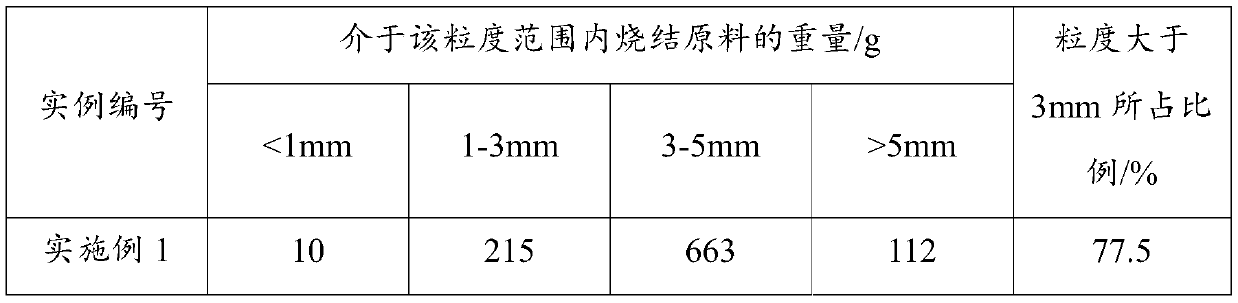

Sintering mixture and mixing method, sintering ore and sintering method

The invention belongs to the technical field of iron ore sintering, and particularly relates to a sintering mixture and a mixing method, sintering ore and a sintering method. The sintering mixture comprises the following components in parts by weight: 90-110 parts of iron ore powder to be sintered, 14-20 parts of returned ore A, 8.5-10.5 parts of returned ore B, 2-4 parts of coke powder, 7-9 partsof quicklime and 6.5-8.5 parts of adhesives, wherein the particle size of the returned ore A is 1-2 mm, and the particle size of the returned ore B is 2.5-5 mm. Through adding the adhesives with an adhesive effect and the returned ore A and the returned ore B with specific particle sizes to the sintered mixture, the particle size and particle structure of the sintering mixture are further improved, so that microparticles with the returned ore as cores are formed, the air permeability of a material layer is greatly improved, the sintering requirement of an ultra-thick material layer of 1000 mmor above is fully met, and the air permeability and the vertical combustion speed of a sintering material layer, and the output and yield of the sintering ore are all improved to various degrees.

Owner:NANKAI UNIV

Preparation method of coal-saving agent used for nitrogen fixation type cement short kiln

ActiveCN109628196ALower reaction energyIncrease the amount of liquid phaseSolid fuelsProcess systemsRare earth

The invention discloses a preparation method of a coal-saving agent used for a nitrogen fixation type cement short kiln. 30-50 parts of rare earth tailings, 10-20 parts of magnesium hydroxide, 15-25 parts of hydrated aluminum oxide are mixed and ground to obtain a mixture; 5-15 parts of aromatic condensates, 5-15 parts of organosilicon polymers and 2-10 parts of zinc borate are added into the mixture, uniform mixing is conducted, and the coal-saving agent used for the nitrogen fixation type cement short kiln is obtained. According to the process system of calcining cement with short flame andrapid burning, high-burning-value coal used in a short-flame kiln is added into the coal-saving mixture coal used in the nitrogen-fixing cement kiln for mixed combustion, compared with combustion of the same amount of raw coal, the NO(x) in coal-burning flue gas is reduced by 50-60%, and the energy consumption of combustion of cement clinker is comprehensively reduced by 5-15%, the formation amount and discharge amount of NO(x) can also be effectively reduced, and the nitrogen fixing effect of the clinker can thus be improved.

Owner:HUBEI UNIV OF TECH

High titan type high alkalinity sinter and method for preparing same

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

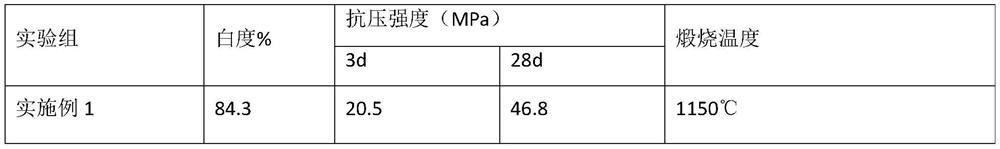

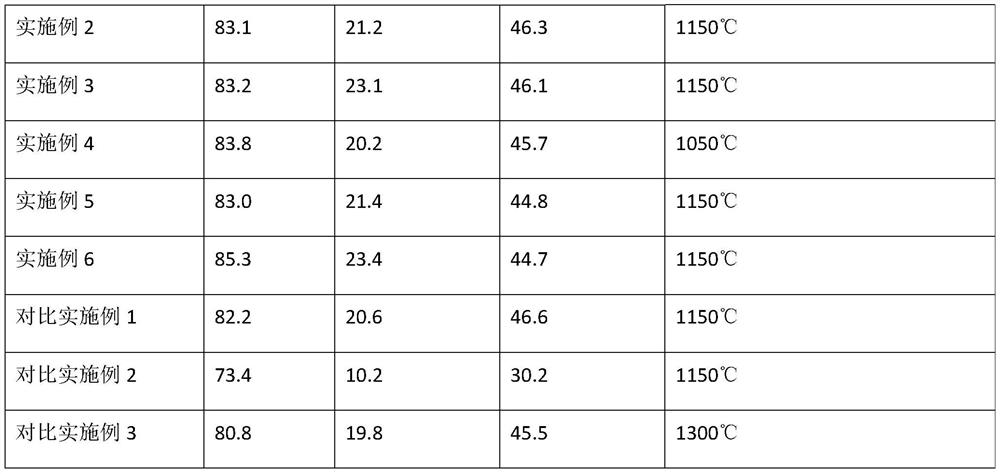

Non-fluorite mineralizer applicable to production of white portland cement

The invention belongs to the technical field of new materials, in particular to a non-fluorite mineralizer applicable to production of white Portland cement and a preparation method thereof. The non-fluorite mineralizer applicable to production of white Portland cement comprises barium oxide, phosphorus pentoxide, magnesium oxide, Portland cement main elements and a small amount of other trace elements. The effective components in the mineralizer are introduced from different industrial waste residues, barium oxide is introduced from low-iron barium slag, phosphorus pentoxide is introduced from phosphorus slag, and magnesium oxide is introduced from white slag. Calcium oxide, silicon oxide and aluminum oxide are main components in the three waste residues, and other trace elements comprisesulfate, chloride and the like. The invention provides the non-fluorite mineralizer applicable to production of white portland cement, which is low in cost, easy to obtain and excellent in performance, and can effectively reduce the production cost of products and improve the performance of the products, and the preparation method thereof.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

High-efficiency sulfur-fixing agent for cement rotary kiln and its application method

The invention belongs to the technical field of environmental protection, and discloses a high-efficiency sulfur fixing agent for a cement rotary kiln and a use method thereof. The high-efficiency sulfur fixing agent for the cement rotary kiln is composed of the following components by the mass percentage: 30-60% of fluorite tailings, 20-40% of strontium slag, and 10-40% of barium slag, wherein the sum of the contents of all the components is 100%. The use method comprises the steps: mixing the components evenly, grinding, mixing with a cement raw material or placing in a coal injection pipe,calcining to obtain a cement clinker, and thus realizing the sulfur fixing effect of the sulfur fixing agent. The sulfur fixing agent has high sulfur fixing efficiency, reduces the SO2 concentration in flue gas of the cement kiln, also reduces the clinker firing temperature, improves the clinker quality, and has great economic, social and environmental significance for energy saving and emission reduction, sustainable development and comprehensive utilization of resources in cement industry.

Owner:广东万引科技股份有限公司

Preparation method of cement raw material regulator

PendingCN114685072AReduce coarse particle contentUniform compositionDicarboxylic acidHydrogen peroxide

The invention relates to the field of cement modifier production, in particular to a preparation method of a cement raw material modifier, the cement raw material modifier comprises the following ingredients: main materials and auxiliary materials, the main materials comprise 20-30 parts of unsaturated dicarboxylic acid or anhydride thereof, 40-50 parts of allyl polyoxyethylene ether, and 30-50 parts of unsaturated polyoxyethylene macromonomer; the auxiliary materials comprise the following components in parts by weight: 20-50 parts of dihydrogenated tallow dimethyl ammonium chloride and 10-30 parts of soluble active nano aluminum salt, and the auxiliary materials comprise the following components in parts by weight: 5-10 parts of hydrogen peroxide, 1-5 parts of a reducing agent, 1-5 parts of potassium persulfate, 5-10 parts of metal oxide and 1-5 parts of trace elements. Calcium oxide absorption is accelerated; the liquid phase is promoted to appear in advance, the liquid phase amount is increased, and the liquid phase viscosity during clinker formation is reduced; the raw material burnability is improved, the solid-phase reaction speed is high, and sintering is easy.

Owner:广东誉益新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com