Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

A technology of road silicate and cement clinker, applied in the direction of cement production, etc., can solve the problems that do not meet the development requirements of low-carbon green, high energy, resource consumption, low nickel slag content, etc., to solve the occupation problem, Improve the mechanical properties, the effect of strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Components: 20 parts of nickel slag, 65 parts of calcium carbide slag, 4 parts of zirconium silicon slag, 2 parts of bauxite tailings, 7 parts of desulfurized gypsum, 2 parts of mineralizer (1.3 parts of lead-zinc tailings, 0.7 parts of phosphorus slag) .

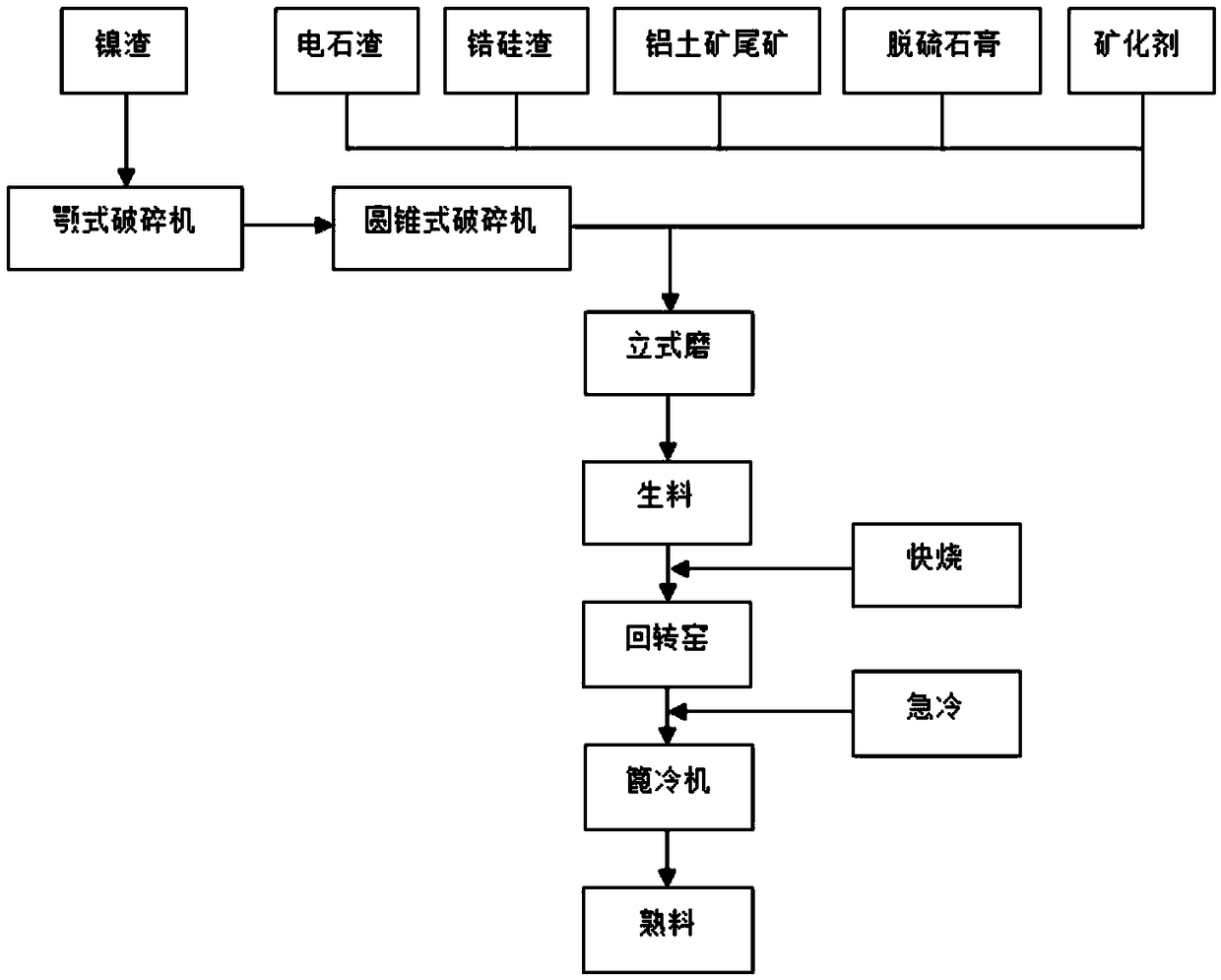

[0036] The preparation method of road portland cement clinker based on industrial waste residue comprises the following steps, as figure 1 Shown:

[0037] (1) Carbide slag is dried, and nickel slag is crushed and ground;

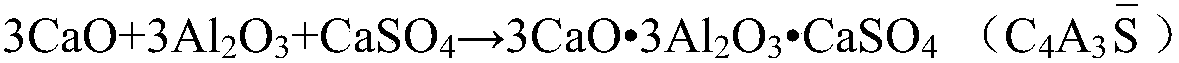

[0038] (2) Mix, grind, and homogenize nickel slag, calcium carbide slag, zirconium silicon slag, bauxite tailings, desulfurized gypsum, and mineralizer to obtain cement raw meal; wherein, the raw meal rate in the cement raw meal is The values are: lime saturation coefficient (KH) is 0.87, silicon ratio (SM) is 1.87, aluminum ratio (IM) is 0.77.

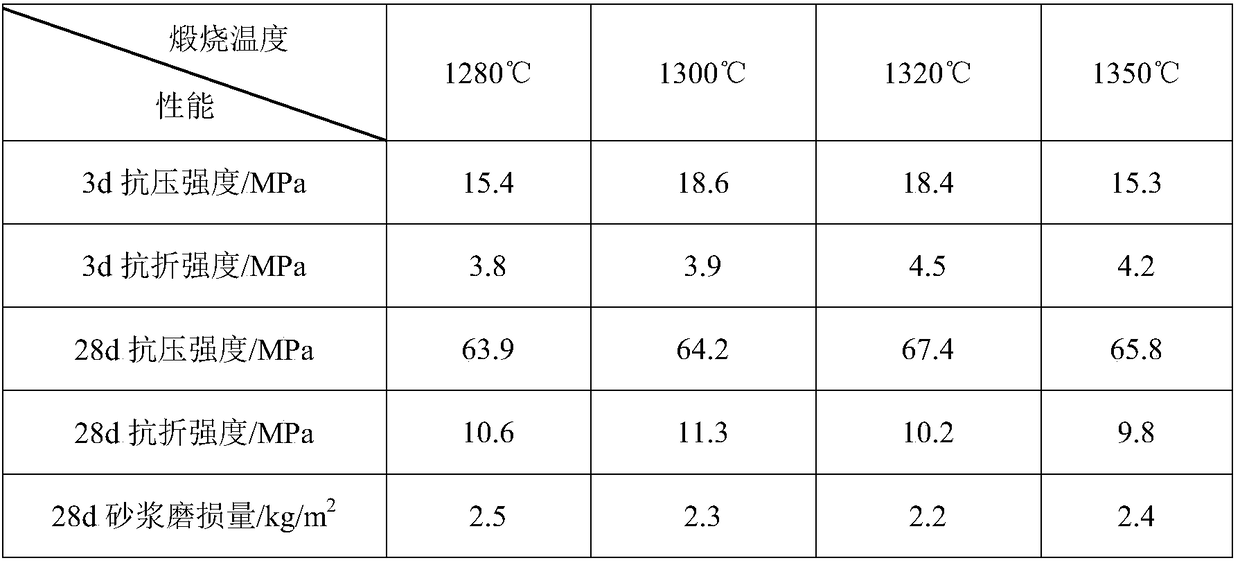

[0039] (3) The prepared raw meal is preheated at 780°C for 4 minutes and then calcined in a rotary kiln. The calcining temperature is 1280-1350°C, ca...

Embodiment 2

[0045] Components: 25 parts of nickel slag, 60 parts of calcium carbide slag, 3 parts of zirconium silicon slag, 3 parts of bauxite tailings, 7.5 parts of desulfurized gypsum, 1.5 parts of mineralizer (1.05 parts of lead-zinc tailings, 0.45 parts of phosphorus slag) .

[0046] The preparation method of the road portland cement clinker based on industrial waste residue comprises the following steps:

[0047] (1) Carbide slag is dried, and nickel slag is crushed and ground;

[0048] (2) Mix, grind, and homogenize nickel slag, calcium carbide slag, zirconium silicon slag, bauxite tailings, desulfurized gypsum, and mineralizer to obtain cement raw meal; wherein, the raw meal rate in the cement raw meal is The values are: lime saturation coefficient (KH) is 0.88, silicon rate (SM) is 1.89, aluminum rate (IM) is 0.66.

[0049] (3) The prepared raw meal is preheated at 780°C for 4 minutes and then calcined in a rotary kiln. The calcining temperature is 1280-1350°C, calcined for 3...

Embodiment 3

[0055] Components: 30 parts of nickel slag, 60 parts of calcium carbide slag, 2 parts of zirconium silicon slag, 2 parts of bauxite tailings, 5 parts of desulfurized gypsum, 1 part of mineralizer (0.75 parts of lead-zinc tailings, 0.25 parts of phosphorus slag) .

[0056] The preparation method of the road portland cement clinker based on industrial waste residue comprises the following steps:

[0057] (1) Carbide slag is dried, and nickel slag is crushed and ground;

[0058] (2) Mix, grind, and homogenize nickel slag, calcium carbide slag, zirconium silicon slag, bauxite tailings, desulfurized gypsum, and mineralizer to obtain cement raw meal; wherein, the raw meal rate in the cement raw meal is The values are: lime saturation coefficient (KH) is 0.90, silicon ratio (SM) is 1.79, aluminum ratio (IM) is 0.74.

[0059] (3) The prepared raw meal is preheated at 780°C for 4 minutes and then calcined in a rotary kiln. The calcining temperature is 1280-1350°C, calcined for 35 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com