Iron ore low-carbon sintering method

A sintering method and iron ore technology, applied in the field of iron and steel smelting, can solve the problems of low effective heat utilization rate and high fuel consumption of a sintering machine, and achieve the effects of increasing non-carbon heat income, reducing carbon distribution, and reducing sintering energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Laboratory test:

[0074] The mixed materials were completed according to Table 2, and 10 groups of parallel experiments were performed. According to the existing sintering process, sintering is carried out in the steps of cloth distribution, ignition, ventilation sintering, thermal crushing, cooling, screening and sizing. The sintering conditions and sintering results are shown in Table 3.

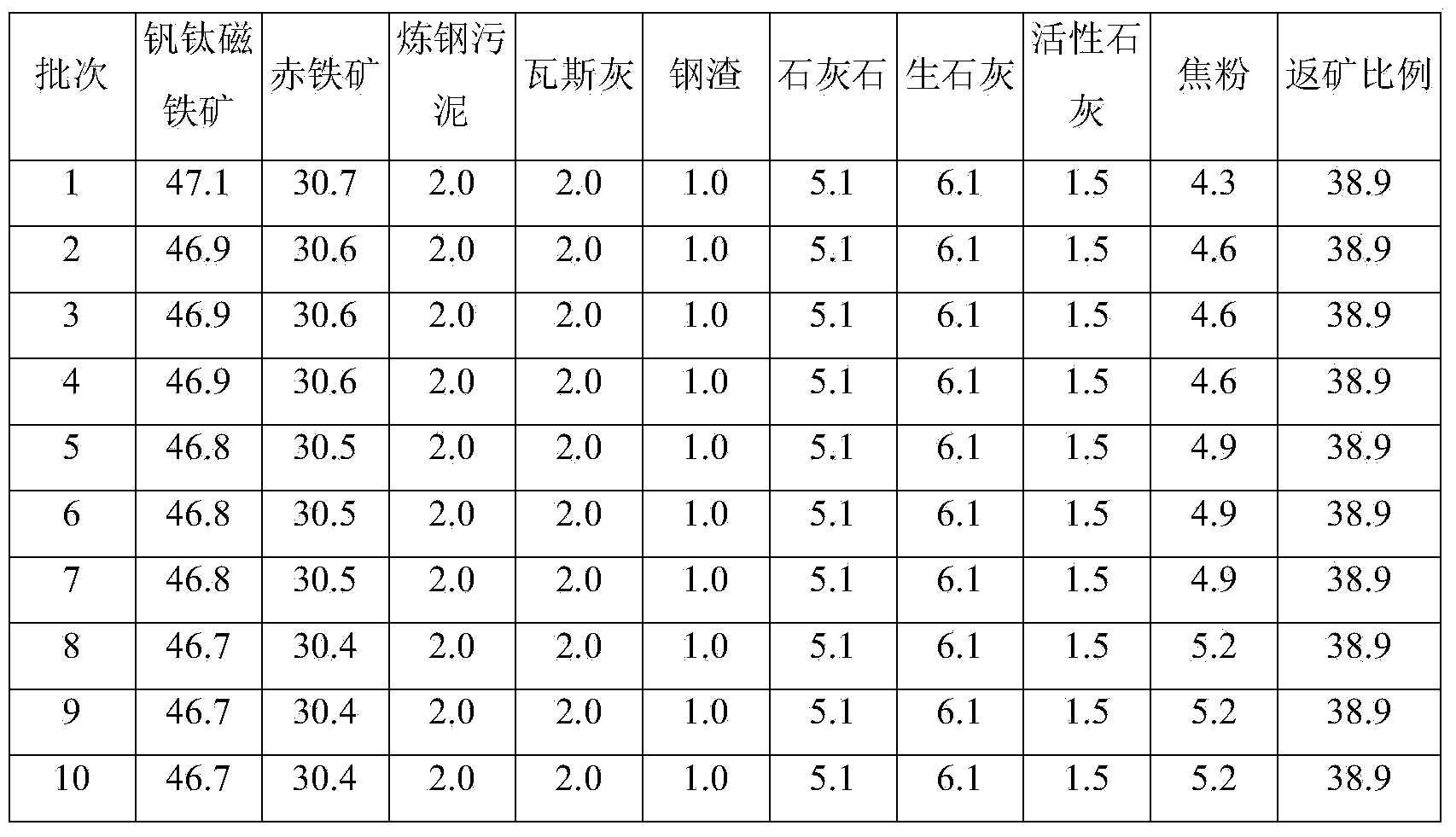

[0075] Table 2 Laboratory low-carbon sintering main material ratio (%)

[0076]

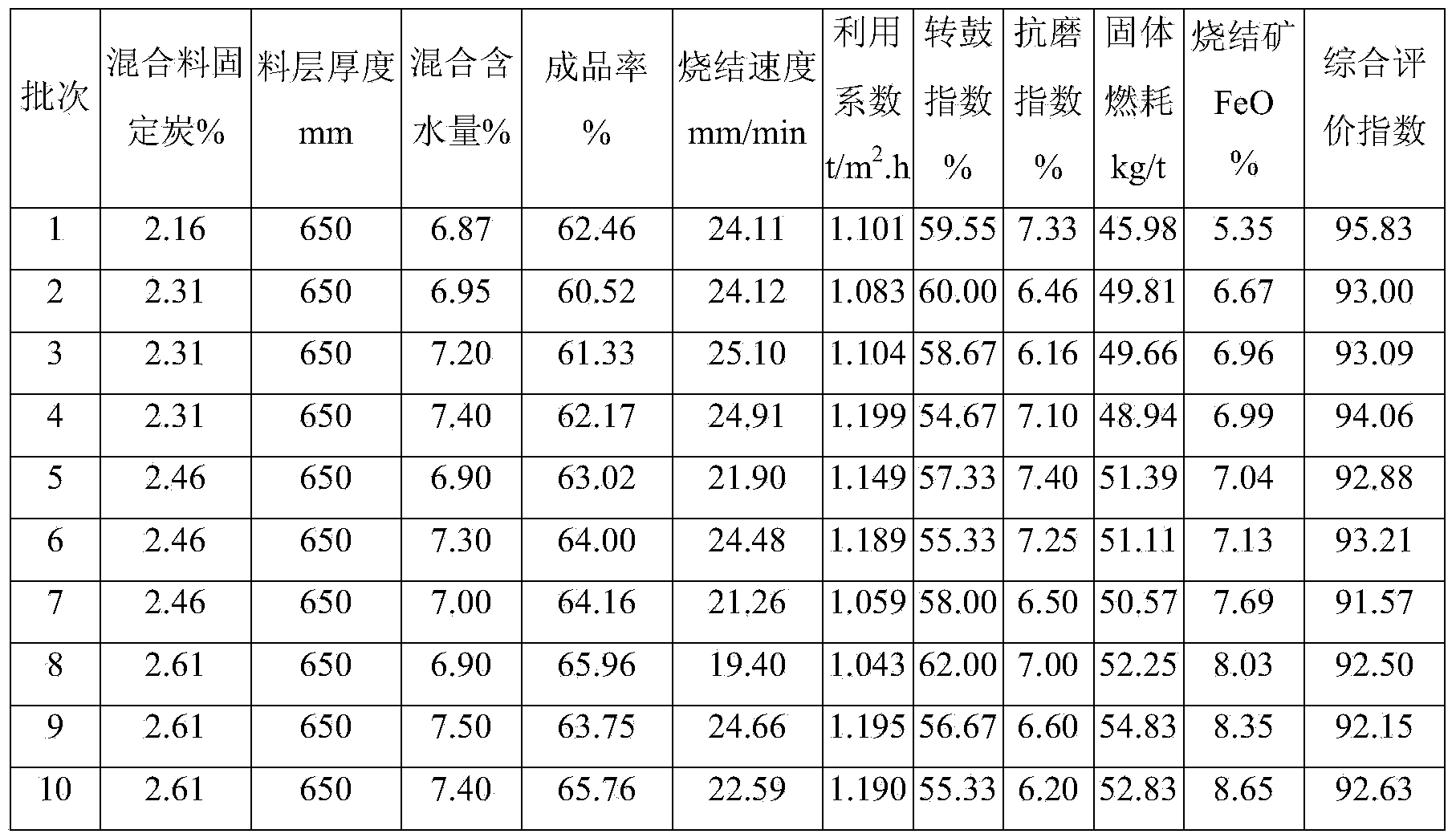

[0077] Table 3 Laboratory low-carbon sintering conditions and sintering results

[0078]

[0079] Test evaluation method: using the comprehensive index method, for multiple indicators of a system, the higher the better some indicators, called high-quality indicators, such as the drum index, utilization coefficient, etc. in this test; the lower the better some indicators , known as low-quality indicators, such as solid fuel consumption, low-temperature reduction pulverization rate, etc. The i...

Embodiment 2

[0082] 260m 2 Sintering machine industrial test:

[0083] Complete the batching and mixing according to the ratio in Table 4, and conduct 7 groups of parallel experiments. According to the existing sintering process, the steps of cloth distribution, ignition, ventilation sintering, thermal crushing, cooling, screening and sizing are carried out for sintering. The experimental results are shown in Table 5.

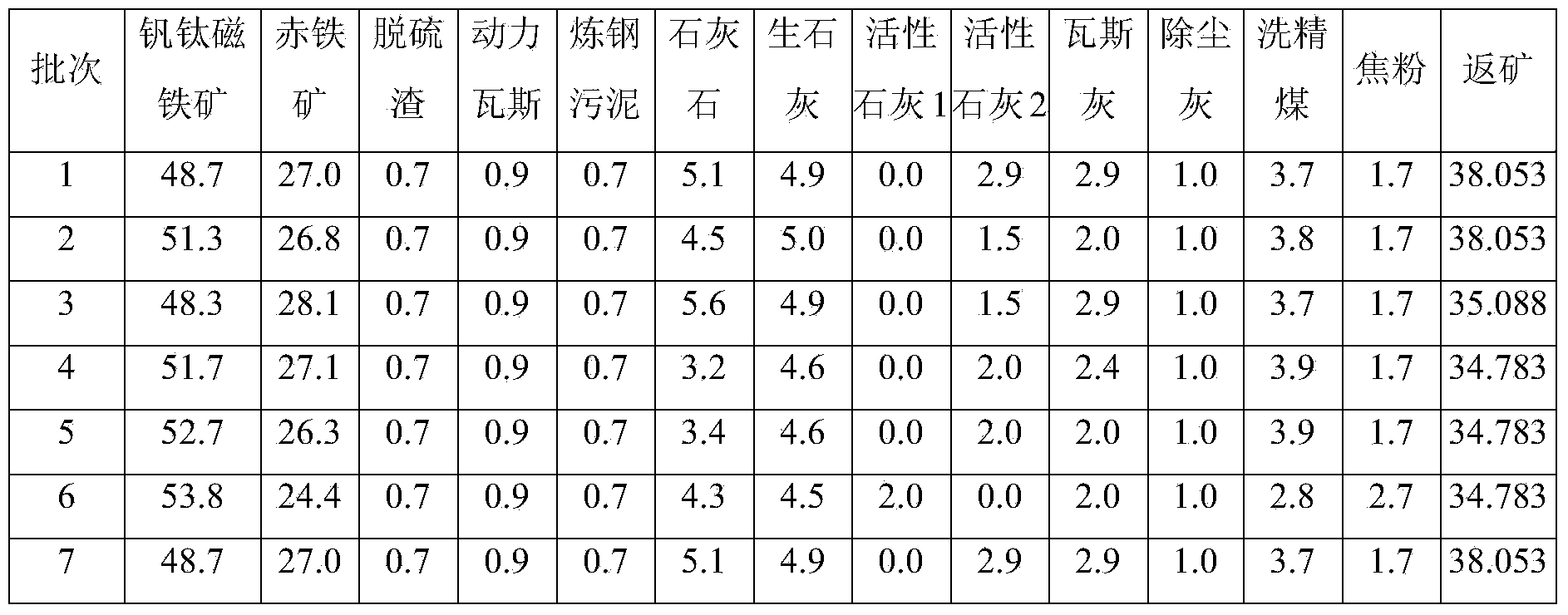

[0084] Table 4260m 2 Sintering machine low-carbon sintering material structure and proportion (%)

[0085]

[0086] Active lime 1 in Table 4 contains CaO90%, and active lime 2 contains CaO85%.

[0087] Table 5260m 2 Industrial test results of low-carbon sintering of sintering machine

[0088]

[0089] 260m in a sintering plant 2 The low-carbon sintering industrial test was carried out on the sintering machine, and 7 groups of experiments were carried out according to the raw material ratio in Table 4. The weight distribution of utilization factor 35, solid fuel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com