Low-energy-consumption method for reducing emission of dioxin in sintering waste gas

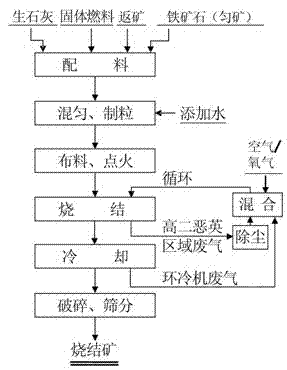

A dioxin emission reduction and low energy consumption technology, applied in waste heat treatment, energy industry, climate sustainability, etc., can solve the problems of inability to reduce the energy consumption of the sintering process, high operating costs, and limited flue gas volume. Effects of dioxin emission, improvement of sintering environment, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

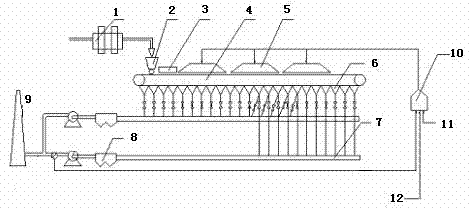

[0033] In one station the area is 132m 2 On the sintering machine, the total number of air boxes is 16, and the hot waste gas at 100~400°C is extracted from the 5 air boxes starting from the tail of the sintering machine and mixed with the hot waste gas of part of the ring cooler after dedusting, and a certain amount of air or Oxygen, keep the oxygen content in the mixed gas at 14%, control the temperature at 100°C, and send it to the surface of the sintering machine as the sintering process gas.

[0034] The material surface area covered by the circulating exhaust gas hood accounts for 90% of the total area of the sintering machine, the proportion of solid fuel in the mixture is 3.8%, and the CaO content of quicklime in the mixture is 65%.

[0035] This embodiment can reduce the total amount of dioxin emissions in the sintering process by 50-60%, the total amount of waste gas discharged by the sintering main exhaust fan by 20%-30%, and the exhaust gas discharge of the r...

Embodiment 2

[0037] In an area of 180m 2 On the sintering machine, the total number of bellows is 21. The 100-400°C hot exhaust gas from the 7 bellows starting from the tail of the sintering machine is extracted and mixed with the hot exhaust gas of part of the ring cooler after dust removal, and a certain amount of air or air is added. Oxygen, keep the oxygen content in the mixed gas at 18%, control the temperature at 150°C, and send it to the surface of the material layer of the sintering machine as the sintering process gas.

[0038] The material surface area covered by the circulating exhaust air hood accounts for 80% of the total area of the sintering machine, the proportion of solid fuel in the mixture is 3.3%, and the CaO content of quicklime in the mixture is 75%.

[0039] This embodiment can reduce the total amount of dioxin emissions in the sintering process by 60-70%, the total amount of waste gas discharged by the sintering main exhaust fan by 30%-40%, and the exhaust gas...

Embodiment 3

[0041] In one station the area is 430m 2 On the sintering machine, the total number of bellows is 23, and the hot exhaust gas at 100~400°C is extracted from the tail of the sintering machine and counted from the 10 bellows at the head. After dust removal, it is mixed with the hot exhaust gas of part of the ring cooler, and a certain amount of air or Oxygen, keep the oxygen content in the mixed gas at 22%, control the temperature at 200°C, and send it to the surface of the material layer of the sintering machine as the sintering process gas.

[0042] The material surface area covered by the circulating exhaust gas hood accounts for 60% of the total area of the sintering machine, the proportion of solid fuel in the mixture is 3.1%, and the CaO content of quicklime in the mixture is 85%.

[0043] This embodiment can reduce the total amount of dioxin emissions in the sintering process by 70-80%, the total amount of waste gas discharged by the sintering main exhaust fan by 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com