Composite agglomeration technology of iron powdered ore

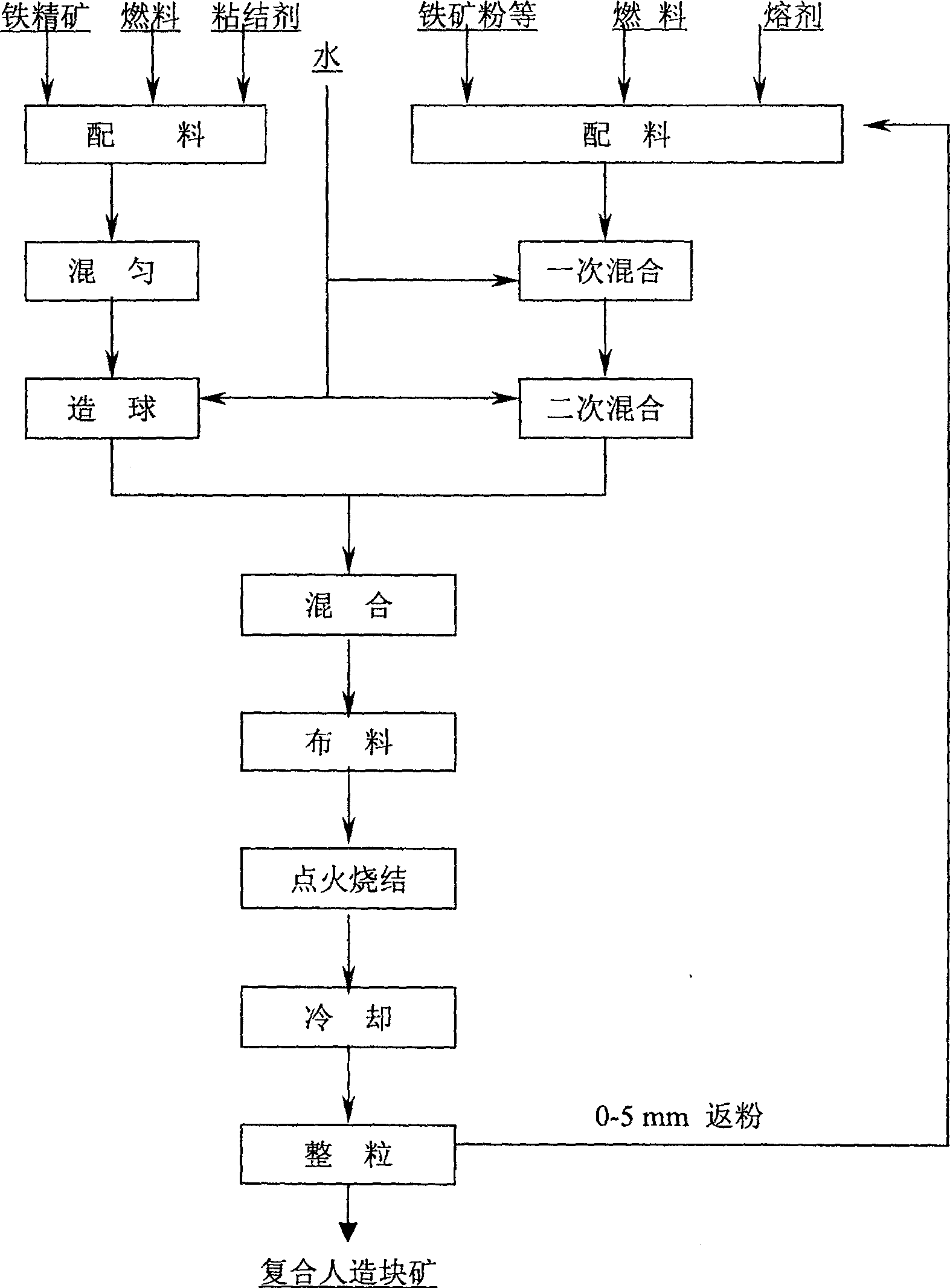

A technology of composite agglomeration and iron ore powder, which is applied in the field of iron and steel metallurgy, can solve the problems that the sintering method is not suitable for large-scale processing of fine-grained iron concentrates, affects the production process of blast furnaces, and the shortage of acid pellets, etc., and achieves the improvement of vertical Effects of sintering speed and utilization coefficient, reduction of energy consumption of sintered solids, and reduction of energy consumption of sintering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. The fine-grained iron ore concentrate in the sintering mixture accounts for 35.5%, and 1.0% of quicklime is added to it without adding fuel. It is pelletized separately in the disc pelletizer, and the alkalinity is kept at 0.6; the fine ore part in the mixture accounts for 64.5%, which is mixed with 5.0% coke powder and 4.38% quicklime, with an alkalinity of 3.2, for primary and secondary mixing. The total alkalinity of the control mixture is 2.25. Mix the prepared green balls and the secondary mixture evenly, spread them in a sintering cup, ignite and sinter. The sintering negative pressure is 7kPa, and the material layer height is 700mm. The finished product rate of sintered ore is 81.11%, the drum strength is 63.52%, and the utilization factor is 2.212t.m -2 .h -1 , The vertical sintering speed is 22.57mm / min.

[0022] 2. The fine-grained iron ore concentrate in the sintering mixture accounts for 30%, and 1.0% of coke powder is added to it, without adding quic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com