Airflow classifying and airflow drying process for coking coal

A technology of airflow classification and airflow drying, which is applied in the direction of separating solids from solids with airflow, drying solid materials, and drying solid materials by heating. Environmental pollution, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

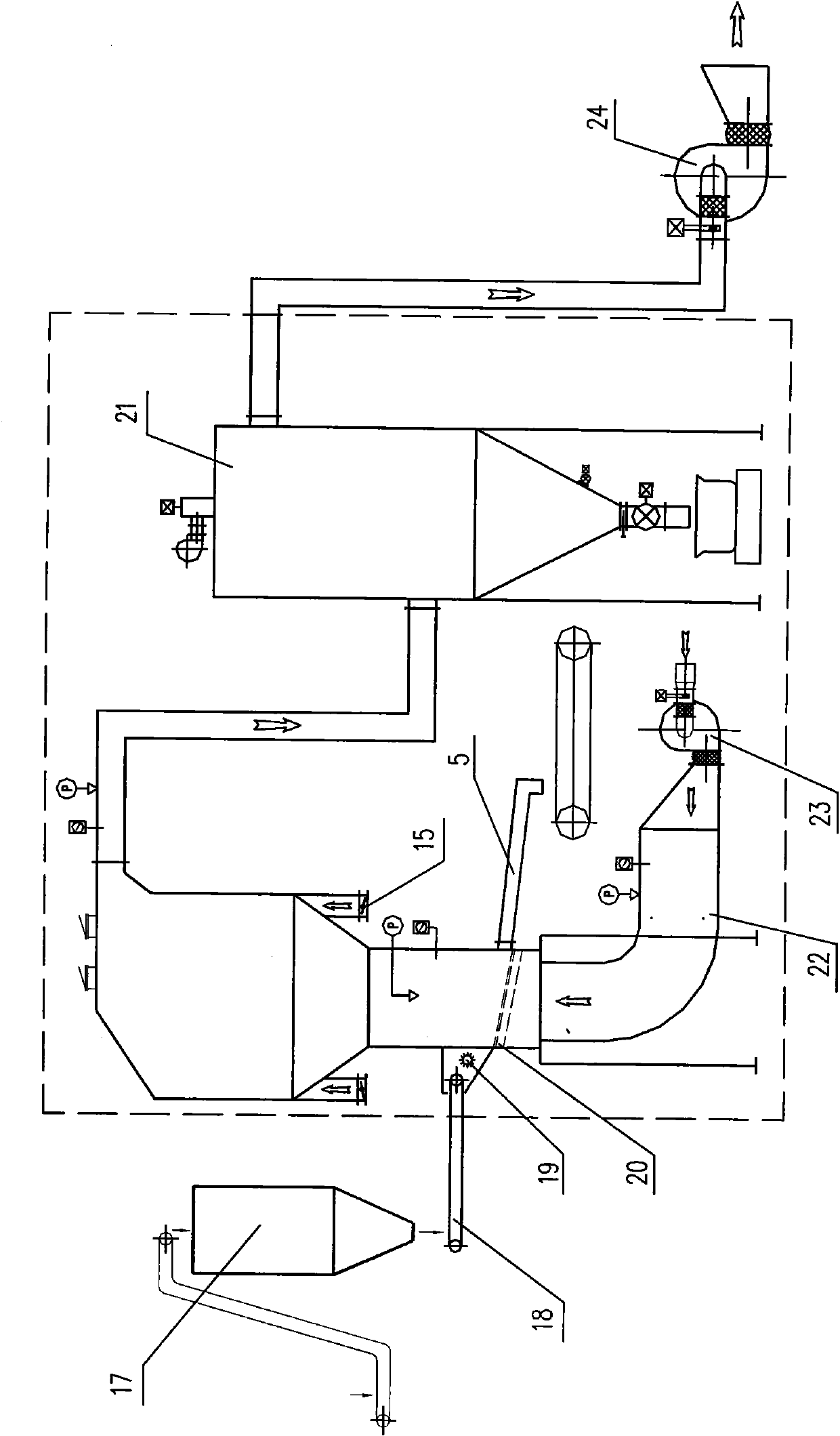

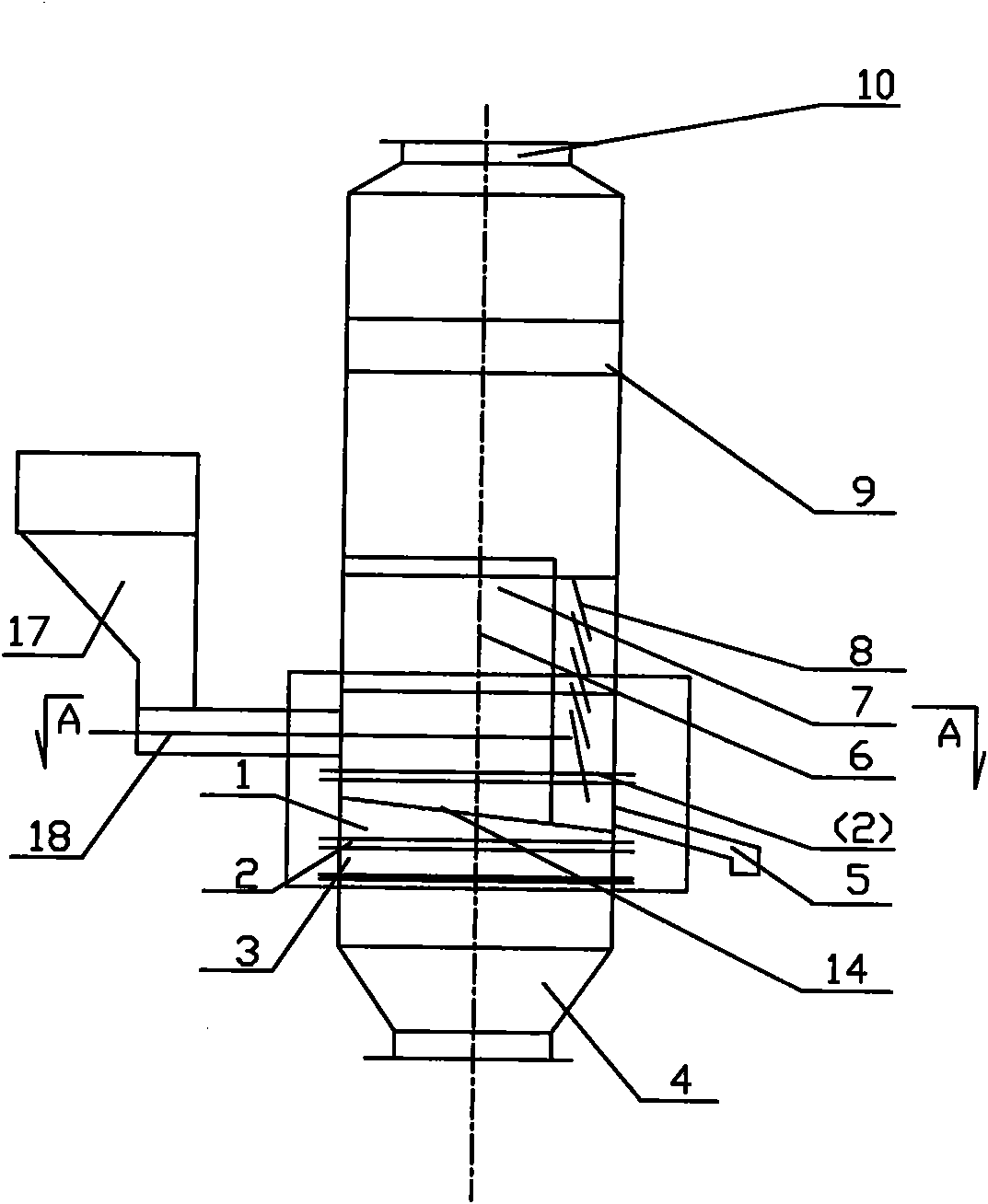

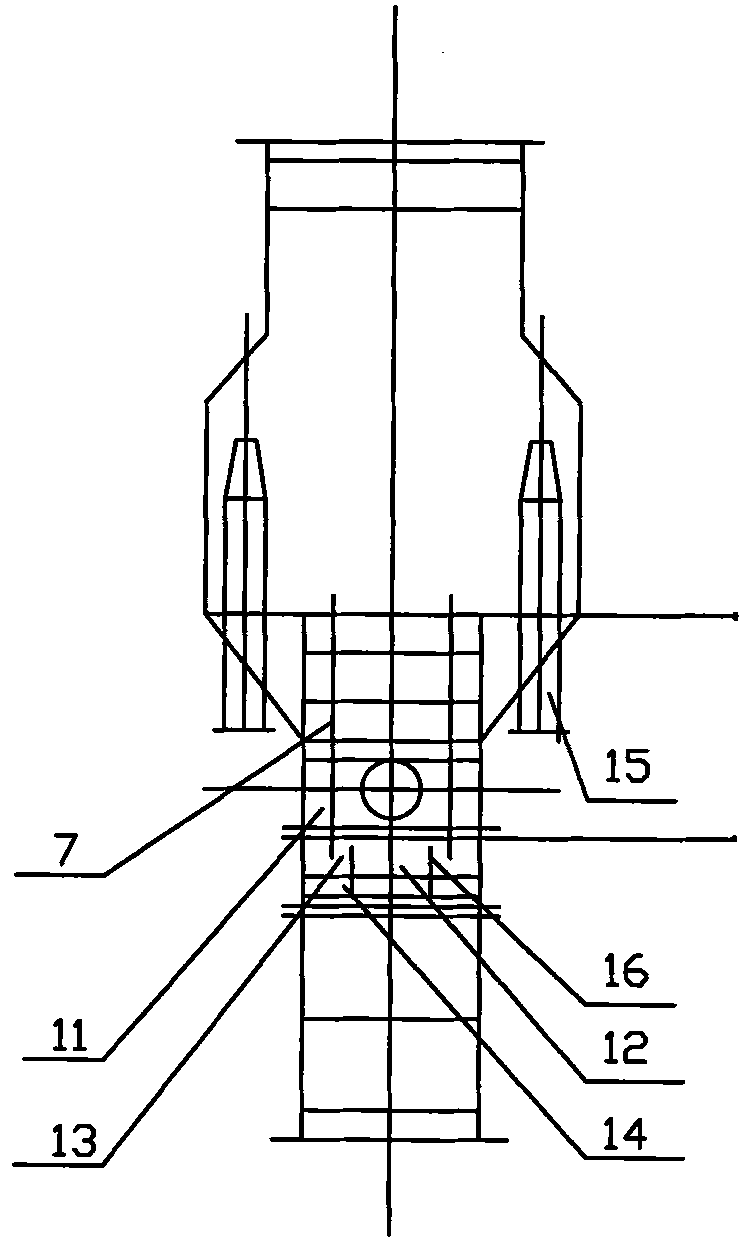

[0025] The airflow classification and airflow drying process of coking coal material utilizes the characteristics of bulk materials in fluidized state, and this process has dual functions of grading and drying coking coal material. It can adapt to various requirements by adjusting the structure size and fluidization speed.

[0026] See figure 1 , is that the device of the present invention consists of two parts, the main body of the fluidized vibrating bed and the classification collection device. The drying and preliminary classification of coal materials are completed in the fluidized vibrating bed; the reclassification of small particles is completed by the classification collection device. The grading and drying process is described as follows:

[0027] The coal material enters the main body 20 of the fluidized vibrating bed from the buffer bin 17 through the quantitative feeding device 18 and the raw material throwing device 19. The coal material is dried and divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com