Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid flying dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

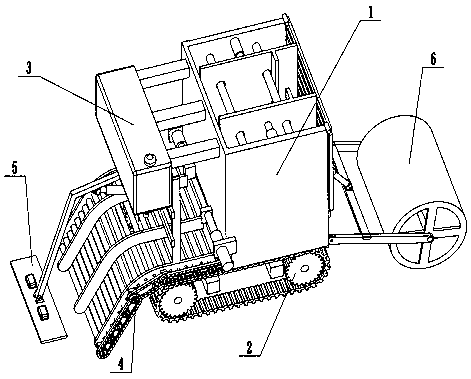

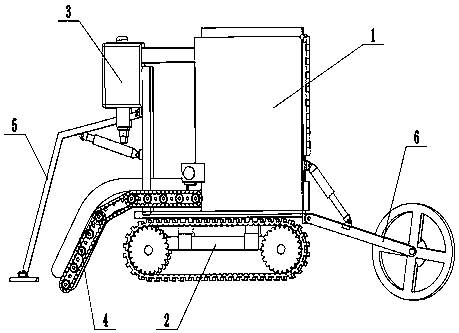

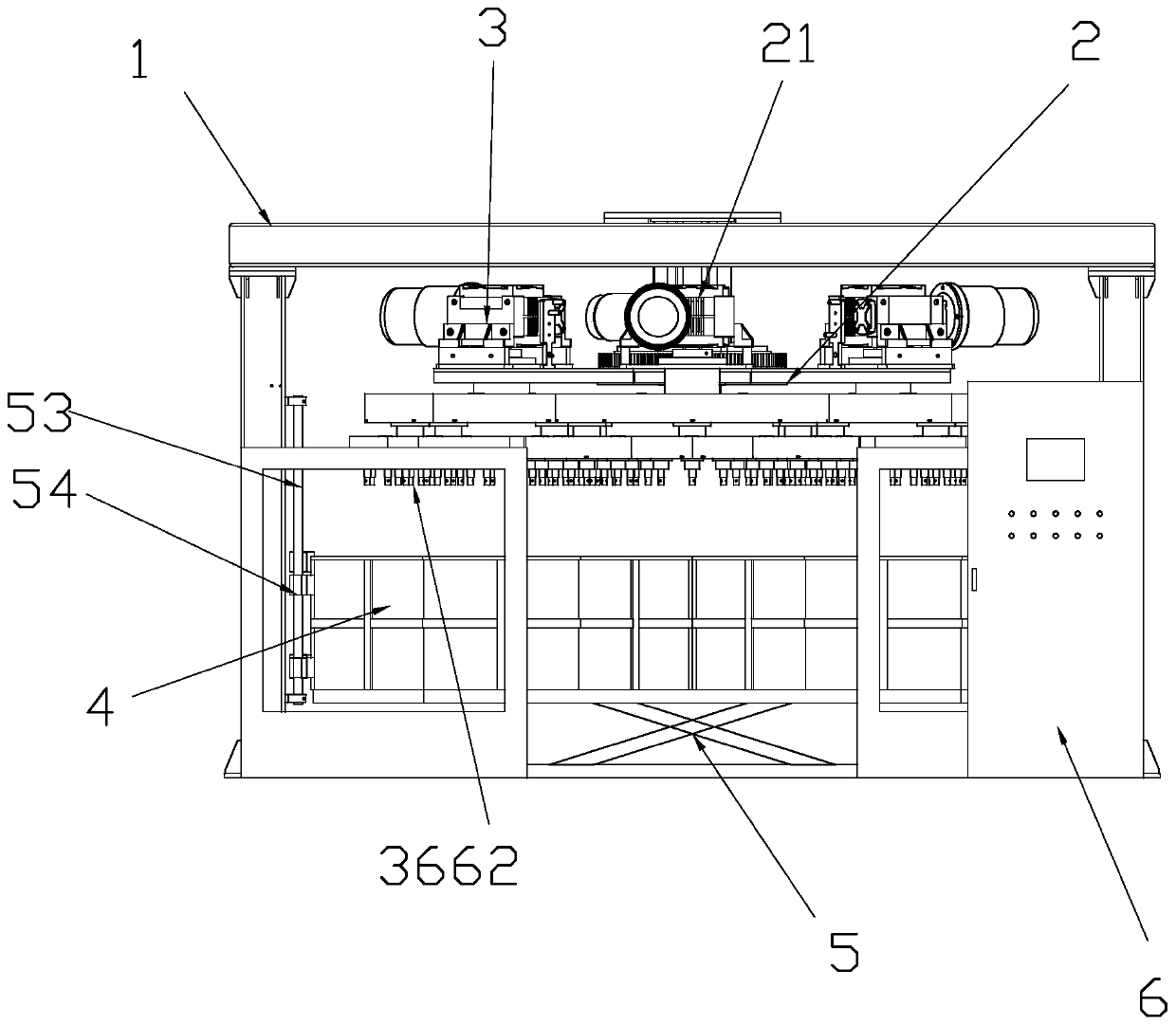

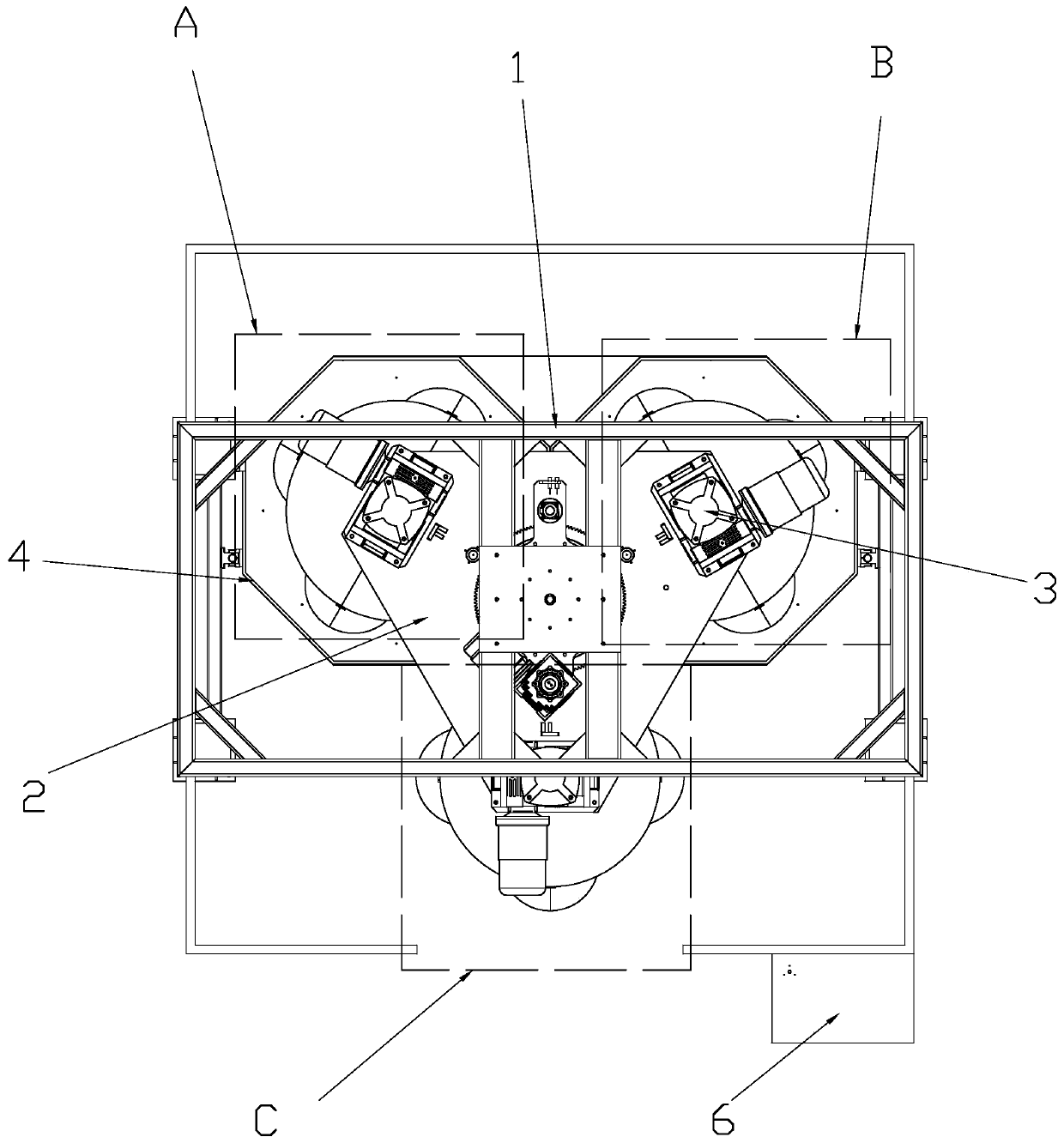

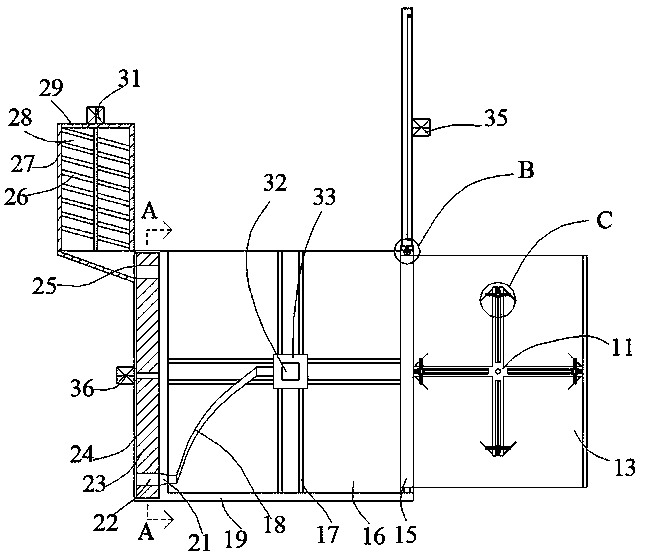

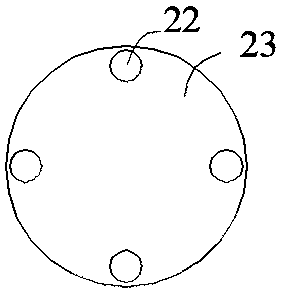

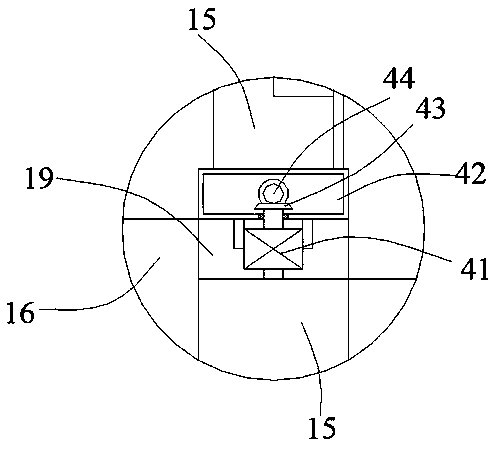

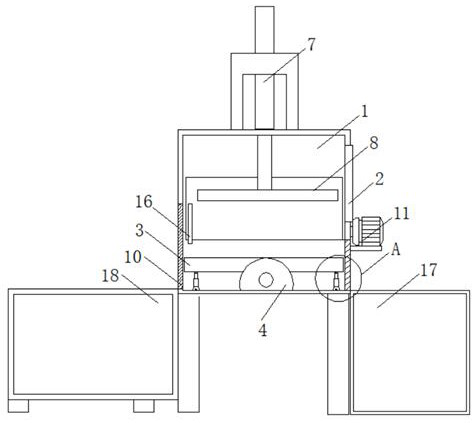

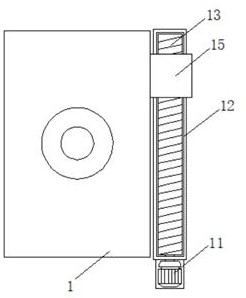

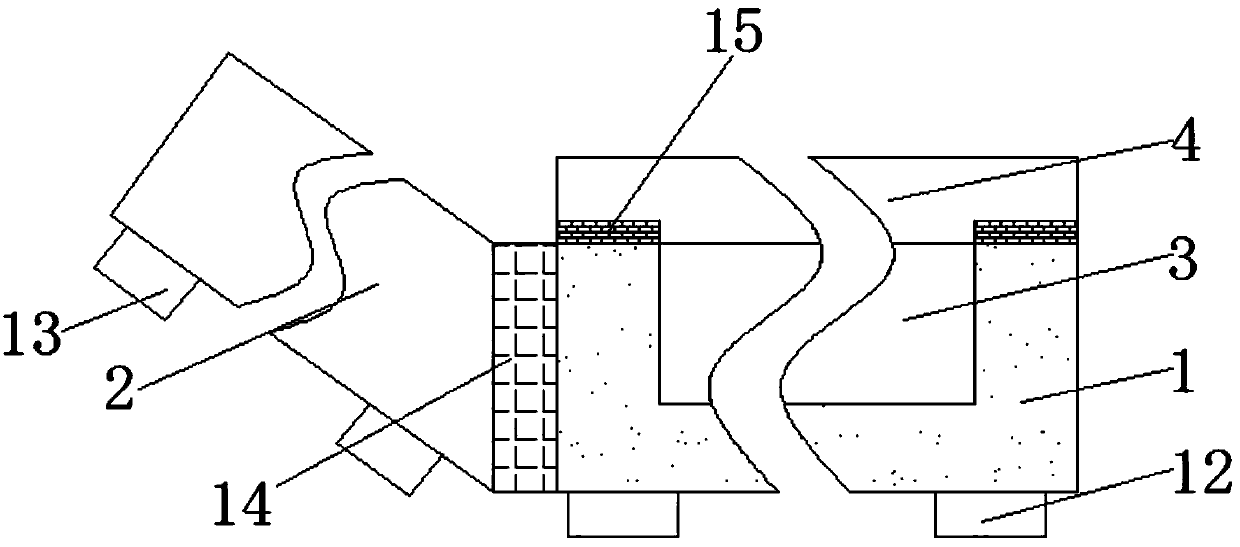

Automatic road floor tile laying equipment

InactiveCN110485241AImprove efficiencyFast layingRoads maintainenceMechanical engineeringWater spray

Owner:陈达

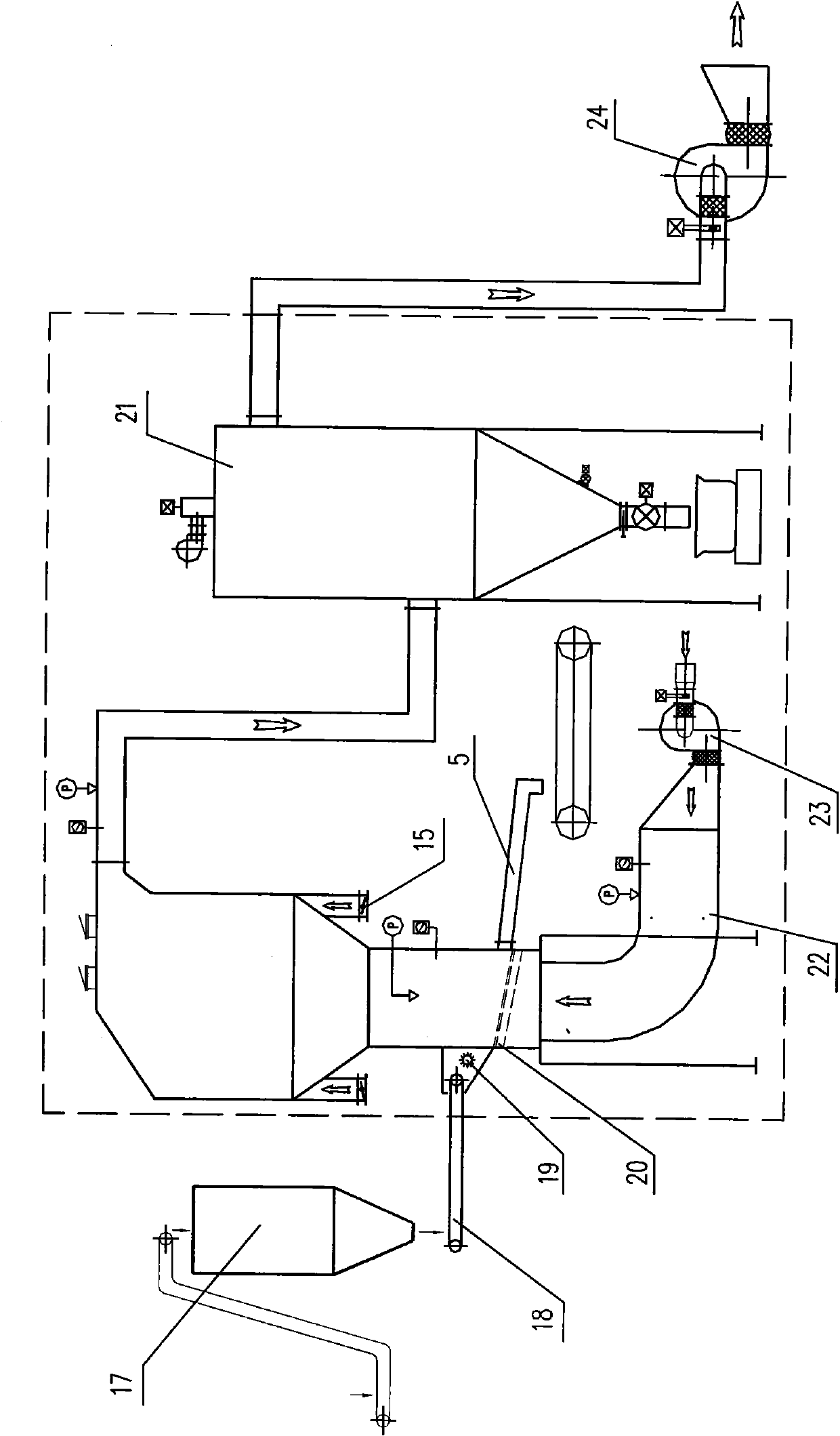

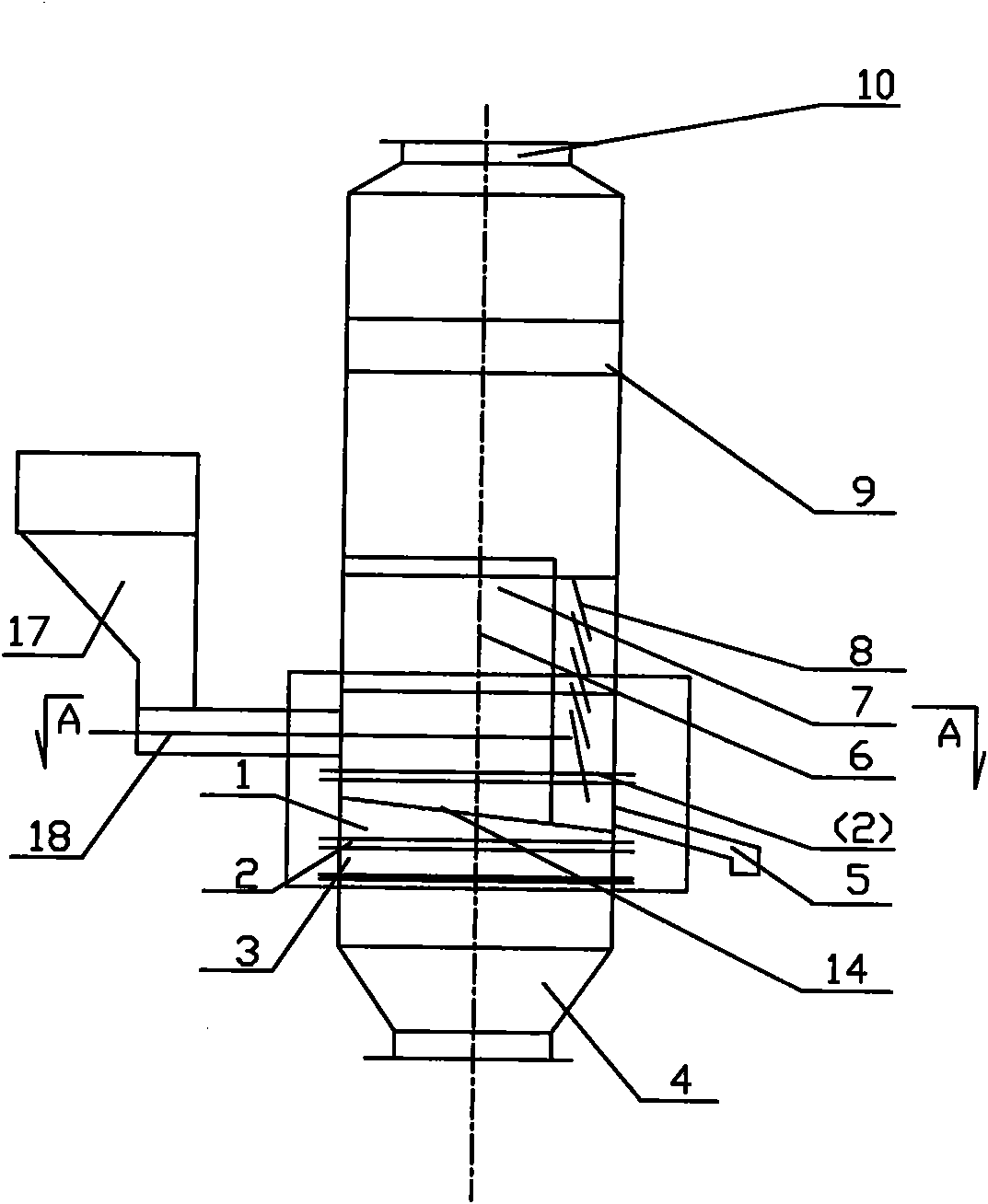

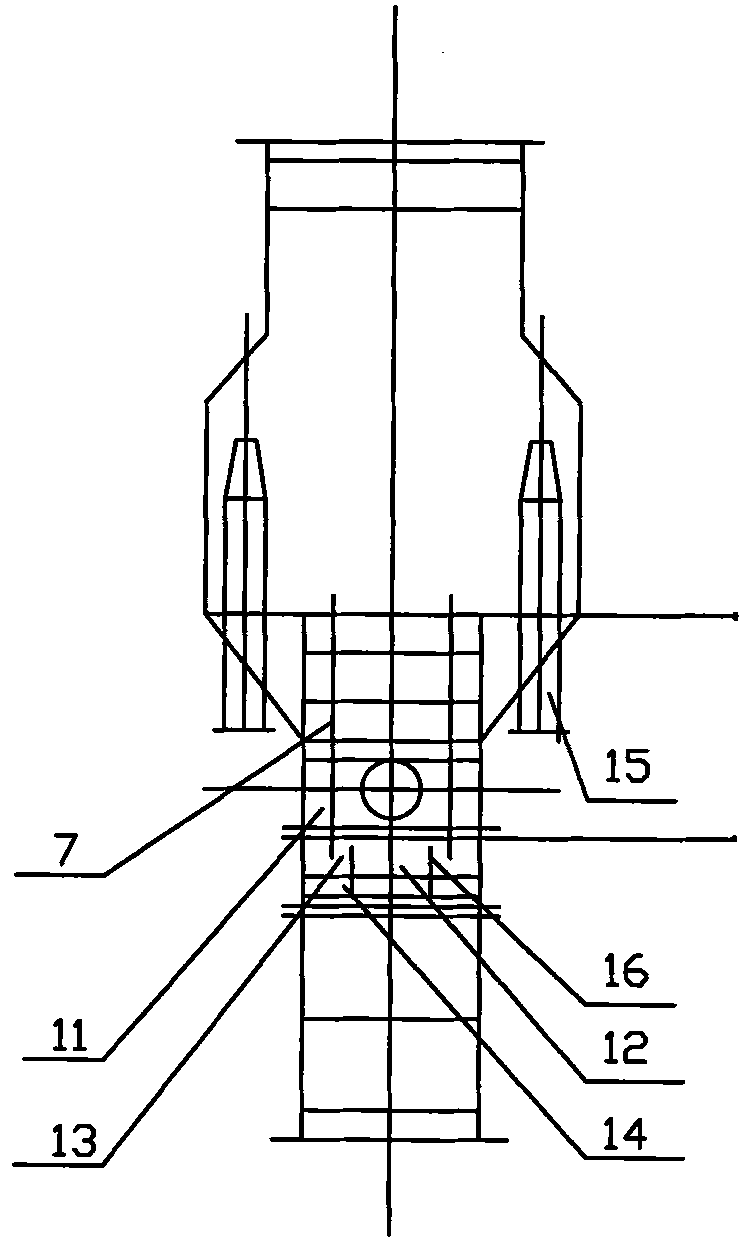

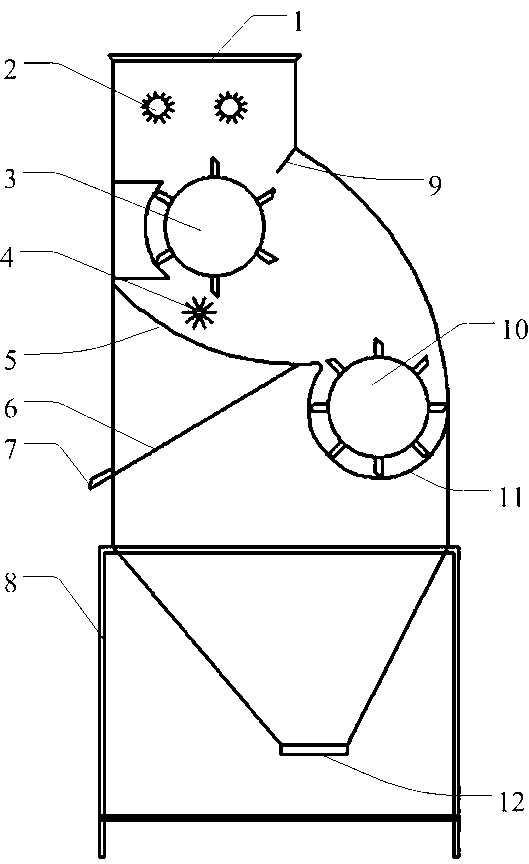

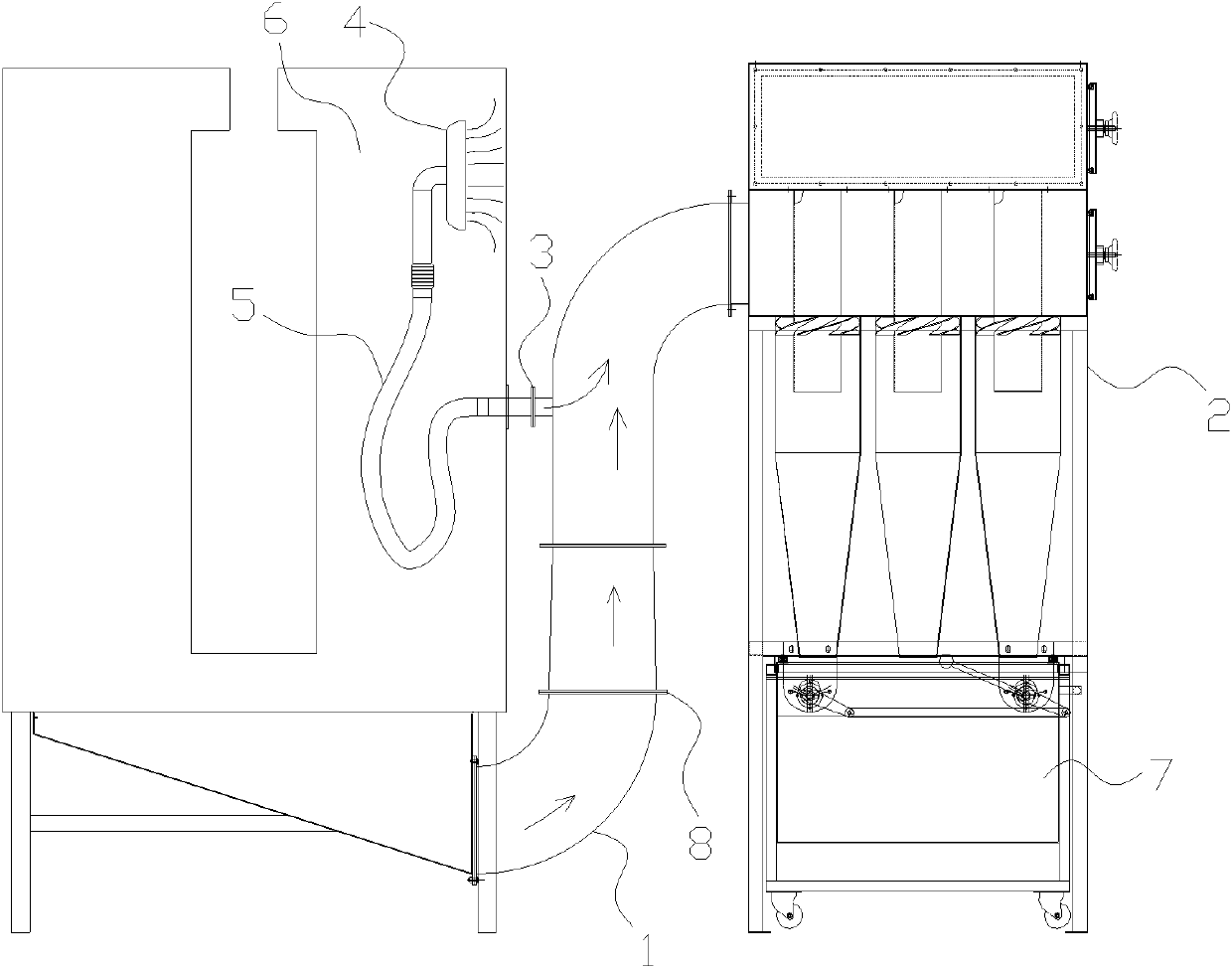

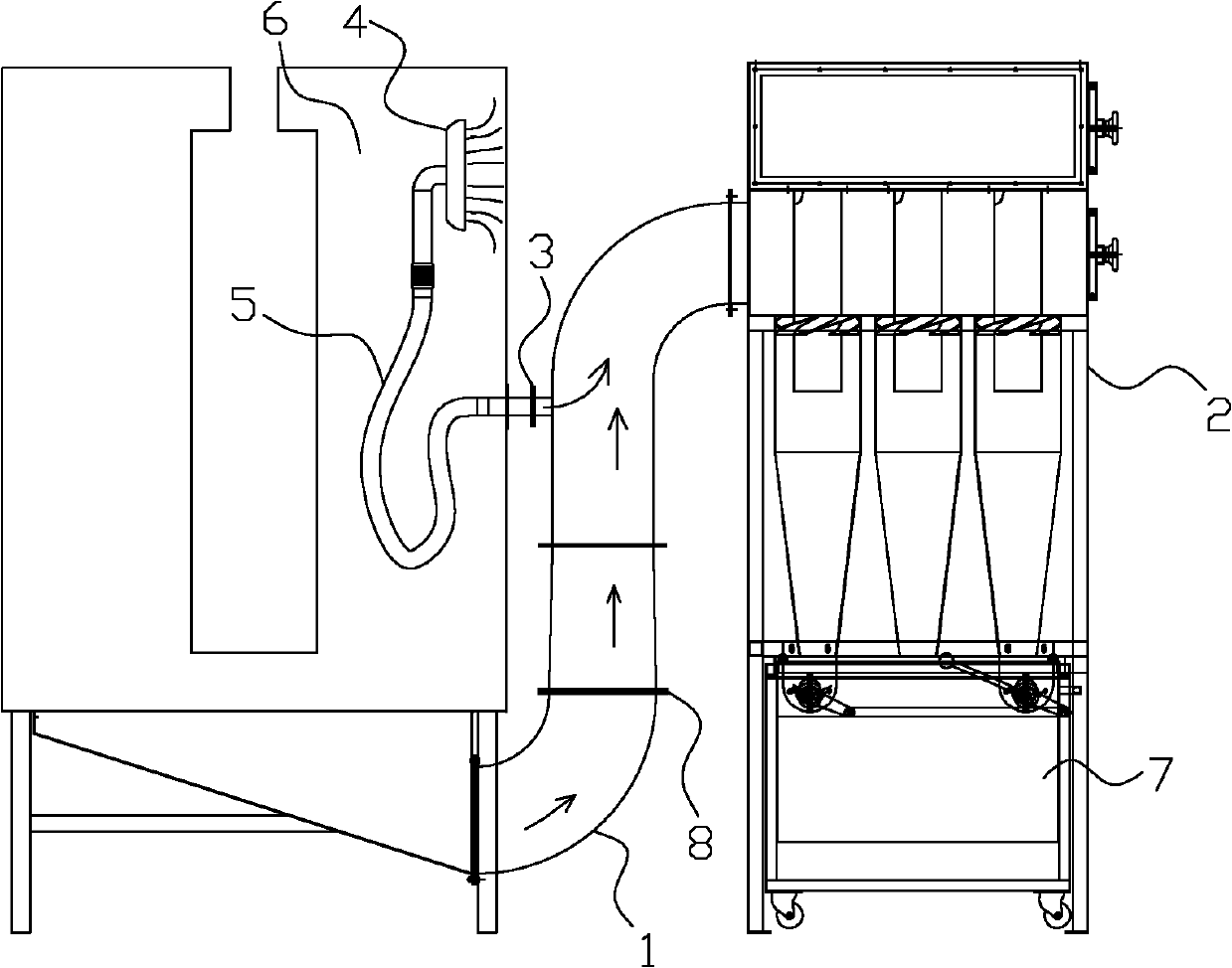

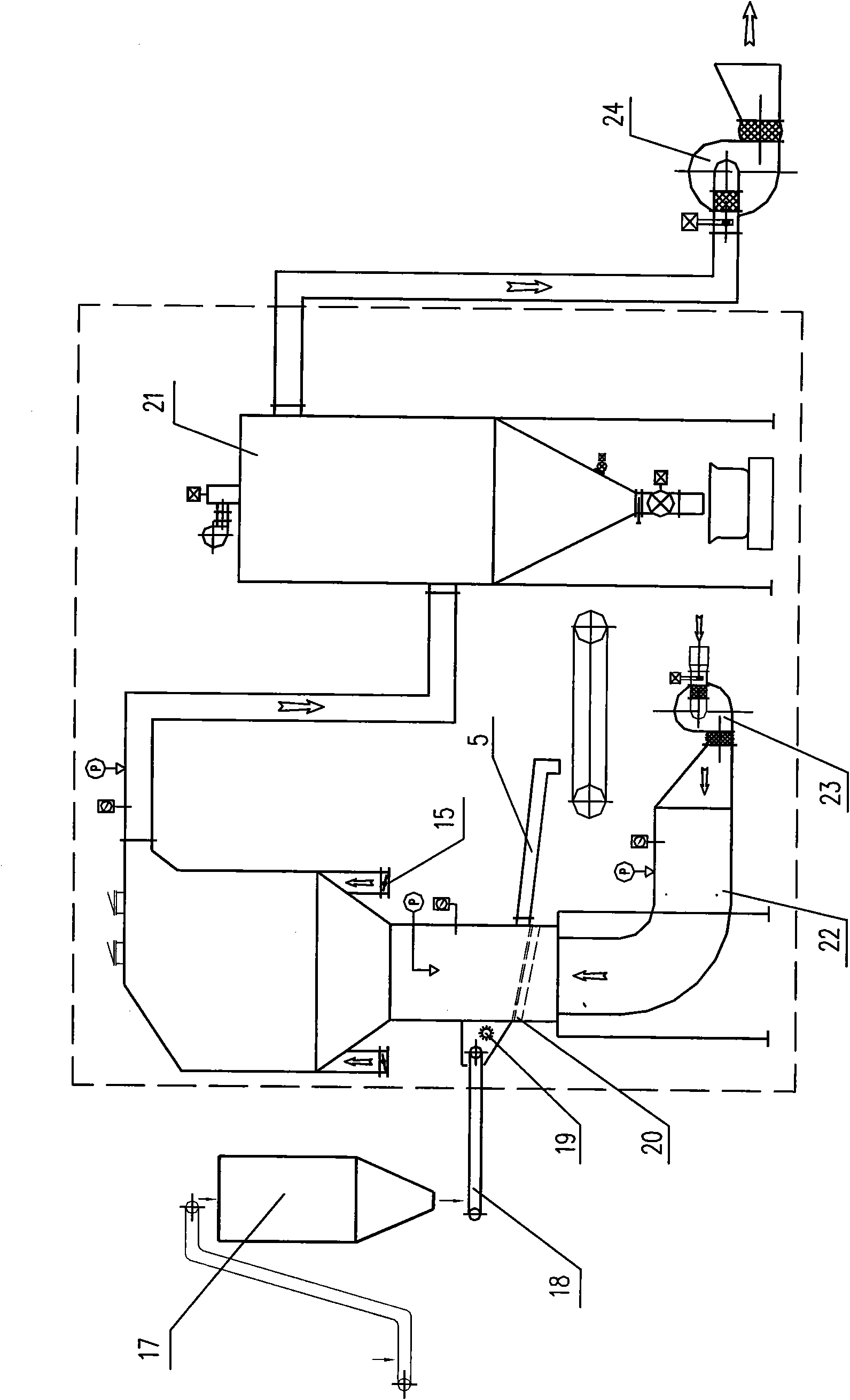

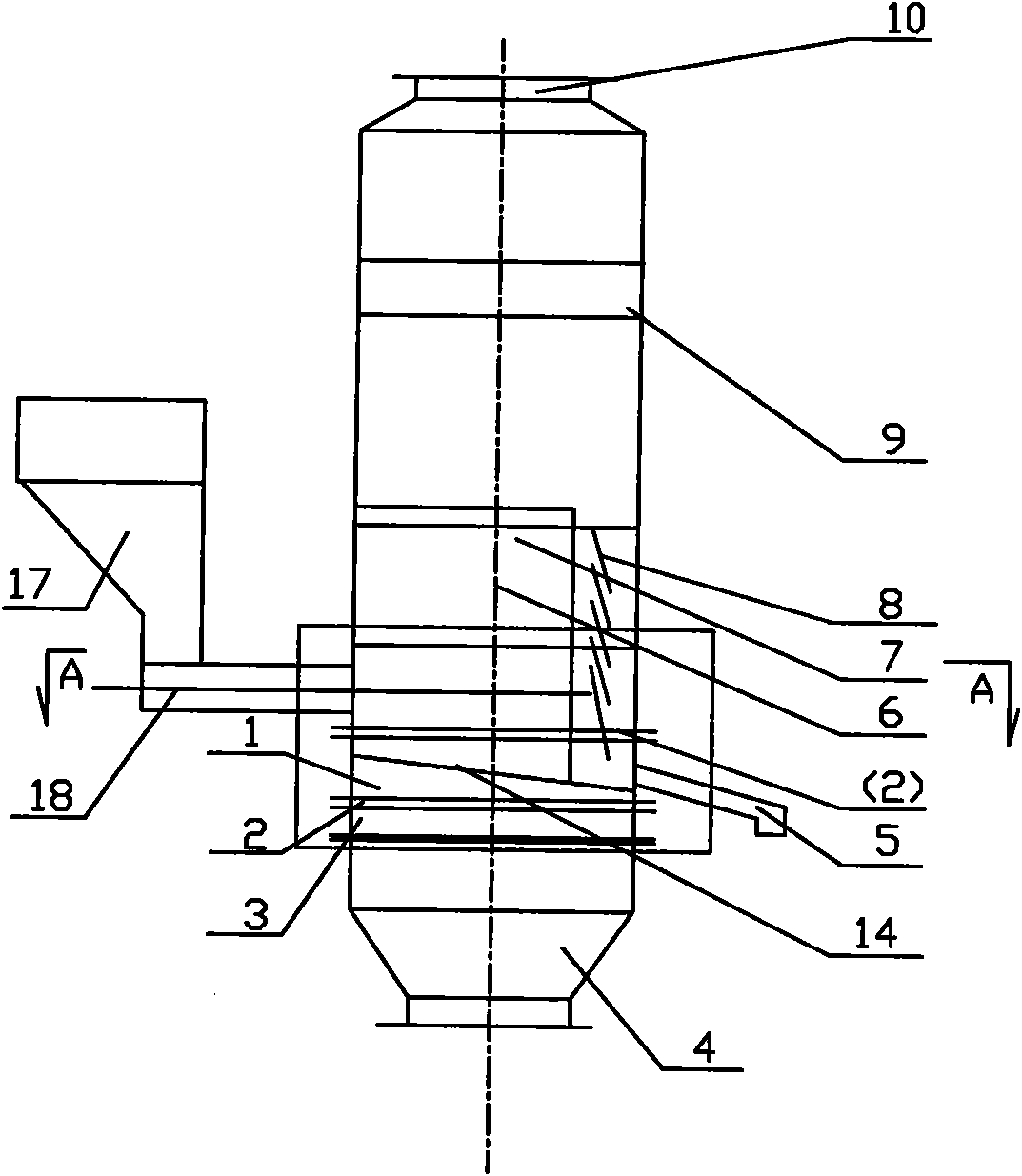

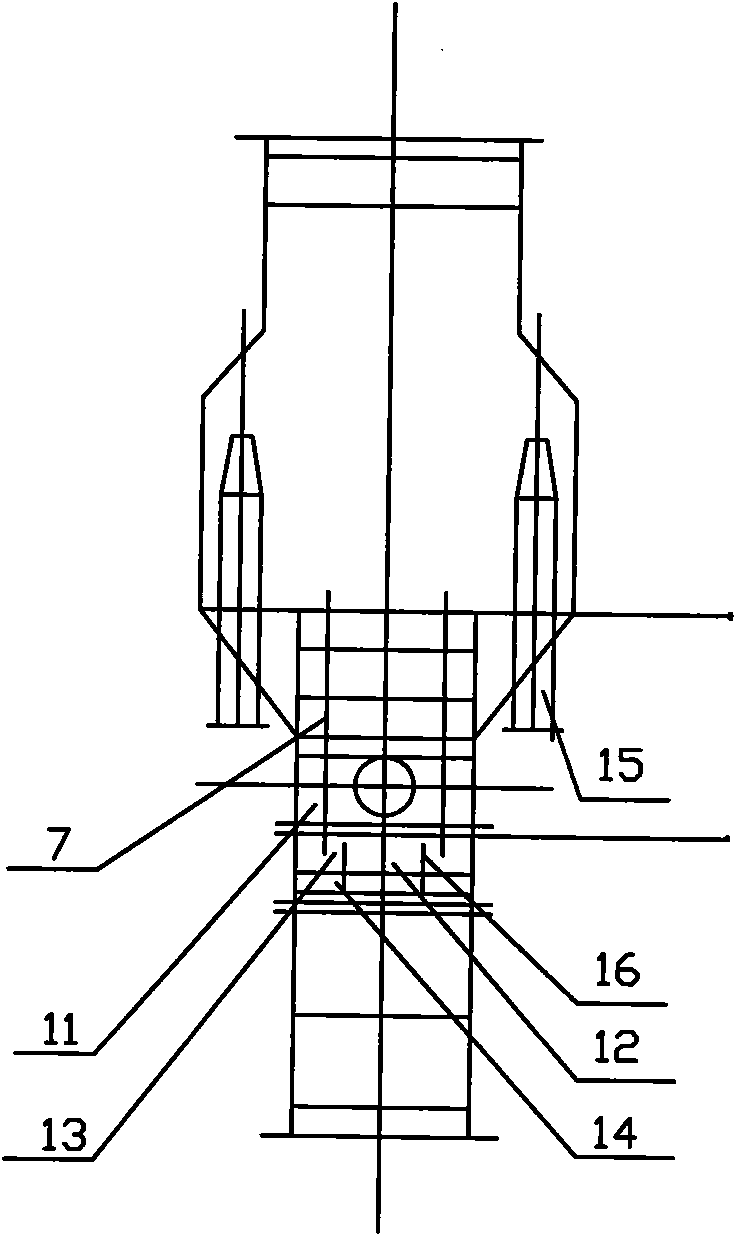

Airflow classifying and airflow drying process for coking coal

ActiveCN102019275ASave energyReduce pollutionDrying solid materials with heatGas current separationWastewaterProcess engineering

The invention relates to an airflow classifying and airflow drying process for coking coal. In the process, coke oven flue waste gas is taken as a drying medium, the fluidization technology is adopted for drying the coal, and simultaneously the coal is classified into several classes according to particle sizes by an airflow separation principle. A device consists of a vibrating fluidized bed main body and a classifying collection device, wherein the vibrating fluidized bed main body comprises a primary air supply device, a vibrating main box body with an air distributing plate, a sedimentation classifying section and a drying section with a secondary air inlet; and the classifying collection device completes the final collection of small-particle materials through a group of dust collection devices or several groups of duct collection devices with different structures according to different requirements of the process on the classification of the particle sizes. The airflow classifying and airflow drying process has the advantages that: energy is saved, the wastewater generated in the coking process is reduced, the environmental pollution is lightened and the production capacity of the coke oven can be improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

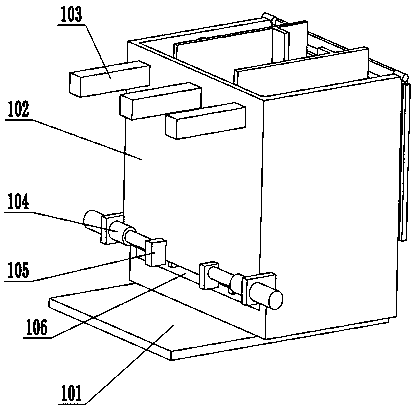

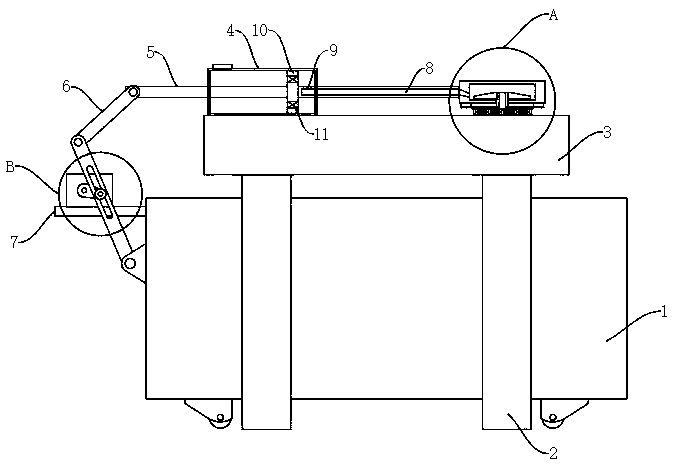

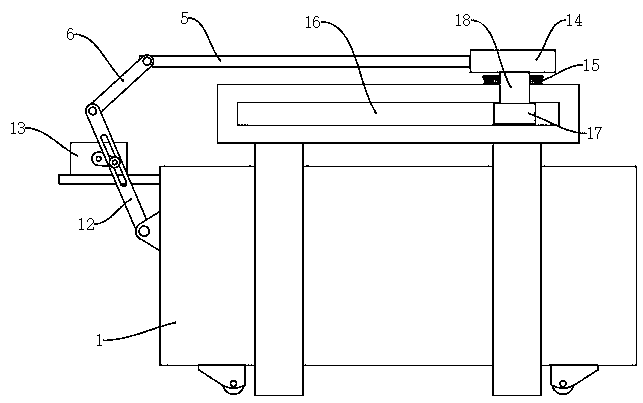

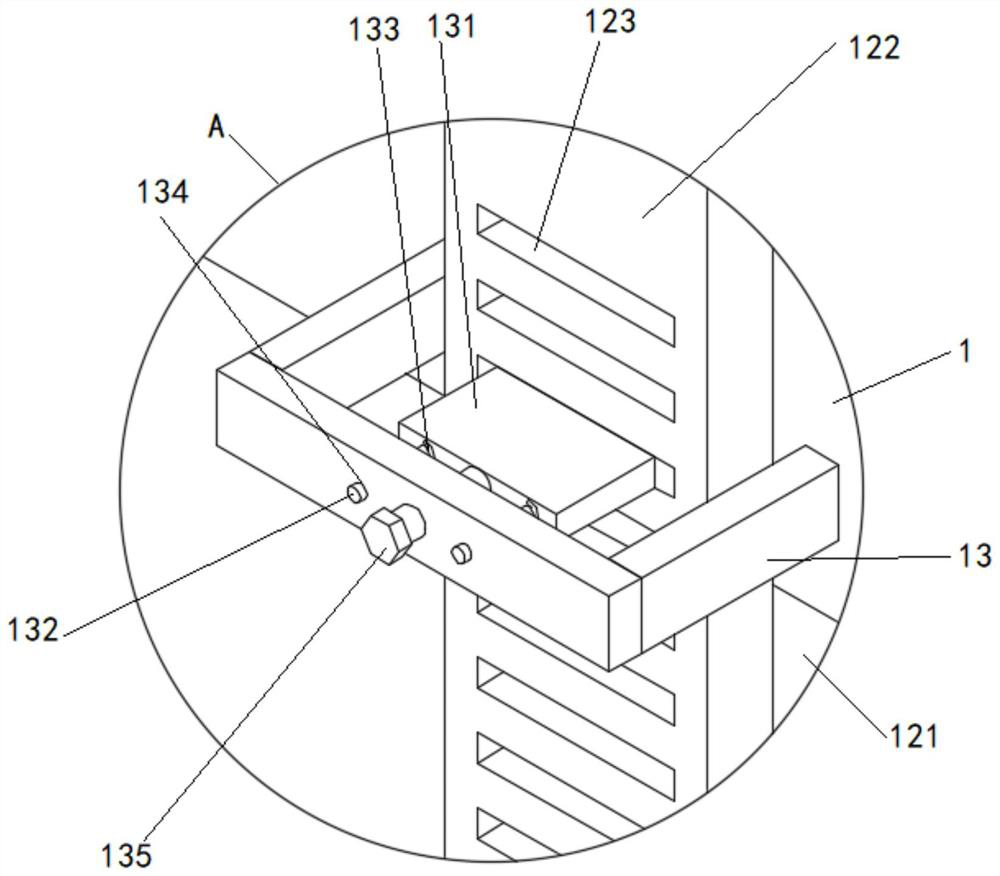

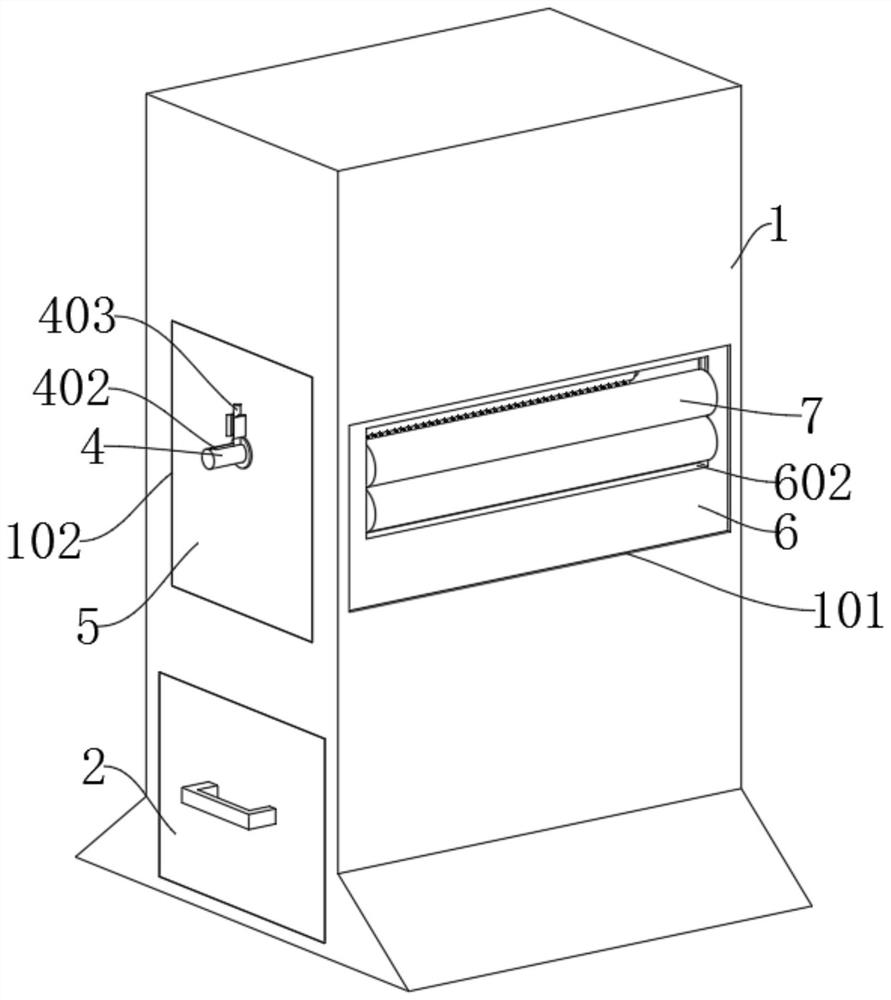

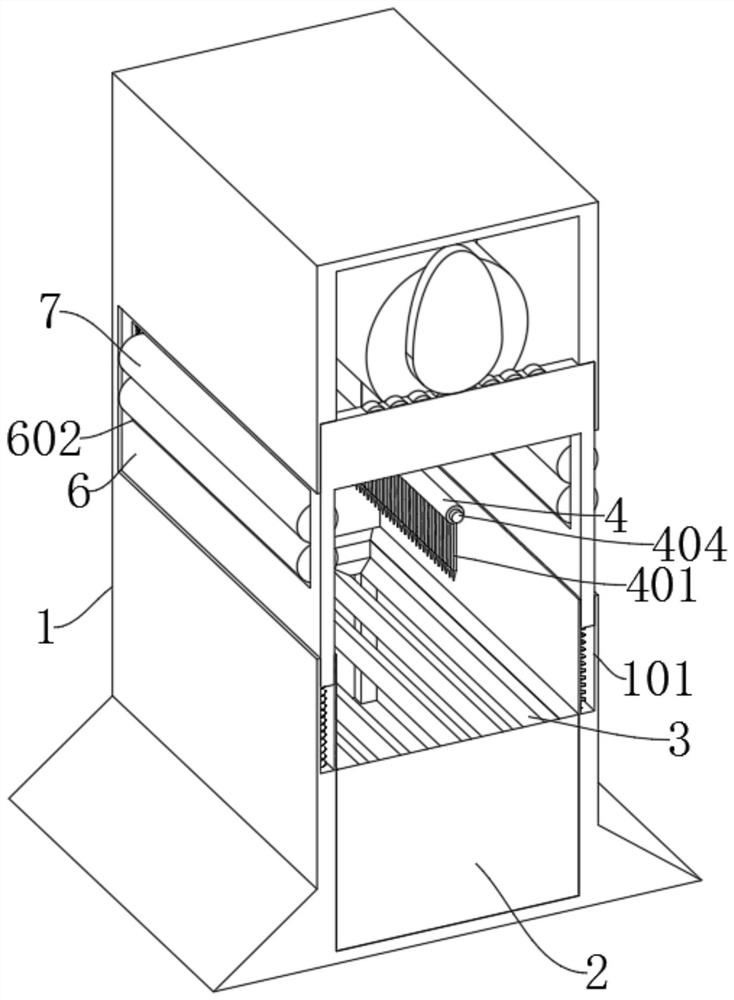

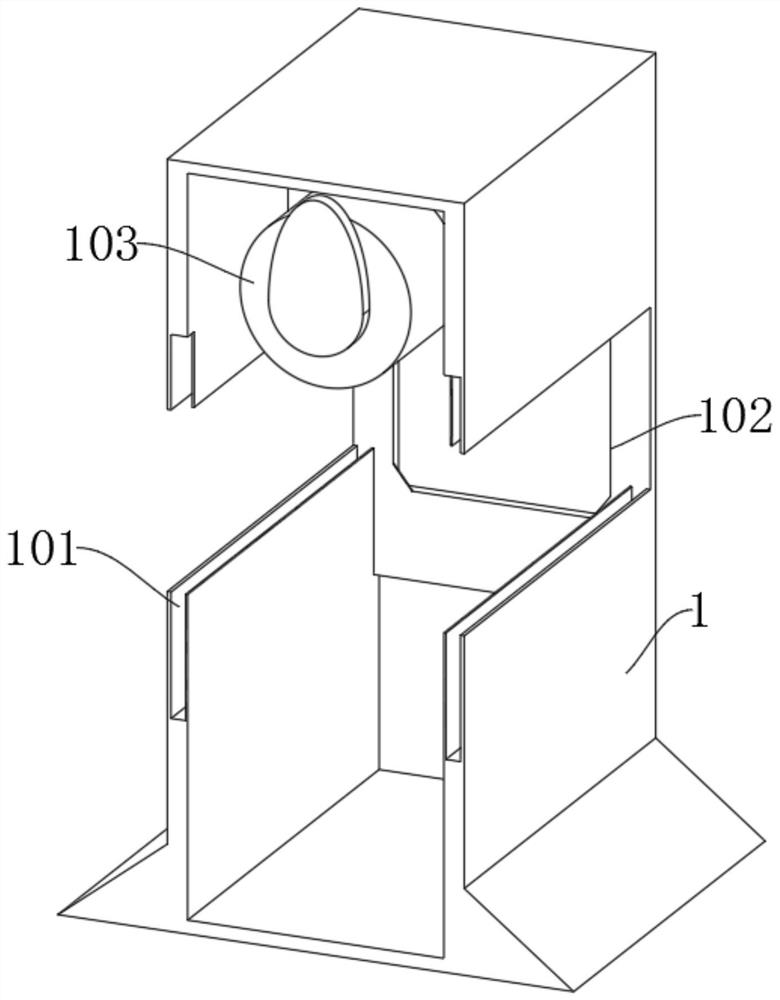

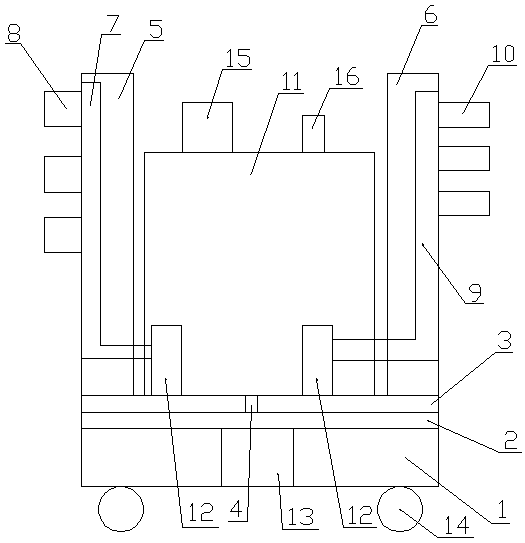

Finished product cutting auxiliary device for casting metal fittings

ActiveCN110587370AAvoid flying dustAvoid flyingWork benchesMaintainance and safety accessoriesTransverse planeEngineering

The invention discloses a finished product cutting auxiliary device for casting metal fittings. The finished product cutting auxiliary device comprises a workbench, wherein a containing box is arranged below the workbench, a sliding groove is formed in the side wall of the workbench, a sliding block is connected in the sliding groove in a sliding manner, a supporting rod is fixedly connected to the upper end of the sliding block, a transverse plate positioned above the workbench is fixedly connected to the upper end of the supporting rod, a fixing rod arranged in the horizontal direction is fixedly connected to the side wall of the transverse plate, the side wall of the containing box is provided with a driving device for driving the transverse plate to move back and forth on the workbench, the side wall of the transverse plate is provided with a cavity, the inner bottom of the cavity is provided with a plurality of rotating shafts in an equidistant penetrating mode, the lower ends ofthe rotating shafts are fixedly connected with a turntable, and the side wall of one end, located in the cavity, of each rotating shaft is fixedly connected with a blade in an equidistant mode. According to the finished product cutting auxiliary device, metal residues on the surface of the workbench can be cleaned, dust on the surface of the workbench can be blown off, and the dust is effectivelyprevented from flying off.

Owner:山东中光电光电技术有限公司

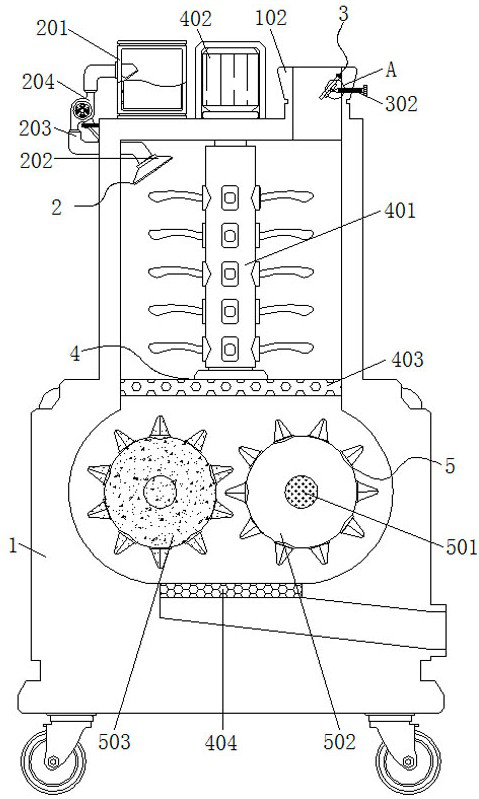

Foamed plastics crusher

InactiveCN103317616ARealize fully closed operationAvoid flying dustPlastic recyclingCrusherPulverizer

The invention discloses a foamed plastics crusher which comprises a guide roll, a rough cutting roll and a cutting roll, wherein the guide roll is arranged at a feeding hole of the foamed plastics crusher, the rough cutting roll is positioned below the guide roll, an impurity screen is arranged below the rough cutting roll, a baffle roll is arranged between the impurity screen and the rough cutting roll, an inclined baffle plate is arranged at the bottom of the impurity screen, the cutting roll is arranged at a discharging hole of the impurity screen, and a discharging screen is arranged at the circumferential surface of the cutting roll, which is close to one side of the discharging hole. According to the foamed plastic crusher disclosed by the invention, two stages of treatment such as rough cutting and precise cutting are adopted, the impurity screen for processing impurities is additionally arranged between the rough cutting part and the precise cutting part, impurities attached on foamed plastics after being roughly cut are removed, and the foamed plastics particles are accurately controlled by meshes of the discharging screen.

Owner:李荣君 +4

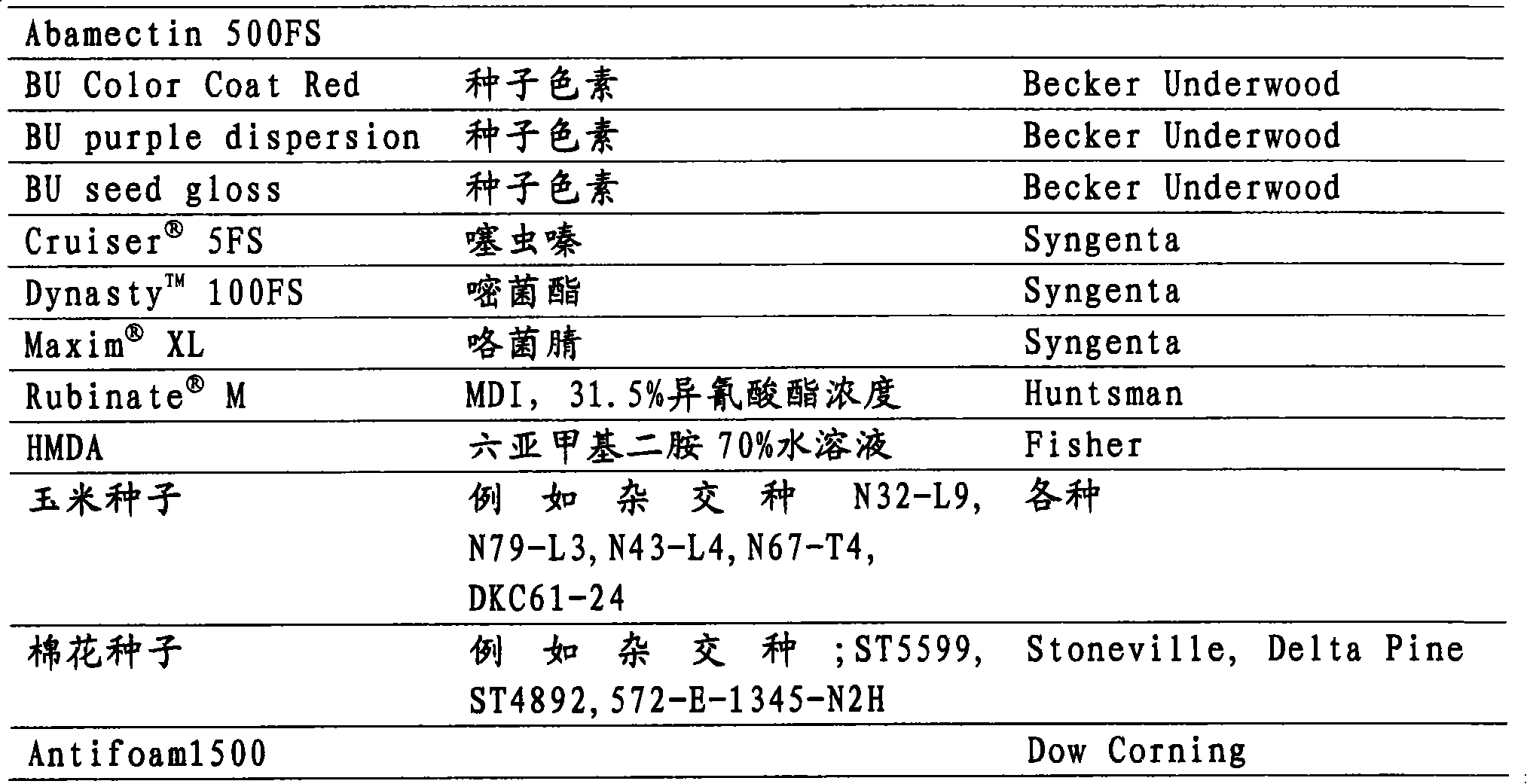

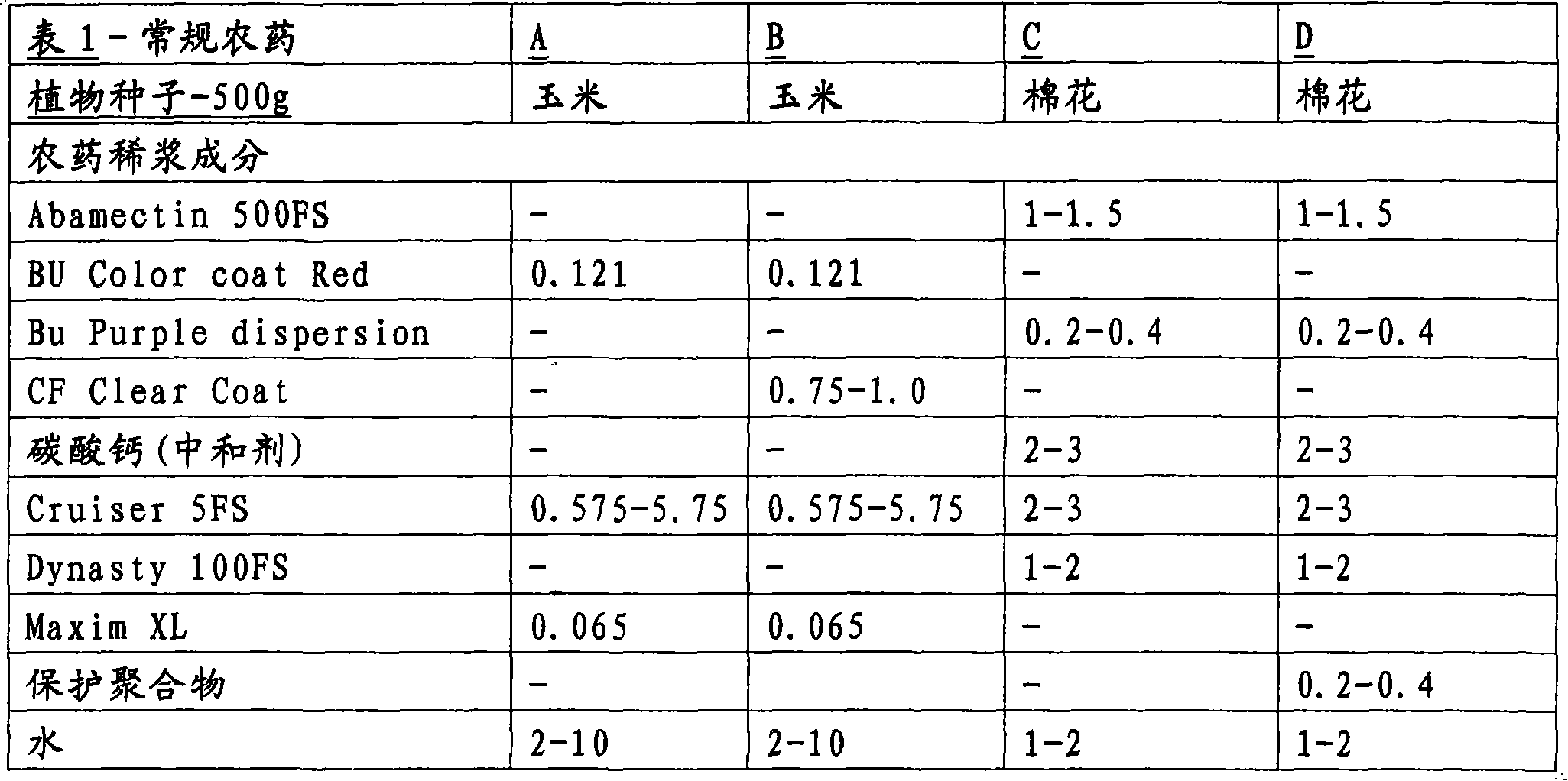

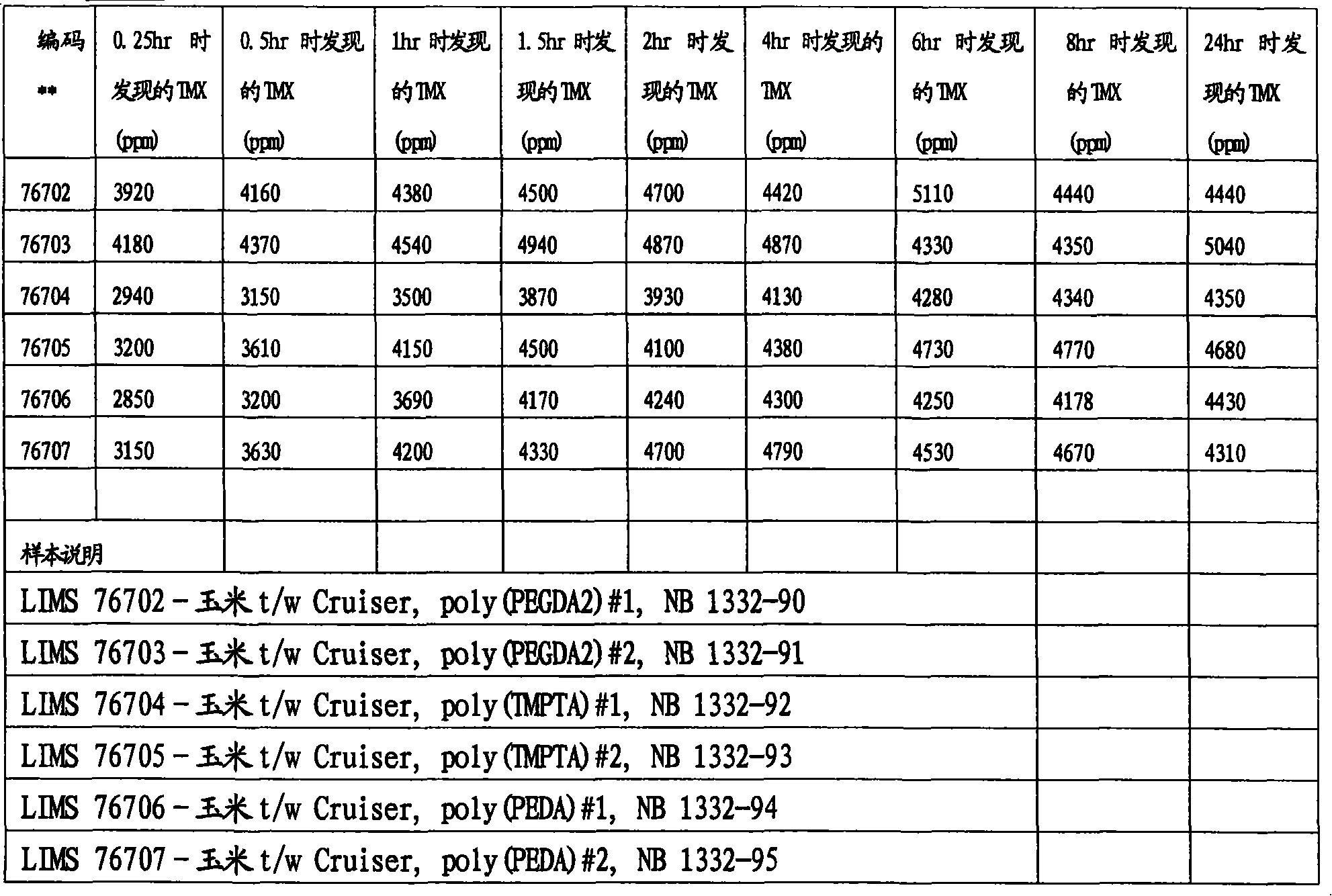

Process and composition for coating propagation material

InactiveCN101208008AEfficient captureAvoid flying dustBiocideDead animal preservationPolymer sciencePlant propagation

The present invention provides a process for coating a plant propagation material, including a seed, comprising: a.) providing a propagation material, such as seed, to be coated; b.) applying to the propagation material a composition comprising at least one reactant having reactive functionality and, optionally, at least one active ingredient; and c.) polymerising, crosslinking, curing or otherwise reacting the reactant having reactive functionality on the surface of the plant propagation material to form a coating thereon which may encompass an a.i., when present. The present invention further provides a method for enhancing the safety, quality and / or viability of a plant propagation material, including a seed, comprising providing a coated material having less dust-off.

Owner:SYNGENTA PARTICIPATIONS AG

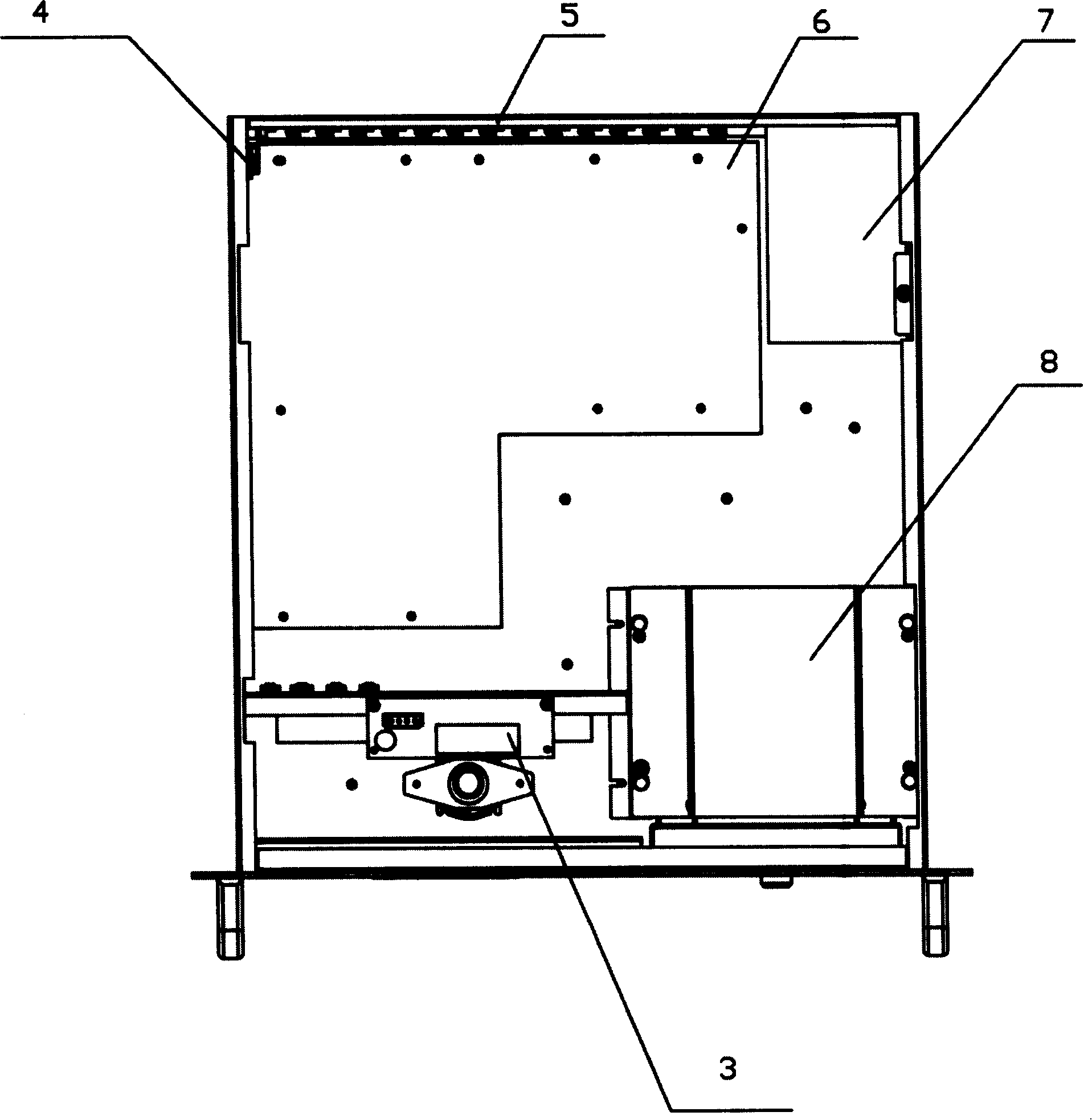

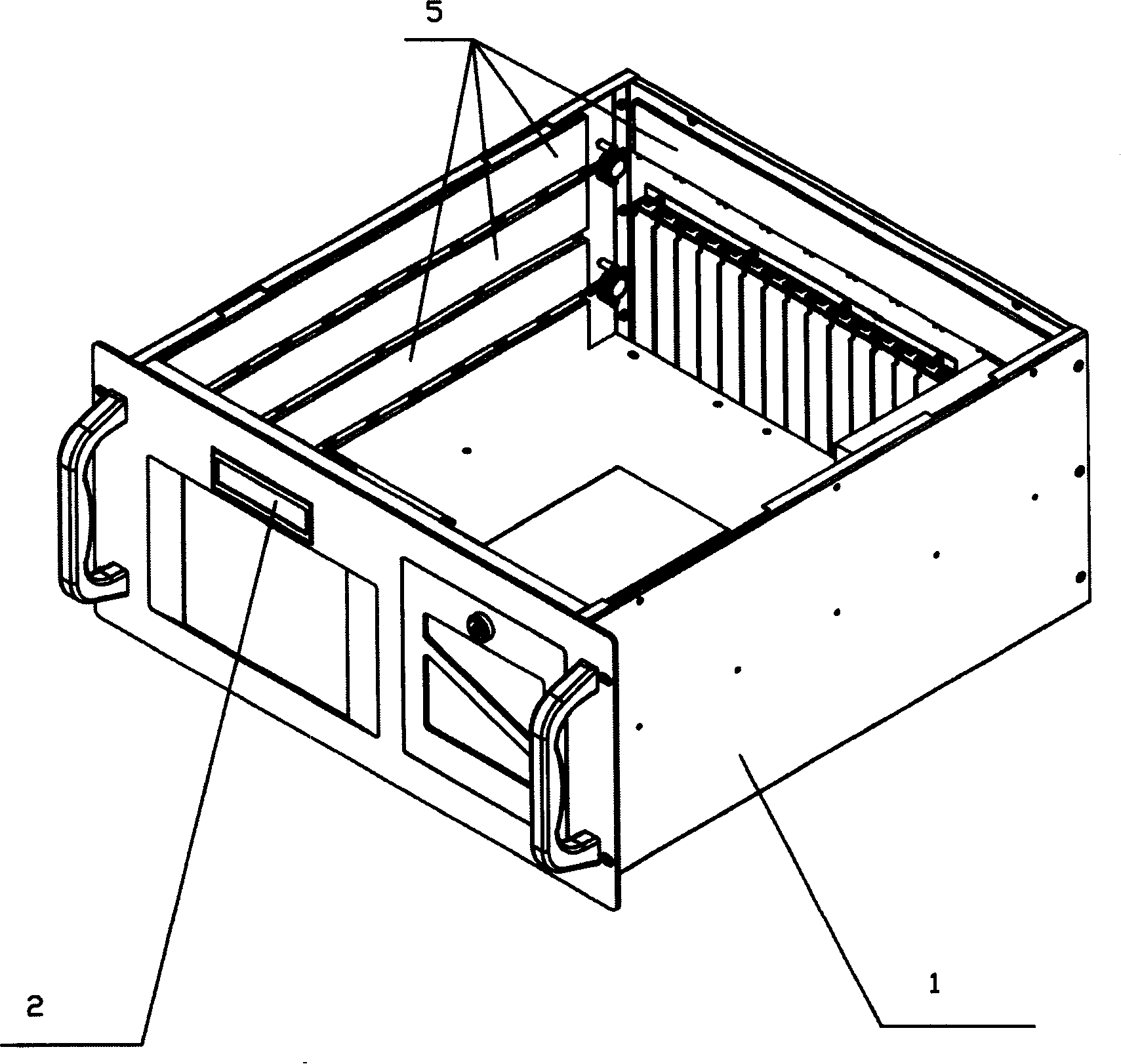

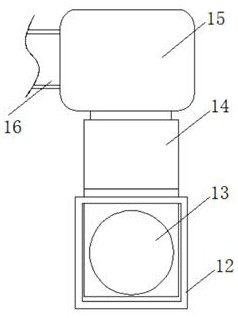

Automatic temperature control cabinet

InactiveCN101222825AImprove mechanical propertiesImprove stabilityTemperatue controlCooling/ventilation/heating modificationsTemperature controlTerra firma

The invention relates to an automatic temperature control cabinet, which comprises a cabinet casing and a cabinet power supply arranged in the cabinet casing, wherein the cabinet casing is also provided with a refrigerating and heating device and a temperature control device which are mutually connected and are respectively connected with the cabinet power supply. Adopting the automatic temperature control cabinet improves the sealing performance, the mechanical performance of the cabinet, the stability and the high reliability, the product tends to be diversified and practical, is beautiful in model and rich and colorful in overall appearance, presenting a fresh stereo sense to people and reducing the manufacturing cost correspondingly, is also convenient to install, easy to maintain and strong in environment adaptability, and can be widely used in various fields such as a commercial cabinet, an industrial cabinet and a military cabinet. In the adverse weather conditions, the invention can better play a unique advantage, brings people great convenience and lays a solid foundation for popularizing and developing computer technology.

Owner:SHANGHAI EVOC INTELLIGENT TECH

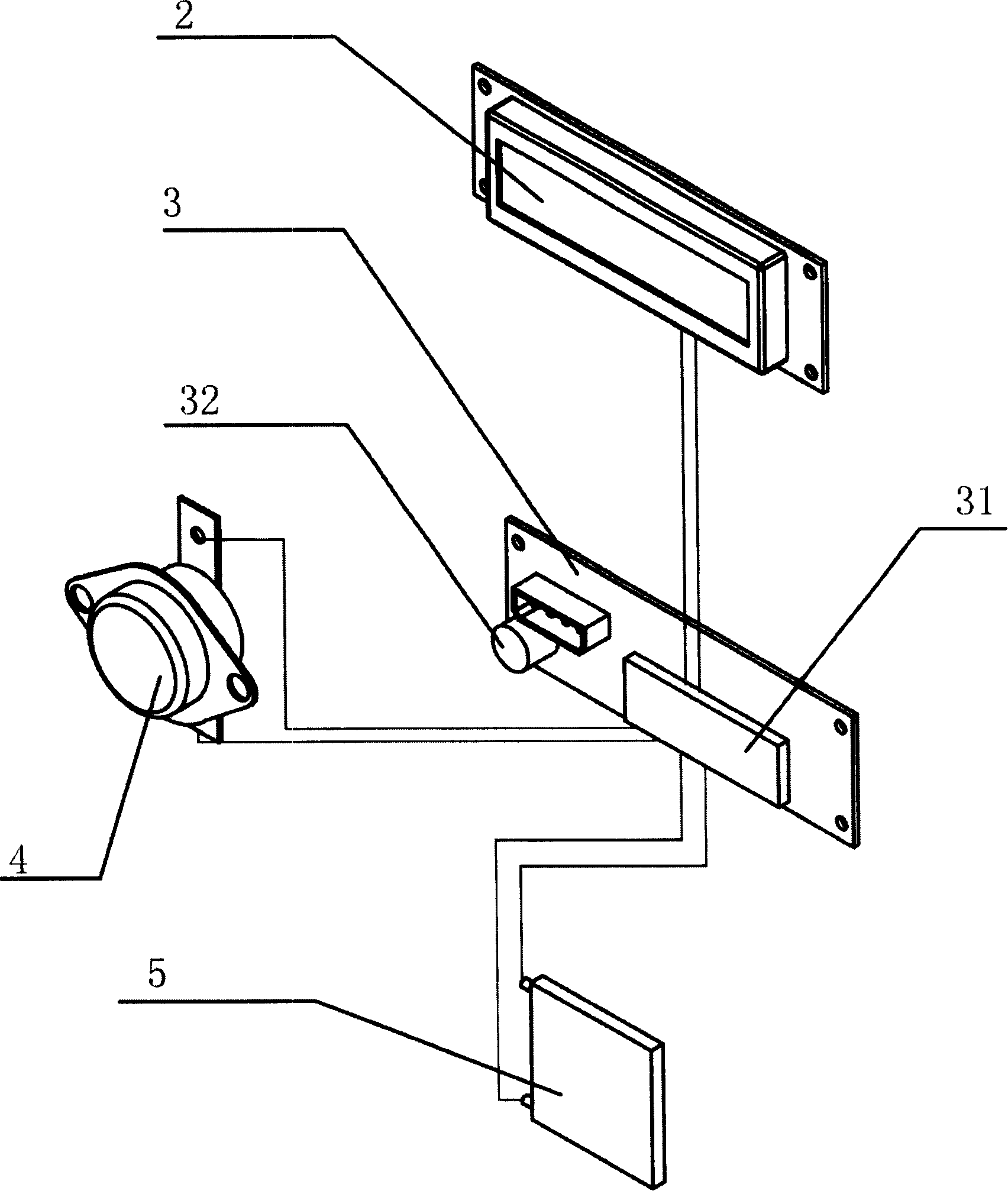

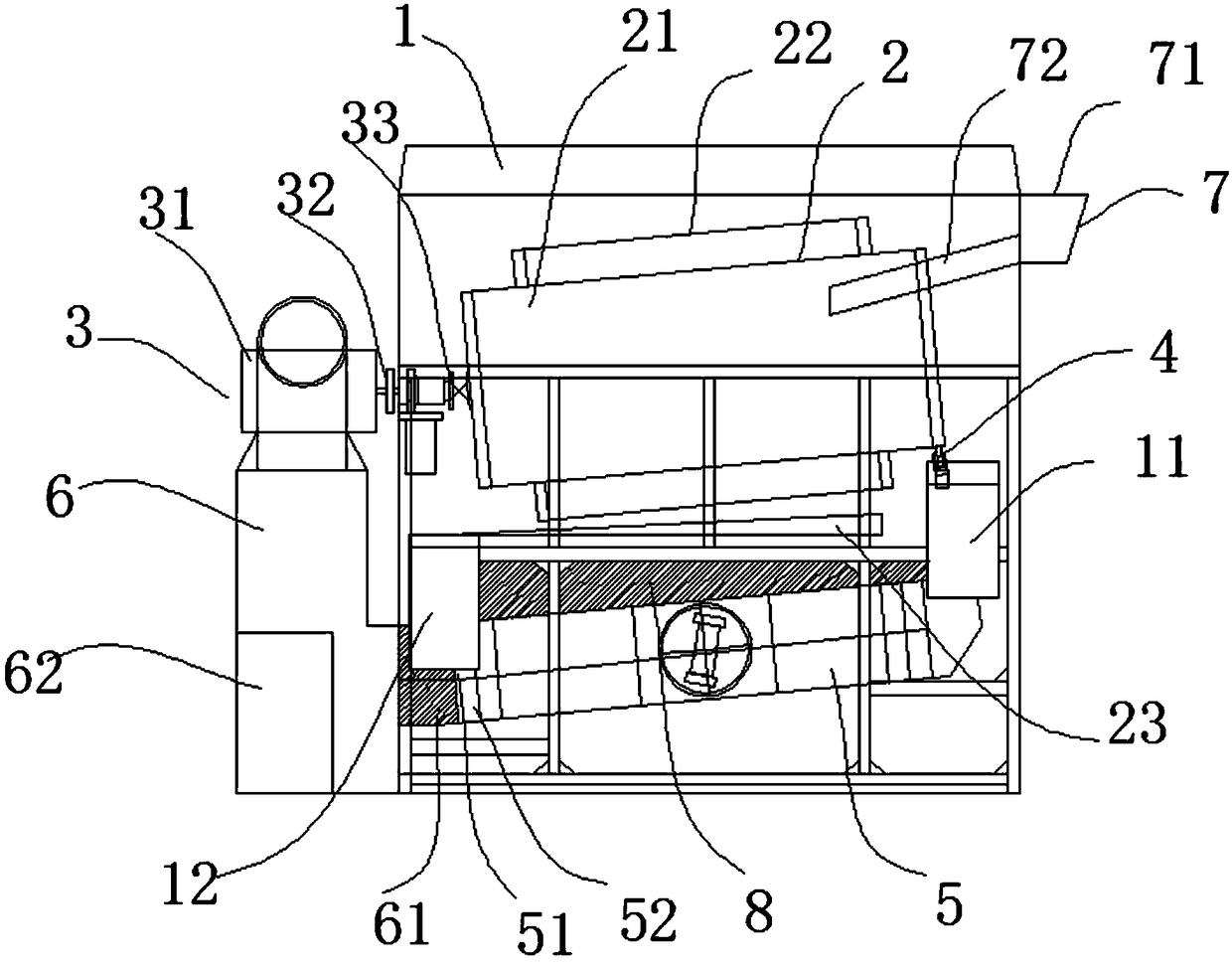

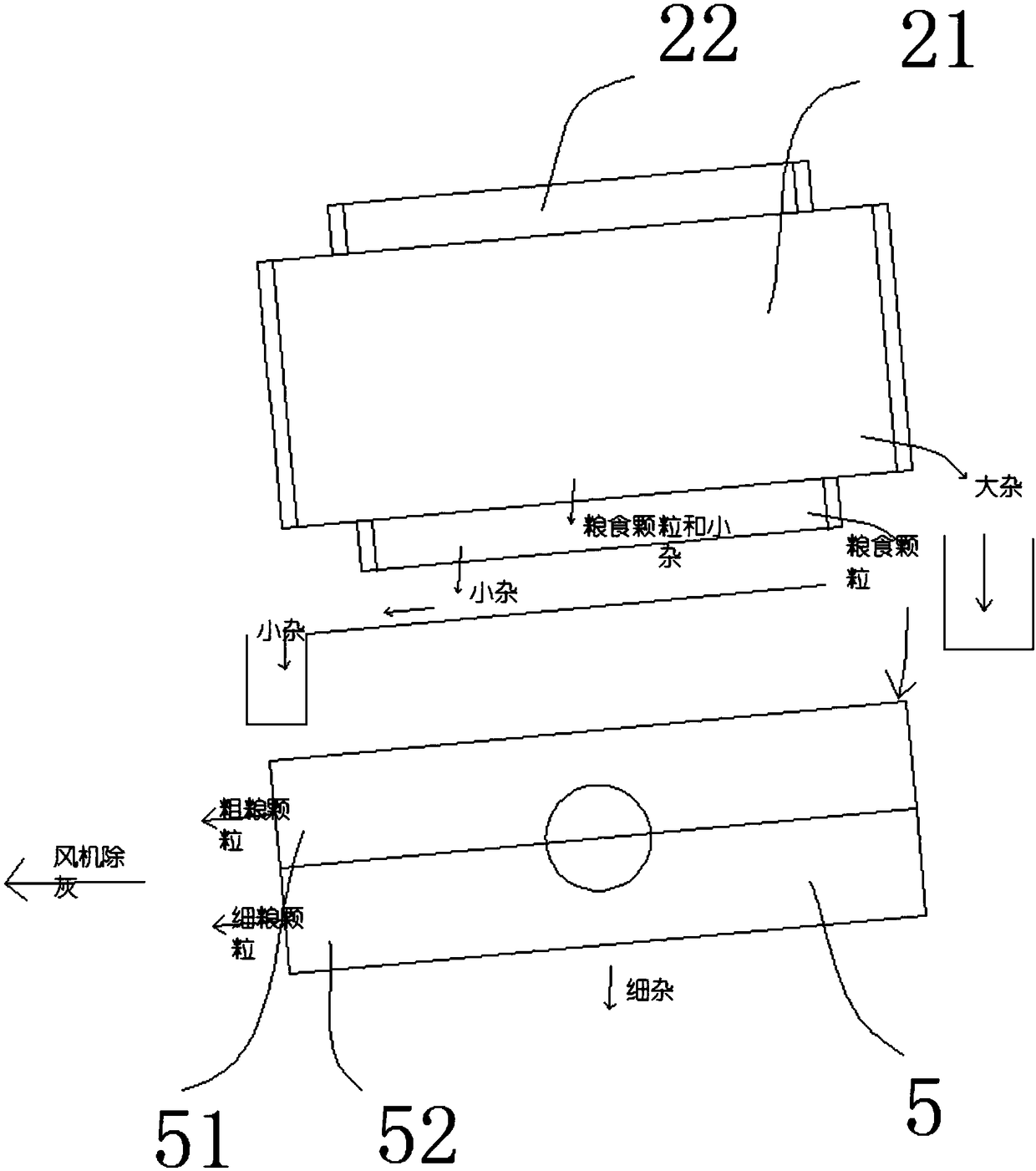

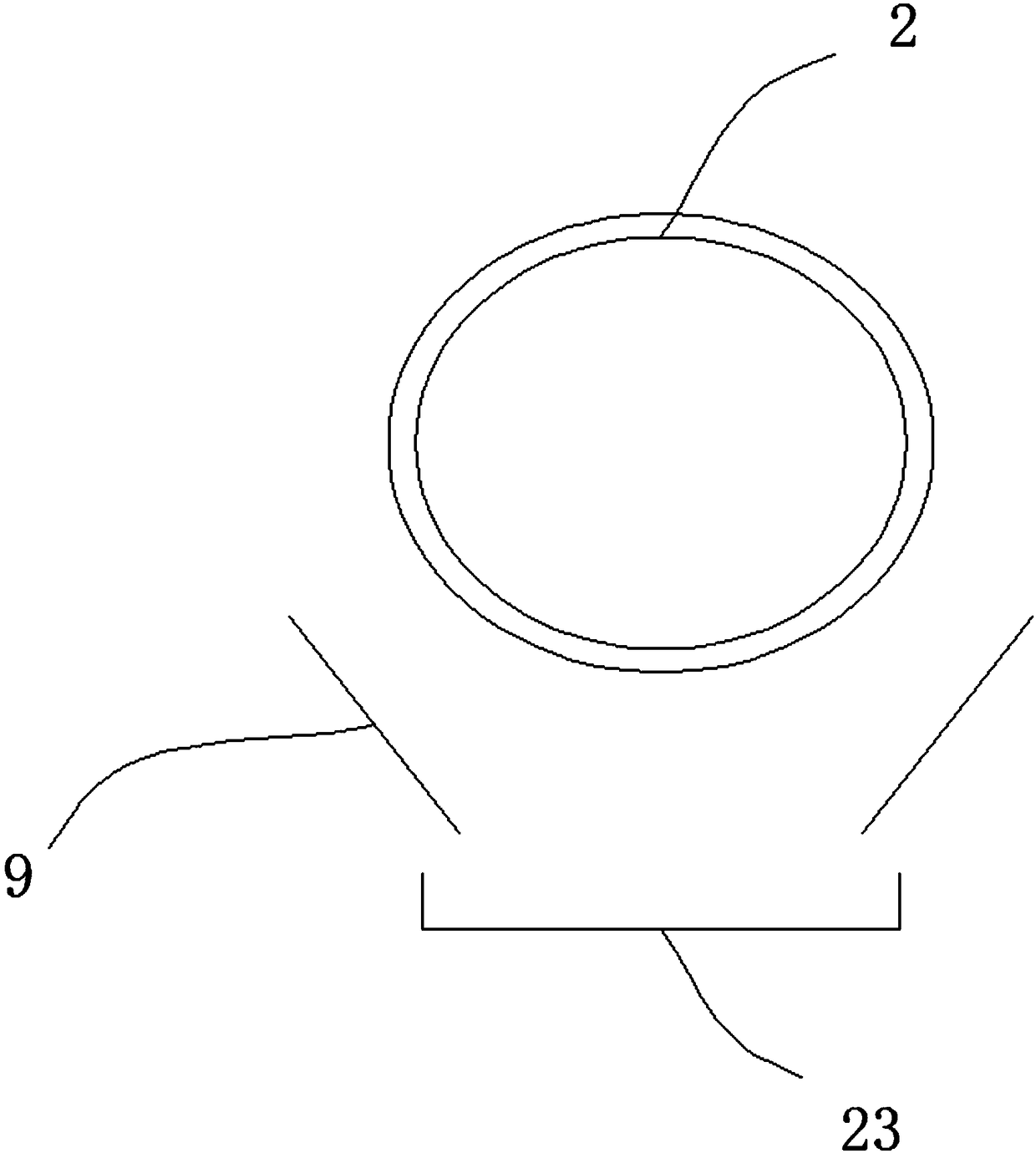

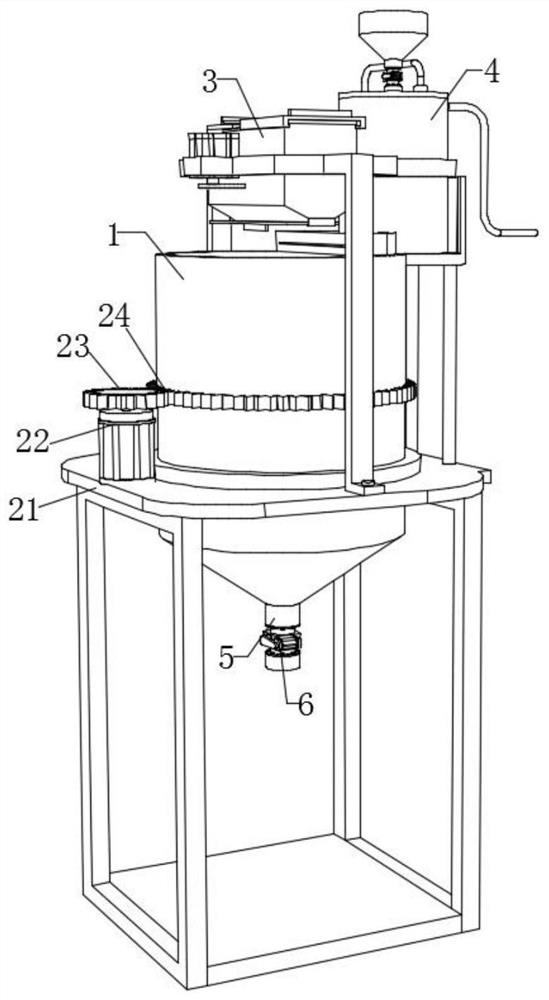

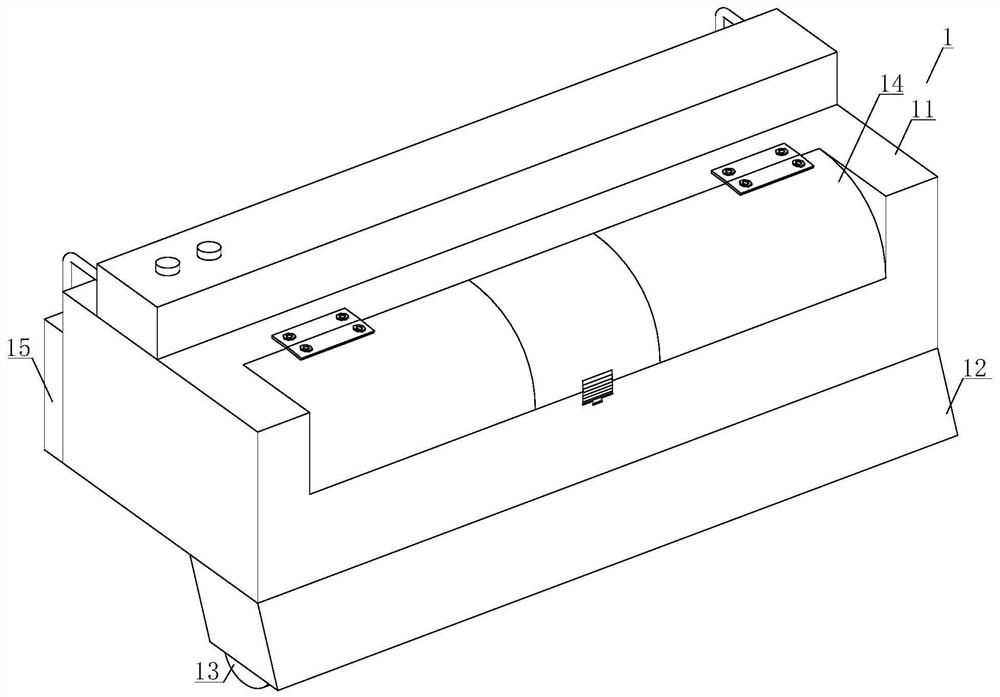

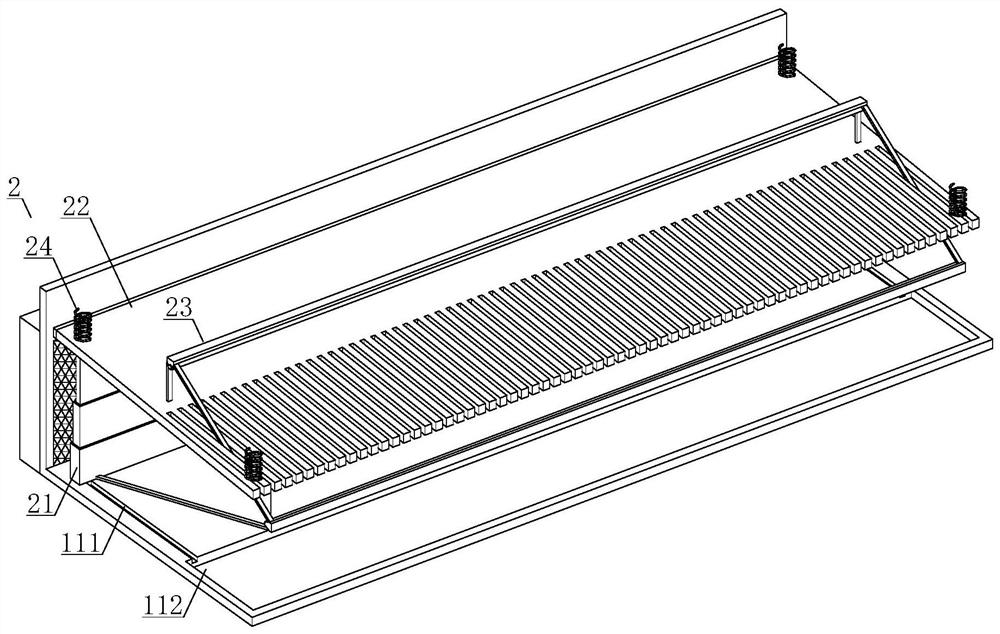

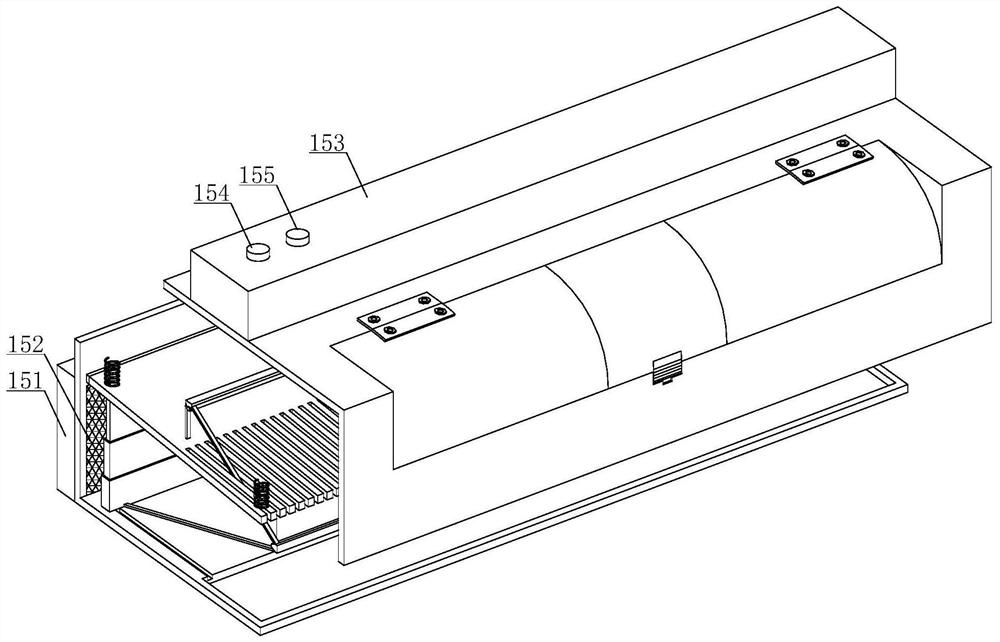

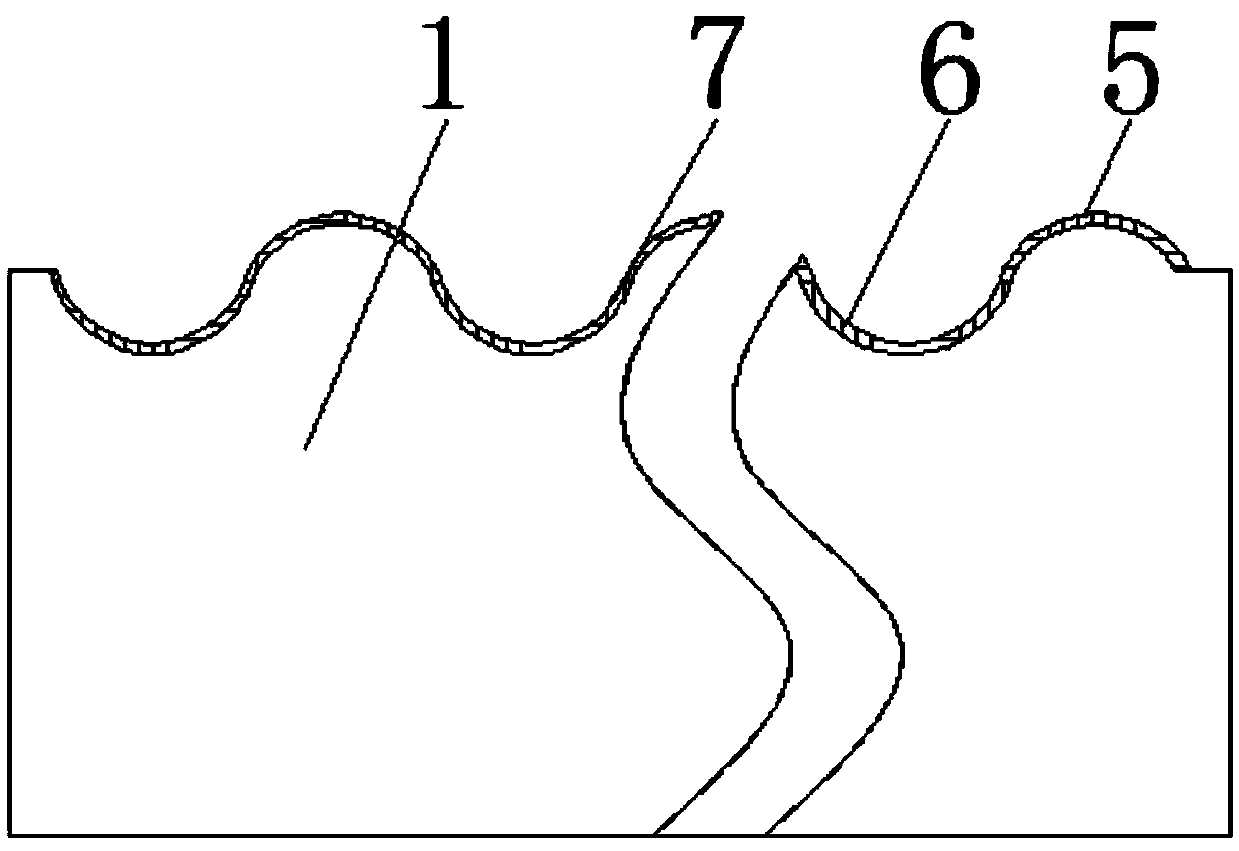

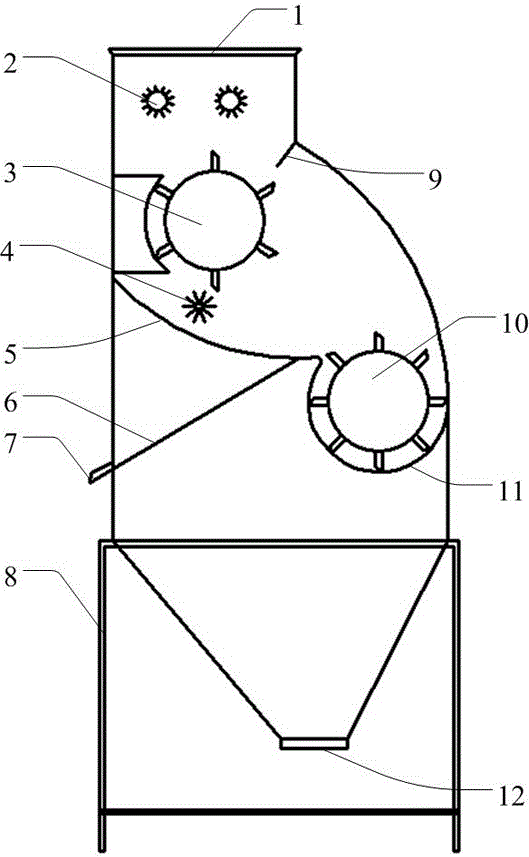

Efficient and environment-friendly multifunctional sorting screen

PendingCN108499866AAvoid flying dustEfficient cleaningSievingGas current separationEngineeringSmall particle

The invention provides an efficient and environment-friendly multifunctional sorting screen, and relates to the field of grain screening equipment. The efficient and environment-friendly multifunctional sorting screen comprises a rack. An opening is formed in the front end of the rack. The rack is internally provided with a double-barrel screen body and further provided with an obliquely-arrangeddouble-layer vibrating screen body. The rear end of the rack is further provided with a draught fan. An air inlet of the draught fan is located in the lower portion of the rear end of the rack. The draught fan is further internally provided with an impurity settling box. An upper layer outlet and a lower layer outlet of the double-barrel screen body are connected with the air inlet of the draughtfan through corrugated hoses. A large-particle grain outlet and a small-particle grain outlet are formed in the air inlet of the draught fan. The rack is provided with a feeding mechanism. A feeding opening of the feeding mechanism is located in the upper end of the rack. A material guiding pipe communicates with the interior of an inner screening barrel of the double-barrel screen body. Accordingto the efficient and environment-friendly multifunctional sorting screen, the clearing effect of a precleaner can be greatly improved, and the classified screening effect is further achieved.

Owner:安徽三虎机械科技有限公司

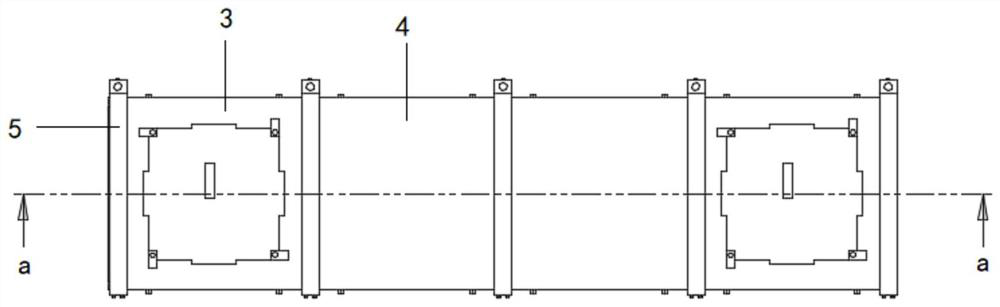

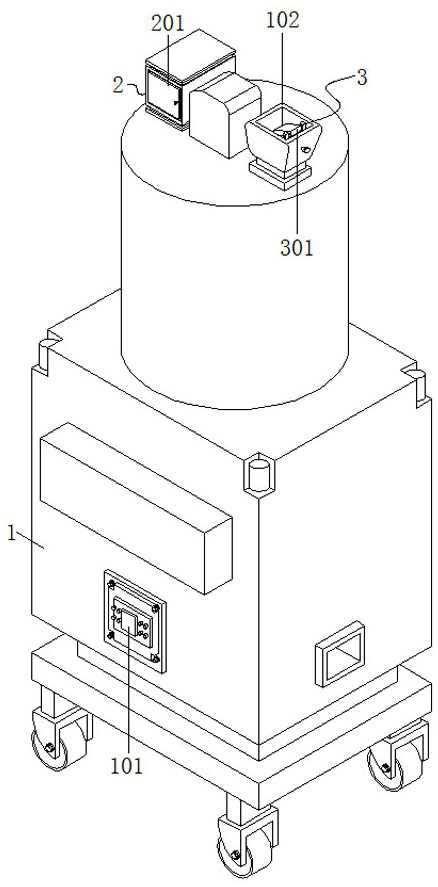

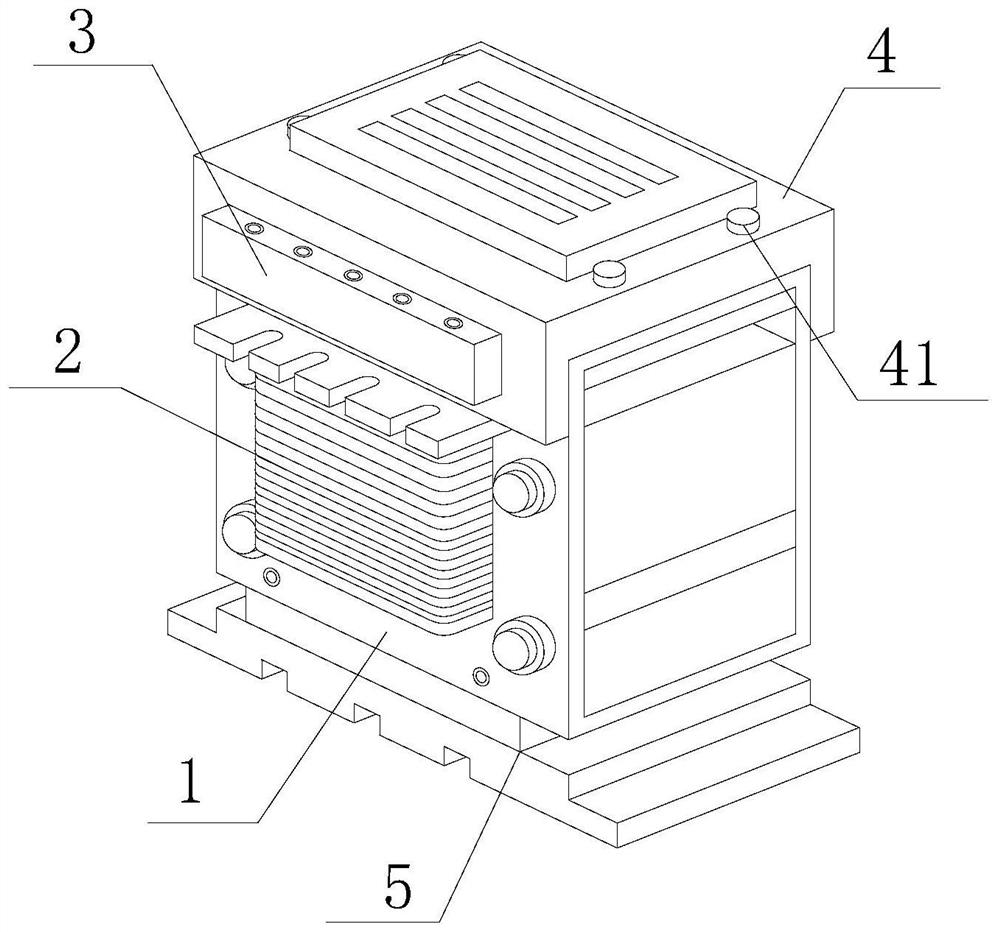

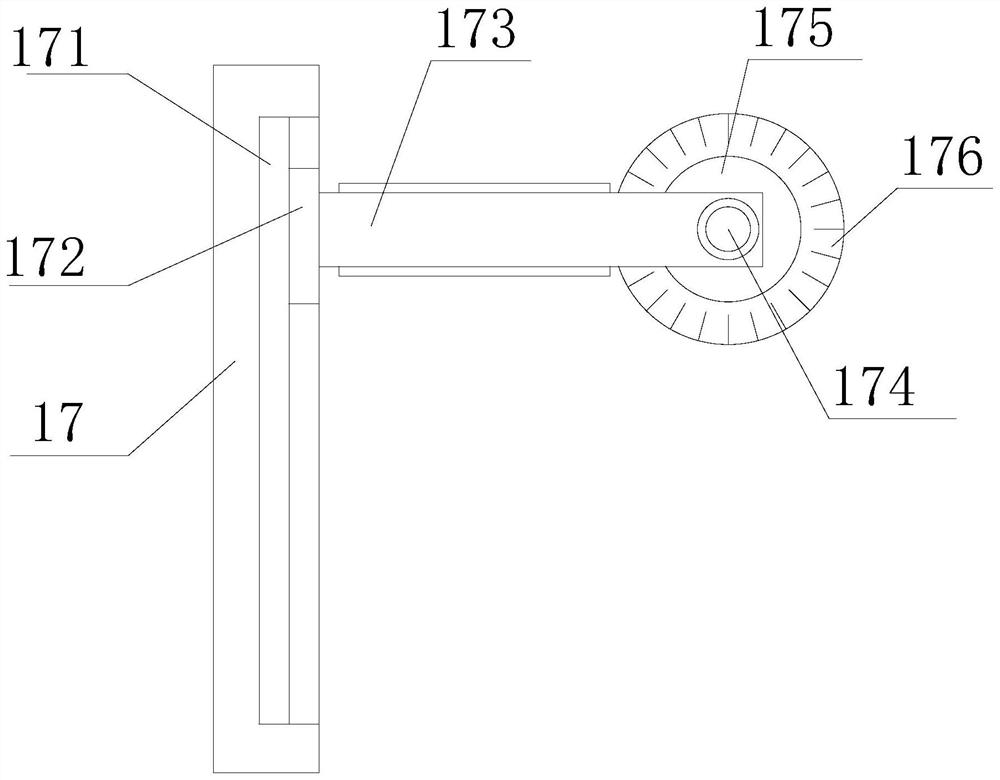

Transformer radiator moving type automatic washing cooling device

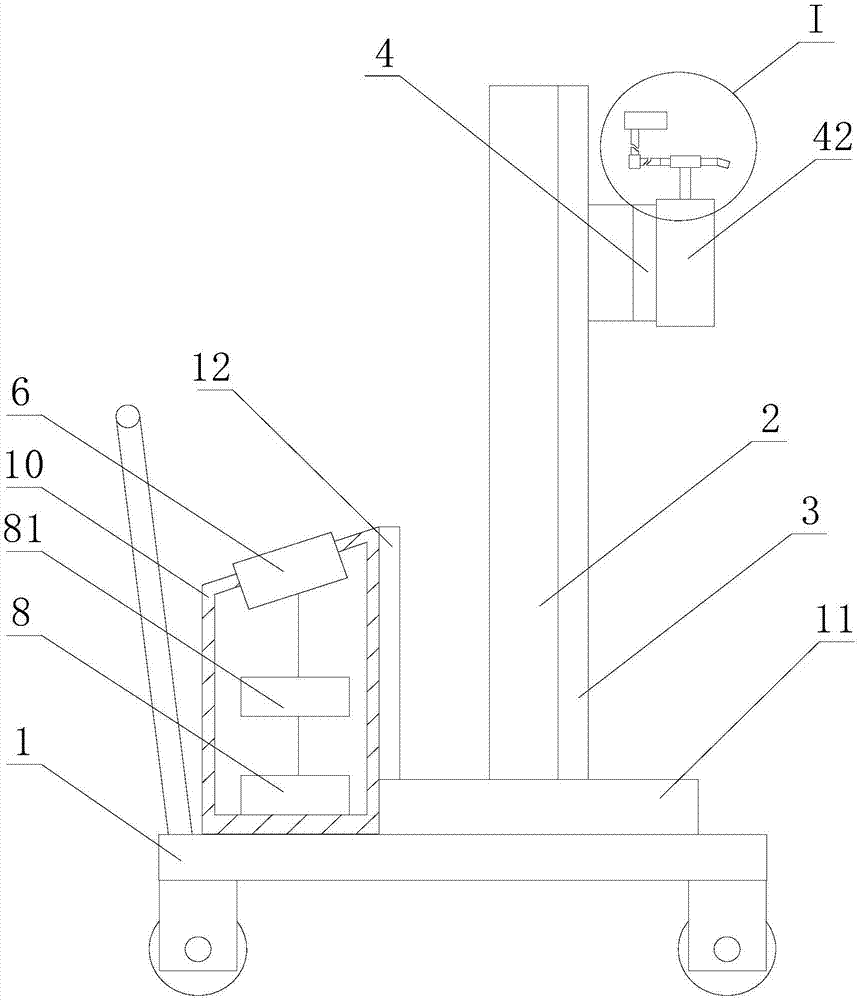

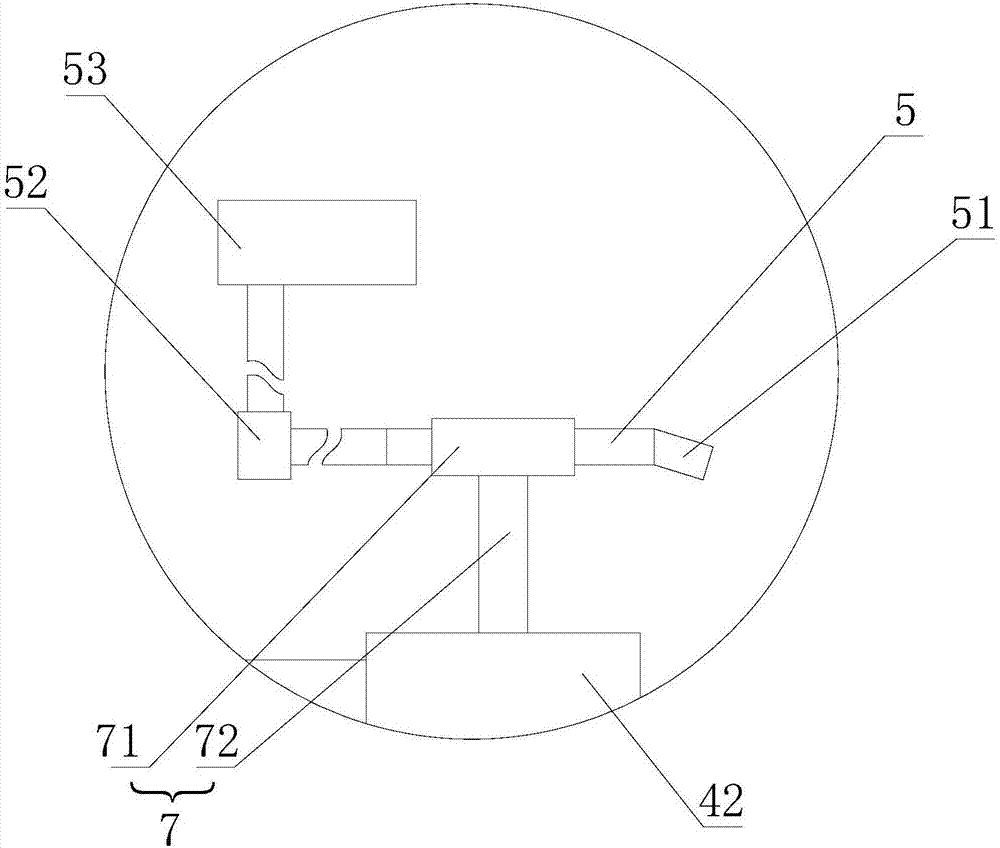

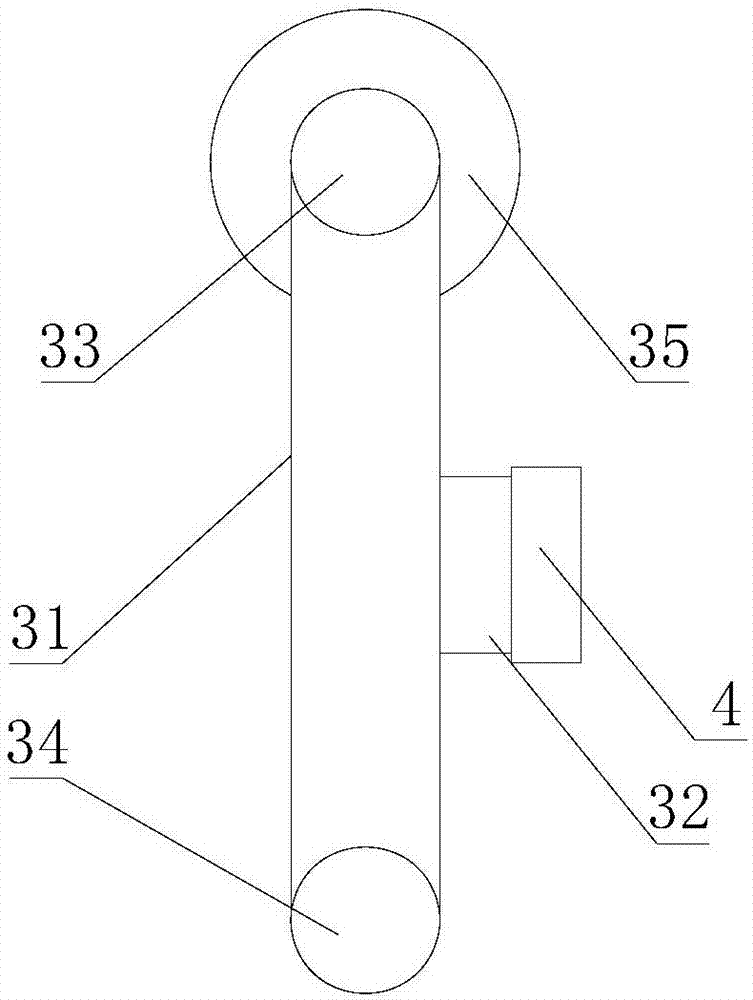

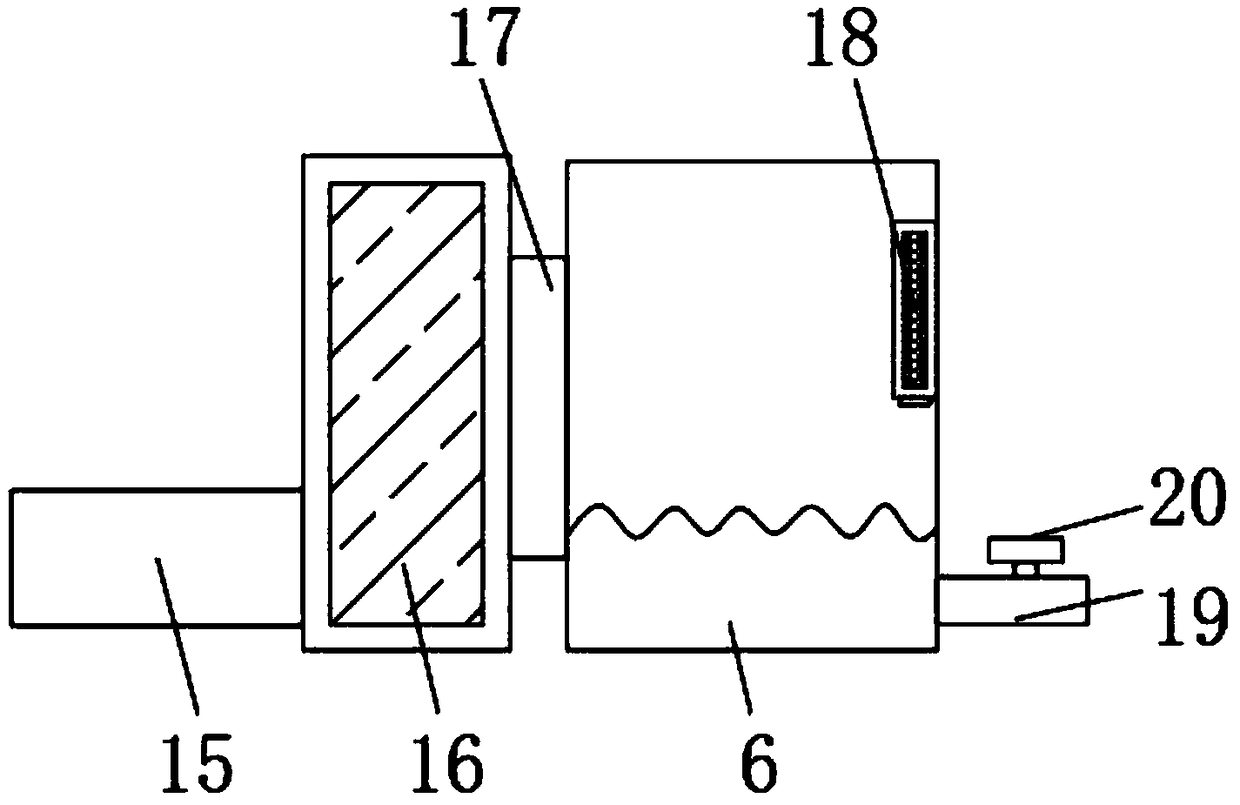

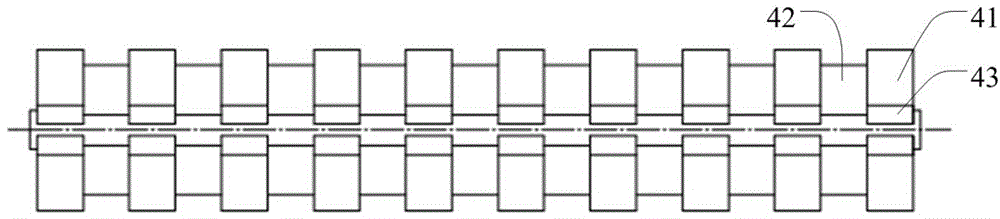

PendingCN107497744ARestoring Cooling EfficiencyEnsure safetyCleaning using liquidsThermal efficiencyWater tanks

The invention relates to a transformer radiator moving type automatic washing cooling device. The transformer radiator moving type automatic washing cooling device comprises a trolley and a bracket. The bracket is provided with a vertical guiding rail and a horizontal guiding rail. The vertical guiding rail is provided with a transmission belt. The transmission belt is provided with a vertical sliding block. The horizontal guiding rail is arranged on the vertical guiding rail. The horizontal guiding rail is provided with a transmission chain. The transmission chain is provided with a horizontal sliding block. The horizontal sliding block is provided with a spray pipe. One end of the spray pipe is provided with a spray head. The other end of the spray pipe is connected with a high-pressure water pump. The high-pressure water pump is connected with a water box. The trolley is provided with a single-chip microcomputer controller. The transformer radiator moving type automatic washing cooling device has the advantages that a spray head in the spray pipe sprays high-pressure water through the high-pressure water pump, dirt in flakes gaps of a radiator is washed away, the radiator is washed, the radiating efficiency of the radiator is restored, manual work is changed to mechanization, the safety in the hot-line washing operation is ensured, the equipment safety hazard is eliminated, the manpower cost is reduced, the health of workers is ensured, and the working efficiency is improved.

Owner:国网浙江台州市黄岩区供电公司 +2

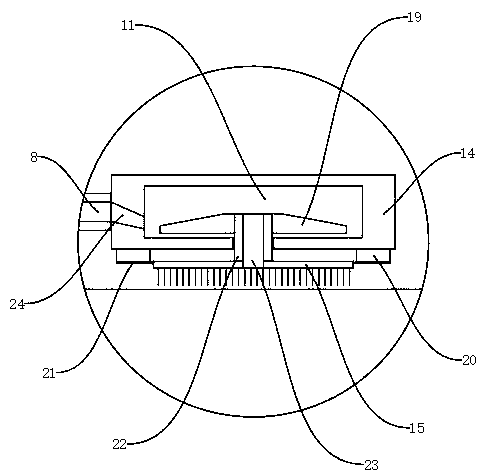

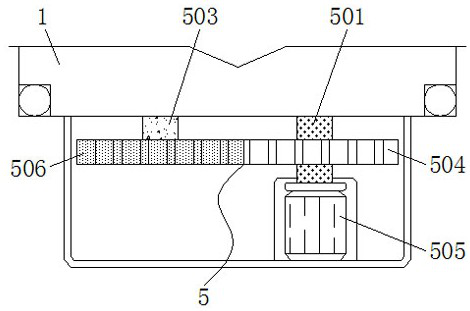

Double-roller type skein fluffing device based on textile processing

The invention provides a double-roller type skein fluffing device based on textile processing, relates to the technical field of textile processing, and aims to solve the problems that when an existing double-roller type skein fluffing device is used, yarn cannot be combed, redundant fine yarn ends and woolen yarn which are attached to the yarn cannot be cleaned and the device cannot assist in cleaning the yarn. The double-roller type skein fluffing device comprises a main body, a bottom piece and blocking pieces; the main body is of a rectangular structure; an inner cavity is formed in the main body; the main body is a skein fluffing device body; and the bottom piece is mounted in an inserting opening of the main body in an inserting manner. An adjusting rod is mounted in the main body, so that when the device is used, the yarn can pass through contact pieces at the bottom of the adjusting rod, the contact pieces can comb the yarn and remove the thread ends and the fine woolen yarn which are attached to the yarn, the removed thread ends or woolen yarn can be reused, and flying dust can be effectively avoided.

Owner:安徽省新远升针纺织有限公司

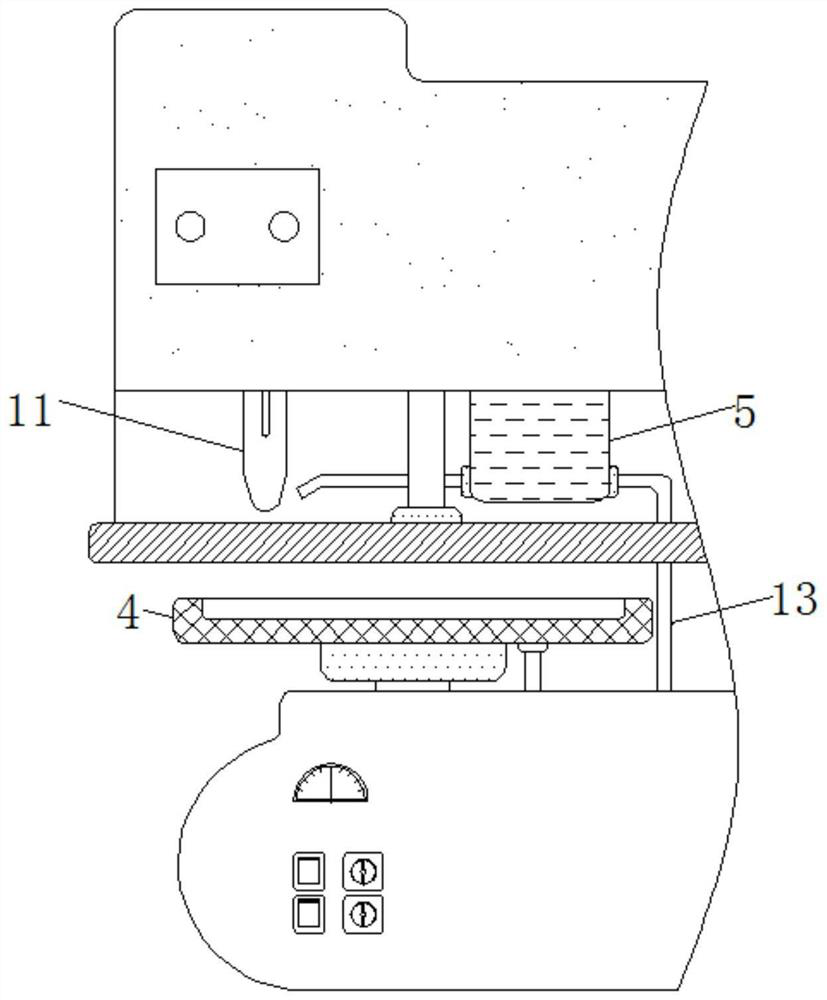

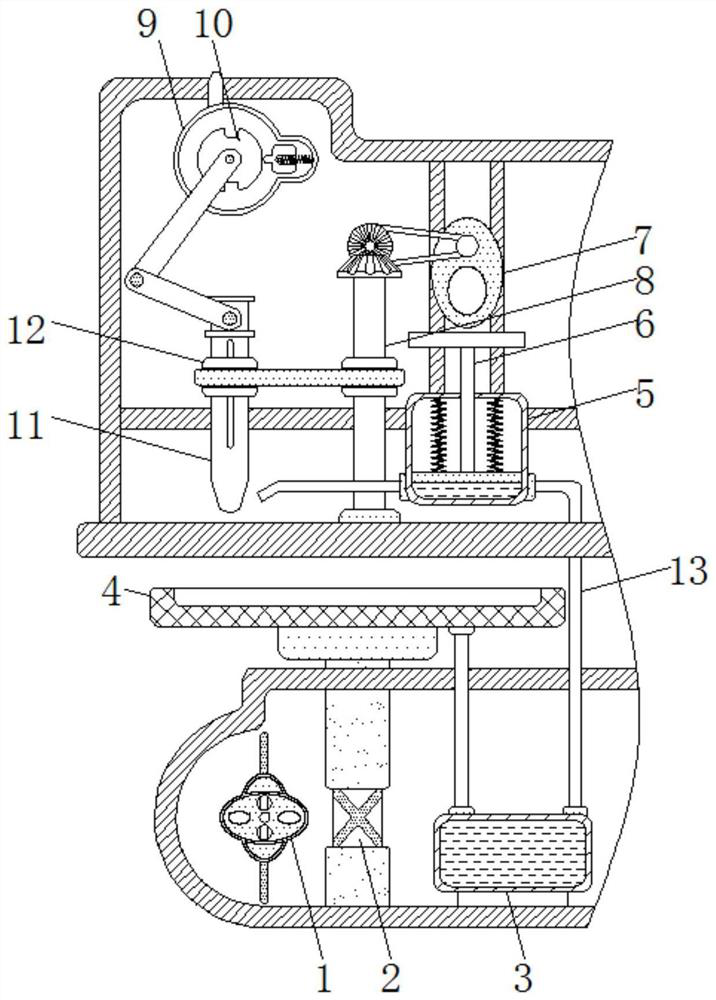

Automobile part perforating device with improved perforating precision and efficiency

InactiveCN112222462AAvoid flying dustReduce wastePositioning apparatusMaintainance and safety accessoriesWater circulationAutomotive engineering

The invention relates to the technical field of automobile parts, and discloses an automobile part perforating device with improved perforating precision and efficiency. The device comprises a specially-shaped disc. Because a transfer box, a push rod, a water storage tank and a water pipe are used in cooperation, cold water is automatically sprayed in the perforating process to cool a perforator and prevent dust from flying, cold water is circulated to reduce waste of water resources, meanwhile, it is avoided that the perforating effect is affected due to deformation caused by temperature riseof the perforator, and the perforating precision is improved; because the specially-shaped disc, a first rotary shaft, a first rotary disc, a second rotary disc and the perforator are used in cooperation, so that automobile parts can automatically rotate in the perforating process, then the next position can be perforated without manual adjustment, the working efficiency of perforation is improved; because the second rotary shaft and a cam are used in cooperation, the two steps of perforation and cold water circulation can be in linkage, and the linkage performance of the whole device is improved.

Owner:广州市人则众汽车用品有限公司

Powder spraying chamber convenient to clean

InactiveCN102553764AProtect your healthSafeguard the environmentLiquid surface applicatorsCoatingsWorking environmentEngineering

The invention discloses a powder spraying chamber convenient to clean. The powder spraying chamber comprises a working chamber with an exhaust inlet at the bottom and an exhaust pipeline communicated with the exhaust inlet. A second exhaust inlet is arranged on the lateral wall of the working chamber; a communication pipeline is arranged between the second exhaust inlet and the exhaust pipeline; a valve is arranged on the communication pipeline; and one side of the second exhaust inlet, which is arranged inside the working chamber, is connected with a power adsorbing brush through a flexible pipe. According to the invention, the exhaust pipeline is led into the working chamber through the communication pipeline and the powder adsorbing brush is connected by the flexible pipe, so that powder on the inner wall of the powder spraying chamber is cleaned by the powder adsorbing brush. Therefore, dust does not fly in the powder spraying chamber, and the body health and the working environment of workers are ensured.

Owner:天津新技术产业园区天博科工贸有限公司

Novel high-efficiency environment-protective dust-free polisher

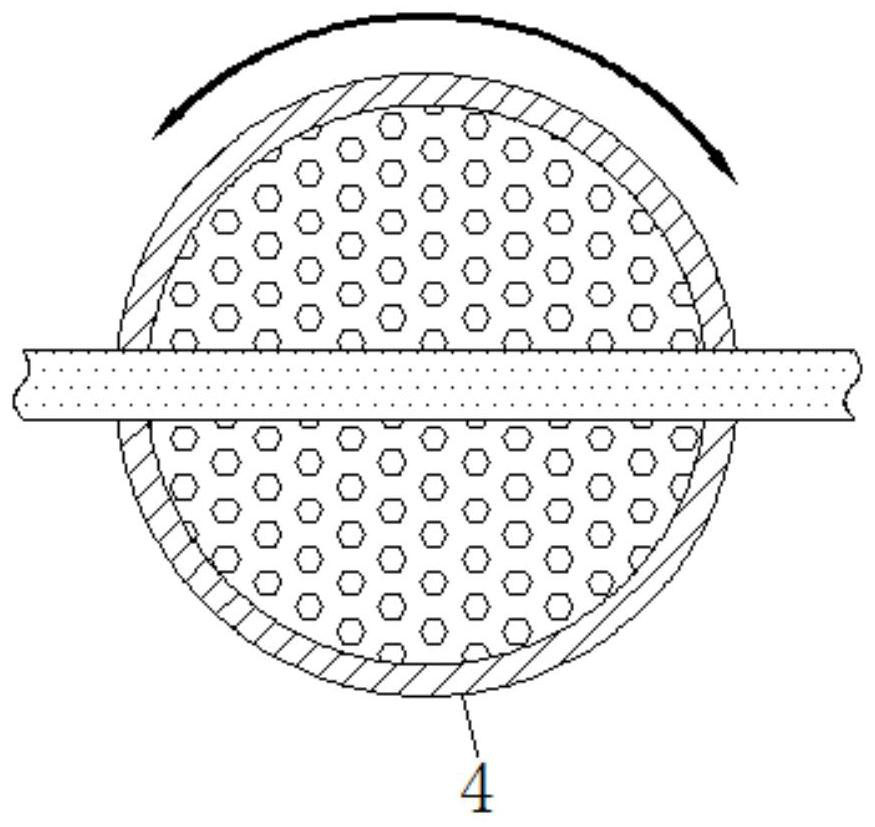

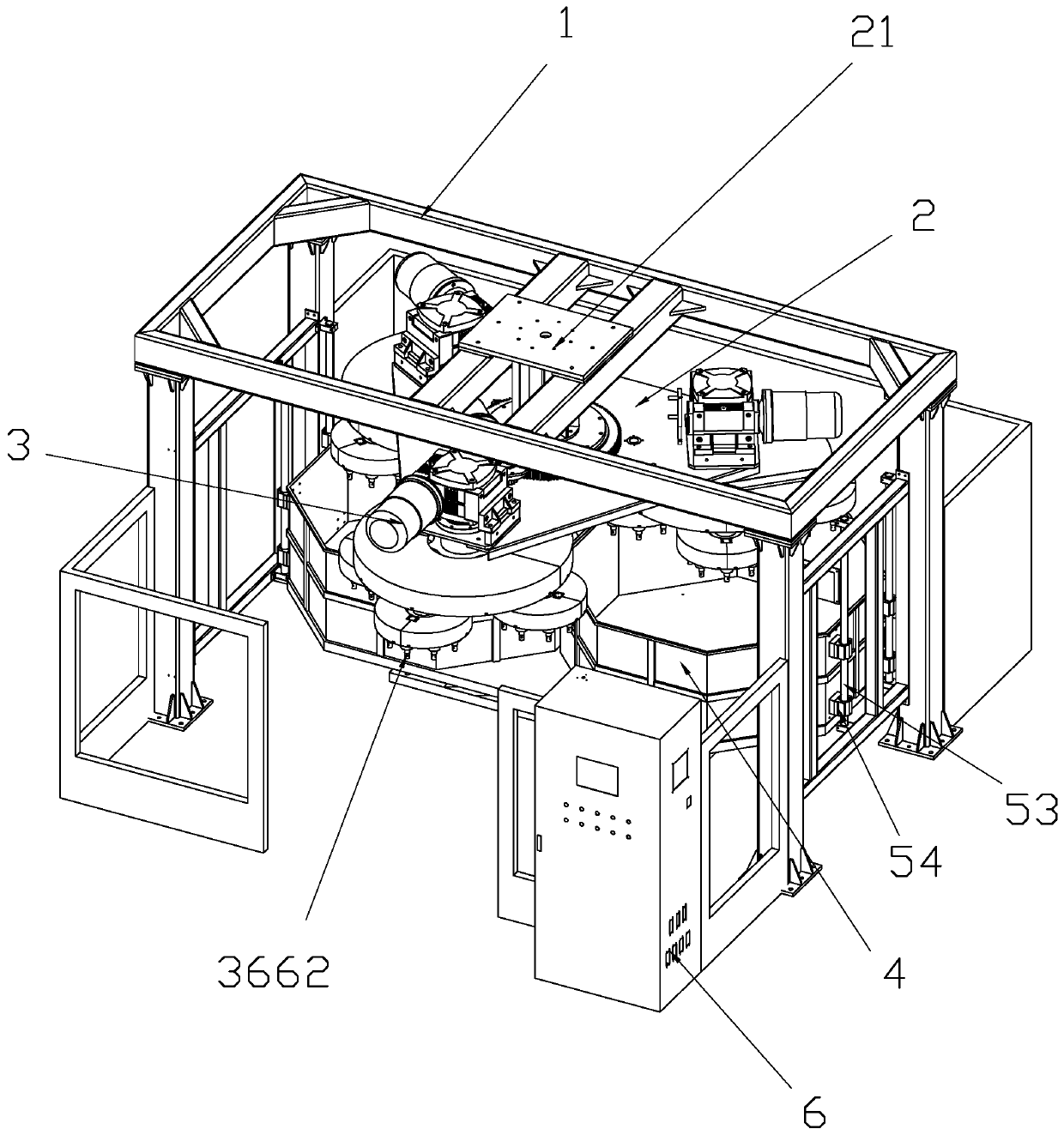

PendingCN110936283AAchieve revolutionRich demandEdge grinding machinesPolishing machinesPolishingEngineering

The invention relates to a novel high-efficiency environment-protective dust-free polisher. The polisher comprises a frame, a station switching mechanism is arranged on the frame and is provided withthree rotation mechanisms, a moving path of the frame rotation mechanisms forms a first processing station, a second processing station and an unloading station, each rotation mechanism is provided with clamps, the clamps make revolution and rotation by the rotation mechanism, two polishing barrels are arranged under the first and second processing stations respectively, each polishing barrel is internally provided for a polishing material suitable for production processing, and a barrel lifting mechanism meeting product polishing needs is arranged at the bottom of the polishing barrel. Thus,a product on the clamps is polished comprehensively without blind areas by the polishing barrels, the polishing precision is improved, and flying dust is avoided; the unloading station is arranged tounload the product in the polishing process, and the production efficiency is improved; and the barrel lifting mechanism are arranged, so that it is not required to life the rotation mechanisms duringpolishing, and the problems that frequent calibration is needed and energy consumption due to too large driving force is too high due to low precision when the too heavy rotation mechanism are liftedfor long time are solved.

Owner:浙江珂斯顿机器人科技有限公司

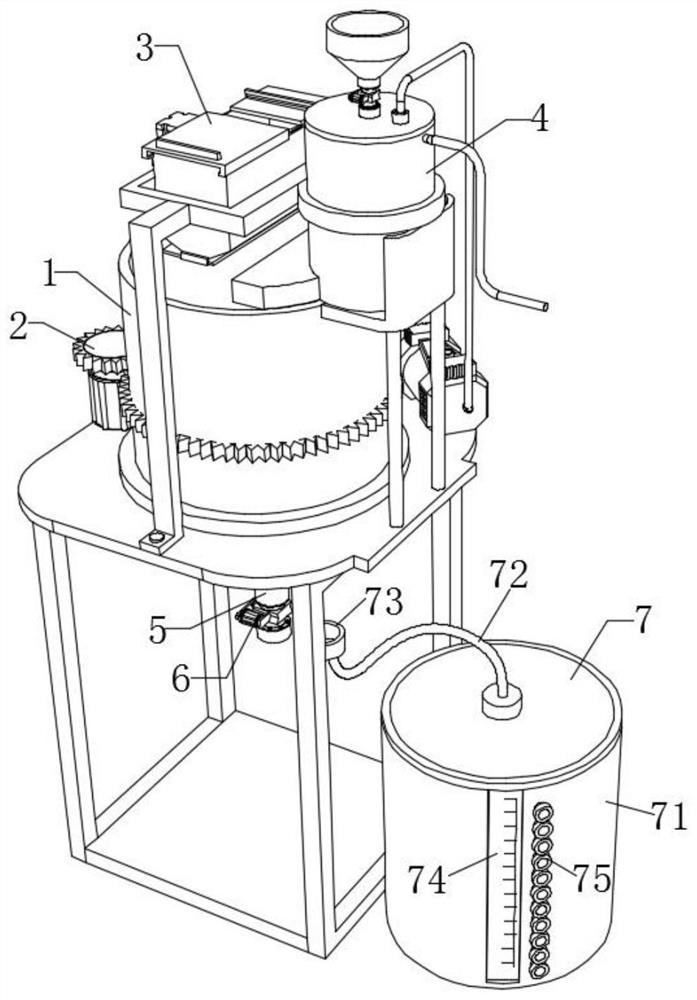

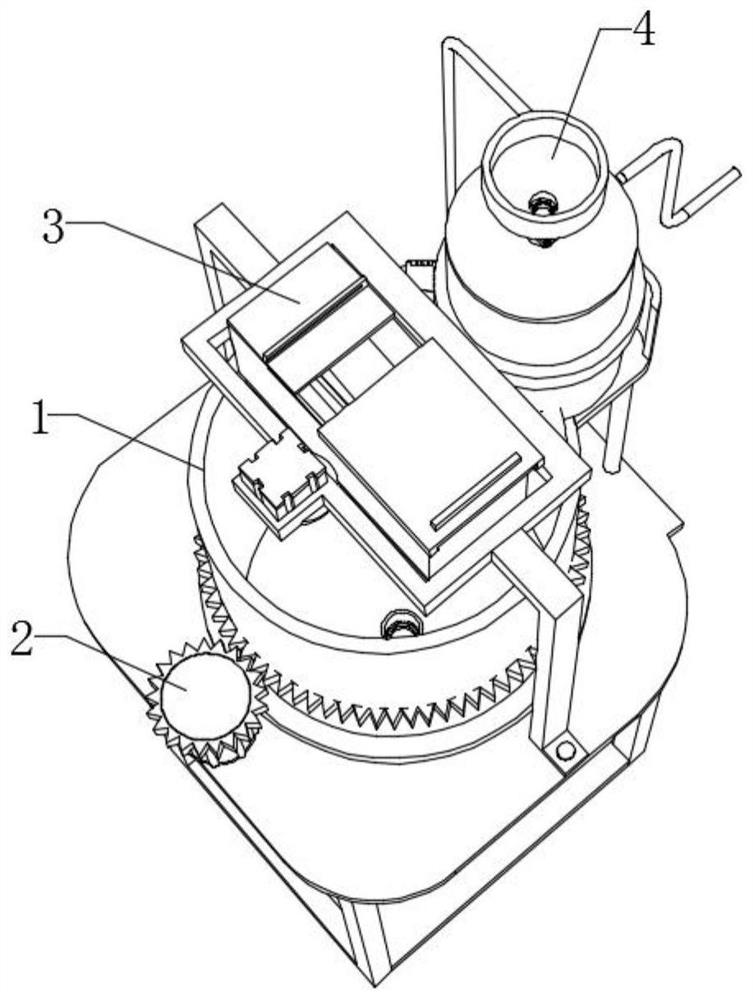

Rapid adjusting device for food additive production process

InactiveCN114307832AAvoid it happening againQuick mixTransportation and packagingMixer accessoriesFood additiveProcess engineering

The invention discloses a rapid adjusting device for a food additive production process, and particularly relates to the related technical field of food additive production.The rapid adjusting device comprises a mixing barrel, and a rotating structure used for rotating the mixing barrel is arranged on the outer side of the mixing barrel; a powder control structure for feeding food additive powder is erected at the top of the mixing barrel and comprises a powder box, and a shaking spring is fixedly mounted on the outer wall of the powder box. The powder control structure is used for feeding powder in a shaking mode, meanwhile, liquid materials are extruded and fed through air pressure, the powder control structure and the original liquid treatment structure are used for feeding the powder and the liquid materials into the mixing barrel from different directions, meanwhile, after the powder and the liquid materials are discharged and treated, the contact area of the powder and the liquid materials is increased, and the mixing effect is improved. Furthermore, the powder is completely wetted at the moment of powder-liquid contact, so that agglomerated lumps are prevented from being generated in the mixing process, and meanwhile, the rotating mixing barrel is matched to realize rapid mixing of the powder and the liquid.

Owner:江苏紫东食品有限公司

Abrasive jet machining equipment

ActiveCN111571457AEasy to recycleEasy to closeAbrasive feedersAbrasive machine appurtenancesEngineeringMachining

The invention discloses abrasive jet machining equipment. The abrasive jet machining equipment comprises a middle box, an open inner cavity is formed in the middle box, a sliding inner cavity locatedin the middle box is formed in one side of the inner cavity, a squeezing cavity is formed in one side of the sliding inner cavity in a communicating mode, a feeding device used for feeding into the sliding cavity is arranged on one side of the squeezing cavity, a conveying device capable of conveying abrasive in the feeding device into the inner cavity is arranged in the sliding inner cavity, tworotating side plates are rotatably arranged in the middle box, and the rotating side plates correspondingly close the side surface and the top surface of the inner cavity. The abrasive jet machining equipment is simple in structure, the mode capable of simultaneously closing and opening the machining working space is adopted, clamping can be carried out according to tools of the upper side and theside surfaces; and meanwhile, abrasive jet grinding machining is carried out on the tools in multiple directions, the sealing efficiency and machining efficiency of the equipment are effectively improved, and abrasive recovery and dust close are convenient.

Owner:邹平丰泰新材料科技有限公司

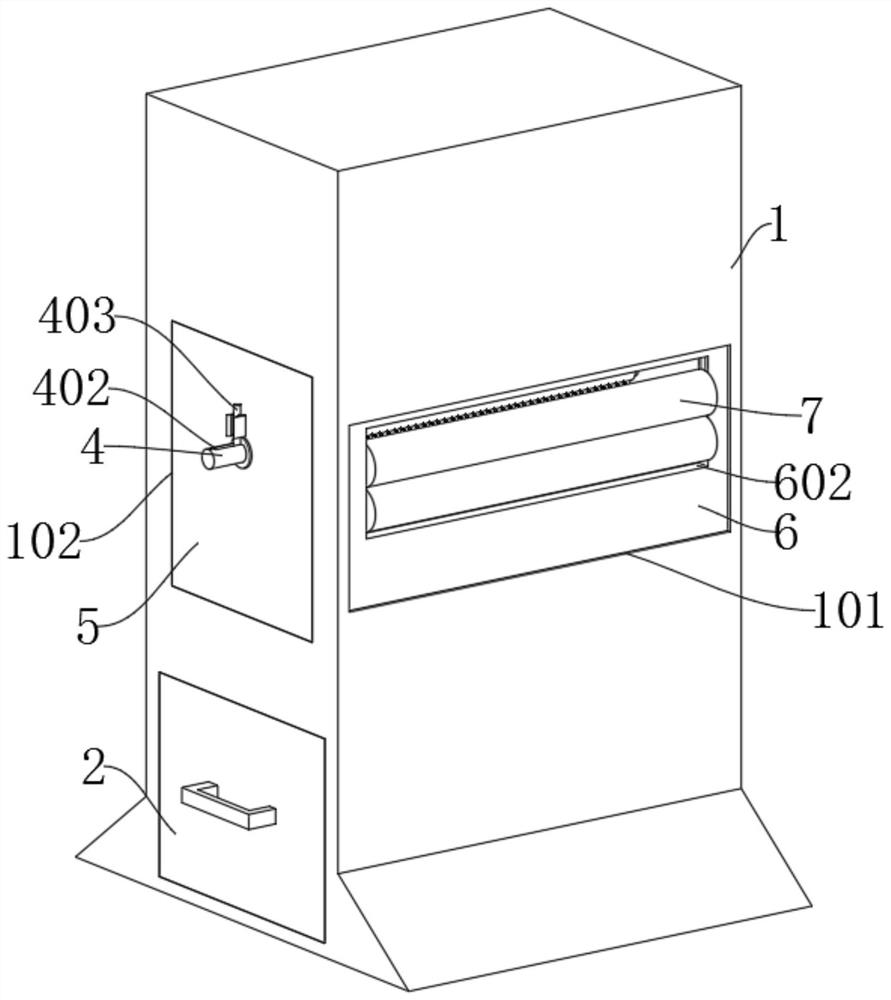

Display type carbon powder storage device with dust suppression structure

InactiveCN112731779AAvoid flying dustWith dust suppression effectElectrographic process apparatusComposite materialMagnetic powder

The invention discloses a display type carbon powder storage device with a dust suppression structure. The display type carbon powder storage device with the dust suppression structure comprises an outer shell and an inner cavity, wherein a magnetic plate is an inclined component, carbon powder slides down along a clamping groove, the carbon powder can be discharged through a discharging opening, when more carbon powder exists at the upper end of the magnetic plate, the carbon powder automatically presses the magnetic plate downwards to enable a spring to extend and enable the magnetic plate to move downwards, a magnetic plate is arranged in the inner cavity to serve as an interlayer, carbon powder is prevented from flying in the inner cavity, a certain dust suppression effect is achieved, the magnetic plate sinks to enable a contact head to be electrically connected with a first touch plate, current enables a first display lamp to be lightened through the first touch plate and a lead wire, an electromagnetic block is arranged at the lower end of a mounting block and electrically connected with the first touch plate through the lead wire, meanwhile, the electromagnetic block generates magnetism, the magnetic plate can move downwards again due to the fact that like poles of the electromagnetic block and the magnetic plate repel each other, all the carbon powder slides down through the clamping groove in the moving process, the magnetic powder at the lower end of the magnetic plate can be conveniently arranged, the surface of the magnetic powder is smooth, and the effect of suppressing magnetic powder flying is further achieved.

Owner:温州乔断机械科技有限公司

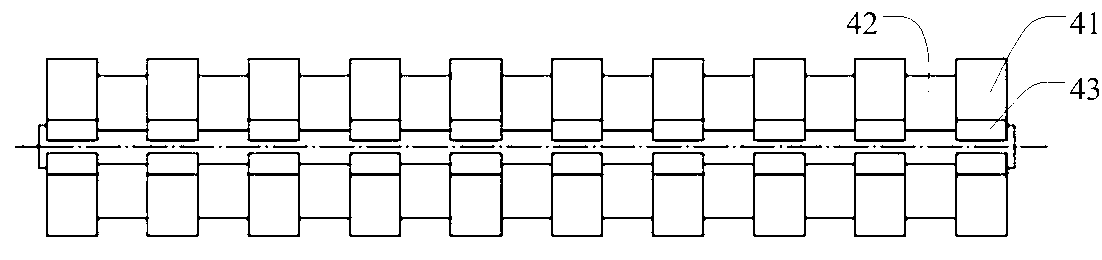

Feed raw material crushing device for animal husbandry

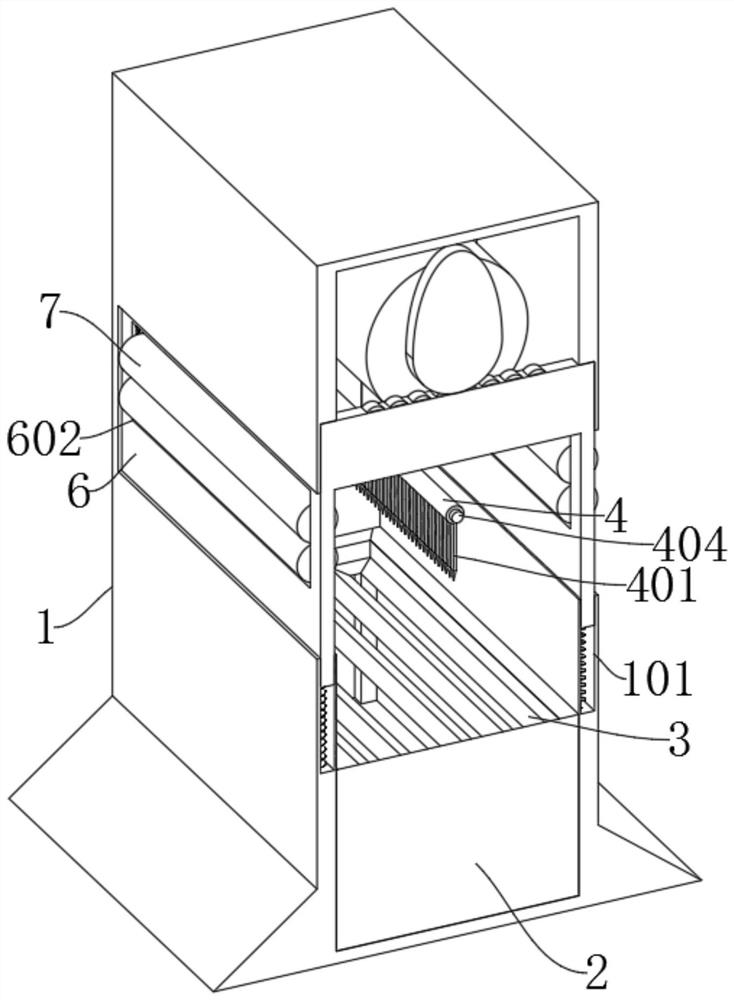

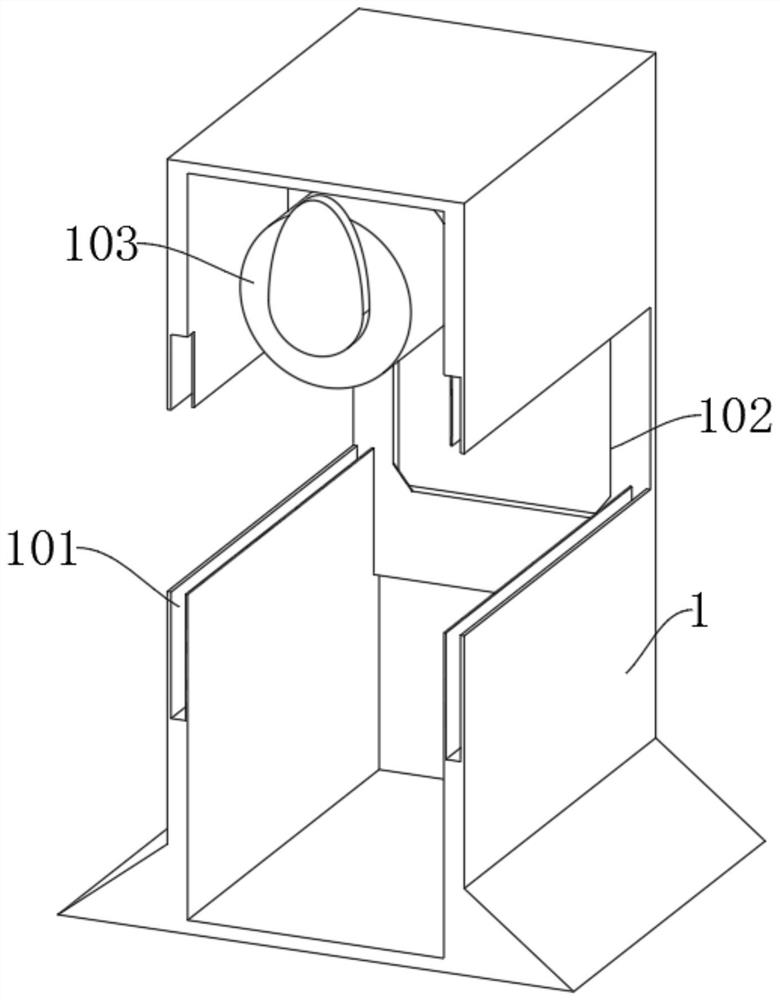

PendingCN114128495AAvoid flying dustSimple structureCrop conditionersMowersAnimal scienceLeather belt

The invention discloses a feed raw material crushing device for animal husbandry, and relates to the technical field of crushing devices. The device comprises a crushing bin, crushing rollers are arranged in the crushing bin, and a discharging mechanism is arranged at the bottom of the crushing bin; a feeding mechanism is arranged at the top of the crushing bin; the feeding mechanism comprises a conveying belt and a belt cover arranged on the outer side of the conveying belt and used for protecting the conveying belt. The belt cover comprises a belt cover body and two side plates, one ends of the two side plates are arranged on the two sides of the crushing bin, and a bottom plate is connected between the bottoms of the two side plates located outside the crushing bin; end plates are welded to the two ends of the two side plates respectively, first belt cover caps are arranged at the two ends of the belt cover respectively, and a second belt cover cap is arranged on the portion, between the two first belt cover caps, of the belt cover body. The belt cover and the discharging mechanism are arranged at the feeding end and the discharging end of the crushing bin, so that the problem that flying dust generated in the existing straw crushing process escapes into air is solved, and flying dust is prevented from escaping.

Owner:丰县鑫耀机械制造有限公司

Plastic recycling, processing and cutting device

InactiveCN112223593AAvoid flying dustSolve the problem that mixed cutting affects the cutting effectPlastic recyclingDirt cleaningElectric machineryKnife blades

The invention discloses a plastic recycling, processing and cutting device, and relates to the field of plastic recycling and processing equipment. The plastic recycling, processing and cutting devicecomprises a processing box, wherein the processing box is provided with a feed inlet, a hydraulic push rod is arranged on the top end of the processing box, and a first material receiving box is arranged on one side of the processing box. By arranging the hydraulic push rod, a pressing plate, a motor, a cutting machine and a cutting plate, the hydraulic push rod operates to drive the pressing plate to move downward to extrude a plastic, so that the plastic with a crisp texture is crushed and slides into the first receiving box through a first discharging groove small in small-caliber, and atthe moment, the motor operates to drive the air cylinder and the cutting machine to move; meanwhile, the air cylinder drives the cutting machine to move up and down, when the cutting machine moves, ablade on the cutting machine is controlled to rotate to cut residual plastic on the cutting plate, and after cutting, small fragments slide into a second receiving box through a second discharging groove large in caliber, so that the problem that the cutting effect is influenced by mixed cutting of plastics of different sizes is effectively solved.

Owner:衡东县祥云塑料有限责任公司

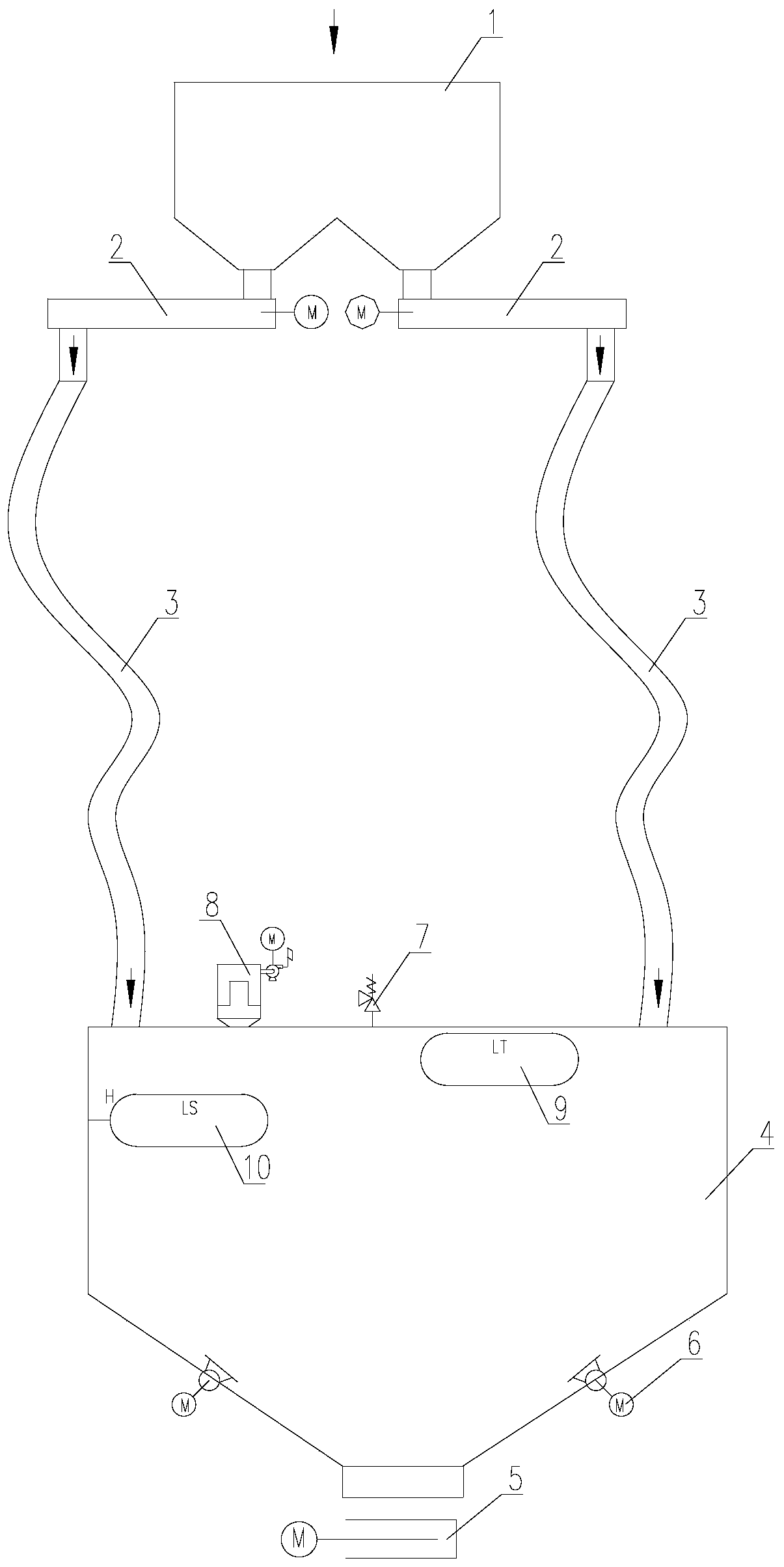

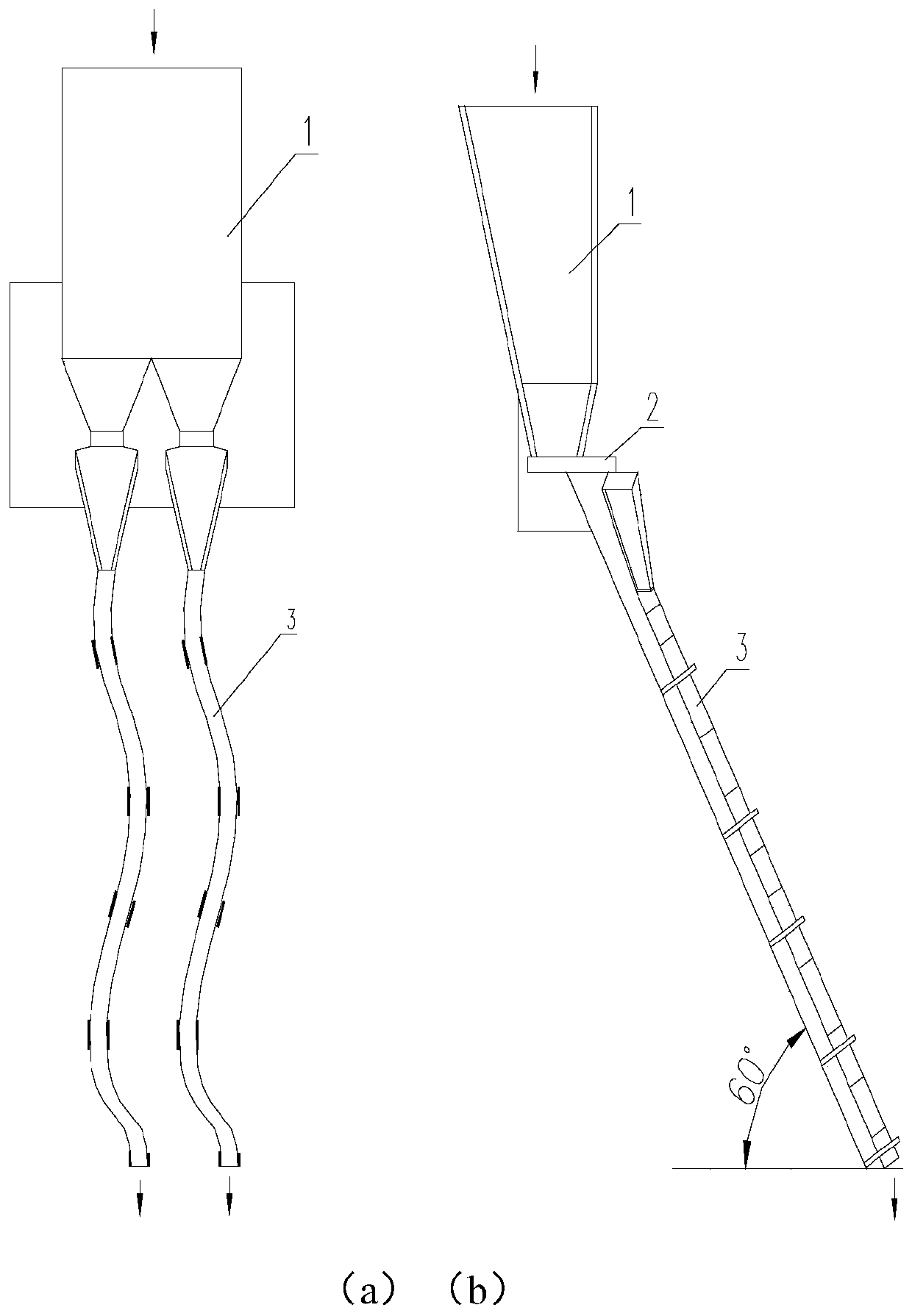

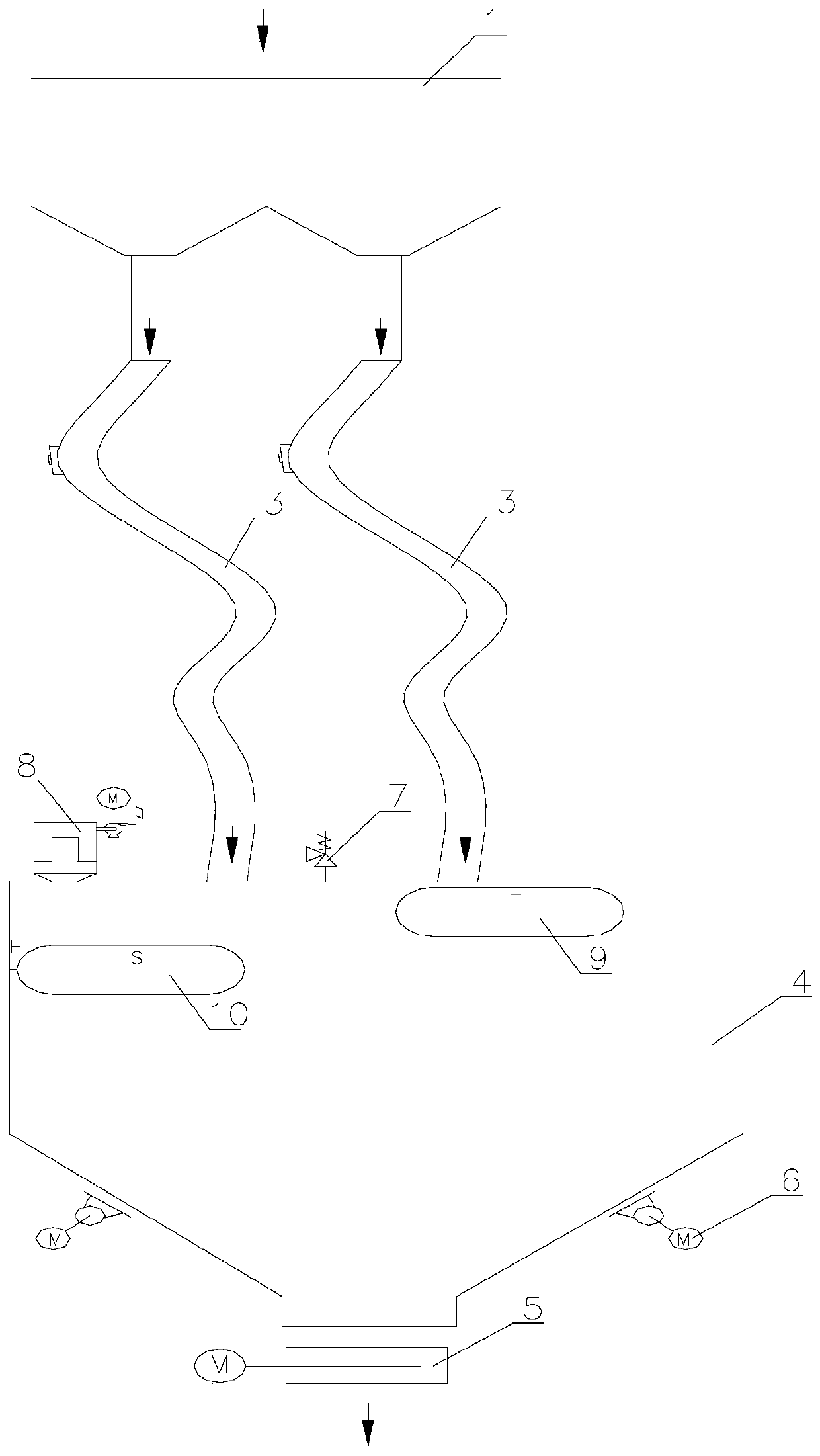

Airflow classifying and airflow drying process for coking coal

ActiveCN102019275BSave energyReduce pollutionGas current separationDrying solid materials with heatWastewaterCoke oven

The invention relates to an airflow classifying and airflow drying process for coking coal. In the process, coke oven flue waste gas is taken as a drying medium, the fluidization technology is adopted for drying the coal, and simultaneously the coal is classified into several classes according to particle sizes by an airflow separation principle. A device consists of a vibrating fluidized bed main body and a classifying collection device, wherein the vibrating fluidized bed main body comprises a primary air supply device, a vibrating main box body with an air distributing plate, a sedimentation classifying section and a drying section with a secondary air inlet; and the classifying collection device completes the final collection of small-particle materials through a group of dust collection devices or several groups of duct collection devices with different structures according to different requirements of the process on the classification of the particle sizes. The airflow classifying and airflow drying process has the advantages that: energy is saved, the wastewater generated in the coking process is reduced, the environmental pollution is lightened and the production capacity of the coke oven can be improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

A twin-roller skein fluffing device based on textile processing

The invention provides a double-roller skein fluffing device based on textile processing, which relates to the technical field of textile processing, and solves the problem that the existing double-roller skein fluffing device cannot comb the yarn when it is in use, and cannot Unable to attach the yarn to excess fine thread ends and wool for cleaning, and unable to assist in cleaning the yarn, including the main body, bottom piece, and stopper; the main body is a rectangular structure, and the interior of the main body is provided with an inner cavity, and the main body is The main body of the skein fluffing device; the bottom part is installed inside the socket of the main body by inserting. The adjusting rod is used to be installed inside the main body, so that when the device is in use, the yarn can pass between the contact parts at the bottom of the adjusting rod, so that the contact parts can comb the yarn and attach it Thread ends and fine wool are removed, so that the cleaned thread ends or wool can be reused, and flying dust can also be effectively avoided.

Owner:安徽省新远升针纺织有限公司

MDB pre-dispersed masterbatch and preparation method thereof

The invention discloses an MDB pre-dispersed masterbatch and a preparation method thereof. By weight part, the masterbatch comprises: 78-81 parts of 2-(4-morpholinyl dithio)benzothiazole, 10-17 partsof a rubber carrier, 1-2 parts of dibutyl phthalate, 1-3 parts of microcrystalline paraffin, 1-2 parts of polyethylene glycol, and 3-8 parts of naphthenic oil. According to the invention, rubber is adopted as the carrier, microcrystalline paraffin and polyethylene glycol are taken as the dispersant to improve the dispersibility of MDB in masterbatch, dibutyl phthalate and naphthenic oil are employed as the plasticizer to reach the effects of synergistic improvement of the fluidity of the masterbatch solution and dispersion promotion, at the same time the original activity of MDB can be effectively retained, and the dust pollution problem can be effectively solved. The preparation method provided by the invention utilizes two premixing to greatly improve the dispersity of all raw materials,ensures that the masterbatch obtained by mixing and extrusion has homogeneous composition, so that MDB can disperse evenly in the masterbatch, thus avoiding agglomeration or clustering phenomenon.

Owner:NINGBO ACTMIX POLYMER

Raw material crushing equipment for microbial feed processing

PendingCN114570509AAvoid accumulationImprove crushing effectFood processingDirt cleaningEngineeringFodder

The invention relates to the technical field of microbial feed, in particular to raw material crushing equipment for microbial feed processing, which comprises a crushing box, a control row key is fixed on the surface of the crushing box, a feeding cylinder is fixed on one side of the top of the crushing box, and an adjusting mechanism is arranged in the feeding cylinder. A primary crushing mechanism is arranged on the surface of the crushing box on one side of the feeding cylinder, a secondary crushing mechanism is arranged on the surface of the crushing box, and a dust collecting mechanism is arranged on one side of the top of the crushing box. According to the crushing equipment, the phenomenon that raw materials are stacked when the crushing equipment is used is avoided, the crushing effect of the raw materials when the crushing equipment is used is improved, and the phenomenon that dust flies when the crushing equipment is used is avoided.

Owner:DANYANG SHANGDE BIOTECH CO LTD +1

2-mercaptotoluimidazole pre-dispersed masterbatch and preparation method thereof

The invention discloses 2-mercaptotoluimidazole pre-dispersed masterbatch and a preparation method thereof. The masterbatch is prepared from the following raw materials in parts by weight: 68 to 72 parts of 2-mercaptotoluimidazole, 9 to 16 parts of a rubber carrier, 1 to 3 parts of zinc stearate, 1 to 2 parts of glyceryl monostearate, 2 to 5 parts of pentaerythritol stearate, and 5 to 12 parts ofindustrial white oil. Rubber is used as the carrier, glyceryl monostearate and zinc stearate are used as dispersing agents, and pentaerythritol stearate and industrial white oil are used as plasticizer, so good dispersibility in the masterbatch is given to MMBI, at the same time, the original activity of the MMBI can be effectively retained, and the problem of dust pollution can be effectively solved; according to the preparation method disclosed by the invention, the dispersity of the raw materials by premixing twice is greatly improved, and uniform composition of the masterbatch obtained bymixing and extrusion is ensured, so that the MMBI is uniformly dispersed in the masterbatch to avoid aggregation or agglomeration.

Owner:NINGBO ACTMIX POLYMER

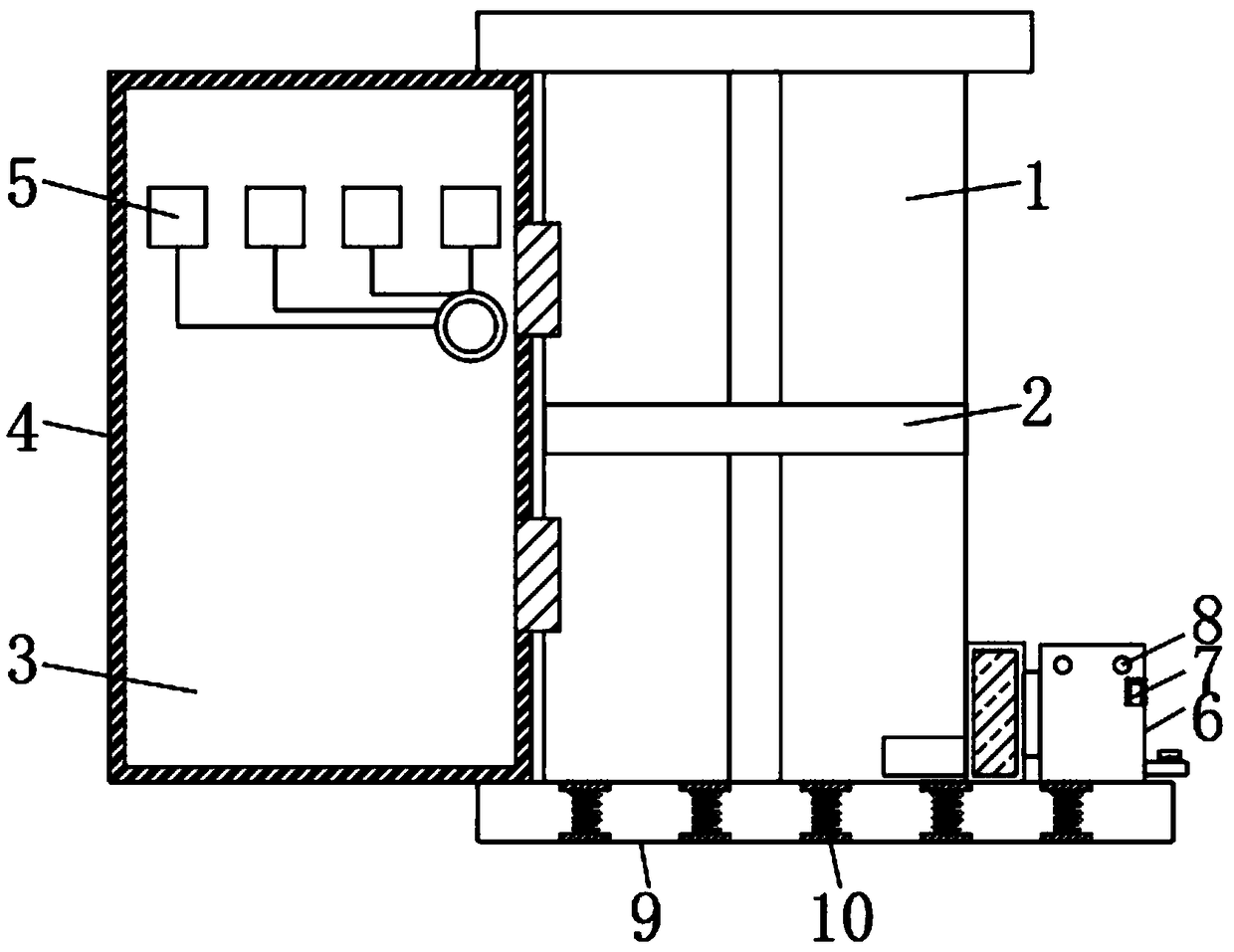

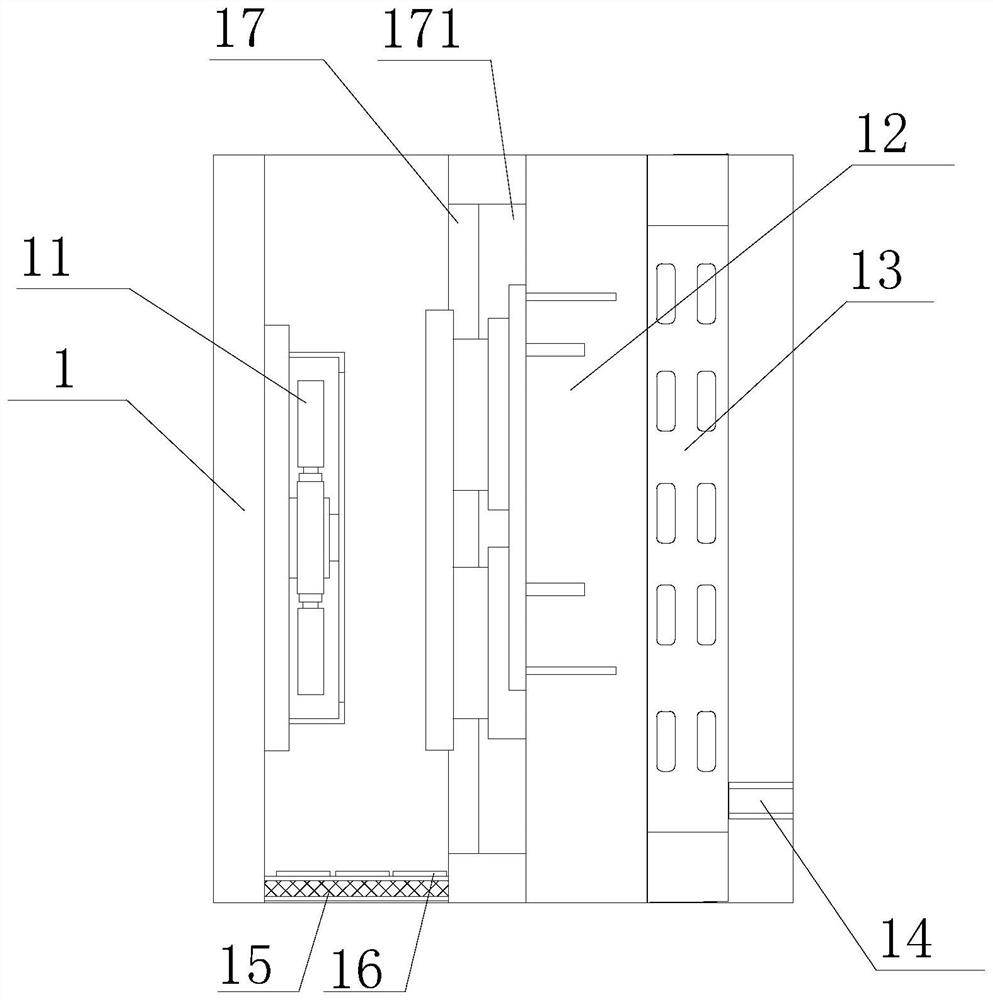

Power cabinet with dust removing function

InactiveCN108963796AEasy to cleanOrganize clearlyBus-bar/wiring layoutsSubstation/switching arrangement casingsEngineeringLiquid level sensor

The invention discloses a power cabinet with a dust removing function, which solves the problems that the dust inside the product is difficult to clean, the induction and management of the line is troublesome and the fixing is inconvenient. The power cabinet comprises a cabinet body, one side of the bottom of the cabinet body is provided with a dust suction port, a dust collector is connected to the end of the dust suction port, a dust outlet is arranged on a side away from the dust suction port of the dust collector, one side of the dust outlet is connected with a water tank, the surface of the water tank is embedded with an indicator light, one side of the indicator light is provided with a PLC controller, a liquid level sensor is installed on the side wall inside the water tank, one side away from the dust collector of the water tank is provided with a water outlet, a valve is installed inside the water outlet, the output end of the liquid level senor is electrically connected to aninput end of the PLC controller, the output end of the PLC controller is electrically connected to the input end of the indicator light, a fixing frame is installed inside the cabinet body, the innerside of the fixing frame is provided with a fixing clamp board, the surface of the fixing clamp board is provided with a clamp groove, the outer side of the fixing frame is provided with a mobile clamp board, and the inner side of the mobile clamp board is provided with a clamp block.

Owner:芜湖辉林奥远自动化科技有限公司

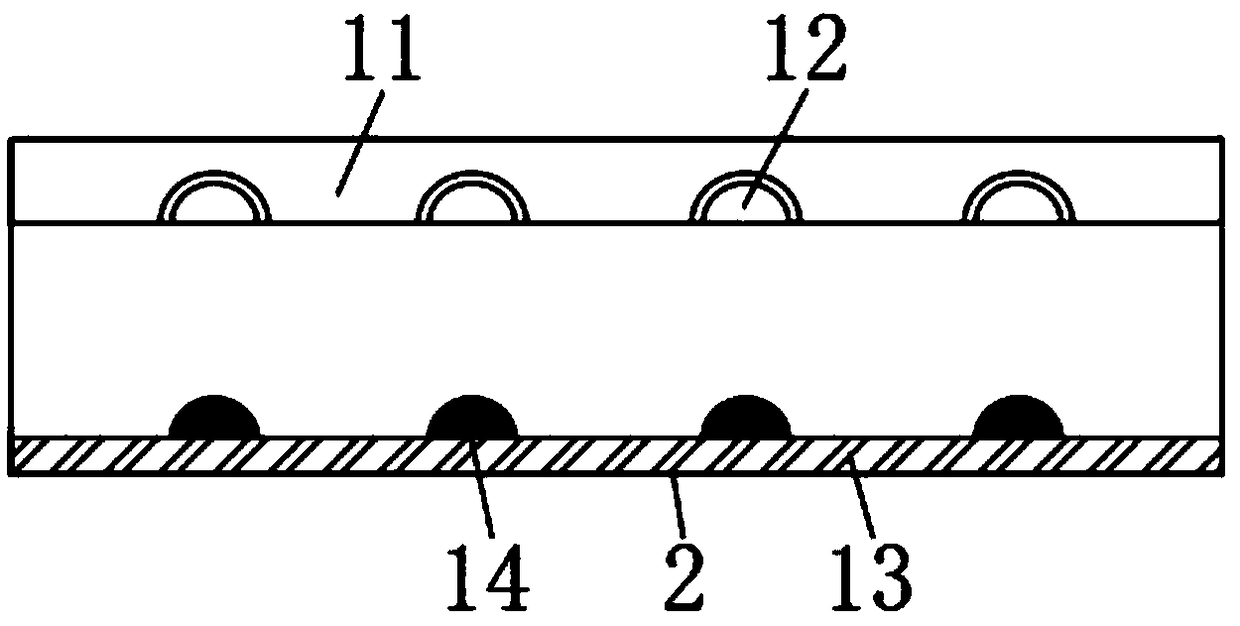

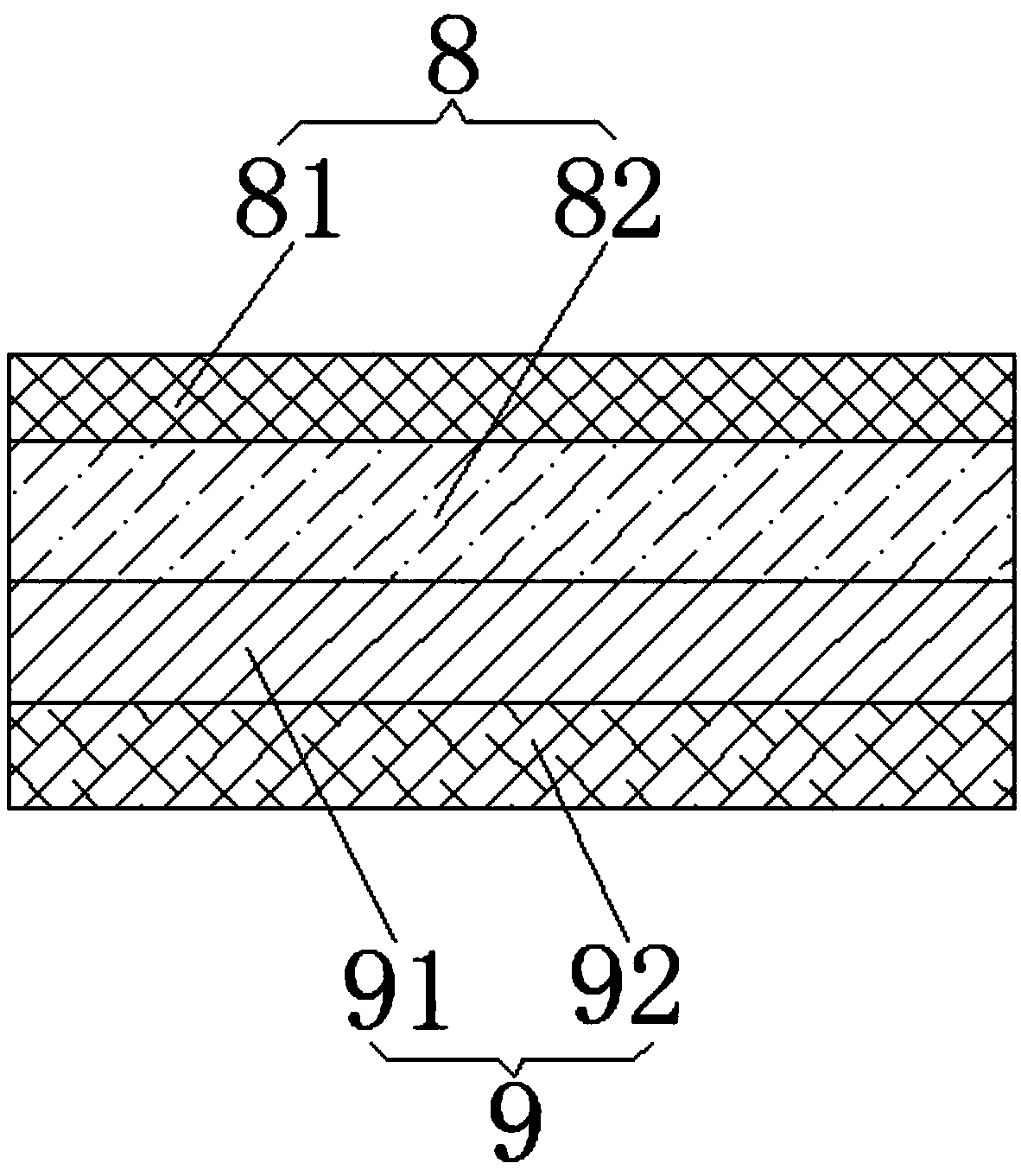

Wear-resistant, anti-sliding, breathable and flame-retardant automobile foot pad

InactiveCN109987009AImprove adsorption capacityAvoid flying dustVehicle arrangementsWear resistantEngineering

The invention discloses a wear-resistant, anti-sliding, breathable and flame-retardant automobile foot pad. The wear-resistant, anti-sliding, breathable and flame-retardant automobile foot pad comprises a first foot pad body, a second foot pad body is movably connected to one side of the first foot pad body, a sundry groove is formed in the top of the first foot pad body, a third foot pad body ismovably connected to the top of the first foot pad body, protrusions are fixedly connected to the top of the third foot pad body, a groove is formed between the two protrusions, the surfaces of the protrusions and the groove are each provided with anti-sliding fiber cloth, the first foot pad body and the second foot pad body are each formed by a wear-resistant layer and a breathable layer, and thethird foot pad body is sequentially formed by a cashmere wool layer, a flame-retardant layer and a wear-resistant layer from top to bottom. According to the wear-resistant, anti-sliding, breathable and flame-retardant automobile foot pad, the adsorption capacity of the foot pad to dust is greatly improved, the environment of an inner chamber is protected, it is avoided that as the foot pad is used for a long time, enormous wear and damage to the automobile foot pad are caused, the economic cost is reduced, the anti-sliding, breathable and flame-retardant performance is improved, the service life is prolonged, and a better using effect is achieved.

Owner:天津冠智地毯有限公司

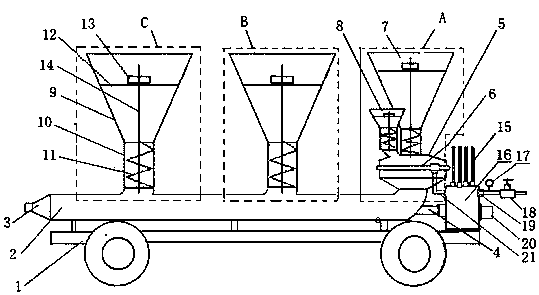

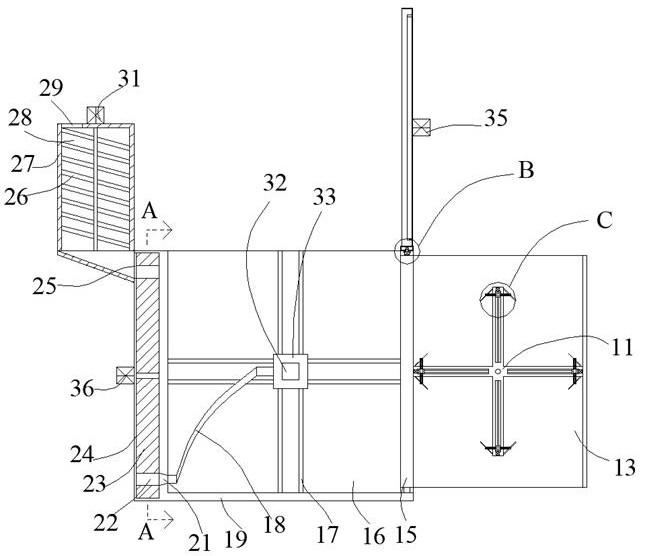

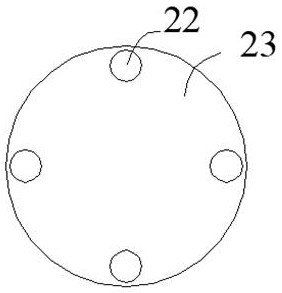

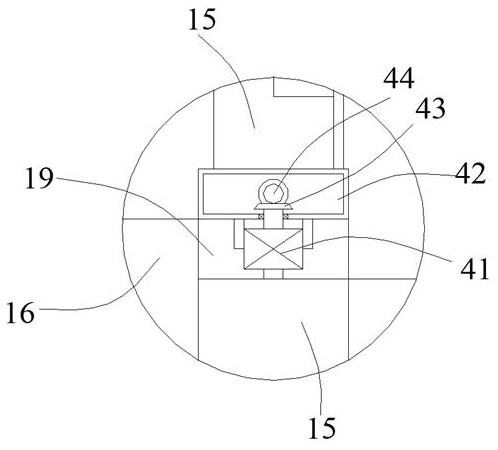

Wind driven automatic-proportioning concrete sprayer

PendingCN110748356AGuaranteed reasonablenessAvoid mismatchUnderground chambersTunnel liningWind drivenStructural engineering

The invention discloses a wind driven automatic-proportioning concrete sprayer which is characterized by comprising a walking rack and a horizontal pipe arranged on the walking rack and used for concrete material proportioning and conveying. A cement paste proportion conveying device, a stone proportion conveying device and a sand proportion conveying device are arranged on a pipe body of the horizontal pipe; and the cement paste proportion conveying device is characterized in that a circle of surrounding water pipe is arranged on a cement paste mixing barrel, and an accelerator proportion conveying device and a cement proportion conveying device are arranged. The wind driven automatic-proportioning concrete sprayer further comprises an integration proportion distribution valve. During spouting, a cement and an accelerator are sprayed with water in the cement paste mixing barrel and are then fully mixed with the water so as to form a cement paste conveyed to the horizontal pipe, the cement paste forwards flows at high speed under the compressed wind action so as to meet and be mixed with stone and sand, and a concrete is output with pressure through a taper pipe at the front end ofthe horizontal pipe.

Owner:SHANDONG UNIV OF SCI & TECH

Abrasive jet processing equipment

ActiveCN111571457BEasy to recycleEasy to closeAbrasive feedersAbrasive machine appurtenancesEngineeringMechanical engineering

The invention discloses an abrasive jet processing equipment, which comprises a middle box body, an open inner cavity is arranged in the middle box body, and a sliding inner cavity located in the middle box body is arranged on one side of the inner cavity, and the sliding inner cavity is arranged in the middle box body. One side of the inner cavity is communicated with a squeeze-in cavity, and one side of the squeeze-in cavity is provided with a feeding device for feeding into the sliding inner cavity. The conveying device in the inner cavity, the middle box is provided with two rotating side plates, and the rotating side plates respectively seal the side and the top surface of the inner cavity. The structure of the device of the present invention is simple. The method of closing and opening the processing space at the same time is adopted. While clamping the tools on the upper side and the side, the tools are sprayed with abrasives for grinding in multiple directions, which effectively improves the sealing efficiency of the equipment and The high efficiency of processing is convenient for abrasive recovery and dust sealing.

Owner:邹平丰泰新材料科技有限公司

Transformer overload protection mechanism and overload protection method

InactiveCN114512319AAvoid flying dustIncrease cleaning dustElectric switchesCleaning using toolsEngineeringStructural engineering

The invention discloses a transformer overload protection mechanism and an overload protection method, and relates to the technical field of transformers, the transformer overload protection mechanism comprises an overload protection box body, a resistance plate, a wire connector, a top plate and a fixed base, the resistance plate is fixedly installed in the overload protection box body, and the wire connector is fixedly installed at the top of the resistance plate; a top plate is fixedly installed on the side face of the wire connector, the bottom of the top plate is arranged on the top of the overload protection box body, and a limiting bolt is arranged on the top of the top plate. The fan mechanism is powered on to rotate, wind power is used for blowing dust of the circuit board mechanism, ventilation holes are matched for ventilation, the dust blowing-off function is achieved, the blown-away dust falls to the top of a dust collection net, the dust is adsorbed and fixed through the adhesion of an adsorption pad, and the problem that the dust flies around is solved; and the dust cleaning function of the device is increased, and the heat dissipation effect of the device is improved.

Owner:广东粤特电力集团有限公司

foam plastic grinder

InactiveCN103317616BRealize fully closed operationAvoid flying dustPlastic recyclingEngineeringCrusher

The invention discloses a foamed plastics crusher which comprises a guide roll, a rough cutting roll and a cutting roll, wherein the guide roll is arranged at a feeding hole of the foamed plastics crusher, the rough cutting roll is positioned below the guide roll, an impurity screen is arranged below the rough cutting roll, a baffle roll is arranged between the impurity screen and the rough cutting roll, an inclined baffle plate is arranged at the bottom of the impurity screen, the cutting roll is arranged at a discharging hole of the impurity screen, and a discharging screen is arranged at the circumferential surface of the cutting roll, which is close to one side of the discharging hole. According to the foamed plastic crusher disclosed by the invention, two stages of treatment such as rough cutting and precise cutting are adopted, the impurity screen for processing impurities is additionally arranged between the rough cutting part and the precise cutting part, impurities attached on foamed plastics after being roughly cut are removed, and the foamed plastics particles are accurately controlled by meshes of the discharging screen.

Owner:李荣君 +4

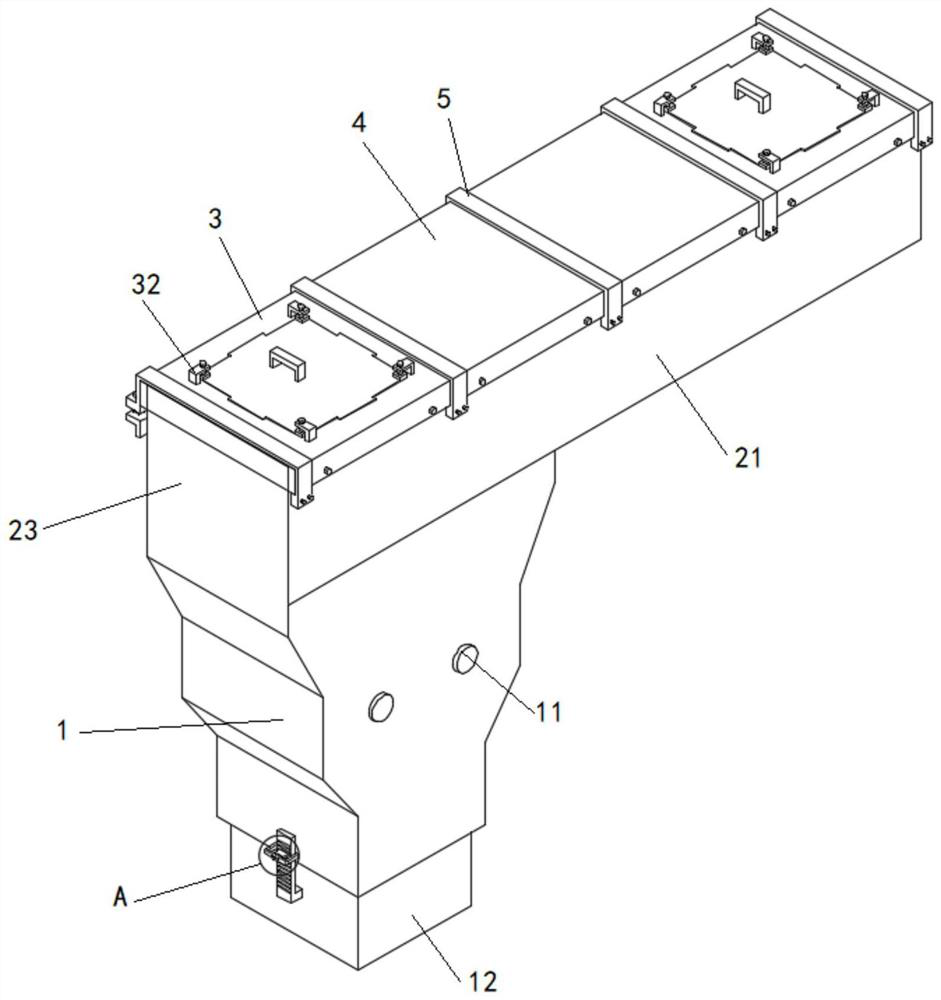

Ash unloading device for large drop ash field

PendingCN110562771AAvoid stickingSolution to short lifeLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses an ash unloading device for a large drop ash field, and belongs to the field of ash conveying. The ash unloading device for the large drop ash field comprises a material receiving hopper, wherein the discharging opening of the material receiving hopper is provided with a curved ash conveying pipe, the discharging opening of the curved ash conveying pipe is provided with a closed material bin, the closed material bin comprises a cylindrical upper end and an inverted circular truncated cone-shaped contractable end, and an ash unloading valve is arranged at the bottom of the contractable end. When ash material in the material receiving hopper falls into the curved ash conveying pipe, the ash material falls under the action of gravity and is continuously accelerated, the fallen ash material continuously impacts the inner wall of the curved ash conveying pipe due to the existence of the curved ash conveying pipe, the deceleration effect is achieved, and the ash material falling speed is controlled; the device is of a fully closed structure, and thus the occurrence of the flying ash condition generated in the ash unloading process is avoided; and on the other hand, due to the existence of the curved ash conveying pipe, the fallen ash material continuously impacts the inner wall of the curved ash conveying pipe, the deceleration effect is achieved, the fallingspeed of the ash material is controlled, so that the source for generating flying ash is further reduced, and secondary flying, caused by too fast speed during ash unloading and conveying, of the ashis prevented.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Cleaning device for exterior of heat boiler

InactiveCN108465691AAvoid flying dustEasy to convertUsing liquid separation agentHollow article cleaningWater pipeEngineering

The invention aims to provide a cleaning device for the exterior of a heat boiler. The cleaning device comprises a base. A middle plate is arranged at the top of the base. A rotary plate is arranged at the top of the middle plate. A rotary head is arranged in the middle of the top of the middle plate and inserted into the rotary plate. A first mounting block and a second mounting block are separately arranged on the left side and the right side of the top of the rotary plate. A first water pipe is mounted in the first mounting block, and atomized water spray heads are distributed on the left side of the first water pipe in a connected mode. A second water pipe is arranged in the second mounting pipe, and high-pressure water spray heads are distributed on the right side of the second waterpipe. The atomized water spray heads spray atomized water to the outer surface of the boiler firstly, so that dust is mixed with water and is prevented from flying everywhere, then the high-pressure water spray heads spray high-pressure water to the outer surface of the boiler, and thus, the outer surface of the boiler is completely cleaned; the rotary plate is arranged so that the atomized waterspray heads and the high-pressure water spray heads can be switched conveniently; and universal wheels are arranged, so that the cleaning device is convenient to move and operate, and the exterior ofthe heat boiler can be efficiently and rapidly cleaned.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com