Double-roller type skein fluffing device based on textile processing

A double-roller, skeining technology, applied in the field of textile processing, can solve the problems of inability to double-layer fluffing of yarn, inability to clean yarn wool, and inability to improve fluffing effect, etc., and achieve the effect of avoiding flying dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

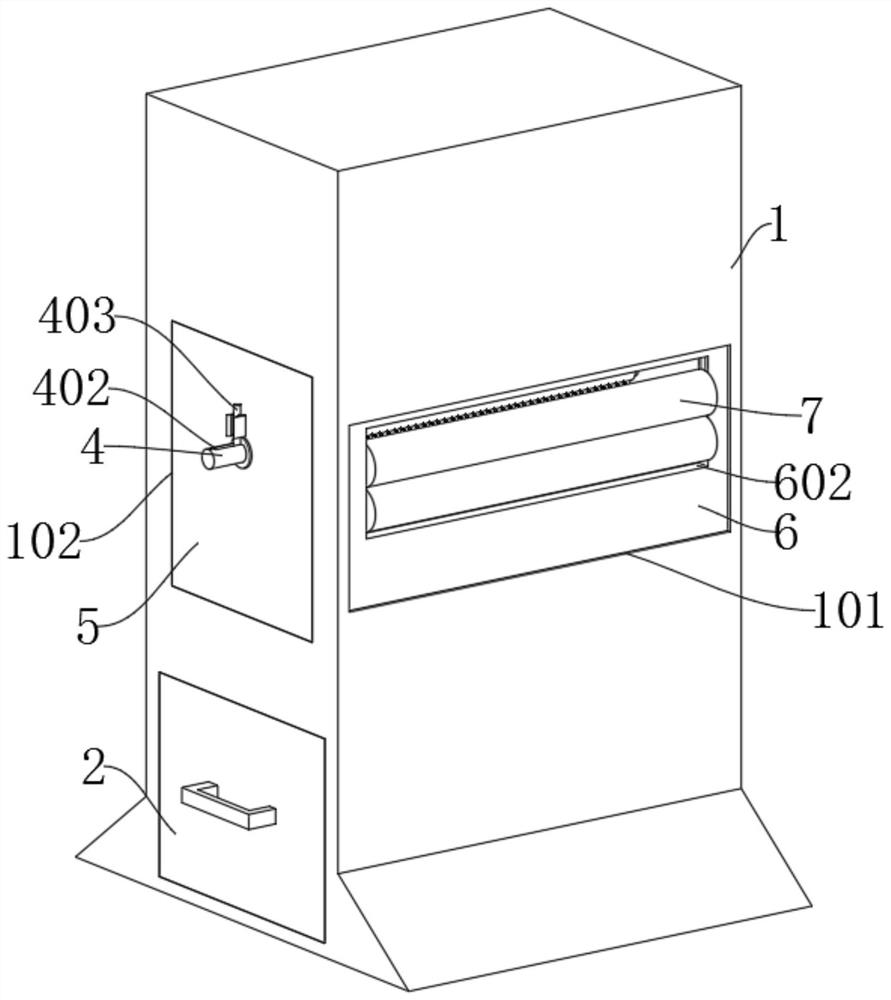

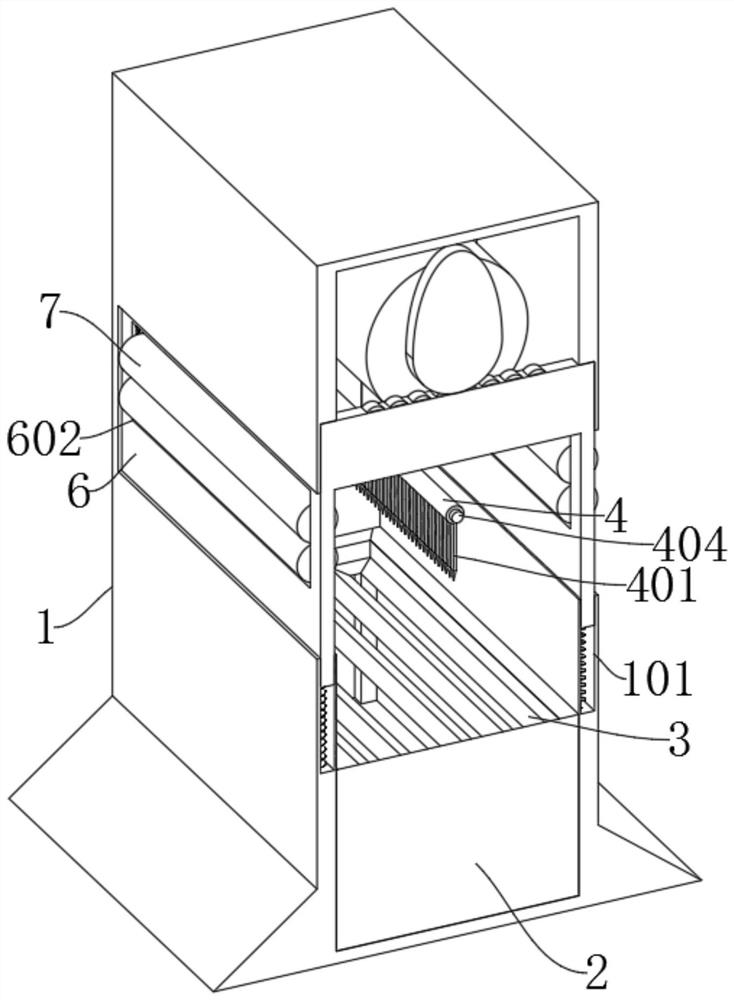

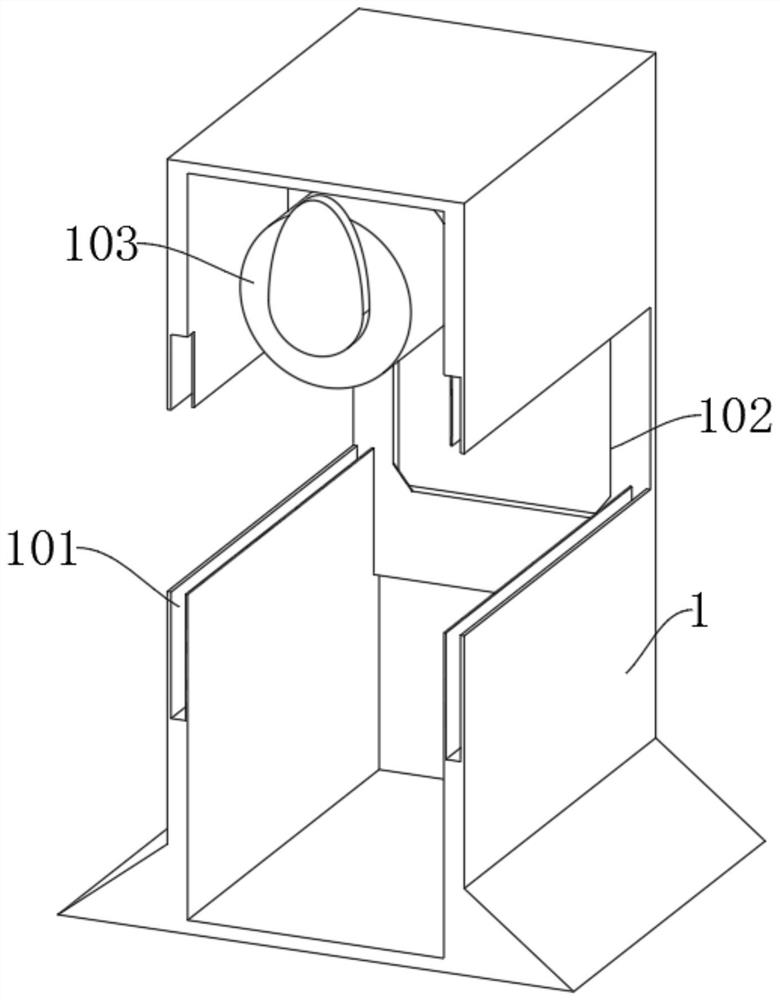

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a double-roller skein fluffing device based on textile processing, which includes a main body 1, a bottom part 2, a stopper 3, an adjustment rod 4, a sealing plate 5, a moving part 6 and a rotating roller 7; the main body 1 is rectangular structure, and the inside of the main body 1 is provided with an inner cavity, and the main body 1 is the main body of the skein fluffing device; the bottom part 2 is installed inside the socket of the main body 1 by inserting, and the bottom part 2 is at the inner bottom of the main body 1; The stopper 3 is installed inside the inner compartment 201 by means of embedding; two grooves of triangular structure are arranged on both sides of the bottom of the inner end of the sealing plate 5, and the inside of the groove is embedded with a baffle plate with a side groove 102; The plate 5 is embedded and installed inside the side groove 102, and the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com