Ethanol gasoline combustion enhancer and preparation method thereof

A technology of combustion enhancer and ethanol gasoline, which is applied in the field of fuel additives, can solve the problems that the stability of ethanol gasoline cannot be improved, the stability of ethanol gasoline is not good, and the power is insufficient, so as to solve the problems of insufficient power, low cost, and low power. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

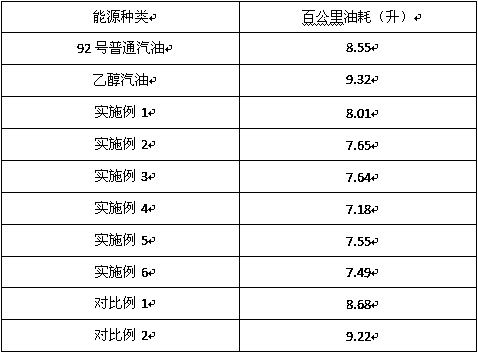

Examples

Embodiment 1

[0039] Adopt the following method to prepare ethanol gasoline combustion enhancer:

[0040] 1) Prepare the wall material solution: dissolve xanthan gum in water to obtain an aqueous solution of xanthan gum with a concentration of 5wt%, that is, the wall material solution.

[0041] 2) Preparation of core material solution: dissolve nitrocellulose and Tween 80 in ethyl acetate to form a core material solution; in the core material solution, the concentration of nitrocellulose is 8wt%; 80%.

[0042] 3) Emulsification: Add the core material solution into the wall material solution at 0-4°C, stir at a high speed at a stirring speed of 1000r / min to obtain an emulsion; according to the volume ratio, core material solution: wall material solution = 1: 8.

[0043] 4) Freeze-drying: freeze-dry the emulsion to obtain nitrocellulose capsules.

[0044] 5) Mixing and dispersing: Mix nitrocellulose capsules, castor oil, dicyclopentadienyl iron, n-hexane, amyl nitrate and surfactants evenl...

Embodiment 2

[0049] Adopt the following method to prepare ethanol gasoline combustion enhancer:

[0050] 1) Preparation of wall material solution: dissolving xanthan gum in water to obtain an aqueous solution of xanthan gum with a concentration of 10wt%, that is, wall material solution.

[0051] 2) Preparation of core material solution: dissolve nitrocellulose and Tween 80 in ethyl acetate to form a core material solution; in the core material solution, the concentration of nitrocellulose is 2wt%; 40%.

[0052] 3) Emulsification: Add the core material solution into the wall material solution at 0-4°C, stir at a high speed at a stirring speed of 500r / min to obtain an emulsion; according to the volume ratio, core material solution: wall material solution = 1: 2.

[0053] 4) Freeze-drying: freeze-dry the emulsion to obtain nitrocellulose capsules.

[0054] 5) Mixing and dispersing: Mix nitrocellulose capsules, castor oil, dicyclopentadienyl iron, n-hexane, amyl nitrate and surfactants even...

Embodiment 3

[0057] Adopt the following method to prepare ethanol gasoline combustion enhancer:

[0058] 1) Preparation of wall material solution: dissolving xanthan gum in water to obtain an aqueous solution of xanthan gum with a concentration of 8wt%, that is, the wall material solution.

[0059] 2) Preparation of core material solution: dissolve nitrocellulose and Tween 80 in ethyl acetate to form a core material solution; in the core material solution, the concentration of nitrocellulose is 6wt%; 60%.

[0060] 3) Emulsification: Add the core material solution into the wall material solution at 0-4°C, stir at a high speed at a stirring speed of 800r / min to obtain an emulsion; according to the volume ratio, core material solution: wall material solution = 1: 4.

[0061] 4) Freeze-drying: freeze-dry the emulsion to obtain nitrocellulose capsules.

[0062] 5) Mixing and dispersing: Mix nitrocellulose capsules, castor oil, dicyclopentadienyl iron, n-hexane, amyl nitrate and surfactants e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com