Polyurea floor coating and preparation and application methods thereof as well as carbamide resin

A technology of polyurea resin and floor coatings, applied in the field of coatings, can solve the problems of slow drying, poor impact resistance, poor flexibility, etc., and achieve the effects of high solid content, film thickness, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the present invention also provides the preparation method of above-mentioned polyurea floor paint, and described preparation method comprises the steps:

[0035] Step S01: Obtain each component according to the components and contents in the polyurea floor coating;

[0036] Step S02: Stir and disperse polyaspartate polyurea resin, titanium dioxide, dispersant, and barium sulfate or glass powder at high speed for 20-30 minutes;

[0037] Step S03: After reducing the rotation speed, add talc powder or fine sand and stir for 5-15 minutes, then add defoamer and leveling agent, stir for 10-20 minutes, unload and pack to obtain polyaspartic acid ester polyurea floor coating.

[0038] Wherein, in step S03, when the raw material composition of the polyurea floor coating also includes a color paste, the color paste is added together with the defoamer and the leveling agent.

[0039] In the above step S02, the polyaspartate polyurea resin can directly add titan...

Embodiment 1

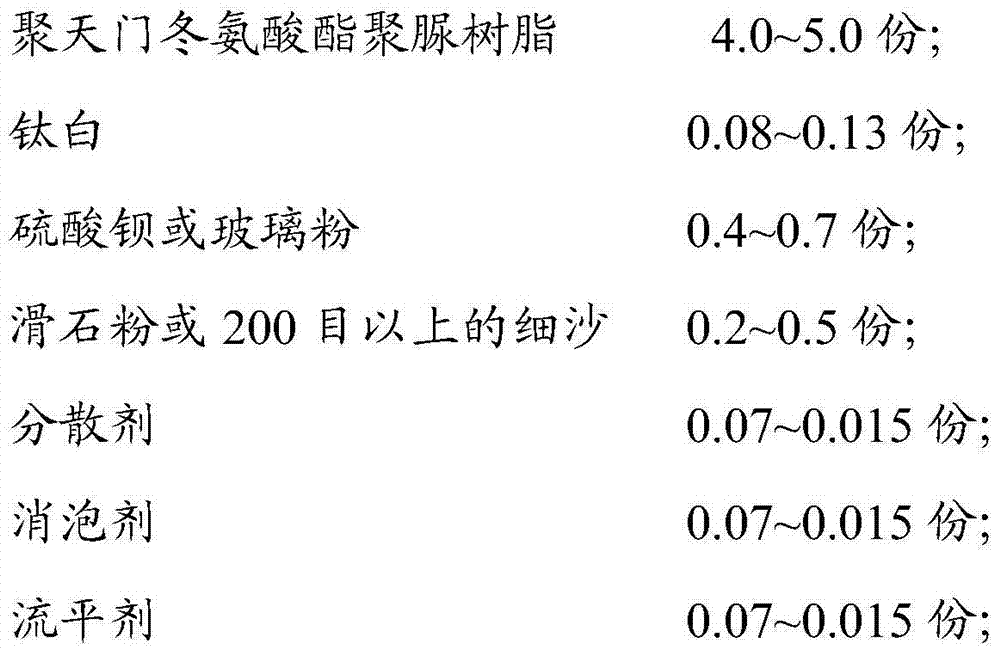

[0048] A method for distributing components of a polyurea floor coating and a preparation method thereof, the polyurea floor coating contains the following components by weight:

[0049]

[0050] Its preparation method technological process comprises the following steps:

[0051] S11. Add 1.80 kg of diethyl maleate and 2.83 kg of DMDC to the reaction kettle, heat up to 65° C., react for 72 hours under stirring, and cool down to room temperature to obtain polyaspartate polyurea resin;

[0052] S12. Add titanium dioxide, barium sulfate, and a dispersant to the polyaspartate polyurea resin in step S11, and stir and disperse at high speed for 25 minutes to obtain a mixed material;

[0053] S13. After reducing the rotating speed, go to step S12 to obtain the talcum powder in the mixed material and stir for 10 minutes, then mix the blue slurry, defoamer, and leveling agent for 15 minutes, then unload, pack, and obtain a polyurea floor coating.

Embodiment 2

[0055] A component formula of polyurea floor paint and a preparation method thereof. This polyurea floor paint contains the components of following parts by weight:

[0056]

[0057] Its preparation method technological process comprises the following steps:

[0058] S21. Add 1.80 kg of diethyl maleate and 2.8 kg of DMDC to the reactor, heat up to 65° C., react under stirring for 72 hours, cool down to room temperature, and obtain polyaspartic acid ester polyurea resin;

[0059] S22. Add titanium dioxide, barium sulfate, and a dispersant to the polyaspartate polyurea resin in step S11, and stir and disperse at high speed for 25 minutes to obtain a mixed material;

[0060] S23. After reducing the rotating speed, go to step S12 to obtain the talcum powder in the mixed material and stir for 10 minutes, then add the blue paste, defoamer and leveling agent, stir for 15 minutes, unload, pack, and obtain polyurea floor coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com