Vapor phase antirust blown polyethylene film and making method thereof

A technology of gas phase rust prevention and film blowing, applied in the field of gas phase rust prevention, can solve the problems of low cost, short effective time and high cost of desiccant rust prevention, achieve environmental protection and human health, improve the rust prevention effect, and prolong the antirust effect. The effect of rust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A polyethylene gas-phase antirust blown film comprises low-density polyethylene resin, diisooctyl phthalate, dibutyl phthalate, light calcium carbonate, sodium benzoate, cyclohexylamine phosphite, Azelaic acid dicyclohexylamine, antioxidant, each component and parts by weight thereof are:

[0015]

[0016] Wherein, the antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate.

[0017] Its preparation method is: after each component is measured in parts by mass, it is divided into materials containing and not containing gas phase antirust agent, stirred in a high-speed mixer for 10-15 minutes, and the stirring temperature is 30-50°C, and then enters the manufacturing process. Granulator, the granulation temperature is 140-152°C, the melt temperature is 147°C, the melt of the mixed material containing the vapor phase rust inhibitor is fed into the inner layer of the die head of the co-extrusion blow molding unit, and the outer layer is made of benzene-...

Embodiment 2

[0021] A polyethylene gas-phase antirust blown film comprises low-density polyethylene resin, dibutyl phthalate, talcum powder, sodium benzoate, cyclohexylamine phosphite, dicyclohexylamine sebacate, antioxidant , each component and its mass parts are:

[0022]

[0023] Wherein, the antioxidant preferably uses 1,1,3-tris(2-methyl-4-hydroxyl-5-tert-butylphenyl)butane.

[0024] The preparation method of the polyethylene gas-phase antirust blown film is the same as that of Example 1.

Embodiment 3

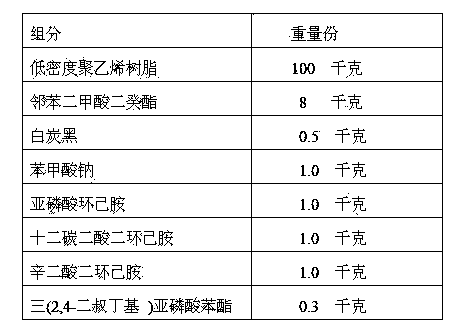

[0026] A polyethylene gas-phase antirust blown film comprises low-density polyethylene resin, didecyl phthalate, white carbon black, sodium benzoate, cyclohexylamine phosphite, dicyclohexylamine dodecanedioic acid, Dicyclohexylamine suberate and tris(2,4-di-tert-butyl)phenyl phosphite, each component and parts by weight thereof are:

[0027]

[0028] The preparation method of the polyethylene gas-phase antirust blown film is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com