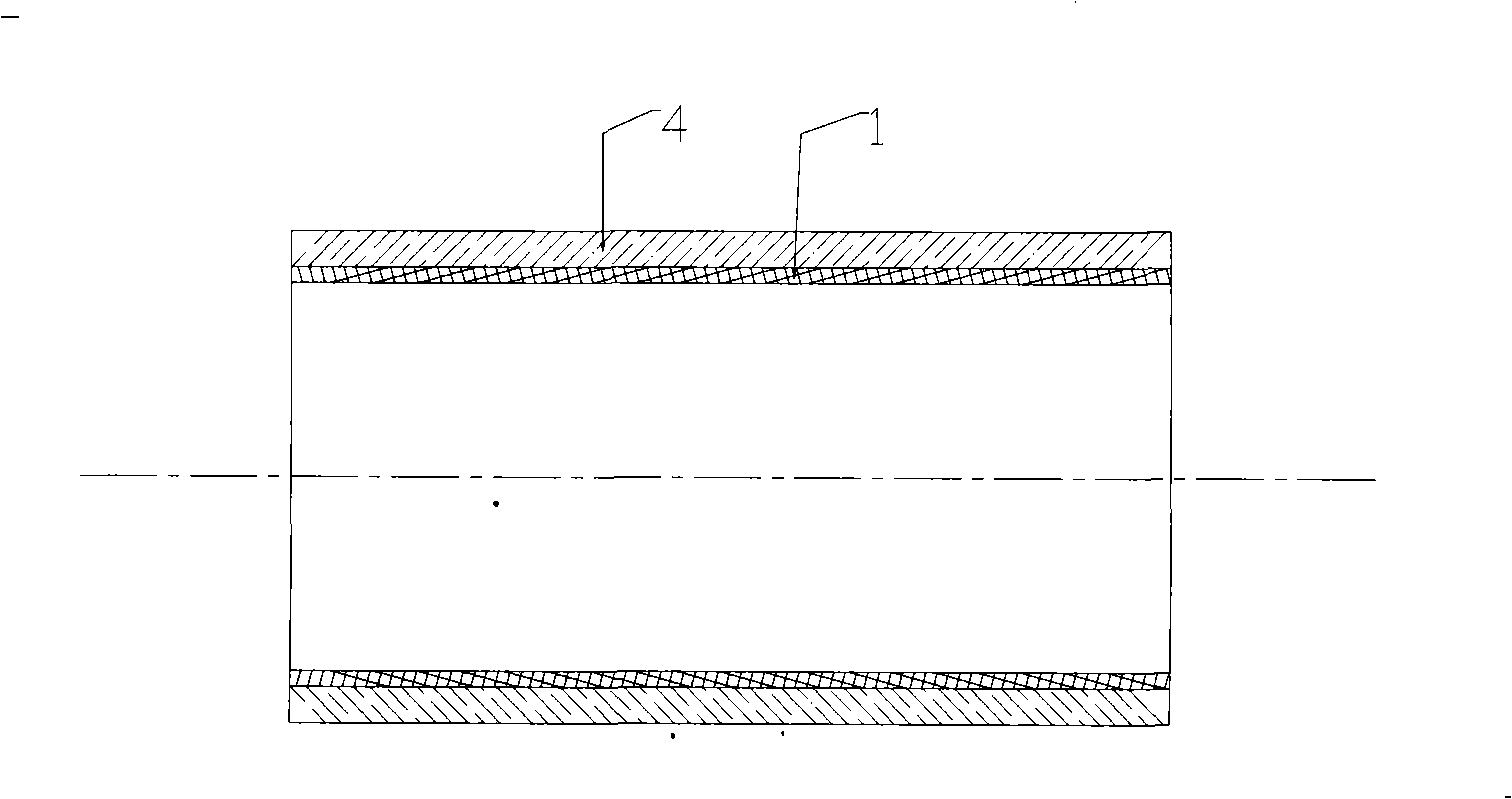

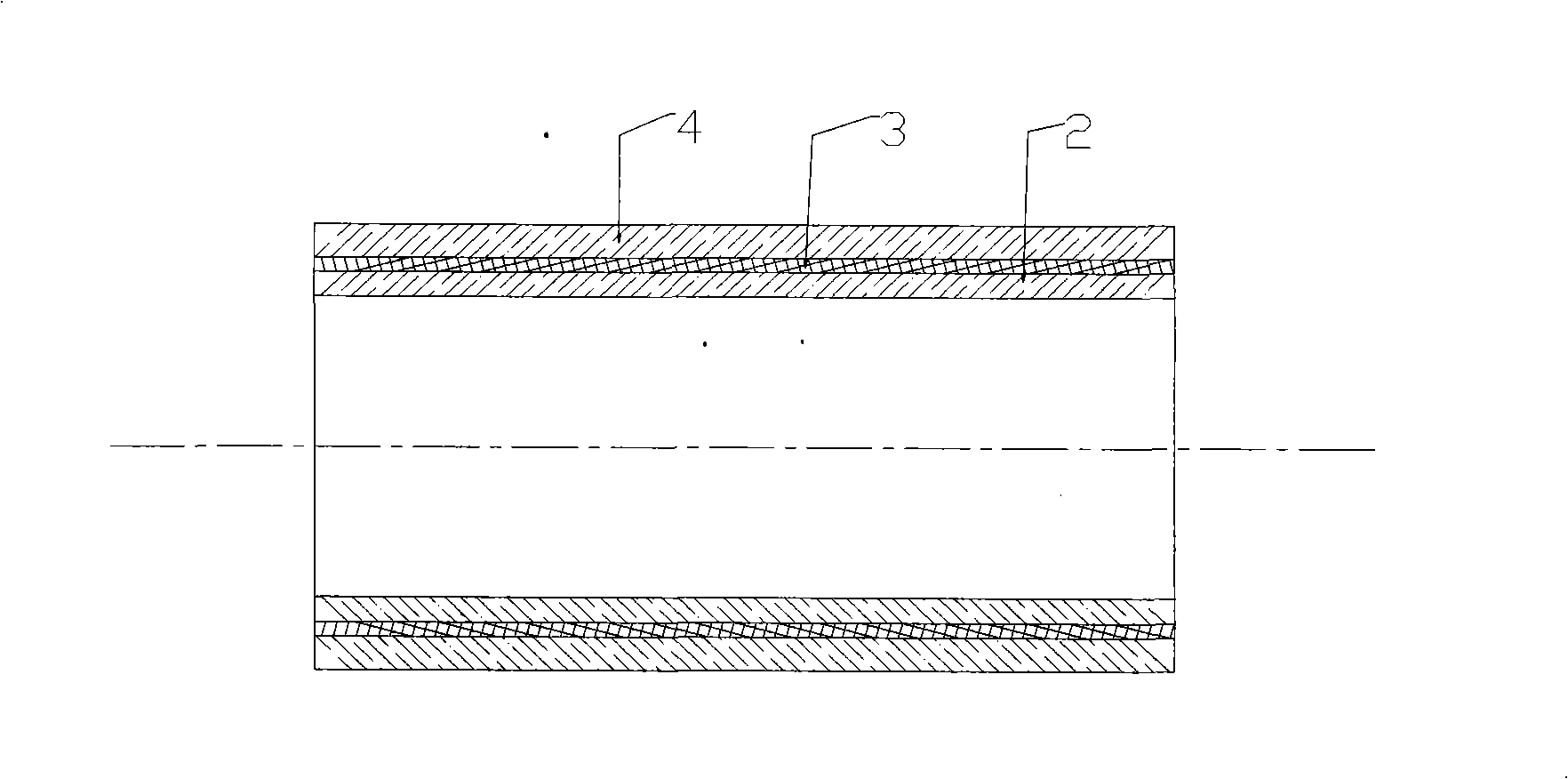

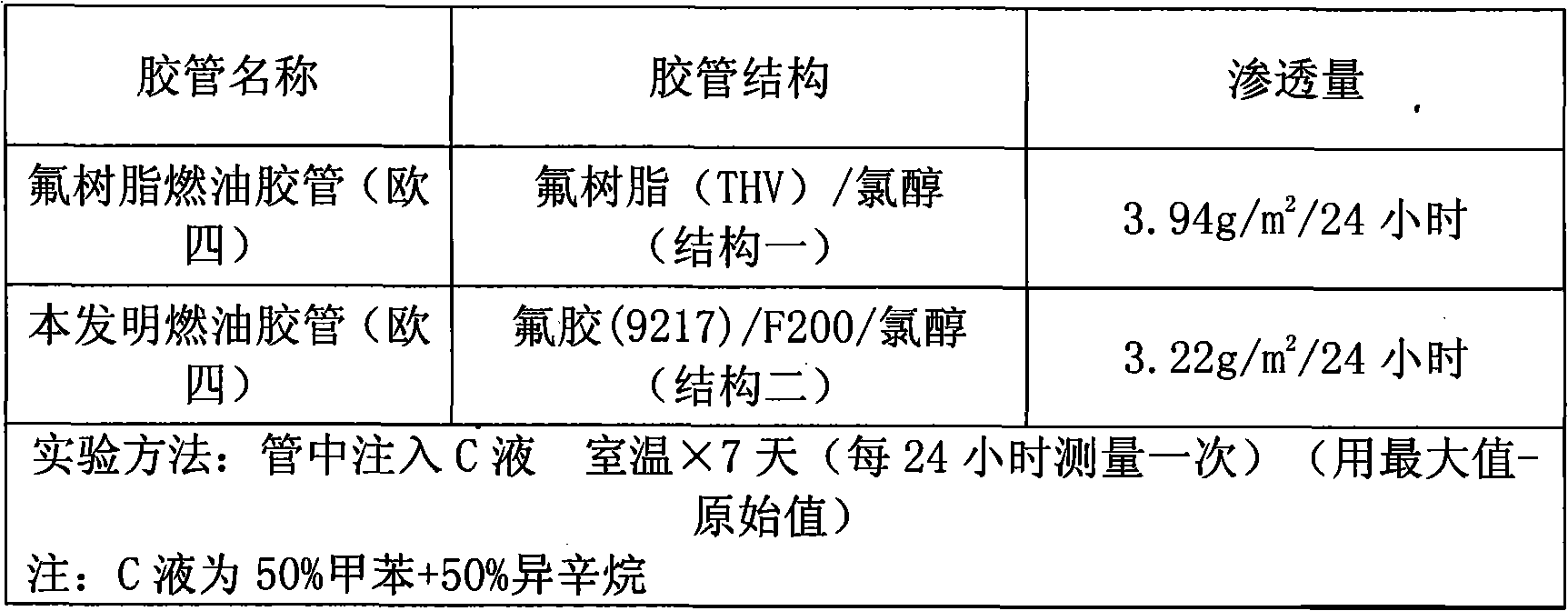

Three-layer tetrafluoroethylene resin film-wound fuel hose and manufacturing method thereof

A technology of tetrafluoroethylene resin and fuel hose, applied in the direction of hoses, pipes, tubular objects, etc., can solve problems such as difficulty in extruding the resin layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] To produce a three-layer fuel hose with an inner diameter of 7.3±0.3mm×10.4±0.5mm×1000±3mm, the steps are as follows:

[0024] 1. Extrusion process

[0025] ①Single-screw straight extruder with a core to extrude the inner layer of fluororubber in the hose, the diameter of the mandrel is 7.3±0.1mm, the extrusion temperature: 95°C, 85°C, 85°C, 75°C, and the extrusion wall thickness is 0.5mm , extrusion speed 16m / min.

[0026] ②Select the F200 film with a model size of 0.05mm×25mm, and wrap it on the outside of the inner rubber through a cloth wrapping machine, with a lap width of 2mm; the winding line speed is 16m / min, and the ratio of rotation speed to line speed is 40:1.

[0027] ③ After traction, the outer layer of rubber is coated directly through a single-screw T-type extruder. The outer layer of rubber can be selected from chlorohydrin rubber, chlorosulfonated polyethylene rubber, chlorinated polyethylene rubber, acrylate rubber, butadiene rubber according to the d...

Embodiment 2

[0037] To produce a three-layer fuel hose with an inner diameter of 14.5±0.3mm×18.8±0.5mm×1000±3mm, the steps are as follows:

[0038] 1. Extrusion process

[0039] ①Single-screw straight extruder with a core to extrude the inner layer of fluorine rubber in the hose, the diameter of the mandrel is 14.2±0.1mm, the extrusion temperature: 90°C, 80°C, 80°C, 70°C; the extrusion wall thickness is 0.7mm , extrusion speed 12m / min.

[0040] ② Select the F200 film with a model size of 0.05mm×35mm, and wrap it on the outside of the inner rubber through a cloth wrapping machine, with a lap width of 2mm; the winding line speed is 16m / min, and the ratio of rotation speed to line speed is 35:1.

[0041] ③ After traction, the outer layer of rubber is coated directly through a single-screw T-type extruder. The outer layer of rubber can be selected from chlorohydrin rubber, chlorosulfonated polyethylene rubber, chlorinated polyethylene rubber, acrylate rubber, butadiene rubber according to the...

Embodiment 3

[0051] To produce a three-layer fuel hose with an inner diameter of 25±0.3mm×29.5±0.5mm×1000±3mm, the steps are as follows:

[0052] 1. Extrusion process

[0053] ①Single-screw straight extruder with a core to extrude the inner layer of fluororubber in the hose, the diameter of the mandrel is 25±0.1mm, the extrusion temperature: 85°C, 75°C, 75°C, 65°C; the extrusion wall thickness is 0.8 mm, extrusion speed 10m / min.

[0054] ②Select the F200 film with a model size of 0.05mm×40mm, and wrap it on the outside of the inner rubber through a cloth wrapping machine, with a lap width of 2mm; the winding line speed is 10m / min, and the ratio of rotation speed to line speed is 32:1.

[0055] ③ After traction, the outer layer of rubber is coated directly through a single-screw T-type extruder. The outer layer of rubber can be selected from chlorohydrin rubber, chlorosulfonated polyethylene rubber, chlorinated polyethylene rubber, acrylate rubber, butadiene rubber according to the design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com