Method for preparing micro-emulsified procetane

An additive and microemulsion technology, applied in the field of chemistry, to improve physical and chemical properties and use effects, rich raw materials, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: the preparation method of a kind of microemulsion diesel oil additive of the present invention, the steps are as follows:

[0011] Step 1: Select by weight percentage: 8% 120# mineral spirits, 8% cyclohexanone, 7% ethyl acetate, 9% calcium sulfonate, 21% isooctyl nitrate, 14% dioctyl sodium iodide succinate Salt, 8% copper naphthenate, 7% manganese naphthenate, 7% barium naphthenate, 3.5% magnesium naphthenate, 7% methyl ethyl ketone peroxide, 0.35% hydrazine hydrate and 0.15% diethylhydroxylamine, at room temperature Under normal pressure, add the above-mentioned raw materials into the mixing tank in order, and make the conditioner after 100 minutes of sufficient stirring;

[0012] Step 2: Select by weight percentage: 60% oleic acid, 10% naphthenic acid, 6% ethanolamine, 2% triethanolamine, 7% cyclohexylamine, 3% n-butanol, 3% isopropanol, Span-802 %, Span-200.5%, polyethylene glycol 0.5%, alkylphenol polyoxyethylene ether OP 4 2%, Alkylphenol polyoxye...

Embodiment 2

[0013] Embodiment 2: select by weight percentage: oleic acid 68%, ethanolamine 6%, triethanolamine 2%, cyclohexylamine 8%, n-butanol 4%, Virahol 3%, Span-80 2%, Span -20 0.5%, polyethylene glycol 0.5%, alkylphenol polyoxyethylene ether OP 4 2%, Alkylphenol polyoxyethylene ether OP 10 0.5%, conditioner 3.5%, under the condition of normal temperature and normal pressure, add the above raw materials into the stirring tank in order, after 40-60 minutes of full stirring, a brownish yellow transparent liquid is obtained, which is the microemulsion diesel oil additive.

Embodiment 3

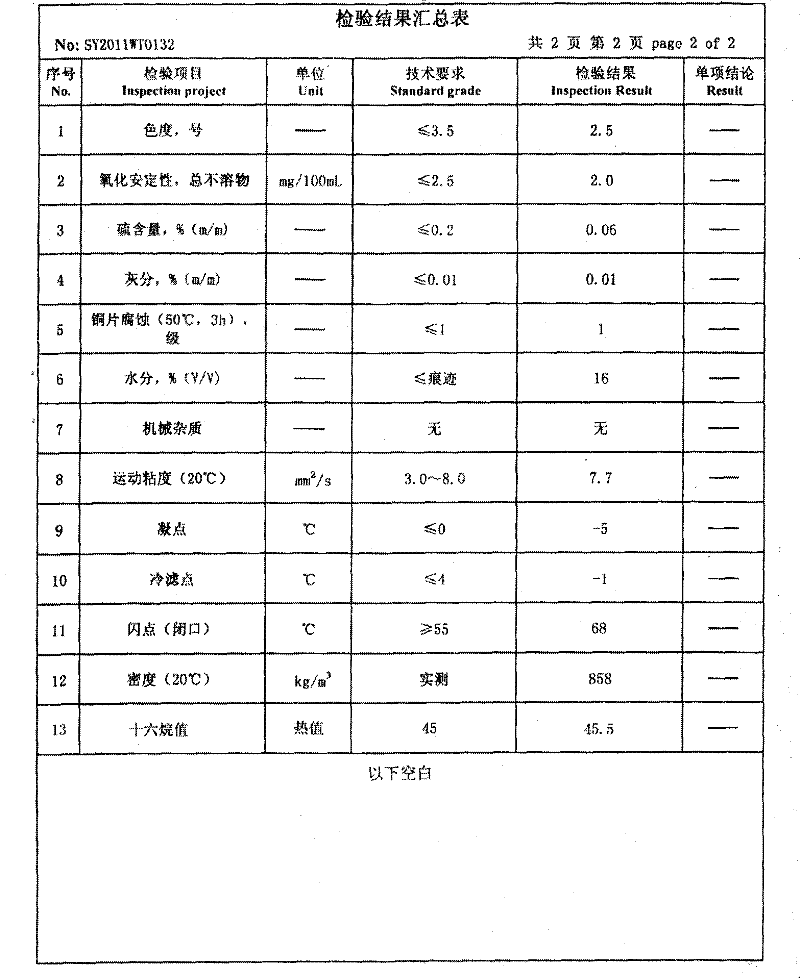

[0014] Embodiment 3: below is the detection report of emulsified diesel oil:

[0015] Heilongjiang Provincial Institute of Quality Supervision and Testing

[0016] The Academy of Quality Supervision and Inspection in Heilongjiang Province

[0017] Inspection Report

[0018] Test Report

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com