Synthetic process of hexazinone

A synthesis process, the technology of hexazinone, which is applied in the field of synthesis process of hexazinone, can solve the problems of low reaction process efficiency, high production cost, and large amount of waste water, so as to improve efficiency, save energy consumption, and reduce waste water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

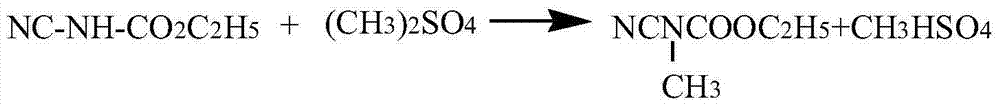

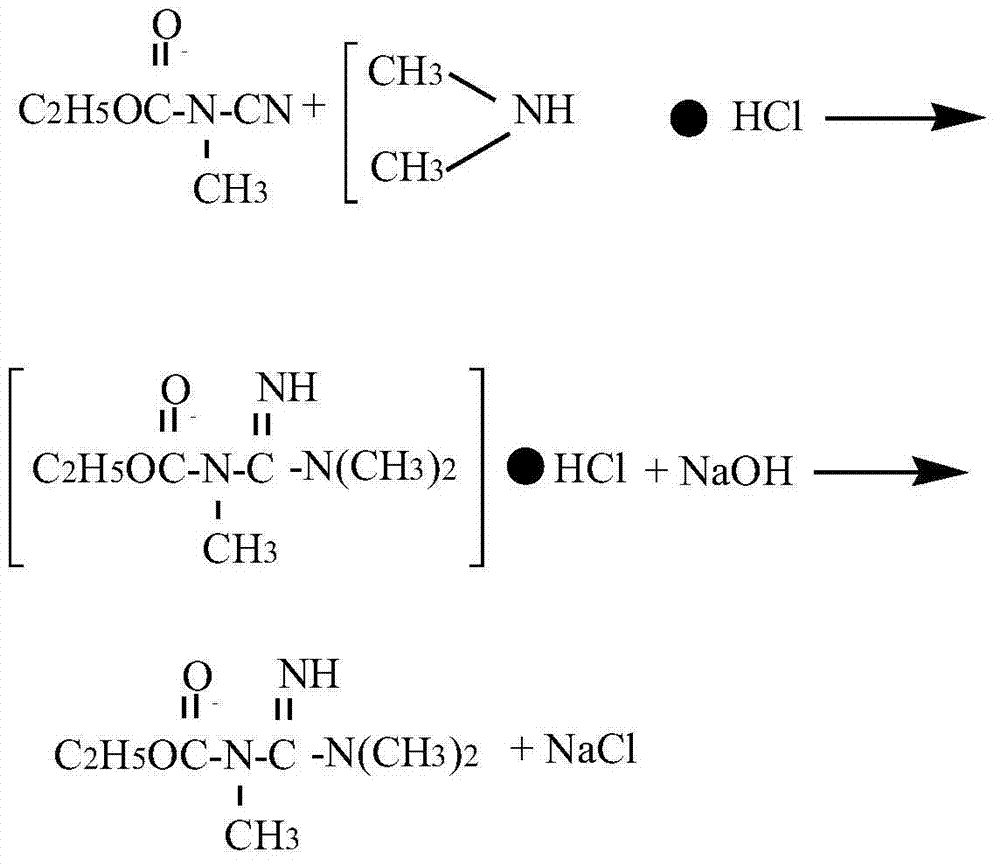

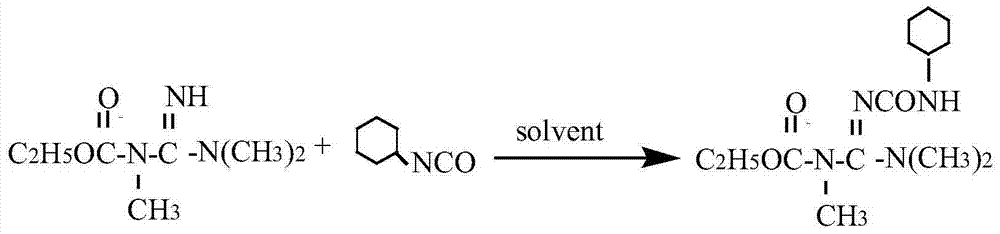

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

[0029]The invention provides a process for synthesizing cycloazinone, the process comprising the following steps: (1) synthesis of ethyl chloroformate: firstly feed ethanol in an esterification tower, slowly feed phosgene, and control the tower The reaction temperature is 35-40 DEG C, the feeding time is 1 hour, and the generated ethyl chloroformate overflows from the top of the esterification tower and enters the ethyl chloroformate storage tank for use. (2) Synthesis of ethyl cyanocarbamate: add water to the hydrolysis kettle, open the jacket steam and heat up to 30-50°C, then put lime nitrogen into the hydrolysis kettle for hydrolysis reaction, the reaction time is 1 hour, then filter, The filtrate is pumped into the amination kettle at one time, and the ethyl chloroformate generated in step 1 is added dropwise under cooling and cooling, and the pH of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com