A Method for Effectively Eliminating Center Defects of Solidified Billet and Refining Solidified Structure

A technology of solidification structure and central defect, which is applied in the field of effectively eliminating the central defect of solidified billet and refining the solidification structure, so as to achieve the effect of improving nucleation particle, shortening feeding distance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

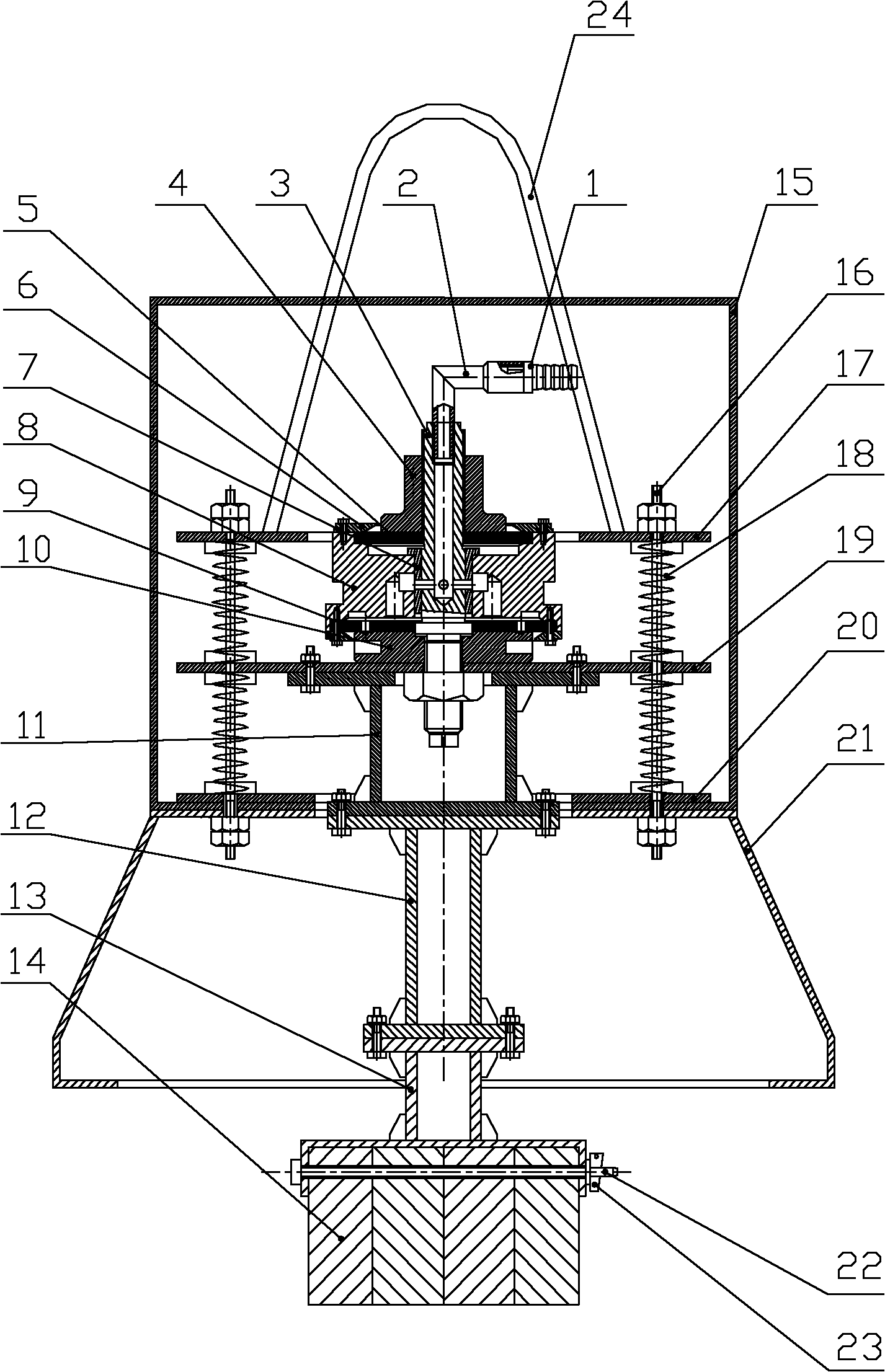

[0050] Pouring 1 ton of sand-cast steel ingot, the steel ingot material is 35CrMo, after the mold assembly tooling is completed, place an oscillating device on the upper end of the riser. The oscillation device adopts the gas oscillation method, and its structure design is as follows: figure 1 shown. The frequency of the oscillating device is 20 Hz, and the amplitude of the oscillating device is 10 mm; in this embodiment, the pressure of the compressed air in the oscillating device is 1 MPa. Conical refractory materials are used, and the specific dimensions are: the diameter of the upper end is Φ100, and the length is 130mm. The refractory material is heated to 750°C before being immersed in the molten metal. After the ingot is poured, an oscillating device is added to the riser of the ingot, and the refractory material is placed at 1 / 2 of the diameter of the riser; In the process of oscillation, the depth of the refractory material in the molten metal is 20mm. The refracto...

Embodiment 2

[0052] Pouring 20 tons of die-cast steel ingot, the material of the steel ingot is 20SiMn, after the mold assembly tooling is completed, an oscillation device is placed on the upper end of the riser. The oscillation device adopts the gas oscillation method, and its structure design is as follows: figure 1 shown. The frequency of the oscillating device is 30 Hz, and the amplitude of the oscillating device is 20 mm. In this embodiment, the pressure of the compressed air in the oscillation device is 4MPa. The circular refractory material is used, and the specific dimensions are: diameter Φ300, length 250mm. The refractory material is heated to 890°C before being immersed in the molten metal. After the ingot is poured, an oscillating device is added to the riser of the ingot, and the refractory material is placed at 1 / 2 of the diameter of the riser; In the process of oscillation, the depth of the refractory material in the molten metal is 50mm. The refractory material adopts h...

Embodiment 3

[0054] Casting 30 tons of continuous casting billets with a size of 600×1000×7000mm and a material of 40Cr2. After the mold assembly tooling is completed, an oscillating device is placed on the upper end of the crystallizer. The oscillation device adopts the gas oscillation method, and its structure design is as follows: figure 1 shown. The frequency of the oscillating device is 50 Hz, and the amplitude of the oscillating device is 30 mm. In this embodiment, the pressure of the compressed air in the oscillation device is 5MPa. Square refractory material is used, and the specific size is: 300×350mm. The refractory material is heated to 900°C before being immersed in the molten metal. During the pouring process of the molten metal, an oscillating device is added to the crystallizer, and the refractory material is placed at 1 / 3 of the crystallizer; In the molten metal, the depth of the refractory in the molten metal is 60mm during the oscillation process. The refractory mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com